HP PageWide Enterprise Color 765, PageWide Enterprise Color 780, PageWide Enterprise Color 785 Troubleshooting Manual

HP PageWide Enterprise Color 765 and MFP 780/785

HP PageWide Managed Color E75160 and MFP E77650/P77660

Troubleshooting Manual

Copyright and License

© Copyright 2017 HP Development Company,

L.P.

Reproduction, adaptation, or translation without prior written permission is prohibited, except as allowed under the copyright laws.

The information contained herein is subject to change without notice.

The only warranties for HP products and services are set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Edition 1, 9/2017

Trademark Credits

Microsoft®, Windows®, Windows® XP, and Windows Vista® are U.S. registered trademarks of Microsoft Corporation.

Adobe®, Acrobat®, and PostScript® are trademarks of Adobe Systems Incorporated.

UNIX® is a registered trademark of The Open Group.

Conventions used in this guide

TIP: Helpful hints or shortcuts.

NOTE: Information that explains a concept or how to complete a task.

NOTE: Information that explains a concept or how to complete a task.

Reinstallation tip: Reinstallation helpful hints, shortcuts, or considerations.

IMPORTANT: Information that help the user to avoid potential printer error conditions.

IMPORTANT: Information that help the user to avoid potential printer error conditions.

CAUTION: Procedures that the user must follow to avoid losing data or damaging the printer.

CAUTION: Procedures that the user must follow to avoid losing data or damaging the printer.

WARNING! Procedures that the user must follow to avoid personal injury, catastrophic loss of data, or extensive damage to the printer.

ENWW |

iii |

iv |

Conventions used in this guide |

ENWW |

For additional service and support information

HP service personnel, go to one of the following Web-based Interactive Search Engines (WISE) sites:

AMS

●https://support.hp.com/wise/home/ams-en

●https://support.hp.com/wise/home/ams-es

●https://support.hp.com/wise/home/ams-pt

APJ

●https://support.hp.com/wise/home/apj-en

●https://support.hp.com/wise/home/apj-ja

●https://support.hp.com/wise/home/apj-ko

●https://support.hp.com/wise/home/apj-zh-Hans

●https://support.hp.com/wise/home/apj-zh-Hant

EMEA

●https://support.hp.com/wise/home/emea-en

Channel partners, go to HP Channel Services Network (CSN) at www.hp.com/partners/csn .

At these locations, nd information on the following topics:

●Install and con gure

●Printer speci cations

●Up-to-date control panel message (CPMD) troubleshooting

●Solutions for printer issues and emerging issues

●Remove and replace part instructions and videos

●Service advisories

●Warranty and regulatory information

Channel partners, access training materials in the HP University and Partner Learning Center at https://content.ext.hp.com/sites/LMS/HPU.page.

To access HP PartSurfer information from any mobile device, go to http://partsurfermobile.hp.com/ or scan the Quick Response (QR) code below.

ENWW |

v |

vi |

For additional service and support information |

ENWW |

Table of contents

1 Theory of operation .................................................................................................................................................................................. |

1 |

Basic operation ......................................................................................................................................................................... |

2 |

Function structure ............................................................................................................................................... |

2 |

Operation sequence ............................................................................................................................................ |

4 |

System control .......................................................................................................................................................................... |

6 |

................................................................................................................................................................................. |

6 |

Formatter and data path .................................................................................................................................... |

6 |

Engine control ...................................................................................................................................................... |

8 |

Pen interface (I/F) .............................................................................................................................................. |

10 |

Power supply ...................................................................................................................................................... |

11 |

AC control module ............................................................................................................................................. |

11 |

Cabling system ....................................................................................................................................................................... |

13 |

Flat Flexible Cables ........................................................................................................................................... |

13 |

FFC routing .......................................................................................................................................................... |

16 |

Discrete cables ................................................................................................................................................... |

19 |

Ground wires ...................................................................................................................................................... |

20 |

Connectors .......................................................................................................................................................... |

21 |

Ferrites ................................................................................................................................................................ |

23 |

Cable management ........................................................................................................................................... |

23 |

Print subsystem ..................................................................................................................................................................... |

25 |

Printhead ............................................................................................................................................................ |

25 |

Printhead air management system ................................................................................................................ |

26 |

Printhead lift ....................................................................................................................................................... |

26 |

Print cartridges .................................................................................................................................................. |

26 |

Optical scan carriage ......................................................................................................................................... |

26 |

Print system operational states ...................................................................................................................... |

26 |

Paper-handling system ......................................................................................................................................................... |

29 |

Printer sensors ................................................................................................................................................... |

29 |

High Capacity Input (HCI) sensors ................................................................................................................... |

30 |

3x550 tray sensors ........................................................................................................................................... |

31 |

1x550 tray sensors ........................................................................................................................................... |

32 |

Inline nisher sensors ....................................................................................................................................... |

33 |

ENWW |

vii |

Printer motors/solenoids ................................................................................................................................. |

34 |

High capacity input (HCI) motors/solenoids .................................................................................................. |

35 |

3x550 tray motors/solenoids .......................................................................................................................... |

36 |

1x550 tray motors/solenoids .......................................................................................................................... |

37 |

Inline nisher motors ........................................................................................................................................ |

38 |

Printer printing system ..................................................................................................................................... |

39 |

Input trays ........................................................................................................................................................... |

40 |

Paper path zones ............................................................................................................................................... |

43 |

Jam detection ..................................................................................................................................................... |

45 |

Servicing system .................................................................................................................................................................... |

48 |

Printhead wiper .................................................................................................................................................. |

48 |

Service fluid and aerosol management systems ............................................................................................................. |

49 |

irflow system ........................................................................................................................................................................ |

51 |

Function .............................................................................................................................................................. |

51 |

Heating ................................................................................................................................................................ |

51 |

irflow ................................................................................................................................................................. |

51 |

Modes .................................................................................................................................................................. |

51 |

Components ....................................................................................................................................................... |

52 |

Document feeder system ..................................................................................................................................................... |

53 |

Document feed system .................................................................................................................................... |

53 |

Sensors in the document feeder .................................................................................................................... |

53 |

Document feeder paper path .......................................................................................................................... |

54 |

Document feeder simplex operation ............................................................................................................. |

55 |

Document feeder e-duplex operation ........................................................................................................... |

56 |

Deskew operation ............................................................................................................................................. |

57 |

Document feeder hinges .................................................................................................................................. |

57 |

Scanning and image capture system (780/785) .............................................................................................................. |

59 |

Fax functions and operation ................................................................................................................................................. |

60 |

Computer and network security features ..................................................................................................... |

60 |

PSTN operation .................................................................................................................................................. |

60 |

The fax subsystem ............................................................................................................................................ |

60 |

Fax card in the fax subsystem ......................................................................................................................... |

60 |

Fax page storage in flash memory ................................................................................................................. |

62 |

Output accessories ................................................................................................................................................................ |

63 |

Inline nisher ...................................................................................................................................................... |

64 |

2 Solve problems ....................................................................................................................................................................................... |

91 |

Problem-solving checklist .................................................................................................................................................... |

92 |

Step 1: Check that the printer power is on .................................................................................................... |

92 |

Step 2: Check the control panel for error messages ................................................................................... |

92 |

Step 3: Test print functionality ........................................................................................................................ |

93 |

viii |

ENWW |

Step 4: Test copy functionality (MFP models only) ...................................................................................... |

93 |

Step 5: Test the fax sending functionality (785f/785zs/785z+) ............................................................... |

94 |

Step 6: Test the fax receiving functionality (fax models only) ................................................................... |

94 |

Step 7: Try sending a print job from a computer ......................................................................................... |

94 |

Step 8: Test the Plug and Print USB Drive printing functionality ............................................................... |

94 |

Factors that a ect printer performance ........................................................................................................ |

94 |

Troubleshooting process ...................................................................................................................................................... |

96 |

Determine the problem source ....................................................................................................................... |

96 |

Power subsystem .............................................................................................................................................. |

98 |

Tools for troubleshooting ................................................................................................................................................... |

129 |

Print the con guration and printhead information pages ........................................................................ |

129 |

Event log messages ........................................................................................................................................ |

132 |

Tools for troubleshooting: Individual component diagnostics ................................................................ |

133 |

Diagrams .......................................................................................................................................................... |

146 |

Print-quality troubleshooting tools .............................................................................................................. |

159 |

Control panel menus ...................................................................................................................................... |

168 |

Control panel message document (CPMD) ................................................................................................. |

243 |

Print quality troubleshooting guide .................................................................................................................................. |

244 |

Printer pre-checks .......................................................................................................................................... |

244 |

Printer speci c image defects ....................................................................................................................... |

258 |

Solve copy/scan problems (780/785) .............................................................................................................................. |

297 |

Solve copy problems (780/785 models only) ............................................................................................ |

297 |

Solve scan problems (780/785 models only) ............................................................................................ |

302 |

Solve paper jam or feed problems ................................................................................................................................... |

308 |

Printer does not pick up paper or misfeeds ................................................................................................ |

308 |

Clear paper jams ............................................................................................................................................. |

310 |

Solve performance problems ............................................................................................................................................ |

340 |

Factors a ecting print performance ............................................................................................................ |

340 |

The printer does not print or it prints slowly .............................................................................................. |

341 |

The printer prints slowly ................................................................................................................................ |

342 |

Solve connectivity problems .............................................................................................................................................. |

343 |

Solve USB connection problems ................................................................................................................... |

343 |

Solve wired network problems ..................................................................................................................... |

343 |

Service mode functions ...................................................................................................................................................... |

345 |

Service menu ................................................................................................................................................... |

345 |

Printer resets ................................................................................................................................................... |

354 |

Format Disk and Partial Clean functions ..................................................................................................... |

356 |

Firmware upgrades ............................................................................................................................................................. |

359 |

Determine the installed revision of rmware ............................................................................................. |

359 |

Perform a rmware upgrade ........................................................................................................................ |

361 |

Solve fax problems .............................................................................................................................................................. |

365 |

ENWW |

ix |

Solve email problems ......................................................................................................................................................... |

366 |

Appendix A Printer speci cations ......................................................................................................................................................... |

367 |

Printer dimensions and weight ......................................................................................................................................... |

368 |

Printer space requirements ............................................................................................................................................... |

369 |

Power consumption, electrical speci cations, and acoustic emissions ...................................................................... |

369 |

Operating-environment range .......................................................................................................................................... |

370 |

Certi cate of Volatility ......................................................................................................................................................... |

371 |

Index ........................................................................................................................................................................................................... |

415 |

x |

ENWW |

List of tables

Table 1-1 |

Operation sequence ................................................................................................................................................................ |

4 |

Table 1-2 |

Printbar components ............................................................................................................................................................ |

25 |

Table 1-3 Service Fluid and Aerosol Management System Components ...................................................................................... |

50 |

|

Table 1-4 Document feeder sensors ................................................................................................................................................... |

54 |

|

Table 1-5 Document feeder paper path .............................................................................................................................................. |

54 |

|

Table 2-1 |

Troubleshooting flowchart .................................................................................................................................................. |

97 |

Table 2-2 |

MPCA LEDs ........................................................................................................................................................................... |

100 |

Table 2-3 MPCA LED sequence at printer power on ....................................................................................................................... |

100 |

|

Table 2-4 |

MPCA LEDs ........................................................................................................................................................................... |

133 |

Table 2-5 MPCA LED sequence at printer power on ....................................................................................................................... |

134 |

|

Table 2-6 |

ACCM LEDs ........................................................................................................................................................................... |

135 |

Table 2-7 ACCMA LED sequence at printer power on ..................................................................................................................... |

135 |

|

Table 2-8 Heartbeat LED, product initialization ............................................................................................................................... |

136 |

|

Table 2-9 Heartbeat LED, product operational ................................................................................................................................ |

139 |

|

Table 2-10 |

Reports menu ................................................................................................................................................................... |

169 |

Table 2-11 |

Settings menu ................................................................................................................................................................... |

171 |

Table 2-12 Copy menu (MFP only) ..................................................................................................................................................... |

197 |

|

Table 2-13 Scan menu (780/785) ..................................................................................................................................................... |

203 |

|

Table 2-14 Fax menu (fax models only) ........................................................................................................................................... |

231 |

|

Table 2-15 Print Options menu .......................................................................................................................................................... |

235 |

|

Table 2-16 |

Supplies menu .................................................................................................................................................................. |

236 |

Table 2-17 |

Trays menu ........................................................................................................................................................................ |

237 |

Table 2-18 |

Backup/Restore menu ..................................................................................................................................................... |

238 |

Table 2-19 |

Calibrate/Cleaning menu ................................................................................................................................................. |

238 |

Table 2-20 |

Troubleshooting menu .................................................................................................................................................... |

240 |

Table 2-21 Printhead health score .................................................................................................................................................... |

251 |

|

Table 2-22 Solve performance problems ......................................................................................................................................... |

340 |

|

Table 2-23 |

Service menu .................................................................................................................................................................... |

345 |

Table A-1 Dimensions for printer base model (SFP; all) ................................................................................................................. |

368 |

|

Table A-2 Dimensions for base models (780dn, 785f; MFP) ......................................................................................................... |

368 |

|

Table A-3 Dimensions for 785zs (MFP) ............................................................................................................................................. |

368 |

|

Table A-4 Dimensions for the 1x550-sheet paper feeder ............................................................................................................. |

368 |

|

ENWW |

xi |

Table A-5 |

Dimensions for the 1x550-sheet paper feeder with stand ......................................................................................... |

369 |

Table A-6 |

Dimensions for the 3x550-sheet paper feeder with stand ......................................................................................... |

369 |

Table A-7 |

Dimensions for the 4,000-sheet HCI with stand ........................................................................................................... |

369 |

Table A-8 |

Operating-environment speci cations ............................................................................................................................ |

370 |

xii |

ENWW |

List of gures

Figure 1-3 FFC insertion line ................................................................................................................................................................. |

13 |

|

Figure 1-4 FFC support tape ................................................................................................................................................................. |

14 |

|

Figure 1-5 |

FFC label ................................................................................................................................................................................ |

14 |

Figure 1-6 FFC wing feature .................................................................................................................................................................. |

15 |

|

Figure 1-7 |

ZIF connector ........................................................................................................................................................................ |

15 |

Figure 1-8 FFC hook arm retainers ...................................................................................................................................................... |

16 |

|

Figure 1-9 FFC pill bump retainers ....................................................................................................................................................... |

17 |

|

Figure 1-10 FFC die-cut retainers ........................................................................................................................................................ |

18 |

|

Figure 1-11 FFC double-sided tape retainer ...................................................................................................................................... |

18 |

|

Figure 1-12 Discrete cable ferrite ........................................................................................................................................................ |

19 |

|

Figure 1-13 Discrete cable tie-wraps .................................................................................................................................................. |

20 |

|

Figure 1-14 |

Ground wires ...................................................................................................................................................................... |

21 |

Figure 1-16 FFC wing feature ............................................................................................................................................................... |

22 |

|

Figure 1-17 |

ZIF connector ..................................................................................................................................................................... |

23 |

Figure 1-18 |

FFC spacing ........................................................................................................................................................................ |

24 |

Figure 1-19 |

Printhead components ..................................................................................................................................................... |

25 |

Figure 1-20 Print engine sensors ......................................................................................................................................................... |

29 |

|

Figure 1-21 |

HCI sensors ........................................................................................................................................................................ |

30 |

Figure 1-22 3x550 Tray sensors .......................................................................................................................................................... |

31 |

|

Figure 1-23 1x550 tray sensors ........................................................................................................................................................... |

32 |

|

Figure 1-24 |

Inline nisher sensors ....................................................................................................................................................... |

33 |

Figure 1-25 |

HCI motors/solenoids ....................................................................................................................................................... |

35 |

Figure 1-26 3x550 tray motors/solenoids ......................................................................................................................................... |

36 |

|

Figure 1-27 1x550 tray motors/solenoids ......................................................................................................................................... |

37 |

|

Figure 1-28 |

Inline nisher motors ........................................................................................................................................................ |

38 |

Figure 1-29 Printer printing system .................................................................................................................................................... |

39 |

|

Figure 1-30 Tray 1 pick and separation system ................................................................................................................................ |

40 |

|

Figure 1-31 Service fluid and aerosol management system .......................................................................................................... |

50 |

|

Figure 1-32 irflow system components ........................................................................................................................................... |

52 |

|

Figure 1-33 Document feeder sensors ............................................................................................................................................... |

54 |

|

Figure 1-34 Document feeder paper path .......................................................................................................................................... |

54 |

|

Figure 1-35 |

Deskew operation ............................................................................................................................................................. |

57 |

ENWW |

xiii |

Figure 1-36 Document feeder open (book mode) ............................................................................................................................ |

58 |

||

Figure 1-37 Document feeder open (60º to 80º) .............................................................................................................................. |

58 |

||

Figure 1-38 FFC insertion line ............................................................................................................................................................... |

67 |

||

Figure 1-39 FFC support tape ............................................................................................................................................................... |

68 |

||

Figure 1-40 |

FFC label ............................................................................................................................................................................. |

68 |

|

Figure 1-41 FFC hook arm retainers .................................................................................................................................................... |

69 |

||

Figure 1-42 FFC pill bump retainers .................................................................................................................................................... |

70 |

||

Figure 1-43 FFC die-cut retainers ........................................................................................................................................................ |

71 |

||

Figure 1-44 FFC double-sided tape retainer ...................................................................................................................................... |

71 |

||

Figure 1-45 Discrete cable ferrite ........................................................................................................................................................ |

72 |

||

Figure 1-46 Discrete cable tie-wraps .................................................................................................................................................. |

73 |

||

Figure 1-47 |

Connectors ......................................................................................................................................................................... |

74 |

|

Figure 1-48 |

FFC spacing ........................................................................................................................................................................ |

75 |

|

Figure 1-49 |

Inline |

nisher control diagram (front) ............................................................................................................................ |

76 |

Figure 1-50 |

Inline |

nisher sensor control diagram (front) ............................................................................................................... |

77 |

Figure 1-51 |

Inline |

nisher motor control diagram (front) ................................................................................................................ |

78 |

Figure 1-52 |

Inline |

nisher sensor diagram (1 of 2) ........................................................................................................................... |

79 |

Figure 1-53 |

Inline |

nisher sensor diagram (2 of 2) ........................................................................................................................... |

80 |

Figure 1-54 |

Inline |

nisher motor diagram .......................................................................................................................................... |

81 |

Figure 1-55 |

Inline |

nisher stapler control diagram ........................................................................................................................... |

82 |

Figure 1-56 |

Inline |

nisher stapler sensor diagram ........................................................................................................................... |

83 |

Figure 1-57 |

Inline |

nisher stapler motor control diagram ............................................................................................................... |

84 |

Figure 2-1 |

MPCA LEDs ......................................................................................................................................................................... |

100 |

|

Figure 2-2 Formatter heartbeat LED ................................................................................................................................................. |

101 |

||

Figure 2-3 Diagnostic-tests access button (765 printers) ............................................................................................................. |

104 |

||

Figure 2-4 Diagnostic-tests access button (780/785 printers) .................................................................................................... |

104 |

||

Figure 2-5 Press the diagnostics-access button (780/785 printers) ........................................................................................... |

105 |

||

Figure 2-6 Control panel version A yellow screen ........................................................................................................................... |

105 |

||

Figure 2-7 Exit the diagnostic mode ................................................................................................................................................. |

107 |

||

Figure 2-8 Open the Pre-boot menu ................................................................................................................................................. |

108 |

||

Figure 2-9 |

Pre-boot menu .................................................................................................................................................................. |

109 |

|

Figure 2-10 Access the administration menu .................................................................................................................................. |

110 |

||

Figure 2-11 Access the diagnostics menu ........................................................................................................................................ |

110 |

||

Figure 2-12 Open the screen test ...................................................................................................................................................... |

111 |

||

Figure 2-13 Blue vertical gradient screen ........................................................................................................................................ |

111 |

||

Figure 2-14 Open the touch test ........................................................................................................................................................ |

115 |

||

Figure 2-15 Touch the white grid ....................................................................................................................................................... |

115 |

||

Figure 2-16 Verify the mark ............................................................................................................................................................... |

116 |

||

Figure 2-17 Open the softkey test .................................................................................................................................................... |

117 |

||

Figure 2-18 |

Select Home .................................................................................................................................................................... |

117 |

|

Figure 2-19 |

Successful test ................................................................................................................................................................ |

118 |

|

xiv |

ENWW |

Figure 2-20 Open the backlight test .................................................................................................................................................. |

119 |

||

Figure 2-21 Open the sound test ....................................................................................................................................................... |

120 |

||

Figure 2-22 Open the keyboard test ................................................................................................................................................. |

121 |

||

Figure 2-23 Open the sound test ....................................................................................................................................................... |

122 |

||

Figure 2-24 Touchscreen blank, white, or dim (no image) ............................................................................................................ |

124 |

||

Figure 2-25 Touchscreen has an unresponsive zone ..................................................................................................................... |

125 |

||

Figure 2-26 No control panel sound .................................................................................................................................................. |

126 |

||

Figure 2-27 Home key is unresponsive ............................................................................................................................................ |

127 |

||

Figure 2-28 Hardware integration pocket (HIP) is not functioning (control panel functional) ................................................ |

128 |

||

Figure 2-29 |

Con guration page ......................................................................................................................................................... |

129 |

|

Figure 2-30 Printhead information page .......................................................................................................................................... |

131 |

||

Figure 2-31 |

MPCA LEDs ....................................................................................................................................................................... |

133 |

|

Figure 2-32 |

ACCM LEDs ....................................................................................................................................................................... |

135 |

|

Figure 2-33 Defeating interlocks (cartridge door) .......................................................................................................................... |

141 |

||

Figure 2-34 Defeating interlocks (left door) .................................................................................................................................... |

142 |

||

Figure 2-35 Defeating interlocks (right door) .................................................................................................................................. |

142 |

||

Figure 2-36 Plug/jack locations (external printer) .......................................................................................................................... |

146 |

||

Figure 2-37 Print engine sensors ...................................................................................................................................................... |

148 |

||

Figure 2-38 |

HCI sensors ...................................................................................................................................................................... |

149 |

|

Figure 2-39 3x550 tray sensors ........................................................................................................................................................ |

150 |

||

Figure 2-40 1x550 tray sensors ........................................................................................................................................................ |

151 |

||

Figure 2-41 |

Inline nisher sensors .................................................................................................................................................... |

152 |

|

Figure 2-42 |

Printer motors/solenoids .............................................................................................................................................. |

153 |

|

Figure 2-43 |

HCI motors/solenoids ..................................................................................................................................................... |

154 |

|

Figure 2-44 3x550 tray motors/solenoids ....................................................................................................................................... |

155 |

||

Figure 2-45 1x550 tray motors/solenoids ....................................................................................................................................... |

156 |

||

Figure 2-46 |

Inline nisher motors ..................................................................................................................................................... |

157 |

|

Figure 2-47 Printer printing system .................................................................................................................................................. |

158 |

||

Figure 2-50 |

Ink smear/redeposit ....................................................................................................................................................... |

255 |

|

Figure 2-51 Print Quality Report page .............................................................................................................................................. |

260 |

||

Figure 2-52 Print Head Diagnostic Page ........................................................................................................................................... |

262 |

||

Figure 2-53 Printhead Details page .................................................................................................................................................. |

264 |

||

Figure 2-67 Paper jam locations (765) ............................................................................................................................................. |

310 |

||

Figure 2-68 Paper jam locations (780/785) .................................................................................................................................... |

312 |

||

Figure 2-69 Open the Pre-boot menu .............................................................................................................................................. |

355 |

||

Figure 2-70 Open the Pre-boot menu .............................................................................................................................................. |

357 |

||

Figure 2-71 Open the Pre-boot menu .............................................................................................................................................. |

358 |

||

Figure 2-72 |

Determine the installed revision of rmware ............................................................................................................ |

360 |

|

Figure 2-73 Open the Pre-boot menu .............................................................................................................................................. |

363 |

||

Figure A-1 |

Certi |

cate of Volatility (750dn; 1 of 3) ........................................................................................................................... |

371 |

Figure A-2 |

Certi |

cate of Volatility (750dn; 2 of 3) ........................................................................................................................... |

372 |

ENWW |

xv |

Figure A-3 |

Certi |

cate of Volatility (750dn; 3 of 3) ........................................................................................................................... |

373 |

|

Figure A-4 |

Certi |

cate of Volatility (750dw; 1 of 4) .......................................................................................................................... |

374 |

|

Figure A-5 |

Certi |

cate of Volatility (750dw; 2 of 4) .......................................................................................................................... |

375 |

|

Figure A-6 |

Certi |

cate of Volatility (750dw; 3 of 4) .......................................................................................................................... |

376 |

|

Figure A-7 |

Certi |

cate of Volatility (750dw; 4 of 4) .......................................................................................................................... |

377 |

|

Figure A-8 |

Certi |

cate of Volatility (772dn; 1 of 3) ........................................................................................................................... |

378 |

|

Figure A-9 |

Certi |

cate of Volatility (772dn; 2 of 3) ........................................................................................................................... |

379 |

|

Figure A-10 |

Certi |

cate of Volatility (772dn; 3 of 3) ........................................................................................................................ |

380 |

|

Figure A-11 |

Certi |

cate of Volatility (772dw; 1 of 4) ........................................................................................................................ |

381 |

|

Figure A-12 |

Certi |

cate of Volatility (772dw; 2 of 4) ........................................................................................................................ |

382 |

|

Figure A-13 |

Certi |

cate of Volatility (772dw; 3 of 4) ........................................................................................................................ |

383 |

|

Figure A-14 |

Certi |

cate of Volatility (772dw; 4 of 4) ........................................................................................................................ |

384 |

|

Figure A-15 |

Certi |

cate of Volatility (777z; 1 of 4) ........................................................................................................................... |

385 |

|

Figure A-16 |

Certi |

cate of Volatility (777z; 2 of 4) ........................................................................................................................... |

386 |

|

Figure A-17 |

Certi |

cate of Volatility (777z; 3 of 4) ........................................................................................................................... |

387 |

|

Figure A-18 |

Certi |

cate of Volatility (777z; 4 of 4) ........................................................................................................................... |

388 |

|

Figure A-19 |

Certi |

cate of Volatility (75050dn; 1 of 3) .................................................................................................................... |

389 |

|

Figure A-20 |

Certi |

cate of Volatility (75050dn; 2 of 3) .................................................................................................................... |

390 |

|

Figure A-21 |

Certi |

cate of Volatility (75050dn; 3 of 3) .................................................................................................................... |

391 |

|

Figure A-22 |

Certi |

cate of Volatility (75050dw; 1 of 4) ................................................................................................................... |

392 |

|

Figure A-23 |

Certi |

cate of Volatility (75050dw; 2 of 4) ................................................................................................................... |

393 |

|

Figure A-24 |

Certi |

cate of Volatility (75050dw; 3 of 4) ................................................................................................................... |

394 |

|

Figure A-25 |

Certi |

cate of Volatility (75050dw; 4 of 4) ................................................................................................................... |

395 |

|

Figure A-26 |

Certi |

cate of Volatility (77740dn; 1 of 3) .................................................................................................................... |

396 |

|

Figure A-27 |

Certi |

cate of Volatility (77740dn; 2 of 3) .................................................................................................................... |

397 |

|

Figure A-28 |

Certi |

cate of Volatility (77740dn; 3 of 3) .................................................................................................................... |

398 |

|

Figure A-29 |

Certi |

cate of Volatility (77740dw; 1 of 4) ................................................................................................................... |

399 |

|

Figure A-30 |

Certi |

cate of Volatility (77740dw; 2 of 4) ................................................................................................................... |

400 |

|

Figure A-31 |

Certi |

cate of Volatility (77740dw; 3 of 4) ................................................................................................................... |

401 |

|

Figure A-32 |

Certi |

cate of Volatility (77740dw; 4 of 4) ................................................................................................................... |

402 |

|

Figure A-33 |

Certi |

cate of Volatility (77740z; 1 of 4) ...................................................................................................................... |

403 |

|

Figure A-34 |

Certi |

cate of Volatility (77740z; 2 of 4) ...................................................................................................................... |

404 |

|

Figure A-35 |

Certi |

cate of Volatility (77740z; 3 of 4) ...................................................................................................................... |

405 |

|

Figure A-36 |

Certi |

cate of Volatility (77740z; 4 of 4) ...................................................................................................................... |

406 |

|

Figure A-37 |

Certi |

cate of Volatility (77750z; 1 of 4) ...................................................................................................................... |

407 |

|

Figure A-38 |

Certi |

cate of Volatility (77750z; 2 of 4) ...................................................................................................................... |

408 |

|

Figure A-39 |

Certi |

cate of Volatility (77750z; 3 of 4) ...................................................................................................................... |

409 |

|

Figure A-40 |

Certi |

cate of Volatility (77750z; 4 of 4) ...................................................................................................................... |

410 |

|

Figure A-41 |

Certi |

cate of Volatility (77760z; 1 of 4) ...................................................................................................................... |

411 |

|

Figure A-42 |

Certi |

cate of Volatility (77760z; 2 of 4) ...................................................................................................................... |

412 |

|

Figure A-43 |

Certi |

cate of Volatility (77760z; 3 of 4) ...................................................................................................................... |

413 |

|

xvi |

ENWW |

Figure A-44 Certi cate of Volatility (77760z; 4 of 4) ...................................................................................................................... |

414 |

ENWW |

xvii |

xviii |

ENWW |

1Theory of operation

●Basic operation

●System control

●Cabling system

●Print subsystem

●Paper-handling system

●Servicing system

●Service fluid and aerosol management systems

●irflow system

●Document feeder system

●Scanning and image capture system (780/785)

●Fax functions and operation

●Output accessories

ENWW |

1 |

Basic operation

Function structure

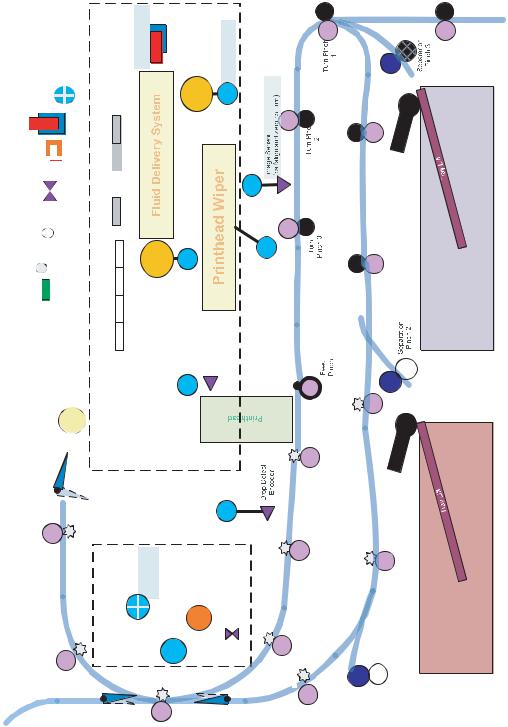

HP recommends printing the following document (on A3 size paper) for troubleshooting reference. It is available on the HP Web-based Interactive Search Engines (WISE). See HP Web-based Interactive Search Engines (WISE) on page 3.

Figure 1-1 Printer printing system

Legend |

VentSolenoid |

S |

PumpFluid |

PumpFluidMotor |

|

N |

|

|

|

|

|

|

|

Motor

Fan/Digital Tach F

Solenoid N S

Opto Sensor

Reflective REDI

Other Sensors Pinch roller

Retard Roller Star Wheel

Star Wheel

Switch/Hall

Effect Sensor

Torque Coupling

Media Path

12.13mm Dia

16.17mm Dia  PTO connection

PTO connection

150 LPI, 1200 Line

Digital Encoder

Acumen

Level Sensors |

|

Air Pump |

Fluid |

|

|

|

|

|

|

|

|

Printhead Assembly

Pinch 1

Ejection

|

Assembly |

F |

Motor |

|

|

AirflowFan |

|

Left Vertical Pinch 2 |

Airflow |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Image Sensor Carriage Motor |

|

|

|

Duplex Pinch 5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Air Pump Motor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Printhead Wiper Motor |

|

|

|

Duplex |

Pinch 4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Printhead Lift |

Motor |

|

Printhead Lift Encoder |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Printhead Lift Sensor |

|

|

|

|

|

|

|

|

|

|

|

Duplex |

Pinch 3 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Output Pinch 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drop Detect Carriage Motor |

|

|

|

|

|

|

|

Output Pinch 3 Output Pinch 2 |

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

Airflow Heater |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

Airflow Assembly Thermistor |

|

|

||||||

Aerosol Fan Motor |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Duplex |

inch1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P |

|

||

Roller

Tray 3 Pick

Sheet 500 Tray 3

Roller

Tray 2 Pick

Duplex Pinch 2 |

500 Sheet Tray 2 |

Tray 1 Separation Pinch |

2 Chapter 1 Theory of operation |

ENWW |

HP Web-based Interactive Search Engines (WISE)

The printer print system document is available on the HP Web-based Interactive Search Engines (WISE). Go to the appropriate Web site (listed below), and then search information by printer name.

NOTE: Make sure that this document is printed on A3 size paper.

NOTE: Make sure that this document is printed on A3 size paper.

AMS

●https://support.hp.com/wise/home/ams-en

●https://support.hp.com/wise/home/ams-es

●https://support.hp.com/wise/home/ams-pt

APJ

●https://support.hp.com/wise/home/apj-en

●https://support.hp.com/wise/home/apj-ja

●https://support.hp.com/wise/home/apj-ko

●https://support.hp.com/wise/home/apj-zh-Hans

●https://support.hp.com/wise/home/apj-zh-Hant

EMEA

●https://support.hp.com/wise/home/emea-en

ENWW |

Basic operation 3 |

Operation sequence

The engine-control system on the main printed circuit board MPCA controls the operational sequences. The following table describes the durations and the operations for each period of a print operation from when the printer is turned on to when the motors stop rotating.

Table 1-1 Operation sequence

Period |

Duration |

Purpose |

|

|

|

|

|

Initial startup and |

When the printer is set up for the |

This one-time setup process gets the printer ready to print for the rst |

|

calibrations |

rst time from the factory. |

time. |

|

|

NOTE: Startup is disabled if the |

● |

Fluid replacement—The printer flushes the shipping and |

|

temperature is 5°C (41°F) or |

|

handling fluid out of the printhead and replaces it with ink. No |

|

lower. The recommend |

|

pages are printed. |

|

temperature range for this |

● |

|

|

function is 15°C (59°F) to 40°C |

Pen energy calibration (TTOE)—No pages are printed. |

|

|

(104°F). |

● |

Die alignment—The printer aligns the 14 die on the printhead |

|

|

||

|

|

|

active face, and then prints and internally analyzes one page. |

|

|

● |

Die density leveling—The printer measures and compensates |

|

|

|

for the drop variation, and then prints and internally analyzes |

|

|

|

multiple pages. |

|

|

|

|

Servicing operations |

Performed just before the |

Servicing maintains print quality by removing debris and excess ink. |

|

|

printhead enters the capped |

Nozzle presence detection is employed to replace missing nozzles. |

|

|

state after printing, when leaving |

● |

|

|

the capped state after a print job |

Nozzle presence detection—The optical scan carriage detects |

|

|

is initiated, or during printer idle |

|

and disables inoperable nozzles, and replaces them with |

|

times when a print job is not |

|

operable nozzles. |

|

impacted. |

● |

Printhead servicing—The web wipe on the printhead wiper |

|

|

||

moves under the printhead to clean the active face and res the nozzles into the ink collection unit to clear clogged or blocked nozzles.

Print preparation |

From the time the printer |

|

receives a print command until |

|

paper enters the print zone. |

Prepares the printer for a print job.

●The printhead leaves the capping state as the printhead wiper moves away from the printhead.

●If needed, some servicing occurs.

●The printhead lowers to the printing position. The media type and printing mode determine the print zone height.

●The printer picks paper from one of the input trays.

●Every page from Tray 1 is measured for edge detection. For Tray 2/3 and optional Trays 3, 4 and 5, the printer performs media

edge detection after printing the rst sheet. The last sheet of each job is also measured for edge detection if at least ve sheets have been printed.

●The printer monitors environmental conditions. The printer can

slow the print speed if conditions are signi cantly di erent from a normal office environment (23°C (73.4°F), 50% relative humidity).

●The formatter PCA processes print data and transmits the data to the printhead.

4 Chapter 1 Theory of operation |

ENWW |

Table 1-1 Operation sequence (continued)

Period |

Duration |

Purpose |

|

|

|

|

|

Printing |

From the start of media pick in |

Processes the print job. |

|

|

the designated input tray until |

● |

|

|

the last sheet is delivered to the |

The page is picked from the designated tray and travels through |

|

|

designated output bin. |

|

the media path to the print zone. |

|

|

● |

As the page passes under the printhead, the printhead applies |

|

|

|

ink to the page. |

|

|

● |

The page then enters the airflow assembly area where heated |

|

|

|

air might be applied to reduce the moisture content of the page. |

|

|

● |

For Simplex print jobs, the page then proceeds to the output bin |

|

|

|

(face-down). |

|

|

● |

For Duplex print jobs, the page then advances until the trailing |

|

|

|

edge of the media moves past the left side vertical path sensor. |

|

|

|

The page then reverses direction and proceeds down through |

|

|

|

the duplex path and underneath the left duplexer (service fluid |

|

|

|

container). Then the page turns upward, and re-enters the print |

|

|

|

zone. |

|

|

|

Ink is then applied to the second side of the page by the |

|

|

|

printhead. |

|

|

● |

The process continues until all the pages of the print job are |

|

|

|

completed. The process might be interrupted by occasional |

|

|

|

printhead servicing events if the job includes many pages. |

|

|

|

|

End of print job |

Performed after the print job is |

This period puts the printer in a state where it’s ready for the next |

|

|

completed, and continues until |

print job. |

|

|

the next job is initiated. |

● |

|

|

|

After a short dwell interval, the printhead will be allowed to cap. |

|

|

|

● |

If needed, servicing or nozzle presence detection occurs, but |

|

|

|

these events are interruptible if another job is initiated. |

|

|

● |

The printhead moves to the capping position. |

|

|

● |

The printhead wiper moves to cap the printhead. |

|

|

|

|

Standby |

The printer is sitting idle, waiting |

This period is intended to conserve energy while the printer is sitting |

|

|

for the next print job to be |