JVC GR-D20, GR-D21, GR-D40E Service Manual

SERVICE MANUAL

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No.86730

2003/04

DIGITAL VIDEO CAMERA

86730200304

GR-D20EK,GR-D20E

X

,GR-D20E

Y

,GR-D20E

Z

,GR-D21EK,

GR-D40EK,GR-D40E

X

,GR-D40E

Y

,GR-D40E

Z

SPECIFICATION

Camcorder

General

Digital Video Camera

Connectors

AC Adapter

For disassembling and assembling of MECHANISM ASSEMBLY, refer to the SERVICE MANUAL No.86700 (MECHANISM ASSEMBLY).

PAL

Power supply : DC 11.0 V (Using AC Adapter)

DC 7.2 V (Using battery pack)

Power consumption

LCD monitor off, viewfinder on : Approx. 3.4 W

LCD monitor on, viewfinder off : Approx. 4.7 W

Dimensions (W x H x D) : 69 mm x 94 mm x 143 mm

(with the LCD monitor closed and the viewfinder pushed

back in)

Weight : Approx. 525 g

Operating temperature : 0°C to 40°C

Operating humidity : 35% to 80%

Storage temperature : -20°C to 50°C

Pickup : 1/6" CCD

Lens : F 1.6, f = 2.7 mm to 43.2 mm, 16:1 power zoom lens

Filter diameter : Ø37 mm

LCD monitor : 2.5" diagonally measured, LCD panel/TFT active

matrix system

Viewfinder : Electronic viewfinder with 0.24" black/white LCD

Speaker : Monaural

Format : DV format (SD mode)

Signal format : PAL standard

Recording/Playback format : Video: Digital component recording

: Audio: PCM digital recording,

32 kHz 4-channel (12-bit),

48 kHz 2-channel (16-bit)

Cassette : Mini DV cassette

Tape speed : SP : 18.8 mm/s

LP : 12.5 mm/s

Maximum recording time : SP : 80 min.

(using 80 min. cassette) LP : 120 min.

S-Video

Output : Y : 1 V (p-p), 75 Ω, analogue

C : 0.29 V (p-p), 75 Ω, analogue

Input* : Y : 0.8 V (p-p) -1.2 V (p-p), 75 Ω, analogue

C : 0.2 V (p-p) -0.4 V (p-p), 75 Ω, analogue

AV

Video output : 1 V (p-p), 75 Ω, analogue

Video input* : 0.8 V (p-p) -1.2 V (p-p), 75 Ω, analogue

Audio output : 300 mV (rms), 1 kΩ, analogue, stereo

Audio input* : 300 mV (rms), 50 kΩ, analogue, stereo

DV

Output : 4-pin, IEEE 1394 compliant

Input* : 4-pin, IEEE 1394 compliant

USB** :5-pin

EDIT Ø3.5 mm, 2-pole

* GR-D50/D30 only

** GR-D50/D40 only

Power requirement AC 110 V to 240 V ~, 50 Hz/60 Hz

Output : DC 11 V , 1 A

Specifications shown are for SP mode unless otherwise indicated. E & O.E. Design and specifications subject

to change without notice.

GR-D20EK,GR-D20EX,GR-D20EY,GR-D20EZ,GR-D21EK,GR-D40EK,GR-D40EX,GR-D40EY,GR-D40EZ M3D122,M3D124

1-6 (No.86730)

1.Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

2.Bit

This bit is slightly longer than those set in conventional torque

drivers.

3.Tweezers

To be used for removing and installing parts and wires.

4.Chip IC replacement jig

To be used for replacement of IC.

5.Cleaning cloth

Recommended cleaning cloth to wipe down the video heads,

mechanism (tape transport system), optical lens surface.

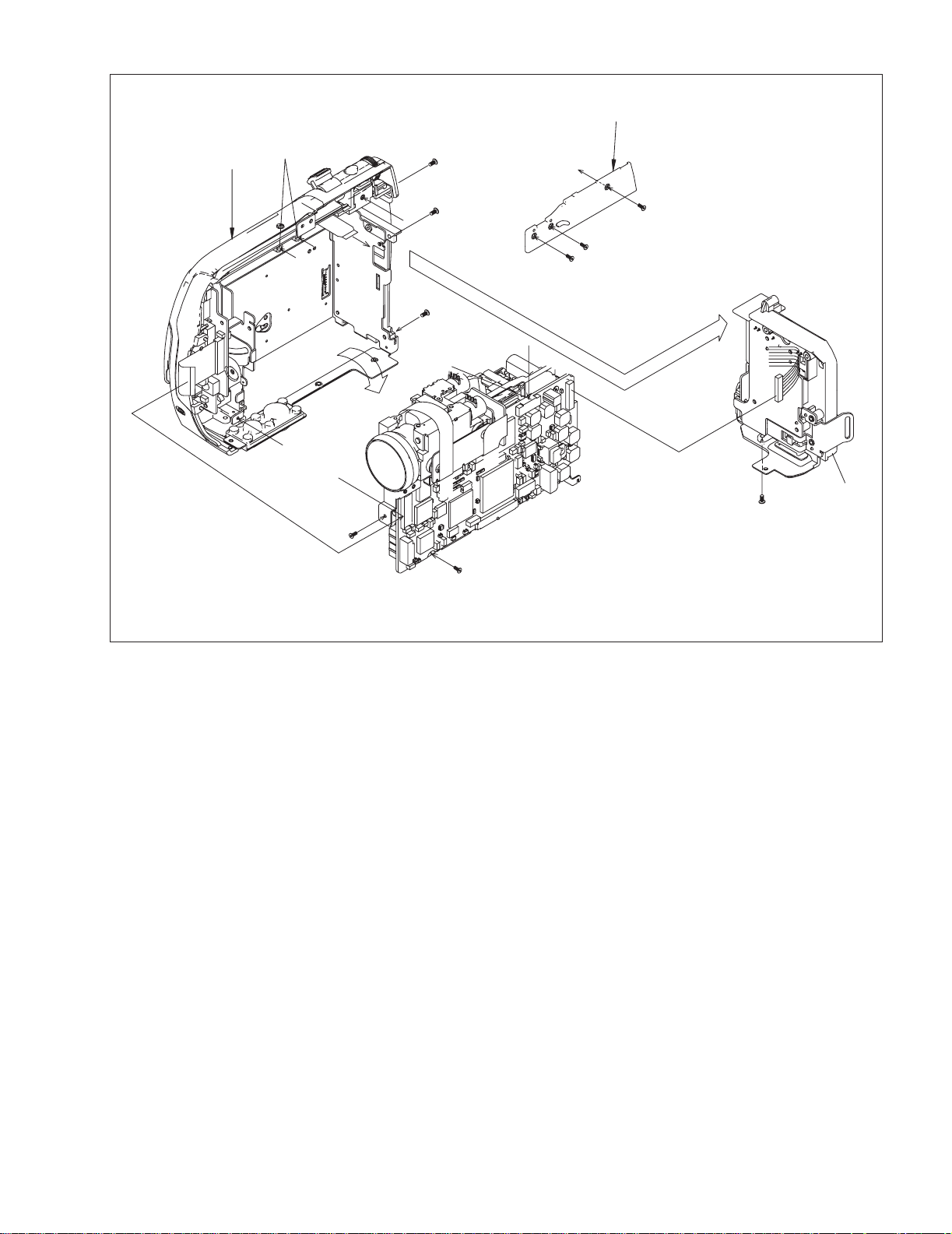

2.2 ASSEMBLY AND DISASSEMBLY OF CABINET PARTS

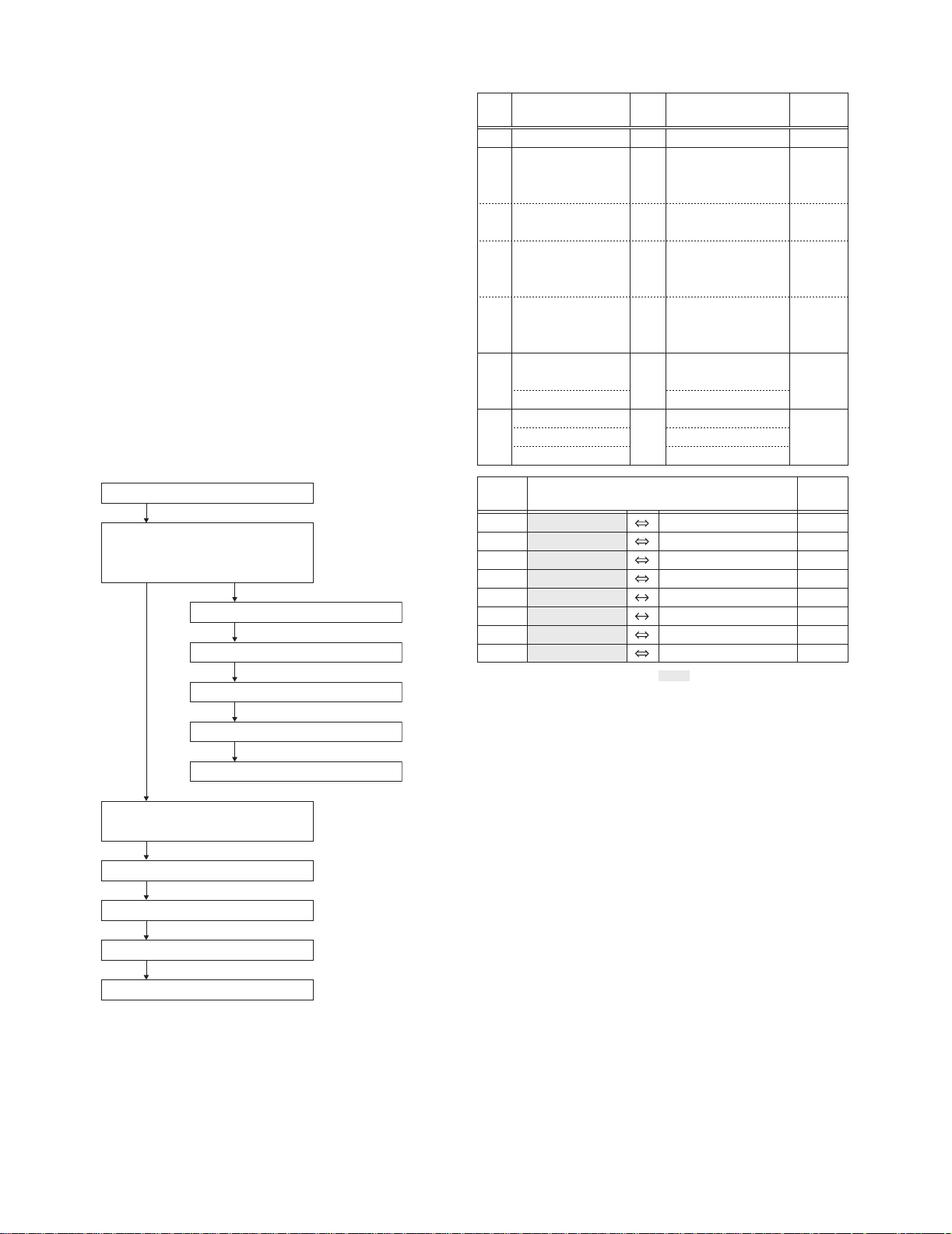

2.2.1 Disassembly flow chart

This flowchart indicates the disassembly step for the cabinet

parts and board assembly in order to gain access to item(s) to be

serviced. When reassembling, perform the step(s) in reverse or-

der.

2.2.2 Disassembly method

NOTE 8a:

Take care not to cut the FPC wire when and after removing the

VF ASSEMBLY.

NOTE 8b:

As for disassembly/assembly of [8]VF ASSEMBLY, see 2.4

ASSEMBLY AND DISASSEMBLY OF [8] VF ASSEMBLY.

NOTE 10a:

Take care not to cut the FPC when and after removing the

MONITOR ASSEMBLY.

NOTE 10b:

As for disassembly/assembly of [10] MONITOR ASSEMBLY,

see 2.5 ASSEMBLY AND DISASSEMBLY OF [10] MONITOR

ASSEMBLY.

NOTE 11a:

Before removing the MONI-BW BOARD ASSEMBLY, check

whether MEMORY CARD is inserted or not. If MEMORY

CARD is inserted, pull out the MEMORY CARD before remov-

ing the MONI-BW BOARD ASSEMBLY.

NOTE 11b:

Since the SPEAKER is soldered to the MONI-BW BOARD AS-

SEMBLY, the SPEAKER should not be separated from the

MONI-BW BOARD ASSEMBLY except when replacing the

SPEAKER.

NOTE 11c:

Take care not to lose the KNOB(SLIDE). When attaching the

KNOB(SLIDE), attach the KNOB(SLIDE) in a proper position.

NOTE 3:

After removing the FRONT COVER ASSEMBLY, OP BLOCK

ASSEMBLY is not covered with anything. Take care not to

damage the OP BLOCK ASSEMBLY when and after removing

the FRONT COVER ASSEMBLY.

[1]

[2]

TOP COVER ASSEMBLY

UPPER ASSEMBLY

(Inc. VF ASSEMBLY,

SPEAKER/MONITOR)

[8]

VF ASSEMBLY

[9]

COVER(UPPER)

[10]

MONITOR ASSEMBLY

[11]

MONI-BW BOARD ASSEMBLY

[12]

SPEAKER

[3]

FRONT COVER ASSEMBLY

(Inc.MIC)

[4]

[5]

[6]

[7]

MIC

COVER(ZOOM)

REAR UNIT

LOWER ASSEMBLY

TOP COVER ASSEMBLY

UPPER ASSEMBLY

(Inc. VF ASSEMBLY,

SPEAKER/MONITOR)

VF ASSEMBLY

COVER(UPPER)

MONITOR ASSEMBLY

MONI-BW BOARD ASSEMBLY

SPEAKER

FRONT COVER ASSEMBLY

(Inc.MIC)

MIC

COVER(ZOOM)

REAR UNIT

LOWER ASSEMBLY

MAIN CN101

MAIN CN103

MONI-BW CN763

MONI-BW CN765

MAIN CN106

MAIN CN104

MAIN CN102

MAIN CN109

MONI-BW CN761

MONI-BW CN762

VF ASSEMBLY -

BL-2.5/3.5 -

MIC -

REAR UNIT -

JACK CN501

ZOOM UNIT -

Fig.C1

Fig.C2-1

Fig.C2-2

Fig.C2-3

Fig.C2-4

Fig.C3

Fig.C4

S1,2(L1)

S2a,2(S2b),3(S2c)

2(S2d),S2e,S2c

L2,CN2a,b

2(S8),L8,CN8a

2(S9),L9

2(S10a),CN10a,2(S10b),L10

2(S11a),2(S11b),4(S11c)

BKT(HINGE),KNOB(SLIDE)

COVER(JACK),S3,L3a,L3b

CN4

S4

S5a,3(S5b),2(L5)

CN6,S6

CN7a,b,S7a,3(S7b)

-

-

NOTE 8a

NOTE 8b

-

NOTE 10a

NOTE 10b

NOTE 11a

NOTE 11b

NOTE 11c

NOTE 3

-

[1]

[2]

[8]

[9]

/[10]

[11]

/[12]

[3]

/

[4]

[5]

/[6]

/[7]

CN2a

CN2b

CN8a

CN10a

CN4

CN6

CN7a

CN7b

40

10

20

32

5

11

22

16

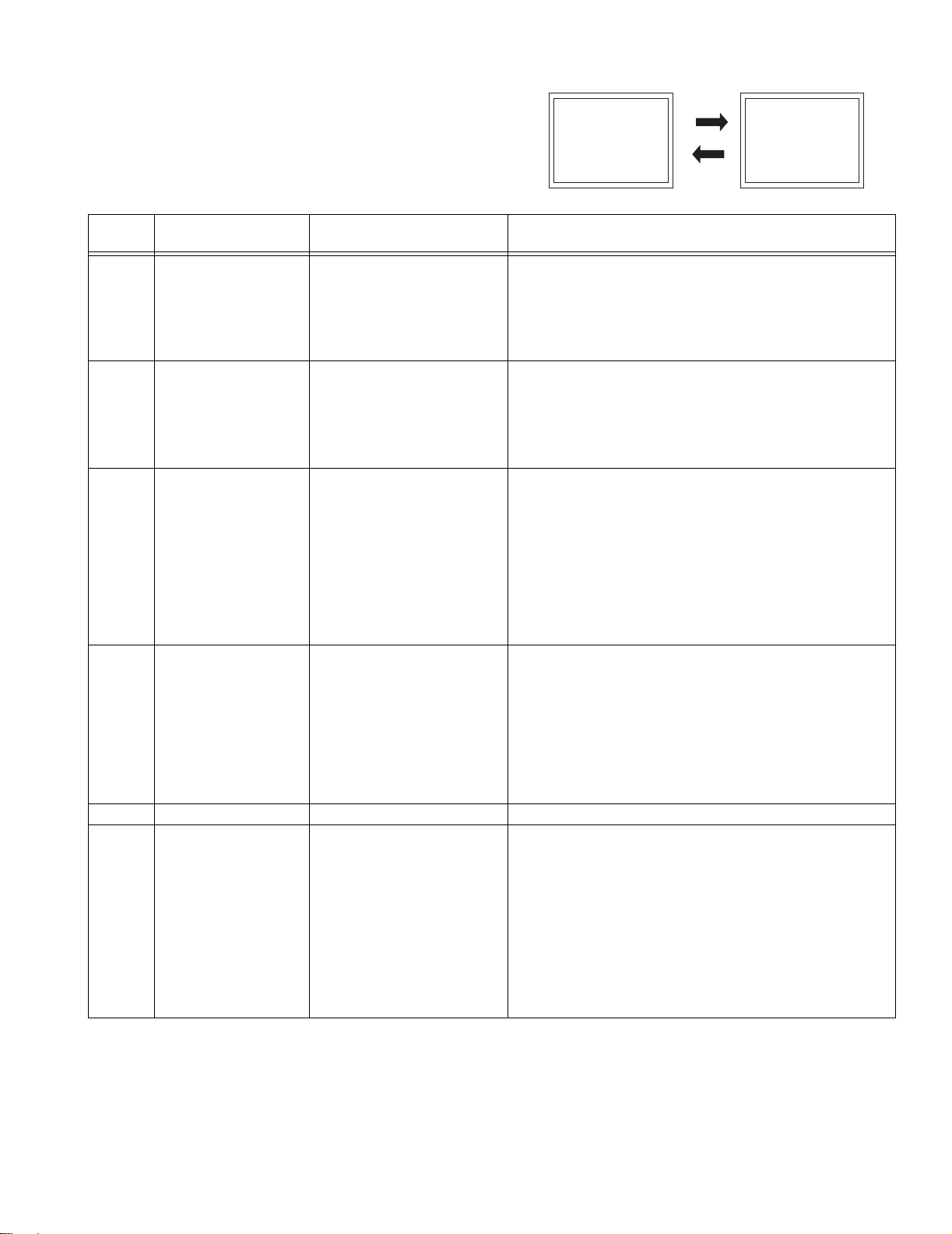

STEP

No.

PART

CONN.

No.

Pin No.

CONNECTOR

NOTE

Fig.

No.

POINT

Remove the parts marked in .

(No.86730)1-7

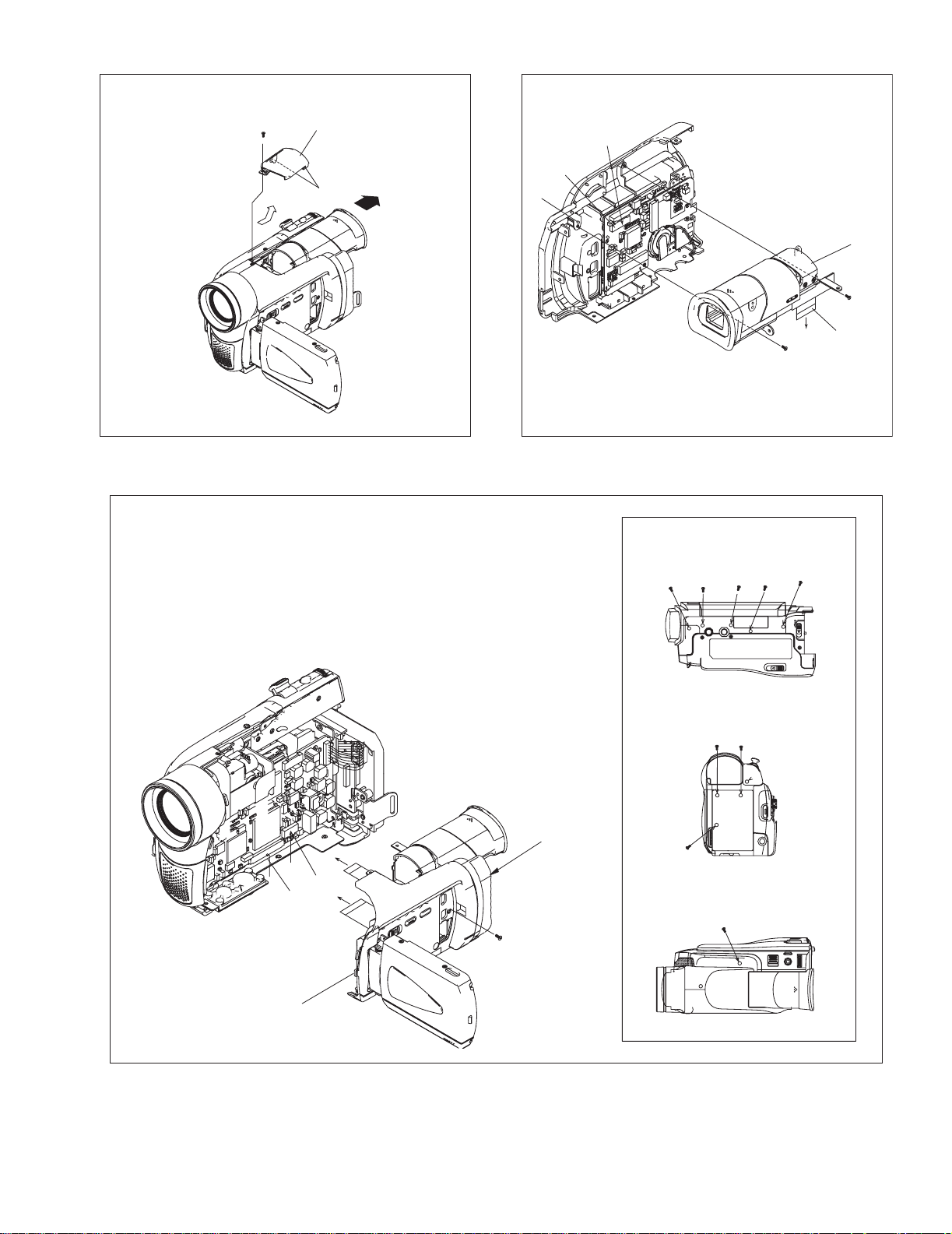

Fig.C1 Fig.C2-2

Fig.C2-1

L1

(S1)

1

[1]

c

NOTE 8a

NOTE 8b

13

(S8)

12

(S8)

[8]

c

L8

CN8a

a

b

b

a

7

[2]

([8]-[12])

(S2c)

2

(S2a)

3

(S2b)

8

(S2d)

10

(S2e)

11

(S2c)

9

(S2d)

4

(S2b)

5

(S2c)

6

(S2c)

CN2a

CN2b

L2

TOP SIDE

REAR SIDE

BOTTOM SIDE

c

1-8 (No.86730)

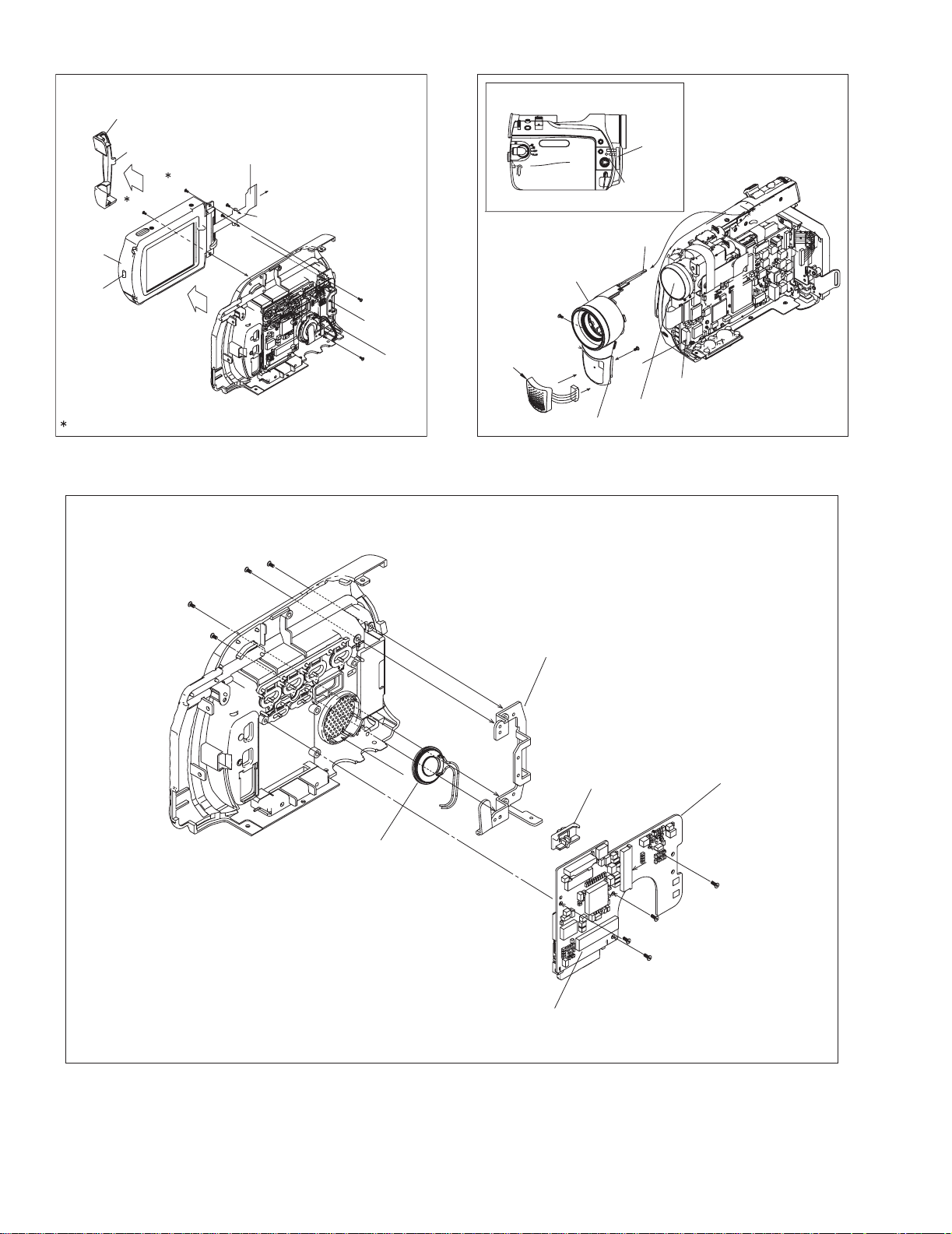

Fig.C2-3 Fig.C3

Fig.C2-4

16

(S10a)

NOTE 10a

d

d

17

(S10a)

14

(S9)

15

(S9)

0.147N

.

m(1.5kgf

.

cm)

L10

[10]

[9]

L9

CN10a

18

(S10b)

19

(S10b)

NOTE 10b

L.CASE SIDE

28

(S3)

CN4

L3a

OP BLOCK ASSEMBLY

NOTE 3

L3b

[4]

[3]

([4])

29

(S4)

28

(S3)

COVER

(JACK)

e

e

20

(S11a)

22

(S11b)

21

(S11a)

23

(S11b)

[12]

NOTE11b

BKT(HINGE)

[11]

NOTE11c

KNOB(SLIDE)

24

(S11c)

25

(S11c)

27

(S11c)

26(S11c)

NOTE 11a

(No.86730)1-9

Fig.C4

[6]

34

(S6)

h

g

h

g

35

(S7a)

38

(S7b)

32

(S5b)

31

(S5b)

33

(S5b)

37

(S7b)

36

(S7b)

30

(S5a)

CN7a

CN7b

CN6

[5]

[7]

L5

f

f

1-10 (No.86730)

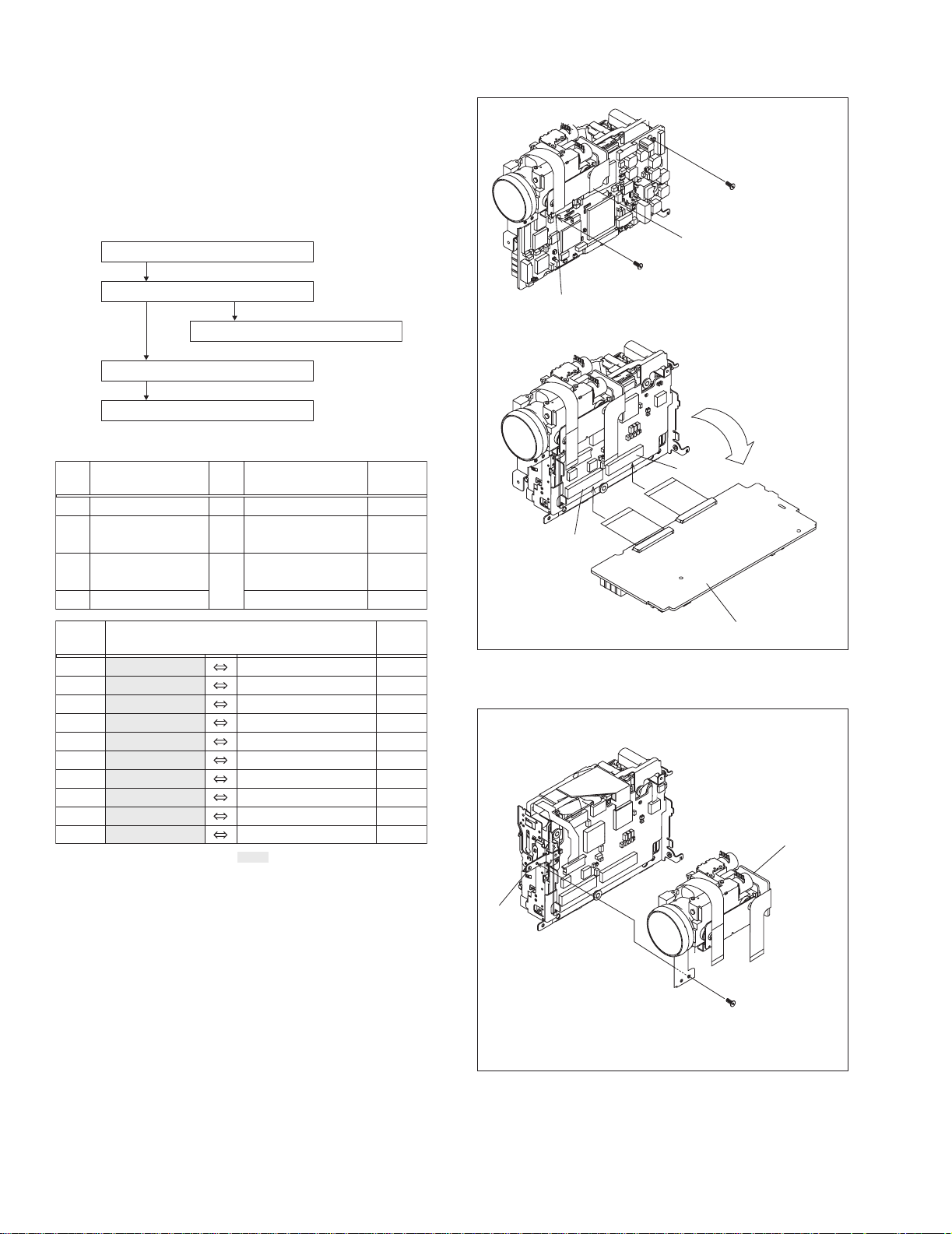

2.3 ASSEMBLY AND DISASSEMBLY OF CAMERA SECTION AND BOARD ASSEMBLY

2.3.1 Disassembly flow chart

This flowchart indicates the disassembly step for the cabinet

parts and board assembly in order to gain access to item(s) to be

serviced. When reassembling, perform the step(s) in reverse or-

der.

NOTE:

Please see Service Manual No. 86700 (MECHANISM ASSY).

2.3.2 Disassembly method

NOTE 2:

As for disassembly/assembly of [2] OP BLOCK ASSEMBLY,

see 2.6 ASSEMBLY AND DISASSEMBLY OF [2] OP BLOCK

ASSEMBLY.

Fig.D1

Fig.D2

[1]

[2]

MAIN BOARD ASSEMBLY

[5]

CCD BOARD ASSEMBLY

[3]

[4]

PREMDA BOARD ASSEMBLY

MECHANISM ASSEMBLY

OP BLOCK ASSEMBLY

MAIN BOARD ASSEMBLY

OP BLOCK ASSEMBLY

/ CCD BOARD ASSEMBLY

PREMDA BOARD ASSEMBLY

MECHANISM

MAIN CN108

MAIN CN107

MAIN CN111

MAIN CN110

PREMDA CN406

PREMDA CN405

PREMDA CN404

PREMDA CN402

PREMDA CN403

PREMDA CN407

OP BLOCK ASSEMBLY CN501

CCD CN5001

PREMDA CN408

PREMDA CN401

SENSOR -

CAPSTAN MOTOR -

DRUM MOTOR -

HEAD -

LOADING MOTOR -

ROTARY ENCODER -

Fig.D1

Fig.D2

Fig.D3

CN1a,b,2(S1),CN1c,d

S2,L2

2(S3a),L3,SHIELD COVER(PR)

CN3a,b,c,d,e,f,2(S3b)

3(S4),BKT(MECHA)

-

NOTE 2

-

-

[1]

[2]/[5]

[3]

[4]

CN1a

CN1b

CN1c

CN1d

CN3a

CN3b

CN3c

CN3d

CN3e

CN3f

24

20

40

40

16

18

11

8

6

6

STEP

No.

PART

CONN.

No.

Pin No.

CONNECTOR

NOTE

Fig.

No.

POINT

Remove the parts marked in .

ASSEMBLY

1

(S1)

2

(S1)

CN1c

CN1d

CN1a

CN1b

[1]

3

(S2)

L2

[2]

([5])

NOTE[2]

(No.86730)1-11

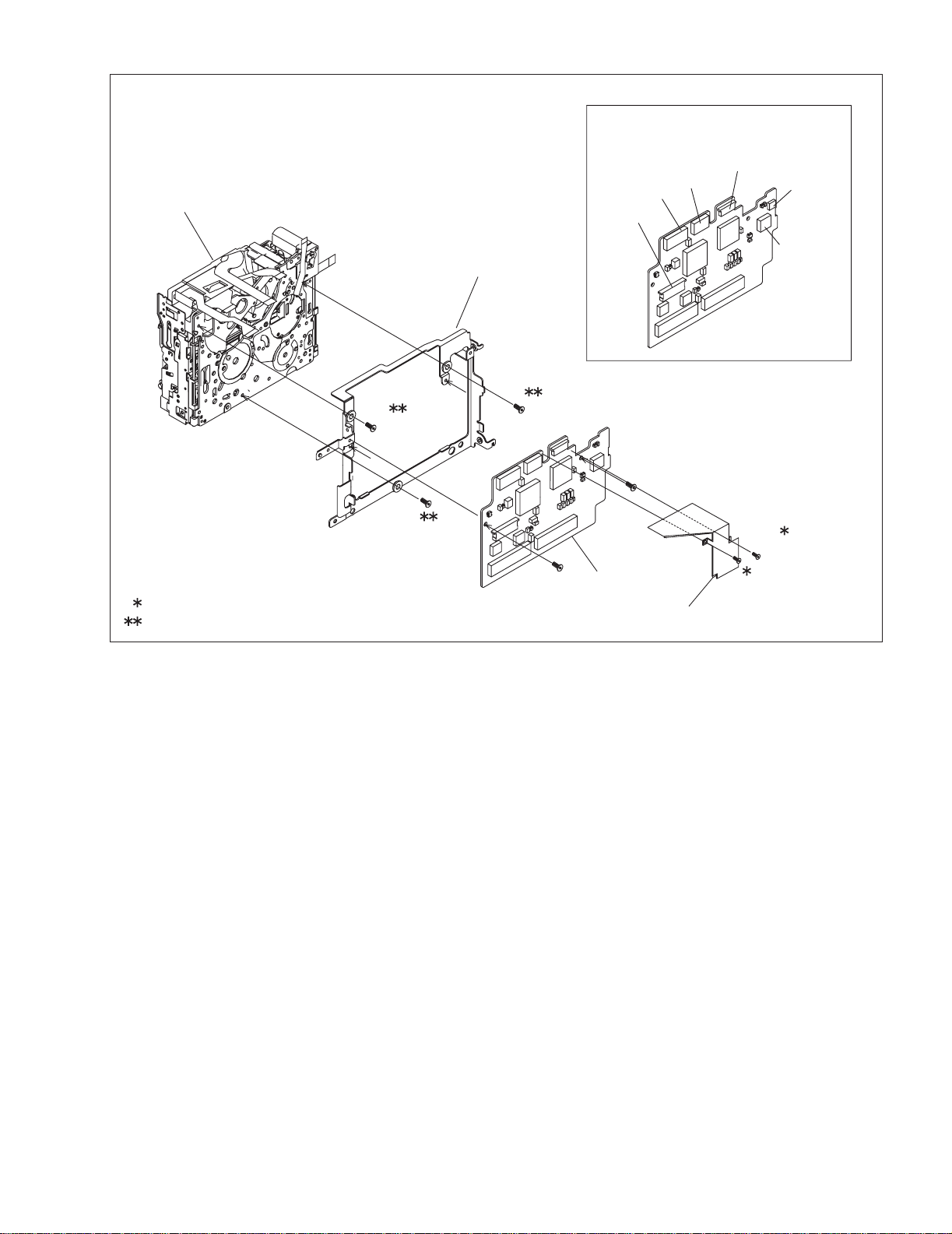

Fig.D3

4

(S3a)

5

(S3a)

L3

PREMDA BOARD ASSEMBLY

6

(S3b)

7

(S3b)

9

(S4)

0.069N

.

m (0.7kgf

.

cm)

0.078N

.

m (0.8kgf

.

cm)

8

(S4)

(PR)

SHIELD COVER

[4]

BKT(MECHA)

CN3a

CN3b

CN3c

CN3e

CN3f

CN3d

[3]

10

(S4)

1-12 (No.86730)

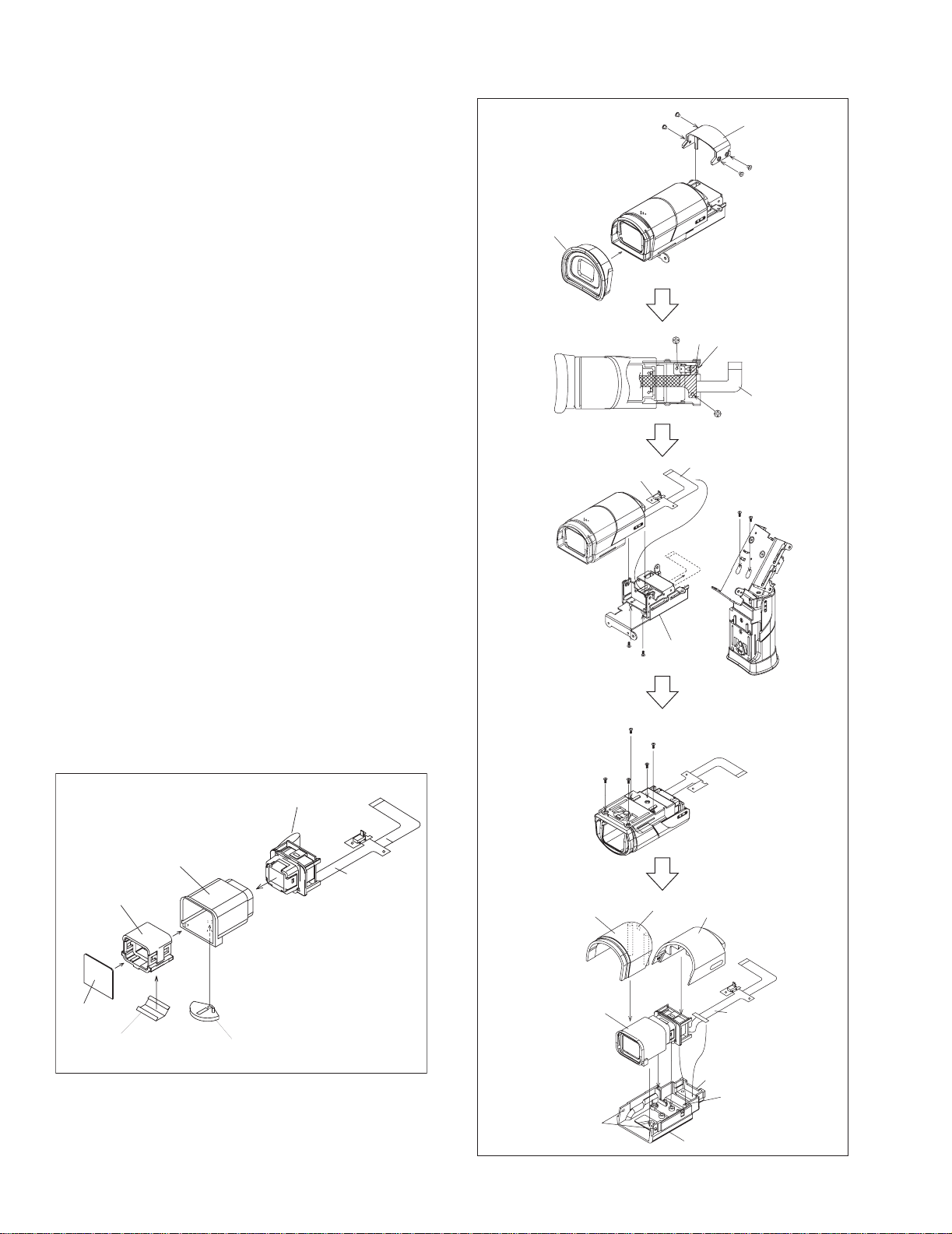

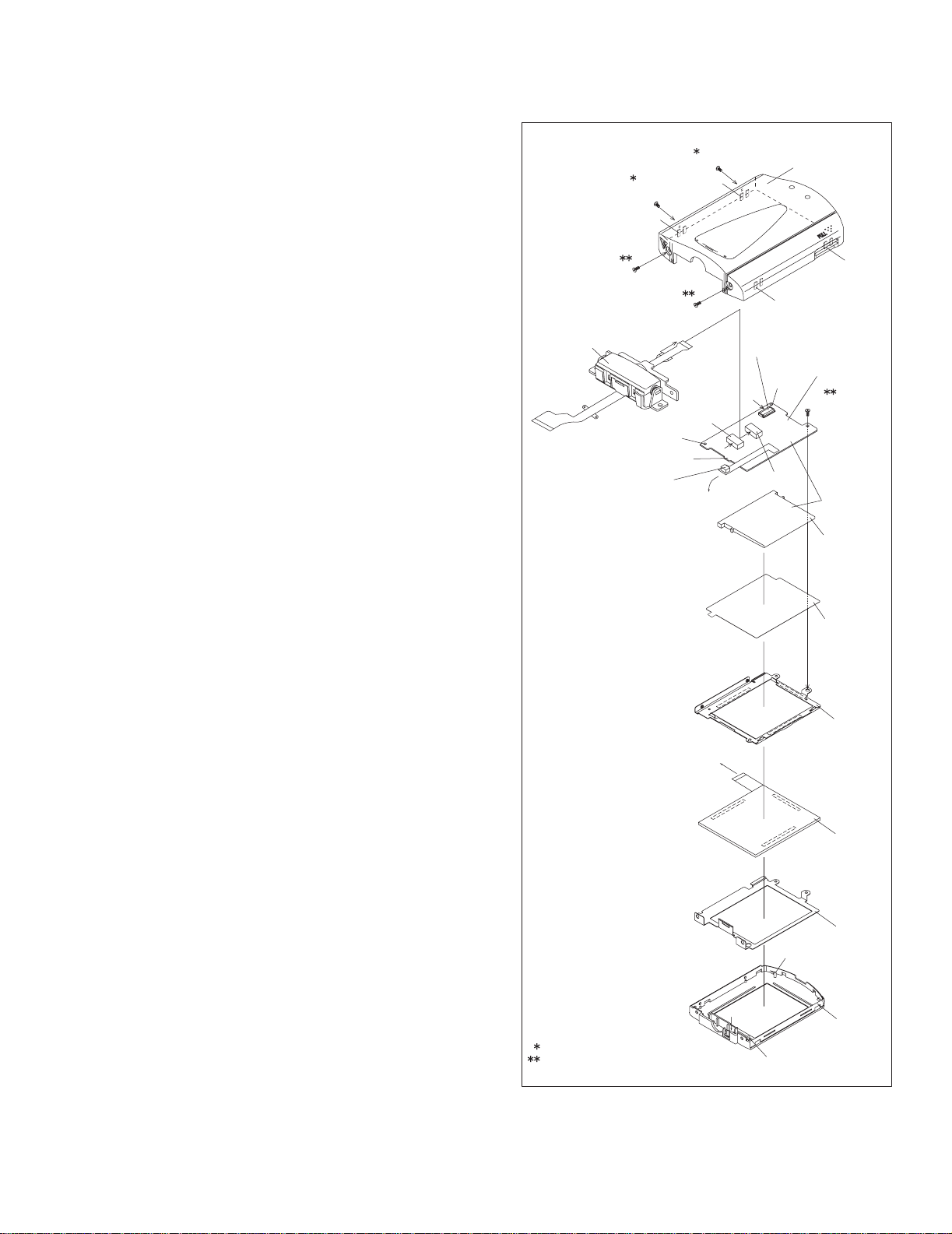

2.4 ASSEMBLY AND DISASSEMBLY OF [8]VF ASSEMBLY

2.4.1 Disassembly of VF ASSEMBLY

(1) Remove the EYE CUP.

(2) Remove the four screws (1 to 4) and then remove the COV-

ER (VF).

(3) Remove the two screws (5 and 6) and then remove the

FPC BOARD from the hook attaching the FPC BOARD.

NOTE 8a:

During the procedure, be careful not to damage the FPC.

When attaching the SW BOARD ASSEMBLY, attach the

SW BOARD ASSEMBLY so that the SW BOARD AS-

SEMBLY comes upwards.

(4) Remove the four screws (7 to 10), and then pull out and re-

move the FPC from the VF HINGE ASSEMBLY.

NOTE 8b:

During the procedure, be careful not to damage the FPC

and the SWITCH.

(5) Remove the five screws (11 to 15).

(6) Remove the UPPER CASE(VF) R.

(7) Remove the UPPER CASE(VF) F and then pull out the

LENS SA and the LCD UNIT ASSEMBLY with the FPC.

NOTE 8c:

In attaching the LCD UNIT ASSEMBLY, put the projec-

tions of the LCD UNIT ASSEMBLY in the slots of the

BOTTOM CASE(VF). Put the STOPPER of the FPC in-

side the BOTTOM CASE(VF). In attaching the UPPER

CASE(VF) F and the UPPER CASE(VF) R, attach the

UPPER CASE(VF) F first and then the UPPER

CASE(VF) R and be careful to keep the FPC inside the

BOTTOM CASE(VF).

2.4.2 Disassembly of the LENS SA

(1) Remove the LEVER(LENS).

(2) Remove the SHEET(LENS).

(3) Remove the LENS ASSEMBLY from the GUIDE

LENS(VF).

NOTE 8d:

Be careful not to lose the SPRING(LENS).

Fig.2-4-2

Fig.2-4-1

SHEET(LENS)

LENS ASSEMBLY

LEVER(LENS)

SPRING(LENS)

NOTE8d:

GUIDE LENS(VF)

LCD UNIT ASSEMBLY

FPC

<LENS SA>

(L8a)

5

(S8b)

6

(S8b)

NOTE8a

FPC

EYE CUP

2

(S8a)

4

(S8a)

3

(S8a)

1

(S8a)

COVER(VF)

EYE CUP

8

(S8a)

7

(S8a)

10

(S8c)

VF HINGE

ASSEMBLY

9

(S8c)

FPC

NOTE8b

12

(S8c)

13

(S8c)

11

(S8c)

15

(S8c)

14

(S8c)

UPPER CASE(VF)F

UPPER CASE(VF)R

LCD UNIT

L8c

ASSEMBLY

NOTE8c

NOTE8c

BOTTOM CASE(VF)

L8b

LENS SA

FPC

(No.86730)1-13

2.5 ASSEMBLY AND DISASSEMBLY OF [10]MONITOR ASSEMBLY (CABINET PARTS)

2.5.1 Disassembly of MONITOR ASSEMBLY (2.5 INCH)

NOTE:

Be careful in removing or handling the monitor assembly, es-

pecially not to soil or scratch the monitor screen during the dis-

assembly procedure.

(1) While removing the four screws (1 to 4) in numerical order

and then disengaging the four hooks (L10a-L10d) in alpha-

betical order, open and remove the MONITOR COVER

ASSEMBLY.

(2) Remove the SENSOR BOARD ASSEMBLY from the

MONITOR CASE.

(3) Disconnect the FPC in the connectors CN10a and CN10b

in this order, and then remove the MONI.HINGE ASSEM-

BLY.

(4) Disconnect the FPC of the LCD MODULE from the connec-

tor CN10c.

(5) Remove one screw (5) and then remove the BL BOARD

ASSEMBLY together with the BACK LIGHT ASSEMBLY.

NOTE 10a:

It depends on the inch size of the monitor assembly

whether the backlight is supplied as an assembly or as

separated parts.

In replacing the backlight assembly, see the Parts List.

NOTE 10b:

Since the BACK LIGHT ASSEMBLY is soldered to the

BL BOARD ASSEMBLY, the BACK LIGHT should not be

separated from the BL BOARD ASSEMBLY except

when replacing them.

(6) Remove the DIFF.SHEET.

(7) Remove the LCD FRAME together with the LCD MODULE.

(8) Remove the SHIELD CASE.

Fig.2-5-1

DIFF. SHEET

NOTE10a

BACK LIGHT

NOTE10b

BL-2.5 BOARD

ASSEMBLY

MONITOR

CASE

L10g

SHIELD CASE

L10f

5

(S10a)

L10b

CN10b

SD10b

SD10a

L10e

CN10a

CN10c

L10a

L10d

L10c

MONITOR COVER

ASSEMBLY

4

(S10b)

3

(S10b)

1

(S10a)

2

(S10a)

b

LCD FRAME

LCD MODULE

c

b

MONI.HINGE

ASSEMBLY

SENSOR BOARD

ASSEMBLY

:0.069N

.

m (0.7kgf

.

cm)

:0.098N

.

m (1.0kgf

.

cm)

a

a

c

1-14 (No.86730)

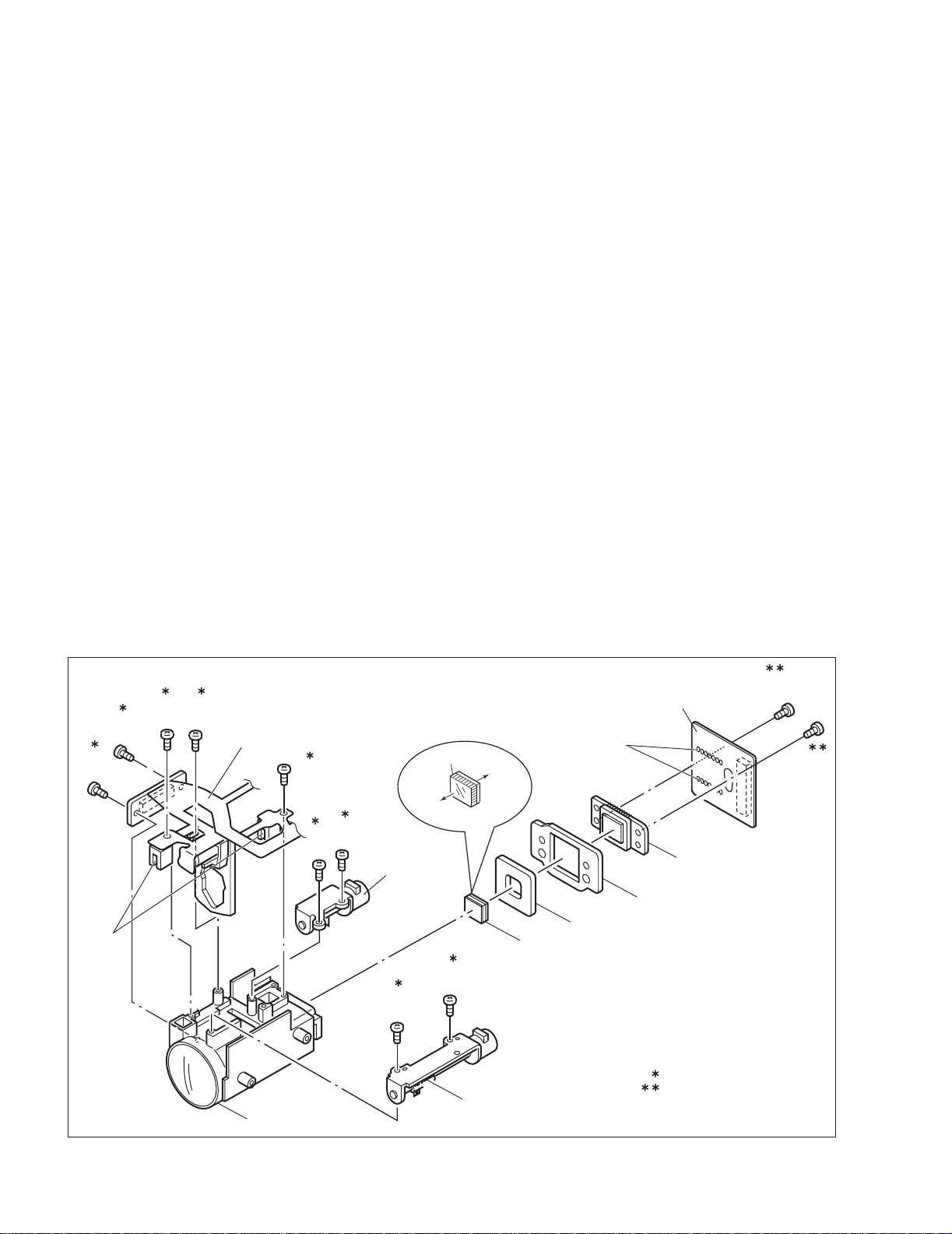

2.6 ASSEMBLY AND DISASSEMBLY OF [2]OP BLOCK ASSEMBLY

/ CCD BOARD ASSEMBLY (CAMERA SECTION AND BOARD ASSEMBLY)

2.6.1 Precautions

(1) Take care in handling the CCD IMAGE SENSOR, OP LPF

and lens components when performing maintenance etc.,

especially with regard to surface contamination, attached

dust or scratching. If fingerprints are present on the surface

they should be wiped away using either a silicon paper,

clean chamois or the cleaning cloth.

(2) The CCD IMAGE SENSOR may have been shipped with a

protective sheet attached to the transmitting glass. When

replacing the CCD IMAGE SENSOR, do not peel off this

sheet from the new part until immediately before it is

mounted in the OP BLOCK ASSEMBLY.

(3) The orientation of the OP LPF is an important factor for

installation. If there is some marking on the OP LPF, be

sure to note it down before removing and to reassemble it

very carefully as it was referring to the marking.

2.6.2 Disassembly of CCD BOARD ASSEMBLY and CCD

BASE ASSEMBLY

(1) Unsolder the CCD BOARD ASSEMBLY by the 14 points

(SD2) and then remove it.

(2) Remove the two screws (1, 2) and remove the CCD BASE

ASSEMBLY.

(3) Remove the SPACER.

(4) Remove the SHEET.

(5) Remove the OP LPF.

2.6.3 Assembly of CCD BASE ASSEMBLY and CCD

BOARD ASSEMBLY

(1) Set the OP LPF to the OP BLOCK ASSEMBLY so that the

OP side touches the OP BLOCK ASSEMBLY.

NOTE 2a:

Pay careful attention to the orientation of the OP LPF.

(2) Set the SHEET to the OP LPF not to come off the right

position.

(3) Attach the SPACER to the OP BLOCK ASSEMBLY.

(4) Fasten them together with the two screws (1, 2).

(5) Set the CCD BOARD ASSEMBLY in the CCD BASE

ASSEMBLY, and then solder it by the 14 points (SD2).

2.6.4 Replacement of service repair parts

The service repair parts for the OP BLOCK ASSEMBLY are as

listed below.

Before replacement of these parts, remove the BRACKET (OP

BLOCK ASSEMBLY) as required.

Take special care not to disconnect any of the FPC wires or

cause any damage due to soldering (excessive heating).

(1) FOCUS MOTOR

(2) ZOOM MOTOR

(3) IRIS MOTOR UNIT

NOTE 2b:

When replacing the FOCUS MOTOR or the ZOOM MOTOR,

solder the FPC at a space of about 1 mm above the terminal

pin.

NOTE 2c:

The IRIS MOTOR UNIT includes the FPC ASSEMBLY and

two sensors.

Fig.2-6-1

2

(S2a)

1

(S2a)

(SD2)

OP

side

CCD

side

Blue

<NOTE 2a>

OP LPF

OP BLOCK

ZOOM MOTOR

<NOTE 2b>

SHEET

OP LPF

SPACER

CCD BASE ASSEMBLY

CCD BAORD

ASSEMBLY

SENSOR

IRIS MOTOR UNIT

<NOTE 2b, c>

FOCUS MOTOR

<NOTE 2b>

0.078N

.

m (0.8kgf

.

cm)

0.118N

.

m (1.2kgf

.

cm)

4

(S2b)

3

(S2b)

6

(S2b)

5

(S2b)

10

(S2b)

11

(S2b)

9

(S2b)

7

(S2c)

8

(S2c)

(No.86730)1-15

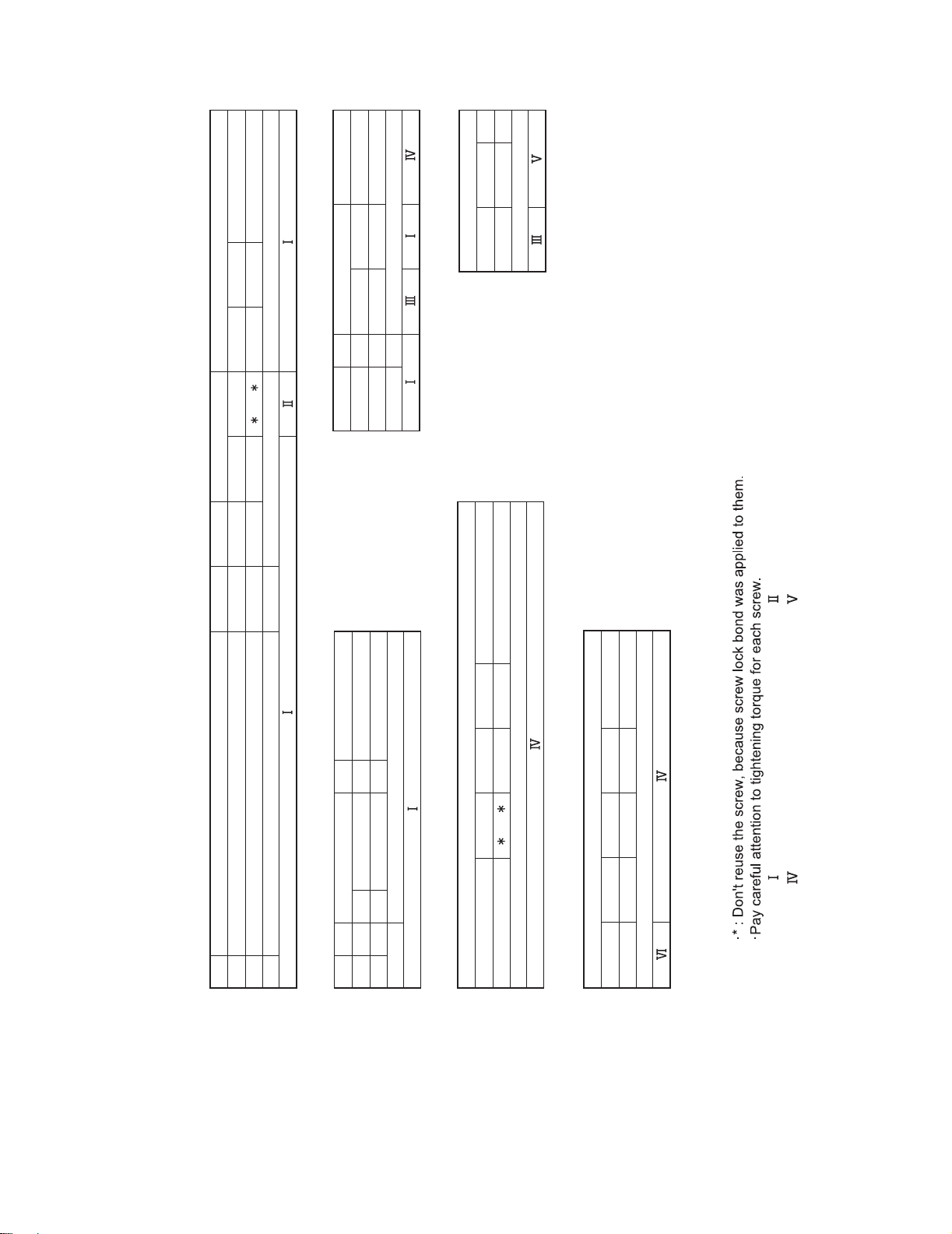

2.7 SERVICE NOTE

Use the following chart to manage screws

[1]

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

C1

C2-4C2-1

2-4-1

2-5-1

2-6-1

C2-2 C2-3

[11] ([12])[2] ([8]-[12]) [8] [10][9]

28 29 30 31 32 33 34 35 36 37 38

C4

[3] [4] [5] [6] [7]

C3

[2]

12345678910

D2 D3

[1] [3] [4]

D1

[8]

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

[2]/[5]

1234567891011

12345

[10]

Symbol No.

Removing order of screw

Place to stick screw

Screw tightening torque

Reference drawing (Fig.No.)

Screw tightening torque

Reference drawing (Fig.No.)

Reference drawing (Fig.No.)

Reference drawing (Fig.No.)

Screw tightening torque

Screw tightening torque

Symbol No.

Removing order of screw

Place to stick screw

Symbol No.

Symbol No.

Removing order of screw

Place to stick screw

Reference drawing (Fig.No.)

Screw tightening torque

Symbol No.

Removing order of screw

Place to stick screw

<MONITOR ASSEMBLY>

Removing order of screw

Place to stick screw

Reference drawing (Fig.No.)

Screw tightening torque

Symbol No.

Removing order of screw

Place to stick screw

<NOTE>

<OP BLOCK ASSEMBLY>

<VF ASSEMBLY>

<CAMERA AND BOARD ASSEMBLY>

<CABINET PART>

: 0.088N

.

m (0.9kgf

.

cm)

: 0.147N

.

m (1.5kgf

.

cm)

㸉

: 0.078N

.

m (0.8kgf

.

cm)

: 0.098N

.

m (1.0kgf

.

cm)

: 0.069N

.

m (0.7kgf

.

cm)

: 0.118N

.

m (1.2kgf

.

cm)

㸌

1-16 (No.86730)

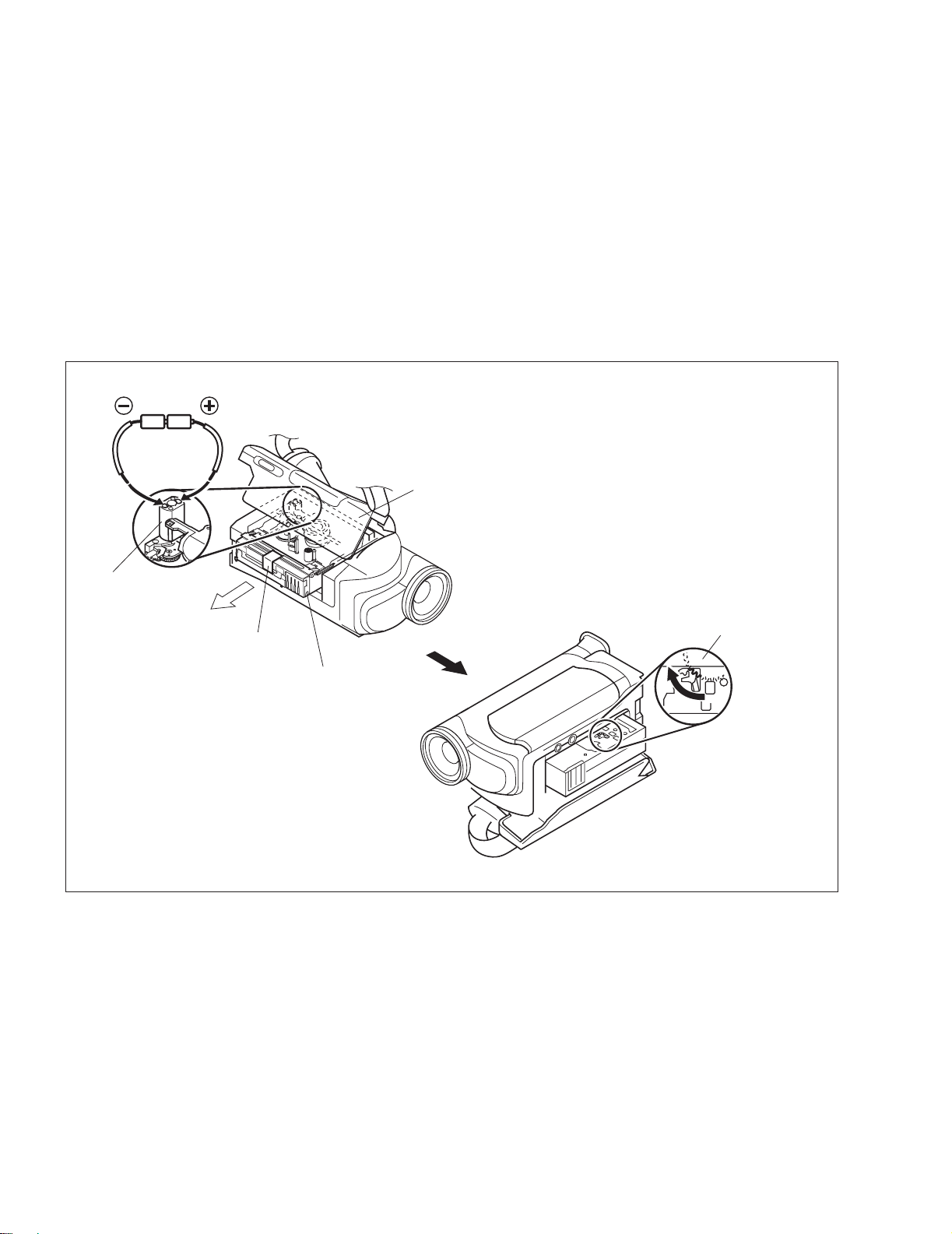

2.8 TAKE OUT CASSETTE TAPE

NOTE :

The following procedure describes a simplified method of

ejecting the cassette tape in case it is not possible to eject it,

due to an electrical failure.

Be careful not to damage any of the parts or the tape when per-

forming repairs or maintenance work.

(1) Remove the Power Unit (battery, DC code, etc.) from the

set.

(2) Open the CASSETTE COVER.

(3) Attach a piece of PVC TAPE at the front of the CASSETTE

HOUSING ASSEMBLY.

NOTE:

This helps prevent the tape from being damaged when

the CASSETTE HOUSING ASSEMBLY is moved up-

ward at the unloading end.

(4) Apply DC 3V to the electrode on the top surface of the

LOADING MOTOR ASSEMBLY to set the MECHANISM

ASSEMBLY to the EJECT mode.

Unloading end is EJECT mode.

(5) If there is any slack tape in the tape transport system, wind

it inside the DVC CASSETTE TAPE by turning the REEL

DISK ASSEMBLY (SUP) from the backside of the SLIDE

DECK ASSEMBLY.

(6) Peel off the PVC TAPE and take out the DVC CASSETTE

TAPE from the CASSETTE HOUSING ASSEMBLY.

NOTE:

Make sure that grease or a similar substance is not at-

tached to the surface of the tape.

Similarly, also make sure that grease or a similar sub-

stance is not attached on the MECHANISM ASSEMBLY.

Fig.2-8-1

REEL DISK ASSEMBLY (SUP)

(DC3V)

PVC T

LOADING MOTOR

ASSEMBLY

APE

CASSETTE HOUSING

ASSEMBLY

CASSETTE COVER

(No.86730)1-17

2.9 EMERGENCY DISPLAY

Whenever some abnormal signal is input to the syscon CPU, an

error number (E01, as an example) is displayed on the LCD mon-

itor or (in the electronic view finder).

In every error status, such the message as shown below alter

nately appear over and over.

• In an emergency mode, all operations except turning on/off the

POWER switch are ineffectual.

Example (in case of the error number E01):

Fig.2-9-1

E01

UNIT IN

SAFEGUARD MODE

E01

REMOVE AND

REATTACH BATTERY

LCD

display

Emergency

mode

Details Possible cause

E01 LOADING In the case the encoder posi-

tion is not shifted to the next

point though the loading motor

has rotated in the loading direc-

tion for 4 seconds or more. This

error is defined as [E01].

1. The mechanism is locked during mode shift.

2. The mechanism is locked at the mechanism loading end,

because the encoder position is skipped during mechanism

mode shift.

3. No power is supplied to the loading MDA.

E02 UNLOADING In the case the encoder posi-

tion is not shifted to the next

point though the loading motor

has rotated in the unloading di-

rection for 4 seconds or more.

This error is defined as [E02].

1. The mechanism is locked during mode shift.

2. The mechanism is locked at the mechanism loading end,

because the encoder position is skipped during mechanism

mode shift.

E03 TU & SUP REEL FG In the case no REEL FG is pro-

duced for 4 seconds or more in

the capstan rotation mode after

loading was complete, the

mechanism mode is shifted to

STOP with the pinch roller set

off. This error is defined as

[E03].

However, no REEL EMG is de-

tected in the SLW/STILL mode.

1. The idler gear does not engage with the reel disk well.

2. Though the idler gear and reel disk are engaged with each

other, the tape is not wound because of overload to the

mechanism.

3. No FG pulse is output from the reel sensor.

4. No power is supplied to the reel sensor.

5. Tape transport operation takes place with a cassette having

no tape inside.

6. The tape slackens and no pulse is produced until the slack

is taken up and the tape comes into the normal status.

E04 DRUM FG In the case there is no DRUM

FG input in the drum rotation

mode for 4 seconds or more.

This error is defined as [E04],

and the mechanism mode is

shifted to STOP with the pinch

roller set off.

1. The drum cannot be started or drum rotation is stopped be-

cause tape transport load is too high.

1) Tape tension is extremely high.

2) The tape is damaged or soiled with grease, etc.

2. The DRUM FG signal is not received by the syscon CPU.

1) Disconnection in the middle of the signal line.

2) Failure of the DRUM FG pulse generator (hall element).

3. No drum control voltage is supplied to the MDA.

4. No power is supplied to the DRUM MDA.

E05 - - -

E06 CAPSTAN FG In the case no CAPSTAN FG is

produced in the capstan rota-

tion mode for 2 seconds or

more. This error is defined as

[E06], and the mechanism

mode is shifted to STOP with

the pinch roller set off.

However, no CAPSTAN EMG

is detected in the STILL/FF/

REW mode.

1. The CAPSTAN FG signal is not received by the syscon

CPU.

1) Disconnection in the middle of the signal line.

2) Failure of the CAPSTAN FG pulse generator (MR ele-

ment).

2. No capstan control voltage is supplied to the MDA.

4. The capstan cannot be started or capstan rotation is

stopped because tape transport load is too high.

1) Tape tension is extremely high. (Mechanical locking)

2) The tape is damaged or soiled with grease, etc. (Tape

tangling occurs, etc.)

1-18 (No.86730)

SECTION 3

ADJUSTMENT

3.1 PREPARATION

(1) Precaution

This model does not contain adjustment controls (VR).

General deck system, camera system and monitor system

adjustment are not required. However, if MAIN board need

replacement, please use original EEP ROM on to new

board. Then adjustment are not required. And if parts such

as the following need replacement, special computerized

adjustment are required. 3.5.1 Electrical adjustment with

personal computer is setup and it adjusts using a service

support system. Please contact to JVC Service for detail in-

formation.

• OP BLOCK ASSEMBLY

• EEP ROM (IC1005 of MAIN board)

• MONITOR / VF ASSEMBLY

In the event of malfunction with electrical circuits, trouble-

shooting with the aid of proper test instruments most be

done first, and then commence necessary repair, replace-

ment and adjustment, etc.

a) In case of wiring to chip test points for measurement,

use IC clips, etc. to avoid any stress.

b) Since connectors are fragile, carefully handle them in

disconnecting and connecting.

c) Short circuit between operation unit and DECK chas-

sis.

(2) Required test equipment

a) Color TV monitor.

b) AC power adapter

c) Oscilloscope (dual-trace type, observable 100 MHz

or higher frequency)

• It is recommended to use one observable 300 MHz

or higher frequency.

d) Digital voltmeter

e) Frequency counter (with threshold level adjuster)

f) Personal computer

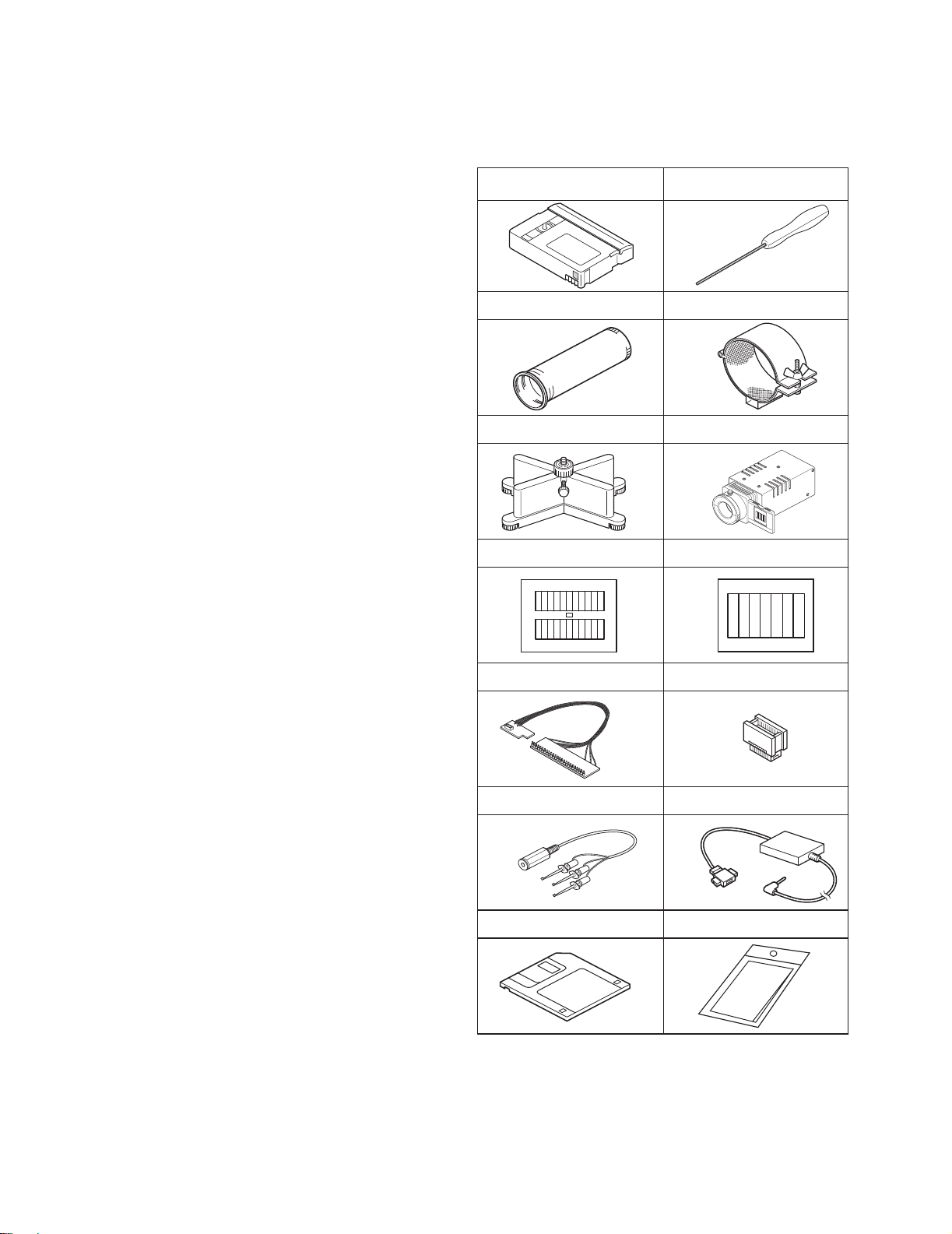

3.2 TOOLS REQUIRED FOR ADJUSTMENT

Fig.3-2-1

1

Alignment tape

MC-2

3

INF adjustment lens

YTU92001B

7

Gray scale chart

YTU94133A

8

Color bar chart

YTU94133C

4

INF lens holder

YTU94087

6

Light box assembly

YTU93096A

5

Camera stand

YTU93079

13

Service support system

YTU94057-67

14

Cleaning cloth

KSMM-01

12

PC cable

QAM0099-005

11

Communication cable

YTU93107A

9

Jig connector cable

YTU93106B

10

Extension connector

YTU94145C-30

2

Guide driver (Hexagonal)

D-770-1.27

Loading...

Loading...