JVC GR-SX25EK, GR-SXM49EK, GR-SX25EX, GR-SX25EZ, GR-SXM49EX Service Manual

...

SERVICE MANUAL

COMPACT VHS CAMCORDER

GR-SX25EK,GR-SX25EX,GR-SX25EZ GR-SXM49EK,GR-SXM49EX,GR-SXM49EZ

VHS

PAL

625

For disassembling and assembling of MECHANISM ASSEMBLY, refer to the SERVICE MANUAL No.86700 (MECHANISM ASSEMBLY).

SPECIFICATION

|

Camcorder |

|||||

General |

|

|

|

|

|

|

Format |

: S-VHS (GR-SXM49/SX25 only)/ |

|||||

Power source |

VHS PAL standard |

|||||

: DC 11 V |

|

|

(Using AC Adapter) |

|||

|

|

|||||

Power consumption |

DC 6 V |

|

(Using battery pack) |

|||

|

||||||

: 4.2 W (GR-SXM49/FXM393/FXM39 only) |

||||||

Viewfinder on |

||||||

LCD monitor* on |

4.0 W (GR-SX25/FX15 only) |

|||||

: 4.7 W (GR-SXM49/FXM393/FXM39 only) |

||||||

Video light** |

: 3.0 W |

|||||

*Applicable models only.

**GR-SXM49/FXM393/SX25 only.

Signal system |

: PAL-type |

|

|||||||

Video recording system |

: FM recording |

|

|||||||

Luminance |

|

||||||||

Colour |

: Converted sub-carrier direct recording |

||||||||

Cassette |

|

Conforms to VHS standard |

|||||||

: |

|

|

|

|

/ |

|

|

cassette |

|

Tape speed |

: 23.39 mm/sec. |

|

|||||||

SP |

|

||||||||

LP |

: 11.70 mm/sec. |

|

|||||||

Recording time (max.) |

: 60 minutes |

|

|||||||

SP |

|

||||||||

LP |

: 120 minutes (with EC-60 cassette) |

||||||||

Operating |

: 0ºC to 40ºC |

|

|||||||

temperature |

|

||||||||

Operating humidity |

: 35% to 80% |

|

|||||||

Storage temperature |

: -20ºC to 50ºC |

|

|||||||

Weight |

: Approx. 840 g (GR-SXM49/FXM393/FXM39 only) |

||||||||

Approx. 760 g (GR-SX25 only)

Approx. 750 g (GR-FX15 only) Dimensions (W x H x D) : 113 mm x 117 mm x 199 mm

(GR-SXM49/FXM393/FXM39 only)

108 mm x 117 mm x 199 mm (GR-SX25/FX15 only) (with the LCD monitor* closed and with the

viewfinder fully tilted downward)

* Applicable models only.

Pickup |

: 1/6" format CCD |

Lens |

: F1.6, f = 2.7 mm to 43.2 mm, |

|

16:1 power zoom lens with auto iris and |

Viewfinder |

macro control, filter diameter 40.5 mm |

: Electronic viewfinder with 0.5" |

|

White balance |

black/white CRT White balance |

: Auto/Manual adjustment |

|

adjustment |

: Monaural |

Speaker |

|

(Applicable models only) |

: 2.5" diagonally measured, LCD panel/ |

LCD monitor |

|

(Applicable models only) |

TFT active matrix system |

Connectors

Video |

: 1 V (p-p), 75 unbalanced, analogue output |

|||

Audio |

(via Video output connector) |

|||

: 300 mV (rms), 1 k |

, analogue output |

|||

S-Video |

(via Audio output connector) |

|||

: Y: 1 V (p-p), 75 , analogue output |

||||

(GR-SXM49/SX25 only) |

C: 0.30 V (p-p), 75 |

, analogue output |

||

|

AC Adapter |

|

||

Power requirement |

: AC 110 V - 240 V ~, 50 Hz/60 Hz |

|||

Output |

: DC 11 V |

|

, 1 A |

|

|

|

|||

Optional Accessories

•Battery Packs BN-V12U, BN-V20U, BN-V400U

•Compact S-VHS (

) Cassettes SE-C45/30

) Cassettes SE-C45/30

•Compact VHS (

) Cassettes EC-60/45/30

) Cassettes EC-60/45/30

•Active Carrying Bag CB-V7U

•Cassette Adapter C-P7U

Some accessories are not available in some areas. Please consult your nearest JVC dealer for details on accessories and their availability.

GR-SX25EK, GR-SX25EX, GR-SX25EZ, GR-SXM49EK, GR-SXM49EX, GR-SXM49EZ M3C7B3,M3C723

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No.86712

2003/01

TABLE OF CONTENTS

Instructions

1 PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.1 SAFTY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

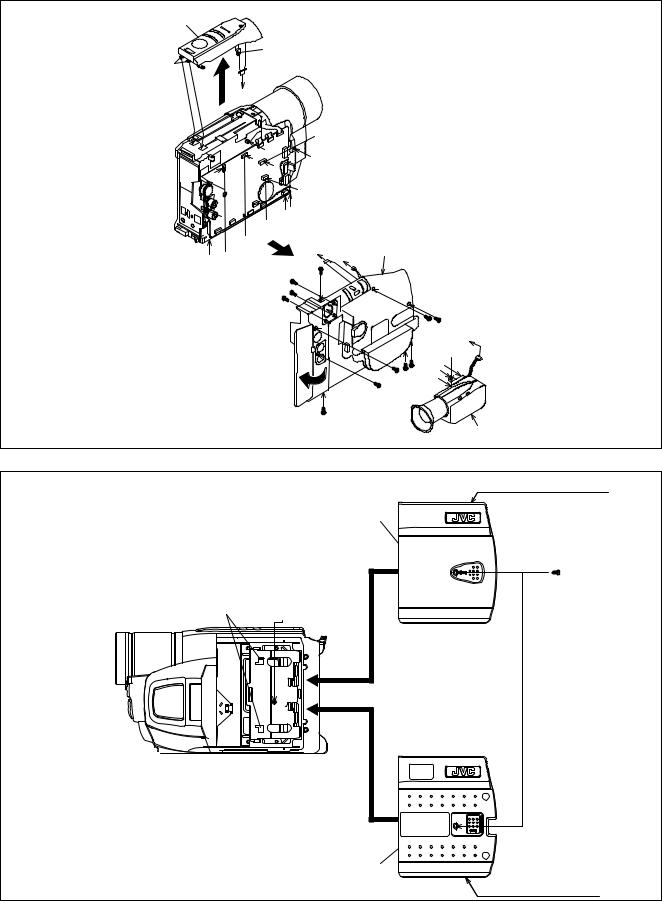

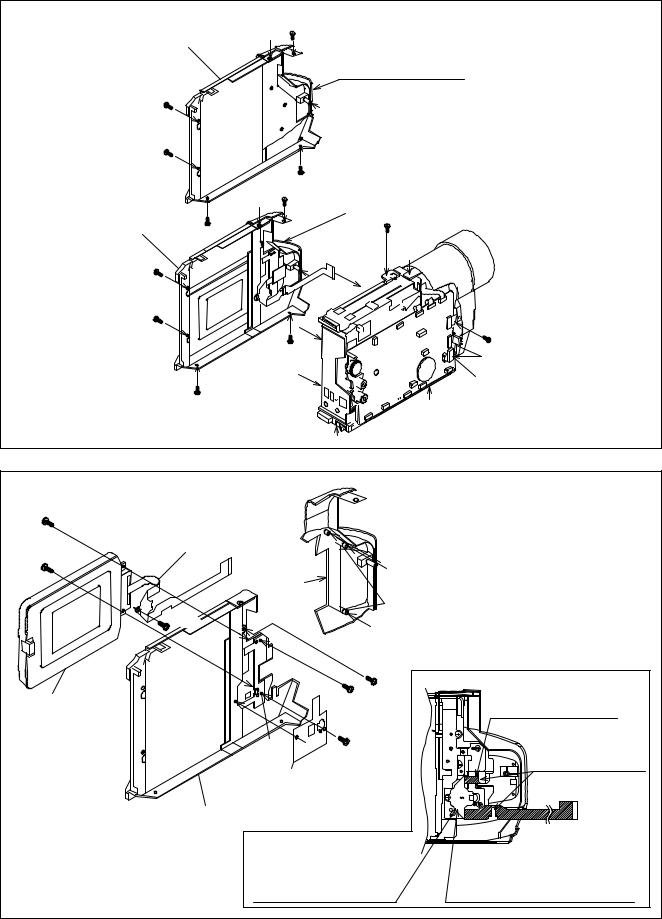

2.1 BEFORE ASSEMBLY AND DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5 2.2 ASSEMBLY AND DISASSEMBLY OF CABINET PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6 2.3 ASSEMBLY AND DISASSEMBLY OF CAMERA SECTION AND BOARD ASSEMBLY . . . . . . . . . . . . . . . . . . . .1-10 2.4 ASSEMBLY AND DISASSEMBLY OF [7]MONITOR ASSEMBLY (CABINET PARTS) . . . . . . . . . . . . . . . . . . . . .1-12

2.5ASSEMBLY AND DISASSEMBLY OF [2]OP BLOCK ASSEMBLYCCD BOARD ASSEMBLY

(CAMERA SECTION AND BOARD ASSEMBLY). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13 2.6 EMERGENCY DISPLAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14 2.7 AUTOMATIC DEMONSTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14 2.8 TAKE OUT CASSETTE TAPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16 2.9 SERVICE NOTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

3 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

3.1 PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18 3.2 TOOLS REQUIRED FOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18 3.3 MECHANISM ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-20 3.4 ELECTRICAL ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-23

CHARTS AND DIAGRAMS

BOARD INTERCONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 CPU SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 M.MDA SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4 ASP SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5 DSP SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6 F/Z/I/MDA SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7 V OUT SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8 TG/CDS SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9 REG SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10 LCD SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11 BW/VF SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12 JACK SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13 SPEAKER SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14 MONITOR SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15 E. VF CHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16 TOP OPE UNIT, ZOOM UNIT, REAR UNIT AND SENSOR SCHEMATIC DIAGRAMS. . . . . . . . . . . . . . . . . . . . . 2-17 MAIN CIRCUIT BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18 COMPONENT PARTS LOCATION GUIDE <MAIN> YB10400-01-02. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19 MAIN CIRCUIT BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21 MONITOR CIRCUIT BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22 CCD CIRCUIT BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23 E.VF CIRCUIT BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23 WAVEFORMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23 VOLTAGE CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24 POWER SYSTEM BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25 CPU/MDA SYSTEM BLOCK DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26 MONITOR SYSTEM BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27 CAMERA AND Y/C SYSTEM BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28 CAMERA AND Y/C SYSTEM BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

PARTS LIST

1 PACKING AND ACCESSORY ASSEMBLY <M1> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 2 FINAL ASSEMBLY <M2> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 3 MECHANISM ASSEMBLY <M3> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5 4 ELECTRONIC VIEWFINDER ASSEMBLY <M4>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7 5 MONITOR ASSEMBLY <M5>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8 6 ELECTRICAL PARTS LIST

MAIN BOARD ASSEMBLY <01> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9 CCD BOARD ASSEMBLY <02> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16 MONITOR BOARD ASSEMBLY <07> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16 E.VF BOARD ASSEMBLY <60>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

|

GR-SX25EK |

GR-SX25EX |

GR-SX25EZ |

GR-SXM49EK |

GR-SXM49EX |

GR-SXM49EZ |

|

|

|

|

|

|

|

LCD MONITOR |

|

NOT USED |

|

|

USED |

|

|

|

|

|

|

|

|

SPEAKER |

|

NOT USED |

|

|

USED |

|

|

|

|

|

|

|

|

SECTION 1

PRECAUTIONS

1.1 SAFTY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the countries in which they are to be sold.However,in order to maintain such compliance, it is equally important to implement the following precautions when a set is being serviced.

1.1.1 Precautions during Servicing

(1)Locations requiring special caution are denoted by labels and inscriptions on the cabinet, chassis and certain parts of the product.When performing service, be sure to read and comply with these and other cautionary notices appearing in the operation and service manuals.

(2)Parts identified by the  symbol and shaded (

symbol and shaded (  ) parts are critical for safety.

) parts are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to comply with X-ray emission standards for products using cathode ray tubes and those specified for compliance with various regulations regarding spurious radiation emission.

(3)Fuse replacement caution notice.

Caution for continued protection against fire hazard. Replace only with same type and rated fuse(s) as specified.

(4)Use specified internal wiring. Note especially:

•Wires covered with PVC tubing

•Double insulated wires

•High voltage leads

(5)Use specified insulating materials for hazardous live parts. Note especially:

•Insulation Tape

•PVC tubing

•Spacers

•Insulation sheets for transistors

•Barrier

(6)When replacing AC primary side components (transformers, power cords, noise blocking capacitors, etc.) wrap ends of wires securely about the terminals before soldering.

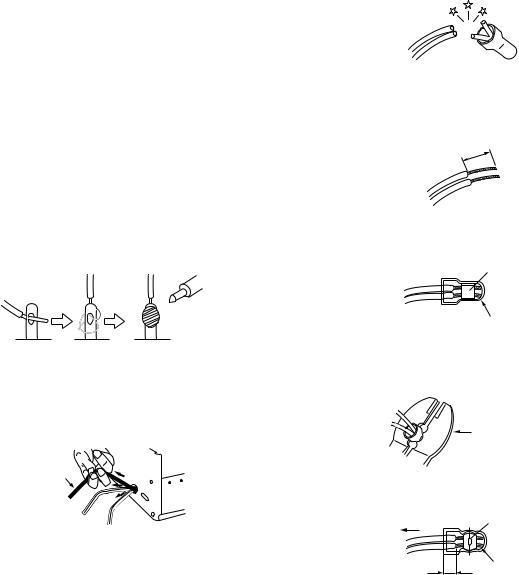

Fig.1

(7)Observe that wires do not contact heat producing parts (heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8)Check that replaced wires do not contact sharp edged or pointed parts.

(9)When a power cord has been replaced, check that 10-15 kg of force in any direction will not loosen it.

Power cord

Fig.2

(10)Also check areas surrounding repaired locations.

(11)Products using cathode ray tubes (CRTs)In regard to such products, the cathode ray tubes themselves, the high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission. Consequently, when servicing these products, replace the cathode

ray tubes and other parts with only the specified parts. Under no circumstances attempt to modify these circuits.Unauthorized modification can increase the high voltage value and cause X-ray emission from the cathode ray tube.

(12)Crimp type wire connector

In such cases as when replacing the power transformer in sets where the connections between the power cord and power trans former primary lead wires are performed using crimp type connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely according to the following steps.

•Connector part number :E03830-001

•Required tool : Connector crimping tool of the proper type which will not damage insulated parts.

•Replacement procedure

a)Remove the old connector by cutting the wires at a point close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

b)Strip about 15 mm of the insulation from the ends of the wires. If the wires are stranded, twist the strands to avoid frayed conductors.

15 mm

Fig.4

c)Align the lengths of the wires to be connected. Insert the wires fully into the connector.

Metal sleeve

Connector

Fig.5

d)As shown in Fig.6, use the crimping tool to crimp the metal sleeve at the center position. Be sure to crimp fully to the complete closure of the tool.

25 |

Crimping tool |

1. |

|

2. |

|

0 |

|

5. |

|

5 |

|

Fig.6

e) Check the four points noted in Fig.7.

Not easily pulled free |

Crimped at approx. center |

|

of metal sleeve |

||

|

||

|

Conductors extended |

Wire insulation recessed more than 4 mm

Fig.7

(No.86712)1-3

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

(1)Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed parts of the set (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.).

See table 1 below.

(2)Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed accessible parts of the set (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.). See Fig.11 below.

(3)Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic parts. See Fig.11 below.

Fig.8 |

(4)Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs and externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See Fig.9 and following Fig12.

|

|

a |

b |

Externally |

Z |

A |

c |

|

|

|

|

exposed |

V |

|

|

accessible part |

|

|

|

Fig.9

(5)Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in, Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See Fig.10 and grounding specifications.

Fig.10

Fig.11

Fig.12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

1-4 (No.86712)

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 BEFORE ASSEMBLY AND DISASSEMBLY

2.1.1 Precautions

1.Be sure to disconnect the power supply unit prior to mounting and soldering of parts.

2.Prior to removing a component part that needs to disconnect its connector(s) and its screw(s), first disconnect the wire(s) from the connector(s), and then remove the screw(s).

3.When connecting/disconnecting wires, pay enough attention not to damage the connectors.

4.Be careful in removing or handling the part to which some spacer or shield is attached for reinforcement or insulation.

5.When replacing chip parts (especially IC parts), first remove the solder completely to prevent peeling of the pattern.

6.Tighten screws properly during the procedures. Unless specified otherwise, tighten screws at a torque of 0.196N•m (2.0kgf•cm).

2.1.2 Assembly and disassembly

[Example]

STEP |

PART |

Fig. |

POINT |

NOTE |

|||||||

No. |

No. |

||||||||||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[1] |

LOWER CASE ASSEMBLY |

Fig.C1 |

8(S1),CN1a,b,c |

- |

|||||||

|

|

|

|

|

|

|

|||||

[2] |

B/W VF ASSEMBLY |

|

|

|

3(S2) |

- |

|||||

|

|

|

|

|

|

|

|||||

[3] |

TOP OPE UNIT |

|

|

|

CN3,L3a,2(L3b) |

- |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

[4] |

CASE COVER(S) ASSEMBLY |

Fig.C2 |

(S4),2(L4) |

- |

|||||||

|

|

CASE COVER(M) ASSEMBLY |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

(1) |

(2) |

(3) |

|

(4) |

(5) |

||||||

(1)Order of steps in Procedure

When reassembling, preform the step(s) in the reverse order. These numbers are also used as the identification (location) No. of parts Figures.

(2)Part to be removed or installed.

(3)Fig. No. showing Procedure or Part Location.

C = CABINET

D = CAMERA AND BOARD ASSEMBLY

(4)Identification of part to be removed, unhooked, unlocked, released, unplugged, unclamped or unsoldered.

P |

= Spring |

W |

= Washer |

S |

= Screw |

* |

= Unhook, unlock, release, unplug or unsolder. |

2(S3) |

= 2 Screws (S3) |

CN |

= Connector |

(5) Adjustment information for installation.

2.1.3 Destination of connectors

Two kinds of double-arrows in connection tables respectively show kinds of connector/wires.

: Flat wire

: Flat wire  : Wire

: Wire

[Example]

CONN. |

|

CONNECTOR |

|

Pin No. |

|

No. |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CN1a |

MAIN CN27 |

|

SPEAKER |

- |

2 |

|

|

|

|

|

|

Remove the parts marked in  .

.

2.1.4 Disconnection of connectors (Wires)

Pull both ends of the connector in the arrow direction, remove the lock and disconnect the flat wire.

Flat wire

Connector

Fig.2-1-1

Extend the locks in the direction of the arrow for unlocking and then pull out the wire. After removing the wire, immediately restore the locks to their original positions because the locks are apt to come off the connector.

Flat wire

Connector

Fig.2-1-2

2.1.5 Tools required for disassembly and assembly

1 |

Torque driver |

2 |

Bit |

|

YTU94088 |

YTU94088-003 |

|||

|

|

|||

3 |

Cleaning cloth |

|

|

|

KSMM-01 |

|

|

||

|

|

|

||

|

|

Fig.2-1-3 |

|

1.Torque driver

Be sure to use to fastening the mechanism and exterior parts because those parts must strictly be controlled for tightening torque.

2.Bit

This bit is slightly longer than those set in conventional torque drivers.

3.Cleaning cloth

Recommended cleaning cloth to wipe down the video heads, mechanism (tape transport system), optical lens surface.

(No.86712)1-5

2.2 ASSEMBLY AND DISASSEMBLY OF CABINET PARTS

2.2.1 Disassembly flow chart

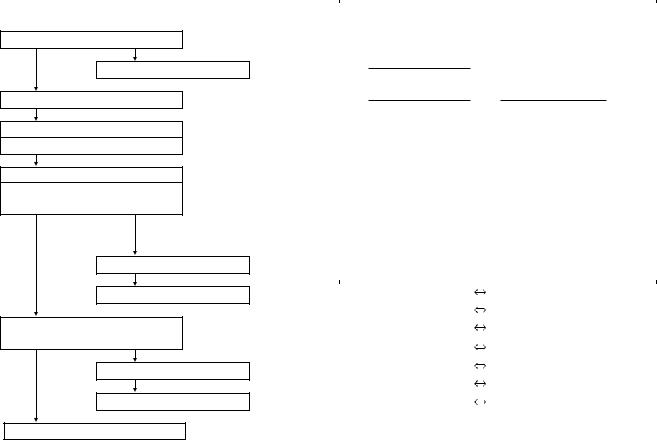

This flowchart indicates the disassembly step for the cabinet parts and board assembly in order to gain access to item(s) to be serviced. When reassembling, perform the step(s) in reverse order.

[1]LOWER CASE ASSEMBLY

[2]B/W VF ASSEMBLY

[3]TOP OPE UNIT

[4]CASE COVER(S) ASSEMBLY

[4]CASE COVER(M) ASSEMBLY

[5]UPPER CASE (S) ASSEMBLY

[5] UPPER CASE (M) ASSEMBLY

Inc. MONITOR ASSEMBLY

NOTE:

MONITOR MODEL ONLY

[6]COVER (UPPER/M) ASSEMBLY

[7]MONITOR ASSEMBLY

[8]FRONT COVER ASSEMBLY

Inc. DC LIGHT,MIC

[9]DC LIGHT ASSEMBLY

[10]MIC

[11]FRONT FRAME SA

1-6 (No.86712)

2.2.2 Disassembly method

STEP |

|

PART |

|

Fig. |

POINT |

|

|

NOTE |

|

No. |

|

|

No. |

|

|

||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

[1] |

LOWER CASE ASSEMBLY |

Fig.C1 |

8(S1),CN1a,b,c |

|

- |

||||

[2] |

B/W VF ASSEMBLY |

|

|

3(S2) |

|

- |

|||

[3] |

TOP OPE UNIT |

|

|

CN3,L3a,2(L3b) |

|

- |

|||

[4] |

CASE COVER(S) ASSEMBLY |

Fig.C2 |

(S4),2(L4) |

|

- |

||||

|

CASE COVER(M) ASSEMBLY |

|

|

|

|

|

|

||

[5] |

UPPER CASE (S) ASSEMBLY |

Fig.C3 |

6(S5a),(S5b) |

|

|

NOTE 5 |

|||

|

UPPER CASE (M) ASSEMBLY |

|

|

CN5,6(S5a),(S5b) |

|

|

|

||

|

Inc. MONITOR ASSEMBLY |

|

|

|

|

|

|

||

[6] |

COVER (UPPER/M) ASSEMBLY |

Fig.C4 |

3(S6),2(L6) |

|

- |

||||

[7] |

MONITOR ASSEMBLY |

|

|

S7a,L7,SHEET(FPC),2(S7b) |

NOTE 7a,b,c,d |

||||

[8] |

FRONT COVER ASSEMBLY |

Fig.C5 |

CN8a,CN8b,(S8),L8a,L8b |

|

NOTE 8a,b |

||||

|

Inc. DC LIGHT,MIC |

|

|

|

|

|

|

||

[9] |

DC LIGHT ASSEMBLY |

|

|

2(L9) |

|

- |

|||

[10] |

MIC |

|

|

|

S10 |

|

- |

||

[11] |

FRONT FRAME SA |

|

|

2(S11) |

|

|

NOTE 11 |

||

|

|

|

|

|

|

|

|

|

|

CONN. |

|

CONNECTOR |

|

|

Pin No. |

||||

No. |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CN1a |

MAIN |

CN27 |

|

|

SPEAKER |

- |

|

2 |

|

CN1b |

MAIN |

CN13 |

|

|

ZOOM UNIT |

- |

|

14 |

|

CN1c |

MAIN |

CN12 |

|

|

B/W VF ASSEMBLY |

|

3 |

||

CN3 |

|

MAIN |

CN18 |

|

|

TOP OPE UNIT |

- |

|

13 |

CN5 |

|

MAIN |

CN16 |

|

|

MONITOR ASSEMBLY - |

|

25 |

|

CN8a |

MAIN |

CN6 |

|

|

DC LIGHT |

- |

|

2 |

|

CN8b |

MAIN |

CN8 |

|

|

MIC |

- |

|

2 |

|

Remove the parts marked in  .

.

NOTE 5 :

Take care not to break or damage the FRAME.

NOTE 7a :

Take care not to cut the FPC wire.

NOTE 7b :

Insert and attach the SHEET(FPC) between the MONITOR FPC and the UPPER CASE(M)ASSEMBLY.

NOTE 7c :

Attachment of the FPC

NOTE 7d :

For disassembly of the MONITOR ASSEMBLY, refer to 2.4 ASSEMBLY AND DISASSEMBLY OF [7]MONITOR ASSEMBLY (CABINET PARTS).

NOTE 8a :

Take care not to damage the OP BLOCK ASSEMBLY when and after the FRONT CASE ASSEMBLY is removed.

NOTE 8b :

Attachment of the WIRE

NOTE 11 :

There are two types of FRONT FRAME ASSEMBLY.

The two types of the FRONT FRAME ASSEMBLY can be distinguished from each other by their shape.

TYPE B consists of the two parts, namely the tape guide and the torsion spring.

In exchanging the FRONT FRAME ASSEMBLY, TYPE A can be exchanged to TYPE B, but TYPE B cannot be exchanged to TYPE A.

As for the part number, refer to the parts list.

[3]

|

|

|

L3a |

|

|

|

|

|

|

|

|

|

L3b |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

v |

|

CN3 |

|

|

|

|

|

|

|

|

|

|

|

w |

|

|

|

|

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

E |

|

D |

|

|

|

|

|

|

|

|

|

|

u |

|

G |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

t |

|

yz |

|

|

|

|

|

|

|

|

|

|

|

CN1a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[1] |

|

|

|

|

|

x |

|

CN1b |

3 F |

G |

|

|

|

|

|

|||

CN1c |

|

|

|

|

|

|

|

|||||

|

9 (S2) |

(S1) |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

10 (S2) |

q |

r |

s1 |

|

v |

w |

|

|

|

|

|

11 (S2) p |

|

|

|

|

|

|

||||

|

|

|

|

E |

|

|

|

|

|

1 |

||

|

|

|

|

|

u |

|

|

|

|

2 |

(S1) |

|

|

|

|

|

|

|

|

|

|

|

z (S1) |

E |

|

|

|

|

|

|

t |

|

|

|

y |

8 |

|

s1 |

|

|

|

|

|

|

|

|

4 |

7 |

(S1)qr |

|

|

|

|

|

|

|

|

|

|

p |

|

|

||

|

|

|

|

|

|

x |

5 |

(S1)(S1) |

|

|

||

|

|

|

|

|

6 |

|

(S1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(S1) |

|

|

|

|

|

[2] |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig.C1 |

|

|

|

|

|

|

|

<SHOOTING MODEL>

[4]

|

12 |

aa |

(S4) |

L4 aa

aa

[4]

<MONITOR MODEL>

Fig.C2

(No.86712)1-7

|

|

|

|

14 |

|

|

|

|

<NOTE 5> |

|

(S5a) |

|

|

|

|||

|

n |

|

|

|

|

|

||

|

[5] |

|

|

m |

|

|

|

|

|

|

|

|

|

|

|

||

15 |

|

|

|

|

|

<SHOOTING MODEL> |

|

|

|

|

|

|

|

|

|

|

|

(S5a) |

|

|

|

|

g |

|

|

|

|

|

|

|

|

|

|

|

|

16 |

k |

|

|

|

|

|

|

|

(S5a) |

|

|

k |

|

|

|

||

|

l |

|

14 |

|

18 |

|

|

|

|

j |

|

|

(S5a) |

|

|

|

|

|

|

(S5a) |

|

|

|

|

||

<NOTE 5> |

|

|

n |

|

|

<MONITOR MODEL> |

|

|

17 |

|

|

|

|

|

|||

|

m |

|

|

|

19 |

|

||

[5] |

(S5a) |

|

|

|

|

|

||

15 |

|

|

|

|

|

(S5b) |

|

|

|

|

|

|

|

|

m |

|

|

(S5a) |

|

|

|

|

g |

|

n |

|

16 |

|

|

|

|

|

C |

|

|

h |

|

|

|

|

|

|

|

|

(S5a) |

|

|

k |

h |

|

|

13 |

|

|

|

|

18 |

|

g |

(S5a) |

||

|

i |

|

|

|

|

|

C |

|

|

j |

|

(S5a) |

|

|

|

||

|

|

|

i |

|

|

|

|

|

|

|

|

|

|

|

|

CN5 |

|

|

17 |

|

|

|

|

|

|

|

|

|

|

|

c |

|

|

|

|

|

(S5a) |

|

|

|

|

k |

|

|

|

|

|

|

d |

|

|

||

|

|

|

|

|

j |

|

|

|

|

|

|

|

|

Fig.C3 |

|

|

|

24 |

|

|

|

|

|

|

|

<MONITOR MODEL> |

|

|

|

|

|

|

|

|

|

(S7b) |

|

|

|

|

|

|

|

|

25 |

FPC |

|

|

|

|

|

|

|

<NOTE 7a> |

|

|

|

|

|

|

|

|

(S7b) |

|

|

|

|

|

|

f d |

|

|

|

|

[6] |

|

|

|||

|

|

|

|

|

|

|||

e |

23 |

|

|

|

|

|

L6 |

|

|

|

|

|

|

|

|

||

|

(S7a) |

f |

|

|

|

|

c |

|

|

|

d |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<NOTE 7c> |

|

|

|

c |

|

|

|

20 |

|

[7] |

|

|

|

|

21 |

(S6) |

DO NOT MAKE FPC |

|

|

|

|

|

|

||||

<NOTE 7d> |

|

|

|

|

|

(S6) |

|

SLACKEN IN THIS PART. |

|

|

|

|

|

|

|

|

|

|

|

|

L7 |

|

e |

22 |

|

|

|

|

|

|

(S6) |

|

PROCESSED |

||

|

|

|

|

|

|

|

||

|

|

|

<NOTE 7b> |

|

|

THROUGH THIS PART. |

||

|

|

|

|

|

|

|||

|

|

|

SHEET(FPC) |

|

|

|||

|

UPPER CASE(M)ASSEMBLY |

|

|

|

||||

AS FOR PUSH SW, DON'T BE BROKEN AND DON'T FLOAT . (SEE AND CHECK SW AFTER ATTACHING FPC.)

INSTALL THE RAINFORCEMENT BOARD WITH MONITOR OPENED . ( FOR THE DAMAGE PREVENTION OF PUSH SWITCH .)

Fig.C4

1-8 (No.86712)

Loading...

Loading...