Lenze 9400 User Manual

EDS94AYAE

.G)!

Ä.G)!ä

Manual

9400

E94AYAE − SM301

Safety module

L−force Drives

Translation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Please read these instructions and the documentation of the standard device before you

start working!

Observe the safety instructions given therein!

0Fig. 0Tab. 0

© 2011 Lenze Automation GmbH, Hans−Lenze−Str. 1, D−31855 Aerzen

No part of this documentation may be reproduced or made accessible to third parties without written consent by Lenze Automation GmbH.

All information given in this documentation has been selected carefully and complies with the hardware and software described. Nevertheless, discrepancies cannot be ruled out. We do not take any responsibility or liability for any damage that may

occur. Necessary corrections will be included in subsequent editions.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Contents

1

3

EDS94AYAE EN 6.0

1 Safety engineering

Contents

1 Safety engineering 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Basics 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Introduction 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Drive−based safety with L−force | 9400 5 . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 Terms and abbreviations of the safety engineering 6 . . . . . . . . . . . . . . . .

1.1.4 Important notes 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.5 Safety instructions 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.6 Hazard and risk analysis 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.7 Standards 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.8 Safety instructions for the installation according to UL or UR 10 . . . . . . . .

1.1.9 Overview of sensors 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Device modules 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Slot 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Function mode of the safety modules 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 SM301 safety module 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.4 Safe inputs 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.5 Safe output 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.6 Further inputs 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.7 Safe speed measurement and position detection 42 . . . . . . . . . . . . . . . . . .

1.3 Safety functions 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 General information 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Integration into the application of the controller 51 . . . . . . . . . . . . . . . . . .

1.3.3 Safe torque off 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.4 Safe stop 1 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.5 Safe stop 2 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.6 Ramp monitoring SS1/SS2 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.7 Emergency stop 67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.8 Safe maximum speed 68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.9 Safely limited speed 71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.10 Safe direction 74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.11 Safe operation mode selector 78 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.12 Safe enable switch 84 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.13 Cascading 85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Safety address 88 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Safe bus interfaces 90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 PROFIsafe connection 90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Contents

1

4

EDS94AYAE EN 6.0

1.6 Safe parameter setting 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.1 Parameter setting 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.2 Parameter sets and axes 102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 Error management 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.1 Error states 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.2 Logbook function in the controller 104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.3 Logbook function in the SM301 104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 Response times 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.1 Response times of the inputs 107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.2 Response time of the safe output 107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.3 Response times of the safety bus 107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.4 Response time of encoder monitoring 108 . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 Acceptance 109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9.1 Description 109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9.2 Periodic inspections 110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10 Appendix 111 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.1 Module internal codes 111 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.2 Module error messages 132 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11 Total index 136 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Basics

Introduction

1

5

EDS94AYAE EN 6.0

1.1 Basics

1.1.1 Introduction

With increasing automation, protection of persons against hazardous movements is

becoming more important. Functional safety describes the measures needed by means of

electrical or electronic equipment to reduce or remove danger caused by failures.

During normal operation, safety equipment prevents people accessing hazardous areas. In

certain operating modes, e.g. set−up mode, work needs to be carried out in hazardous

areas. In these situations the machine operator must be protected by integrated drive and

control measures.

Drive−based safety provides the conditions in the controls and drives to optimise the safety

functions. Planning and installation expenditure is reduced. In comparison to the use of

standard safety engineering, drive−based safety increases machine functionality and

availability.

1.1.2 Drive−based safety with L−force | 9400

The controllers of the L−force|9400 range can be equipped with a safety module. The

functional range of the safety module types varies in order to optimally implement

different applications.

"Drive−based safety" stands for applied safety functions, which can be used for the

protection of persons working on machines.

The motion functions are continued to be executed by the controller. The safety modules

monitor the safe compliance with the limit values and provide the safe inputs and outputs.

When the limit values are exceeded the safety modules start the control functions

according to EN 60204−1 directly in the controller.

The safety functions are suitable for applications according to IEC 61508 to SIL 3 and meet,

depending on the module, the requirements of Performance Level e (PL e) and control

category 4 according to EN ISO 13849−1.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Basics

Terms and abbreviations of the safety engineering

1

6

EDS94AYAE EN 6.0

1.1.3 Terms and abbreviations of the safety engineering

Abbreviation Meaning

9400 Lenze servo controller

Cat. Category according to EN ISO 13849−1 (formerly EN 954−1)

OSSD Output Signal Switching Device, tested signal output

PS PROFIsafe

PWM Pulse width modulation

SD−In Safe input (Safe Digital Input)

SD−Out Safe output (Safe Digital Output)

SIL Safety Integrity Level according to IEC 61508

SM Safety module

Optocoupler

supply

Optocoupler supply for the driver control

PELV Protective extra low voltage

SELV Safety extra low voltage

OFF state Signal status of the safety sensor technology when it is released or responding

ON state Signal status of the safety sensor technology in normal operation

PM PN−switched signal paths

PP PP−switched signal paths

GSE File containing device−specific data to establish PROFIBUS communication

GSDML File containing device−specific data to establish PROFINET communication

S−Bus Safety bus

Abbreviation Safety function

SLS Safely limited speed

SLI Safely limited increment

SOS Safe operating stop

SS1 Safe stop 1

SS2 Safe stop 2

SSM Safe speed monitor

STO Safe torque off

Formerly: safe standstill

SMS Safe maximum speed

SDI Safe direction

SSE Safe stop emergency

ES Safe enable switch

OMS Operation mode selector

AIE Error acknowledgement (Acknowledge In Error)

AIS Restart acknowledgement (Acknowledge In Stop)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Basics

Important notes

1

7

EDS94AYAE EN 6.0

1.1.4 Important notes

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

Danger!

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger!

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Stop!

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

Note!

Important note to ensure troublefree operation

Tip!

Useful tip for simple handling

Reference to another documentation

Special safety instructions and application notes for UL and UR

Pictograph and signal word Meaning

Warnings!

Safety or application note for the operation of a UL−approved

device in UL−approved systems.

Possibly the drive system is not operated in compliance with UL

if the corresponding measures are not taken.

Warnings!

Safety or application note for the operation of a UR−approved

device in UL−approved systems.

Possibly the drive system is not operated in compliance with UL

if the corresponding measures are not taken.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Basics

Safety instructions

1

8

EDS94AYAE EN 6.0

1.1.5 Safety instructions

Application as directed

The safety modules SMx (E94AYAx) may only be used together with Lenze drive controllers

of the L−force | 9400 (E94A...) series.

Any other use shall be deemed inappropriate!

Installation/commissioning

Danger!

Danger to life through improper installation

Improper installation of the safety engineering systems can cause

anuncontrolled starting action of the drives.

Possible consequences:

ƒ Death or severe injuries

Protective measures:

ƒ Safety engineering systems may only be installed and commissioned by

qualified and skilled personnel.

ƒ All control components (switches, relays, PLC, ...) and the control Cabinet

must comply with the requirements of EN ISO 13849−1 and EN ISO 138492.

This includes:

– Switches, relays in IP54 enclosure.

– Control cabinet in IP54 enclosure.

– Please refer to EN ISO 13849−1 and EN ISO 138492 for all further

requirements.

ƒ It is essential to use insulated wire end ferrules for wiring.

ƒ All safety relevant cables outside the control cabinet must be protected, e.g.

by means of a cable duct:

– Ensure that there are no short circuits.

– For further measures see EN ISO 138492.

ƒ If an external force acts upon the drive axes, additional brakes are

required.Please observe that hanging loads are subject to the force of

gravity!

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Basics

Safety instructions

1

9

EDS94AYAE EN 6.0

Danger!

When the request for the safety function is deactivated, the drive can restart

automatically. The behaviour can be set via the parameter "Restart behaviour"

(C15300/1/2).

In the case of an automatic restart, you must provide external measures which

ensure that the drive only restarts after an acknowledgement (EN 60204).

Danger!

When the "safe torque off" (STO) function is used, an "emergency

switching−off" according to EN 60204 is not possible without additional

measures. There is no electrical isolation, no service switch or repair switch

between motor and controller!

Emergency switching−off" requires an electrical isolation, e.g. by a central

mains contactor!

During operation

After the installation is completed, the operator must check the wiring of the safety

function.

The functional test must be repeated at regular intervals. The time intervals to be selected

depend on the application, the entire system and the corresponding risk analysis. The

inspection interval should not exceed one year.

Residual hazards

In case of a short−circuit of two power transistors a residual movement of the motor of up

to 180 °/number of pole pairs may occur! (Example: 4−pole motor Þ residual movement

max. 180 °/2 = 90 °)

This residual movement must be considered in the risk analysis, e.g. safe torque off for

main spindle drives.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Basics

Hazard and risk analysis

1

10

EDS94AYAE EN 6.0

1.1.6 Hazard and risk analysis

This documentation can only accentuate the need for hazard analysis. The user of the

integrated safety system must read up on standards and the legal situation:

Before the launch of a machine, the manufacturer of the machine must conduct a hazard

analysis according to Machinery Directive 2006/42/EC to determine the hazards

associated with the application of the machine. The Machinery Directive refers to three

basic principles for the highest possible level of safety:

ƒ Hazard elimination / minimisation by the construction itself.

ƒ Required protective measures must be taken against hazards which cannot be

eliminated.

ƒ Existing residual hazards must be documented and the user must be informed of

them.

Detailed information on the hazard analysis procedure is provided in the EN 1050, risk

assessment principles. The results of the hazard analysis determine the category for

safety−related control systems according to EN ISO 13849−1. Safety−oriented parts of the

machine control must be compliant.

1.1.7 Standards

Safety regulations are confirmed by laws and other governmental guidelines and

measures and the prevailing opinion among experts, e.g. by technical regulations.

The regulations and rules to be applied must be observed in accordance with the

application.

1.1.8 Safety instructions for the installation according to U

L

or U

R

Warnings!

ƒ Maximum surrounding air temperature: 55 °C.

ƒ External fuse for 24 Vdc supply voltage. Rated 4 A DC fuse UL248−14.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Basics

Overview of sensors

1

11

EDS94AYAE EN 6.0

1.1.9 Overview of sensors

Passive sensors

Passive sensors are two−channel switching elements with contacts. The connecting cables

and the sensor function must be monitored.

The contacts must switch simultaneously (equivalently). Nevertheless, safety functions

will be activated as soon as at least one channel is switched.

The switches must be wired according to the closed−circuit principle.

Examples of passive sensors:

ƒ Door contact switch

ƒ Emergency−off control units

Active sensors

Active sensors are units with 2−channel semiconductor outputs (OSSD outputs). With the

integrated safety system of this device series, test pulses < 1 ms for monitoring the

outputs and cables are permissible. The maximally permissible connection capacity of the

outputs is to be observed.

P/M−switching sensors switch the positive and negative cable or the signal and ground

wire of a sensor signal.

The outputs have to switch simultaneously. Nevertheless, safety functions are triggered

as soon as at least one channel is switched.

Examples of active sensors:

ƒ Lightgrid

ƒ Laser scanner

ƒ Control systems

Sensor inputs

For unused sensor inputs, "Input deactivated" must be parameterised.

Connected deactivated sensors can create the false impression of safety technology being

provided. For this reason, a deactivation of sensors by parameter setting only is not

permissible and not possible. It is monitored that no sensor signal is pending.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

Slot

1

12

EDS94AYAE EN 6.0

1.2 Device modules

1.2.1 Slot

The slot for the safety modules is marked in the documentation with M4. It is the lowest

slot in the controller (see overview in the documentation of the controller).

1.2.1.1 Mounting

E94AYAX001

1.2.1.2 Dismounting

E94AYCXX001H

1.2.1.3 Module exchange

Stop!

Before mounting/dismounting, switch off the supply voltage to prevent

electronic modules from damage.

Every module exchange is detected by the standard device and documented in a logbook.

When a module is replaced by the same type, no restrictions arise. Depending on the

module type it may be necessary to take further measures (e.g. address setting, safe

parameter setting, ...).

When the module is replaced by a different type, the drive is inhibited by the controller. The

inhibit can only be deactivated when the parameter setting of the required safety module

complies with the plugged safety module.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

Slot

1

13

EDS94AYAE EN 6.0

Codes

Parameter: Name: Data type: Index:

C00214 Required safety module

UNSIGNED_8 24361d = 5F29

h

Setting of the expected safety module

l If a safety module deviating from this setting is detected, an error (fault) is caused. The error can only be

removed by mains switching.

Selection list

(Lenze setting bold) Information

1 SM0

2 SM100

4 SM300

5 SM301

þ Read access þ Write access o Controller inhibit o PLC-STOP o No transfer o COM o MOT

Note!

In case you exchange the module, the address switch must be set identically

to the module to be replaced. Only then the corresponding safe parameter set

can be transferred to the module.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

Function mode of the safety modules

1

14

EDS94AYAE EN 6.0

1.2.2 Function mode of the safety modules

C00214

The setting in C00214 must comply with the plug−in safety module type so that the

controller is able to operate.

Disconnecting paths

The transmission of the pulse width modulation is safely disconnected by the safety

module. Hence the drivers do not create a rotating field. The motor is safely switched to

torqueless operation (STO).

M

SMx

PWM

µC

PC

3x

3x

Xx

SSP94SM320

Fig. 1−1 Disconnecting paths of the safety modules

SMx Safety module

xx Input / output terminal

C Control section

mC Microcontroller

PWM Pulse width modulation

P Power section

M Motor

Safety status

When the controller is switched off by the safety module, the controller switches to the

"Safe torque off"device state.

ƒ "Controller in STO state" is entered into the logbook (0x00750003).

ƒ "Safe torque off active" is displayed in C00183.

Fail−safe status

Note!

If internal errors of the safety modules are detected, the motor is safely

switched to torque−free operation (fail−safe status).

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

15

EDS94AYAE EN 6.0

1.2.3 SM301 safety module

Validity information

These instructions are valid for

SM301 safety module

Type HW SW

E94AYAE from VA from 01.00

Identification

L

'

Type

E94YCEI003C E94AYXX001

E94 A Y A x xx xx nn

Product series

Version

Module identification: Device module

Module type: Safety module

Design

A = SM0

B = SM100

E = SM301

Hardware version

Software version (SM301 only)

Serial number

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

16

EDS94AYAE EN 6.0

Application range

The use of this module is permissible with standard devices of the 9400 product series from

nameplate designation

Type HW SW

E94AxHExxxx VA 01.49

E94AxPExxxx 2A 02.xx

Safe position and speed detection with a resolver selected as the motor encoder and an

additional position encoder is permissible with SM301 V1.3 and standard devices of the

9400 product series from nameplate designation

Type HW SW

E94AxHExxxx xx 07.xx

E94AxPExxxx 2A 02.xx

Safe position and speed detection with a resolver selected as the motor encoder is

permissible with SM301 V1.4 and standard devices of the 9400 product series from

nameplate designation

Type HW SW

E94AxHExxxx xx 08.xx

E94AxPExxxx 2A 02.xx

The use of this module is permissible with the PROFIBUS communication module from

nameplate designation

Type HW SW

E94AYCPM VB 01.10

This module as of SM301 V1.1 may be used in conjunction with the PROFINET

communication module with the following nameplate data

Type HW SW

E94AYCER VC 00.70

Note!

A safety bus system (PROFIsafe) can only be operated via the upper module

slot (MXI1) of the Servo Drive 9400.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

17

EDS94AYAE EN 6.0

1.2.3.1 Overview

Functions

ƒ Safe torque off (STO)

(formerly: Safe standstill, protection against unexpected start−up)

ƒ Safe stop 1 (SS1)

ƒ Safe stop 2 (SS2) − see SOS

ƒ Safe stop emergency (SSE)

ƒ Safe operational stop (SOS) − in accordance with EN 61800−5−2: SOS is designed with

speed monitoring

ƒ Safe maximum speed (SMS)

ƒ Safely limited speed 1 (SLS1)

ƒ Safe operation mode selector (OMS)

ƒ Safe enable switch (ES)

ƒ Safe speed monitor (SSM)

ƒ Safe monitor (output)

ƒ Connection of safety sensors

ƒ Safe parameterisation

ƒ Safety bus connection (PROFIsafe V1)

Additional functions from SM301 V1.1

ƒ Safely limited speed 2 (SLS2)

ƒ Safely limited speed 3 (SLS3)

ƒ Safely limited speed 4 (SLS4)

ƒ Safe cascading (CAS) via SD−In4/SD−Out1

ƒ Safety bus connection (PROFIsafe V2)

Additional functions from SM301 V1.2

ƒ Parameterisable response time of encoder monitoring

Additional functions from SM301 V1.3

ƒ Safe operational stop (SOS) − compliant with EN 61800−5−2: SOS is designed with

position monitoring

ƒ Safe direction (SDI)

ƒ Safe speed measurement and position detection with resolver using a motor

encoder and an additional position encoder (two−encoder−concept)

Additional functions as of SM301 V1.4

ƒ Safely limited increment (SLI)

ƒ Safely monitored brake ramp for SS1/SS2

ƒ Safe speed and position detection with resolver selected as the motor encoder

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

18

EDS94AYAE EN 6.0

Motor−encoder combinations

Drive systems with Servo Drives 9400 and safety module SM301 provide speed−dependent

safety functions for safe speed monitoring and/or safe relative−position monitoring.

Observe permissible motor−encoder combinations during configuration.

ƒ Possible speed−dependent safety functions with safety module SM301:

– Safe stop 1 (SS1)

– Safe operational stop (SOS)

– Safely limited speed (SLS)

– Safe maximum speed (SMS)

– Safe direction (SDI)

– Safe speed monitor (SSM)

– Safely limited increment (SLI)

ƒ Permissible motor−encoder combinations for these functions:

Synchronous

servo motors

Encoder

Safe speed monitoring with SM301

Type Product key

MCS 06 ... 19

MDXKS 56 / 71

Sin/cos absolute value, single−turn AS1024−8V−H

Single−encoder

concept

PL d / SIL 2

Sin/cos absolute value, multi−turn AM1024−8V−H

Resolver RS0

Two−encoder concept bis PL e / SIL 3

Asynchronous

servo motors

Encoder

Safe speed monitoring with SM301

Type Product key

MCA 10 ... 26

MQA 20 ... 26

Sin/cos incremental IG1024−5V−V

Single−encoder

concept

PL e / SIL 3

Resolver RS0 PL d / SIL 2

Two−encoder concept bis PL e / SIL 3

Three−phase

asynchronous

motors

Encoder

Safe speed monitoring with SM301

Type Product key

MDxMA063−xx ...

MDxMA225−xx

Sin/cos incremental

IG2048−5V−V

Single−encoder

concept

PL e / SIL 3

MHxMA080−xx ...

MHxMA225−xx

MFxMA063−xx ...

MFxMA132−xx

Two−encoder

concept

bis PL e / SIL 3

A "two−encoder concept" includes e.g. a resolver as motor encoder and, at the same time,

an absolute value encoder (sin/cos), an incremental encoder (TTL), or digital encoder

(SSI/bus) as position encoder on the machine.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

19

EDS94AYAE EN 6.0

Compatibility

Compatibility of SM301/SM300

The SM301 safety module is compatible with the SM300. The controller needs to be

adapted since the safe parameter set is required. Observe the following:

ƒ The GSE file can be used.

ƒ The PROFIsafe bits that are not used with SM300 must be suppressed in the SM301,

since unset bits would activate safety functions.

ƒ Speed−dependent functions cannot be used.

Compatibility of different SM301 versions

Replacement of an SM301 by an SM301 with a higher firmware version (SW):

ƒ Every SM301 can be used with a safe parameter set of an elder firmware version

without any changes.

ƒ The safe parameter set including CRC in the memory module of the drive is not

changed when the parameter set from the memory module is accepted.

ƒ The CE Declaration of Conformity remains valid.

ƒ The replacement of the safety module by an equivalent module is ensured. Thus,

there is no need for spare part stockage of SM301 safety modules with elder

firmware versions.

ƒ Safe parameter sets of the "SM301 safety module" component can be loaded into

an SM301 with a higher firmware version without any changes.

– Extended functionalities of the newer firmware version cannot be selected and

executed.

The safe parameter set of an SM301 with a newer firmware version cannot be loaded into

an SM301 with an elder firmware version.

1.2.3.2 Safety category

The implemented safety functions meet the requirements of the standards:

ƒ Control category 3 according to EN ISO 13849−1

In order to comply with category 3, the external wiring and cable monitoring must also

meet the requirements of category 3.

ƒ Performance Level (PL) "e" according to EN ISO 13849−1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

20

EDS94AYAE EN 6.0

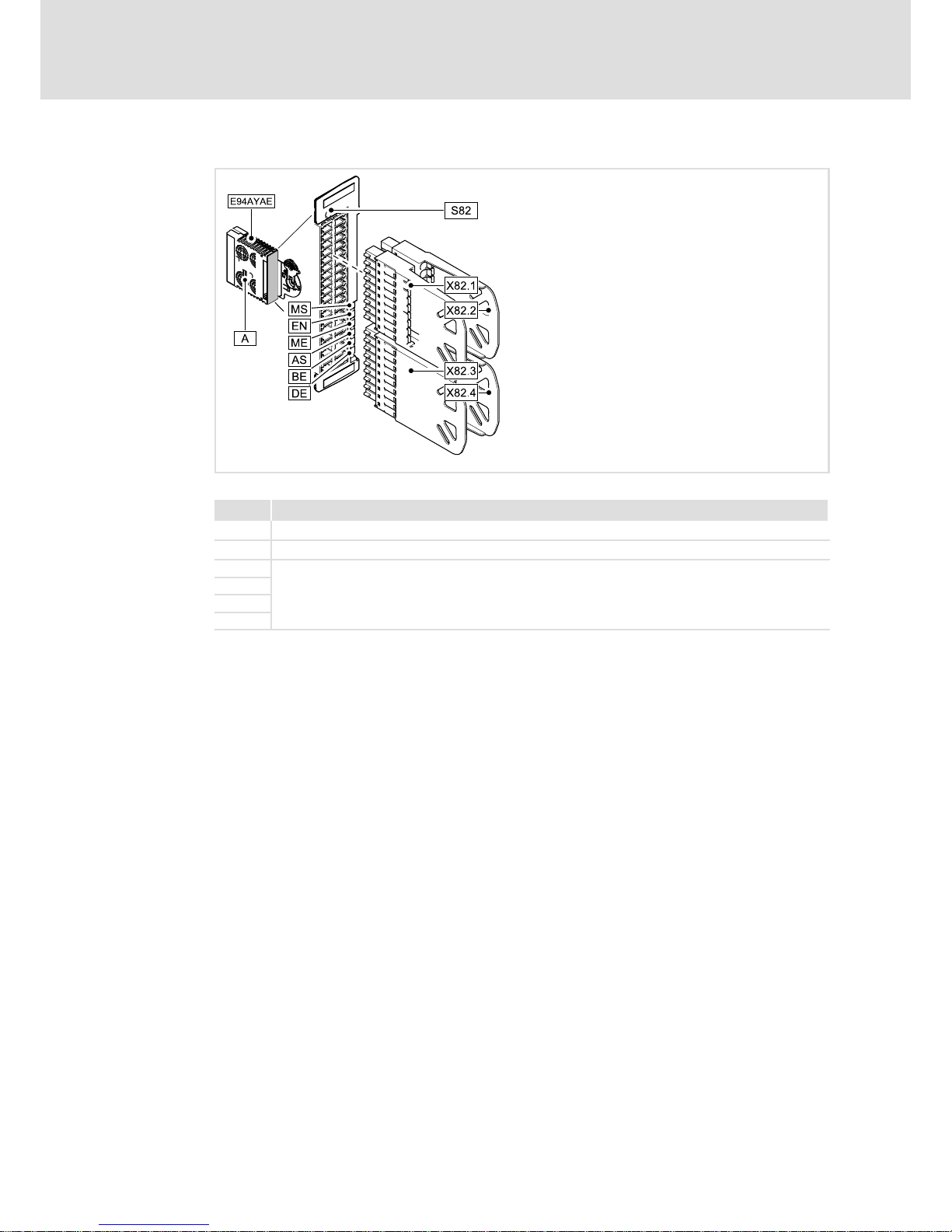

1.2.3.3 Elements of the module

SSP94SM321

Fig. 1−2 Module view

Pos. Description

Safety address switch (in the left part of the housing)

S82 Module switch for parameter set adoption from the memory module

X82.1

Plug−in terminal strips for input and output signals

X82.2

X82.3

X82.4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

21

EDS94AYAE EN 6.0

Displays

Pos. Colour State Description

MS

(Module State)

Green

On

Drive−based safety has initialised without a fault.

Blinking

Drive−based safety has initialised without a fault. Internal

communication to the standard device is not possible.

Flashing

Drive−based safety is in service status.

For exiting, parameterise the drive−based safety.

Off

Drive−based safety is not initialised.

Acknowledgement is not possible.

EN

(Enable)

Yellow

On

Controller enabled

Off

Non−safe display "STO"

ME

(Module Error)

Red

On

System error

Blinking

Trouble

Flashing

Warning

Off Error−free operation

AS

(Acknowledge Stop)

Yellow

On

Request of an acknowledgement for the restart or the

parameter set adoption

Blinking

SS1/STO active

Flashing

SS2/SOS active

Off No stop function active

BE

(Bus Error)

Red

On

Safety bus error:

l Communication is not possible.

l Acknowledgement is possible.

Blinking

Safety bus error: no valid configuration.

Off Safety bus: error−free operation.

DE

(Drive Error)

Red

On

Drive−based safety is not accepted by the standard device

(see notes in the instructions for the standard device).

Off

Drive−based safety is correctly recognised by the standard

device.

Blinking: on/off every 0.5 s Flashing: on/off every 0.1/0.9 s

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

22

EDS94AYAE EN 6.0

Terminal assignment

Danger!

Danger to life through improper installation

Improper installation of the safety engineering systems can cause

anuncontrolled starting action of the drives.

Possible consequences:

ƒ Death or severe injuries

Protective measures:

Total cable length between X82 and its connected components (e.g. sensors,

devices, ...) > 3 m:

ƒ A shielded laying system must be used for the cable between X82 and its

connected components:

– The shield must at least cover the shield connection at the installation

backplane.

– The shield should also cover the connected component if possible.

ƒ Unshielded wiring is permissible from hardware version 1A.

Total cable length between X82 and its connected components (e.g. sensors,

devices, ...) < 3 m:

ƒ Unshielded wiring is permissible.

X82.1 Labelling Description

This part of the terminal strip is not assigned.

GO

GND SD−Out1

O1B

Safe monitor SD−Out1, channel B

O1A

Safe monitor SD−Out1, channel A

This part of the terminal strip is not assigned.

X82.2 Labelling Description

−

GND external supply

+

+24 V external supply via a safely separated power supply unit (SELV/PELV)

GIR

This part of the terminal strip is reserved.

RI1

GO

GND 24O

24O

+24 V external supply for the safe monitor SD−Out1 (SELV/PELV)

AIE

Error acknowledgement input ("Acknowledge In Error")

CLA Clock output for passive sensors, channel A (Clock A)

CLB Clock output for passive sensors, channel B (Clock B)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

23

EDS94AYAE EN 6.0

X82.3 Labelling Description

GCL

GND clock output

GI2

GND SD−In2

I2B

Sensor input SD−In2, channel B

I2A

Sensor input SD−In2, channel A

GCL

GND clock output

GI1

GND SD−In1

I1B

Sensor input SD−In1, channel B

I1A

Sensor input SD−In1, channel A

AIS

Restart acknowledgement input ("Acknowledge In Stop", 1−channel,

bridged to X82.4/AIS)

X82.4 Labelling Description

GCL

GND clock output

GI4

GND SD−In4

I4B

Sensor input SD−In4, channel B

I4A

Sensor input SD−In4, channel A

GCL

GND clock output

GI3

GND SD−In3

I3B

Sensor input SD−In3, channel B

I3A

Sensor input SD−In3, channel A

AIS

Restart acknowledgement input ("Acknowledge In Stop", 1−channel,

bridged to X82.3/AIS)

Cable cross−sections and tightening torques

Type [mm2] [Nm] AWG [lb−in]

Wire end ferrule,

insulated

0.25 ... 0.75

Spring terminal

24 ... 18

Spring terminal

Rigid

0.14 ... 1.5 26 ... 16

Stripping length or contact length: 9 mm

Insulated wire end ferrules according to DIN 46228, part 4, 0.5 mm2 or 0.75 mm2 − length

L1 = 10 mm can be used.

Note!

Provide for a sufficient strain relief, so that the terminals are not pulled from

the plug connectors, in particular when you use rigid cables.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

24

EDS94AYAE EN 6.0

1.2.3.4 Technical data

24 V supply

The module and the safe output must be supplied with 24 V from safely separated power

supply units. To maintain electrical isolations, separate voltage supplies are required.

Detailed features of the 24−V supply

Terminal Specification [Unit] min. typ. max.

+, −

Supply voltage of the module via a safely separated

power supply unit (SELV/PELV)

[V] 19.2 24 30

Input current [mA] 350

24O, GO

Supply voltage of the safe output via a safely

separated power supply unit (SELV/PELV)

[V] 18 24 30

Input current [mA] 1100

If the voltage of the SELV/PELV power supply unit can exceed 30 V in the event of an error,

provide for an external fuse ( 1.1.8).

Inputs and output

The inputs and the output are isolated and designed for a low−voltage supply of 24 V DC.

The digital inputs are protected against polarity reversal.

Detailed features of the safe inputs and the safe output

Terminal Specification [Unit] min. typ. max.

I1A, I1B

I2A, I2B

I3A, I3B

I4A, I4B

AIE, AIS

PLC input, IEC−61131−2, 24 V, type 1

Low signal input voltage

V −3 0 5

Input current at low signal mA 15

High signal input voltage

V 15 24 30

Input current at high signal mA 2 15

Input capacitance

nF 3.5

Repetition rate of the test pulses

ms 50

AIE, AIS Input delay (operating time) s 0.3 10

CLA, CLB

PLC output, IEC−61131−2, 24 V DC, 50 mA

Low signal output voltage

V 0 0.8

High signal output voltage

V 17 24 30

Output current

mA 60

Cable capacity

nF 100

Cable resistance of a passive sensor

W 200

O1A, O1B

PLC output, IEC−61131−2, 24 V DC

Low signal output voltage

V 0 0.8

High signal output voltage

V 17 24 30

Output current

mA 500

Cable capacity

nF 100

Cable resistance

W 200

Tab. 1−1 Technical data

The chapter "Response times" must be observed as well ( 1.8).

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

25

EDS94AYAE EN 6.0

1.2.3.5 Example circuit

AIS

GCL

GI3

I3B

I3A

AIS

GO

24O

GO

O1B

O1A

GCL

GI4

I4B

I4A

GCL

GI2

I2B

I2A

GCL

GI1

I1A

I1B

AIE

-

+

CLA

CLB

S4

S3

S1

S2

X82.1 X82.2

X82.3

X82.4

SM301

E94AYAE

24 V ext.

K

SSP94SM360

Fig. 1−3 Wiring example

E94AYAE SM301 safety module

S1

passive sensor with channel A and B

S2

S3 higher−level safety control (active sensor)

S4 lightgrid (active sensor)

24 V ext. 24−V voltage supply of the module (SELV/PELV)

24−V voltage supply of the output (SELV/PELV)

safe output to higher−level safety control

K to AIS of the next module

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

26

EDS94AYAE EN 6.0

1.2.3.6 Commissioning

ƒ For commissioning and safe parameter setting, the Lenze »Engineer« PC

software from version 1.4 must be used.

If you select the safety module in the Project view, various tabs are available in the

Operating range via which the safety module can be parameterised. In all other

program parts the parameters of the safety module can only be read. Thus, the write

access of these parameters (codes) is marked with .

ƒ Settings in or at the module:

– Safety address

– Safe parameter setting of the functions to be used

ƒ Required settings in the standard device:

– C00214, type of safety module

– Implementation of the SM301 into the drive application by evaluating the control

information and status information.

ƒ During commissioning and after the replacement of a module it is vital to check the

safety function. Additional information contains the "Acceptance" chapter. ( 109).

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

27

EDS94AYAE EN 6.0

1.2.3.7 Test certificate

SSP94TUEV3 _2010

Fig. 1−4 TÜV Certificate

The type test was carried out by ’TÜV Rheinland (Group)’ and confirmed with a certificate.

ƒ SM301 V1.0

Contents Specifications

Test institute TÜV Rheinland Industrie Service GmbH, ASI range

Test report 968/EL 420.00/06

Test fundamentals EN 954−1, EN 60204−1, EN 50178, EN 61800−3, IEC 61508 Part 1−7

Object to be examined SM301, type E94AYAE VA1.0x of the 9400 Servo Drives series

Test result The module meets the requirements according to EN 954−1, category 3.

Special conditions The safety instructions in the corresponding user documentation must be

observed.

Place of issue Cologne

Issue date 01.08.2006

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

28

EDS94AYAE EN 6.0

ƒ from SM301 V1.1

Contents Specifications

Test institute TÜV Rheinland Industrie Service GmbH, ASI range

Test report 968/EL 420.03/07

Test fundamentals EN 954−1, EN 60204−1, EN 50178, EN 61800−3, EN 61508 Part 1−7,

EN ISO 13849−1, EN 62061

Object to be examined SM301, type E94AYAE VB1.1x of the 9400 Servo Drives series

Test result The module meets the requirements according to

l EN 954−1, category 3

l EN 61508, SIL 3

l EN ISO 13849−1, PL e

Special conditions The safety instructions in the corresponding user documentation must be

observed.

Place of issue Cologne

Issue date 08.05.2007

ƒ from SM301 V1.2

Contents Specifications

Test institute TÜV Rheinland Industrie Service GmbH, ASI range

Test report 968/EL 420.04/07

Test fundamentals EN 954−1, EN 60204−1, EN 50178, EN 61800−3, EN 61508 Part 1−7,

EN ISO 13849−1, EN 62061

Object to be examined SM301, type E94AYAE of the Servo Drives 9400 series

Test result The module meets the requirements according to

l EN 954−1, category 3

l EN 61508, SIL 3

l EN ISO 13849−1, category 3/PL e

Special conditions The safety instructions in the corresponding user documentation must be

observed.

Place of issue Cologne

Issue date 18.10.2007

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

SM301 safety module

1

29

EDS94AYAE EN 6.0

ƒ from SM301 V1.3

Contents Specifications

Test institute TÜV Rheinland Industrie Service GmbH, ASI range

Test report 968/EL 420.07/10

Certification body NB 0035

Registration no. 01/205/0718/10

Test fundamentals EN 60204−1, EN 61800−3, EN 61508 Part 1−7, EN ISO 13849−1, EN 62061,

EN 61800−5−2, EN 61800−5−1

Object to be examined SM301, type E94AYAE of the Servo Drives 9400 series

Test result The module meets the requirements according to

l EN 61508, SIL 3

l EN ISO 13849−1, category 3/PL e

Special conditions The safety instructions in the corresponding user documentation must be

observed.

Place of issue Berlin

Issue date 29.01.2010

Valid until 29.01.2015

ƒ from SM301 V1.4

Contents Specifications

Test institute TÜV Rheinland Industrie Service GmbH, ASI range

Test report 968/EL 420.08/10

Test fundamentals EN 60204−1, EN 61800−3, EN 61508 Part 1−7, EN ISO 13849−1, EN 62061,

EN 61800−5−2, EN 61800−5−1

Object to be examined SM301, type E94AYAE of the Servo Drives 9400 series

Test result The module meets the requirements according to

l EN 61508, SIL 3

l EN ISO 13849−1, category 3/PL e

Special conditions The safety instructions in the corresponding user documentation must be

observed.

Place of issue Cologne

Issue date 11.10.2010

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety engineering

Device modules

Safe inputs

1

30

EDS94AYAE EN 6.0

1.2.4 Safe inputs

1.2.4.1 General

The following applies to the sensors at the SM301 V1.0:

ƒ Sensor type and sensor function can be parameterised in C15030, C15031 and

C15032.

ƒ A local evaluation is executed if corresponding parameters are set.

ƒ If a safety bus is activated, the sensor signals are sent as status information to the

higher−level control.

ƒ Deactivated sensor inputs must not be connected. The status of a non−connected

input is in the OFF state.

ƒ If a signal is detected at deactivated sensor inputs during initialisation, the drive

remains inhibited (STO).

ƒ Faulty inputs are assessed as OFF state.

Additional conditions for SM301 V1.1:

ƒ With active cascading in C15035 the SD−In4 input cannot be used freely anymore.

Codes

Parameter: Name: Data type: Index:

C15030 SD-In sensor type

UNSIGNED_8 9545d = 2549

h

Configuration of the sensor types which are connected to the safe inputs.

Selection list

(Lenze setting bold) Information

0 Input deactivated

1 Passive sensor

2 Active sensor

Subcodes Information

C15030/1 SD-In1 sensor type

C15030/2 SD-In2 sensor type

C15030/3 SD-In3 sensor type

C15030/4 SD-In4 sensor type

þ Read access Write access o Controller inhibit o PLC-STOP o No transfer

C15031 SD-In sensor function

UNSIGNED_8 9544d = 2548

h

Function configuration of the safe inputs.

l The "operation mode selector" and "enable switch" functions may only be assigned to one of the four safe

inputs.

Selection list

(Lenze setting printed in bold) Information

0 Free assignment Safety function set in C15032

1 Emergency stop Safe stop emergency function (SSE)

2 Operation mode selector Safe operation mode selector (OMS)

3 Enable switch Safe enable switch (ES)

Subcodes Information

C15031/1 SD-In1 sensor function

C15031/2 SD-In2 sensor function

C15031/3 SD-In3 sensor function

C15031/4 SD-In4 sensor function

þ Read access Write access o Controller inhibit o PLC-STOP o No transfer

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...