Page 1

QUADRA-CHEK 2000 Demo

User's Manual

Evaluation Unit

English (en)

06/2018

Page 2

Contents

Contents

1 Fundamentals....................................................................................................................................7

2 Software Installation......................................................................................................................11

3 Basic Operation.............................................................................................................................. 17

4 Software Configuration..................................................................................................................41

5 Quick Start...................................................................................................................................... 47

6 Measurement Report Template.................................................................................................... 69

7 ScreenshotClient.............................................................................................................................83

8 Index.................................................................................................................................................89

9 List of Figures.................................................................................................................................91

2

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 3

Contents

1 Fundamentals....................................................................................................................................7

1.1 Overview................................................................................................................................................. 8

1.2 Information on the product.................................................................................................................. 8

1.2.1 Demo software for demonstration of the device functions...................................................... 8

1.2.2 Demo software features............................................................................................................8

1.3 Intended use...........................................................................................................................................9

1.4 Improper use.......................................................................................................................................... 9

1.5 Demo software for demonstration of the device functions.............................................................. 9

1.6 Notes on reading the documentation................................................................................................. 9

1.7 Symbols and fonts used for marking text........................................................................................ 10

2 Software Installation......................................................................................................................11

2.1 Overview............................................................................................................................................... 12

2.2 Downloading the installation file.......................................................................................................12

2.3 System requirements...........................................................................................................................12

2.4 Installing QUADRA-CHEK 2000 Demo under Microsoft Windows.................................................. 13

2.5 Uninstalling QUADRA-CHEK 2000 Demo.......................................................................................... 15

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

3

Page 4

Contents

3 Basic Operation.............................................................................................................................. 17

3.1 Overview............................................................................................................................................... 18

3.2 Using the touchscreen and input devices.........................................................................................18

3.2.1 Touchscreen and input devices............................................................................................... 18

3.2.2 Gestures and mouse actions...................................................................................................19

3.3 General operating elements and functions.......................................................................................21

3.4 QUADRA-CHEK 2000 Demo – startup and shut-down.....................................................................23

3.4.1 Starting QUADRA-CHEK 2000 Demo......................................................................................23

3.4.2 Shutting down QUADRA-CHEK 2000 Demo...........................................................................24

3.5 User login and logout......................................................................................................................... 24

3.5.1 User login.................................................................................................................................24

3.5.2 User logout.............................................................................................................................. 24

3.6 Setting the language...........................................................................................................................25

3.7 User interface....................................................................................................................................... 25

3.7.1 User interface after Startup.....................................................................................................25

3.7.2 Main menu of the user interface............................................................................................ 26

3.7.3 Measure menu.........................................................................................................................28

3.7.4 Measurement report menu..................................................................................................... 31

3.7.5 File management menu...........................................................................................................32

3.7.6 User login menu...................................................................................................................... 33

3.7.7 Settings menu..........................................................................................................................34

3.7.8 Switch-off menu.......................................................................................................................35

3.8 Position display.................................................................................................................................... 35

3.8.1 Operating elements of the position display............................................................................ 35

3.9 Working in the workspace.................................................................................................................. 36

3.9.1 Operating elements in the workspace....................................................................................36

3.10 Using the Inspector............................................................................................................................. 37

3.10.1 Operating elements of the Inspector......................................................................................37

3.11 Using measuring tools........................................................................................................................ 40

3.11.1 Measuring tools....................................................................................................................... 40

4

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 5

Contents

4 Software Configuration..................................................................................................................41

4.1 Overview............................................................................................................................................... 42

4.2 Activating a license key.......................................................................................................................43

4.3 Copying the configuration file............................................................................................................44

4.4 Uploading the configuration file........................................................................................................ 45

4.5 Setting the language...........................................................................................................................46

4.6 Selecting the product version (optional)...........................................................................................46

5 Quick Start...................................................................................................................................... 47

5.1 Overview............................................................................................................................................... 48

5.2 Conducting a measurement............................................................................................................... 49

5.2.1 Measuring with an OED sensor..............................................................................................49

5.2.2 Displaying and editing the measurement results.................................................................... 57

5.2.3 Creating a measurement report.............................................................................................. 64

6 Measurement Report Template.................................................................................................... 69

6.1 Overview............................................................................................................................................... 70

6.2 Creating and editing a template........................................................................................................ 71

6.2.1 Opening a new template with the editor................................................................................72

6.2.2 Editing the default settings for the measurement report........................................................73

6.2.3 Configuring the page header................................................................................................... 74

6.2.4 Configuring the report header................................................................................................. 76

6.2.5 Defining data for a measurement report.................................................................................78

6.2.6 Saving a template....................................................................................................................81

6.2.7 Exiting or canceling the creation of a template.......................................................................81

6.3 Transferring a measurement report template to the unit................................................................ 81

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

5

Page 6

Contents

7 ScreenshotClient.............................................................................................................................83

7.1 Overview............................................................................................................................................... 84

7.2 Informationen about ScreenshotClient..............................................................................................84

7.3 Starting ScreenshotClient...................................................................................................................85

7.4 Connecting ScreenshotClient with the demo software...................................................................85

7.5 Connecting ScreenshotClient with the unit......................................................................................86

7.6 Configuring ScreenshotClient for taking screenshots..................................................................... 86

7.6.1 Configuring the storage location and file name for screenshots.............................................86

7.6.2 Configuring the user interface language of screenshots.........................................................87

7.7 Creating screenshots........................................................................................................................... 88

7.8 Exiting ScreenshotClient.....................................................................................................................88

8 Index.................................................................................................................................................89

9 List of Figures.................................................................................................................................91

6

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 7

1

Fundamentals

Page 8

1

Fundamentals | Overview

1.1 Overview

This chapter contains information about the product and these instructions.

1.2 Information on the product

1.2.1 Demo software for demonstration of the device functions

QUADRA-CHEK 2000 Demo is a software application you can install on a

computer independently of the device. QUADRA-CHEK 2000 Demo helps you to

become familiar with, try out or present the functions of the device.

1.2.2 Demo software features

Because of the missing hardware environment, the range of features of the demo

software does not correspond to the complete functional range of the device.

With QUADRA-CHEK 2000 Demo you can try out or present the following

features:

"Conducting a measurement"

"Displaying and editing the measurement results"

"Creating a measurement report"

The following features cannot be tried out or presented with

QUADRA-CHEK 2000 Demo:

Connecting measuring devices

Connecting a network drive

Connecting a USB mass storage device

Connecting a printer

8

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 9

Fundamentals | Intended use

1.3 Intended use

The products of the QUADRA-CHEK 2000 series are advanced digital evaluation

electronics for the measurement of 2-D features in metrology applications. The

products are used primarily on measuring machines and profile projectors.

QUADRA-CHEK 2000 Demo is a software product for demonstration of the basic

features of the QUADRA-CHEK 2000 series products. QUADRA-CHEK 2000 Demo

may be used only for presentation, training or testing purposes.

1.4 Improper use

QUADRA-CHEK 2000 Demo is not intended for any use other than the intended

use. Any use for other purposes is prohibited, specifically:

For productive purposes in production systems

As part of production systems

1

1.5 Demo software for demonstration of the device functions

QUADRA-CHEK 2000 Demo is a software application you can install on a

computer independently of the device. QUADRA-CHEK 2000 Demo helps you to

become familiar with, try out or present the functions of the device.

1.6 Notes on reading the documentation

Would you like to see any changes made, or have you found any errors?

We are continuously striving to improve our documentation for you. Please help us

by sending your requests to the following e-mail address:

userdoc@heidenhain.de

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

9

Page 10

1

Fundamentals | Symbols and fonts used for marking text

1.7 Symbols and fonts used for marking text

In these instructions the following symbols and fonts are used for marking text:

Depiction Meaning

Bold

...

...

...

...

Identifies an action and the result of this action

Example:

Tap OK

The message is closed

Identifies an item of a list

Example:

TTL interface

EnDat interface

...

Identifies menus, displays and buttons

Example:

Tap Shut down

The operating system shuts down

Turn the power switch off

10

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 11

2

Software

Installation

Page 12

2

Software Installation | Overview

2.1 Overview

This chapter provides all of the information needed for downloading and properly

installing QUADRA-CHEK 2000 Demo on a computer.

2.2 Downloading the installation file

Before you can install the demo software on a computer, you need to download an

installation file from the HEIDENHAIN Portal.

To download the installation file from the HEIDENHAIN Portal, you

need access rights to the Software portal folder in the directory of the

appropriate product.

If you do not have access rights to the Portal's Software folder, you can

request the access rights from your HEIDENHAIN contact person.

Download the latest version of QUADRA-CHEK 2000 Demo here:

www.heidenhain.de

Select the download folder of your browser

Unpack the downloaded file with the extension .zip into a temporary storage

folder

The following files will be unpacked into the temporary storage folder:

Installation file with the extension .exe

File DemoBackup.mcc

2.3 System requirements

If you want to install QUADRA-CHEK 2000 Demo on a computer, the computer

system must meet the following requirements:

Microsoft Windows 7 or higher

Screen resolution of at least 1280 × 800 recommended

12

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 13

Software Installation | Installing QUADRA-CHEK 2000 Demo under Microsoft Windows

2.4 Installing QUADRA-CHEK 2000 Demo under Microsoft Windows

Select the temporary storage folder into which you unpacked the downloaded

file with the .zip extension

Further information: "Downloading the installation file", Page 12

Run the installation file with the extension .exe

The installation wizard is opened:

2

Figure 1: Installation wizard

Tap Next

In the License Agreement installation step, accept the terms of the license

Tap Next

In the Select Destination Location installation step, the

installation wizard suggests a storage location. We recommend

retaining the suggested storage location.

In the Select Destination Location installation step, select the storage

location to which you want to save QUADRA-CHEK 2000 Demo

Tap Next

In the Select Components installation step, the ScreenshotClient

program is also installed by default. ScreenshotClient enables you

to take screenshots of the active screen.

If you want to install ScreenshotClient

In the Select Components installation step, leave the default

settings unchanged

Further information: "ScreenshotClient", Page 83

In the Select Components installation step:

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

13

Page 14

2

Software Installation | Installing QUADRA-CHEK 2000 Demo under Microsoft Windows

Select the type of installation

Activate or deactivate the option Screenshot Utility

Figure 2: Installation wizard with activated demo software option and Screenshot

Utility

Tap Next

In the Select Start Menu Folder installation step, select the storage location at

which you want to create the start menu folder

Tap Next

In the Select Additional Tasks installation step, select or deselect Desktop

icon

Tap Next

Tap Install

Installation starts—the status of installation is shown in the progress bar

After installation has been completed successfully, use Finish to close the

installation wizard

The program has been successfully installed on your computer

14

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 15

Software Installation | Uninstalling QUADRA-CHEK 2000 Demo

2.5 Uninstalling QUADRA-CHEK 2000 Demo

Select in succession in Microsoft Windows:

Start

All programs

HEIDENHAIN

QUADRA-CHEK 2000 Demo

Tap Uninstall

The uninstallation wizard opens

To confirm unistallation, tap Ja

Unistallation starts, and the progress bar indicates the status of the unistallation

process

After uninstallation has been completed successfully, close the uninstallation

wizard with OK

The program has been successfully removed from your computer

2

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

15

Page 16

Page 17

3

Basic Operation

Page 18

3

Basic Operation | Overview

3.1 Overview

This chapter describes the user interface, operating elements, and basic functions

of QUADRA-CHEK 2000 Demo.

3.2 Using the touchscreen and input devices

3.2.1 Touchscreen and input devices

The operating elements on the user interface from QUADRA-CHEK 2000 Demo

are operated via a touchscreen or a connected mouse.

To enter data, you can use the screen keyboard of the touchscreen or a connected

keyboard keyboard.

18

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 19

Basic Operation | Using the touchscreen and input devices

3.2.2 Gestures and mouse actions

To activate, switch or move the operating elements of the user interface, you can

use QUADRA-CHEK 2000 Demo's touchscreen or a mouse. Gestures are used to

operate the touchscreen and the mouse.

The gestures for operating the touchscreen may differ from the

gestures for operating the mouse.

If the gestures for operating the touchscreen differ from those for

operating the mouse, then these instructions describe both operating

options as alternative actions.

The alternative actions for operating the touchscreen or the mouse are

identified by the following symbols:

Operation using the touchscreen

Operation using the mouse

3

The following overview describes the different gestures for operating the

touchscreen or the mouse:

Tapping

Means touching the screen briefly with your fingertip

Means pressing the left mouse button once

The actions initiated by tapping include

Selection of menus, features or parameters

Entering characters with the screen keyboard

Closing dialogs

Displaying and hiding the main menu in the Measure menu

Displaying and hiding the Inspector in the Measure menu

Holding

Means touching the screen and holding your finger(s) on it for a

few seconds

Means pressing the left mouse button once and holding it

down

The actions initiated by holding are

Quickly changing the values in input fields with plus and

minus buttons

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

19

Page 20

3

Basic Operation | Using the touchscreen and input devices

Dragging

Is a combination of long press and then swipe, moving a finger

over the touchscreen when at least the starting point of motion

is defined

Means pressing the left mouse button once and holding it

down while moving the mouse; at least the starting point of the

motion is defined

The actions initiated by dragging include

Scrolling through lists and texts

Opening the Details dialog in the Inspector

Two-finger drag

Refers to the movement of two fingers across the touchscreen

when at least the starting point of the movement is clearly

defined

Refers to pressing the right mouse button once and holding it

down while moving the mouse; at least the starting point of the

movement is defined

Two-finger dragging initiates the following action

In the Measure menu, moving the features view within the

workspace

20

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 21

Basic Operation | General operating elements and functions

3.3 General operating elements and functions

The operating elements described below are available for configuration and

operating the product via the touchscreen or input devices.

Screen keyboard

With the screen keyboard, you can enter text into the input fields of the user

interface. The displayed screen keyboard is either numeric or alphanumeric,

depending on the input field.

To enter values, tap an input field

The input field is highlighted

The screen keyboard is displayed

Enter text or numbers

In some input fields, a green check mark indicates that the entry is correct

If the entry is incomplete or incorrect, a red exclamation mark is displayed. The

entry cannot be concluded in this case

To apply the values, confirm the entry with RET

The values are displayed

The screen keyboard disappears

3

Input fields with plus and minus buttons

To adjust a numerical value, use the + (plus) and – (minus) buttons to the left and

right of the numerical value.

Tap + or – until the desired value is displayed

Long-press + or – to scroll through the values more

quickly

The selected value is displayed

Toggle switch

Use the toggle switch to switch between functions.

Tap the desired function

The active function is shown in green

The inactive function is shown in light gray

Slide switch

With the sliding switch, you can activate or deactivate a function.

Drag the sliding switch to the desired position or tap the

sliding switch

The function is activated or deactivated

Slider

With the slider, you can continuously adjust values.

Drag the slider to the desired position

The selected value is displayed graphically or in percent

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

21

Page 22

3

Basic Operation | General operating elements and functions

Drop-down list

Buttons that open drop-down lists are indicated by a triangle pointing down.

Tap the button

The drop-down list opens

The active entry is highlighted in green

Tap the desired entry

The selected entry is applied

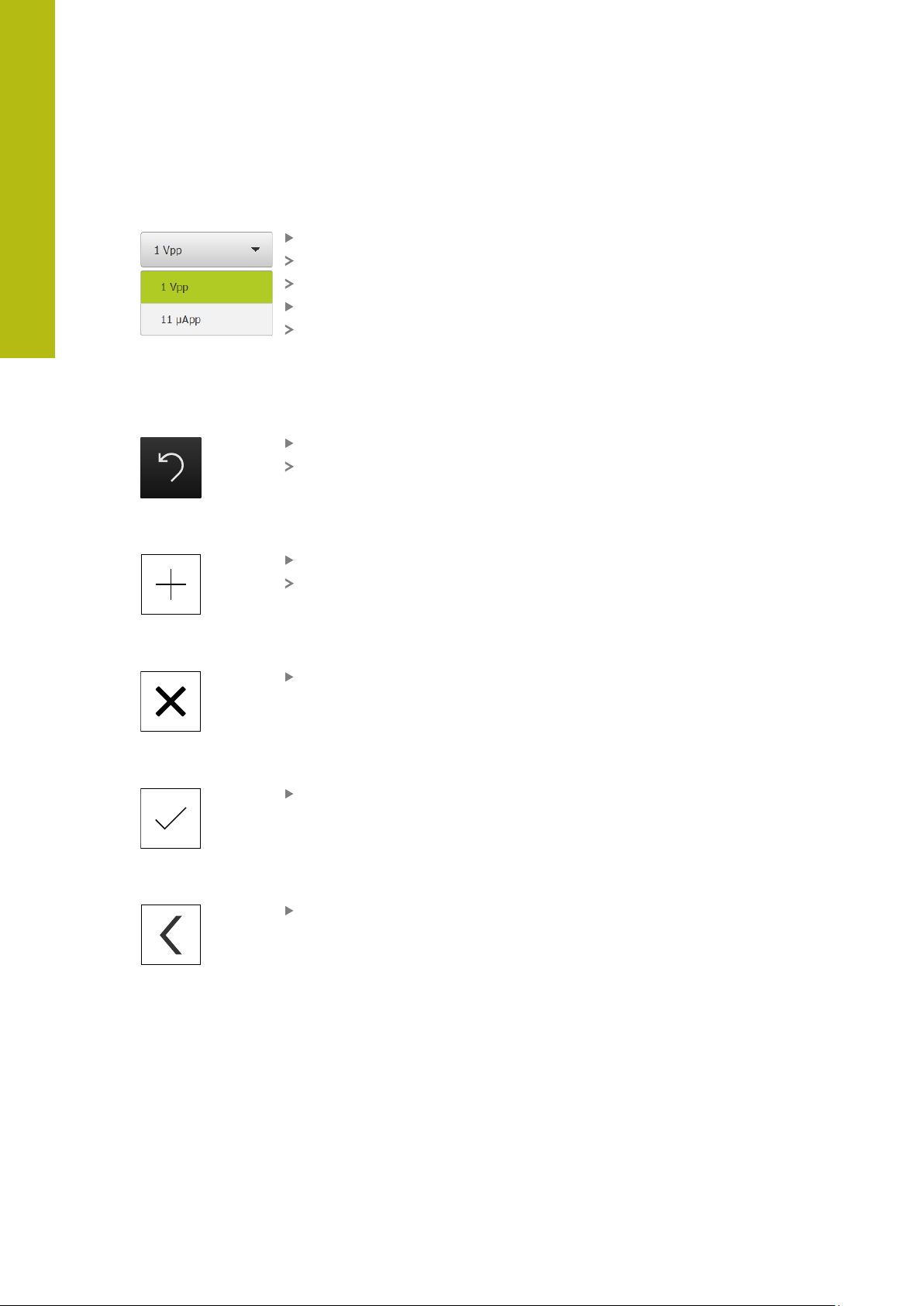

Undo

With this button, you can undo the last action.

Processes that have already been concluded cannot be undone.

Tap Undo

The last action is undone

Add

Close

Confirm

Back

To add a feature, tap Add

The new feature is added

Tap Close to close a dialog

Tap Confirm to conclude an activity

Tap Back to return to the higher level in the menu

structure

22

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 23

Basic Operation | QUADRA-CHEK 2000 Demo – startup and shut-down

3.4 QUADRA-CHEK 2000 Demo – startup and shut-down

3.4.1 Starting QUADRA-CHEK 2000 Demo

Before using QUADRA-CHEK 2000 Demo, you need to perform the

steps for configuring the software.

Tap QUADRA-CHEK 2000 Demo on the Microsoft Windows

desktop

or

Select in succession in Microsoft Windows:

Start

All programs

HEIDENHAIN

QUADRA-CHEK 2000 Demo

3

Two executable files with different modes of

appearance are available:

QUADRA-CHEK 2000 Demostarts within a

Microsoft Windows window

QUADRA-CHEK 2000 Demo (full screen):

starts in full-screen mode

Tap QUADRA-CHEK 2000 Demo or

QUADRA-CHEK 2000 Demo (full screen)

QUADRA-CHEK 2000 Demo starts an output window in the

background. The output window is not relevant for operation

and is closed again when QUADRA-CHEK 2000 Demo is shut

down

QUADRA-CHEK 2000 Demo starts the user interface with

the User login menu

Figure 3: User login menu

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

23

Page 24

3

Basic Operation | QUADRA-CHEK 2000 Demo – startup and shut-down

3.4.2 Shutting down QUADRA-CHEK 2000 Demo

Tap Switch off in the main menu

Tap Shut down

QUADRA-CHEK 2000 Demo is shut down

To shut down QUADRA-CHEK 2000 Demo in the Microsoft Windows

window, also use the Switch-off menu.

If you use Close to close the Microsoft Windows window, all settings

will be lost.

3.5 User login and logout

In the User login menu, you can log in and out of the product as a user.

Only one user can be logged in to the product at a time. The logged-in user is

displayed. Before a new user can log in, the logged-in user has to log out.

The product provides various authorization levels that grant the user full

or restricted access to management and operation functionality.

3.5.1 User login

Tap User login in the main menu

In the drop-down list, select the OEM user

Tap the Password input field

Enter the password "oem" of the OEM user

Confirm entry with RET

Tap Log in

The user is logged in and the Measure menu is displayed

3.5.2 User logout

24

Tap User login in the main menu

Tap Log out

The user is logged out

All functions of the main menu are inactive, except for Switch

off

The product can only be used again after a user has logged in

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 25

Basic Operation | Setting the language

3.6 Setting the language

The default language for the user interface is English. You can switch the user

interface to the desired language.

Tap Settings in the main menu

Tap User

The logged-in user is indicated by a check mark

Select the logged-in user

The language selected for the user is indicated by a national

flag in the Language drop-down list

Select the flag for the desired language in the Language

drop-down list

The user interface is displayed in the selected language

3

3.7 User interface

3.7.1 User interface after Startup

User interface after startup

If automatic user login is active and the last user who logged in was of the

Operator type, the Measure menu with the workspace and the Inspector is

displayed after the product has started up.

If automatic user login is not active, the product opens the User login menu.

Further information: "User login menu", Page 33

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

25

Page 26

3

1

2

0

Basic Operation | User interface

3.7.2 Main menu of the user interface

User interface with QUADRA-CHEK 2000 OED software option

Figure 4: User interface with QUADRA-CHEK 2000 OED software option

1

Message display area, which displays the time and the number of unclosed

messages

2

Main menu with operating elements

Operating elements of the main menu

The main menu is displayed regardless of the activated software options.

Operating

element

Function

Message

Display of an overview of all messages as well as the

number of messages that have not been closed

Measure

Manual measurement, construction, and definition of

features by means of measuring programs and predefined

geometries

Further information: "Measure menu", Page 28

Measurement report

Creation of measurement reports based on templates

Further information: "Measurement report menu",

Page 31

File management

26

Management of the files that are available on the product

Further information: "File management menu",

Page 32

User login

Login and logout of the user

Further information: "User login menu", Page 33

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 27

Basic Operation | User interface

3

Operating

element

Function

Settings

Settings of the unit, such as setting up users, configuring

sensors, and updating the firmware

Further information: "Settings menu ", Page 34

Switch-off

Shutdown of the operating system or activation of energysaving mode

Further information: "Switch-off menu", Page 35

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

27

Page 28

3

1

2

3

4

6 5

Basic Operation | User interface

3.7.3 Measure menu

Activation

Tap Measure in the main menu

The user interface for manual measuring, constructing and

defining is displayed

Measure menu with QUADRA-CHEK 2000 OED software option

Figure 5: Measure menu with QUADRA-CHEK 2000 OED software option

1

The function palette provides functions for manual measuring and defining. The

selected function is displayed as an active operating element.

2

The sensor palette contains the optional sensors (e.g., OED). It is only visible if

the software option is active.

3

The workspace displays, for example, the position display or the input area for

constructing and defining features.

4

The Inspector contains the quick access menu, the position preview, the

features preview, and the feature list or the program step list. The feature list

contains the features that have been measured, constructed, or defined.

5

The geometry palette provides all of the geometries for manual measuring,

constructing, and defining. The geometries are partially combined into

geometry groups. The selected geometry is displayed as an active feature. The

geometries available on the geometry palette depend on the selected function.

6

The tool palette provides the measuring tools required for conducting the

selected measurement.

28

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 29

Basic Operation | User interface

Measure

Define

Operating elements of the function palette

3

Manual

Defining

measuring

Operating elements of the sensor palette

The operating elements of the sensor palette are only available if software options

are active. If one software option is active, the software option is displayed. If

multiple software options are active, you can choose between the options.

Optical edge

detection

(OED)

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

29

Page 30

3

Point

Circle

Arc

Ellipse

Slot

Rectangle

Distance

Angle

Zero point

Alignment

Ref. plane

Crosshair

OED

Auto OED

Basic Operation | User interface

Operating elements of the geometry palette

Measure Magic

Point

Line

Circle Arc Ellipse

Slot Rectangle

Distance Angle

Blob

Zero point Alignment Reference

plane

The Reference plane operating element is only available if

the Z axis is active.

30

Operating elements of the OED tool palette

The operating elements of the tool palette are only available if a software option

is active. They are only displayed in the manual measuring function if optical edge

detection is activated.

Crosshair OED Auto OED

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 31

Basic Operation | User interface

1

2

3

3.7.4 Measurement report menu

Activation

Tap Measurement report in the main menu

The user interface for displaying and creating the

measurement reports appears

Short description

3

Figure 6: Measurement report menu

1

List of default templates

2

Preview of the selected template

3

Display of information on the selected template

In the Measurement report menu, you can select report templates. A list of the

templates is shown in the left-hand column. A preview of the selected template is

displayed in the right-hand column.

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

31

Page 32

3

1

2

Basic Operation | User interface

3.7.5 File management menu

Activation

Tap File management in the main menu

The user interface for file management is displayed

Short description

Figure 7: File management menu

1

List of available storage locations

2

List of folders in the selected storage location

The File management menu shows an overview of the files stored in the unit’s

memory.

32

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 33

Basic Operation | User interface

1

2

3.7.6 User login menu

Activation

Tap User login in the main menu

The user interface for user login and logout is displayed

Short description

3

Figure 8: User login menu

1

Display of the logged-in user

2

User login

The User login menu shows the logged-in user in the column on the left. The login

of a new user is displayed in the right-hand column.

To log in another user, the logged-in user must first log out.

Further information: "User login and logout", Page 24

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

33

Page 34

3

1 2

Basic Operation | User interface

3.7.7 Settings menu

Activation

Tap Settings in the main menu

The user interface for the device settings is displayed

Short description

Figure 9: Settings menu

1

List of setting options

2

List of setting parameters

The Settings menu shows all options for configuring the product. With the setting

parameters, you can adapt the product to on-site requirements.

The product provides various authorization levels that grant the user full

or restricted access to management and operation functionality.

34

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 35

Basic Operation | User interface

X

R

R

3.7.8 Switch-off menu

Activation

Tap Switch off in the main menu

The operating elements for shutting down the operating

system, for activating the energy-saving mode and for

activating the cleaning mode are displayed

Short description

The Switch off menu provides the following options:

3

Operating

element

Further information: "QUADRA-CHEK 2000 Demo – startup and shut-down",

Page 23

Function

Shut down

Shuts down QUADRA-CHEK 2000 Demo

Energy saving mode

Switches the screen off and puts the operating system into

energy-saving mode

Cleaning mode

Switches the screen off; the operating system continues

unchanged

3.8 Position display

The unit’s position display shows the axis positions and additional information

about the configured axes (if applicable).

3.8.1 Operating elements of the position display

Symbol Meaning

Axis key

Axis key functions:

Tapping the axis key: Opens the input field for position value

Holding down the axis key: sets the current position as zero

point

Reference mark search performed successfully

Reference mark search not performed or no reference mark

detected

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

35

Page 36

3

Basic Operation | Working in the workspace

3.9 Working in the workspace

The workspace is only available in the Measure menu.

Activation

Tap Measure in the main menu

The user interface for manual measuring, constructing and

defining is displayed

3.9.1 Operating elements in the workspace

Operating elements of the manual measuring function for adjusting the

features view in the case of reduced workspace

Display

annotations

Zoom functions

Regardless of the size of the workspace, the available functions are gathered

together in the Zoom functions.

Zoom

functions

Operating elements of the definition function

Depending on the selected geometry, the input fields required for definition are

displayed in the workspace.

Settings

Zoom to all Zoom to

selection

Magnify

graphic

Reduce

graphic

36

Figure 10: Operating elements of the Define function for the Circle geometry

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 37

Basic Operation | Using the Inspector

3.10 Using the Inspector

The Inspector is only available in the Measure menu.

Activation

Tap Measure in the main menu

The user interface for measuring, constructing and defining is

displayed

3.10.1 Operating elements of the Inspector

3

Operating

element

Short description

Quick access menu

The quick access menu displays the current settings for

manual measuring, constructing and defining:

Unit of measurement for linear values (millimeters or

inches)

Magnification used

Type of measuring point acquisition (automatic or

manual)

Coordinate system used

To adjust the settings of the quick access menu, tap the

quick access menu

Position preview

The position preview is only available in the manual

measuring function.

The current axis positions are displayed. If no reference

mark search has been performed, the axis positions are

displayed in red.

To display the position preview in the workspace, tap

the Position preview

The position preview is displayed in the workspace

The current content of the workspace switches to the

Inspector

Features preview

The features preview is available only in the measuring

function.

The features preview displays a reduced view of the

measured, constructed and, defined features.

To display the features view in the workspace, tap

Features preview

The features view is displayed in the workspace

The current content of the workspace switches to the

Inspector

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

37

Page 38

3

1

2

3

45

Basic Operation | Using the Inspector

Operating

element

Short description

Feature list

The feature list contains a list of all features that have been

measured, constructed, or defined. The feature list provides

the following information:

1: Measured feature with symbol, name, and

consecutive number

2: Function that was used for creating the feature

Symbol Meaning

Measured feature

Constructed feature

Defined feature

3: Concludes the measuring point acquisition

4: Number of measuring points that have been acquired

5: Newly acquired feature with symbol

Each feature contains details on the measurement results

as well as selectable tolerances.

To display the measured values and adjust the

tolerances, drag a feature into the workspace

The detail window with the Overview and Tolerance

tabs opens in the workspace

To select or deselect features, tap the features in

succession

The selected features are highlighted in green

To delete a feature, drag the feature to the right and out

of the Inspector

Measurement result preview

The measurement result preview is displayed in the

workspace after a measurement process is concluded and

shows information about the measured feature. For each

geometry time, it is possible to define which parameters

are shown in the measurement result preview. The respective geometry type determines which parameters are available.

38

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 39

Basic Operation | Using the Inspector

3

Operating

element

Short description

Program step list

The program step list shows all actions that occur during

the measurement. It is displayed instead of the feature list

in the Inspector.

The program steps can be combined and saved as measuring programs.

Auxiliary functions

The auxiliary functions contain the following functions:

Switching the display between feature list and program

step list

Creating, saving, and opening a program

Calling the program control in the workspace

Opening and saving a coordinate system

Deleting selected features or all features from the

feature list

Feature selection

Multiple selection of features of the same geometry type

Tap Feature selection

To select all features of a geometry type in the feature

list, tap the desired geometry type

Confirm with OK

The selected features are highlighted in green

Enter

Acquisition of measuring points with the following options:

If measuring point acquisition is deactivated, then the

measuring points will be acquired manually

If automatic measuring point acquisition is active, then

a red dot will be shown in the operating element. The

measuring points will be acquired after expiration of the

set timeout

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

39

Page 40

3

Crosshair

OED

Auto OED

Basic Operation | Using measuring tools

3.11 Using measuring tools

The operating elements of the tool palette are only available if an optical

sensor is active. They are shown in the manual measuring function with

the following views of the workspace:

With OED optical sensor, if the position display or the features view is

in the workspace

3.11.1 Measuring tools

Depending on the optical sensor, various measuring tools are available for

acquiring the measuring points. The measuring tools can be operated by gestures

in the workspace.

OED measuring tools

Symbol Measuring tool Functions and characteristics

Crosshair Manual acquisition of single measuring points

No automatic acquisition of light-to-dark transitions

OED Active measuring tool

Acquisition of light-to-dark transitions

Buffering of a single measuring point (manual

confirmation required)

If the OED sensor traverses an edge, a measuring

point is buffered in the clipboard. If the OED sensor

traverses a further edge, the buffered measuring

point is overwritten. By tapping Enter, the previously

buffered measuring point is added to the feature calculation.

Auto OED Active measuring tool

Automatic acquisition of measuring points, e.g. on

circles and circular arcs

Acquisition of light-to-dark transitions

If the OED sensor traverses an edge, a measuring

point is automatically acquired and added to the

feature calculation.

40

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 41

4

Software

Configuration

Page 42

4

Software Configuration | Overview

4.1 Overview

Make sure that you have read and understood the "Basic Operation"

chapter before carrying out the actions described below.

Further information: "Basic Operation", Page 17

Before you can use QUADRA-CHEK 2000 Demo correctly after successful

installation, you need to configure QUADRA-CHEK 2000 Demo. This chapter

describes how to perform the following settings:

Activating a license key

Copying the configuration file

Uploading the configuration file

Setting the language

Selecting the product version (optional)

42

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 43

Software Configuration | Activating a license key

4.2 Activating a license key

With QUADRA-CHEK 2000 Demo, you can also simulate functions that are

dependent on a software option. To do so, you must enable the software option

with a license key. The required license key is stored in a license file in the folder

structure of QUADRA-CHEK 2000 Demo.

You must upload the license file in order to enable the available software options.

Tap Settings in the main menu

The unit’s settings appear

4

Figure 11: Settings menu

Tap Service

Open in the sequence

Software options

Activate options

Tap Read license file

Select the storage location in the dialog:

Select Internal

Select User

Select the PcDemoLicense.xml license file

Confirm your selection with OK

Tap OK

The license key is activated

Tap OK

You are prompted to restart

Use Cancel to deny restarting

The functions dependent on the software options are

available

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

43

Page 44

4

Software Configuration | Copying the configuration file

4.3 Copying the configuration file

Before you can load the configuration data in QUADRA-CHEK 2000 Demo, you

must first copy the downloaded configuration file DemoBackup.mcc to an area

that can be accessed by QUADRA-CHEK 2000 Demo.

Move to the temporary storage folder

For example, copy the configuration file DemoBackup.mcc to the following

folders:C: HEIDENHAIN [product name] Metrology ProductsMGE5

[product designation] user User

In order for QUADRA-CHEK 2000 Demo to access the

configuration file DemoBackup.mcc, you must retain the following

part of the path when you save the file: [product name]

ProductsMGE5 Metrology [product abbreviation] user

User.

The configuration file can be accessed by QUADRA-CHEK 2000 Demo

44

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 45

Software Configuration | Uploading the configuration file

4.4 Uploading the configuration file

Before you can upload the configuration data, you must first activate

the license key.

Further information: "Activating a license key", Page 43

In order to configure QUADRA-CHEK 2000 Demo for the application on the

computer, you must upload the configuration file DemoBackup.mcc.

Tap Settings in the main menu

The product settings are displayed

4

Figure 12: Settings menu

Tap Service

Open in the sequence

Back up and restore

Restore settings

Complete restoration

Select the storage location in the dialog:

Internal

User

Select the DemoBackup.mcc configuration file

Confirm your selection with OK

The settings are applied

You are prompted to shut down the application

Tap OK

QUADRA-CHEK 2000 Demo is shut down, and the Microsoft

Windows window is closed

Restart QUADRA-CHEK 2000 Demo

QUADRA-CHEK 2000 Demo is ready for use

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

45

Page 46

4

Software Configuration | Setting the language

4.5 Setting the language

The default language for the user interface is English. You can switch the user

interface to the desired language.

Tap Settings in the main menu

Tap User

The logged-in user is indicated by a check mark

Select the logged-in user

The language selected for the user is indicated by a national

flag in the Language drop-down list

Select the flag for the desired language in the Language

drop-down list

The user interface is displayed in the selected language

4.6 Selecting the product version (optional)

QUADRA-CHEK 2000 is available in different versions. These versions differ in their

interfaces for connectible encoders:

QUADRA-CHEK 2013 version for encoders with 1 VPP interface

QUADRA-CHEK 2023 version for encoders with TTL interface

The QUADRA-CHEK 2093 version for encoders with various interfaces (1 V

and TTL)

In the Settings menu, you can select the version that is to be simulated with

QUADRA-CHEK 2000 Demo

Tap Settings in the main menu

Tap Service

Tap Product designation

Select the desired version

You are now prompted to perform a restart

QUADRA-CHEK 2000 Demo is ready for use in the desired

version

PP

46

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 47

5

Quick Start

Page 48

5

Quick Start | Overview

5.1 Overview

In this chapter an example is used to describe the steps of a typical measuring

sequence. The steps range e.g. from aligning the measured object and measuring

the features through to creating the measurement report.

For a detailed description of the individual activities, please refer to the

"Measuring," "Measurement evaluation" and "Measurement reports"

chapters in the QUADRA-CHEK 2000 operating instructions.

Make sure that you have read and understood the "Basic Operation"

chapter before carrying out the actions described below.

Further information: "Basic Operation", Page 17

48

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 49

Quick Start | Conducting a measurement

5.2 Conducting a measurement

5.2.1 Measuring with an OED sensor

The measurements shown here cannot be simulated with QUADRACHEK 2000 Demo, because the corresponding measuring point

acquisition is not possible without a measuring device and OED sensor.

However, you can use the descriptions to familiarize yourself with the

most important functions and the user interface.

For the measurement of edges and contours with an OED sensor, various

measuring tools are available to you for the acquisition of measuring points.

Further information: "Measuring tools", Page 40

Aligning the measured object

Before you can evaluate the measuring points, you need to align the measured

object. During this process, the coordinate system of the measured object

(workpiece coordinate system) is determined, which is specified in the technical

drawing.

This makes it possible to compare the measured values with the data in the

technical drawing and assess them.

5

Figure 13: Example of aligning a 2-D demo part

Measured objects are usually aligned in the following steps:

1 Measuring the alignment

2 Measuring a straight line

3 Constructing the zero point

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

49

Page 50

5

Quick Start | Conducting a measurement

Measuring the alignment

Define the reference edge for the alignment according to the technical drawing.

Tap Measure in the main menu

Select Manual measuring in the function palette

If multiple sensors are activated, then select OED sensor in

the sensor palette

The geometry palette and the OED measuring tools are now

displayed

The workspace now shows the position display

In the quick access menu, select the magnification that is set

on the measuring machine

Select Alignment in the geometry palette

Select Auto OED in the tool palette

Cross over the reference edge multiple times with the OED

sensor

A new feature is displayed in the feature list of the Inspector

A new measuring point is added for each pass over the

reference edge

Distribute the measuring points along the entire

length of the edge, as far as possible. This

minimizes the angular error.

Tap Finish in the new feature

The alignment is displayed in the feature list of the Inspector

The measurement result preview is now displayed

50

Figure 14: Alignment feature in the feature list with Measurement result preview

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 51

Quick Start | Conducting a measurement

Measuring a straight line

A straight line is measured as the second reference edge.

Select Line in the geometry palette

Select Auto OED in the tool palette

Cross over the reference edge multiple times with the OED

sensor

A new feature is displayed in the feature list of the Inspector

A new measuring point is added for each pass over the

reference edge

Distribute the measuring points along the entire

length of the edge, as far as possible. This

minimizes the angular error.

5

Tap Finish in the new feature

The line is displayed in the feature list of the Inspector

The measurement result preview is now displayed

Figure 15: Line feature in the feature list with Measurement result preview

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

51

Page 52

5

Quick Start | Conducting a measurement

Constructing the zero point

The zero point is constructed from the point of intersection between the alignment

and the straight line.

Select Zero point in the geometry palette

Select the Alignment and Line features in the Inspector or in

the features view

The selected features are displayed in green

A new feature with the selected geometry is displayed

Tap Finish in the new feature

The zero point is created

The workpiece coordinate system for the measured object

has been determined

Tap Features preview

The coordinate system is shown in the workspace

52

Figure 16: Workspace with zero point displayed in the coordinate system

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 53

Quick Start | Conducting a measurement

Measuring features

To measure features, you can use the geometries of the geometry palette.

5

Figure 17: Examples of measuring a 2-D demo part

The section below describes measuring the following features:

1 Circle

2 Slot

3 Blob

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

53

Page 54

5

Quick Start | Conducting a measurement

Measuring a circle

A minimum of three measuring points is required to measure a circle. For

measuring point acquisition, you can use the OED measuring tool, for example.

Tap Measure in the main menu

Select Manual measuring in the function palette

If multiple sensors are activated, then select OED sensor in

the sensor palette

The geometry palette and the OED measuring tools are

displayed

The workspace now shows the position display

In the quick access menu, select the magnification that is set

on the measuring machine

Select Measure Magic in the geometry palette

or

Select Circle in the geometry palette

Select OED in the tool palette

Cross over the edge of the circle with the OED sensor

multiple times

The unit records the measuring point in the clipboard

To confirm the measuring point acquisition, tap Enter in the

Inspector

A new feature is displayed in the feature list

A new measuring point is recorded every time

you cross over an edge of the feature to be

measured using the OED sensor. The clipboard

is updated with the newly recorded measuring

point. If you tap Enter in the Inspector, then only

the most recently acquired measuring point is

confirmed.

To acquire more than one measuring point along the edge,

repeat the process

Tap Finish in the new feature

A new feature is calculated from the captured measuring

points and the selected geometry

The measured circle is displayed in the features preview

The measurement result preview is now displayed

54

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 55

Quick Start | Conducting a measurement

5

Figure 18: Circle feature in the feature list with Measurement result preview

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

55

Page 56

5

Quick Start | Conducting a measurement

Measuring a slot

A minimum of five measuring points is required in order to measure a slot. For

measuring point acquisition, you can use the Auto OED measuring tool, for

example. Place at least two measuring points on the first long side and one

measuring point on the second long side, and at least one measuring point on

each arc of the slot. You can capture the points in any sequence.

Select Slot in the geometry palette

Select Auto OED in the tool palette

Cross over the edge of the slot multiple times with the OED

sensor

A new feature is displayed in the feature list

A new measuring point is added for each pass over the

reference edge

Distribute the measuring points along the entire

length of the first side, as far as possible.

Tap Finish in the new feature

A new feature is calculated from the captured measuring

points and the selected geometry

The measured slot is displayed in the features preview

The measurement result preview is now displayed

56

Figure 19: Slot feature in the feature list with Measurement result preview

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 57

Quick Start | Conducting a measurement

Measuring a blob

A minimum of three measuring points is required to measure a blob. For

measuring point acquisition, you can use theAuto OED measuring tool, for

example. Multiple measuring points are automatically distributed along the entire

contour according to the specified settings.

Select Blob in the geometry palette

Select Auto OED in the tool palette

Cross over the edge of the blob multiple times with the OED

sensor

A new feature is displayed in the feature list

A new measuring point is added for each pass over the

reference edge

Distribute the measuring points as evenly as

possible along the contour of the feature.

5

Tap Finish in the new feature

A new feature is calculated from the captured measuring

points and the selected geometry

The measured blob is displayed in the features preview

The measurement result preview is now displayed

Figure 20: Blob feature in the feature list with Measurement result preview

5.2.2 Displaying and editing the measurement results

You can edit the measured features immediately after capturing the measuring

points. Drag individual features into the workspace and edit them in the Details

dialog.

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

57

Page 58

5

1 2

3

4

7

9

6

8

5

Quick Start | Conducting a measurement

Short description

Figure 21: Overview tab in the Details dialog

1

Name of the feature

2

Axis positions of the center point

3

The coordinate system to which the coordinate values of the feature are

referenced

4

Feature parameter dependent on the geometry type: For the circle geometry

type, it is possible to switch between radius and diameter

5

Number of measuring points used for calculating the feature

6

Fitting algorithm used for calculating the feature; depends on the geometry and

the number of measuring points

7

Informational text field; if an annotation is active, then its contents are shown in

the features view as an annotation

8

List of geometry types to which the feature can be converted

9

View of the measuring points and the form

Renaming a feature

Drag the feature from the feature list into the workspace

The Details dialog appears with the Overview tab selected

Tap the input field containing the current name

Enter a new name for the feature

Confirm entry with RET

The new name is displayed in the feature list

Tap Close to close the dialog

58

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 59

Quick Start | Conducting a measurement

Changing the Fitting algorithm

You can adjust the fitting algorithm depending on the measured feature. The

Gaussian fitting algorithm is used by default.

Move a feature (e.g., a Circle) from the features list into the

workspace

The Details dialog appears with the Overview tab selected

The fitting algorithm used is shown in the Fitting algorithm

drop-down list

In the Fitting algorithm drop-down list, select the desired

fitting algorithm (e.g., Min. circumscribed)

The feature is displayed according to the selected fitting

algorithm

5

Figure 22: Circle feature with new fitting algorithm

Tap Close to close the dialog

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

59

Page 60

5

Quick Start | Conducting a measurement

Converting a feature

The feature can be converted to a different type of geometry. The list of possible

geometry types is provided as a drop-down list in the Details dialog.

Drag the Slot feature from the feature list into the workspace

The Details dialog appears with the Overview tab selected

The geometry type of the feature is displayed

In the New type of geometry drop-down list, select the

Point type of geometry

The 2-D profile geometry type is currently not

yet supported.

The feature is displayed in the new form

Figure 23: Type of geometry changed from Slot to Point

Tap Close to close the dialog

60

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 61

Quick Start | Conducting a measurement

1

2

3

Changing Tolerances

On the Tolerances tab, you can adjust the tolerances for a measured feature. The

tolerances are grouped.

5

Figure 24: Details dialog with Tolerances tab

1

Display of general tolerance

2

List of tolerances, depending on feature

3

Status of the tolerance: Active and within the tolerance or active and outside

the tolerance

In the Tolerances tab, you can define the geometrical tolerancing of a feature. The

tolerances are grouped.

Drag a feature (e.g., Circle) from the feature list into the

workspace

The Details dialog appears with the Overview tab

Tap the Tolerances tab

The tab for tolerancing the selected feature is displayed

Tap the size tolerance X

An overview of the selected size tolerance appears

Figure 25: Overview of Size tolerance with activated size

tolerance X

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

61

Page 62

5

Quick Start | Conducting a measurement

Activate tolerancing of the measured value with the ON/OFF

slide switch

The selection and input fields become active

Tap the Nominal dimension input field and enter 76.2

Confirm entry with RET

Tap the Upper tolerance input field and enter 0.1

Confirm entry with RET

Tap the Lower tolerance input field and enter 0.1

Confirm entry with RET

The nominal value is shown in red if it is out of tolerance

The nominal value is shown in green if it is within tolerance

Tap Back

The Tolerances tab is displayed

Symbols are used to display the result of the tolerance check

on the Tolerances tab and, after closing the dialog, in the

feature list

Activated tolerances are maintained

One or more activated tolerances are exceeded

62

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 63

Quick Start | Conducting a measurement

1

2

3

4

Adding annotations

You can add an annotation to every feature in the features view (e.g.,

measurement information or informational texts).

5

Figure 26: Operating elements for annotations and feature with annotations

1

Edit annotations operating element

2

Operating elements for adding annotations

3

Measurement information

4

Explanatory text

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

63

Page 64

5

Quick Start | Conducting a measurement

5.2.3 Creating a measurement report

You can create a measurement report in four steps:

"Selecting the template and features"

"Entering information on the measuring task"

"Selecting document settings"

"Exporting a measurement report"

Selecting the template and features

Tap Measurement report in the main menu

The user interface for editing the measurement reports

appears

Select the Standard template

The preview of the selected template is displayed

Tap Create to create the measurement report

The Features menu appears with a list of all features that

have been measured, constructed, and defined

To add all features to the measurement report, tap Select all

in the Select drop-down list

All features in the list and in the features preview are

activated and displayed in green

64

Figure 27: Measurement report menu with feature list and features

view

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 65

Quick Start | Conducting a measurement

Filtering features

You can filter the feature list in the Features menu by various criteria. By this

means, only those features are shown that fulfill the filter criteria (e.g., only circles

with a certain minimum diameter).

You can use any combination of filters.

Tap the Filter drop-down list

Select the desired filter criterion in the dialog

Select the operator

Select the function

In order to deactivate a filter criterion, deselect it

Tap Close to activate the filter criteria

5

Filter precondition

Type

Size

Tolerance

Selection

Operator Function

Is

Is not

Equal

Greater than

Less than

Is

Is not

Is

Is not

Only features of the selected geometry type

are shown.

Only features of the non-selected geometry

type are shown.

Only features of the specified size are shown.

Only features that are larger than the specified

size are shown.

Only features that are smaller than the speci-

fied size are shown.

Only features that fulfill the selected character-

istic are shown:

Passed

Failed

Inactive

Only features that do not fulfill the selected

characteristic are shown.

Only the selected features are shown.

Only the non-selected features are shown.

Creation type

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Is

Is not

Only features that fulfill the selected characteristic are shown.

Only features that do not fulfill the selected

characteristic are shown.

65

Page 66

5

Quick Start | Conducting a measurement

Entering information on the measuring task

The information entered depends on the configuration of the template.

Tap the Information menu

In the Job input field, enter Demo1 to identify the measurement job

Confirm entry with RET

Enter the part number 681047-02 of the measured object into the Part number

input field

Confirm entry with RET

Selecting document settings

Tap the Document menu

Select the YYYY-MM-DD hh:mm (date and time) format in the Date and time

format drop-down list

Tap the Preview menu

The preview of the measurement report is displayed

66

Figure 28: Preview of the measurement report

Exporting a measurement report

Measurement reports can be exported as PDF or CSV files.

Select the Export as PDF export format in the Export drop-down list

Select the Internal/Reports storage location in the dialog

Enter the name Demo1 for the measurement report

Confirm entry with RET

Tap Save as

The measurement report is exported in the selected format and stored in the

storage location

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 67

Quick Start | Conducting a measurement

Canceling a measurement report or closing it after saving

Tap Close

Close the message with OK

The measurement report is closed

Opening a measurement report

In the File management main menu, you can open the saved report.

Tap File management in the main menu

Select the Internal/Reports storage location

Select the desired Demo1.pdf file

A preview image as well as information about the file are

displayed

5

Figure 29: Preview of the measurement report and file information

To display the measurement report, tap View

The file contents are displayed

Tap Close to close the view

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

67

Page 68

Page 69

6

Measurement

Report Template

Page 70

6

1

2

3

Measurement Report Template | Overview

6.1 Overview

This chapter describes how you can create your own measurement report

templates with QUADRA-CHEK 2000 Demo and transfer them to your unit so that

you can use the templates for creating measurement reports on your unit.

Make sure that you have read and understood the "Basic Operation"

chapter before carrying out the actions described below.

Further information: "Basic Operation", Page 17

Short description

In the Measurement report menu, you can create detailed reports for your

measuring tasks. You can document one or more measured features in a

measurement report. The measurement reports can be printed, exported and

saved. For the creation of measurement reports, you can choose between several

standard templates.

With the QUADRA-CHEK 2000 Demo PC software, you can create your own

report templates and then transfer them to your unit. Your own custom templates

then appear next to the standard templates in the Measurement report menu and

can be used for creating measurement reports.

Activation

Tap Measurement report in the main menu

70

Figure 30: Measurement report menu

1

List of default templates

2

Preview of the selected template

3

Display of information on the selected template

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 71

Measurement Report Template | Creating and editing a template

6.2 Creating and editing a template

With the editor, you can create your own custom measurement report templates:

Opening a new template with the editor

Editing the default settings for the measurement report

Configuring the page header

Configuring the report header

Defining the data for the measurement report

Saving the template

6

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

71

Page 72

6

Measurement Report Template | Creating and editing a template

6.2.1 Opening a new template with the editor

Tap Measurement report in the main menu

Maximize the window of the software on the computer

screen

The Add button appears in the list of templates

Figure 31: Measurement report menu with the list of templates and the Add button

Tap Add to create a new template

The Default settings for the template are displayed

Figure 32: Editor for measurement report templates

72

HEIDENHAIN | QUADRA-CHEK 2000 Demo | User's Manual | 06/2018

Page 73