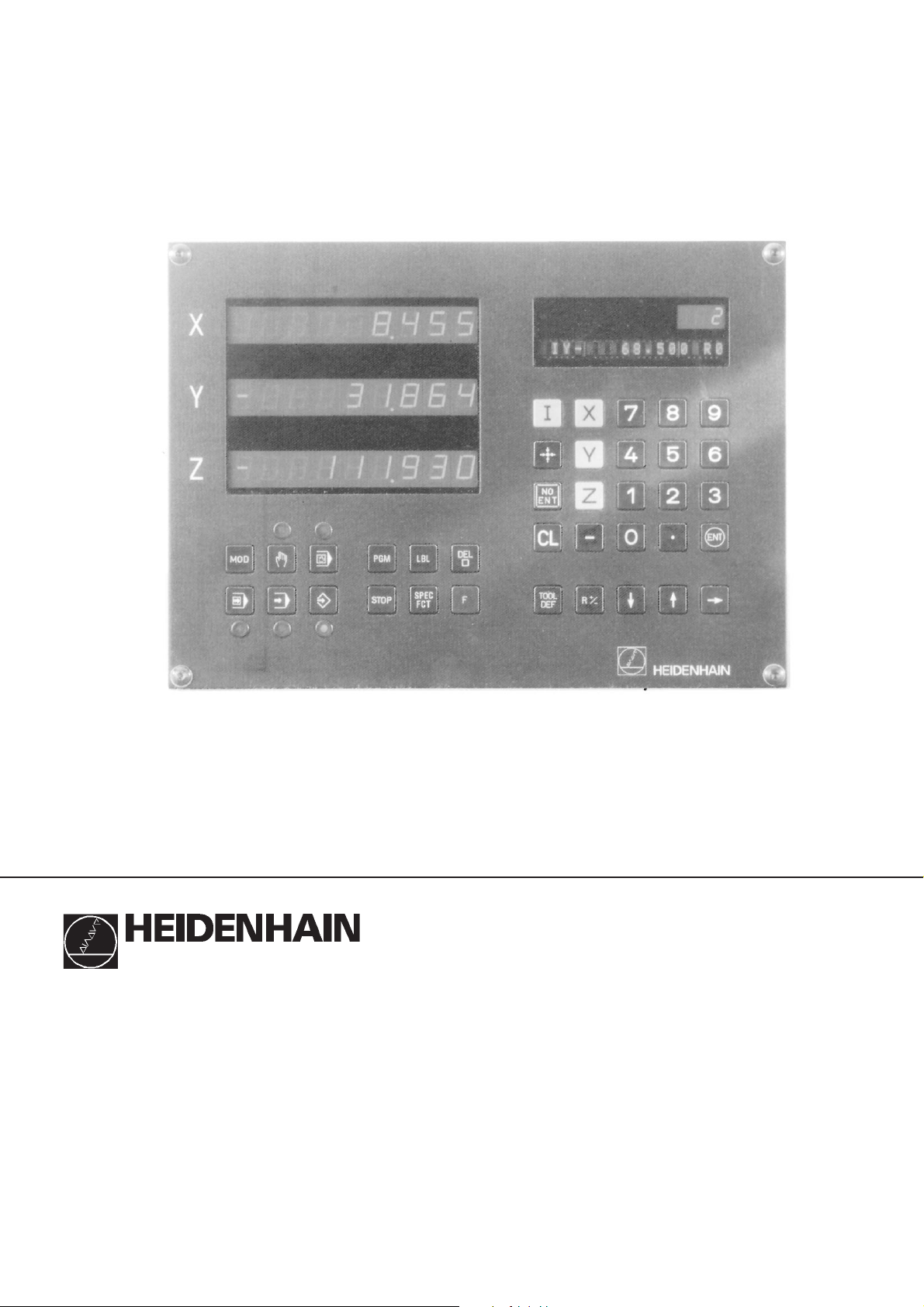

Page 1

User's Manual

TNC 122

December 1994

Page 2

Display

X

Y

Z

LBL

PGM

MOD

SPEC

STOP

FCT

7 8 9

X

Y

4 5 6

NO

Z

1 2 3

ENT

ENT

CL

0

–

DEL

TOOL

+

F

R

/–

DEF

HEIDENHAIN

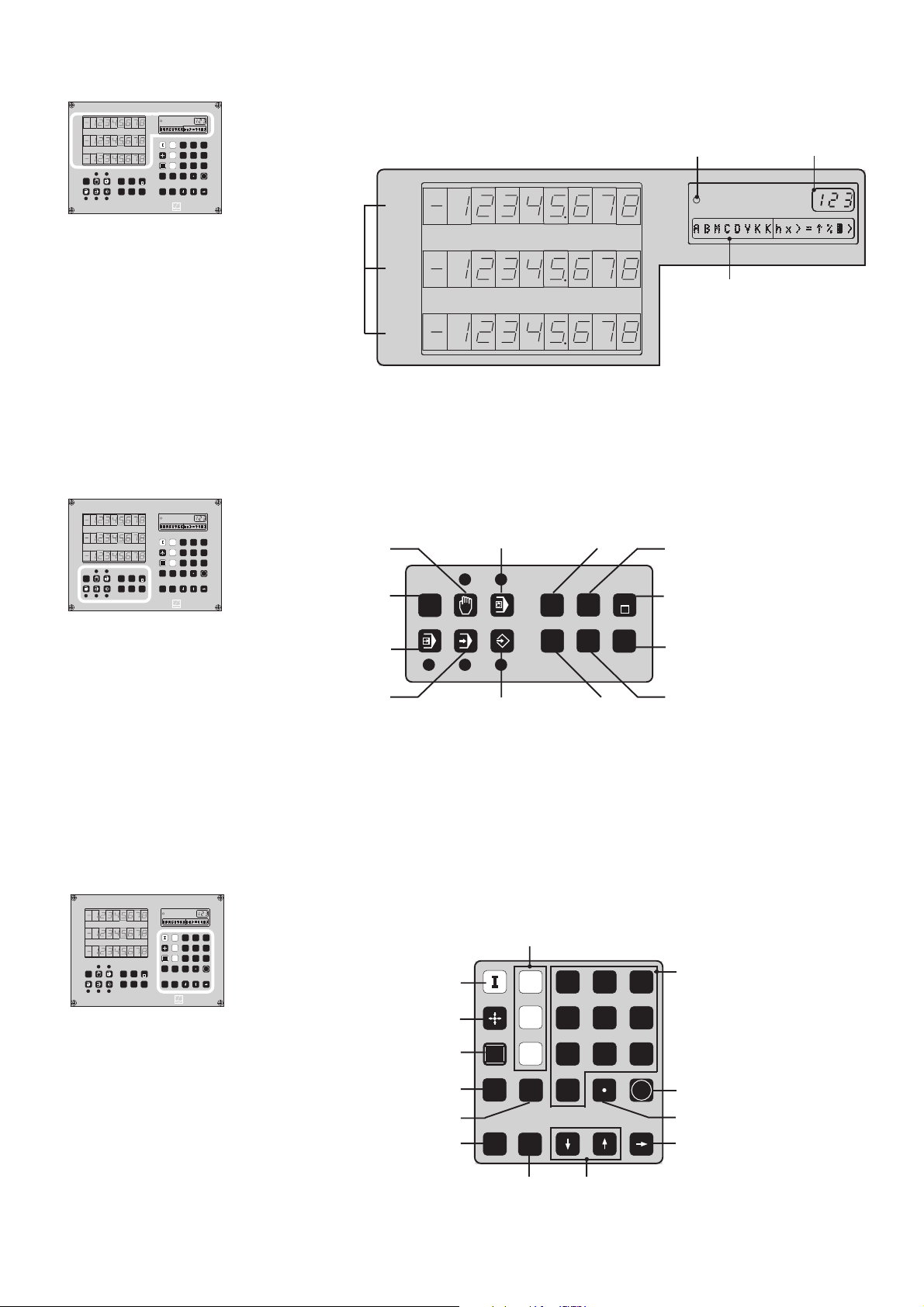

Position displays

for the

coordinate axes

Operating modes, Programming

X

Y

Z

LBL

PGM

MOD

SPEC

STOP

FCT

7 8 9

X

Y

4 5 6

NO

Z

1 2 3

ENT

ENT

CL

0

–

DEL

TOOL

+

F

R

/–

DEF

HEIDENHAIN

User parameters

MANUAL

OPERATION

X

Y

Z

POSITIONING

WITH MDI

MOD

Program

management

LBL

PGM

Program run

indicator

DEL

Block number

7

X

Input line

Y

NO

Z

ENT

8 9

4 5 6

1 2

Labels for subprograms

and program section

repeats

Delete block;

abort function

3

PROGRAM RUN

SINGLE BLOCK

PROGRAM RUN

FULL SEQUENCE

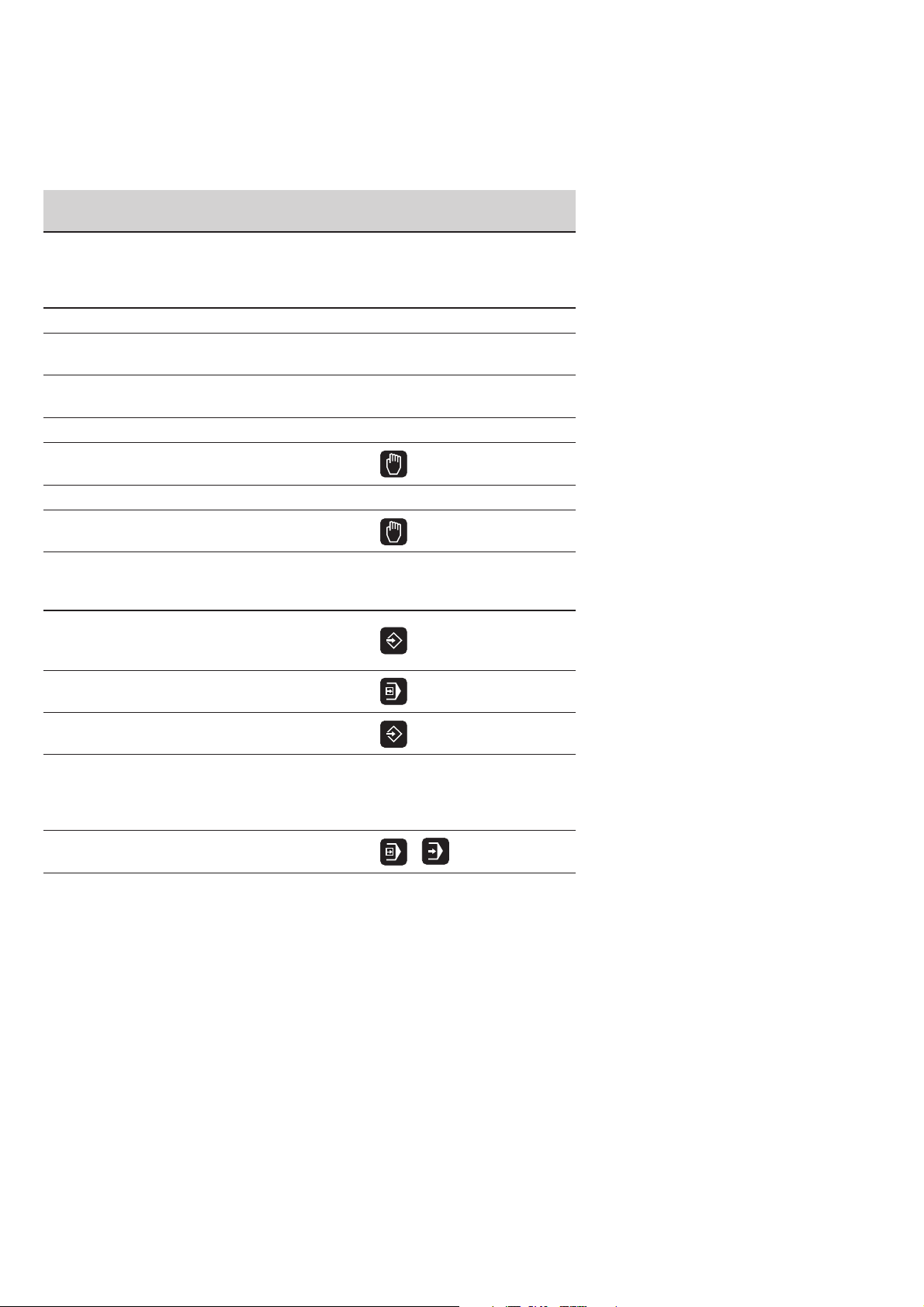

Input in all modes of operation

X

Y

Z

LBL

PGM

MOD

SPEC

STOP

FCT

7 8 9

X

Y

4 5 6

NO

Z

1 2 3

ENT

ENT

CL

0

–

DEL

TOOL

+

F

R

/–

DEF

HEIDENHAIN

Incremental dimensions

Actual position capture

Clear entry

STOP

PROGRAMMING

& EDITING

Coordinate axes

X

Y

NO

Z

ENT

SPEC

F

FCT

Stop

7 8 9

4 5 6

1 2

Feed rate

Special

functions

Numerical input

3

Reset entry

Change sign

Tool length and radius

CL

TOOL

DEF

0

–

+

R

/–

Tool radius

compensation

ENT

Confirm entry

Decimal point

Change program block

Program block selection

Page 3

The TNC Guideline

From the workpiece drawing to

program-controlled machining

Step Task TNC mode Starting

of operation on page

Preparation

1 Select tools —— ——

2 Set workpiece datum

for coordinate system —— ——

3 Determine spindle speeds

and feed rates —— ——

4 Switch on TNC and machine —— 15

5 Cross over reference marks 15

6 Clamp workpiece —— ——

7 Set datum/

set position displays 21

Entering and testing part programs

8 Enter part program or

download over external

data interface from 31

9 Test run: Run program block

by block without tool 51

10 If necessary:

Optimize the part program from 31

Machining the workpiece

12 Insert tool and

run part program 51

Page 4

TNC Accessory

Floppy disk unit

With the HEIDENHAIN FE 401 B floppy disk unit you can store

programs from the TNC on diskette.

It is also a means of transferring programs created on a personal

computer to the TNC.

The FE 401 B Floppy Disk Unit

Page 5

Contents

Scope of this Manual ......................................................................................... 7

TNC 122 ............................................................................................................. 7

How to Use This Manual .................................................................................... 8

Dialog Flowcharts ............................................................................................... 8

Special Notes in This Manual ............................................................................. 9

1 Fundamentals of Positioning ................................................... 11

Reference system and coordinate axes ........................................................... 11

Datums and positions ...................................................................................... 12

Machine axis movements and position feedback ............................................ 14

2 Working with the TNC 122 – First Steps .................................15

Before you begin .............................................................................................. 15

Switch on the TNC ........................................................................................... 15

Operating modes ............................................................................................. 16

Error messages ................................................................................................ 16

Selecting the position display mode ................................................................. 17

3 Manual Operation and Setup ................................................... 19

Moving the machine axes with the axis direction buttons ............................... 19

Entering tool length and radius ......................................................................... 20

Setting the datum ............................................................................................ 21

4 Positioning with Manual Data Input (MDI) ............................. 23

Before you machine the part ............................................................................ 23

Taking the tool radius into account ................................................................... 23

Entering the miscellaneous function M ............................................................ 24

Entering and changing the feed rate F ............................................................. 24

Entering and moving to positions ..................................................................... 25

Hole patterns ................................................................................................... 27

Input for a bolt hole circle ................................................................................. 27

Input for linear hole patterns ............................................................................ 27

Drilling the hole pattern .................................................................................... 27

5 Programming ............................................................................. 31

Entering the program number .......................................................................... 32

Deleting programs ............................................................................................ 32

Selecting program blocks ................................................................................. 33

Changing program blocks ................................................................................. 33

Deleting program blocks .................................................................................. 34

Feed rate F and miscellaneous function M ...................................................... 35

Entering a program interruption ....................................................................... 36

Entering workpiece positions ........................................................................... 37

Actual-position capture: Teach-In programming ............................................... 38

Hole patterns in programs ................................................................................ 39

Bolt hole circle .................................................................................................. 39

Linear hole patterns ......................................................................................... 41

Subprograms and Program Section Repeats ................................................... 43

Subprograms .................................................................................................... 44

Program section repeats .................................................................................. 46

Contents

Page 6

6 Transferring Programs over the Data Interface ...................... 49

Transferring a program to the TNC ................................................................... 49

Transferring programs out of the TNC ............................................................. 50

7 Executing Programs ..................................................................51

Interrupting program run .................................................................................. 52

Single block ...................................................................................................... 52

Automatic ......................................................................................................... 52

8 User Parameters ........................................................................ 53

9 Tables and Overviews ............................................................... 55

Miscellaneous functions (M functions) ............................................................ 55

Pin layout and connecting cable for the data interface ..................................... 57

TNC Messages ................................................................................................. 58

Specifications ................................................................................................... 60

Accessory ........................................................................................................ 60

Subject Index .............................................................................61

Page 7

Scope of this Manual

This manual describes the operation of the TNC 122 from the

software version

The three x's represent any numbers.

For detailed technical information, refer to the Technical

Manual for the TNC 122.

TNC 122

TNC-Familie

What is NC?

NC stands for Numerical Control, that is, control of a machine tool

by means of numbers. Modern controls such as the TNC have a

built-in computer for this purpose and are therefore called CNC

(Computerized Numerical Control).

From the very beginning, the TNCs from HEIDENHAIN were developed specifically for shop-floor programming by the machinist. This

is why they are called TNC, for “Touch Numerical Controls.”

The TNC 122 is a straight cut control for milling, drilling, and boring

machines with up to three axes.

Progr. 246 xxx 01.

Differences from the TNC 121

The TNC 122 features the following improvements over the

TNC 121:

• Larger program memory

• Tool compensation

• Programmable feed rate

• RS-232-C/V.24 data interface

Programming

Workpiece machining is defined in a part program. It contains a

complete list of instructions for machining a part, for example the

target position coordinates or the feed rate

TNC 122 7

Page 8

How to Use This Manual

As a TNC beginner, you can use the operating instructions as a

step-by-step workbook. This part begins with a short introduction

to some important basics concepts, and provides an overview of

the available features. Then each feature is explained in detail,

using a practical example that you can immediately try out on the

machine — so you can't get lost in the theory. As a beginner you

should work through all the examples presented.

The examples are intentionally brief; it generally won't take you

longer than 10 minutes to enter the example data.

As a TNC expert, you can use this manual as a comprehensive

review and reference guide. The clear layout and the subject index

make it easy to find the desired topics.

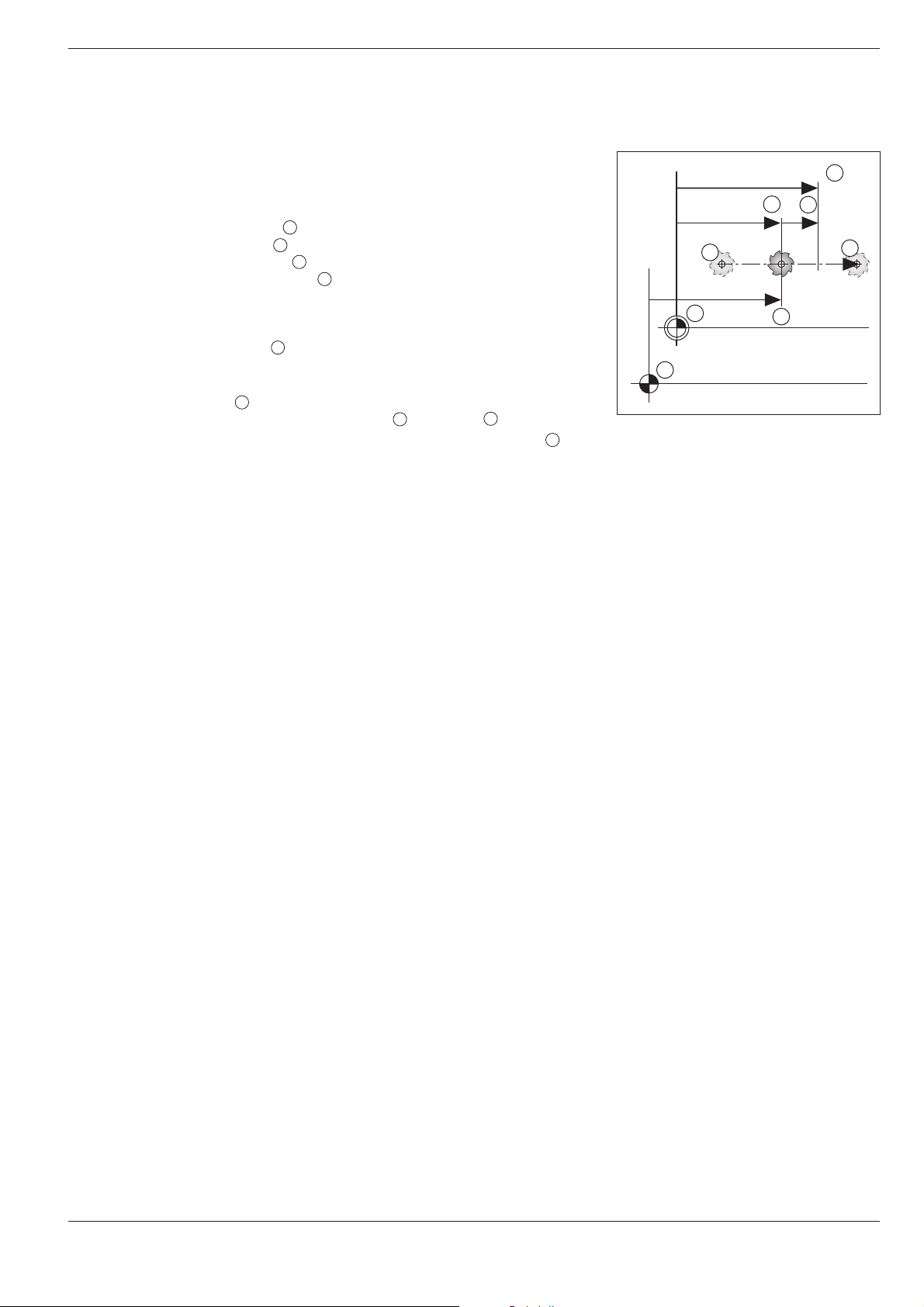

Dialog Flowcharts

Dialog flowcharts are used for each example in this manual.

They are laid out as follows:

The operating mode is indicated above the first dialog flowchart.

This area shows the

keys keys

keys to press.

keys keys

This area explains the function of the key or the work step.

If necessary, supplementary information will also be included.

Prompt

This area shows the

keys keys

keys to press.

keys keys

A prompt appears with some actions (not always) above the input

keypad.

Abbreviated flowcharts

Abbreviated flowcharts supplement the examples and

explanations. An arrow (

This area explains the function of the key or the work step.

If necessary, supplementary information will also be included.

If there is an arrow at the end of the flowchart, this means that it

continues on the next page.

⇒⇒

⇒) indicates a new input or a work step.

⇒⇒

8 TNC 122

Page 9

Special Notes in This Manual

Especially important information is shown as a separate note in a

gray box. Pay special attention to these notes. Ignoring them

would prevent effective use of the control, or even result in

damage to the tool or workpiece.

Symbols in the gray boxes

The symbols in the left of the gray boxes indicate the nature of the

provided information.

General information

for example on the machine tool.function

Information for the machine tool builder

for example that he must implement a certain function

Essential information

for example that a certain tool is needed for the

described function

TNC 122 9

Page 10

NOTES

10 TNC 122

Page 11

1 Fundamentals of Positioning

1

Fundamentals of Positioning

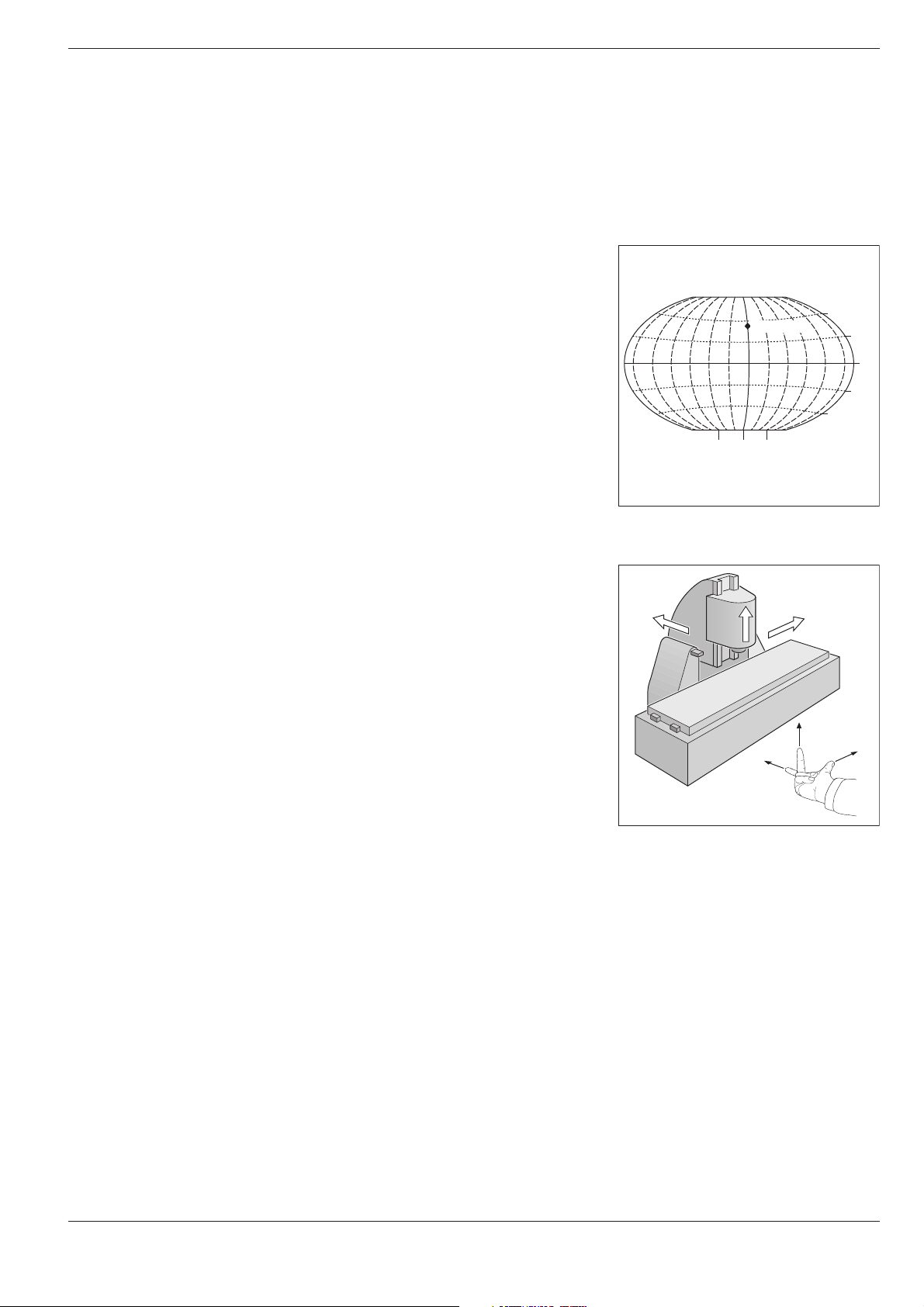

Reference system and coordinate axes

Reference system

In order to define positions on a surface one needs a reference

system. For example, positions on the earth's surface can be

defined “absolutely” by their geographic coordinates of longitude

and latitude. The term “coordinate” comes from the Latin word for

“that which is arranged.” The network of horizontal and vertical

lines on the globe constitute an absolute reference system in contrast to the “relative” definition of a position that is referenced to

some other known location.

The illustration at right shows the 0° longitude at the Greenwich

observatory and the 0° latitude at the equator.

0° 90°90°

Greenwich

60°

30°

0°

30°

60°

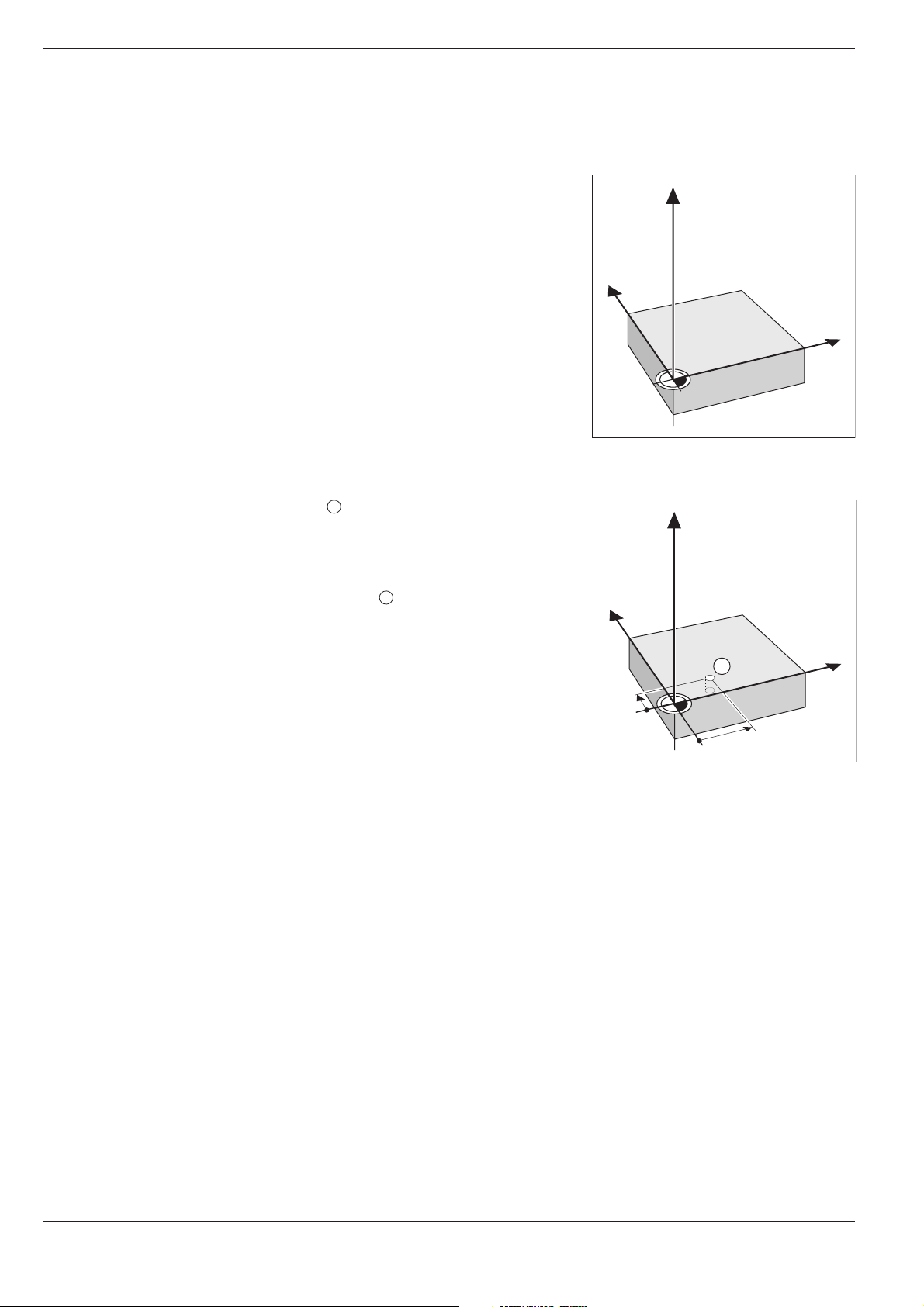

Cartesian coordinate system

On a milling or boring machine, workpieces are normally machined

according to a workpiece-based Cartesian coordinate system (a

rectangular coordinate system named after the French mathematician and philosopher Renatus Cartesius, who lived from 1596 to

1650). The Cartesian coordinate system is based on three coordinate axes designated X, Y and Z which are parallel to the machine

guideways.

The figure at right illustrates the “right-hand rule” for remembering

the three axis directions: the middle finger is pointing in the positive direction of the tool axis from the workpiece toward the tool

(the Z axis), the thumb is pointing in the positive X direction, and

the index finger in the positive Y direction. X, Y and Z are the main

axes of the Cartesian coordinate system.

Fig. 1.1: The geographic coordinate system

Fig. 1.2: Designations and directions of the

is an absolute reference system

+Y

+Y

axes on a milling machine

+Z

+X

+Z

+X

TNC 122 11

Page 12

1 Fundamentals of Positioning

Y

X

Z

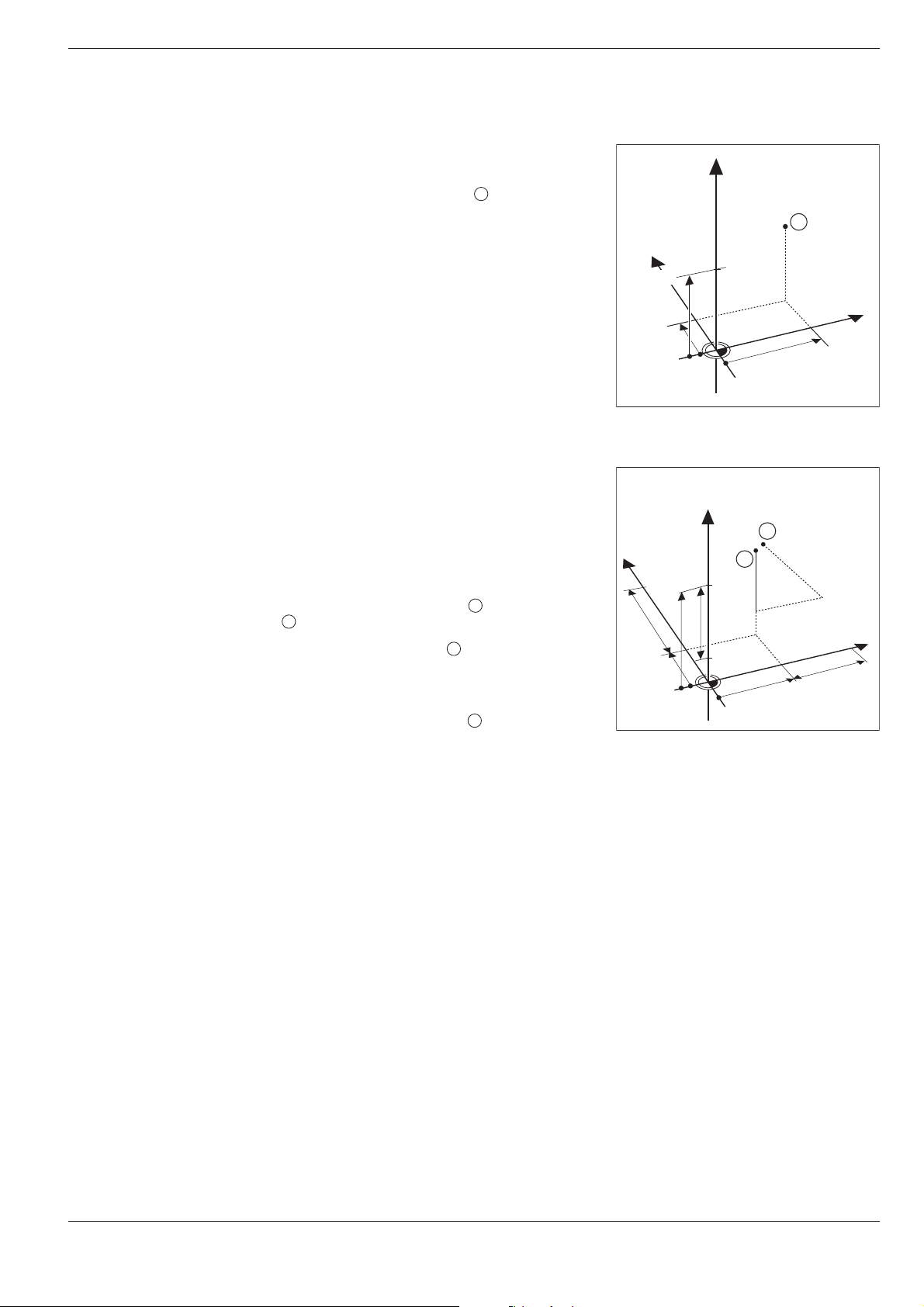

Datums and positions

Setting the datum

The workpiece drawing identifies a certain point on the workpiece

(usually a corner) as the “absolute datum” and perhaps one or

more other points as relative datums. The datum setting procedure

establishes these points as the origin of the absolute or relative coordinate systems: The workpiece, which is aligned with the machine axes, is moved to a certain position relative to the tool and

the display is set either to zero or to another appropriate value

(e.g., to compensate the tool radius).

Example: Coordinates of hole :

1

X = 10 mm

Y = 5 mm

Z = 0 mm (hole depth: Z = – 5 mm)

The datum of the Cartesian coordinate system

is located 10 mm from hole on the X axis and

5 mm from it in the Y axis (in negative direction).

Fig. 1.3: The workpiece datum represents the

origin of the Cartesian coordinate

system

Z

1

Y

X

1

5

10

Fig. 1.4: Hole defines the coordinate system

12 TNC 122

Page 13

1 Fundamentals of Positioning

Y

X

Z

1

20

10

Z=15mm

X=20mm

Y=10mm

15

IZ=–15mm

Y

X

Z

2

10

5

5

15

20

10

10

I

X=10mm

I

Y=10mm

3

0

0

Datums and positions

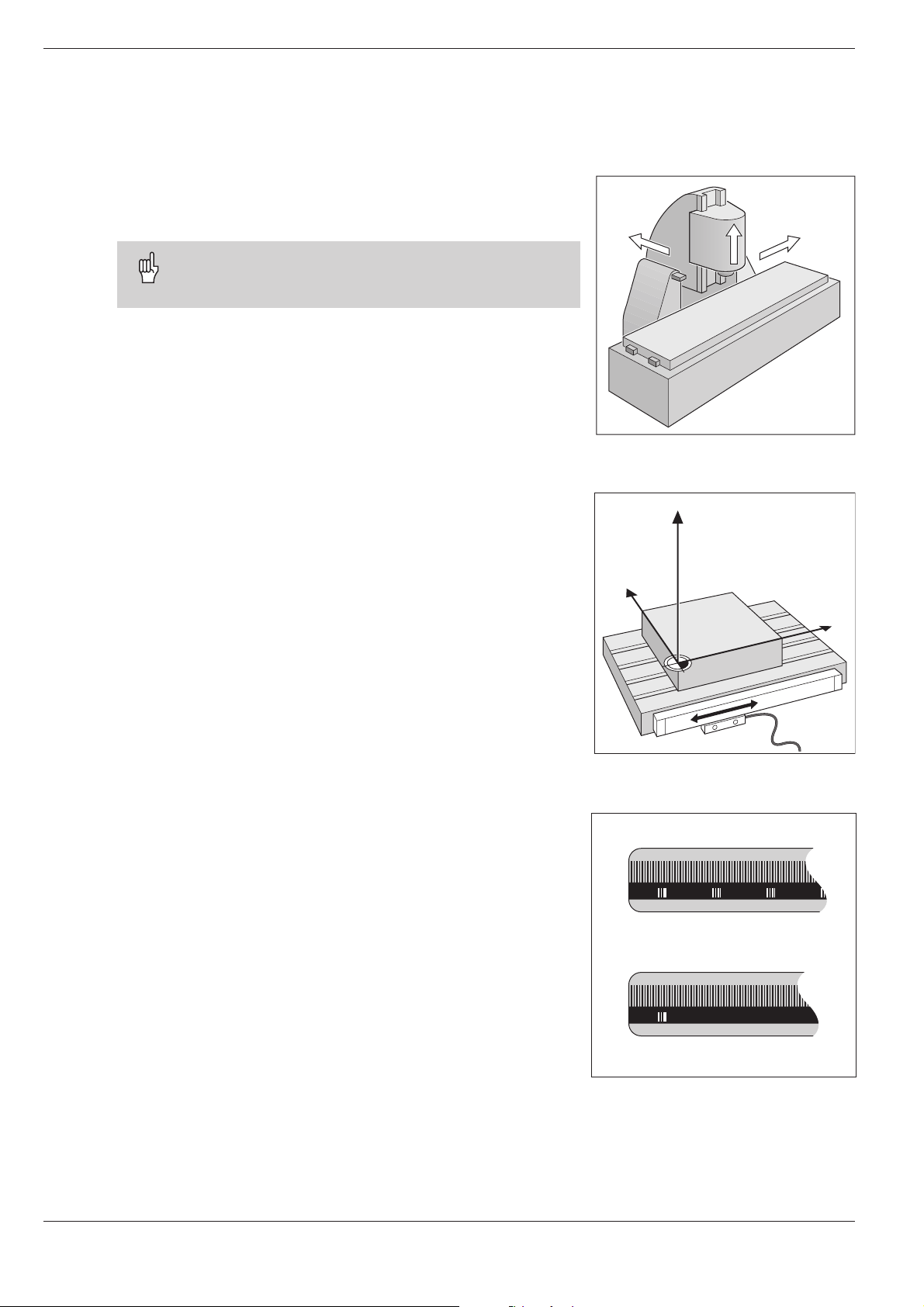

Absolute workpiece positions

Each position on the workpiece is uniquely identified by its absolute coordinates.

Example: Absolute coordinates of the position :

X= 20 mm

Y= 10 mm

Z= 15 mm

If you are drilling or milling a workpiece according to a workpiece

drawing with absolute coordinates, you are moving the tool to the

value of the coordinates.

1

Incremental workpiece positions

A position can also be referenced to the preceding nominal position. In this case the relative datum is always the last programmed position. Such coordinates are referred to as incre-

mental coordinates (increment = increase). They are also

called incremental or chain dimensions (since the positions are

defined as a chain of dimensions). Incremental coordinates are

designated with the prefix I.

Example: Incremental coordinates of position referenced to

position

2

Absolute coordinates of position :

X= 10 mm

Y= 5 mm

Z= 20 mm

Incremental coordinates of position :

IX= 10 mm

IY= 10 mm

IZ=–15 mm

If you are drilling or milling a workpiece according to a drawing with

incremental coordinates, you are moving the tool by the value of

the coordinates.

Fig. 1.5: Position definition through absolute

coordinates

3

2

3

Fig. 1.6: Position definition through incremen-

tal coordinates

TNC 122 13

Page 14

1 Fundamentals of Positioning

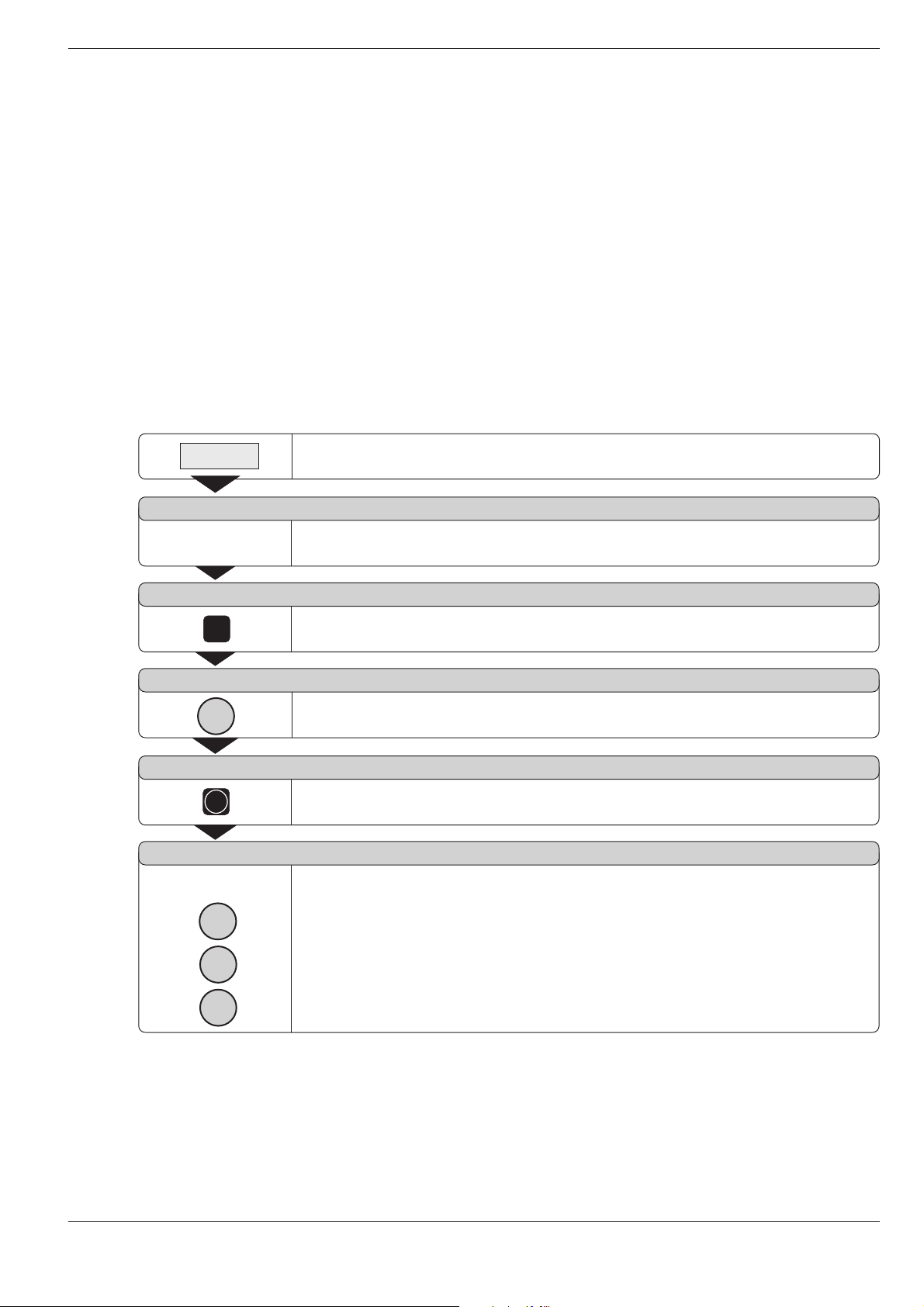

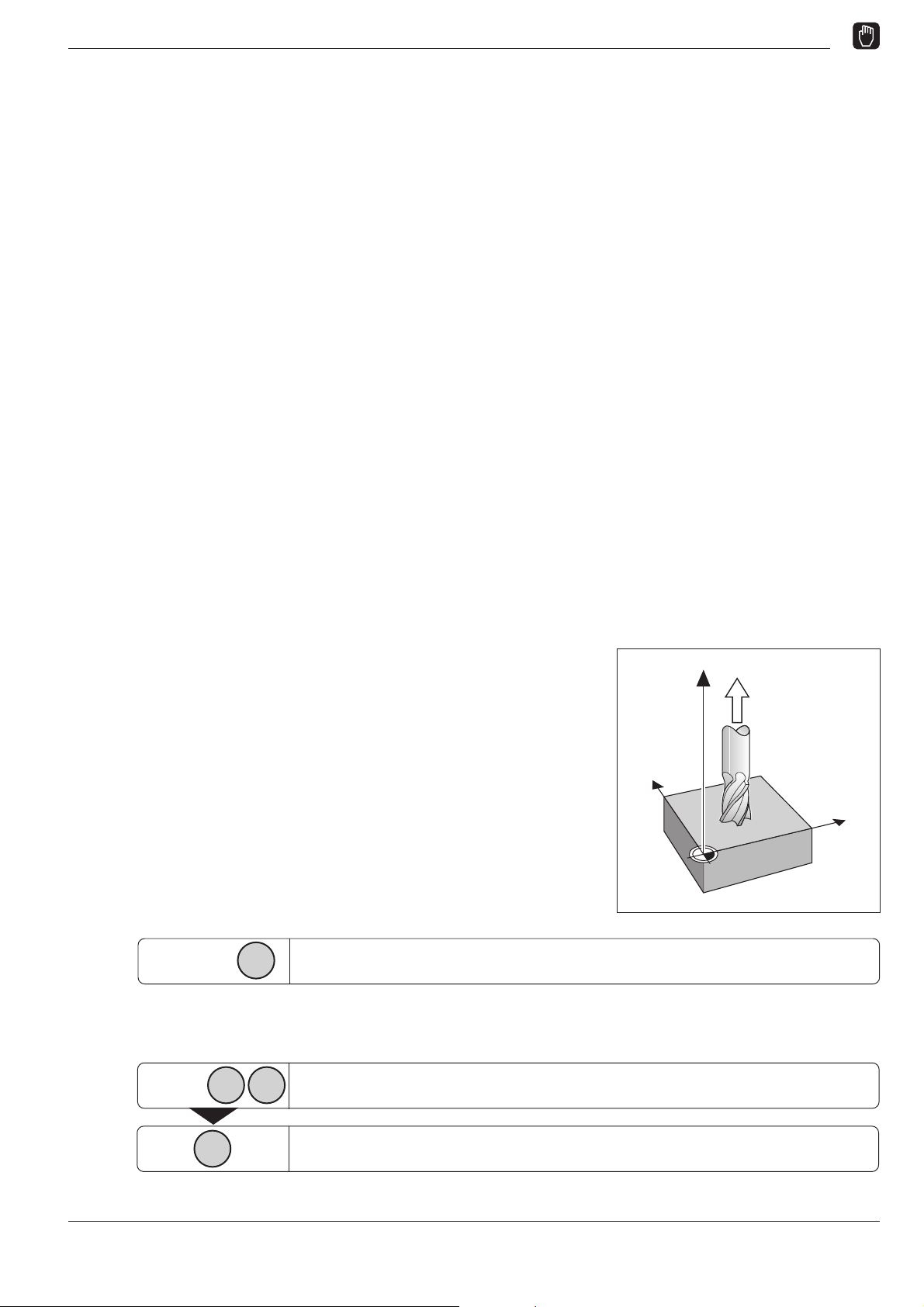

Machine axis movements and position feedback

Programming tool movements

During workpiece machining, an axis position is changed either by

moving the tool or by moving the machine table on which the

workpiece is fixed.

When entering tool movements in a part program you

always program as if the tool is moving and the workpiece is stationary.

+Y

+Z

+X

Position feedback

The position feedback encoders convert the movement of the machine axes into electrical signals. The control evaluates these signals and constantly calculates the actual position of the machine

axes.

If there is an interruption in power, the calculated position will no

longer correspond to the actual position. When power is restored,

the TNC can re-establish this relationship with the aid of the encoders' reference marks.

Reference marks

The scales of the position encoders have one or more reference

marks. When a reference mark is passed over, it generates a signal which identifies that position as the reference point (scale reference point = machine reference point). With the aid of this reference mark the TNC can re-establish the assignment of displayed

values to machine axis positions.

Fig. 1.7: On this machine the tool moves in

the Y and Z axes; the workpiece

moves in the X axis.

Z

Y

X

Fig. 1.8: Linear position encoder, here for the

X axis

If the position encoders feature distance-coded reference marks,

each axis need only move a maximum of 20 mm (0.8 in.) for linear

encoders, and 20° for angle encoders.

Fig. 1.9: Linear scales: above with distance-

coded reference marks, below with

one reference mark

14 TNC 122

Page 15

2 Working with the TNC 122 – First Steps

2

Working with the TNC 122 – First Steps

Before you begin

You must cross over the reference marks after every switch-on.

From the positions of the reference marks, the TNC automatically

re-establishes the relationship between axis slide positions and

display values that you last defined by setting the datum.

When you set a new datum point, the control automatically stores

the new relationship between axis positions and display values.

Switch on the TNC

⇒⇒

⇒

⇒⇒

0

MEMORY TEST

Please wait...

POWER INTERRUPTED

CL

NO CONTROL VOLTG

I

REF TRAV ENT/NOE

ENT

REF MARK XYZ

Press and hold:

1

Switch on the TNC and the machine tool.

The TNC automatically checks its internal memory.

Clear the TNC message indicating that the power was interrupted.

Switch on the control voltage.

The TNC automatically checks the function of the EMERGENCY STOP button.

Select reference mark evaluation.

X

Y

Cross the reference marks in any direction:

Press and hold

axis disappears from the screen.

Sequence in this example: X axis, Y axis, Z axis

the machine axis direction button until the moving

Z

The TNC 122 is now ready for operation in the

MANUAL OPERATION mode.

If you do not wish to cross over the reference marks:

⇒⇒

⇒ Answer the REF TRAV ENT/NOE dialog prompt with NO ENT

⇒⇒

(this feature must be implemented by the machine tool

builder).

TNC 122 15

Page 16

2 Working with the TNC 122 – First Steps

Operating modes

Selecting an operating mode makes a specific group of functions

available.

Usable functions Operating mode Key

Moving the machine axes; MANUAL

Setting the datum OPERATION

Entering positioning blocks POSITIONING

and executing them block WITH MANUAL

by block; DATA INPUT

Changing feed rate and

miscellaneous functions;

Entering tool data

Storing working steps for PROGRAMMING

small-lot production by AND EDITING

• Keyboard entry

• Teach-In

Transferring programs

through the data interface

Running programs SINGLE BLOCK

blockwise

Running programs AUTOMATIC

continuously

You can switch to another operating mode at any time by pressing key for the desired mode.

Error messages

If an error occurs while you are operating the TNC, a message will

appear in plain language. You will find an overview of error message in Chapter 9.

To clear an error message:

⇒⇒

⇒ Press the CL key.

⇒⇒

Blinking error messages

W A R N I N G !

A blinking error messages means that the operational

reliability of the TNC has been impaired.

If the TNC shows a blinking error message:

⇒⇒

⇒ Write down the message.

⇒⇒

⇒⇒

⇒ Switch off the TNC and the machine tool.

⇒⇒

⇒⇒

⇒ Try to correct the error with the power off.

⇒⇒

⇒⇒

⇒ If the error cannot be corrected or if a blinking error message

⇒⇒

persists, call your service representative.

16 TNC 122

Page 17

2 Working with the TNC 122 – First Steps

Selecting the position display mode

The TNC can show different types of position values for a tool

position.

Fig 2.1 shows the following positions

• Starting position of the tool

• Target position of the tool

• Workpiece datum

• Scale reference point

A

Z

W

M

The TNC position display can be set to show the following types of

information:

• Actual position

2

The position at which the tool is presently located as referenced to the workpiece datum.

• Servo lag

The difference between nominal and actual positions

• Actual position referenced to the scale reference point

3

1

2

4

To change position display modes:

⇒⇒

⇒ Set another position display mode in the user parameter

⇒⇒

MP 7322 (see Chapter 8).

2

3

A

W

M

Fig 2.1: Tool and workpiece positions

4

1

Z

TNC 122 17

Page 18

2 Working with the TNC 122 – First Steps

NOTES

18 TNC 122

Page 19

3 Manual Operation and Setup

3

Manual Operation and Setup

The TNC 122 provides two methods for manually moving the machine axes:

• Axis direction buttons

• Positioning with Manual Data Input (see Chapter 4)

Changing the feed rate F

Some machines are equipped with a potentiometer to enable you

to vary the feed rate.

Moving the machine axes with the axis direction buttons

In the MANUAL OPERATION mode you can move a machine axis

by pressing the appropriate axis direction button on the machine

control panel. As soon as you release the button the axis stops.

Continuing machine axis movement

With the user parameter MP7680 (see Chapter 8) you can set the

TNC for continuing machine axis movement. The machine then

continues to move the axis after you have released the axis direction button. To stop the machine axis you must press a button

again (see example 2 below).

Example:Moving the machine axis with the machine axis direction

button in the Z+ direction (retracting the tool)

Example 1: Moving the machine axis

Mode of operation: MANUAL OPERATION

Press and hold:

Example 2: Moving the machine axis (continuing movement)

Mode of operation: MANUAL OPERATION

Together:

Z

I

Z

Press the direction button, e.g. Z, and hold it as long as you wish the machine

axis to move.

To start the axis, press an axis direction button, such as Z, and the NC start

button at the same time.

Z

Y

X

0

TNC 122 19

Stop the axis with the NC stop button.

Page 20

3 Manual Operation and Setup

Entering tool length and radius

You can enter the length and radius of you tool in the TNC. The

TNC includes the tool radius in the position value when you position with radius compensation (see p. 21).

TOOL

DEF

Z

The tool length is the difference in length ∆L between the tool and

the zero tool.

Sign for the length difference

∆∆

∆L

∆∆

If the tool is longer than the zero tool: ∆L > 0

If the tool is shorter than the zero tool: ∆L < 0

Position display in the tool axis

User parameter MP7285 defines whether the tool axis display

value shows the position of the tool tip or the tool datum.

Checking the tool data

To display the tool data:

⇒⇒

⇒ Press the TOOL DEF key.

⇒⇒

To display the tool length and tool axis:

⇒⇒

⇒ Press the downward-arrow key twice.

⇒⇒

To return to the position display:

⇒⇒

⇒ Press the NO ENT key.

⇒⇒

Example:Entering the tool length and radius

Tool radius: 8 mm

Tool length: 12 mm

Tool axis: Z

T

1

R

1

=0

∆L

1

Fig. 3.1: Tool lengths and radii

Z

T

2

R

2

T

0

R

R

∆L

>0

2

T

7

7

T

3

3

∆L3<0

X

X

L7>0

TOOL

DEF

Call the tool definition function.

=0

L

0

R A D I U S = .....

ENT

8

Enter the tool RADIUS ( 8 mm ). Confirm your entry.

L E N G T H = .....

ENT

2

1

Enter the tool LENGTH ( 12 mm ). Confirm your entry.

AXIS=.

ENT

Z

Enter the tool AXIS ( Z ). Confirm your entry.

20 TNC 122

Page 21

3 Manual Operation and Setup

Setting the datum: Moving to the datum surface and entering the actual value

To set the datum, you move the tool to the respective datum surfaces and enter the tool position as datum.

Example: Setting the datum in the X and Z axes

Procedure

Working plane: X / Y

Tool axis: Z

Tool radius: R = 5 mm

Sequence for

datum setting

in this example: X, Z

⇒⇒

⇒ Insert the tool.

⇒⇒

⇒⇒

⇒ Enter the tool data.

⇒⇒

⇒⇒

⇒ Switch on the spindle, e.g. with the miscellaneous

⇒⇒

function M 3.

Mode of operation: MANUAL OPERATION

Touch surface with the tool.

X

Select the X axis.

1

DATUM X=

X =

Z

Y

X

1

5

ENT

Z

DATUM Z=

Z =

0

ENT

Enter the position of the tool center (X = – 5 mm)

and

transfer the X coordinate of the datum.

Touch the top surface with the tool.

Select the Z axis.

Enter the position of the tool tip (Z = 0 mm)

and

transfer the Z coordinate to the display.

TNC 122 21

Page 22

3 Manual Operation and Setup

NOTES

22 TNC 122

Page 23

4 Positioning with MDI

R–

R+

Y

X

R

0

4

Positioning with Manual Data Input (MDI)

For many simple machining tasks, for example if a part is to be machined only once, or if you are machining simple geometrical

shapes, it would be too time consuming to enter the individual machining steps in an NC program.

In the POSITIONING WITH MDI mode of operation you can execute the working steps as you enter them instead of storing them

in a part program.

Simple milling and drilling operations

Enter the following nominal position data manually in the POSITIONING WITH MDI mode of operation:

• Coordinate axis

• Position value

• Radius compensation

The TNC then moves the tool to the desired position.

Hole patterns

he POSITIONING WITH MDI mode of operation also supports the

TNC "Cycles" (see Chapter 5):

• Bolt hole circle patterns

• Linear hole patterns

Before you machine the part

⇒⇒

⇒ Insert the tool.

⇒⇒

⇒⇒

⇒ Pre-position the tool so that the tool and workpiece will not be

⇒⇒

damaged during workpiece approach.

⇒⇒

⇒ Select an appropriate feed rate F.

⇒⇒

⇒⇒

⇒ Select an appropriate spindle speed S.

⇒⇒

⇒⇒

⇒ Switch on the spindle, e.g. with the miscellaneous function

⇒⇒

M3.

Taking the tool radius into account

The TNC can compensate the tool radius (see Fig. 4.1). This allows

you to enter workpiece dimensions directly from the drawing. The

TNC automatically lengthens (R+) or shortens (R–) traverse by the

tool radius.

Entering tool data

⇒⇒

⇒ Press the TOOL DEF key

⇒⇒

⇒⇒

⇒ Enter in sequence the tool radius, length, and axis.

⇒⇒

TNC 122 23

Fig. 4.1: Tool radius compensation

Page 24

4 Positioning with MDI

Entering and changing the feed rate F

Example: Enter the feed rate F

F

Select the feed rate function F for the next tool movement.

F

1

0 0

ENT

Changing the feed rate F

Some machines are equipped with a potentiometer to allow you to

vary the feed rate.

F blinks:

Enter the feed rate F, e.g. 100 mm/min.

Confirm feed rate F for the next tool movement.

Entering the miscellaneous function M

The machine tool builder determines which miscellaneous

functions are available on your TNC and what effect they

have.

SPEC

FCT

Press the SPEC FCT key for special functions.

Repeatedly

3

Page to M FUNCTION.

M FUNCTION

ENT

Select M FUNCTION.

M 0

ENT

I

M blinks: Enter the desired M function, e.g. M3 (spindle on, clockwise).

Confirm your entry.

Execute the M function.

24 TNC 122

Page 25

4 Positioning with MDI

Entering and moving to positions

For simple tasks, use the POSITIONING WITH MDI mode of operation

to machine the dimensions as you enter them.

Example: Milling a shoulder

The coordinates are entered as absolute dimensions referenced to

the workpiece datum.

Corner : X = 0 mm Y = 20 mm

Corner : X = 30 mm Y = 20 mm

Corner : X = 30 mm Y = 50 mm

Corner : X = 60 mm Y = 50 mm

Procedure:

⇒⇒

⇒ Enter the tool data.

⇒⇒

⇒⇒

⇒ Move the tool to a good starting position

⇒⇒

⇒⇒

⇒ Move the tool to the milling depth.

⇒⇒

Mode of operation: POSITIONING WITH MDI

1

2

3

4

(e.g. X = Y = – 20 mm).

Y

50

20

0

1 2

0

3 4

30

X

60

Y

Select the Y axis.

YR 0

2

R+/

0

ENT

–

I

X

Y blinks:

Enter the nominal position for corner point : Y = + 20 mm,

1

select the tool radius compensation: R +

and confirm your entry.

Move the tool to the programmed position.

Select the X axis.

XR 0

3

R+/

0

ENT

–

I

X blinks:

Enter the nominal position for corner point : Y = + 30 mm,

2

select the tool radius compensation: R –

and confirm your entry.

Move the tool to the programmed position.

TNC 122 25

Page 26

4 Positioning with MDI

Entering and moving to positions

Y

Select the Y axis.

YR 0

Y blinks:

Enter the nominal position for corner point : Y = +50 mm,

3

Select tool radius compensation: R + and

confirm your entry.

Move the tool to the entered position.

Select the X axis.

R+/

5

0

ENT

–

I

X

XR 0

X blinks:

Enter the nominal position for corner point : Y = +60 mm,

4

Select tool radius compensation: R + and

confirm your entry.

Move the tool to the entered position.

R+/

0

6

ENT

–

I

26 TNC 122

Page 27

4 Positioning with MDI

Hole patterns

The hole pattern functions BOLT HOLE CIRCLE and LINEAR

PATTERN are provided in the POSITIONING WITH MDI mode of

operation.

You select the BOLT HOLE CIRCLE or LINEAR HOLE PATTERN

function and enter the necessary data. This data, such as the

number of holes and the coordinates of the first hole, is normally

shown on the production drawing.

The TNC calculates the positions of the holes.

Pre-positioning the drill

You pre-position the drill in the Z axis above the surface of the

workpiece. The TNC positions the drill in the X and Y axes (in the

working plane) above each hole position.

Hole depth

If you wish to use a spindle sleeve to drill the holes manually:

⇒⇒

⇒ Answer the dialog prompt DEPTH = with NO ENT.

⇒⇒

Input for a bolt hole circle

• Full circle or circle segment

• Number of holes

• Center point coordinates and radius of the circle

• Starting angle (angular position of first hole)

• For circle segment: angle step between the holes

• Hole depth

Input for linear hole patterns

• Coordinates of the first hole

• Number of holes per row

• Spacing between holes on a row

• Angle between the first row and the angle reference axis

• Number of rows

• Spacing between rows

• Hole depth

Drilling the hole pattern

After you have entered all the data:

⇒⇒

⇒ Press the NC start key repeatedly.

⇒⇒

The TNC moves the axes one at a time in the working plane and

the tool axis. After drilling it returns the tool to the starting height.

Skipping holes

If you wish to skip certain holes, or bore in a different sequence

than that calculated by the TNC:

⇒⇒

⇒ Select the desired hole with the upward and downward arrow

⇒⇒

keys.

TNC 122 27

Page 28

4 Positioning with MDI

Hole patterns

Example: Entering and machining a bolt hole circle

Number of holes: 8

Center point coordinates: X = 50 mm

Y = 50 mm

Bolt hole circle radius: 20 mm

Starting angle: Angle between

the X axis and the first hole: 30°

Hole depth: 8 mm

Mode of operation: POSITIONING WITH MDI

50

0

Y

30°

R20

0

50

X

Repeatedly

Repeatedly

8

5 0

SPEC

FCT

Press the SPEC FCT key for special functions.

Page to the BOLT HOLE CIRCLE function.

B O L T H O L E C I R C L E

ENT

Select the BOLT HOLE CIRCLE function.

Page to the FULL CIRCLE function.

F U L L C I R C L E

ENT

Select FULL CIRCLE

N O H L =

Enter the number of holes NO HL ( 8 ).

Confirm your entry and continue the dialog.

C E N T X =

Enter the X coordinate of the bolt hole circle center ( X = 50 mm ).

Confirm your entry and continue the dialog.

C E N T Y =

5 0

Enter the Y coordinate of the bolt hole circle center ( Y = 50 mm ).

Confirm your entry and continue the dialog.

R A D I U S =

0

2

Enter the RADIUS of the bolt hole circle ( 20 mm ).

Confirm your entry and continue the dialog.

A N G L E =

3

0

28 TNC 122

Enter the starting ANGLE from the X axis to the first hole ( 30° ).

Confirm your entry and continue the dialog.

Page 29

4 Positioning with MDI

Hole patterns

D E P T H =

8

B O L T H O L E C I R C L E ?

Enter the hole DEPTH ( 8 mm ).

Confirm your entry and continue the dialog.

ENT

Start the bolt hole circle.

C Y C L F U L L C I R C L E

I

Start the FULL CIRCLE cycle.

B L T C I R H O L E 1 ...

Repeatedly

I

Example: Entering and machining linear hole patterns

X coordinate of hole X = 20 mm

Y coordinate of hole Y = 15 mm

1

1

Number of holes per row 4

Hole spacing 10 mm

Angle between rows and

X axis 18°

Number or rows 3

Row spacing 12 mm

Hole depth: 8 mm

For each hole move the axes in the working plane and drill until all holes in the

full circle are completed.

15

0

Y

10

1

12

18°

X

0

20

Mode of operation: POSITIONING WITH MDI

SPEC

Repeatedly

FCT

Press the SPEC FCT key for special functions.

Page to the LINEAR PATTERN function.

L I N E A R P A T T E R N

ENT

Select the LINEAR PATTERN function.

H . 1 X =

2

0

Enter the X coordinate of hole ( X = 20 mm ).

Confirm your entry and continue the dialog.

1

TNC 122 29

Page 30

4 Positioning with MDI

Hole patterns

H . 1 Y =

1

5

Enter the Y coordinate of hole ( Y = 15 mm ).

1

N O H L =

4

Enter the number of holes per row ( 4 ).

H L . S P C =

1

0

Enter the spacing between holes in the row (10 mm).

A N G L E =

1

8

Enter the ANGLE between the X axis and the hole pattern (18°).

D E P T H =

8

Enter the DEPTH of the holes ( 8 mm ).

N O . R W =

3

Enter the number of rows ( 3 ).

1

ENT

Repeatedly

R W . S P C =

2

Enter the spacing between rows (12 mm).

S T A R T L I N . P A T T ?

Start the linear hole pattern.

C Y C L L I N E A R P A T T

I

Start the LINEAR PATTERN cycle.

L I N R . H O L E 1 ...

I

For each hole move the axes in the working plane and drill until all holes in the

linear pattern are completed.

30 TNC 122

Page 31

5 Programming

5

Programming

In the PROGRAMMING AND EDITING mode of operation you can

store the individual work steps required for recurring machining

operations, for example in small-lot production.

Programs in the TNC

The part programs stored in the TNC contain the working steps for

machining a part. You can edit, add to and run these programs as

often as you wish.

You can store programs on floppy disk with the HEIDENHAIN

FE 401 floppy disk unit and load them into the TNC again on demand — you don't need to retype them. You can also transfer programs to a personal computer or printer.

Program storage capacity

The TNC 122 stores up to 20 programs with a maximum of 500 NC

blocks. A single program can contain up to 500 NC blocks.

Programmable functions

• Interrupt the program (STOP)

• Feed rate F

• Miscellaneous function M

• Nominal position values

• Teach-In: capturing the actual position

• Bolt hole circle and linear hole patterns

• Program section repeats:

A section of a program only has to be entered once and can

then be run up to 999 times in succession.

• Subprograms:

A section of a program only has to be entered once and can

then be run at various places in the program.

Tool and workpiece movement

During workpiece machining, the machine moves an axis by moving either the tool or the machine table on which the workpiece is

fixed.

When entering tool movements in a part program you

always program as if the tool is moving and the workpiece is stationary.

Pre-positioning the tool

Preposition the tool to prevent the possibility of damaging the tool

or workpiece. The best pre-position lies on the extension of the

tool path.

What happens with the completed programs?

The completed program is used to machine the part in the PROGRAM RUN mode of operation. See Chapter 7 for an explanation

of this mode.

TNC 122 31

Page 32

5 Programming

Entering the program number

Select a program with a number from 1 to 20.

Mode of operation: PROGRAMMING AND EDITING

PGM

ENT

ENT

7

The BEGIN block of the selected program appears.

Deleting programs

If you no longer need certain programs, or if you need to make

space in the TNC's memory, you can delete programs.

Mode of operation: PROGRAMMING AND EDITING

Select program management.

Switch to the EDIT PGM function.

E D I T P G M

Select the EDIT PGM function.

P G M N O . =

ENT

The equal sign blinks: Enter the PGM-NO., for example 7.

Confirm your entry. Now you can enter and edit the program.

5

After deletion the BEGIN block of the deleted program appears.

The contents of the program is deleted and the BEGIN and END

blocks of the deleted program remain in the TNC's memory.

Erase all programs

⇒⇒

⇒ Use the upward arrow key to go from the DELETE PGM func-

⇒⇒

tion to the DELETE ALL PGM function.

⇒⇒

⇒ Press ENT to erase all programs.

⇒⇒

PGM

Select program management.

Switch to the DELETE PGM function.

D E L E T E P G M

ENT

Select the DELETE PGM function.

P G M N O . =

ENT

The equals sign blinks: enter the PGM NO. 5 to erase program 5.

32 TNC 122

Page 33

5 Programming

Selecting program blocks

Current block

The current block appears in the entry line above the numeric keypad. The block number appears to the right and above the entry

line.

The TNC inserts new blocks behind the current block. No more

blocks can be entered if the END PGM block appears in the entry

line

Overview of functions

Function Key

Select the next block

Select the previous block

Go directly to a program block

In large programs it can take a long time to scroll to the desired

block using the arrow keys. A quicker way is to use the GOTO

function to go directly to the desired block.

⇒⇒

⇒ Enter the number of the desired block.

⇒⇒

⇒⇒

⇒ Confirm your entry with the ENT key.

⇒⇒

The desired block appears in the entry line.

Changing program blocks

You can make changes in program blocks the incorrect numerical

entries in a program.

Clearing incorrect numerical entries

If you notice an incorrect numerical entry immediately after you've

made it, you can clear it and try again:

⇒⇒

⇒ Press the CL key.

⇒⇒

Confirming a change

Any change made with CL must be confirmed with ENT to become effective!

Example: Changing a program block

Mode of operation: PROGRAMMING AND EDITING

/

Move to the program block that you wish to change.

Select the block for editing.

The display (e.g. the axis designation) starts blinking.

2 0

ENT

TNC 122 33

Enter the desired change, for example a new nominal position value ( 20 ).

Confirm the change.

Page 34

5 Programming

Deleting program blocks

You can delete any blocks in an existing program except the

BEGIN and END blocks

To delete a block:

⇒⇒

⇒ Use the arrow keys to move to the block, or enter the block

⇒⇒

number.

⇒⇒

⇒ Press the DEL key.

⇒⇒

When a block is deleted, the TNC automatically renumbers the remaining blocks. The block before the deleted block becomes the

current block.

It is also possible to delete an entire program section:

⇒⇒

⇒ Select the last block of the program section.

⇒⇒

⇒⇒

⇒ Press the DEL key repeatedly until all the blocks in the

⇒⇒

section have been deleted.

34 TNC 122

Page 35

5 Programming

Feed rate F and miscellaneous function M

The feed rate F and miscellaneous function M are entered as

separate blocks. They become effective as soon as the TNC has

run the block in which they are programmed.

These blocks must be run before the positioning blocks for which

they are intended.

Entering the feed rate F

The machining feed rate is “modal.” That means that the entered

feed rate remains effective until you replaced it by entering a new

one.

Example

Mode of operation: PROGRAMMING AND EDITING

F

1

0

ENT

Varying the feed rate

Some machines are equipped with a potentiometer to enable you

to vary the feed rate.

Press the F key for feed rate.

A blinking F appears.

F E E D R A T E F

0

Enter the desired feed rate F , for example 100 mm/min.

Confirm the feed rate F for the following positioning blocks.

TNC 122 35

Page 36

5 Programming

Feed rate F and miscellaneous function M

Entering the miscellaneous function M

The machine tool builder determines which miscellaneous

functions are available on your TNC and what effect

they have.

Example: Entering a miscellaneous function

Mode of operation: PROGRAMMING AND EDITING

Repeatedly

SPEC

FCT

Press the SPEC FCT key for special functions.

Page to M FUNCTION.

M FUNKTION

ENT

Select M FUNCTION.

M

3

ENT

Enter the miscellaneous function e.g. M3 (Spindle ON, clockwise).

Confirm your M function entry.

Entering a program interruption

You can divide your program into logical sections by setting stop

blocks. The TNC interrupts the program at the stop block and

resumes it when you press a button.

Mode of operation: PROGRAMMING AND EDITING

STOP

Enter the STOP block in the program.

To restart a program after an interruption

⇒⇒

⇒ Press the NC-Start button

⇒⇒

36 TNC 122

Page 37

5 Programming

Entering workpiece positions

Programming example: milling a shoulder

The coordinates are programmed in absolute dimensions.

The datum is the workpiece zero.

Corner X = 0 mm Y = 20 mm

Corner X = 30 mm Y = 20 mm

Corner X = 30 mm Y = 50 mm

Corner X = 60 mm Y = 50 mm

Summary of programming steps

⇒⇒

⇒ Press the PGM key.

⇒⇒

⇒⇒

⇒ Key in the number of the program you want to work on,

⇒⇒

⇒⇒

⇒ Enter the nominal positions.

⇒⇒

Running a completed program

Once a program has been completed it can be executed in the

PROGRAM RUN mode (see Chapter 10).

1

2

3

4

and press ENT.

Y

50

20

0

1 2

0

3 4

30

X

60

Example: Entering a nominal position in a program

(Block 9 in the example)

X

Select the coordinate axis ( X axis ).

X R 0

3

0

R+/

–

ENT

Program blocks

0 BEGIN PGM 10 Start of program, program number

1 F 9999 High feed rate for pre-positioning

2 Z+20.000 Clearance height

3 X–20.000 R0 Pre-position the tool in the X axis

4 Y–20.000 R0 Pre-position the tool in the Y axis

5 Z–10.000 Move tool to milling depth

6 F 200 Machining feed rate

7M 3 Spindle ON, clockwise

8 Y+20.000 R+ Y coordinate, corner

9 X+30.000 R– X coordinate, corner

10 Y+50.000 R+ Y coordinate, corner

11 X+60.000 R+ X coordinate, corner

12 F 9999 High feed rate for retracting

13 Z+20.000 Clearance height

14 M 2 Stop program run, spindle OFF, coolant OFF

15 END PGM 10 End of program, program number

Enter the nominal position value, for example 30 mm

and

select tool radius compensation R – .

Confirm your entry. The nominal position now appears in the program block

display.

1

2

3

4

TNC 122 37

Page 38

5 Programming

Y

X

Z

Actual-position capture: Teach-In programming

With teach-in programming, you enter the position values by moving to the position and then transferring the actual position value

into the program.

Changing the captured position values

Teach-in blocks can be edited later just like any other program

blocks.

Selecting radius compensation

If you wish to change the radius compensation:

⇒⇒

⇒ Press the R +/– key.

⇒⇒

Programming example: Capturing a Z-coordinate value (top surface

of workpiece) for a part program

Mode of operation: PROGRAMMING AND EDITING

Move the tool until it touches the surface of the workpiece.

Z

Select the axis, for example Z.

Z

Capture the position of the tool point for the program.

ENT

Store the position in the tool axis ( Z ).

38 TNC 122

Page 39

5 Programming

Hole patterns in programs

The BOLT HOLE CIRCLE and LINEAR PATTERN cycles can

also be entered in a part program and saved for repeated execution. Each item of information then comprises its own program

block.

These blocks are introduced by a block with a block number, followed by the word CYCL and the name of the cycle. The cycles

contain all information required by the TNC for machining a hole

pattern.

The TNC executes a hole pattern automatically as soon as it

reaches the cycle in the program.

Cycles must be complete

Do not delete any blocks from the cycle. If you do, it will provoke

the error message CYCLE INCOMPLETE when the program is

executed.

Entering cycles

Press the SPEC FCT key and select the desired cycle. The TNC

automatically asks for all data required to execute the cycle.

Bolt hole circle

Programming example: FULL CIRCLE cycle

Number of holes NO.HL :8

Center point coordinates: CENT X = 50 mm

CENT Y = 50 mm

Bolt hole circle radius RADIUS : 20 mm

Starting angle between X axis

and first hole ANGLE :30°

Drilling depth DEPTH : – 8 mm

Mode of operation: PROGRAMMING AND EDITING

Repeatedly

SPEC

FCT

Press the SPEC FCT key for special functions.

Page to the BOLT HOLE CIRCLE function.

50

Y

30°

R20

0

0

50

X

B O L T H O L E C I R C L E

ENT

Select the BOLT HOLE CIRCLE function.

F U L L C I R C L E

ENT

TNC 122 39

Select FULL CIRCLE

Page 40

5 Programming

Bolt hole circle

5

5

2

N O . H L =

ENT

8

CENT X =

ENT

0

CENT Y =

ENT

0

RADIUS =

ENT

0

Enter the number of holes ( NO.HL = 8 ).

Confirm your entry.

Enter the X coordinate of the bolt circle center ( X = 50 mm ).

Confirm your entry.

Enter the Y coordinate of the bolt circle center ( Y = 50 mm ).

Confirm your entry.

Enter the RADIUS of the bolt hole circle ( 20 mm ).

Confirm your entry.

ANGLE=

3

ENT

0

Enter the ANGLE from the X axis to the first hole ( 30° ).

Confirm your entry.

DEPTH =

ENT

8

Program blocks

0 BEGIN PGM 40 MM Start of program, program number, unit of measurement

1 F 9999 High feed rate for pre-positioning

2 Z+20.000 Clearance height

3M 3 Spindle ON, clockwise

4 CYCL FULL CIRCLE The data for the FULL CIRCLE cycle follow this block

5 NO.HL = 8 Number of holes

6 CENT X= 50.000 X coordinate of the center of the bolt circle

7 CENT Y= 50.000 Y coordinate of the center of the bolt circle

8 RADIUS= 20.000 Radius

9 ANGLE= 30.000 Starting angle of first hole

10 DEPTH= – 8.000 Depth of holes

11 M 2 Stop program run, spindle STOP, coolant OFF

12 END PGM 40 MM End of program, program number, unit of measurement

Enter the DEPTH of the holes ( – 8 mm ).

Confirm your entry.

For a circle segment ( CYCL CIRCL SEGMT ) you also

enter the angle step (ANGLE) between the holes (after the

starting angle).

The bolt hole circle is then executed in the PROGRAM RUN mode of operation (see Chapter 7).

40 TNC 122

Page 41

5 Programming

Linear hole patterns

Programming example: LINEAR PATTERN cycle

X coordinate of the first hole H.1 X = 20 mm

Y coordinate of the first hole H.1 Y = 15 mm

Number of holes per row NO.HL 4

Hole spacing HL.SPC 10 mm

Angle between hole row

and X axis ANGLE 18°

DEPTH of holes – 8 mm

Number of rows NO.RW 3

Row spacing RW.SPC 12 mm

Mode of operation: PROGRAMMING AND EDITING

1

1

15

0

Y

10

1

12

18°

X

0

20

SPEC

FCT

Press the SPEC FCT key for special functions.

B O L T H O L E C I R C L E ?

ENT

Select BOLT HOLE CIRCLE.

H . 1 X =

2 0

ENT

Enter the X coordinate of hole ( X = 20 mm ).

Confirm your entry.

H . 1 Y =

1

ENT

5

Enter the Y coordinate of hole ( Y = 15 mm ).

Confirm your entry.

N O . H L =

ENT

4

Enter the number of holes per row (NO.HL = 4 ).

Confirm your entry.

H L . S P C =

1

ENT

0

Enter the hole spacing in the row (HL.SPC = 10 mm).

Confirm your entry.

1

1

ANGLE =

1

ENT

8

TNC 122 41

Enter the ANGLE between the X axis and the rows of holes (ANGLE = 18°).

Confirm your entry.

Page 42

5 Programming

Linear hole patterns

3

1

Program blocks

0 BEGIN PGM 50 Start of program, program number

1 F 9999 High feed rate for pre-positioning

2 Z+20.000 Clearance height

3M 3 Spindle ON, clockwise

4 CYCL LINEAR PATT The data for the LINEAR PATTERN cycle follow this block

5 H.1 X= 20.000 X coordinate of first hole

6 H.1 Y= 15.000 Y coordinate of first hole

7 NO.HL= 4 Number of holes per row

8 HL.SPC= 10.000 Distance between holes on the row

9 ANGLE= 18.000 Angle between the rows and the X axis

10 DEPTH= –8.000 Depth of the holes

11 NO.RW= 3 Number of rows

12 RW.SPC= 12.000 Spacing between rows

13 M 2 Stop program run, spindle STOP, coolant OFF

DEPTH =

ENT

8

N O . R W =

ENT

R W . S P C =

ENT

2

Enter the DEPTH of the holes ( – 8 mm ).

Confirm your entry.

Enter the number of rows (NO.RW = 3 ).

Confirm your entry.

Enter the spacing between rows ( RW.SPC = 12 mm ).

Confirm your entry.

14 END PGM 50 End of program, program number

The hole pattern is then executed in the PROGRAM RUN mode of operation (see Chapter 7).

42 TNC 122

Page 43

5 Programming

Subprograms and Program Section Repeats

Subprograms and program section repeats only need to be entered

once in the program. You can then run them up to 999 times.

Subprograms can be run at any point in the program, while program section repeats are run several times in succession.

Inserting program markers (labels)

You identify subprograms and program section repeats with labels

(abbreviated in the program to LBL).

Labels 1 to 99

Labels 1 to 99 identify the beginning of a subprogram or a program

section that is to be repeated.

Label 0

Label 0 is used only to identify the end of a subprogram.

Label call

Subprogram and program sections are called within the program

with a CALL L command.

The command CALL L 0 is not allowed.

Subprograms:

When it reaches a CALL L block, the TNC immediately executes

the called subprogram.

Program section repeats:

The TNC repeats the program section above the CALL L block.

Together with the CALL L command you also enter the number

of desired repetitions.

Nesting

You can run subprograms and repeat program sections within

other subprograms and program sections. This is called nesting.

An example of nesting is when you call a subprogram from within

another subprogram.

Maximum nesting depth: 8 levels

0 BEGIN PGM ...

.

1

.

.

.

CALL LBL 1

.

.

3

.

.

L Z + 100 M2

.

LBL 1

.

.

2

.

LBL 0

END PGM ...

Fig 8.1: Operating sequence of a

subprogram

0 BEGIN PGM ...

.

.

.

.

.

.

.

.

.

.

.

.

1

LBL 1

2

3

4

R

R

CALL LBL 1 REP 2/2

5

END PGM ...

Fig. 8.2: Operating sequence of a program

section repeat

TNC 122 43

Page 44

5 Programming

Subprograms

Programming example: Subprogram for slots

Slot lengths: 20 mm + tool diameter

Slot depths: – 10 mm

Slot diameters: 8 mm (= tool diameter)

Infeed point coordinates

Slot X = 20 mm Y = 10 mm

1

Slot X = 40 mm Y = 50 mm

2

3

Slot X = 60 mm Y = 40 mm

This example requires a center-cut end mill (ISO 1641).

Example: Inserting a label for a subprogram

Mode of operation: PROGRAMMING AND EDITING

LBL

Select the LBL function.

S E T = E N T / C A L L = L B L

ENT

Select SET to set a label.

L B L ...

ENT

5

Enter a label number.

Confirm your entry. The resulting program block is: LBL 5

50

40

10

Y

8

20

2

3

20

1

X

40

60

0

0

The beginning of a subprogram (or a program section repeat) is

now marked with the label. Enter the program blocks for the subprogram after the LBL block.

Label 0 (LBL 0) is used only to identify the end of a subprogram.

Example: Entering a subprogram call: CALL L

Mode of operation: PROGRAMMING AND EDITING

LBL

Select the LBL function.

S E T = E N T / C A L L = L B L

LBL

Select CALL to call a label.

C A L L L 0

ENT

5

Enter the label number of the desired subprogram.

Confirm your entry.

C A L L L 5 R

NO

ENT

R stands for “repetitions” and has no significance for subprogramming. Skip

this prompt by pressing NO ENT. The resulting program block is: CALL L5

44 TNC 122

Page 45

5 Programming

Subprograms

After a CALL L block in the operating mode PROGRAM RUN, the

TNC executes those blocks in the subprogram that are located between the LBL block with the called number and the next block

containing LBL 0.

Program blocks

0 BEGIN PGM 60 Start of program, program number

1 F 9999 High feed rate for pre-positioning

2 Z+20.000 Clearance height

3 X+20.000 R0 X coordinate infeed point slot

4 Y+10.000 R0 Y coordinate infeed point slot

5M 3 Spindle ON, clockwise

6 CALL L 1 Call subprogram 1: execute blocks 16 to 20

7 X+40.000 R0 X coordinate infeed point slot

8 Y+50.000 R0 Y coordinate infeed point slot

9 CALL L 1 Call subprogram 1: execute blocks 16 to 20

10 X+60.000 R0 X coordinate infeed point slot

11 Y+40.000 R0 Y coordinate infeed point slot

12 CALL L 1 Call subprogram 1: execute blocks 16 to 20

1

1

2

2

3

3

13 Z+20.000 Clearance height

14 M 2 Stop program run, spindle STOP, coolant OFF

15 LBL 1 Start of subprogram 1

16 F 200 Machining feed rate during subprogram

17 Z–10.000 Infeed to slot depth

18 IY+20.000 R0 Mill slot

19 F 9999 High feed rate for retracting and pre-positioning

20 Z+2.000 Retract

21 LBL 0 End of subprogram 1

22 END PGM 60 End of program, program number

TNC 122 45

Page 46

5 Programming

Program section repeats

A program section repeat is entered like a subprogram. The end of

the program section is identified simply by the command to repeat

the section.

Label 0 is therefore not set.

CALL LBL block for a program section repeat

Example of a call label block: CALL L 1 R10 / 10 .

The two numbers with the slash between them indicate that this is

a program section repeat. The number in front of the slash is the

number of repetitions you programmed. The number behind the

slash is the number of repetitions remaining to be run.

Programming example: Program section repeat for slots

Slot lengths 16 mm + tool diameter

Slot depths – 12 mm

Incremental offset

of the infeed point 15 mm

Slot diameter 6 mm (= tool diameter)

Infeed point coordinates

1

Slot X = 30 mm Y = 10 mm

70

55

40

Y

6

16

This example requires a center-cut end mill (ISO 1641).

Example: Label for a program section repeat

Mode of operation: PROGRAMMING AND EDITING

LBL

Select the LBL function.

S E T = E N T / C A L L = L B L

ENT

Select SET to set a label.

L B L ...

ENT

5

Enter the blocks for the program section repeat after the

LBL block.

Enter the label number.

Confirm your entry. The resulting program block is LBL 5

25

10

1

0

0

30

X

46 TNC 122

Page 47

5 Programming

Program section repeats

Example: Entering a program section repeat: CALL L

LBL

Select the LBL function.

S E T = E N T / C A L L = L B L

LBL

Select CALL to call the label.

C A L L L 0

ENT

5

Enter the label number.

Confirm your entry.

C A L L L 5 R

ENT

4

After a CALL L block in the operating mode PROGRAM RUN, the

TNC repeats those program blocks that are located below the L

block with the called number and above the CALL LBL block.

Note that the program section will always be executed one more

time than the programmed number of repetitions.

Program blocks

Enter the desired number of repetitions R, for example 4.

Confirm your entry. The resulting program block is CALL L 5 R4 / 4

0 BEGIN PGM 70 Start of program, program number

1 F 9999 High feed rate for pre-positioning

2 Z+20.000 Clearance height

5M 3 Spindle ON, clockwise

6 X+30.000 R0 X coordinate infeed point slot

7 Y+10.000 R0 X coordinate infeed point slot

8 LBL 1 Start of program section 1

9 F 150 Machining feed rate during the program section repeat

10 Z-12.000 Infeed

11 IX+16.000 R0 Mill the slot

12 F 9999 High feed rate for retracting and pre-positioning

13 Z+2.000 Retract

14 IX-16.000 R0 Positioning in X

15 IY+15.000 R0 Positioning in Y

16 CALL L1 R4 / 4 Repeat program section 1 four times

17 Z+20.000 Clearance height

18 M 2 Stop program run, spindle STOP, coolant OFF

19 END PGM 70 End of program, program number

TNC 122 47

Page 48

5 Programming

NOTES

48 TNC 122

Page 49

6 Transferring Programs over the Data Interface

6

Transferring Programs over the Data Interface

The TNC 122 features an RS-232-C/V.24 interface for external data

storage on a device such as the HEIDENHAIN FE 401 floppy disk

unit or a PC.

Programs can also be archived on diskette and loaded back into the

TNC again as required.

Pin layout, wiring and connections for the data interface

are described in the Technical Manual for the TNC 122.

Transferring a program to the TNC

Mode of operation: PROGRAMMING AND EDITING

Repeatedly

1

PGM

Select program management.

To transfer from an FE 401 or PC, select PGM INPUT FE..

To transfer from an ME, select PGM INPUT EXT.

P G M I N P U T F E

ENT

Select FE for transferring to the TNC from an FE 401, for example.

P G M N O . =

2

ENT

Enter the program number, for example number 12.

Transfer the program to the TNC.

TNC 122 49

Page 50

6 Transferring Programs over the Data Interface

Transferring programs out of the TNC

Example: Transferring a program from the TNC to an FE 401

The TNC automatically transfers the program that you last selected

for programming.

Mode of operation: PROGRAMMING AND EDITING

Repeatedly

PGM

Select program management.

To transfer to an FE 401 or PC, select PGM OUTPUT FE.

To transfer to an ME, select PGM OUTPUT EXT.

P G M O U T P U T F E

ENT

C A U T I O N

A program on the external device with the same number

as that being read out will be overwritten. No confirmation will be requested to overwrite.

Select FE for transferring from the TNC to an FE 401, for example.

The TNC immediately transfers the program to the external device.

50 TNC 122

Page 51

7 Executing programs

7

Executing Programs

There are two ways to run programs on the TNC:

PROGRAM RUN SINGLE BLOCK

Use the NC start key to separately start each block. It is recommended that you use SINGLE BLOCK when running a program for

the first time.

PROGRAM RUN AUTOMATIC

The TNC automatically executes the program block by block until

program run is interrupted or execution of the program has been

completed. Use AUTOMATIC when you are sure the program contains no errors and you want to run it quickly.

Pre-positioning the tool

Before running a part program, always pre-position the tool to pre-

vent the possibility of damaging the tool or workpiece. The best

pre-position lies outside the programmed contour on the extension

of the tool path for machining the first contour point.

Sequence in which the tool approaches the pre-position for milling

⇒⇒

⇒ Change the tool at the clearance height.

⇒⇒

⇒⇒

⇒ Pre-position the tool in X and Y (when the tool axis is Z).

⇒⇒

⇒⇒

⇒ Move the tool to the working depth.

⇒⇒

Preparation

⇒⇒

⇒ Clamp the workpiece to the machine table.

⇒⇒

⇒⇒

⇒ Set the workpiece datum.

⇒⇒

⇒⇒

⇒ Select the program that you wish to run.

⇒⇒

Changing the feed rate F during program run

Some machines are equipped with a potentiometer to allow you to

vary the feed rate.

Skipping program blocks

If you wish to start a program at a certain block:

⇒⇒

⇒ Enter the block number.

⇒⇒

⇒⇒

⇒ Start the program as described in this chapter.

⇒⇒

Overview of functions

Function key

Stop machine axis movements;

Interrupt program run

Enter the tool data

0

TOOL

DEF

TNC 122 51

Page 52

7 Executing programs

Single block

Mode of operation: PROGRAM RUN SINGLE BLOCK

For each block:

Continue positioning and calling blocks with the NC start key until machining is complete.

I

Automatic

Mode of operation: PROGRAM RUN AUTOMATIC

I

The TNC automatically executes the next position block as soon as

it has reached the programmed position.

Interrupting program run

To interrupt the program run, without aborting:

⇒⇒

⇒ Press the NC-Stop button.

⇒⇒

The program run indicator blinks.

To resume program run after the interruption:

⇒⇒

⇒ Press the NC-Start button

⇒⇒

The program run indicator glows.

Position for each individual program block.

Position.

The program run indicator glows during program run.

To abort the program run

⇒⇒

⇒ Press the NC-Stop button.

⇒⇒

The program run indicator blinks.

⇒⇒

⇒ Press the STOP key.

⇒⇒

The program run indicator goes out.

To restart program run after STOP

The TNC interrupts program run as soon as it reaches a STOP

block. The program run indicator goes out.

To restart the program run:

⇒⇒

⇒ Press the NC-Start button

⇒⇒

52 TNC 122

Page 53

8 User Parameters

8

User Parameters

With user parameters you define the way the TNC operates in

various situations. You can change user parameters without first

having to enter a code number.

Selecting user parameters

Mode of operation: any

MOD

C O D E N O . =

E D I T U S E R P A R A M

ENT

To change user parameters

⇒⇒

⇒ Use the vertical arrow keys to select the desired user

⇒⇒

parameter.

⇒⇒

⇒ Enter the new parameter value.

⇒⇒

⇒⇒

⇒ Confirm your entry with ENT.

⇒⇒

To leave the user parameters

⇒⇒

⇒ Press the DEL key to leave the user parameters.

⇒⇒

The changes are effective immediately.

Press MOD to select the user parameters.

Page to EDIT USER PARAM.

Call the list of user parameters.

TNC 122 53

Page 54

8 User Parameters

User Parameters in the TNC 122

Parameters whose functions are determined by the machine tool builder

The machine tool builder determines the function of the machine

parameters:

• MP4310.0

• MP4310.1

Sequence for crossing the reference marks

MP1340.0:

MP1340.1:

MP1340.2:

Programming station setup

MP7210

1st axis X axis:

2nd axis Y axis:

3rd axis Z axis:

TNC with machine:

TNC as a programming station with active PLC:

TNC as programming station with inactive PLC:

1

2

3

No reference mark evaluation:

0

0

1

2

Dialog language

3

2

1

0

4

1

0

2

0

1

MP7230

Position display in the tool axis

MP7285

Select the position display

MP7322

Enable continuing traverse with the direction keys

MP7680

German:

English:

French:

Italian:

Spanish:

Display the position of the tool datum:

Display the position of the tool point:

Actual position:

Servo lag:

Reference position:

Continuing traverse disabled:

Continuing traverse enabled:

00

0

00

1

54 TNC 122

Page 55

9 Tables and Overviews

9

Tables and Overviews

This chapter contains information which you will frequently need

when working with the TNC:

• Miscellaneous functions (M functions) with predetermined

effect

• Vacant miscellaneous functions

• Frequently occurring display messages and their meanings

• Technical information

• Accessories: FE 401 floppy disk unit

Miscellaneous functions (M functions)

M functions with predetermined effect

With the M functions the TNC controls:

• Coolant (ON/OFF)

• Spindle rotation (ON/OFF/direction of rotation)

• Program run

• Tool change

The machine tool builder determines which miscellaneous

functions are available on your TNC and what effect they

have.

M number Standard miscellaneous function

M00 Stop program run, spindle STOP, coolant OFF

M02 Stop program run, spindle STOP, coolant OFF,

go to block 1

M03 Spindle ON, clockwise

M04 Spindle ON, counterclockwise

M05 Spindle STOP

M06 Tool change, stop program run, spindle STOP

M08 Coolant ON

M09 Coolant OFF

M13 Spindle ON, clockwise, coolant ON

M14 Spindle ON, counterclockwise, coolant ON

M30 Stop program run, spindle STOP, coolant OFF,

go to block 1

TNC 122 55

Page 56

9 Tables and Overviews

Miscellaneous functions (M functions)

Vacant miscellaneous functions

The machine manufacturer can inform you of the tasks he has assigned to the vacant miscellaneous functions listed on this page.

M number Vacant miscellaneous function M number Vacant miscellaneous function

M01 M50

M07 M51

M10 M52

M11 M53

M12 M54

M15 M55

M16 M56

M17 M57

M18 M58

M19 M59

M20 M60

M21 M61

M22 M62

M23 M63

M24 M64

M25 M65

M26 M66

M27 M67

M28 M68

M29 M69

M31 M70

M32 M71

M33 M72

M34 M73

M35 M74

M36 M75

M37 M76

M38 M77

M39 M78

M40 M79

M41 M80

M42 M81

M43 M82

M44 M83

M45 M84

M46 M85

M47 M86

M48 M87

M49 M88

M89

56 TNC 122

Page 57

9 Tables and Overviews

Pin layout and connecting cable for the data interface

HEIDENHAIN devices

External

unit

eg. FE

GND

TXD

RXD

RTS

CTS

DSR

GND

DTR

10

11

12

13

14

15

16

17

18

19

20

10

11

12

13

14

15

16

17

18

19

20

X21

TNC

1

1

2

3

4

5

6

7

8

9

GND

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Chassis

RXD

Receive Data

TXD

Transmit Data

CTS

Clear To Send

RTS

Request To Send

DTR

Data Terminal Ready

GND

Signal Ground

DSR Data Set Ready

HEIDENHAIN

standard cable

3 m

Id.-Nr. 274 545 01

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

11

12

13

14

15

16

17

18

19

20

gn

ge

gr

rs

bl

rt

br

V.24-Adapter-Block

Id.-Nr. 239 758 01

ws/brws/br

1

2

3

4

5

6

7

8

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

HEIDENHAIN

connecting cable

max. 17 m

Id.-Nr. 239 760..

ws/brws/br

10

11

12