HP PageWide Pro 352, PageWide Pro 377, PageWide Pro 452, PageWide Pro 477, PageWide Pro 552 Troubleshooting Manual

...

PageWide Pro 352/377, 452/477, and 552/577

Troubleshooting Manual

352 |

377 |

452 |

477 |

552 |

577 |

www.hp.com/support

www.hp.com/support

HP PageWide Pro 352/377, 452/477, and 552/577

Troubleshooting Manual

Copyright and License

© Copyright 2016 HP Development Company,

L.P.

Reproduction, adaptation, or translation without prior written permission is prohibited, except as allowed under the copyright laws.

The information contained herein is subject to change without notice.

The only warranties for HP products and services are set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Edition 1, 3/2016

Trademark Credits

ENERGY STAR® and the ENERGY STAR® mark are registered U.S. marks.

Conventions used in this guide

TIP: Tips provide helpful hints or shortcuts.

NOTE: Notes provide important information to explain a concept or to complete a task.

NOTE: Notes provide important information to explain a concept or to complete a task.

CAUTION: Cautions indicate procedures that you should follow to avoid losing data or damaging the product.

WARNING! Warnings alert you to specific procedures that you should follow to avoid personal injury, catastrophic loss of data, or extensive damage to the product.

ENWW |

iii |

iv |

Conventions used in this guide |

ENWW |

Table of contents

1 Theory of operation ....................................................................................................................................... |

1 |

Basic operation ...................................................................................................................................................... |

2 |

Function structure ............................................................................................................................... |

2 |

Operation sequence ............................................................................................................................ |

6 |

System control ....................................................................................................................................................... |

8 |

Formatter and data path ..................................................................................................................... |

8 |

Engine control ..................................................................................................................................... |

9 |

Pen interface (I/F) .............................................................................................................................. |

11 |

Power supply ..................................................................................................................................... |

11 |

Print subsystem ................................................................................................................................................... |

12 |

Printbar .............................................................................................................................................. |

13 |

Printbar air management system ..................................................................................................... |

14 |

Printbar lift ........................................................................................................................................ |

15 |

Ink cartridges ..................................................................................................................................... |

15 |

Optical scan carriage ......................................................................................................................... |

15 |

Print system operational states ....................................................................................................... |

15 |

Paper-handling system ....................................................................................................................................... |

17 |

Input trays ......................................................................................................................................... |

24 |

Paper path zones ............................................................................................................................... |

24 |

Servicing system .................................................................................................................................................. |

28 |

Service sled ........................................................................................................................................ |

30 |

Transmission system ........................................................................................................................................... |

31 |

Components ...................................................................................................................................... |

32 |

States ................................................................................................................................................. |

32 |

Aerosol management system ............................................................................................................................. |

34 |

Document feeder system (377/477/577/P57750 models) ............................................................................... |

36 |

Document feed system ..................................................................................................................... |

36 |

Rollers and sensors in the document feeder .................................................................................... |

36 |

Document feeder operation .............................................................................................................. |

37 |

Deskew operation .............................................................................................................................. |

38 |

Scanning and image capture system (377/477/577/P57750 models) .............................................................. |

39 |

Fax functions and operation (377/477/577/P57750 models) ........................................................................... |

40 |

ENWW |

v |

Computer and network security features ......................................................................................... |

40 |

PSTN operation .................................................................................................................................. |

40 |

The fax subsystem ............................................................................................................................ |

40 |

Fax card in the fax subsystem ........................................................................................................... |

40 |

Fax page storage in ash memory .................................................................................................... |

42 |

2 Solve problems ............................................................................................................................................ |

43 |

Restore the factory-set defaults ......................................................................................................................... |

44 |

Menu access ......................................................................................................................................................... |

44 |

Menu access on monochrome control panels .................................................................................. |

45 |

Menu access on color control panels ................................................................................................ |

47 |

Perform tap tests and interpret results .............................................................................................................. |

49 |

10 tap test results (OOBE states) ...................................................................................................... |

49 |

12 tap test results (REDI sensor values) ........................................................................................... |

51 |

61 tap results (Align and color calibrations) ..................................................................................... |

53 |

909 tap test results (BDD status) ...................................................................................................... |

54 |

Verify that the pig tails have an adequate seal ................................................................................ |

55 |

Troubleshooting owchart .................................................................................................................................. |

56 |

Front-panel error codes ....................................................................................................................................... |

57 |

Control-panel messages ...................................................................................................................................... |

60 |

Error-related symptoms ...................................................................................................................................... |

64 |

Check symptoms .................................................................................................................................................. |

65 |

Power and electronics ....................................................................................................................... |

65 |

Solve print quality problems ............................................................................................................. |

67 |

Solve paper handling problems ........................................................................................................ |

96 |

Solve connectivity problems ........................................................................................................... |

113 |

Solve copy/scan problems .............................................................................................................. |

119 |

Solve fax problems .......................................................................................................................... |

126 |

Solve memory device problems ...................................................................................................... |

138 |

Appendix A Event log codes ........................................................................................................................... |

139 |

Interpret event log codes .................................................................................................................................. |

140 |

Index ........................................................................................................................................................... |

151 |

vi |

ENWW |

List of figures

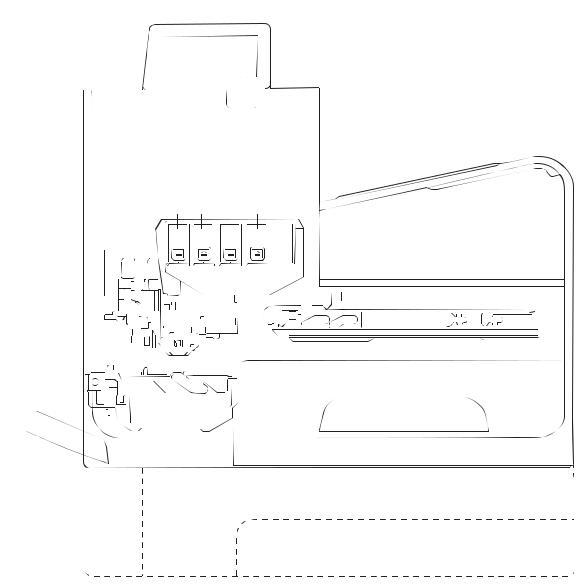

Figure 1-1 Main components (352/452 models) ................................................................................................................. |

2 |

|

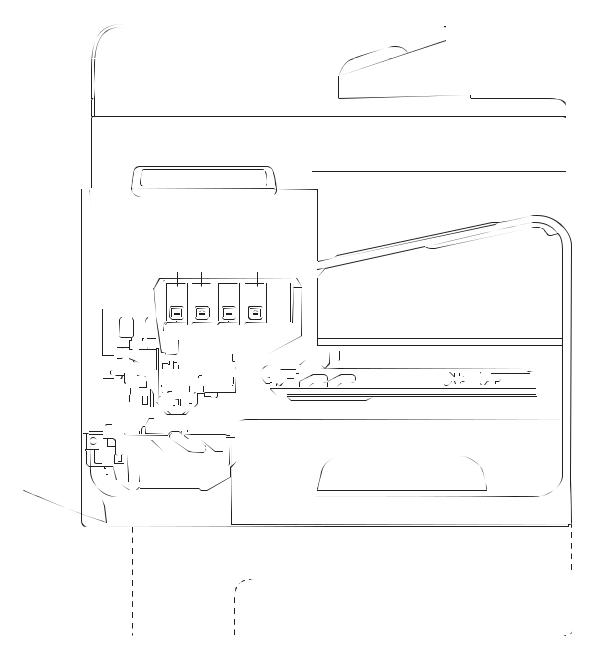

Figure 1-2 Main components (377/477 models) ................................................................................................................. |

3 |

|

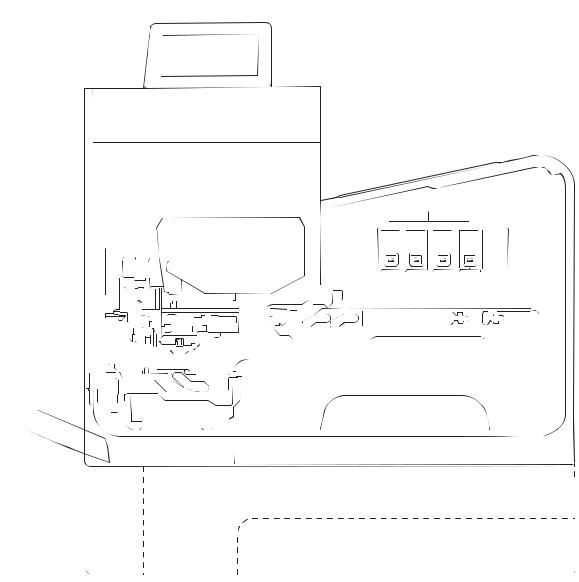

Figure 1-3 Main components (552/P55250 models) ........................................................................................................... |

4 |

|

Figure 1-4 Main components (577/P57750 models) ........................................................................................................... |

5 |

|

Figure 1-5 |

System control .................................................................................................................................................... |

8 |

Figure 1-6 Print subsystem components (300/400 series) ............................................................................................... |

12 |

|

Figure 1-7 Print subsystem components (500 series) ....................................................................................................... |

13 |

|

Figure 1-8 |

Printbar components ........................................................................................................................................ |

14 |

Figure 1-9 Paper-handling system paper path (300/400 series) ...................................................................................... |

17 |

|

Figure 1-10 Paper-handling system paper path (500 series) ............................................................................................ |

18 |

|

Figure 1-11 Printer sensors (300/400 series) .................................................................................................................... |

19 |

|

Figure 1-12 Printer sensors (500 series) ............................................................................................................................ |

20 |

|

Figure 1-13 Paper-handling-system motors (300/400 series) ......................................................................................... |

22 |

|

Figure 1-14 Paper-handling-system motors (500 series) ................................................................................................. |

23 |

|

Figure 1-15 Paper path zones (300/400 series) ................................................................................................................ |

25 |

|

Figure 1-16 Paper path zones (500 series) ........................................................................................................................ |

26 |

|

Figure 1-17 Servicing system components (300/400 series) ........................................................................................... |

28 |

|

Figure 1-18 Servicing system components (500 series) ................................................................................................... |

29 |

|

Figure 1-19 Service sled components ................................................................................................................................ |

30 |

|

Figure 1-20 Transmission components, rear view ............................................................................................................. |

31 |

|

Figure 1-21 Transmission main components ..................................................................................................................... |

32 |

|

Figure 1-22 Aerosol management process ........................................................................................................................ |

34 |

|

Figure 1-23 Aerosol management system components ................................................................................................... |

35 |

|

Figure 1-24 Document feeder rollers and sensors ............................................................................................................ |

36 |

|

Figure 1-25 Document feeder operation ........................................................................................................................... |

37 |

|

Figure 1-26 |

Deskew operation ........................................................................................................................................... |

38 |

Figure 2-1 Printer status report—determining genuine HP ink usage ............................................................................. |

68 |

|

Figure 2-2 Mark the Web wipe ............................................................................................................................................ |

90 |

|

Figure 2-3 Tray lift mechanism .......................................................................................................................................... |

98 |

|

ENWW |

vii |

viii |

ENWW |

1Theory of operation

●Basic operation

●System control

●Print subsystem

●Paper-handling system

●Servicing system

●Transmission system

●Aerosol management system

●Document feeder system (377/477/577/P57750 models)

●Scanning and image capture system (377/477/577/P57750 models)

●Fax functions and operation (377/477/577/P57750 models)

ENWW |

1 |

Basic operation

Function structure

The printer consists of the following components.

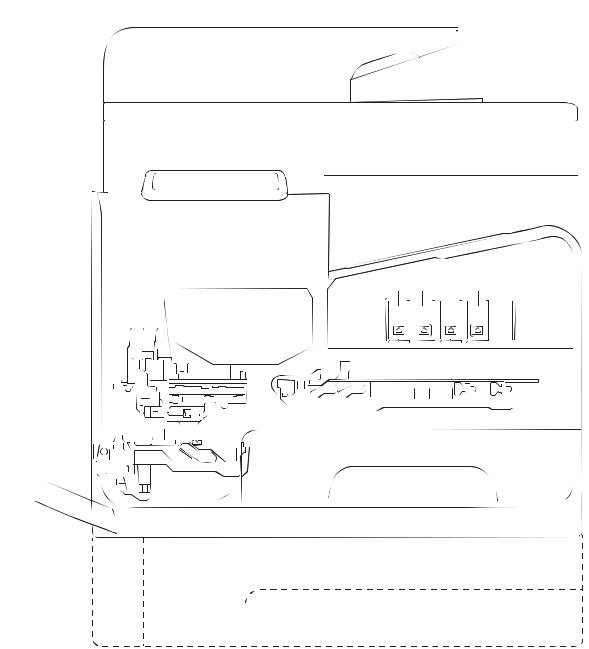

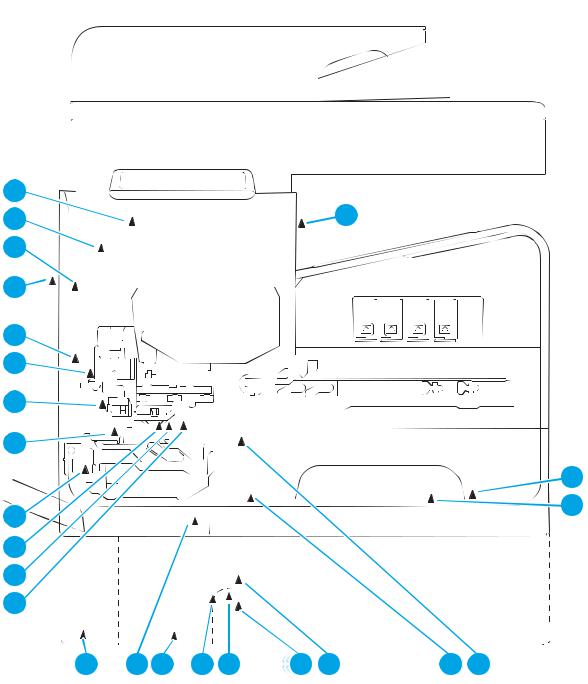

Figure 1-1 Main components (352/452 models)

Control panel

Output bin

Ink cartridges

Optical scan carriage

Printbar

Service sled

Main input tray (Tray 2)

Multipurpose tray |

Ink collection unit |

|

(Tray 1) |

||

|

||

|

|

Optional trays (Trays 3 and 4)

2 Chapter 1 Theory of operation |

ENWW |

Figure 1-2 Main components (377/477 models)

ENWW |

|

|

|

|

Basic operation 3 |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

|

|

|

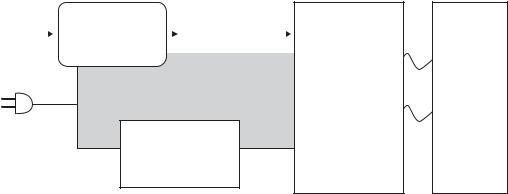

Figure 1-3 Main components (552/P55250 models)

Multipurpose tray (Tray 1)

Control panel

Output bin

Ink cartridges

Optical scan carriage

Printbar

Service sled

Main input tray (Tray 2)

Duplex module\

Waste ink module

Optional trays (Trays 3 and 4)

4 Chapter 1 Theory of operation |

ENWW |

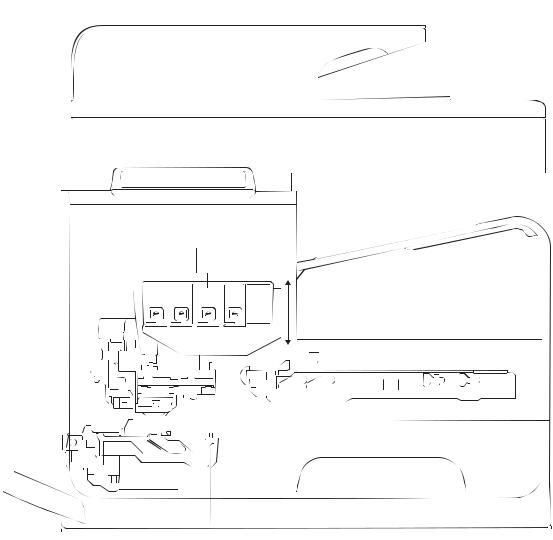

Figure 1-4 Main components (577/P57750 models)

Document feeder

Scanner

Control panel

Multipurpose tray (Tray 1)

Output bin

Ink cartridges

Optical scan carriage

Printbar

Service sled

Main input tray (Tray 2)

Duplex module\

Waste ink module

Optional trays (Trays 3 and 4)

The printer contains the following systems:

●Engine control system

●Print subsystem

●Paper-handling system

●Servicing system

●Aerosol management system

●Scanner and document feeder system

ENWW |

Basic operation 5 |

Two elements in uence the printer architecture:

●The first is the need to orient the printbar with its active face downwards and statically located above the print media. This requires the printbar to move vertically to access its active face.

●The second is producing face-down output. Rather than ejecting the page face-up immediately after the ink is applied, the printer routes the printed page up and back over the printbar to eject face-down.

Operation sequence

The engine-control system on the formatter PCA controls the operational sequences. The following table describes durations and operations for each period of a print operation from when the printer is turned on until the motor stops rotating.

Table 1-1 Operation sequence

Period |

Duration |

Purpose |

|

|

|

|

|

Initial startup and |

When the printer is set up for the |

This period gets the printer ready to print for the first time. |

|

calibrations |

first time from the factory. |

● |

Fluid replacement—The printer ushes the shipping and |

|

|

||

|

|

|

handling uid out of the printbar and replaces it with ink. |

|

|

● |

Die alignment—The printer aligns the 10 die on the printbar |

|

|

|

active face. |

|

|

● |

Die density leveling—The printer measures and compensates |

|

|

|

for the drop variation. |

|

|

|

|

Servicing operations |

Performed when the printbar is |

Servicing maintains print quality by removing debris and excess ink |

|

|

entering the capping state after |

and replacing missing nozzles. |

|

|

printing, when leaving the |

● |

Nozzle presence detection—The optical scan carriage detects |

|

capping state after a print job is |

||

|

initiated, or during extended |

|

and disables inoperable nozzles, and replaces them with |

|

print jobs. |

|

operable nozzles. |

|

|

● |

Printbar servicing—The web wipe on the service sled moves |

|

|

|

under the printbar to clean the active face and fires the nozzles |

|

|

|

into the ink collection unit to clear clogs. |

Print preparation |

From the time the printer |

|

receives a printer command until |

|

paper enters the print zone. |

Prepares the printer for a print job.

●The printbar leaves the capping state as the service sled moves away from the printbar.

●If needed, some servicing occurs.

●The printbar lowers to the printing position. The media type and printing mode determine the print zone height.

●The printer picks media from one of the input trays.

●Every page from Tray 1 is scanned. For Tray 2 and optional Trays 3 and 4, the printer performs media edge detection after printing the first sheet after the tray is loaded. The last sheet of each job is also scanned if at least five sheets have been printed.

●The printer monitors environmental conditions. The printer can slow the print speed if conditions are significantly different than a normal office environment (23° C (73.4° F), 50% relative humidity).

●The formatter PCA processes print data and transmits the data to the printbar.

6 Chapter 1 Theory of operation |

ENWW |

Table 1-1 Operation sequence (continued)

Period |

Duration |

Purpose |

|

|

|

|

|

Printing |

From the end of the preparation |

Processes the print job. |

|

|

period until the last sheet is |

● |

As the page travels through the print zone, the printbar applies |

|

delivered. |

||

|

|

|

ink to the page. |

|

|

● |

Simplex print job—the page moves up, over the printbar, and |

|

|

|

out to the output bin (face-down). |

|

|

● |

Duplex print job—the page moves up until the trailing edge is |

|

|

|

40 mm (1.5 in) past the star-wheel jam re ective sensor. The |

|

|

|

page reverses direction down through the duplex path and |

|

|

|

underneath the ink collection unit. Then, it reenters the print |

|

|

|

zone, where the printbar applies ink to the second side. |

|

|

● |

The process continues until all the pages of the print job are |

|

|

|

completed. The process can be interrupted by occasional |

|

|

|

nozzle presence detection and servicing events, if the job |

|

|

|

includes many pages. |

|

|

|

|

End of print job |

Performed after the print job is |

This period puts the printer in a state where it’s ready for the next |

|

|

completed, and continues until |

print job. |

|

|

the next job is initiated. |

● |

If needed, some servicing occurs. |

|

|

||

|

|

● |

The printbar moves to the capping position after a short dwell |

|

|

|

interval. |

|

|

● |

The service sled moves to cap the printbar. |

|

|

|

|

Standby |

The printer is sitting idle, waiting |

This period is intended to conserve energy when the printer is |

|

|

for the next print job to be |

sitting idle. Certain functions might be disabled to save power and |

|

|

initiated. |

then re-started only when needed. The printer has two sleep |

|

|

|

modes: |

|

|

|

● |

Idle mode—The printbar is capped and the printer is ready to |

|

|

|

immediately start a new job |

|

|

● |

Sleep mode—After the printer is inactive for about 10 minutes |

|

|

|

(a setting that can be adjusted from the control panel or the |

|

|

|

Embedded Web Server), the control panel turns off and the |

|

|

|

power LED blinks to indicate the unit is in Sleep mode. All |

|

|

|

printer functions are available. |

|

|

|

|

ENWW |

Basic operation 7 |

System control

The system control coordinates all the other systems, according to commands from the formatter.

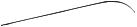

Figure 1-5 System control

I/O |

|

Formatter |

|

|

Datapath |

|

|

|

|

|

I/O, PDL, UI control |

|

|

ASIC +memory |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power supply

Engine control

Motor + sensor drive

The system consists of five major sections.

●Formatter

●Data path

●Engine control

●Pen interface

●Power supply

Pen I/F

•Pen energy control

•Pen voltage sequencing

• Signal integrity |

Printbar |

|

• Ink-short protection |

||

40,000 nozzles |

||

|

•Printhead interconnects

•Ink supply

The engine PCA integrates both formatter and engine control electronics onto a single assembly. The wireless radio unit (wireless models only) plugs into the back of the engine PCA, and the fax connects to the PCA via a short atexible cable (FFC).

Formatter and data path

The formatter controller ASIC controls the input/output (I/O) control, the user interface, and the rendering of page description language files into printer-specific commands.

Input/output (I/O) control

The printers support 10/100 Ethernet, 802.11 wireless (HP wireless direct models), a rear USB host port, a control panel USB host port (552/P55250/377/477/577/P57750 models), and an analog fax port (377/477/577/P57750 models). For Ethernet networks, the formatter ASIC uses a separate integrated circuit (Broadcom 5241) to provide the physical network layer.

The formatter ASIC controls the USB device and USB host as well.

Wireless I/O is provided via a separate radio module.

User interface

The printers contain either a 2-inch (352/452 models) monochrome display or an 4.3-inch (552/ P55250/377/477/577/P57750 models) color graphics display. An icon on the control panel of wireless models denotes that the wireless feature is enabled. The 552, P55250, 377, 477, 577, and P57750 models include a walk-up USB host port for connection to thumb drives.

8 Chapter 1 Theory of operation |

ENWW |

Formatter digital ASIC

The formatter digital ASIC contains dual ARM CPUs (1.2 GHz and 600MHz) that execute firmware code that provides high-level device control. The digital ASIC uses a standard PCle interface to pass data to the engine control ASIC.

Formatter analog ASIC

The formatter analog ASIC generates the system voltage for the formatter, drives the scanner and ADF motors, manages the real-time clock, and drives the fax speaker. Also, the engine uses this ASIC to drive the ISS pumps, solenoids, and aerosol fan.

Real-time clock

The real-time clock (RTC) allows the fax module to time-stamp outgoing faxes. In addition, it determines the elapsed time between printhead and ISS calibration events. The RTC uses a special block inside the engine analog ASIC, along with a crystal and a battery.

Engine control

The engine controller digital ASIC receives high-level commands from the formatter, and it then provides lowlevel control to the print mechanism. In particular, the engine controller digital ASIC and its firmware control motors, system sensors, and the printbar. The engine controller analog ASIC integrates motor drivers, voltage regulators, sensor interfaces, and supervisory circuits.

Engine controller digital ASIC

The engine controller digital ASIC has a high-performance 480 MHz ARM CPU and DSP co-processors that execute firmware code to provide low-level engine control. It also drives the printbar via 15 high-speed LVDS transmission lines, which are routed from the engine PCA to the printbar via two large FFC cables. The engine controller digital ASIC receives pre-rendered data from the formatter digital ASIC over a standard PCle interface.

When a product has entered sleep mode, many functions of the printer have gone into a low-power mode. If a print job is received while the product is in sleep mode, the printer will take a short period of time to "wake up". This can take up to 15 seconds, which will delay the first page out (FPO) time accordingly.

Engine controller analog ASIC

The engine uses two analog ASICs to generate the system voltages for the engine, drive the engine motors, control various engine sensors, and monitor printbar power delivery for correct operation.

The engine has seven motors, some of which are shared with other subsystems:

●Pick motor

●Feed motor

●Duplex motor

●Lift motor

●Eject motor

●Sensor carriage motor

●Aerosol fan motor

ENWW |

System control 9 |

Each one is a DC motor with encoder feedback, to provide precision servo control. These motors are driven directly by one of the engine analog ASICs. Small DC motors also are used to drive the ISS pump and the aerosol fan. There are solenoids that actuate the ejection ap and the ISS priming system.

The printer uses many sensors to track the media as it travels through the paper path. Most of these are optical REDI sensors, which are used in conjunction with mirrors to sense the presence or absence of paper in a particular location. These are carefully aligned and calibrated at the factory, so care must be taken when servicing these sensors. See the Remove and Replace chapter in the repair manual for more details.

Other printed circuit-board assemblies (PCAs)

In addition to hosting the system ASICs, the engine PCA is home to many circuits needed to interface to sensors and other sub-system components. In some cases, this circuitry is located on a smaller remote PCA (SLB) to optimize cable interconnects.

●Humidity sensor—The humidity sensor causes the printer to adjust printing speed if ambient conditions are outside the optimal humidity range. This sensor is calibrated at the factory to ensure maximum accuracy.

●Temperature sensor—The temperature sensor causes the printer to adjust printing speed if ambient conditions are outside the optimal temperature range. In some printers, this sensor resides on a separate, remote PCA.

●Main tray presence sensor—The hall-effect sensor that detects if the main tray is properly engaged resides on the back of the engine PCA. A small magnet on the back of the main tray actuates the sensor. If the tray is fully engaged, the magnetic field strength is sufficient to trigger the sensor.

Additionally, the printer includes the following PCAs:

●Front USB PCA—This PCA governs the control panel USB port.

●Fax PCA—This PCA governs the printer fax module.

●Duplex module presence sensor–This hall-effect sensor detects whether the duplex module is properly seated.

●Power button PCA—This PCA includes the power button and power LED, as well as interface cables to the duplex module presence sensor and the MP tray empty REDI sensor.

●Accessory tray interconnect PCA—This PCA provides communication to optional Tray 3.

●Pick encoder distribution PCA—This PCA includes the pick motor encoder and the pick motor interconnect cable.

●Eject encoder distribution PCA—This PCA includes the eject motor encoder, plus the interconnect cables to the eject motor and the aerosol fan.

●Print zone distribution PCA—This PCA joins interconnect cables to the following sensors: separator REDI, feed motion encoder, main tray empty sensor, Top of Form (TOF) REDI sensor, and the Print zone REDI sensor.

●REDI distribution PCA—This PCA includes hall-effect sensors that detect ink cartridge door and left door positions. It also combines the interconnect cables for the eject REDI sensor, the upper paper path REDI

sensor, the lower paper path REDI sensor, and the eject ap opto ag sensor.

●Sensor carriage PCA—This PCA includes a carriage motion encoder, a ZIM sensor, and the BDD sensor.

●Printbar lift encoder distribution PCA—This PCA includes the printbar lift motion encoder and combines

interconnect cables to the printbar lift motor, carriage motor, and eject ap solenoid.

10 Chapter 1 Theory of operation |

ENWW |

●Duplex encoder PCA—This PCA contains the motion encoder for the duplex motor.

●SHAID PCA—This PCA contains interfaces to the out-of-ink sensors for the ink cartridges, and combines the interface cables to the acumen PCA, the ISS pump, and the ISS solenoids.

●Acumen PCA—This PCA contains interfaces to the acumen memory devices for the ink cartridges.

Pen interface (I/F)

The printbar is the key component that differentiates these printers from other inkjet printers. The conventional approach is to print a page in horizontal swaths by moving a “scanning” printhead horizontally over a fixed sheet of paper, advancing the paper a fixed amount, and then printing the next swath. With these printers, the paper moves underneath a fixed page-wide printhead in a single smooth motion.

Single pass page-wide printing requires that data and power be delivered to the printbar at a very high rate, while also maintaining good control of paper position as it moves past the printhead nozzles.

The engine PCA sends power and data to the printbar via two large at exible cables (36 and 38 pins). The printbar PCA routes power and data to 10 printhead die, which are attached to the PCA using a exible tab circuit and wire-bonding process.

The printers also contain electronics to control the ink supply station (ISS). The SHAID PCA detects low-ink conditions. It gauges ink levels by means of electrically sensing the presence of ink and/or ink foam in the X- chamber. The SHAID PCA also collects and distributes electrical signals that drive the push-prime pump(s), engage the solenoids, and read the ink supply acumen data. All are routed through a single 17-pin FFC from the SHAID PCA to the engine PCA.

Each ink supply has a memory tag that stores information about its type of ink, the amount of ink remaining, and other critical data. It uses a special authentication scheme to ensure that only genuine HP supplies are used and the printer is not damaged by using invalid supplies. Acumen uses a two-line serial bus, which, along with 3.3 V and ground, is cabled via the SHAID PCA to the engine PCA and the engine control digital ASIC.

Power supply

The power supply module converts 100-240 VAC to 34 VDC to power the system. The power supply module has a sleep mode that reduces power consumption in system low-power modes. When in its sleep mode, the power supply generates less than 4 W.

The power supply module supplies 34 V to the engine PCA. The power supply module has two operating modes, depending upon the state of its nSLEEP input pin:

●Printing: = up to 13 W ( nSLEEP = high logic level)

●Sleep mode: = < 4 W ( nSLEEP = low logic level)

The power supply is a self-contained module that can be replaced if it is determined to be defective (see the Remove and Replace chapter of the Repair Manual).

To ensure safe operation, the power supply will “latch off if a persistent over-current fault condition exists. This would typically be caused by a short-circuit from 34 V to ground in the printer. Less severe faults can cause the power supply to latch off, if present for an extended period of time, or if the printer is operated above the recommended operating temperature range.

NOTE: In some countries/regions, the printer is equipped with a high-voltage power supply in order to prevent power supply unit failures due to over-voltage conditions.

NOTE: In some countries/regions, the printer is equipped with a high-voltage power supply in order to prevent power supply unit failures due to over-voltage conditions.

ENWW |

System control 11 |

Print subsystem

The print subsystem includes the following components.

●Printbar

●Printbar lift

●Ink cartridges

●Optical scan carriage

Figure 1-6 Print subsystem components (300/400 series)

|

Ink cartridges |

Optical |

|

scan |

|

carriage |

Printbar lift |

|

|

|

Printbar |

12 Chapter 1 Theory of operation |

ENWW |

Figure 1-7 Print subsystem components (500 series)

Printbar

The printbar’s fundamental purpose is to convert the digital firing instructions from the printer electronics into properly formed and timed microscopic drops of the four ink colors. The printbar spans the full width of a letter/A4-size sheet (216 mm (8.5 in)), which allows the printbar to be statically positioned within the printer and have the media move underneath it, printing the entire page in a single motion.

ENWW |

Print subsystem 13 |

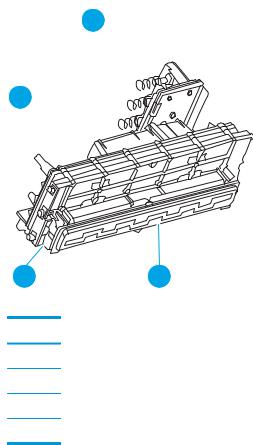

Figure 1-8 Printbar components

1

4

3 2

Table 1-2 Printbar components

Item Description

1Ink cartridge connections

2Thermal inkjet (TIJ) die array

3Data/power ow and regulation

4nk ow channels and pressure regulation

The printbar has a fixed array of 10 thermal inkjet (TIJ) die oriented in two staggered rows. Each die contains more than 1,000 nozzles for each of the four ink colors—black (K), cyan (C), magenta (M) and yellow (Y). Behind the die array are the ink ow channels and pressure regulation mechanisms that supply the die array with ink at the proper pressure and ow. The die must also be fed power and data at the appropriate levels and rates, which is the function of the onboard electronic circuitry. Finally, situated at the top of the printbar, there are four ink cartridge receptacles, one for each color. These cartridges are linked by ow connections to the rest of the printbar and supply the ink necessary for its operation.

A sensor technology called back-scatter drop detect (BDD) monitors printbar health and calibrations. This system looks at the re ection of the miniscule drops in ight, and then passes these signals through highspeed, high-gain, bandpass filters. A complex artificial intelligence (AI) system decides which drop ejectors are currently out of specifications, and which are not.

After the AI system determines which drop ejectors are out of specification, the printer compensates for them. Some ejectors use neighboring nozzles and at times even tiny amounts of other inks—whichever combination of methods necessary to deliver the best print quality possible at that moment. In some cases, fully half of the nozzles can be “out” without a noticeable degradation in quality. The compensation is done in real time with a dedicated high-speed DSP. The system can scan portions of the system after print jobs, but it is fully interruptible by new, incoming print jobs.

Printbar air management system

The printbar uses a passive air gain management system. Air can enter the printbar from the following sources:

14 Chapter 1 Theory of operation |

ENWW |

●Die outgassing (from air in the ink)

●Air entering nozzles due to temperature or pressure variations

●Air entry through the printbar structure

●Air entry through the nozzles due to shipment vibration

Air that enters the printbar is warehoused. There is no mechanism to remove the air in the field. Of the various mechanisms for air entry, the first three are generally benign, and rarely cause issues during the expected life of the printer. The fourth mechanism generally occurs during shipment. New printers are shipped with the printbar taped—which limits the amount of air gained. If the printbar isn’t well restrained during shipment, then air gain can be significant. If the printer is shipped after removal of the printbar tape, air gain can be reduced either by ensuring that the printer stays on its base, or that the printbar is restrained. Both would be best.

Printbar lift

The printbar lift is responsible for positioning the printbar within the printer and moving it up and down as required. This vertical motion is both to establish proper spacing to the paper during printing, and to raise it to either access the active face or perform necessary calibrations.

During printing, the lift mechanism sets the printbar height and paper height depending on the type of paper.

Ink cartridges

These printers have new, state-of-the-art pigmented inks. They are filtered using proprietary processes to prevent printhead contamination. These inks are designed to produce optimal print quality on ColorLok office papers, but also produce very good print quality on regular office papers and specialty paper.

Optical scan carriage

The optical scan carriage has optical sensors used for calibration. Its motion is along the long axis of the printbar. These sensors are used by a number of printer calibration features that are important for proper subsystem function. The BDD sensor is located on the optical scan carriage.

Print system operational states

The print subsystem has a number of distinct operational states besides active printing.

Startup

As it comes from the factory, the printbar is initially filled with an inert ink-substitute called Shipping and Handling Fluid (SHF). This uid, essential for the manufacture and transportation of the printbar, must be ushed and replaced with actual ink. This is accomplished during the Startup phase. The ushing process automatically commences when ink supplies are inserted and the unit is powered up for the first time. The

SHF is removed by sustained printbar operation and replaced by ink from the supplies. The process terminates once all the SHF has been ushed from the printbar.

Special host supplies are supplied with the printer prior to its first use. These supplies contain additional ink so that there will be 100 percent ink level after the SHF is replaced with ink. These supplies can be used only to initialize the printer. You cannot use them in another printer that has been initialized.

NOTE: The initial startup time is noticeably longer than the following regular startup times.

NOTE: The initial startup time is noticeably longer than the following regular startup times.

ENWW |

Print subsystem 15 |

Die alignment

Since 10 die comprise the printbar active face, each with associated positional tolerances, an active calibration must be performed to prevent errors and allow a uniform ink application to the paper (without any gaps or overlaps between adjacent die). This die alignment is done by printing a special diagnostic image on a sheet of paper and then scanning it with the optical scan carriage. Die alignment is performed as part of initial unit startup, and can be performed manually as part of the print quality recovery tool.

Die density leveling

Tolerances are also associated with the drops fired by the individual printbar die. Another active calibration measures and compensates for these variations to produce a visually uniform ink application to the paper. Another set of diagnostic images is printed and scanned by the optical scan carriage to achieve this die density leveling. Die alignment and die density leveling are usually paired together.

Nozzle presence detection

In printing, since all the ink is applied in a single smooth motion of the paper past the printbar, any inoperable nozzle can show up as a noticeable streak. The operational state of each of the thousands of nozzles on the printbar is periodically measured. The printbar lift raises the printbar, and the BDD assembly on the optical scan carriage watches for drop presence as each nozzle is fired. Inoperable nozzles are turned off and other operable nozzles are used on subsequent printed pages to apply the missing ink. Nozzle presence detection is fully interruptible by new, incoming print jobs.

Media edge position detection

The printer uses a learning algorithm to define media center as a function of input source—Tray 1, Tray 2, or optional Trays 3 and 4. The edge scan is located downstream of the print zone. As paper is scanned, the media center database is updated. The image is registered to the page using the media center database.

Servicing and capping

When in the capped state, the printbar is fully raised, the service sled is positioned underneath, and the printbar cap is engaged against the printbar active face. Servicing—the cleaning of the active face and the firing of the nozzles—can occur either during Sleep2 mode or after extended time in storage. It can also occur during extended print jobs.

Printing

The printing state begins by the printbar leaving the capping state, and lowering to the printing position after the service sled moves out of the way. At the same time, a sheet of paper is picked from one of the three trays and the leading edge staged at the entrance to the print zone. Once the print data has been sent, the sheet of paper feeds at a constant velocity through the print zone and the printbar applies the ink.

In the case of one-sided printing, the inked sheet is moved up, over and out to the output tray. For two-sided printing, the sheet is moved until its trailing edge is past the merge to the vertical path. The sheet is then reversed down through the duplex path underneath the ink collection unit, and reintroduced into the print zone for inking of the second side.

This process continues until all the pages of the print job are completed. If the print job is large enough, it can be interrupted by servicing processes.

16 Chapter 1 Theory of operation |

ENWW |

Paper-handling system

The paper-handling system moves paper through the printer according to commands from the formatter. The following figures show the printer paper path.

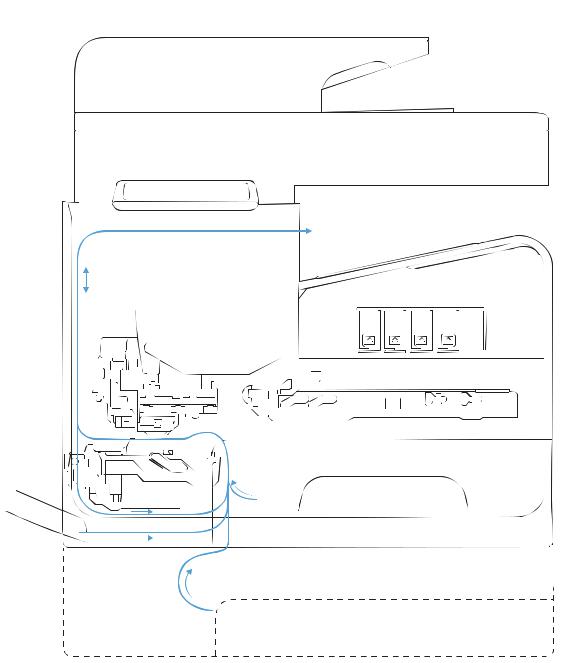

Figure 1-9 Paper-handling system paper path (300/400 series)

ENWW |

Paper-handling system 17 |

Figure 1-10 Paper-handling system paper path (500 series)

The paper path consists of the following major components:

●Two integrated input trays plus one optional accessory tray

●Four motors and a solenoid plus two more motors in the accessory tray

●Duplex module

●Sensors placed throughout the device, including the paper trays

18 Chapter 1 Theory of operation |

ENWW |

●Multiple feed rollers, pinch rollers, star wheels, and media guides

●Transmission components (gears, shafts, levers, swingarms) that interface with other subsystems such as the printbar and service sled.

Components of the paper path move the paper from the input tray to a position 1 to 2 mm (.04 to .08 in) underneath the printbar, and then deliver the printed result to the output tray. The combined orientations and actions of the printbar, the printbar lift, and the paper path establish the print-zone, where the ink drops move from the active face of the printbar to the paper.

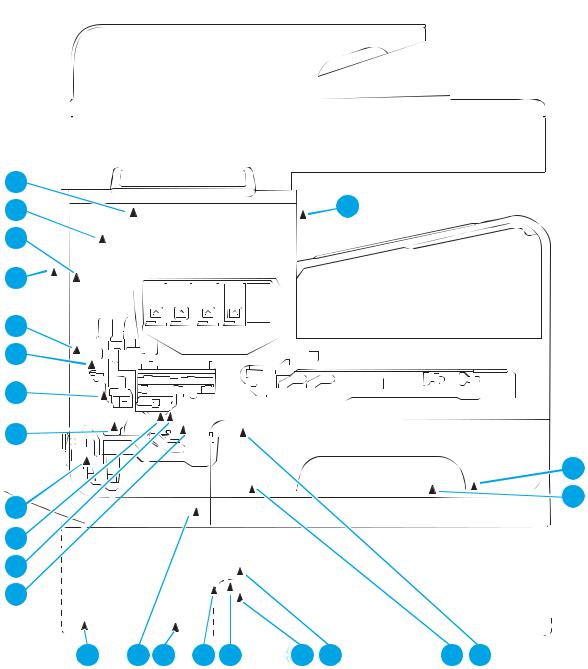

The following figures show the printer sensors.

Figure 1-11 Printer sensors (300/400 series)

24 |

1 |

23 |

|

22 |

|

21 |

|

20

19

18

17

|

|

|

|

|

|

|

2 |

16 |

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

13 |

|

|

|

|

|

|

|

12 |

11 10 |

9 |

8 |

97 |

6 |

5 |

4 |

ENWW |

Paper-handling system 19 |

Figure 1-12 Printer sensors (500 series)

24 |

1 |

23 |

|

22 |

|

21 |

|

20

19

18

17

|

|

|

|

|

|

|

|

2 |

16 |

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

|

13 |

|

|

|

|

|

|

|

|

|

12 |

11 10 |

9 |

8 |

97 |

6 |

5 |

4 |

Table 1-3 Printer sensors |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Item |

Description |

|

|

Item |

|

Description |

|

|

|

|

|

|

|

|

|

|

|

1 |

Output |

ap jam sensor |

|

|

13 |

|

Top of Form (TOF) REDI sensor (located on platen) |

|

|

|

|

|

|

|

|

|

|

2 |

Ambient temperature sensor |

|

|

14 |

|

Feed roller encoder |

|

|

|

|

|

|

|

|

|

|

|

3 |

Ambient humidity sensor |

|

|

15 |

|

Feed roller home sensor |

|

|

|

|

|

|

|

|

|||

4 |

Tray 2 pickup tire home sensor |

|

16 |

|

Duplex module presence sensor |

|||

|

|

|

|

|

|

|

||

5 |

Tray 2 tray presence sensor |

|

|

17 |

|

Print zone REDI sensor (located on platen) |

||

|

|

|

|

|

|

|

|

|

20 Chapter 1 Theory of operation |

ENWW |

Loading...

Loading...