Page 1

HEIDENHAIN

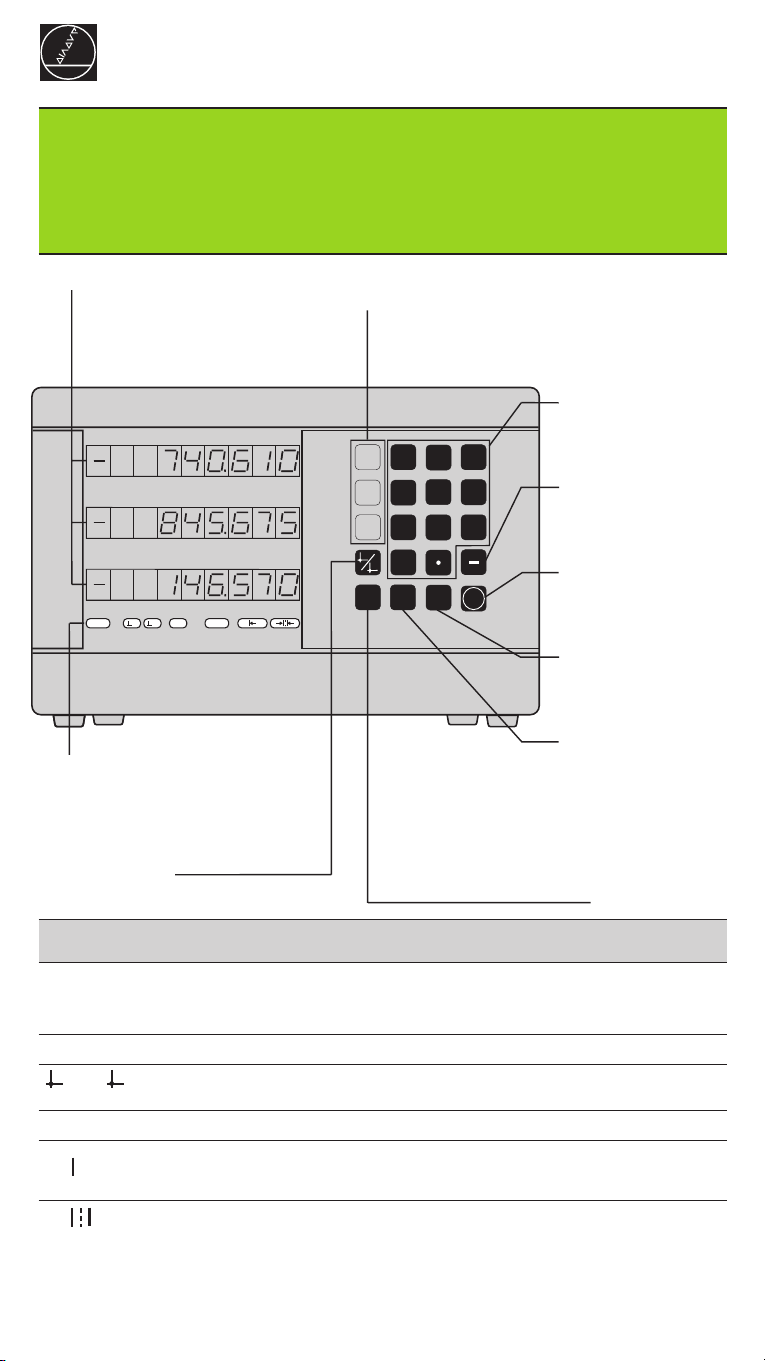

Working with the digital readouts

ND 510 ND 550

Actual value and input display

(7-segment LED,

8 decades and sign)

Downwards: X-axis, Y-axis,

ND 550 only: Z-axis

• Select coordinate axis

(Z-axis with ND 550 only)

• Select axis-based operating parameters

Numeric keypad

and decimal point

1

REF

HEIDENHAIN

Status indicators

2

SCL

in.

• Select datum

• Page backward in

parameter list

X

7

4

Y

1

Z

1

0

2

SPEC

CL

FCT

• Clear entry

• CL plus two-digit number:

select parameter

• Clear parameter entry

MOD

9

8

5

6

3

2

ENT

• Sign

• Change parameter

Confirm

entry values

• Call operating

parameters

• Page forward in

parameter list

Datum setting

function

Indicator Meaning

REF Reference mark was crossed over – datum points are now stored

in non-volatile memory.

Blinking: Waiting for reference mark to be crossed over.

in. Position values displayed in inches.

1 / 2 Datum point 1 / Datum point 2 currently active.

SCL Scaling factor active.

←←

←

←←

←←

→→

←

→

←←

→→

Define workpiece edge as datum.

Blinking: Waiting for operator to confirm selection.

Define centerline between two workpiece edges as datum.

Blinking: Waiting for operator to confirm selection.

Page 2

The ND 510 and ND 550 digital readouts accept HEIDENHAIN linear encoders with

sinusoidal output signals.

These linear encoders have one or more reference marks, preferably of the distancecoded

type. When a reference mark is crossed over, a signal is generated which

identifies that position as a reference point.

After switch-on, simply crossing over the reference mark restores the relationship

between axis positions and display values last defined by datum setting.

With distance-coded reference marks, a maximum traverse of only 20 mm is suffi-

cient to re-establish the relationship between axis positions and display values after

switch-on.

Switch-On

Turn on the power

➤ The power switch is located on the rear panel.

The display shows and REF blinks.

Turn on reference mark evaluation

➤ Press the ENT key.

The display shows the value last assigned to the reference mark position, the REF

indicator glows and the decimal point blinks.

Cross over the reference mark in each axis

➤ Move the axes one after the other until the display becomes active and the

decimal point glows.

The display unit is now ready for operation.

If you do not

wish reference mark evaluation, press CL instead of ENT.

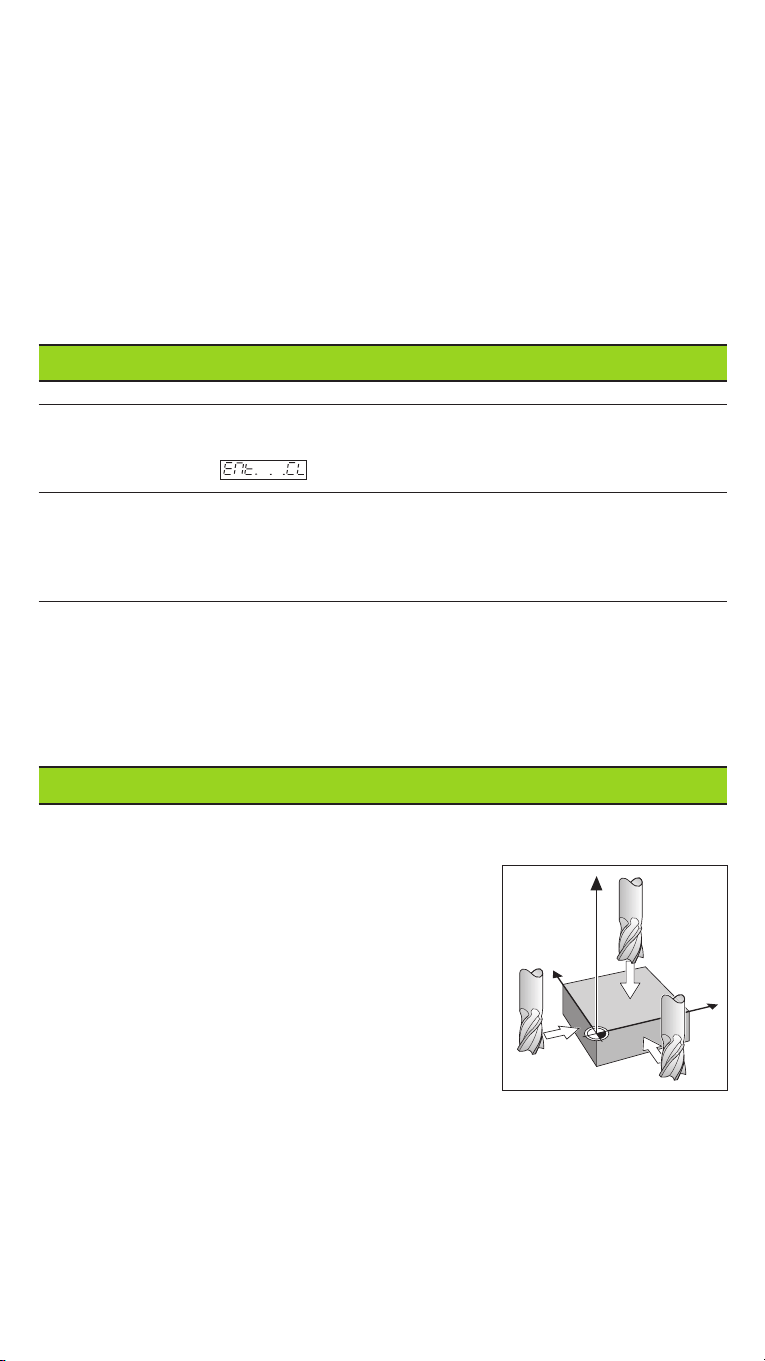

Setting the Datum

The datum setting procedure assigns a display value to a specific axis position.

Two separate datum points can be defined.

You can switch from one datum to the other

at the touch of a key.

Use datum 2 if you want to display

incremental values.

➤ Select the datum.

➤ Select the coordinate axis

in which the tool moves,

for example the X-axis.

➤ Touch the workpiece with the tool.

➤ Enter the position of the tool center

with the numeric keypad, for example X = –5 [mm]. The minus sign can only be

entered when at least one digit is shown in the display.

➤ Press ENT.

The display unit stores the value for this tool position.

Follow the above procedure for other axes.

Touching the workpiece

Z

Y

X

Page 3

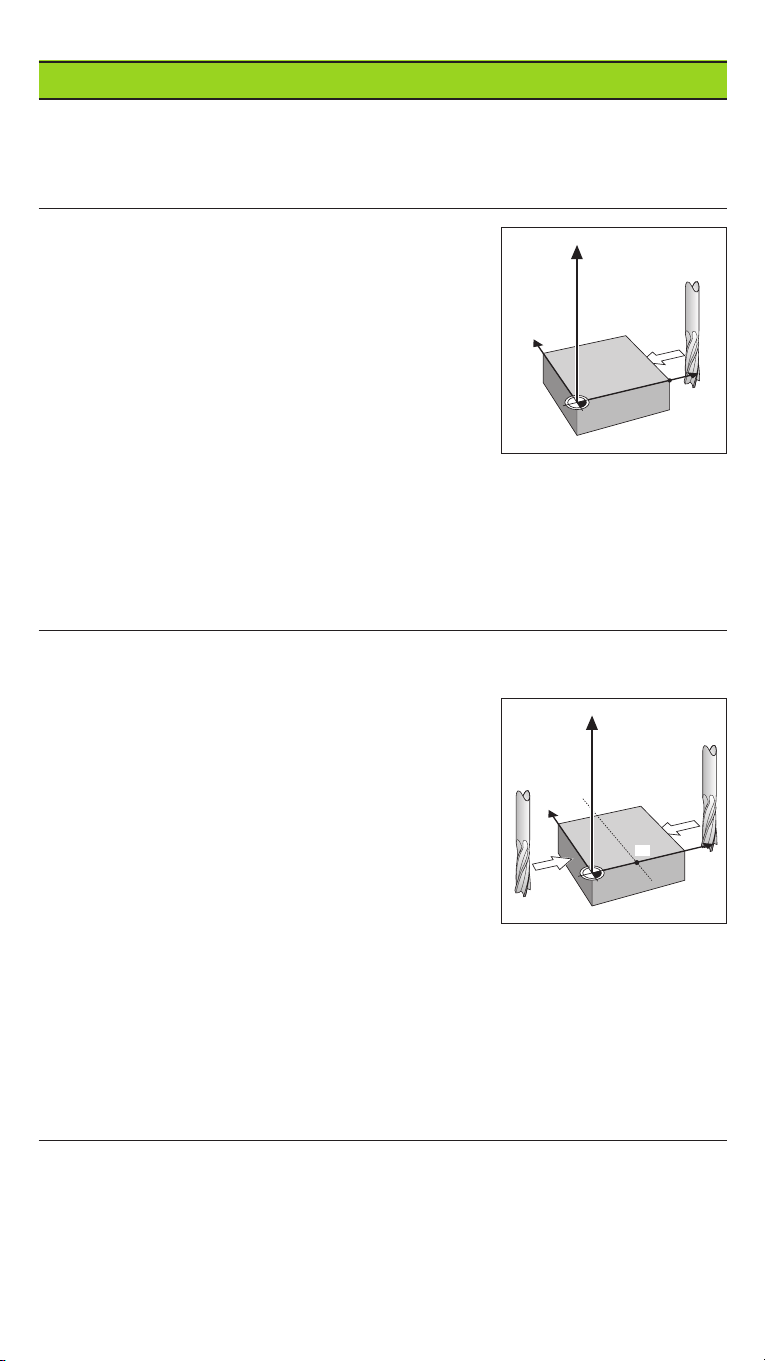

Datum Setting Functions

The special functions which your display unit is capable of allow you to define a

workpiece edge or the centerline between two workpiece edges as the datum. With

the SPEC FCT feature, the display unit takes into account the tool diameter you

entered in operating parameter P25.

Workpiece edge as datum

➤ Select the datum.

➤ Press the SPEC FCT key once.

The indicator "Workpiece edge as datum"

starts blinking.

➤ Press ENT.

The indicator glows.

➤ Select the coordinate axis in which the

tool moves.

The selected coordinate axis glows more brightly.

➤ Touch the workpiece with the tool.

➤ Press ENT.

The display shows the current position of the edge.

➤ Enter the new coordinate value for the workpiece edge that was touched.

➤ Press ENT.

The display unit sets the workpiece edge to the new value and displays the

position of the tool center based on the new datum.

This function ends automatically.

Centerline between two workpiece edges as datum

➤ Select the datum.

➤ Press the SPEC FCT key twice.

The indicator "Centerline as datum"

starts blinking.

➤ Press ENT.

The indicator glows.

➤ Select the coordinate axis in which the

tool moves.

The selected coordinate axis glows more brightly.

➤ Touch the first workpiece edge with the tool.

➤ Press ENT.

The decimal point in the display blinks.

➤ Touch the second workpiece edge with the tool.

➤ Press ENT.

The display shows the current position of the centerline.

➤ Enter the new coordinate value for the centerline between the two touched

workpiece edges.

➤ Press ENT.

The display unit sets the centerline to the new value and displays the position

of the tool center based on the new datum.

This function ends automatically.

Z

Y

X?

Workpiece edge as datum

Z

Y

X?

Centerline as datum

X

X

Aborting the datum setting functions

➤ To abort when the indicator for the function is blinking:

Press CL.

➤ To abort when the indicator for the function is glowing steadily:

Press SPEC FCT.

Page 4

Non-linear Error Compensation

To work with the non-linear error compensation it is necessary to

• activate the function via the operating parameter P40.

• traverse the reference marks after switching on.

• enter the compensation values in the table.

For every axis compensation values can be entered over 16 compensation points.

To determine the compensation values with a comparator system from

HEIDENHAIN, such as VM 101, you must select the REF display.

Selecting the Compensation Value Table

➤ Select the operating parameter P00 and enter the code number 105 296. Use

the following keys for the entries:

Key Function

MOD Save input value and select next input parameter.

1 / 2 Save input value and select preceding input value.

SPEC FCT Select REF display.

ENT • Save entry.

• Exit compensation value table.

CL • Delete entry.

• Delete all compensation values.

➤ Enter the parameters and compensation values as follows:

Display Entry

Enter the axis to be compensated, e.g. X.

Enter the axis causing the error, e.g. X, i.e. X = F(X).

Enter the datum on the axis causing the error.

Enter the distance of the compensation points on the error-

causing axis, e.g. 14 (= 2

Minimum input value: 10 (= 1.024 mm)

Maximum input value: 23 (= 8388.608 mm)

Select compensation point No. 1. The compensation point

number can be seen while pressing the MOD key. After letting

go of the MOD key the coordinates of the selected compensation

point can be seen in the upper line. Enter the compensation value

in the lower line.

Enter all following compensation points.

Delete all compensation values:

Display Entry

Press key CL.

Press key ENT. Compensation values are deleted.

14

µm = 16.384 mm).

Page 5

Working with Scaling Factors

The ND 510 and the ND 550 can display the axis traverse lengthened or shortened by

a scaling factor. You enter a scaling factor separately for each axis in the user

parameter P12, then activate the scaling factor function with the user parameter

P11. SCL is highlighted.

Error Messages

Message Cause and effect

Traverse distance with datum setting function (SPEC FCT) is

too short

Incorrect input value

Input frequency too high for encoder input

(will occur for example when traverse speed too high)

Internal counter overflow

Error while crossing over reference marks

To clear the error message: Switch of the display unit.

Should any of these error codes recur, contact your

HEIDENHAIN service agency.

Compensation values for nonlinear axis error compensation have

been erased

Datums have been erased

Erase the operating parameters

If all decimal points light up, the measured value is too large or too small.

Set a new datum.

To clear error message :

When you have removed the cause of the error,

➤ press CL.

Page 6

Operating Parameters

User Parameters

User parameters are operating parameters that can be changed without entering the

codes: P00 to P25

Axis assignment

Parameters which are entered separately for each axis have axis codes:

"1" signifies the X-axis, "2" the Y-axis, and (with the ND 550) "3" the Z-axis.

A point separates the axis code from the parameter number.

In the operating parameter list, these parameters are set off with a superscript "A",

the parameter for the X-axis (e.g. ) is in the list.

You select axis-specific operating parameters with the yellow arrow keys.

To call the operating parameter list:

➤ Press MOD.

To go directly to a certain operating parameter:

➤ Press and hold CL, then press the first digit of the parameter number.

➤ Release both keys and enter the second digit of the parameter number.

Protected Operating Parameters

In order to change protected operating parameters, the code number 95 148 must be

entered via P00 Code: They remain accessible until the position display is switched

off.

To page through the operating parameter list:

➤ Page forward: press MOD.

➤ Page backward: press the 1 / 2 key.

Any changes are automatically activated when you resume paging.

To change a parameter setting:

➤ Change the value with the minus key, or

➤ Enter the desired value directly, e.g. for P25.

To correct an entry:

➤ Press CL.

To exit the operating parameters:

➤ Press ENT.

This activates all changes made.

Operating Parameter List

Parameter Meaning Function / Effect Setting

Code Number 95148: protected operating parameter

105296: select compensation value table

Unit of Display in mm

measurement Display in Zoll

Radius-/diameter Radius

display

Scaling factor Scaling factor on

Scaling

Scaling factor AEnter value for each axis separately

Tool diameter Enter tool diameter

Tool

A

Diameter

Scaling factor off

Page 7

Operating Parameter List – cont'd.

Parameter Meaning Function / Effect Setting

Counting Normal

direction

A

Inverse

Signal period of encoder

(

Period

:) 2, 4, 10, 20, 40, 100, 200

(Direction: Positive)

(Direction: Negative)

A

Subdivision of the encoder signals

(

Subdivision

:) 4, 2, 1, 0.8, 0.5, 0.4, 0.2, 0.1

Select Error compensation not active

error Linear error compensation active

Compensation

compensation

Linear error compensation1)

– 99 999 < P41 < + 99 999 [µm/m]

Non-linear error compensation active

A

Reference One reference mark

A

marks

Distance-coded with 500 • SP

(SP = signal period)

Distance-coded with 1000 • GP

(e.g. for LS 303 C / LS 603 C)

Distance-coded with 2000 • SP

Distance-coded with 5000 • SP

Encoder

Encoder Monitoring off

monitoring

Axis display

(

Axis

) Do not display measured position /

A

Monitoring on

A

Display measured position

(Alarm Off)

(Alarm On)

no encoder

Function of Resets display to zero

CL key Does not reset display to zero

1)

Calculate the entry value for P41

Example: Displayed measuring length La = 620.000 mm

Actual length (determined with, for example, the VM 101 comparator

system from HEIDENHAIN) Lt = 619.876 mm

Length difference ∆L = Lt – La = –124 µm

Compens. factor k: k = ∆L / La = –124 µm / 0.62 m = –200 [µm/m]

A

Parameter Settings for HEIDENHAIN Linear Encoders

Display step

(unit: P01)

Model

Signal

period [µm]

Reference

marks

P43

mm inches

LS 303 20 one single 0.005 0.000 2 4

LS 603 dist.c. 1 000 0.01 0.000 5 2

LB 302 40 one single 0.01 0.000 5 4

LIDA 10x dist.c. 2 000

LB 3xx 100 one single 0.025 0.001 4

dist.c. 1 000 0.05 0.002 2

0.1 0.005 1

Example: Linear encoder with signal period s = 20 µm

Desired display step a = 0.005 mm

Subdivision P32

= =

= 0.001

= =

••

• s / a = 4

••

Subdivision

P32

Page 8

Rear Panel

Inputs for HEIDENHAIN linear encoders

(ND 510: 2, ND 550: 3)

with sinusoidal output signals

(7µA

to 16 µApp),

Connecting cable max. 20 m (66 ft),

pp

Input frequency max. 50 kHz with

6 m/20 ft cable (35 kHz with 10 m/32.8 ft,

20 kHz with 20 m/66 ft)

Power switch

Ground terminal

Interfaces X1, X2 and X3 comply with the recommendations in EN 50 178

for separation from line power.

Installation

You can mount the display unit on a surface

using M4 screws, or on a tilting base from

HEIDENHAIN (Id.-Nr. 281 619 01).

Power Supply and Connection

Danger of electrical shock!

Unplug the power cable before opening the housing.

Connect a protective ground. This connection should never be interrupted.

93+2

3.66+.08"

X2 X1

X3

43.3

1.704"

92

3.622"

0

20

.79"

21±0.2

1±.008"

4

M

56±0.2

2.204±.008"

29+0.5

209±0.2

8.228±.008"

1.14+.02"

230±0.2

9.055±.008"

Danger to internal components!

Do not engage or disengage any connections while the unit is under power.

Use only original replacement fuses.

Primary-clocked power supply.

Voltage range 100 V to 240 V (–15% to +10 %) Frequency 48 Hz to 62 Hz

Power consumption ND510: 9 W, ND550: 12 W Line fuse F 1 A (in unit)

Minimum cross-section of power cable: 0.75 mm

2

To increase the noise immunity, connect the ground terminal on the rear panel

to the central ground point of the machine. (Minimum cross-section 6 mm

Ambient Conditions

Temperature range Operation: 0°C to +45°C (32°F to 113°F)

Storage: –30°C to +70°C (–32°F to 158°F)

Rel. humidity Annual average: < 75%; maximum: < 90%

Weight 2.3 kg

DR. JOHANNES HEIDENHAIN GmbH

Dr.-Johannes-Heidenhain-Straße 5

D-83301 Traunreut, Deutschland

86

(0

(0

Service (0 86 69) 31-12 72

69) 31-0 . 56 831

FAX

86

69) 50 61

TNC-Service (0

FAX

(0 86 69) 98 99

281 615-23 · SW 246 119 02 · 10 · 6/99 · H · Printed in Germany · Subject to change without notice

86

69) 31-14 46

2

)

Loading...

Loading...