Page 1

User’s Manual

ND 720

ND 760

Position Display Units

for Milling Machines

English (en)

12/2001

Page 2

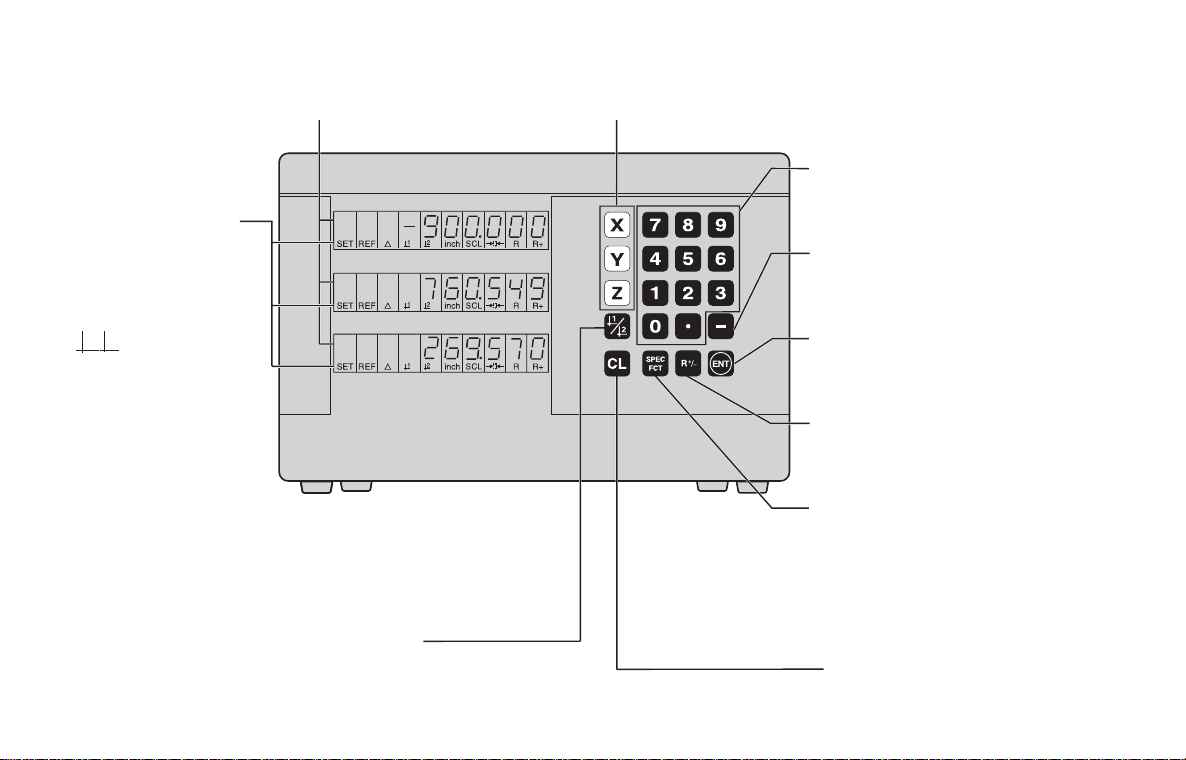

Position display

(ND 720 only two axes)

Select coordinate axes

(ND 720 only X and Y)

Select axis-specific operating parameters

Status display:

SET = Datum setting

REF = blinking:

Traverse the

reference points.

On continuously:

Reference points

have been traversed.

D = Distance-to-go display

1 2 Datum 1 or 2

Inch = Display in inches

SCL = Scaling factor

->❘❘<- = Probing an edge /

centerline

R = Radius/diameter display

R+/ = Radius compensation

• Select datum 1 or 2

• Page backward in the list of

special functions

• Page backward in the list of

parameters

HEIDENHAIN

Numerical input

• Change the algebraic sign

• Call the last dialog

• Edit parameters in the

list of parameters

• Confirm entry

• Page forward in the

list of parameters

Call radius compensation

of the current tool

• Select special functions

• Page forward in the

list of special functions

• Cancel entry

• Reset the operating mode

• Zero the selected axis

(if activated in P80)

• Select parameters

CL plus two-digit number

Page 3

This manual is for the ND display units with the

following software numbers or higher:

Part I Operating Instructions

ND 720 for two axes 246 271-07

ND 760 for three axes 246 271-07

About this manual

This manual is divided into two parts:

Part I: Operating Instructions

Fundamentals of positioning

ND functions

Part II: Installation and Specifications

Mounting the display unit on the machine

Description of operating parameters

Switching inputs, switching outputs

Fundamentals 4

Switch-On, Traversing the Reference Marks 9

Datum Setting 10

Datum setting with the tool 11

Datum setting with the KT Edge Finder 13

Tool Compensation 20

Moving the Axes with Distance-To-Go 21

Bolt Hole Circles and Bolt Hole Circle Segments 23

Linear Hole Patterns 26

Working with a Scaling Factor 29

Error Messages 30

Part II

Installation and

Specifications Page 31

and following

Part I Operating Instructions

3

Page 4

Fundamentals

You can skip this chapter if you are already familiar with

coordinate systems, incremental and absolute dimensions,

nominal positions, actual positions and distance-to-go.

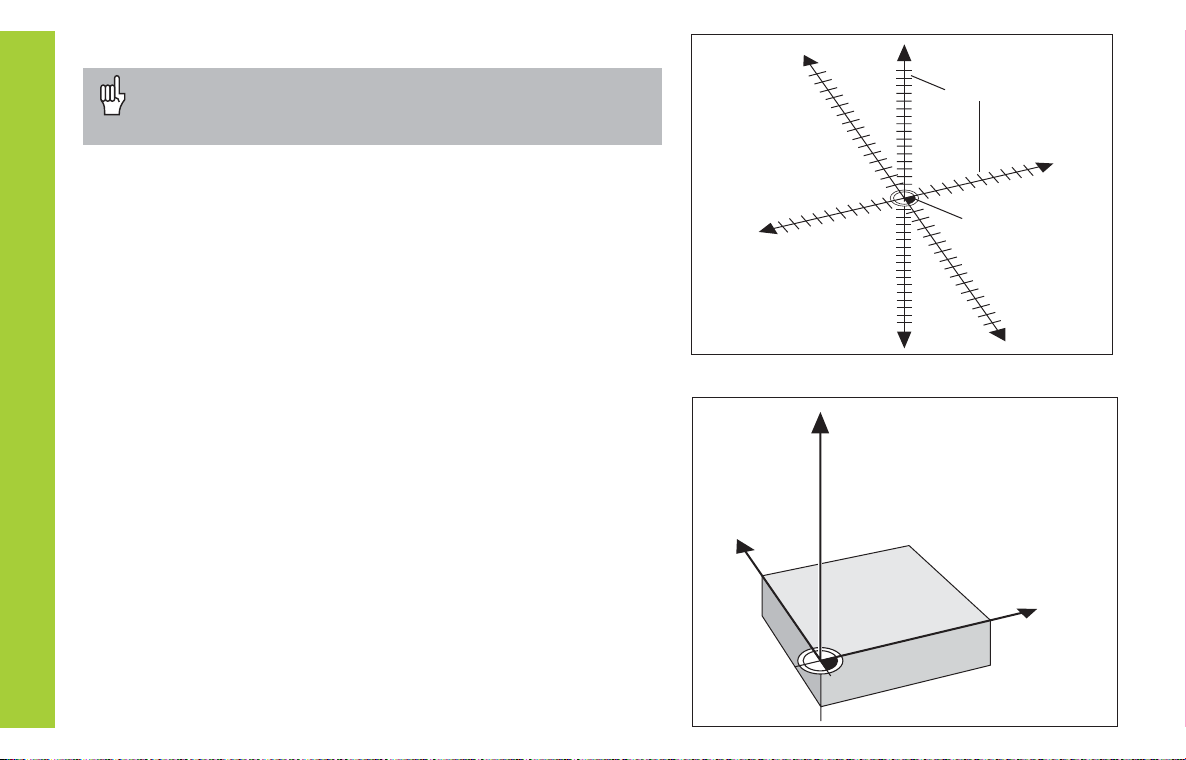

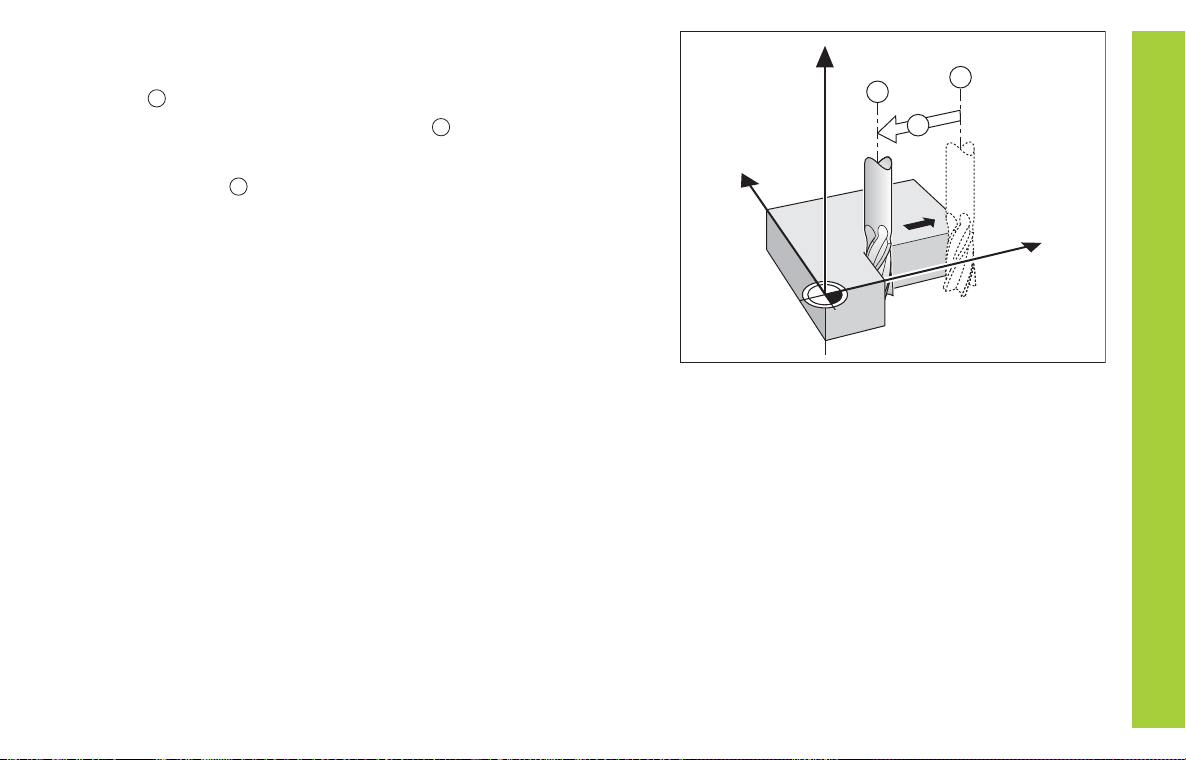

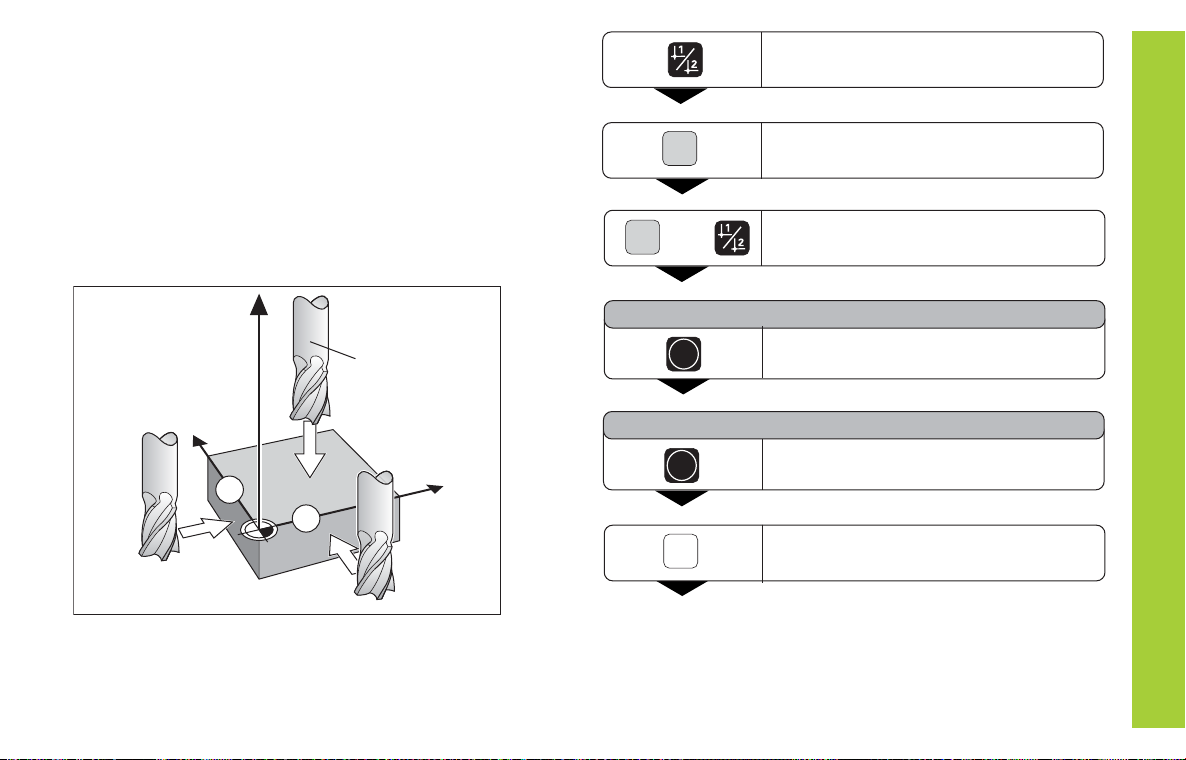

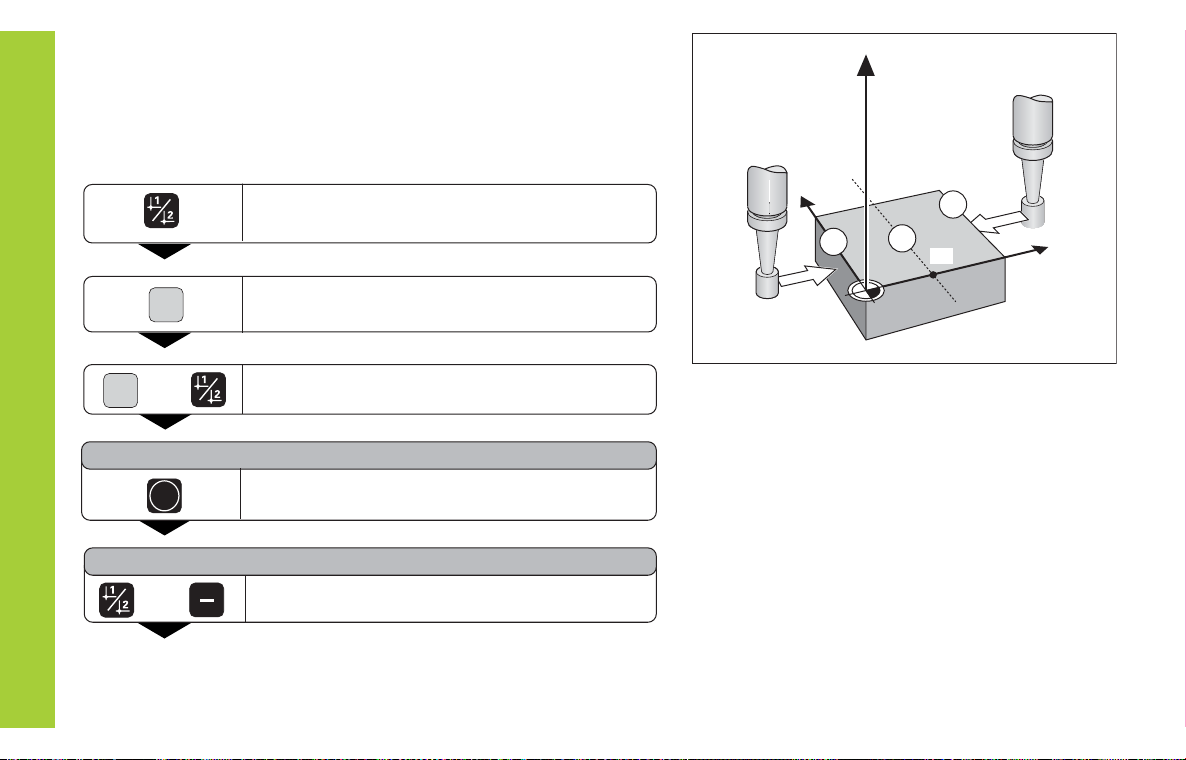

Coordinate system

The Cartesian

Fundamentals

a workpiece. The Cartesian coordinate system consists of three

mutually perpendicular axes X, Y and Z. The point of intersection of

these axes is called the datum or origin of the coordinate system.

Think of the axes as scales with divisions (usually in millimeters) which

allow us to fix points in space referenced to the datum.

To determine positions on a workpiece, the coordinate system is

laid onto the workpiece.

The machine axes are parallel to the axes of the coordinate system.

The Z axis is normally the tool axis.

1)

coordinate system is used to describe the geometry of

Y

–X

+Y

+Z

Graduation

+X

Datum or

origin

–Z

–Y

Z

X

1)

4

Named in honor of the French mathematician and philosopher

René Descartes (1596 to 1650)

Page 5

Datum setting

The workpiece drawing is used as the basis for machining the

workpiece. To enable the dimensions in the drawing to be converted

into traverse distances of machine axes X, Y and Z, each drawing

dimension requires a datum or reference point on the workpiece

(since a position can only be defined in relationship to another

position).

The workpiece drawing always indicates one absolute datum (the

datum for absolute dimensions). However, it may contain additional

relative datums.

In the context of a numerical position display unit, datum setting

means bringing the workpiece and the tool into a defined position in

relation to each other and then setting the axis displays to the value

that corresponds to that position. This establishes a fixed relationship

between the actual positions of the axes and the displayed positions.

You can set 9 absolute datum points and store them in nonvolatile

memory.

1225

750

320

Absolute

datum

0

700

125

216,5

900

950

250

216,5

125

0

-125

-216,5

Relative

datum

250

Fundamentals

-250

-250

-125

-216,5

150

0

-150

0

300±0,1

0

0

325

450

5

Page 6

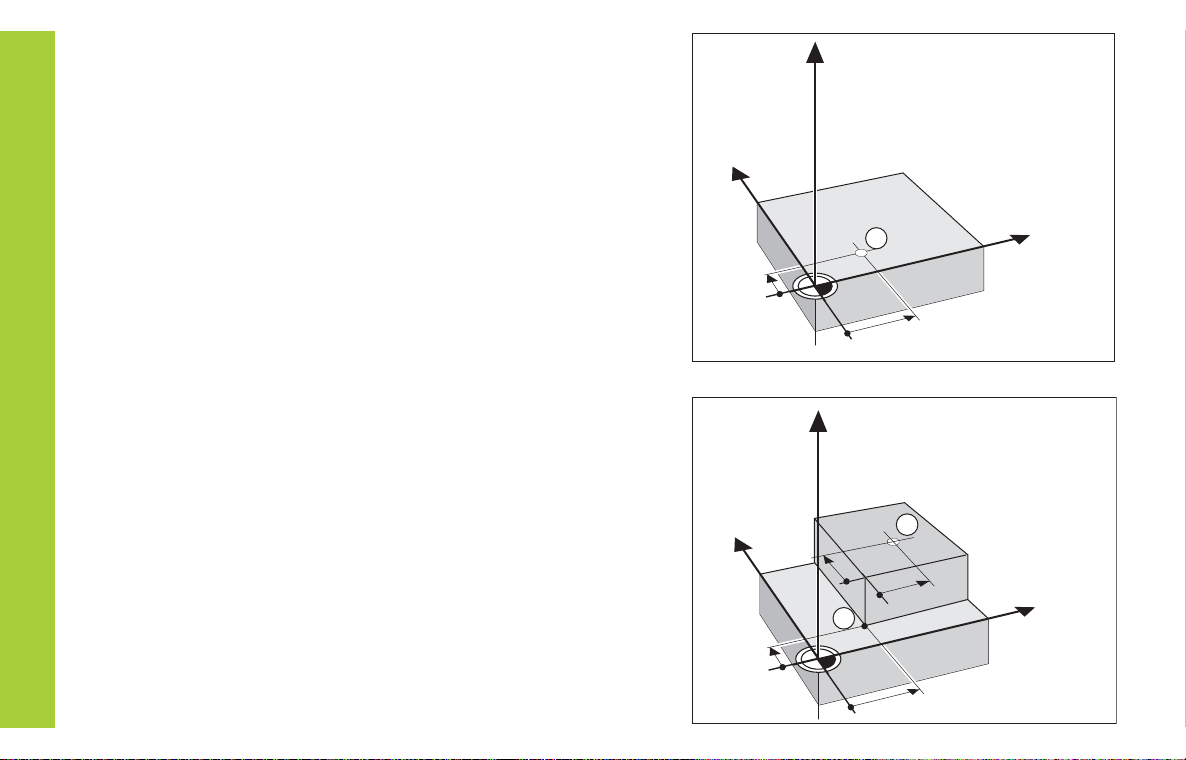

Absolute workpiece positions

Each position on the workpiece is uniquely defined by its absolute

coordinates.

Example Absolute coordinates of position 1:

Fundamentals

If you are working according to a workpiece drawing with absolute

dimensions, then you are moving the tool to the coordinates.

Relative workpiece positions

A position can also be defined relative to the previous nominal

position. The datum for the dimension is then located at the previous

nominal position. Such coordinates are termed relative coordinates or

chain dimensions. Incremental coordinates are indicated by a

preceding I.

Example Relative coordinate of position 2 referenced to

If you are working according to a workpiece drawing with incremental

dimensions, then you are moving the tool by the dimensions.

Sign for incremental dimensioning

A relative dimension has a positive sign when the axis is moved in the

positive direction, and a negative sign when it is moved in the

negative direction.

6

X = 10 mm

Y = 5 mm

Z = 0 mm

position 1

:

IX = 10 mm

IY = 10 mm

Z

Y

X

1

5

10

Z

Y

10

1

5

2

10

1

10

X

Page 7

Nominal position, actual position and distance-to-go

The position to which the tool is to move is called the nominal

S

position (

given moment is called the actual position (I).

The distance from the nominal position to the actual position is called

the distance-to-go (

Sign for distance-to-go

When you are using the distance-to-go display, the nominal position

becomes the relative datum (display value 0). The distance-to-go is

therefore negative when the tool moves in the positive axis direction,

and positive when it moves in the negative axis direction.

). The position at which the tool is actually located at any

).

R

Y

Z

I

S

R

X

Fundamentals

7

Page 8

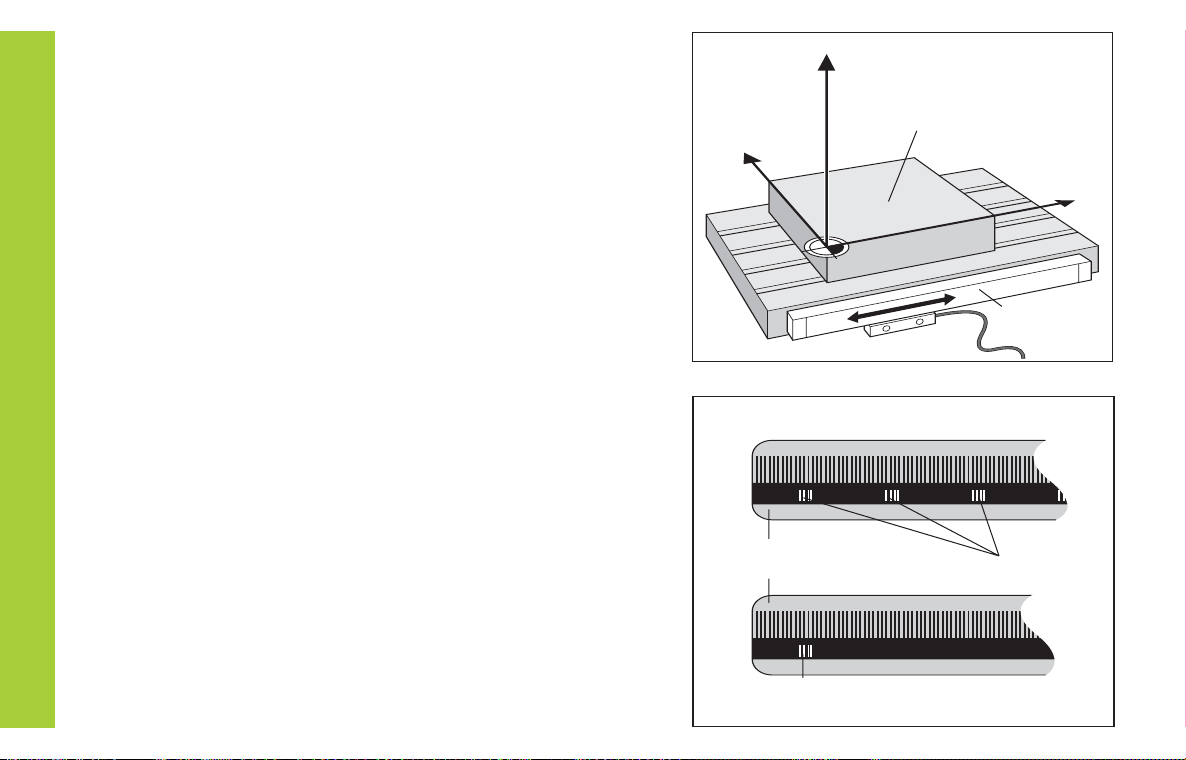

Position encoders

The position encoders on the machine convert the movements of the

machine axes into electrical signals. The ND display unit evaluates

these signals, determines the actual position of the machine axes and

displays the position as a numerical value.

Z

Y

Workpiece

If the power is interrupted, the relationship between the machine axis

positions and the calculated actual positions is lost. The reference

Fundamentals

marks on the position encoders and the REF reference mark

evaluation feature enable the ND to quickly reestablish this

relationship again when the power is restored.

Reference marks

The scales of the position encoders contain one or more reference

marks. When a reference mark is crossed over, a signal is generated

which identifies that position as a reference point (scale datum =

machine datum).

When this reference mark is crossed over, the ND's reference mark

evaluation feature (REF) restores the relationship between axis slide

positions and display values which you last defined by setting the

datum. If the linear encoders have distance-coded reference marks,

you only need to move the machine axes a maximum of 20 mm to do

this.

8

X

Position encoder

Scale in Distance-coded

linear encoder reference marks

Reference marks

Page 9

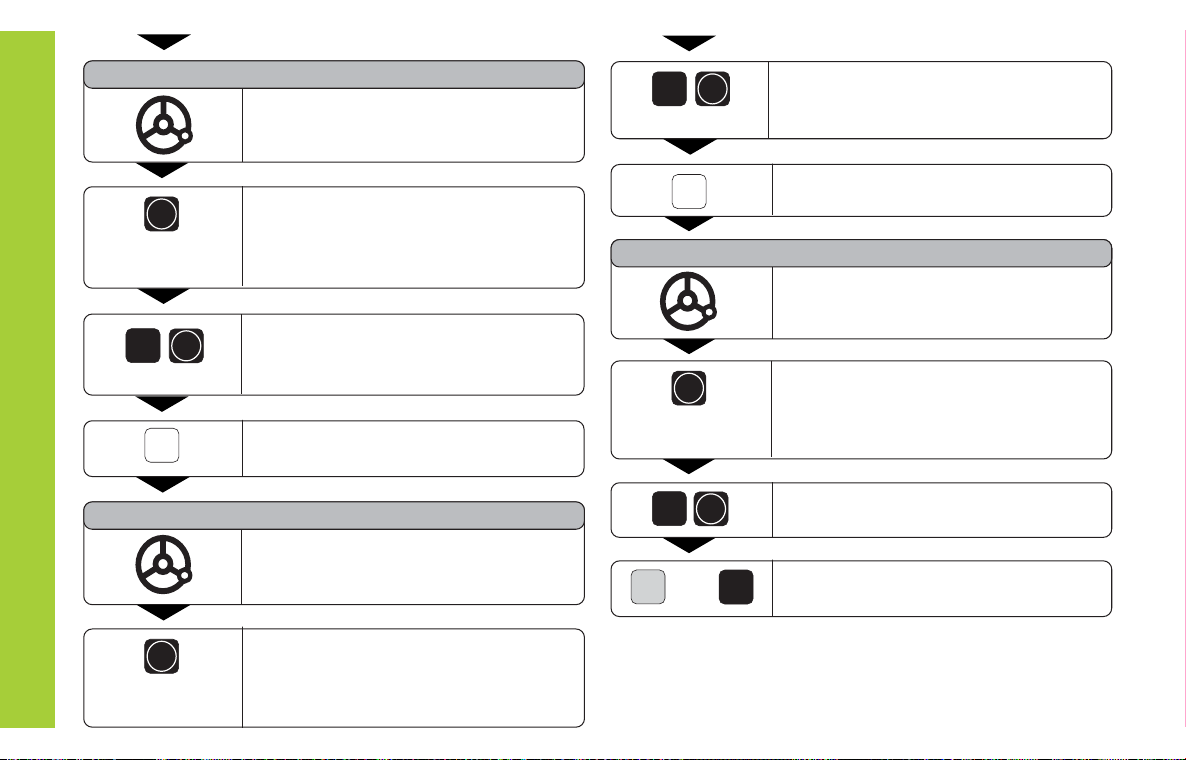

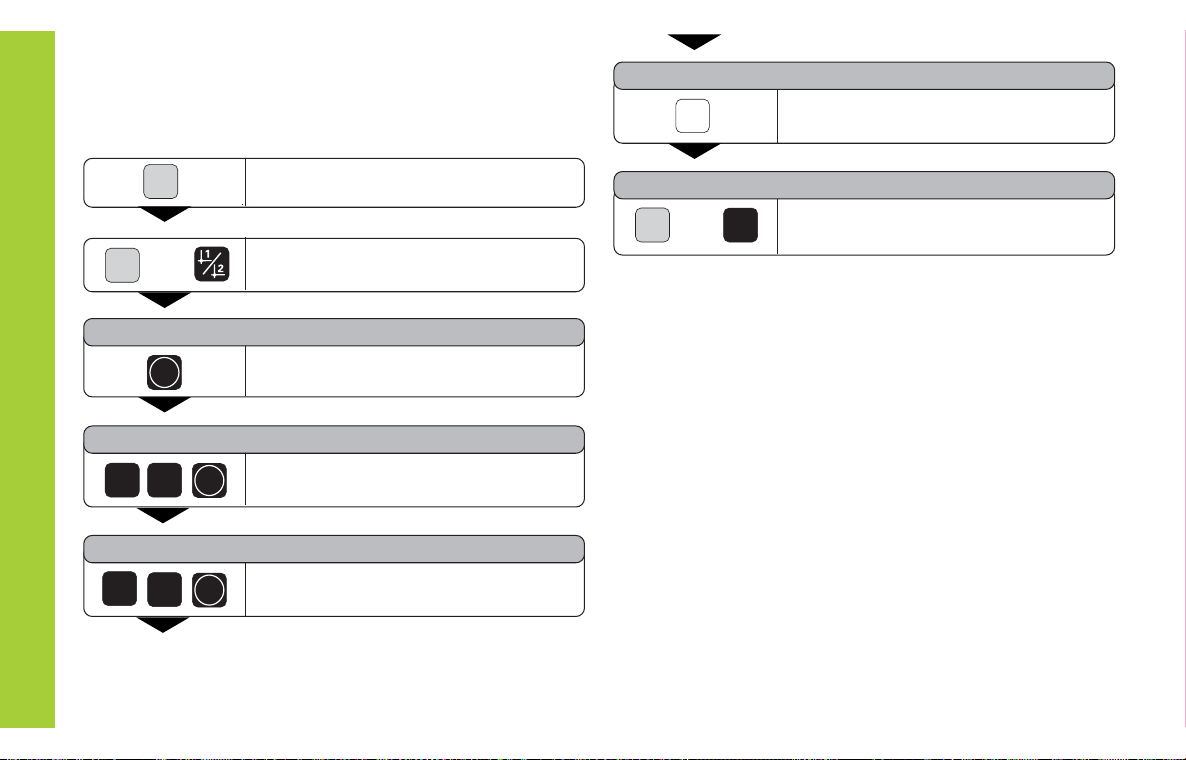

Switch-On, Traversing the Reference Marks

0 è 1

ENT...CL

ENT

Crossing over the reference marks stores the most recently defined

assignment of display values to axis slide positions for datum points 1

and 2 in nonvolatile memory.

Note that if you choose not to traverse the reference marks (by

clearing the dialog ENT ... CL with the CL key), this relationship will be

lost if the power is interrupted or when the unit is switched off.

If you wish to use multipoint axis error compensation you

must traverse the reference marks (see Multipoint axis error

compensation)!

Turn on power (switch located on rear panel).

REF in status display starts blinking.

Confirm reference traverse mode. REF

remains on continuously. Decimal points start

blinking.

Cross over the reference marks in all axes in any

sequence. Each axis display becomes active

when its reference mark is crossed over.

Switch-On, Traversing the Reference Marks

9

Page 10

Datum Setting

If you want to save the datum points in nonvolatile

memory, you must first cross over the reference

marks.

Only after crossing over the reference marks can you set

new datums or activate existing ones.

Datum Setting

In P70, you can select:

Two datum points: The selected datum point

is displayed via 1 or 2

Nine datum points: The selected datum point

is displayed in the lowest axis via d1 to d9.

There are two ways to set datums:

Touch the workpiece with the tool and then set the desired

datum (see example). You can also touch two edges and set

the centerline between them as a datum. The dimensions of

the tool used for this are automatically accounted for (see

Tool Compensation).

Probe the workpiece with the edge finder and then set the

desired datum. You can also probe two edges and set the

centerline between them as a datum, or touch the inside of a

circle and set the circle center as a datum (see examples).

The stylus radius and length are automatically accounted for

if they have been entered in parameters P25 and P26,

respectively (see Operating Parameters).

To call a datum you have set, proceed as follows:

You have set two datum points in P70:

Select datum 1 or 2.

You have set nine datum points in P70:

Press the datum key (d starts

blinking).

ENT

1

Enter a datum number (1 to 9).

10

Page 11

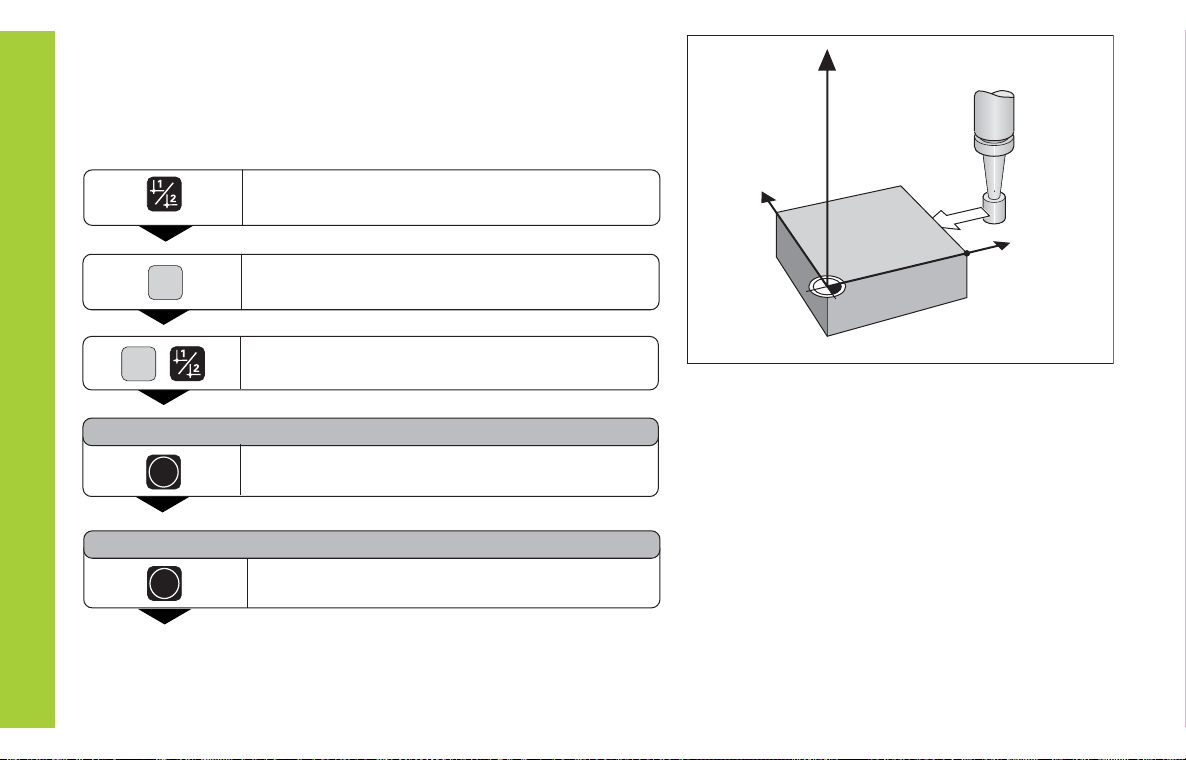

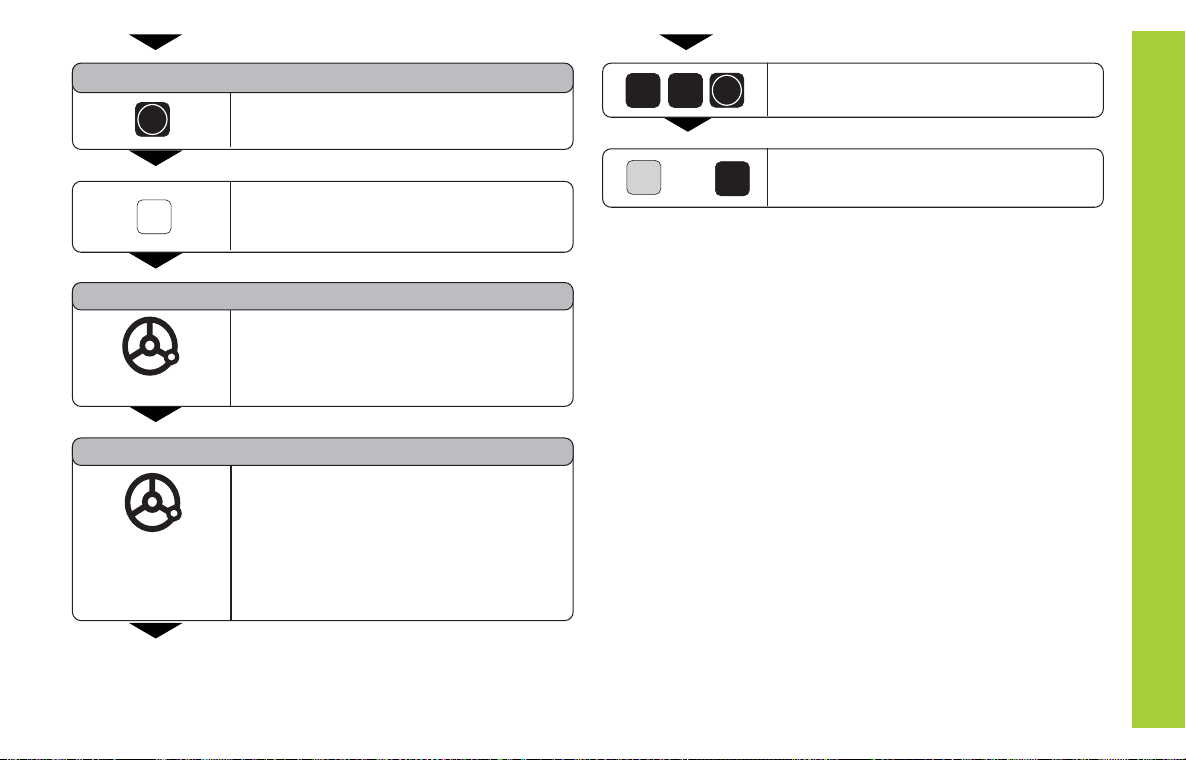

Datum setting with the tool

Example:

Select a datum number (see page 10).

Working plane X / Y

Tool axis Z

Tool radius R = 5 mm

Axis sequence X Y Z

for datum setting

Z

R=5mm

Y

1

2

Select the special functions.

Select the probing function.

Datum Setting

SPEC

FCT

SPEC

FCT

or

PROBING

ENT

Confirm selection.

PROBE EDGE

X

ENT

Confirm Probe edge.

Select X axis (if not already selected).

X

SET lights. The ❘<- symbol starts to blink.

11

Page 12

PROBE X (appears only briefly)

Touch workpiece edge 1 with the tool.

ENT

0

Enter position value for the datum

in the Y axis. Tool radius is automatically

compensated.

Datum Setting

0

PROBE Y (appears only briefly)

12

ENT

Y

ENT

1)

X position is captured. SET edge is

Z

The ❘<- status symbol starts blinking.

Select the Z axis. SET lights.

shown briefly. SET starts blinking.

Retract tool from workpiece.

The ❘<- status symbol lights.

PROBE Z (appears only briefly)

1)

Touch the top of the workpiece with the

tool.

ENT

Enter position value for the datum.

Tool radius is automatically

compensated.

ENT

Z position is captured. SET edge is

shown briefly. SET starts blinking.

1)

Retract the tool from the workpiece.

Select the Y axis. SET lights.

The ❘<- status symbol lights.

The ❘<- status symbol starts blinking.

ENT

0

Enter the position value for the datum in

the Z axis.

1)

Touch workpiece edge 2 with the tool.

SPEC

FCT

or

After setting the datum, exit the probing

CL

functions.

Y position is captured. SET edge is

shown briefly. SET starts blinking.

Retract tool from workpiece.

The ❘<- status symbol lights.

1)

only with ND 760

Page 13

Datum setting with the KT Edge Finder

The ND position display units provide the following probing functions:

PROBE EDGE Setting a workpiece edge as datum

PROBE MIDPOINT Setting a midpoint between two

workpiece edges as datum

PROBE CIRCLE Setting the center of a circle as datum

The probing functions are accessible in the SPEC FCT mode of

operation.

Before using the edge finder you must enter the stylus diameter and

length in parameters P25 and P26, respectively (see Operating

Parameters).

During all probing functions, the ND position display unit accounts for

the entered dimensions.

The PROBE EDGE, PROBE MIDPOINT and PROBE CIRCLE

functions are described on the following pages.

Datum Setting

13

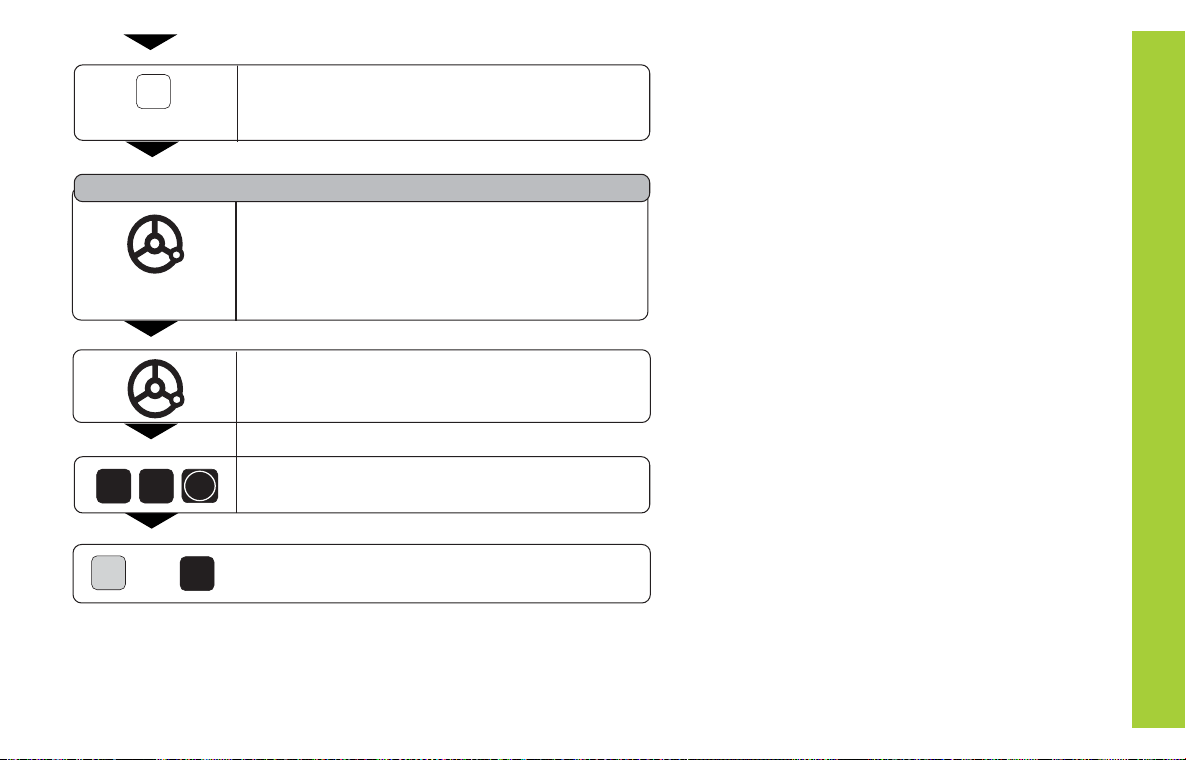

Page 14

Probing a workpiece edge to find a datum

The edge to be probed is parallel to the Y axis. You can probe edges

and surfaces as described below to set all the coordinates of a datum.

Z

Datum Setting

SPEC

FCT

PROBING

PROBE EDGE

14

SPEC

FCT

ENT

ENT

Select a datum number (see page 10).

Select the special functions.

Select the probing function.

Confirm the probing function.

Confirm probe edge function.

Y

X?

X

Page 15

X

PROBE X (appears only briefly)

5

2

Select the X axis (if not already selected).

SET lights. The ❘< status symbol

starts blinking.

Move the edge finder to edge of workpiece until

indicator in edge finder lights. SET edge is

shown briefly. SET starts blinking. The ND

displays the position of the edge. The ❘< status

symbol lights.

Back the edge finder away from the workpiece.

Assign a position value to this edge, e.g. 52.

ENT

Datum Setting

SPEC

FCT

or

Exit the probing function.

CL

15

Page 16

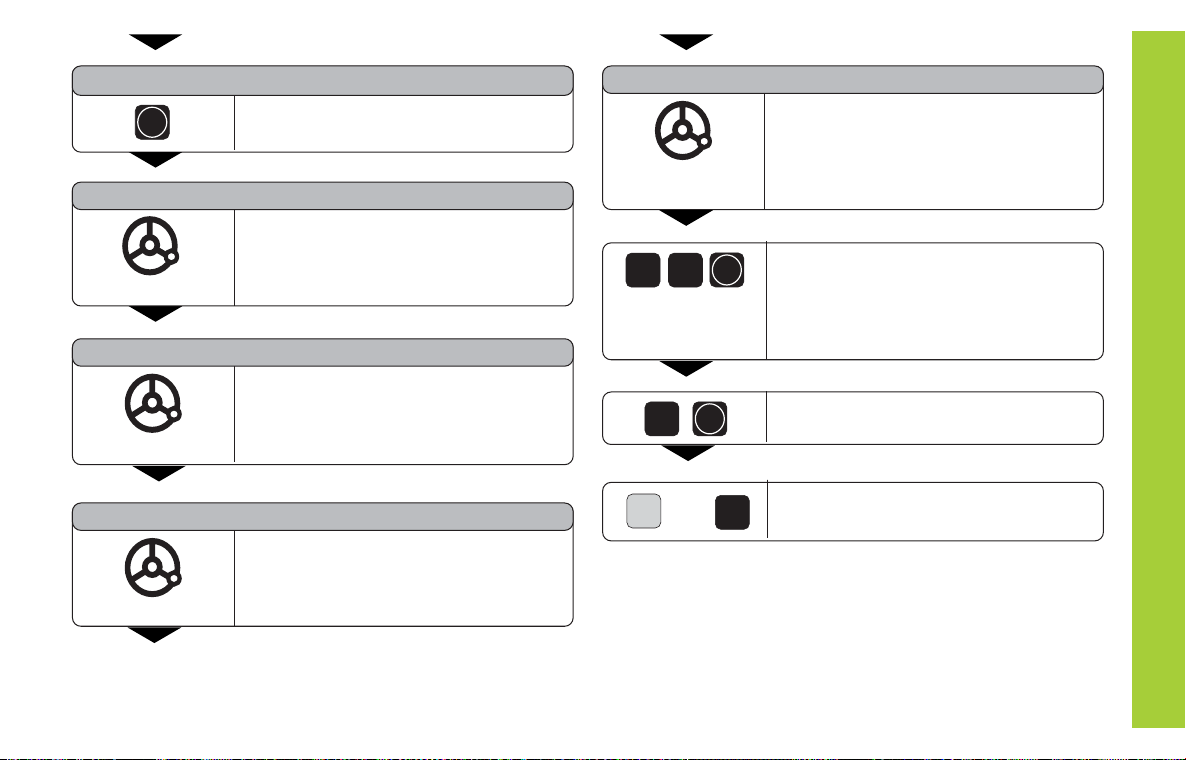

Probing workpiece edges to find a midpoint datum

The edges to be probed run parallel to the Y axis.

Follow the procedure below for all midpoints between two edges.

Z

Datum Setting

SPEC

FCT

PROBING

PROBE EDGE

ANTASTEN MITTE

or

16

SPEC

or

ENT

FCT

Select a datum number (see page 10).

1

2

M

X?

X

Select the special functions.

Select the probing function.

Confirm the probing function.

Select the midpoint probing function.

Y

Page 17

PROBE MIDP.

ENT

Confirm the probe midpoint function.

SET lights.

Set the position value for the midpoint

2

ENT

6

between the edges, e.g. 26.

Select the X axis (if not already selected).

X

1ST POS X (appears only briefly)

2ND POS X (appears only briefly)

The ->❘❘<- status symbol starts blinking.

Move edge finder toward workpiece

edge 1 until the indicator in the edge

finder lights. Back edge finder away

from the workpiece.

Move edge finder toward workpiece

edge 2 until the indicator in the edge

finder lights. SET MIDPOINT is

shown briefly. SET begins to blink.

Back the edge finder away from the

workpiece. The ->❘❘<- symbol begins to

blink.

SPEC

FCT

or

Exit the probing functions.

CL

Datum Setting

17

Page 18

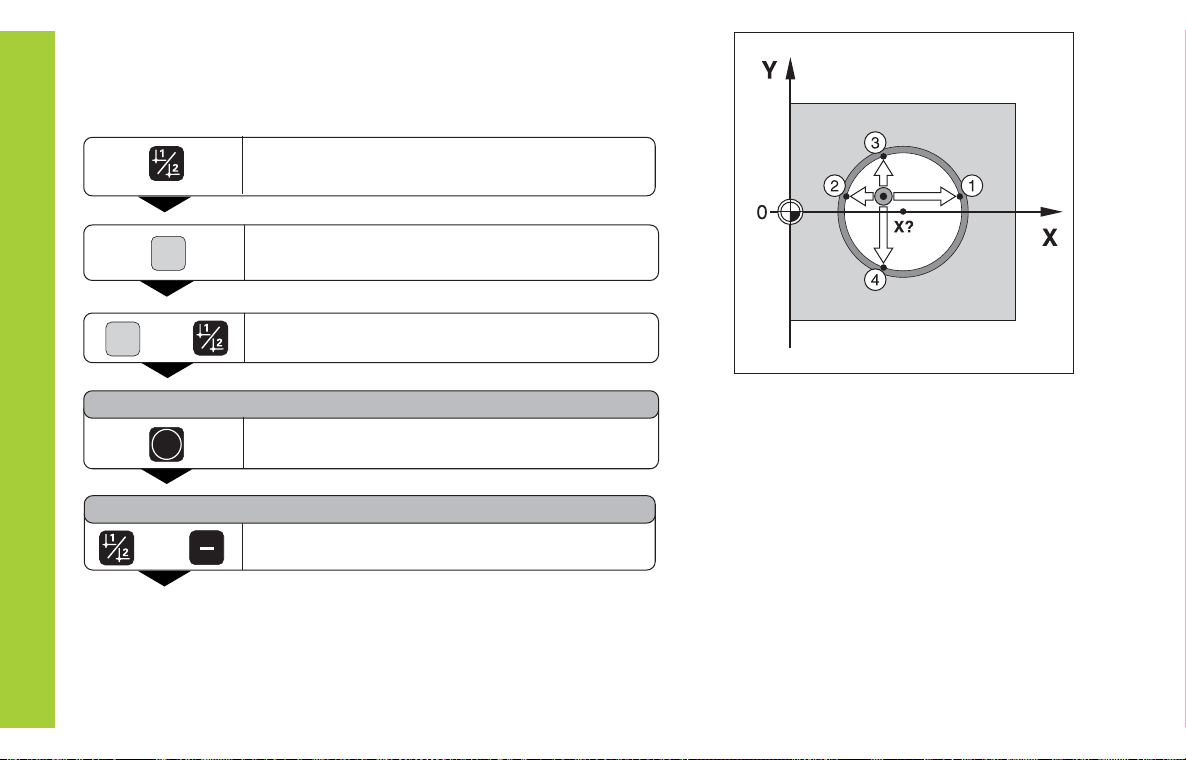

Probing the inside of a circle to set its center as datum

To determine the circle center, the tool must probe four points. The

points to be probed are located in the X-Y plane.

Select a datum number (see page 10).

Datum Setting

SPEC

FCT

PROBING

PROBE CIRC.

ANTASTEN MITTE

or

18

or

SPEC

FCT

ENT

Select the special functions.

Select the probing function.

Confirm the probing function.

Select the circle probing function.

Page 19

PROBE CIRC.

ENT

1ST POS X (appears only briefly)

2ND POS X (appears only briefly)

Confirm Probe circle.

Move edge finder toward position 1

until the indicator in the edge finder

lights. Back edge finder away from

workpiece.

Move edge finder toward position 2

until the indicator in the edge finder

lights. Back edge finder away from

workpiece.

4TH POS Y (appears only briefly)

Move edge finder toward

position 4 until the indicator in the

edge finder lights. CENTER X is

shown briefly. The SET status display

starts to blink in the X axis.

Enter position value for the

2

0

ENT

6

ENT

X coordinate of circle center, e.g. 26.

CENTER Y is shown briefly. The SET

status display starts to blink in the Y

axis.

Enter position value for the Y coordinate

of circle center, e.g. 0.

Datum Setting

3RD POS Y (appears only briefly)

Move edge finder toward position 3

until the indicator in the edge finder

lights. Back edge finder away from

workpiece.

SPEC

FCT

or

Exit the probing functions.

CL

19

Page 20

Tool Compensation

You can enter the axis, length and diameter of the current tool.

SPEC

Tool Compensation

FCT

TOOL DATA

TOOL DIAM.

2

TOOL LENGTH

5

20

1)

only with ND 760

SPEC

FCT

or

ENT

TOOL AXIS

Set the tool axis.

Exit the special functions.

CL

Select the special functions.

Z

TOOL AXIS

SPEC

or

FCT

Select tool data.

Confirm tool data input mode.

0

0

and confirm with ENT.

Enter the tool length, e.g. 50 mm,

ENT

and confirm with ENT.

1)

Enter the tool diameter, e.g. 20 mm,

ENT

Page 21

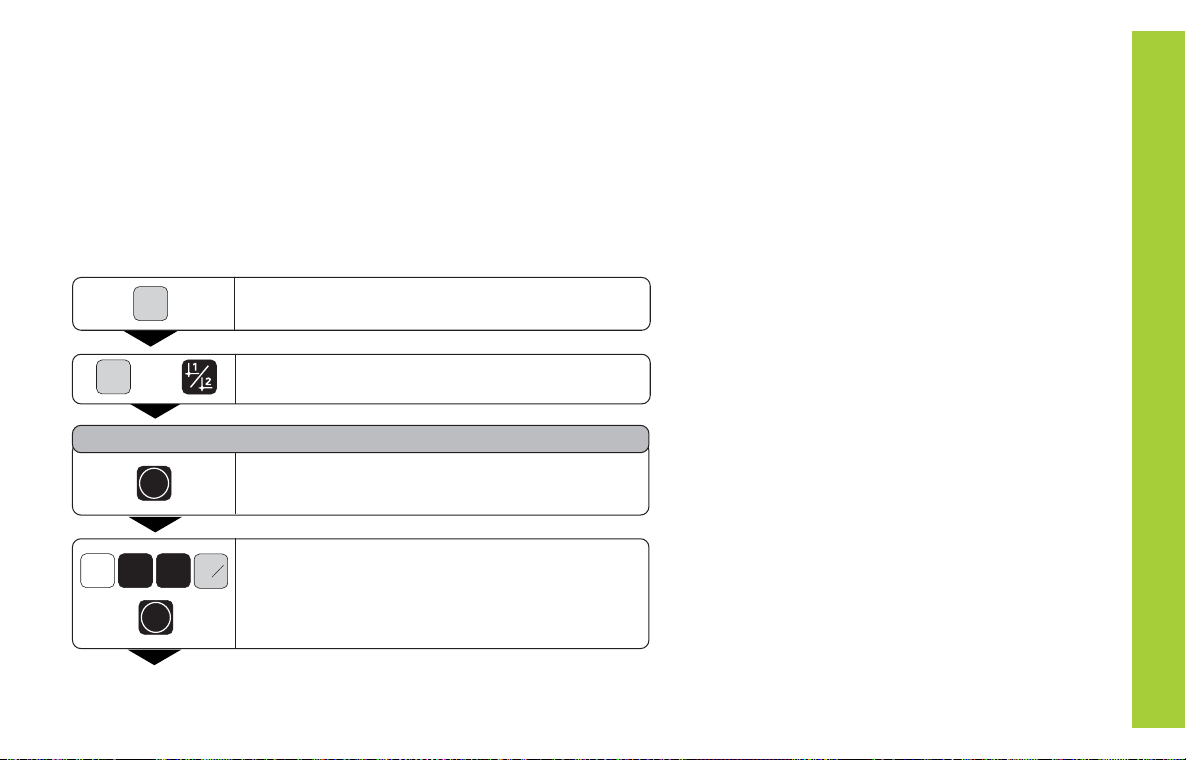

Moving the Axes with Distance-To-Go Display

Normally, the display shows the actual position of the tool. However, it

is often more helpful to display the distance remaining to the nominal

position (the distance-to-go). You can then position simply by moving

the axis until the display value is zero.

You can enter the absolute coordinates in the distance-to-go display.

An active radius compensation will be considered.

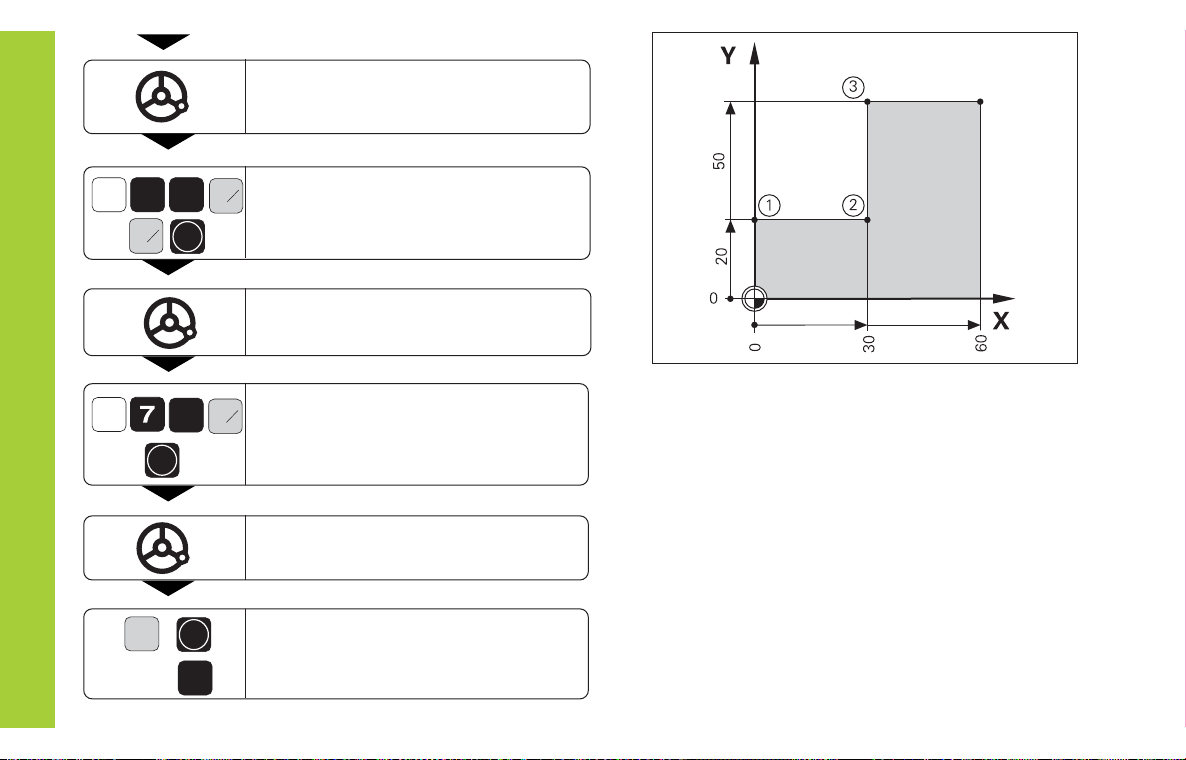

Example: Milling a shoulder with distance-to-go

SPEC

FCT

SPEC

or

FCT

DELTA MODE

ENT

0

2

Y

ENT

Select the special functions.

Select delta mode.

Confirm your selection, the D symbol lights.

Select the axis, enter the nominal value,

+

R

-

e.g. 20 mm, select radius compensation R+,

confirm with ENT.

Moving the Axes with Distance-To-Go Display

21

Page 22

Moving the Axes with Distance-To-Go Display

X

Y

Move the machine axis to zero (1).

Select the axis, enter the nominal value,

+

R

03

-

e.g. 30 mm, select radius compensation

+

ENT

R

-

R, and confirm with ENT.

Move the machine axis to zero (2).

Select the axis, enter the nominal

+

R

0

-

value, e.g. 70 mm, select radius

ENT

compensation R+, confirm with ENT.

Move the machine axis to zero (3).

22

SPEC

FCT

or

ENT

CL

If appropriate, switch off the distanceto-go display.

Page 23

Bolt Hole Circles and Bolt Hole Circle Segments

Your display unit enables you to quickly and easily produce bolt hole

circles and bolt hole circle segments. The required data is requested in

the message field.

Each hole can be moved to by traversing to display value zero. This

requires entry of the following data:

Number of holes (maximum: 999)

Circle center

Circle radius

Starting angle for first hole

Angle step between the holes (only for circle segments)

Hole depth

Example

Number of holes 8

Coordinates of the center X = 50 mm

Y = 50 mm

Circle radius 20 mm

Starting angle 30 degrees

Hole depth Z = 5 mm

50

Y

30°

R20

0

0

50

X

Bolt Hole Circles/Bolt Hole Circle Segments

23

Page 24

SPEC

FCT

or

SPEC

FCT

Select the special functions.

Select bolt hole circle.

CENTER X

5

ENT

0

Enter the X coordinate of circle center,

e.g. 50 mm, confirm with ENT.

Bolt Hole Circles/Bolt Hole Circle Segments

24

BOLT HOLE

ENT

FULL CIRCLE

If req.

NUMB. HOLES

ENT

8

ENT

Confirm your selection.

Confirm full circle.

Enter the number of holes, e.g. 8.

Confirm with ENT.

CENTER Y

0

5

ENT

RADIUS

02

ENT

START ANGLE

3

0

ENT

Enter the Y coordinate of circle center,

e.g. 50 mm, confirm with ENT.

Enter the radius of the bolt hole circle,

e.g. 20 mm. Confirm with ENT.

Enter the start angle for the first hole,

e.g. 30°. Confirm with ENT.

Page 25

HOLE DEPTH

1)

5

ENT

START

ENT

ENT

SPEC

or

FCT

1)

only with ND 760

CL

Enter the total hole depth, e.g. 5 mm, and

confirm with ENT.

Start the display of the hole positions.

After the start, the distance-to-go mode becomes

active (the D symbol lights). The hole number is

shown briefly in the X axis. The individual holes

are reached by traversing to zero. The holes can

be selected with the ENT key or the 1 2 key.

If you press the minus key, the hole number is

shown again.

Exit the bolt hole circle function.

Bolt Hole Circles/Bolt Hole Circle Segments

25

Page 26

Linear Hole Patterns

The linear hole pattern feature allows you to easily create rows of

holes to cover an area. The required data are requested in the

message field.

You can position to each hole by traversing to display value zero.

The following data are required:

Coordinates of the first hole

Number of holes per row (maximum: 999)

Spacing between holes

Linear Hole Patterns

Angle between the rows and the reference axis

Hole depth

Number of rows (maximum: 999)

Spacing between rows

26

Example

Coordinates of the first hole X = 20 mm

Y = 15 mm

Number of holes per row 4

Spacing between holes 16 mm

Angle 15 degrees

Hole depth Z = -30 mm

Number of rows 3

Spacing between rows 20 mm

15

Y

12

16

9

8

7

6

5

2

1

0

0

20

3

15°

20

4

X

Page 27

SPEC

FCT

SPEC

or

FCT

Select the special functions.

Select hole pattern.

HOLES ROW

4

ENT

Enter the number of holes per row,

e.g. 4, and confirm with ENT.

LIN. HOLE

ENT

1ST HOLE X

2

ENT

0

1ST HOLE Y

ENT

5

1

1)

only with ND 760

Confirm linear hole pattern.

Enter the X coordinate of the first holes,

e.g. 20, and confirm with ENT.

Enter the Y coordinate of the first holes,

e.g. 15, and confirm with ENT.

HOLE SPACE

1

6

ENT

ANGLE

1 5

ENT

HOLE DEPTH

0

3

ENT

Enter the spacing between holes in the

row and confirm with ENT.

Enter the angle, e.g. 15 degrees,

and confirm with ENT.

Enter the hole depth, e.g. 30 mm,

and confirm with ENT.

Linear Hole Patterns

1)

27

Page 28

NUMBER ROW

ROW SPACE

Linear Hole Patterns

START

SPEC

FCT

ENT

ENT

3

ENT

02

ENT

Enter the number of rows, e.g. 3,

and confirm with ENT.

Enter the spacing of the rows, e.g. 20,

and confirm with ENT.

Start the display of hole positions.

The distance-to-go mode is now active (the D

symbol lights). The hole number appears briefly

in the X axis. Move to the individual hole

positions by traversing to the display value zero.

Hole can be selected with the ENT key or with

the 1 2 key. Pressing the minus key shows

the hole number again.

or

Exit the linear hole patterns function.

CL

28

Page 29

Working with a Scaling Factor

Scaling factors enable you to increase or decrease the display values

based on the actual traverse distance. The display values are changed

symmetrically about the datum.

Enter scaling factors separately for each axis in parameter P12.

Y

Parameter P11 activates and deactivates the scaling factors in all axes

(see Operating Parameters).

Example for enlarging a workpiece:

P12.1 3.5

P12.2 3.0

P11 ON

This results in a larger workpiece as shown in the illustration at right:

1 is the original size, 2 is with axis-specific scaling factors.

If a scaling factor is active, SCL lights in the status display.

Scaling Factor

∗ 3.0

1

0

2

∗ 3.5

X

0

29

Page 30

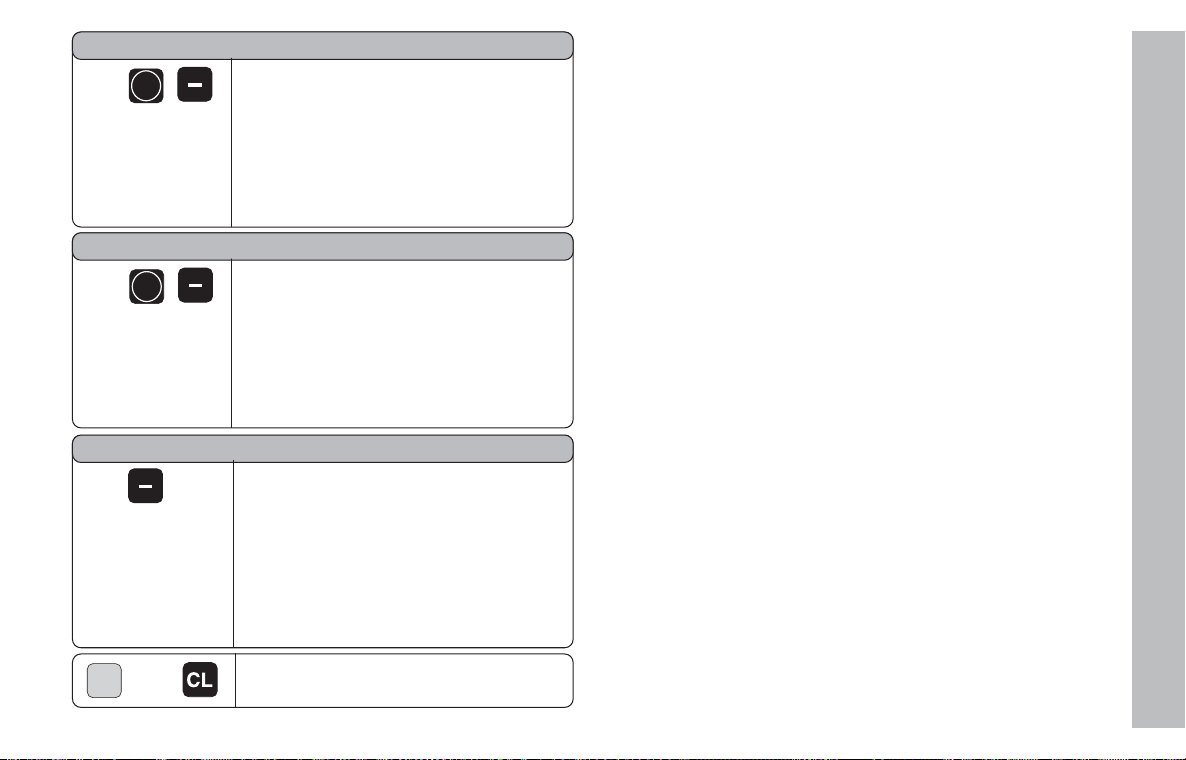

Error Messages

Message Cause and Effect

RS TOO FAST Time interval between two commands

SIGNAL X Encoder signal is too weak,

PROB. ERROR Before touching off on the workpiece,

Error Messages

DSR MISSING The connected device is not

ERR. REF. X The spacing of the reference marks as

FORMAT. ERR. Data format, baud rate, etc. do not

FRQ. X The input frequency for this encoder

too short.

e.g. when an encoder is contaminated.

the tool must move by a distance of at

least 0.2 mm.

transmitting a DSR signal.

defined in P43 is not the same as the

actual spacing.

match.

input is too high. This can occur when

the scale is moved too fast.

Message Cause and Effect

ERR. MEMORY Checksum error: Check the

datum, operating parameters and

compensation values for

multipoint axis error

compensation. If the error recurs,

contact your service agency!

REC. ERROR Error during reception of

parameter lists or

compensation-value lists.

To erase error messages:

After you have removed the cause of error:

➤ Press the CL key.

30

Page 31

Part II Installation and Specifications

Items Supplied 32

Connections on Rear Panel 33

Mounting 34

Power Connection 34

Connecting the Encoders 35

Operating Parameters 36

Entering/changing operating parameters 36

Operating parameter list 37

Linear Encoders 40

Setting the display step

Display step, signal period and subdivision 40

Compatible HEIDENHAIN linear encoders 41

Multipoint Axis Error Compensation 43

Pin Layout of X10 46

Data Interface RS-232-C/V.24 47

Measured-Value Output 48

Input/Output of Parameter Lists and 54

Compensation-Value Lists

Output Structure of Parameter Lists 56

Output Structure of Compensation-Value Tables 62

External Operation via RS-232-C/V.24 66

Data Interface

Specifications 70

Dimensions of ND 720/ND 760 71

Part II Installation and Specifications

31

Page 32

Items Supplied

ND 720 for 2 axes

or

ND 760 for 3 axes

Power connector Id. Nr. 257 811-01

Items Supplied

User's Manual

Optional accessories

Tilting base for housing bottom

Id. Nr. 281 619-01

KT 130 Edge Finder Id. Nr. 283 273-01

Page 33

Connections on Rear Panel

ID label

Power switch

Power input

Edge finder input

RS-232-C/V.24

data interface

Connections on Rear Panel

Protective ground Encoder inputs X1 to X3 Rubber feet with M4 thread

The interfaces X1, X2, X3, and X10 comply with the requirements for electrical separation according to EN 50 178!

33

Page 34

Mounting

ND 720/ND 760

To mount the display unit on a support, use the M4 threaded holes in

the rubber feet. You can also mount the display unit on the optional

tilting base.

Power Connection

Mounting/Power Connection

N

Power leads: and

Connect protective ground to !

Power supply: 100 Vac to 240 Vac (-15 % to +10 %)

A voltage selector is not necessary.

L

50 Hz to 60 Hz (± 2 Hz)

Danger of electrical shock!

Connect a protective ground. This connection must never

be interrupted.

Unplug the power cord before opening the housing.

HEIDENHAIN

Tilting base

Support

To increase the noise immunity, connect the ground terminal

on the rear panel to the central ground point of the machine.

(Minimum cross-section: 6 mm

2

).

Page 35

Connecting the Encoders

Your display unit will accept all HEIDENHAIN linear encoders with

sinusoidal output signals (7 to 16 mA

reference marks.

Assignment of the encoder inputs

Encoder input X1 is for the X axis

Encoder input X2 is for the Y axis

Encoder input X3 is for the Z axis (ND 760 only)

Encoder monitoring system

Your display unit features a monitoring system for checking the

amplitude and frequency of the encoder signals. If it detects a faulty

signal, one of the following error messages will be generated:

SIGNAL X

FRQ. X

Encoder monitoring can be activated with parameter P45.

If you are using linear encoders with distance-coded reference marks,

the encoder monitoring system also checks whether the spacing of

the reference marks as defined in parameter P43 is the same as the

actual spacing on the scales. If it is not, the following error message

will be generated:

) and distance-coded or single

pp

Z Y X

Connecting the Encoders

ERR. REF. X

35

Page 36

Operating Parameters

Operating parameters allow you to modify the operating

characteristics of your display unit and define the evaluation

of the encoder signals. Operating parameters that can be

changed by the user are called user parameters, and can be

accessed with the SPEC FCT key and the dialog PARAMETER (user parameters are identified as such in the

parameter list). The full range of parameters can only be

accessed through the dialog CODE and by entering 95148.

Operating parameters are designated by the letter P and a

Operating Parameters

number. Example: P11. The parameter designation is shown

in the input field when you select it with the DATUM and

ENT key in the X display. The parameter setting is shown in

the Y display.

Some operating parameters have separate values for each

axis. Such parameters have an additional index number from

1 to 3 with the ND 760 and from 1 to 2 with the ND 720.

Operating parameters with an index number can be selected

with the axis-direction keys.

Example: P12.1 scaling factor, X axis

P12.2 scaling factor, Y axis

P12.3 scaling factor, Z axis (ND 760 only)

The operating parameters are preset before the unit leaves

the factory. These factory default settings are indicated in the

parameter list in boldface type.

Entering and changing operating parameters

To access the operating parameters

➤ Press the SPEC FCT key.

➤ Press the SPEC FCT key or 1 2 , until

PARAMETER appears in the X display.

➤ Confirm your selection by pressing ENT.

To select protected operating parameters

➤ Press the 1 2 key to select the

P00 CODE user parameter.

➤ Enter the code number 95148.

➤ Confirm with the ENT key.

To page through the operating parameters

➤ Page forwards by pressing the ENT key.

➤ Page backwards by pressing the 1 2 key.

To change parameter settings

➤ Press the minus key or enter the value and confirm

with the ENT key.

To correct an entry

➤ Press CL: the old value reappears in the input line and

becomes effective again.

To exit the operating parameters

➤ Press the SPEC FCT or CL key.

Page 37

List of operating parameters

P00 CODE Enter code number

9 51 48: Change protected operating parameters

66 55 44: Display the software version (in the X axis)

Display the date of release (in the Y axis)

10 52 96: Multipoint axis error compensation

48 61 53: Input and output of parameter lists and

compensation-value lists

P01 Unit of measure

1)

Display in millimeters MM

Display in inches INCH

P03.1 to P03.3 Radius/diameter display

1)

Display position value as radius RADIUS

Display position value as diameter DIAMETER

P11 Activate scaling factor

1)

Active SCALING ON

Not active SCALING OFF

P12.1 to P12.3 Define scaling factor

1)

Enter a scaling factor separately for each axis:

Entry value > 1: workpiece will grow

Entry value = 1: workpiece will remain the same size

Entry value < 1: workpiece will shrink

Input range: 0.100000 to 9.999999

Default setting: 1.000000

P25 Stylus diameter

1)

Input range (mm): 0.000 to 999.999

Default setting: 6

P26 Stylus length

1)

Input range (mm): 0.000 to 999.999

P30. 1 to P3 0.3 Counting direction

Positive counting direction with

positive direction of traverse DIRECT. POS

Negative counting direction with

positive direction of traverse DIRECT. NEG

P31.1 to P31.3 Signal period of the encoder

Input range: 0.00000001 to 99999.9999 µm

Default setting: 20 µm

P33.1 to P33.3 Counting mode

0 - 1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - 9

0 - 2 - 4 - 6 - 8

0 - 5

P38.1 to P38.3 Decimal places

2 / 3 / 4 / 5 / 6 / 7 / 8

1)

User parameter

Operating Parameters

37

Page 38

P40.1 to P40.3 Select type of axis error compensation

No axis error compensation COMP. OFF

Linear error compensation active,

multipoint error comp. not active COMP. LIN

Multipoint error compensation active,

linear error compensation not active COMP. MULTI

P41.1 to P41.3 Linear axis error compensation

Input range (µm): -99999 to +99999

Factory default setting: 0

Operating Parameters

Example: Displayed length Ld = 620.000 mm

Actual length (as determined for example with

the VM 101 from HEIDENHAIN)

La = 619.876 mm

Difference DL = La Ld = 124 µm

Compensation factor k:

k = DL/Ld = 124 µm/0.62 m = 200 [µm/m]

P42.1 to P42.3 Backlash compensation

Input range (mm): +9,999 to –9,999

Default setting: 0,000 = no backlash

compensation

A change in direction might cause a clearance between

rotary encoder and table. This is referred to as backlash.

Positive backlash: The rotary encoder is ahead of the table.

The distance traversed by the table is too short (entry of

positive value).

Negative backlash: The rotary encoder follows the table. The

distance traversed by the table is too large (entry of negative

value).

P43.1 to P43.3 Reference marks

One reference mark SINGLE REF.M.

Distance-coded with 500 SP 500 SP

Distance-coded with 1000 SP 1000 SP

Distance-coded with 2000 SP 2000 SP

Distance-coded with 5000 SP 5000 SP

(SP: signal period)

P44.1 to P44.3 Reference mark evaluation

Evaluation REF. X ON

No evaluation REF. X OFF

P45.1 to P45.3 Encoder monitoring

Amplitude and frequency

monitoring ALARM ON

No monitoring ALARM OFF

P48.1 to P48.3 Activate axis display

Axis display active AXIS ON

Not active AXIS OFF

P49.1 to P49.3 Axis designation for measured value output

An axis designation for the measured value output can be set

through the number of the ASCII character. The axis

designation is output together with the measured value.

Input range: 0 to 127

Measured value output disabled 0

ASCII character from ASCII table 1 to 127

Default setting: P49.1 88

P49.2 89

P49.3 90

Page 39

P50 Baud rate

1)

110 / 150 / 300 / 600 / 1200 / 2 400 / 4 800 / 9600 /

19 200 / 38 400

P51 Line feeds for measured value output

1)

Input range: 0 to 99

Default setting: 1

P70 Number of datum points

2 datum points 2 DATUM PT.

9 datum points 9 DATUM PT.

P80 Function of the CL key

Set to zero with CL CL....RESET

No set to zero with CL CL......OFF

P81 Function of the R+/- key

The R+/- key divides the actual R+/- 1/2 ON

value by two.

The actual value is not divided. R+/- 1/2 OFF

P96 Measured value output for probing

Measured value output active PROBE ON

Measured value output not active PROBE OFF

P97 Characters for measured values

ASCII characters for designation of the measured values for

output through probing, contact, or pulse.

Input range: 0 to 127

No ASCII character 0

ASCII character from ASCII table 1 to 127

P98 Conversational language

1)

German LANGUAGE DE

English LANGUAGE EN

French LANGUAGE FR

Italian LANGUAGE IT

Dutch LANGUAGE NL

Spanish LANGUAGE ES

Danish LANGUAGE DA

Swedish LANGUAGE SV

Finnish LANGUAGE FI

Czech LANGUAGE CS

Polish LANGUAGE PL

Hungarian LANGUAGE HU

Portuguese LANGUAGE PT

Operating Parameters

1)

User parameter

39

Page 40

Linear Encoders

Selecting the display step with linear encoders

To select a certain display step, you must define the

following operating parameters:

Signal period (P31)

Counting mode (P33)

Decimal places (P38)

Linear Encoders

Example

Linear encoder with a signal period of 20 µm

Desired display step ................ 0.000 5 mm

Signal period (P31) ................... 20

Counting mode (P33) ............... 5

Decimal places (P38) ............... 4

The following tables will help you select the

parameters.

Page 41

Parameter settings for HEIDENHAIN linear encoders with 11 µA

Model

P 31 P 43

CT

MT xx01

LIP 401A/401R

LF 103/103C

LF 401/401C

LIF 101/101C

LIP 501/501C

LIP 101

MT xx 10 single 0.0005

LS 303/303C

LS 603/603C

2

4

20 single/1000 0.01

Reference

marks

Signal period

[µm]

single 0.0005

single

single/5000

single

Millimeters Inches

Display step

[mm]

Count

P 33 P 38

5

0.0002

0.0001

0.00005

Recommended only for LIP 401

0.00002

0.00001

0.000005

0.001

0.0005

0.0002

0.0001

0.00005

Recommended only for LIP 101

0.00002

0.00001

0.0002

0.0001

0.005

2

1

5

2

1

5

1

5

2

1

5

2

1

5

2

1

1

5

signals

PP

Decimal

4

4

4

5

5

5

6

3

4

4

4

5

5

5

4

4

4

2

3

Display

step [inch]

places

0.00002

0.00001

0.000005

0.000002

0.000001

0.0000005

0.0000002

0.00005

0.00002

0.00001

0.000005

0.000002

0.000001

0.0000005 15

0.00002

0.00001

0.000005

0.0005

0.0002

Count

P 33 P 38

2

1

5

2

1

5

2

5

2

1

5

2

2

1

5

5

2

Decimal

5

5

6

6

6

7

7

5

5

5

6

6

6

7

5

5

6

4

4

places

Linear encoders

41

Page 42

Parameter settings for HEIDENHAIN linear encoders with 11 µAPP signals (continued)

Signal period

[µm]

Reference

marks

single/1000

-

Model

Linear Encoders

LS 106/106C

LS 406/406C

LS 706/706C

ST 1201

LB 302/302C

LIDA 10x/10xC

LB 301/301C 100 single/1000 0.005

LIM 501 10240 single 0.1

P 31 P 43

20

40 single/2000

Millimeters Inches

Display step

[mm]

Count

P 33 P 38

0.001

0.0005

0.005

0.002

0.001

0.0005

Recommended only for LB 302

0.0002

0.0001

0.002

0.001

0.01

0.05

1

5

5

2

1

5

2

1

5

2

1

1

1

5

3

4

3

3

3

4

4

4

3

3

3

1

2

2

Decimal

places

Display

step [inch]

0.00005

0.00002

0.0002

0.0001

0.00005

0.00002

0.000001

0.0000005 15

0.0002

0.0001

0.00005

0.005

0.0005

0.002

Count

P 33 P 38

5

2

2

1

5

2

2

1

5

5

5

2

Decimal

5

5

4

4

5

5

5

6

4

4

5

3

4

3

places

Page 43

Multipoint Axis Error Compensation

Entries in the compensation-value table

If you want to use the multipoint axis error

compensation feature, you must

activate this feature with operating parameter 40

(see "Operating Parameters"),

traverse the reference marks after switching on the

display unit,

enter a compensation value table.

Your machine may have a nonlinear axis error due to factors

such as axis sag or drivescrew errors. Such deviations are

usually measured with a comparator measuring system (such

as the HEIDENHAIN VM 101).

You can, for example, determine the screw pitch error X=F(X)

for the X axis.

An axis can only be corrected in relation to one axis that has

an error. In each axis, a compensation value table with

64 compensation values can be generated. You can select

the compensation table with the SPEC FCT key and the

PARAMETER\CODE dialog.

To determine the compensation values (e.g. with a VM 101),

the REF display must be selected after selecting the

compensation-value table.

+

R

-

Select the REF display.

The decimal point in the left display field indicates that the

displayed values are referenced to the reference point. If the

decimal point blinks, the reference marks have not been

traversed.

Axis to be corrected: X, Y or Z (Z axis only with ND 760)

Axis causing the error: X, Y or Z (Z axis only with ND 760)

Datum for the axis to be corrected:

Here you enter the point starting at which the axis with

error is to be corrected. This point indicates the absolute

distance to the reference point.

Do not change the datum point after measuring the

axis error and before entering the axis error into the

compensation table.

Spacing of the compensation points

The spacing of the compensation points is expressed as

x

2

[µm].

Enter the value of the exponent x into the compensation

value table.

Minimum input value: 6 (= 0.064 mm)

Maximum input value: 20 (= 1048.576 mm)

23 (= 8388.608 mm)

Example: 900 mm traverse and 15 compensation points:

results in 60.000 mm spacing between points.

Nearest power of two: 2

16

[µm] = 65.536 mm

Entry in compensation value table: 16

Compensation value

You enter the measured compensation value (in

millimeters) for the displayed compensation point.

Compensation point 0 always has the value 0 and

cannot be changed.

Multipoint Axis Error Compensation

43

Page 44

Selecting the compensation table, entering an axis correction

Select the special functions.

Select the "parameter" function if

required, by repeatedly pressing the

SPEC

FCT

SPEC

FCT

or

1 2 key.

PARAMETER

Select dialog for entering the code

number.

CODE

Enter code number 105296 and

confirm with ENT.

Multipoint Axis Error Compensation

AXIS X

ENT

Select axis to be corrected, e.g. X.

Confirm with ENT.

X FCT. X

DATUM X

SPACING X

27.000

ENT

ENT

ENT

ENT

ENT

Enter the axis causing the error, e.g. X

(screw pitch error), and confirm with

ENT.

Enter the active datum for the error on

the axis to be corrected (e.g. 27 mm)

and confirm with ENT.

Enter the spacing of the compensation

points on the axis to be corrected, for

example 2

10

mm (equals 1.024 mm) and

confirm with ENT.

Compensation point no. 1 is displayed.

Enter the associated compensation

value (e.g. 0.01 mm) and confirm with

ENT.

Page 45

Deleting a compensation value table

28.024

or

Enter all further compensation points. If

you press the minus key, the unit will

show the number of the current

compensation point in the X display.

Direct selection of compensation

points: Press the minus key together

with the number (two-digit) of the

desired compensation point.

Conclude entry.

SPEC

FCT

SPEC

or

FCT

PARAMETER

CODE

AXIS X

DELETE Z

Select the special functions.

Select the parameter" function.

Select the dialog for entering the code

number.

Enter the code number 105296 and

confirm with ENT.

Multipoint Axis Error Compensation

Select the compensation value table

(e.g., for the Z axis), and delete the table.

Confirm with ENT, or cancel with CL.

Conclude entry.

45

Page 46

Pin Layout of X10 for KT 130 Edge Finder and

Data Interface

Pin Signal Function

1 Internal shield

2 Standby

3RXD Receive data

4RTS Request to send

5CTS Clear to send

Pin Layout of X10

6U

P

+5 V

7 SIGN. GND Signal ground

8U

P

0 V

9TXD Transmit data

10 DSR Data set ready

11 DTR Data terminal ready

12 Meas. value output by contact

13 Switching signals

14 Meas. value output by pulse

15 CHASSIS Housing

GND

Page 47

RS-232-C/V.24

In addition to a connection for the edge finder, the X10 socket also

provides an RS-232-C/V.24 data interface.

The data interface on your ND display unit enables you to use a printer or

a PC for transferring measured values or programs.

The interface is permanently set to the following data format:

1 start bit

7 data bits

Even parity bit

2 stop bits

The baud rate is set with parameter P50.

Full wiring

ND X10

CHASSIS

TXD

RXD

RTS

CTS

DSR

GNDSIGNAL

DTR

15GND

9

3

4

5

10

7

11

CHASSIS

GND

TXD

RXD

RTS

CTS

DSR

GNDSIGNAL

DTR

For connection to peripheral devices you can use either full wiring

(figure at upper right) or simplified wiring (below right).

Levels for TXD and RXD

Logic levels Voltage levels

1 3 V to 15 V

0 + 3 V to +15 V

Levels for RTS, CTS, DSR and DTR

Logic levels Voltage levels

1 + 3 V to +15 V

0 3 V to 15 V

Simplified wiring

ND X10

CHASSIS GND

TXD

RXD

RTS

CTS

DSR

GNDSIGNAL

DTR

15GND

9

3

4

5

10

7

11

CHASSIS

RS-232-C / V.24 Data Interface

TXD

RXD

RTS

CTS

DSR

GNDSIGNAL

DTR

47

Page 48

Measured Value Output

Measured values can be output over the RS-232-C/V.24 interface. This

can be done with the following functions:

Probing with the KT Edge Finder

Contact input on X10

Pulse input on X10

CTRL B via the RS-232-C interface

Code letters with the measured value

Parameter P97 allows you to select a code letter to be output together

with the measured value when using Probe, Contact or Pulse. The

Measured Value Output

decimal number you enter in the parameter is the ASCII character

number in the ASCII table. If you enter 0, no code letter will be output.

The code letter enables you to recognize whether the measured value

was generated with CTRL B or with an external signal.

Axis designation for measured value output

Parameter P49 allows you to enter an axis designation for each

measured value that is output. The decimal number you enter in the

parameter is the ASCII character number in the ASCII table. If you enter

0, no axis designation will be output.

Example of measured value output:

Parameter settings:

P49.1 = 88 (X)

P49.2 = 89 (Y)

P49.3 = 90 (Z)

P51 = 0 (no line feeds)

P97 = 69 (E)

Output:

E (CR)(LF)

X=...(CR)(LF)

Y=...(CR)(LF)

Z=...(CR)(LF)

Page 49

Measured value output when probing

Parameter P96 allows you to activate measured value output when

probing with the KT edge finder. The edge finder is connected to

D-sub input X10.

Whenever the Probe Edge function is used, your display unit outputs

the position of the edge in the selected axis and the actual positions of

the other axes over the TXD line of the RS-232-C/V.24 interface.

Whenever the Probe Midpoint function is used, your display unit

outputs the calculated midpoint in the selected axis and the actual

positions of the other axes.

Measured value output with CTRL B is disabled when a probing

function is active.

Delay times with data output

Duration of the latch signal: t

Storage delay: t

Data output after: t

Regeneration time: t

³ 4 µs

e

£ 4.5 ms

1

£ 50 ms

2

³ 0

3

Duration of data output in seconds:

209 number of axes + 11 number of line feeds

t

=

D

Baud rate

* 1.08

t

e

t

1

t

2

t

D

t

e

t

3

Measured Value Output

Next possible signal for measured value output: t

= t1 + t2 + tD + t3 [s]

E

49

Page 50

Examples of measured value output when probing

Example: Probe edge, X axis

P R X : + 58541 . 2504 R <CR> <LF>

Y:- 10122 . 8660 R <CR> <LF>

Z : + 85903 . 3042 ? R <CR> <LF>

Example: Probe midpoint, X axis

Measured Value Output

Example: Probe circle

C L X : + 34761 . 2504 R <CR> <LF>

Y:- 10122 . 8660 R <CR> <LF>

Z : + 85903 . 3042 R <CR> <LF>

C C X : + 234 . 786 R <CR> <LF>

CCY:+ 452 . 816 R <CR> <LF>

Z : - 4563 . 305 R <CR> <LF>

➀ ➁➂➃➄➅➆➇➈ ➉

➀ Probed axis <PR>, <CL> / other axes

➁ Colon

➂ Plus or minus sign

➃ 1 to 8 places before the decimal point

➄ Decimal point

➅ 1 to 8 decimal places

➆ Unit: blank = mm, " = inches, ? = error message

➇ R = radius display, D = diameter display

➈ Carriage Return

➉ Line Feed

Page 51

Pin 8 (0V)

Pin 12

Pin 14

Pin 8 (0V)

X10

X10

Measured value output over the contact and pulse inputs

Measured value output over the contact input (pin 12 on X10) and

pulse input (pin 14 on X10) can be triggered when these inputs are

closed against 0 V.

The measured values are output over the TXD line of the RS-232-C

interface.

A commercially available switch can be attached to the contact input.

This switch generates a signal for data output when it makes contact

against 0 V.

The pulse input can be triggered with TTL logic devices (for example,

SN74LSXX).

Delay times for data output

Latch signal duration: Pulse t

Latch signal duration: Contact t

Storage delay: Pulse t

Storage delay: Contact t

Data output follows t

2

Regeneration time t

³ 1.2 µs

e

³ 7 ms

e

£ 0.8 µs

1

£ 4.5 ms

1

t2£ 30 ms

³ 0

3

Measured Value Output

t

e

t

e

Duration of data output in seconds:

187 number of axes + 11 number of line feeds

t

=

D

Baud rate

* 1.08

Next possible signal for measured value output: tE = t1 + t2 + tD + t3 [s]

t

1

t

2

t

3

t

D

51

Page 52

Measured value output with CTRL B

If the control character STX (CTRL B) is received over the RS-232-C

interface, the measured value referenced to this time point will be

sent over the interface. CTRL B is received over the RXD line and the

measured values are output over the TXD line.

The measured values can be received and stored using a terminal

program (e.g. Hyper Terminal, included with Windows® ).

The basic program at the upper right illustrates the basic structure of a

program for measured-value output.

Measured Value Output

Delay times for data output

BASIC program for measured value output:

10 L%=48

20 CLS

30 PRINT "RS232/V.24"

40 OPEN "COM1:9600,E,7" AS#1

50 PRINT #1, CHR$ (2);

60 IF INKEY$<>""THEN 130

70 C%=LOC(1)

80 IF C%<L%THEN 60

90 X$=INPUT$(L%,#1)

100 LOCATE 9,1

110 PRINT X$;

120 GOTO 50

130 END

Storage delay t

Data output follows t

2

Regeneration time after data output t

£ 0.5 ms

1

t2£ 30 ms

³ 0 ms

3

Duration of data output in seconds:

187 number of axes + 11 number of line feeds

t

=

D

Next possible signal for measured value output: t

Baud rate

= t1 +t2 + tD + t3 [s]

E

* 1.08

CTRLB CTRLB

t

1

t

2

t

3

t

D

Page 53

Example of measured value output over the contact and pulse

inputs or CTRL B:

E <CR> <LF>

X = + 58541 . 2504 R <CR> <LF>

Y = - 10122 . 8660 R <CR> <LF>

Z = + 85903 . 3042 R <CR> <LF>

➀➁➂ ➃ ➄ ➅ ➆➇ ➈ ➉

➀ Axis designation

➁ Equality sign

➂ Plus or minus sign

➃ 1 to 8 places before the decimal point

➄ Decimal point

➅ 1 to 8 decimal places

➆ Unit: blank = mm, " = inches, ? = error message

➇ R(r) = radius display, D(d) = diameter display,

( ) = distance-to-go display

➈ Carriage Return

➉ Line Feed

Measured Value Output

53

Page 54

Input/Output of Parameter and

Compensation-Value Lists

To call the "data transfer" function:

SPEC

FCT

SPEC

or

FCT

PARAMETER

ENT

CODE

Data transfer function:

TRANSFER

Input/Output of Parameter and Compensation-Value Lists

ENT

Select the special functions.

Select "parameter."

Select the dialog for entering

the code number.

Enter the code number 486153 and

confirm with ENT.

Proceed by pressing the ENT key.

SEND PARAM.

ENT

If req.

REC. PARAM.

If req.

SEND COMP. X

If req.

ENT

With the ENT key, the parameter list is

output over the RS-232-C/V.24 interface.

After output is completed, the display

unit returns to "TRANSFER" to send or

receive further lists. To proceed with the

data transfer menu, press the minus

key.

The display unit is ready to receive a

parameter list over the RS-232-C/V.24

interface. If no error occurs during the

reception of the parameter list, the

display unit is automatically reset and

restarted. To proceed with the data

transfer menu, press the minus key.

With the ENT key, the compensation

value list for the X axis is output over the

RS-232-C/V.24 interface. After output is

completed, the display unit returns to

"TRANSFER" to send or receive further

lists. To proceed with the data transfer

menu, press the minus key.

Page 55

SEND COMP.Y

If req.

ENT

SEND COMP.Z

ENT

If req.

REC. COMP.

If req.

SPEC

or

FCT

1) Only with ND 760

With the ENT key, the compensation

value list for the Y axis is output over the

RS-232-C/V.24 interface. After output is

completed, the display unit returns to

"TRANSFER" to send or receive further

lists. To proceed with the data transfer

menu, press the minus key.

With the ENT key, the compensation

value list for the Z axis is output over the

RS-232-C/V.24 interface. After output is

completed, the display unit returns to

"TRANSFER" to send or receive further

lists. To proceed with the data transfer

menu, press the minus key.

The display unit is ready to receive a

compensation value list (X, Y or Z) over

the RS-232-C/V.24 interface. If no error

occurs during the reception of the

parameter list, the display unit returns to

"TRANSFER" to send or receive further

lists. To proceed with the data transfer

menu, press the minus key.

Exit the transfer function.

Note on the input/output of parameter and

compensation-value lists

With a terminal program (e.g. Hyper Terminal, included with

Windows

the RS-232-C/V.24 interface as text files and store them on your

PC. Each list must be saved as a separate text file. To transfer the

text files to the display unit, you can also use the terminal program.

If you wish, you can edit the text files with a text editor and

change, for example, the parameter values. However, this requires

knowledge of the different output structures of the lists (see the

1)

following pages). When receiving lists, the display unit assumes the

same list structure as used for the output.

When receiving lists, the display unit first waits for the starting

character < * >.

The receiving mode ends as soon as the display unit has received

the final character < * >.

The lists received are first checked for the type of display unit

(line 2 of output list). The receiving display unit accepts only lists

prepared by the same type of display unit. Furthermore, the list is

checked for completeness. Lists that contain, for example, too

many or too few parameters are ignored. If an error occurs, the

following error message appears:

REC. ERROR

To clear the error message, press the CL key.

When receiving non-valid parameter values, the display unit sets

the respective operating parameter to the default setting.

Example: "P01 INCH = INCH = 3"

Value 3 is not allowed. The parameter P01 is set to the default

setting "P01 MM = MM = 0".

®

), you can receive the lists output by the display unit over

Input/Output of Parameter and Compensation-Value Lists

55

Page 56

Output Structure of Parameter Lists

Line 1

Each parameter output starts with the starting character < * > ( HEX: 0x2A)

* <CR> <LF>

3 characters

Line 2

Output of model designation

N D - 7 6 0 <CR> <LF>

13 characters 2 characters

Type of display unit End

Subsequent lines for the individual parameters:

Output Structure of Parameter Lists

a: Parameters:

The parameter setting can be edited by pressing the minus key (e.g. positive counting direction / negative counting direction,

etc.)

Examples:

P 0 1 I N C H = 1 <CR> <LF>

6 characters 13 characters 3 ch. 6 characters 2 characters

P 3 1 . 1 D P P O S . 5 = 5 <CR> <LF>

6 characters 13 characters 3 ch. 6 characters 2 characters

Parameter designation Parameter in plain language Sep.block Parameter value End

Left-aligned Right-aligned Right-aligned

Page 57

b: Parameters:

The parameter setting can be edited by entering a value.

(e.g. LINEAR COR. 13,600 etc.)

P 3 1 . 1 S . P E R . = 1 2 8 0 0 <CR> <LF>

6 characters 13 characters 3 ch. 13 characters 2 characters

P 3 8 . 1 L I N E A R C M P . = + 1 2 4 6 7 <CR> <LF>

6 characters 13 characters 3 ch. 13 characters 2 characters

Parameter designation Parameter in plain language Sep. block Parameter value End

Left-aligned Right-aligned Right-aligned

Last line:

Each parameter list ends with the final character <*> (HEX: 0x2A)

* <CR> <LF>

The parameter text is sent in the language you have set and corresponds to the dialog text that is shown on the display unit.

However, the parameter value, not the text, is the decisive information when parameters are transferred to the display unit.

Output Structure of Parameter Lists

57

Page 58

ND 720 parameter list: (factory default setting)

Parameter list Description

* Starting character (*);

ND-720 Type of display unit

P01 MM = 0 MM = 0; INCH = 1;

P03.1 RADIUS = 0 X axis: RADIUS = 0; DIAMETER = 1;

P03.2 RADIUS = 0 Y axis: RADIUS = 0; DIAMETER = 1;

P11 SCALING OFF = 0 SCALING OFF = 0; ON = 1;

P12.1 SCL = 1.000000 X axis: SCALING FACTOR = 1.000000; (value input)

P12.2 SCL = 1.000000 Y axis: SCALING FACTOR = 1.000000; (value input)

P25 PRO BE DIA. = + 6.000 PROBE DIAMETER = 6.000 mm; (value input)

P30.1 DIRECT.POS = 0 X axis: DIRECTION POS. = 0; NEG. = 1;

P30.2 DIRECT.POS = 0 Y axis: DIRECTION POS. = 0; NEG. = 1;

P31.1 S.PER. = 20 X axis: SIGNAL PERIOD = 20µm; (value input)

P31.2 S.PER. = 20 Y axis: SIGNAL PERIOD = 20µm; (value input);

P33.1 COUNT 0-1 = 1 X axis: COUNT 0-1 = 1; 0-2 = 2; 0-5 = 5;

P33.2 COUNT 0-1 = 1 Y axis: COUNT 0-1 = 1; 0-2 = 2; 0-5 = 5;

P38.1 DP POS. 3 = 3 X axis: DECIMAL PLACES 3 (range: 1-8)

Output Structure of Parameter Lists

P38.2 DP POS. 3 = 3 Y axis: DECIMAL PLACES 3 (range: 1-8)

P40.1 COMP. OFF = 0 X axis: COMPENSATION OFF = 0; LIN = 1; MULTI = 2;

P40.2 COMP. OFF = 0 Y axis: COMPENSATION OFF = 0; LIN = 1; MULTI = 2;

P41.1 LINEAR CMP. = + 0 X axis: LINEAR COMPENSATION = 0 µm/m (value input)

P41.2 LINEAR CMP. = + 0 Y axis: LINEAR COMPENSATION = 0 µm/m (value input)

P42.1 BKLASH = + 0.000 X axis: BACKLASH COMPENSATION 0.000 mm (value input)

P42.2 BKLASH = + 0.000 Y axis: BACKLASH COMPENSATION 0.000 mm (value input)

P43.1 1000 SP = 1000 X axis: ONE REF.M. = 0; 500; 1000; 2000; 5000 SP;

P43.2 1000 SP = 1000 Y axis: ONE REF.M. = 0; 500; 1000; 2000; 5000 SP;

P44.1 REF. ON = 1 X axis: REF.ON = 1; REF. OFF = 0;

P44.2 REF. ON = 1 Y axis: REF.ON = 1; REF. OFF = 0;

P45.1 ALARM ON = 1 X axis: ALARM ON = 1; ALARM OFF = 0;

P45.2 ALARM ON = 1 X axis: ALARM ON = 1; ALARM OFF = 0;

Page 59

Parameter list Description

P48.1 AXIS ON = 1 X axis: AXIS ON = 1; AXIS OFF = 0;

P48.2 AXIS ON = 1 Y axis: AXIS ON = 1; AXIS OFF = 0;

P49.1 AXIS NAME = 88 X axis: AXIS NAME = 88; (0 - 127)

P49.2 AXIS NAME = 89 Y axis: AXIS NAME = 88; (0 - 127)

P50 9600 BAUD = 9600 BAUD RATE = 9600; (110-38400)

P51 EMPTY LINE = 1 LINE FEEDS = 1; (0-99)

P70 2 DATUM PT. = 2 2 DATUM POINTS = 2; 9 DATUM POINTS = 9;

P80 CL......OFF = 0 CL....OFF = 0; CL....RESET = 1;

P81 1/2 OFF = 0 ½ KEY OFF = 0; ½ KEY ON = 1;

P96 PROBING OFF = 0 PROBING OFF = 0; PROBING ON = 1;

P97 OUTPUT ID. = 0 OUTPUT ID. = 0; (0 - 127)

P98 LANGUAGE DE = 1 LANGUAGE: 0 = EN; 1 = DE; 2 = FR;

* 3 = IT; 4 = NL; 5 = ES;

6 = DA; 7 = SV; 8 = FI;

9 = CS; 10 = PL; 11= HU;

12 = PT;

Final character (*);

Output Structure of Parameter Lists

59

Page 60

ND 760 parameter list: (factory default setting)

Parameter list Description

* Starting character (*);

ND-760 Type of display unit

P01 MM = 0 MM = 0; INCH = 1;

P03.1 RADIUS = 0 X axis: RADIUS = 0; DIAMETER = 1;

P03.2 RADIUS = 0 Y axis: RADIUS = 0; DIAMETER = 1;

P03.3 RADIUS = 0 Z axis: RADIUS = 0; DIAMETER = 1;

P11 SCALING OFF = 0 SCALING FACTOR OFF = 0; ON = 1;

P12.1 SCL = 1.000000 X axis: SCALING FACTOR = 1.000000; (value input)

P12.2 SCL = 1.000000 Y axis: SCALING FACTOR = 1.000000; (value input)

P12.3 SCL = 1.000000 Z axis: SCALING FACTOR = 1.000000; (value input)

P25 PR OB E DIA. = + 6.000 PROBE DIAMETER = 6.000 mm; (value input)

P26 PR OB E LEN. = + 0.000 PROBE LENGTH = 0 mm; (value input)

P30.1 DIRECT. POS = 0 X axis: DIRECTION POS. = 0; NEG. = 1;

P30.2 DIRECT. POS = 0 Y axis: DIRECTION POS. = 0; NEG. = 1;

P30.3 DIRECT. POS = 0 Z axis: DIRECTION POS. = 0; NEG. = 1;

P31.1 S.PER. = 20 X axis: SIGNAL PERIOD = 20µm; (value input)

Output Structure of Parameter Lists

P31.2 S.PER. = 20 Y axis: SIGNAL PERIOD = 20µm; (value input)

P31.3 S.PER. = 20 Z axis: SIGNAL PERIOD = 20µm; (value input)

P33.1 COUNT 0-1 = 1 X axis: COUNT. MODE 0-1 = 1; 0-2 = 2; 0-5 = 5;

P33.2 COUNT 0-1 = 1 Y axis: COUNT. MODE 0-1 = 1; 0-2 = 2; 0-5 = 5;

P33.3 COUNT 0-1 = 1 Z axis: COUNT. MODE 0-1 = 1; 0-2 = 2; 0-5 = 5;

P38.1 DP POS. 3 = 3 X axis: DECIMAL PLACES 3 (range: 1-8)

P38.2 DP POS. 3 = 3 Y axis: DECIMAL PLACES 3 (range: 1-8)

P38.3 DP POS. 3 = 3 Z axis: DECIMAL PLACES 3 (range: 1-8)

P40.1 COMP. OFF = 0 X axis: COMPENSATION OFF = 0; LIN = 1; MULTI = 2;

P40.2 COMP. OFF = 0 Y axis: COMPENSATION OFF = 0; LIN = 1; MULTI = 2;

P4 0 . 3 COMP. OFF = 0 Z axis: COMPENSATION OFF = 0; LIN = 1; MULTI = 2;

P41.1 LINEAR CMP. = + 0 X axis: LINEAR COMPENSATION = 0 µm/m (value input)

P41.2 LINEAR CMP. = + 0 Y axis: LINEAR COMPENSATION = 0 µm/m (value input)

Page 61

Parameter list Description

P41.3 LINEAR CMP. = + 0 Z axis: LINEAR COMPENSATION = 0 µm/m (value input)

P42.1 BKLASH = + 0.000 X axis: BACKLASH compensation 0.000 mm (value input)

P42.2 BKLASH = + 0.000 Y axis: BACKLASH compensation 0.000 mm (value input)

P42.3 BKLASH = + 0.000 Z axis: BACKLASH compensation 0.000 mm (value input)

P43.1 1000 SP = 1000 X axis: ONE REF.MARK = 0; 500; 1000; 2000; 5000 SP;

P43.2 1000 SP = 1000 Y axis: ONE REF.MARK = 0; 500; 1000; 2000; 5000 SP;

P43.3 1000 SP = 1000 Z axis: ONE REF.MARK = 0; 500; 1000; 2000; 5000 SP;

P44.1 REF. ON = 1 X axis: REF.ON = 1; REF. OFF = 0;

P44.2 REF. ON = 1 Y axis: REF.ON = 1; REF. OFF = 0;

P44.3 REF. ON = 1 Z axis: REF.ON = 1; REF. OFF = 0;

P45.1 ALARM ON = 1 X axis: ALARM ON = 1; ALARM OFF = 0;

P45.2 ALARM ON = 1 Y axis: ALARM ON = 1; ALARM OFF = 0;

P45.3 ALARM ON = 1 Z axis: ALARM ON = 1; ALARM OFF = 0;

P48.1 AXIS ON = 1 X axis: AXIS ON = 1; AXIS OFF = 0;

P48.2 AXIS ON = 1 Y axis: AXIS ON = 1; AXIS OFF = 0;

P48.3 AXIS ON = 1 Z axis: AXIS ON = 1; AXIS OFF = 0;

P49.1 AXIS NAME = 88 X axis: AXIS NAME = 88; (0 - 127)

P49.2 AXIS NAME = 89 Y axis: AXIS NAME = 89; (0 - 127)

P49.3 AXIS NAME = 90 Z axis: AXIS NAME = 90; (0 - 127)

P50 9600 BAUD = 9600 BAUD RATE = 9600; (110-38400)

P51 EMPTY LINES = 1 LINE FEEDS = 1; (0 - 99)

P70 2 DATUM PT. = 2 2 DATUM POINTS = 2; 9 DATUM POINTS = 9;

P80 CL......OFF = 0 CL....OFF = 0; CL....RESET = 1;

P81 1/2 OFF = 0 ½ KEY OFF = 0; ½ KEY ON = 1;

P96 PROBING OFF = 0 PROBING OFF = 0; PROBING ON = 1;

P97 OUTPUT ID. = 0 OUTPUT ID. = 0; (0 - 127)

P98 LANGUAGE DE = 1 LANGUAGE: 0 = EN; 1 = DE; 2 = FR;

* 3 = IT; 4 = NL; 5 = ES;

6 = DA; 7 = SV; 8 = FI;

9 = CS; 10 = PL; 11= HU; 12 = PT;

Final character (*);

Output Structure of Parameter Lists

61

Page 62

Output Structure of Compensation-Value Table

A separate compensation-value table is prepared and output for each axis to be corrected.

Line 1

Each compensation-value output starts with the starting character < * > ( HEX: 0x2A)

* <CR> <LF>

3 characters

Line 2

Output of model designation and unit of measure

N D - 7 6 0 M M <CR> <LF>

13 characters 5 characters 2 characters

Type of display unit left-aligned Unit of measure End

Line 3

Output of axis to be corrected

A X I S X = 0 <CR> <LF>

13 characters 3 ch. 6 characters 2 characters

Output Structure of Compensation-Value Table

Axis to be corrected left-aligned Sep. block Axis value End

Right-ali gned

Page 63

Line 4

Output of axis causing the error

X F C T . X = 0 <CR> <LF>

13 characters 3 ch. 6 characters 2 characters

Axis causing the error Sep. block Axis value End

Left-aligned Right-aligned

Line 5

Output of spacing between compensation points

S P A C I N G X = 1 4 <CR> <LF>

13 characters 3 ch. 6 characters 2 characters

Spacing left-aligned Sep. block Spacing End

Right-ali gned

Line 6

Output of datum point for compensation

D A T U M X = + 0 . 0 0 0 <CR> <LF>

13 characters 3 ch. 13 characters 2 characters

Datum left-aligned Sep. block Datum value right-aligned End

Line 7

Output of compensation value no. 0

X N R . 0 0 = + 0 . 0 0 0 <CR> <LF>

13 characters 3 ch. 13 characters 2 characters

Compensation value no. left-aligned Sep. block Compensation value right-aligned End

Output Structure of Compensation-Value Table

63

Page 64

Subsequent lines: Output of compensation values 1 - 63

Output of compensation values

X N R . 6 3 = + 0 . 1 2 3 <CR> <LF>

13 characters 3 ch. 13 characters 2 characters

Compensation value no. left-aligned Sep. block Compensation value right-aligned End

Last line:

Each compensation-value table ends with the final character <*> (HEX: 0x2A)

* <CR> <LF>

3 characters

Compensation-value table ND 720, X axis

Compensation-value table Description

* Starting character (*);

ND-720 MM Type of display unit; unit of measure (MM or IN);

AXIS X = 0 Axis to be corrected, X = 0; Y = 1; Z = 2;

X FCT. X = 0 Axis causing the error, X = 0; Y = 1; Z = 2;

SPACING X = 1 4 Spacing (Range : 6 23)

DATUM X = + 0.000 Datum point 0 mm (value input)

Output Structure of Compensation-Value Table

X NR. 00 = + 0.000 Compensation value 0 = 0.000 mm (compensation value 0 is always 0)

X NR. 01 = ---------- Compensation value 1 = no value entered

X NR. 02 = ---------- Compensation values 2 63: no value entered (axis is not corrected)

X NR. 03 = ---------.

.

Page 65

Compensation-value table Description:

.

X NR. 60 = ---------X NR. 61 = ---------X NR. 62 = ---------X NR. 63 = ---------*

Compensation-value table ND 760, Z axis

Compensation-value table Description:

* Starting character (*);

ND-760 MM Type of display unit; unit of measure (MM or IN);

AXIS = 2 Axis to be corrected, X = 0; Y = 1; Z = 2;

Z FCT. Z = 2 Axis causing the error, X = 0; Y = 1; Z = 2;

SPA CING Z = 15 Spacing (range: 6 23)

DATUM Z = + 15.225 Datum point: +15.225 mm (value input)

Z NR. 00 = + 0.000 Compensation value 0 = 0.000 mm (compensation value 0 is always 0)

Z NR. 01 = - 0.030 Compensation values 1 10 are assigned values (value input)

Z NR. 02 = - 0.042 The axis is corrected from 15.225 mm to 342.905.

Z NR. 03 = - 0.008

Z NR. 04 = + 0.000

Z NR. 05 = + 0.009

Z NR. 06 = + 0.018

Z NR. 07 = + 0.025

Z NR. 08 = + 0.042

Z NR. 09 = + 0.051

Z NR. 10 = + 0.062

Z NR. 11 = ---------- Compensation values 11 63: no value entered (memory empty)

Z NR. 12 = ---------.

Z NR. 63 = ---------* Final character (*);

Final character (*);

Output Structure of Compensation-Value Table

65

Page 66

External Operation via RS-232-C/V.24 Data Interface

You can operate the display unit over the RS-232-C/V.24 data

interface using an external device.

The following commands are available on the ND 720 /

ND 760:

Format:

<ESC>TXXXX<CR> Key is pressed

<ESC>AXXXX<CR> Output of screen contents

<ESC>SXXXX<CR> Special function

Sequence of commands Meaning

<ESC>T0000<CR> 0 key

<ESC>T0001<CR> 1 key

<ESC>T0002<CR> 2 key

<ESC>T0003<CR> 3 key

<ESC>T0004<CR> 4 key

<ESC>T0005<CR> 5 key

<ESC>T0006<CR> 6 key

<ESC>T0007<CR> 7 key

<ESC>T0008<CR> 8 key

<ESC>T0009<CR> 9 key

<ESC>T0100<CR> CL key

<ESC>T0101<CR> - key

External Operation via RS-232-C/V.24 Data Interface

<ESC>T0102<CR> . key

<ESC>T0104<CR> ENT key

<ESC>T0107<CR> 1/2 key (datum)

<ESC>T0109<CR> X key

Sequence of commands Meaning

<ESC>T0110<CR> Y key

<ESC>T0111<CR> Z key (only ND 760)

<ESC>T0129<CR> SPEC FCT key

<ESC>T0142<CR> R+/- key

<ESC>T1000<CR> CE+0 keys

<ESC>T1001<CR> CE+1 keys

<ESC>T1002<CR> CE+2 keys

<ESC>T1003<CR> CE+3 keys

<ESC>T1004<CR> CE+4 keys

<ESC>T1005<CR> CE+5 keys

<ESC>T1006<CR> CE+6 keys

<ESC>T1007<CR> CE+7 keys

<ESC>T1008<CR> CE+8 keys

<ESC>T1009<CR> CE+9 keys

<ESC>A0000<CR> Output of model designation

<ESC>A0100<CR> Output of 14-segment display

<ESC>A0200<CR> Output of current value

<ESC>A0301<CR> Output of error text

<ESC>A0400<CR> Output of software number

<ESC>A0900<CR> Output of indicators

<ESC>S0000<CR> Counter RESET

<ESC>S0001<CR> Lock keyboard

<ESC>S0002<CR> Unlock keyboard

Page 67

Description of RS-232-C/V.24 commands:

The display unit supports the XON-XOFF protocol when

executing commands. As soon as the internal character

buffer (100 characters) is full, the display unit sends the

control character XOFF to the sender. After the buffer has

been executed, the display unit sends the control character

XON to the sender. Following that, it is ready to receive data

again.

String: STX;

10 characters; CR; LF;

10 characters; CR; LF;

10 characters; CR; LF;

Output of 14-segment display:

The screen contents displayed are output (also dialogs and

error messages).

Key is pressed (TXXXX commands)

The display unit acknowledges each identified key command

by sending the control character ACK (Acknowledge

Control-F). Following that, the key command becomes

effective.

The display unit responds to commands that cannot be

identified or to invalid commands by sending the control

character NAK (No acknowledge Control-U)

Output of model designation: