Honeywell L6008 User Manual

L4008A,B,E,L; L6008A,G,H

Aquastat® Controllers

APPLICATION

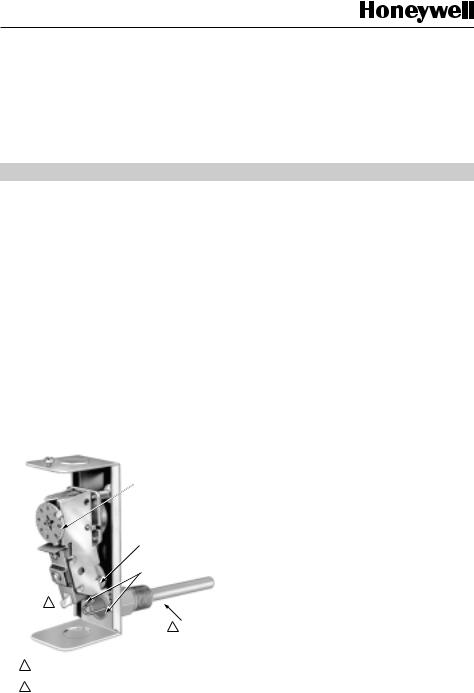

These remote bulb (see Fig. 7), immersion type (see Fig. 1) controllers operate in response to temperature changes in hydronic heating systems and other heated liquids.

Electrical Ratings:

Switch ratings are shown on the inside cover of each device. The electrical requirements on controlled equipment must not exceed this rating.

L4008A—breaks the burner circuit on a rise in water temperature. It is normally used as a limit controller. When used as an operating controller or low limit, a separate high limit control must be used.

L4008B—makes a control circuit on a rise in water temperature. It is normally used as a circulator controller to prevent circulator operation until boiler water temperature is at or above the control setting.

L4008E—breaks the burner circuit and locks out on a rise in water temperature. It is used as a high limit controller where manual reset is desirable.

L4008L—is used as a 2-stage Aquastat® controller. L6008A—makes the burner circuit on a drop in water temperature. It is normally used as a circulator and

low limit cooling controller.

SETPOINT

INDICATING DIAL

DIFFERENTIAL

ADJUSTMENT

WHEEL

ADAPTER CLAMP

SCREWS

2

INSERTION 1 ELEMENT

1WITH VERTICAL MOUNTING OF IMMERSION WELL, ELEMENT IS ATTACHED TO BOTTOM OF THE CASE.

2SELECT MODELS HAVE SCREW TERMINAL, NOT TAB

TERMINAL. |

M8806 |

INSTALLATION INSTRUCTIONS

L6008G—is used as a 2-stage Aquastat® controller to cycle 2-stage gas valve.

L6008H—is used as a low fire Aquastat® controller.

If immersion well or capillary compression fitting must be ordered, refer to form 68-0040, Wells and Fittings for Temperature Controllers, for part numbers and ordering information.

INSTALLATION

When Installing this Product…

1.Read these instructions carefully. Failure to follow them could damage the product or cause a hazard ous condition.

2.Check the ratings given in the instructions and on the product to make sure the product is suitable for your application.

3.Installer must be a trained, experienced service technician.

4.After installation is complete, check out product operation as provided in these instructions.

CAUTION

CAUTION

Disconnect power supply before installation to prevent electrical shock or equipment damage.

Depending on model and installation requirements, install the temperature sensing bulb either in an immersion well (see Fig. 2) that extends into the boiler or tank, or directly immerse the temperature sensing bulb in the liquid. For installations not using a well, secure the bulb with a bulb compression fitting (see Fig. 3), or a capillary compression fitting (see Fig. 4). Order the well or the fitting separately.

The boiler manufacturer generally provides a tapping for inserting the Aquastat® controller sensing element. Locate this tapping in a representative point where typical water temperature can be measured. Never locate the bulb or protecting immersion well close to a hot or cold water inlet or steam coil. Install the bulb in the supply line of an indirect water heater, in the indirect water heater itself, or in the feed riser about 6 in. (152 mm) above the boiler. If the riser is valved, install the bulb between the boiler and the valve.

Fig. 1. Internal view.

®U.S. Registered |

Trademark |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

95-5971-2 |

|||||||||||||||||||||||||||||||||||||||||||||||||

Copyright © 1995 |

Honeywell Inc. • All Rights Reserved |

||||||||||||||||||||||||||||||||||||||||||||||||

L4008A,B,E,L; L6008A,G,H REMOTE BULB AQUASTAT® CONTROLLERS

The Aquastat® controller can be remotely mounted— either vertically on a wall or panel, or directly on the boiler, tank, or vessel.

If the system is filled, drain the system to a point below the boiler tapping, or to wherever the sensing bulb is to be installed.

Mounting the Case

Remove the cover and fasten the case to the wall or panel using the three mounting holes in the back of the case.

When mounting the remote bulb, if desirable, route the tubing to run through any of the other three corner notches in the case. Be careful not to kink or bend tubing sharply. Be sure bends have at least 1 in. (25.4 mm) radius.

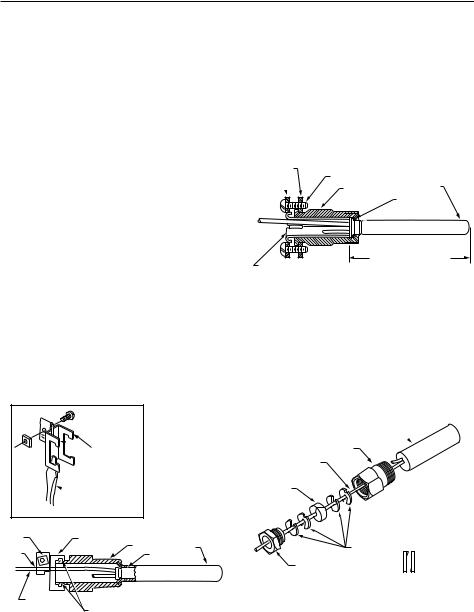

Installing Remote Bulb with Immersion Well

Fit well, if used, to sensing bulb snugly for good thermal response. Insert bulb until it rests against the bottom of the well; then hold it there while tightening the tubing clamp.

Screw the well into the boiler, tank or pipe tapping.

Insert the bulb into the well, pushing the tubing until the bulb bottoms in the well.

Attach the retainer clamp to the end of the well spud. Loosen the draw nut and spread the jaws of the clamp with the screwdriver if necessary.

With the retainer clamp attached to the well spud (be sure jaws of clamp hook over ridge at end of the spud, as shown in Fig. 2, points A). Adjust tubing to fit through retainer clamp groove, as shown at point B.

Tighten the draw nut so the retainer clamp is firmly attached to the well spud and the tubing is held by the clamp.

JAWS

JAWS

SPREAD JAWS

TO FIT OVER

RIDGE ON

WELL SPUD

SCREWDRIVER

SCREWDRIVER

INSERT— MOUNTING CLAMP

DRAW |

|

|

|

NUT |

MOUNTING |

SPUD |

|

B |

CLAMP |

WELL |

|

|

|

BULB |

|

TUBING |

|

|

M8777 |

A

Fig. 2. Immersion well fitting.

IMPORTANT

Do not secure draw nut so tightly that retainer clamp could cut or collapse tubing.

Mounting with Bulb Compression Fitting

Screw the fitting into the boiler or pipe tapping.

Slide sealing washer onto the bulb.

Insert the bulb into the fitting until bulb bottoms.

Slide split sleeve into fitting.

Place clamps A and B on assembly so that sleeve is drawn into fitting when screws are tightened.

NOTE: Make sure that the nub on clamp A engages space between sleeve and clamp.

Tighten clamp screws evenly.

CLAMP B

CLAMP SCREWS (2)

CLAMP A

BULB |

|

BULB |

COMPRESSION |

SEALING |

|

FITTING |

|

|

|

WASHER |

|

|

|

|

|

INSERTION LENGTH |

|

|

APPROX. 3-3/16 IN. (81 MM) |

|

SPLIT SLEEVE

M8815

Fig. 3. Bulb compression fitting.

Mounting with Capillary Compression Fitting

Screw fitting into the boiler or pipe tapping.

Place packing nut on tubing.

Slide bulb completely through fitting.

Place composition disc and 4 slotted brass washers on tubing in the order shown in Fig. 4. Turn brass washers so that slots are 180 degrees to each other.

Slide seal assembly into fitting and tighten packing nut.

IMMERSION

BULB

BOILER PLUG

CAPILLARY TUBING

COMPOSITION DISK (SLOTTED)

|

EXAMPLE OF SLOTTED WASHERS |

|

ASSEMBLED |

PACKING NUT |

IN PAIRS: |

M8816 |

Fig. 4. Capillary compression fitting.

WIRING

All wiring must agree with applicable codes and ordinances and regulations in such matters as wire size, type of insulation, and enclosure. The controllers are provided with conduit knockouts in the top and bottom of case.

Refer to Fig. 5 or 6 for a typical connection diagram.

95-5971—2 |

2 |

Loading...

Loading...