Honeywell L8148A, L8148E, L8148J User Manual

L8148A,E,J

Aquastat® Relays

|

INSTALLATION INSTRUCTIONS |

|

APPLICATION |

to 240°F (82°C to 116°C). |

|

|

Scale Range: 140°F to 240°F (60°C to 116°C) or 180°F |

|

The L8148A,E,J Aquastat® Relays are immersion-type |

Differential: Nonadjustable. |

|

controllers for use with forced hydronic heating systems. |

|

|

The combination high limit and intermediate switching |

High Limit Dial Stop: Adjustable. |

|

relay works with a low voltage (24V) thermostat to control |

|

|

burner and circulator circuits. A call for heat by the |

Maximum Pressure on Immersion Well: 255 psi (1758 |

|

thermostat starts both the burner and the circulator. |

kPa). |

|

When boiler-water temperature exceeds the high-limit |

|

|

settings, the burner circuit is broken; the circulator |

Maximum Ambient Temperature: 150°F (66°C) with |

|

continues to operate during the thermostat call for heat. |

1.2A, 24V load; 77°F (25°C) with 1.4A, 24V load. |

|

The L8148A controls line-voltage burner circuits; the |

Maximum Bulb Temperature: 40°F over setpoint, up to |

|

L8148E,J control low-voltage burner circuits; the L8148J |

265°F (4°C over setpoint, up to 129°C). |

|

controls millivoltage burner circuits. All models control |

|

|

line-voltage circulator circuits. |

Thermostat Heat Anticipator Setting: 0.2A. |

|

L8148A,E,J have provisions for adding low-limit |

Material Safety Data Sheets (MSDS): For information |

|

controllers; L8148E,J can power valves in multizone |

on heat-conductive compound, see form number |

|

systems. |

69-0955. |

|

L8148E is available with a plug and 50 VA transformer for |

INSTALLATION |

|

use with Honeywell Smart Valve SV9500/SV9600. |

||

|

||

SPECIFICATIONS |

When Installing This Product… |

Electrical Ratings:

Table 1. Circulator Control Circuit (A):

Type |

|

|

120 Vac |

240 Vac |

|

|

|

|

|

Full Load |

|

7.4 |

|

3.7 |

|

|

|

|

|

Locked Rotor |

|

44.4 |

|

22.7 |

|

|

|

|

|

Table 2. Burner Control Circuit: |

||||

|

|

|

||

Model No. |

Voltage |

Electrical Rating |

||

L8148A |

Line |

Same as circulator control |

||

|

|

|

circuit. |

|

|

|

|

||

L8148E,J |

Low |

0.8A maximum at 24 Vac. |

||

|

|

|

|

|

1.Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous condition.

2.Check the ratings given in the instructions and on the product to make sure the product is suitable for your application.

3.Installer must be a trained, experienced service technician.

4.After installation is complete, check out product operation as provided in these instructions.

WARNING

WARNING

Explosion Hazard.

Can cause severe injury, death or property damage.

This product is intended for use only in systems with a pressure relief valve.

® U.S. Registered Trademark |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2002 Honeywell • |

•All Rights Reserved |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

95694012 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

L8148A,E,J AQUASTAT® RELAYS

WARNING

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property damage.

1.Disconnect power supply before beginning installation to prevent electrical shock or equipment damage.

2.Never apply a jumper across (or short) terminals B1, B2, or B3. This burns out the transformer.

Mounting

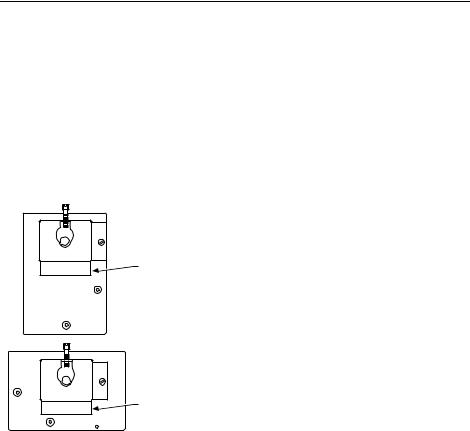

The L8148A,J has a case that can be converted to either horizontal or vertical mounting (Fig. 1).

BRACKET POSITION FOR

VERTICAL MOUNTING

BRACKET POSITION FOR

HORIZONTAL MOUNTING

M8890

Fig. 1. Case is designed for vertical or horizontal mounting.

New Installation

Order well assemblies and 124904 Well Adapter for the Aquastat Relay separately; refer to form 68-0040, Wells and Fittings for Temperature Controllers. Boilers usually have tappings that allow the well to be mounted horizontally so boiler water of average temperature can circulate freely.

1.Turn off all power and drain the boiler.

2.If no tapping is provided, prepare properly sized and threaded tapping near the top of the boiler.

3.Coat the well threads sparingly with pipe dope; install the well in the boiler tapping and tighten securely.

NOTE: Do not attempt to tighten by using the case as a handle.

4.Refill boiler and check for water leakage.

5.Insert the bulb element into the well until it bottoms. If necessary, slightly bend the tube inside the case to hold the bulb against the bottom of the well.

6.Center the loop of excess tubing in front of the immersion well so it cannot touch any electrical parts.

NOTE: Some models have an adjustable tubing length to 3 in. (76 mm). For these models, pull out extra tubing from inside the case, if needed.

7.Fit the case into the well so the clamp on the case slides over the flange on the well.

IMPORTANT

Best thermal response is obtained with a well that snugly fits the sensing bulb. Insert the bulb until it rests against the bottom of the well. Use a well of correct length and bend the tubing, if necessary, to hold the bulb against the bottom of the well, but do not make a sharp bend in the tubing.

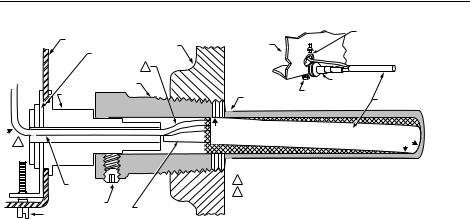

If the well is not a snug fit on the bulb, use the heat-conductive compound (furnished with TRADELINE® models) as follows: Fold the plastic bag of compound lengthwise and twist it gently. Then snip off end of bag and work the open end of bag all the way into the well. Slowly pull the bag out while squeezing it firmly to distribute compound evenly in the well. Bend the tubing, if necessary, to hold the bulb against the bottom of the well and to hold outer end of the bulb in firm contact with the side of the well. See Fig. 2. Wipe excess compound from the outer end of the well.

Replacement Installation

Turn off all power and remove the old control. Refer to the cover insert of the old control to identify and tag each external lead as it is disconnected. If old well is unsuitable for new installation, remove it and proceed with instructions for new installation. If old well is suitable, use it and a 124904 immersion well adapter (ordered separately from form 68-0040, Wells and Fittings for Temperature Controllers) for the installation. (If the well clamp fits directly over the flange of the existing well spud, adapter use is not necessary.) The adapter has a flange at the wide end that fits into the well clamp and is slotted lengthwise to accommodate both the capillary tube and the short length of tube extending from the bulb.

1.Loosen but do not remove the well clamp screw on the side of the control case.

2.Pull out the capillary until the bulb bottoms in the well. Place adapter (if used) around the capillary tube so it fits into the slot. See Fig. 2. Center the loop of excess capillary tubing in front of the immersion well so it cannot touch any electrical parts.

NOTE: Some models have a tubing length adjustable to 3 in. (76 mm). For these models, extra tubing inside the case can be pulled out, if needed.

3.Make sure the wide end of the adapter fits into the hole in the case. Position immersion well clamp snugly over the flange on the adapter and tighten the clamp screw.

4.Insert sensing bulb into well as shown in Fig. 2. (Distribute the heat-conductive compound in the tube prior to bulb insertion.)

5.Securely tighten setscrew (if present on old well) against adapter.

95-6940—12

|

|

|

L8148A,E,J AQUASTAT® RELAYS |

|

|

|

BACK OF |

|

IMMERSION |

CONTROLLER |

|

CONTROLLER |

|

WELL CLAMP |

BOILER |

CASE |

|

|

|

CASE |

|

|

||

|

|

|

||

IMMERSION |

|

|

|

|

WELL CLAMP |

|

|

|

|

|

1 |

|

|

|

IMMERSION |

|

|

ADAPTER |

|

WELL SPUD |

|

|

||

|

|

|

|

|

ADAPTER |

|

|

IMMERSION |

|

|

OLD IMMERSION |

WELL CLAMP |

SENSING |

|

|

|

|||

|

|

WELL ASSEMBLY |

SCREW |

BULB |

(A)

(C)

2

CAPILLARY

TUBE

SETSCREW

|

SHORT TUBE |

IMMERSION |

FITS IN CENTRAL |

WELL CLAMP SCREW |

RECESS OF ADAPTER |

(D)

(B)

HEAT-CONDUCTIVE COMPOUND

HEAT-CONDUCTIVE COMPOUND

1 BEND THE CAPILLARY TUBE TO HOLD THE SENSING BULB IN GOOD THERMAL CONTACT WITH THE IMMERSION WELL AT POINTS (A) AND (B).

2

ASSURE THAT CAPILLARY TUBE FITS FREELY IN THE ADAPTER SO THE TENSION OF THE CAPILLARY TUBE AT POINT (C) HOLDS THE SENSING

BULB IN GOOD THERMAL CONTACT WITH THE IMMERSION WELL AT POINT (D).

M8830

Fig. 2. Proper position of sensing bulb in immersion well, and use of well adapter in existing well.

WIRING

IMPORTANT

The terminals of these Aquastat® Relays are approved for use with copper wire only.

WARNING

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property damage.

Disconnect power supply before making wiring connections to prevent electrical shock or equipment damage.

All wiring must comply with local electrical codes and ordinances. Do not exceed the specifications in the Application section when applying this control.

L8148J can power up to two V8043 Zone Valves. Additional valves, in groups of two or less, require an additional transformer. Follow the appropriate wiring diagrams when using zone valves or a low limit controller. See Fig. 3 through 7.

If the B1 terminal on the device being replaced is a 1/4 in. tab terminal, use the existing wiring harness terminals to install the replacement device. If the B1 terminal on the device being replaced is a screw terminal, insert the provided tab terminal to screw terminal adapter onto the 1/4 in. tab terminal of the replacement device. After the adapter is installed, reuse the existing wraparound wire end to make an electrical connection to the B1 terminal.

CAUTION

CAUTION

Equipment Damage Hazard. Can cause incorrect operation.

1.If L8148E,J are used to power zone valves, low voltage (24 Vac) load must not exceed 1.4A; a 1.2A load is the maximum permissible when ambient temperature exceeds 77°F (25°C). Use additional transformer(s) when load exceeds these ratings.

2.When L8148E is used to power SV9500/ SV9600, use separate transformer to power zone valves.

3 |

95-6940—12 |

Loading...

Loading...