HEIDENHAIN Inverter Systems and Motors Technical Manual

Technical Manual

Inverter Systems

and

Motors

for the Contouring Controls

TNC 410 M

TNC 426 M

TNC 430 M

iTNC 530

MANUALplusM

MANUALplus 4110

CNC PILOT 4290

Januar 2010 Ver08

208 962-21 (208 962-E8) · 12/2010 · pdf

Foreword

This Technical Manual has been written for all machine tool manufacturers. It

contains all of the information necessary for the mounting and electrical

installation of HEIDENHAIN inverter systems and HEIDENHAIN motors.

With each update, you will receive a set of supplementary pages free of

charge. Always sort these pages into your Technical Manual immediately. In

this way, your manual will always be up-to-date.

You can use extracts from this manual to supplement your machine

documentation. If you increase the size of the manual format (17 cm x 24 cm)

by the factor 1.225, you will have DIN A4 format.

No documentation can be perfect. To stay up to date, documentation must

change constantly. It is also thrives on your comments and suggestions for

improvement. Please help us by telling us your ideas.

DR. JOHANNES HEIDENHAIN GmbH

E/P Department

Dr.-Johannes-Heidenhain-Str. 5

83301 Traunreut

April 2007 Ve 06

208 962-21 (208 962-E6) · 3 · 4/2007 · S · Printed in Germany · Subject to change without notice

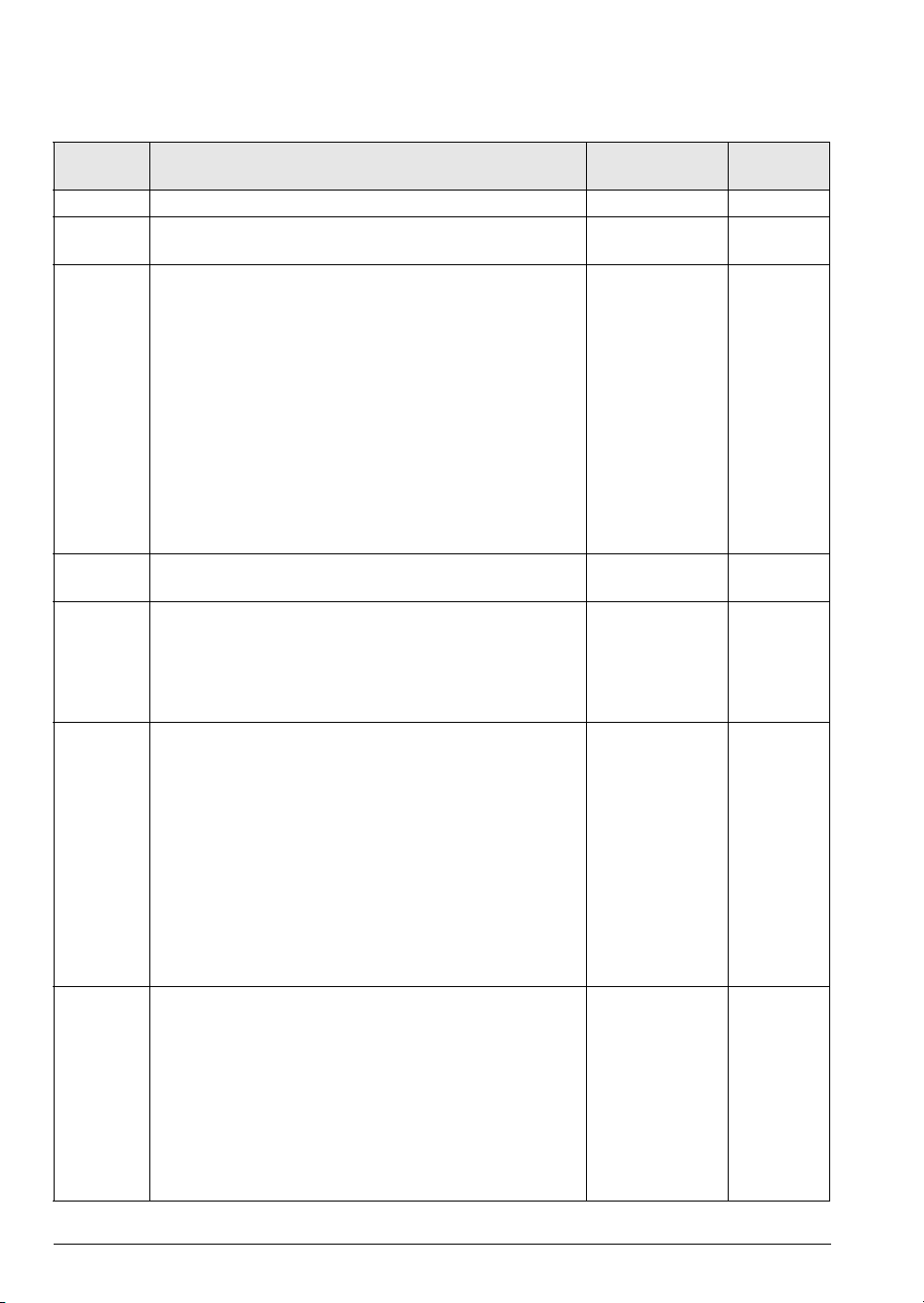

1 Update Information No. 1

1.1 Compact Inverters

New compact inverters

• UE 211B: Continuous load on axes: 2 x 7.5 A; 1 x 15 A

• UE 241B: Continuous load on axes: 2 x 7.5 A; 1 x 23 A

New connections on the bottom of the UE 2xxB compact inverter. These

connections are reserved for future applications and must not be wired.

New sliding switch on the front of the UE 2xxB compact inverter. This

enables the spindle unit of the compact inverters to be used as an axis.

1.2 Modular Inverters

New UV 120 regenerative power supply unit with KDR 120 commutation

reactor

UV 120: DC-link full-load power: 22 kW

New line filters for UV 120 and UV 140

Note the dimensions of the new line filter!

New UP 110 braking resistor module

The UP 110 braking resistor module is required so that, if the power supply

from the UV 120 and UV 140 power supply modules fails, the braking energy

from the motors can be dissipated.

Continuous load on spindle: 20 A

Continuous load on spindle: 31 A

1.3 Motors

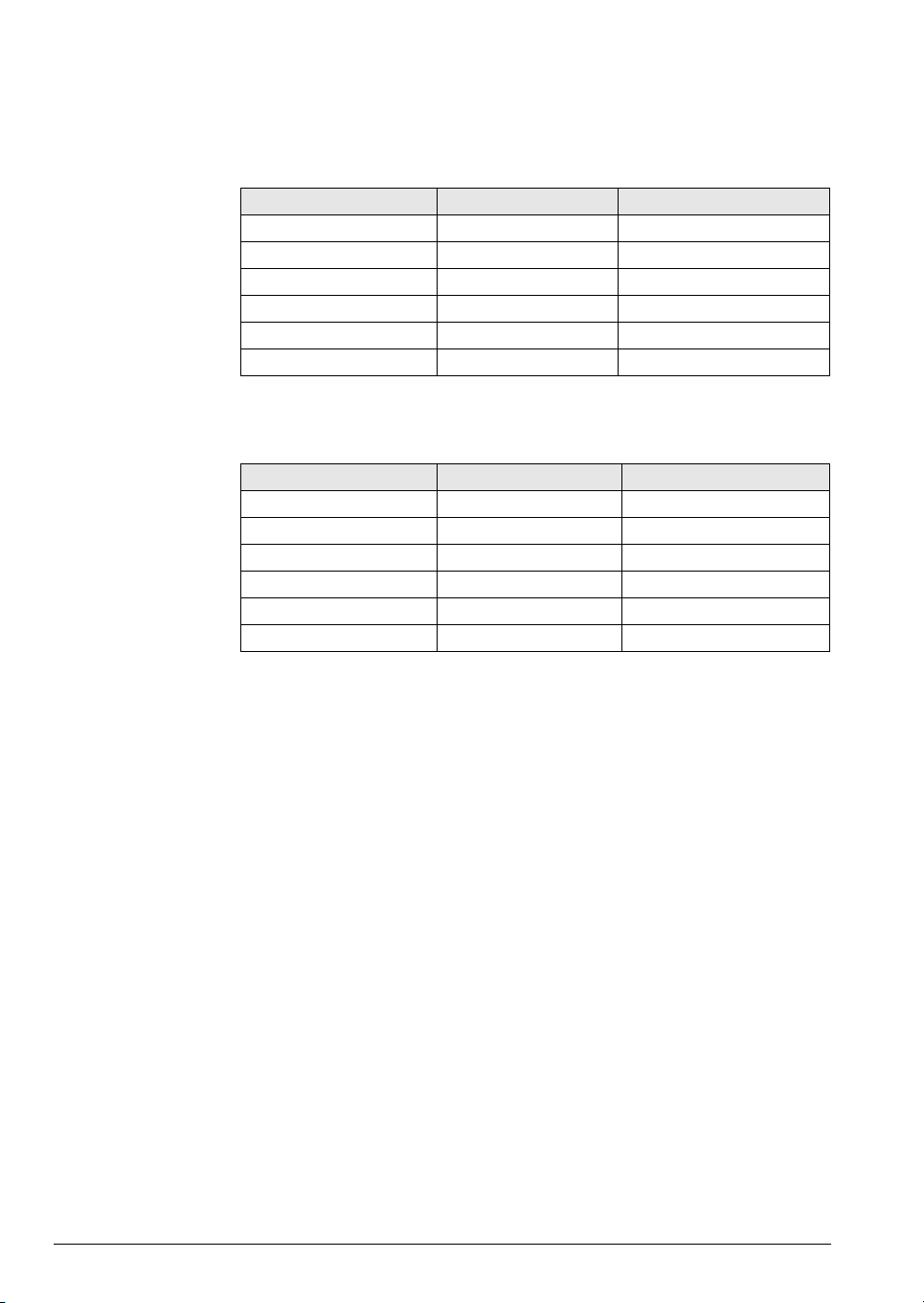

New synchronous motors QSY 96G, QSY 112D, the QSY 116 series, and

QSY 155

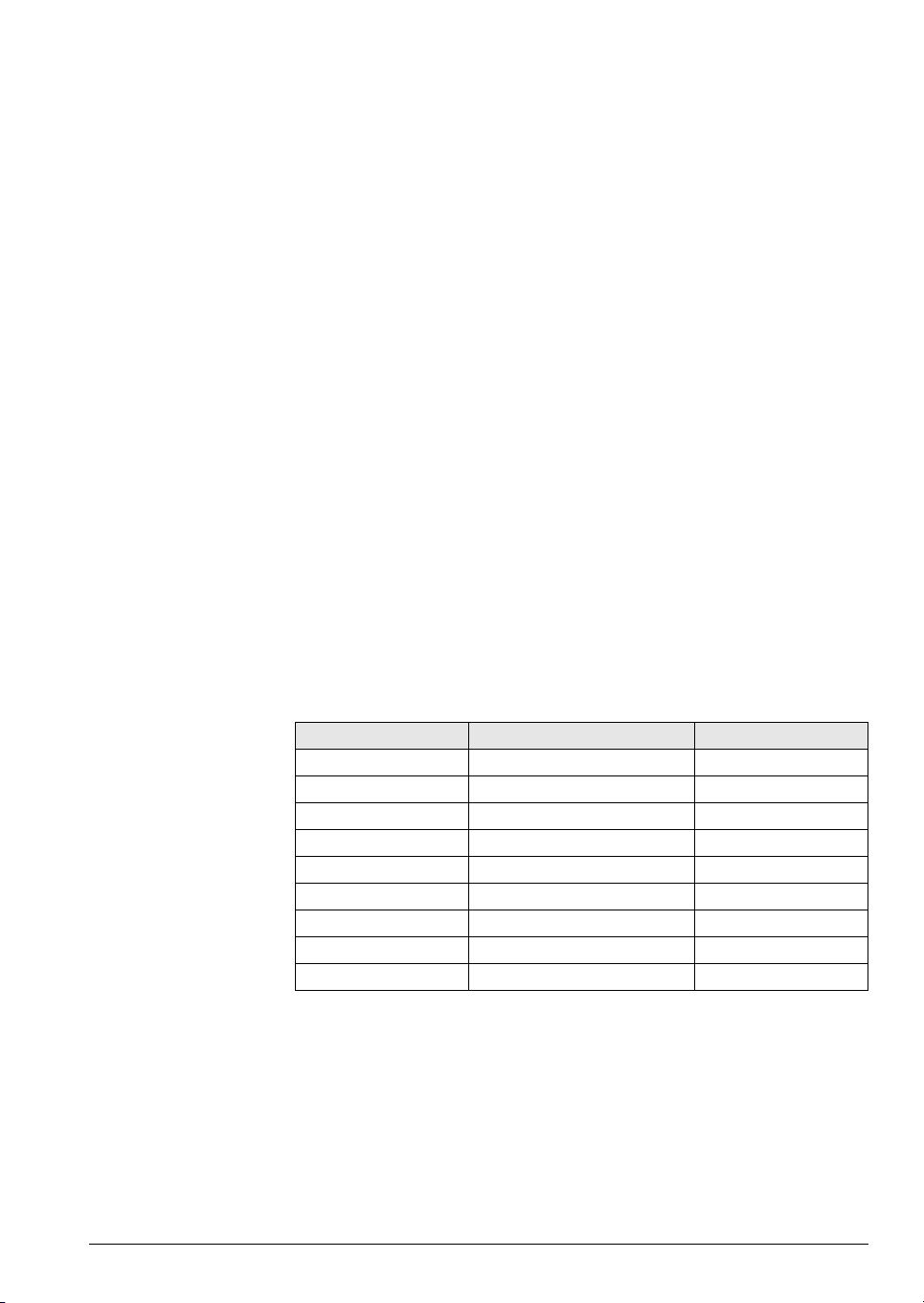

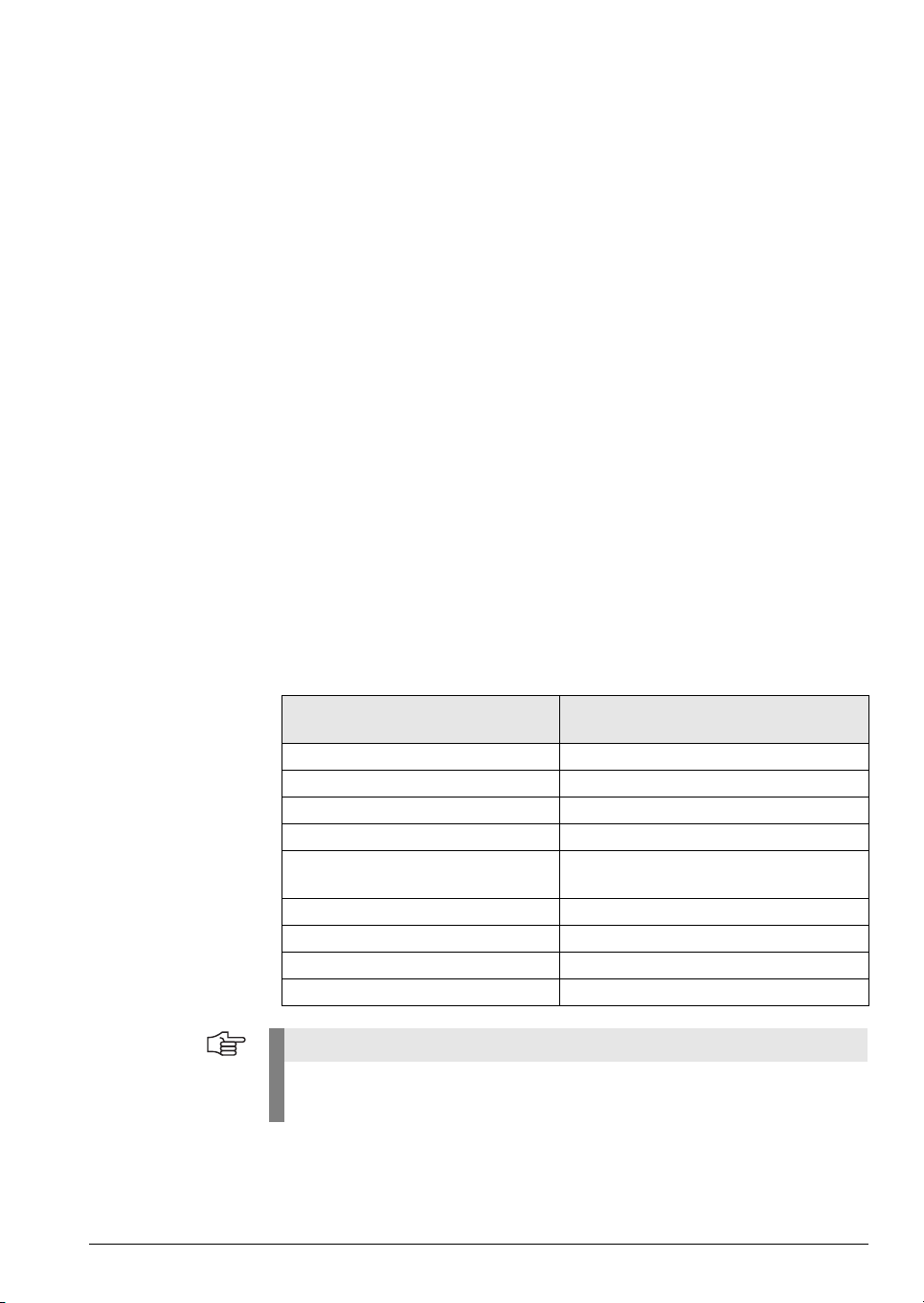

Designation Stall torque M

QSY 96G 5.2 Nm 4500 rpm

QSY 116C 5.2 Nm 3000 rpm

QSY 116E 7.2 Nm 3000 rpm

QSY 116J 10.0 Nm 3000 rpm

QSY 155A 8.3 Nm 3000 rpm

QSY 155B 12.2 Nm 3000 rpm

QSY 155D 21.6 Nm 3000 rpm

QSY 155F 26.1 Nm 3000 rpm

QSY 112D 72.0 Nm 2000 rpm

New QAN 164B asynchronous motor

• Rated speed n

• Power rating P

This Technical Manual lists the input values for the machine parameters of

the current controller of the TNC and MANUALplusM for HEIDENHAIN

motors.

: 1350 rpm

N

: 31.5 kW

N

0

Rated speed n

N

April 2000 Update Information No. 1 1 – 1

1.4 Replacing Instructions

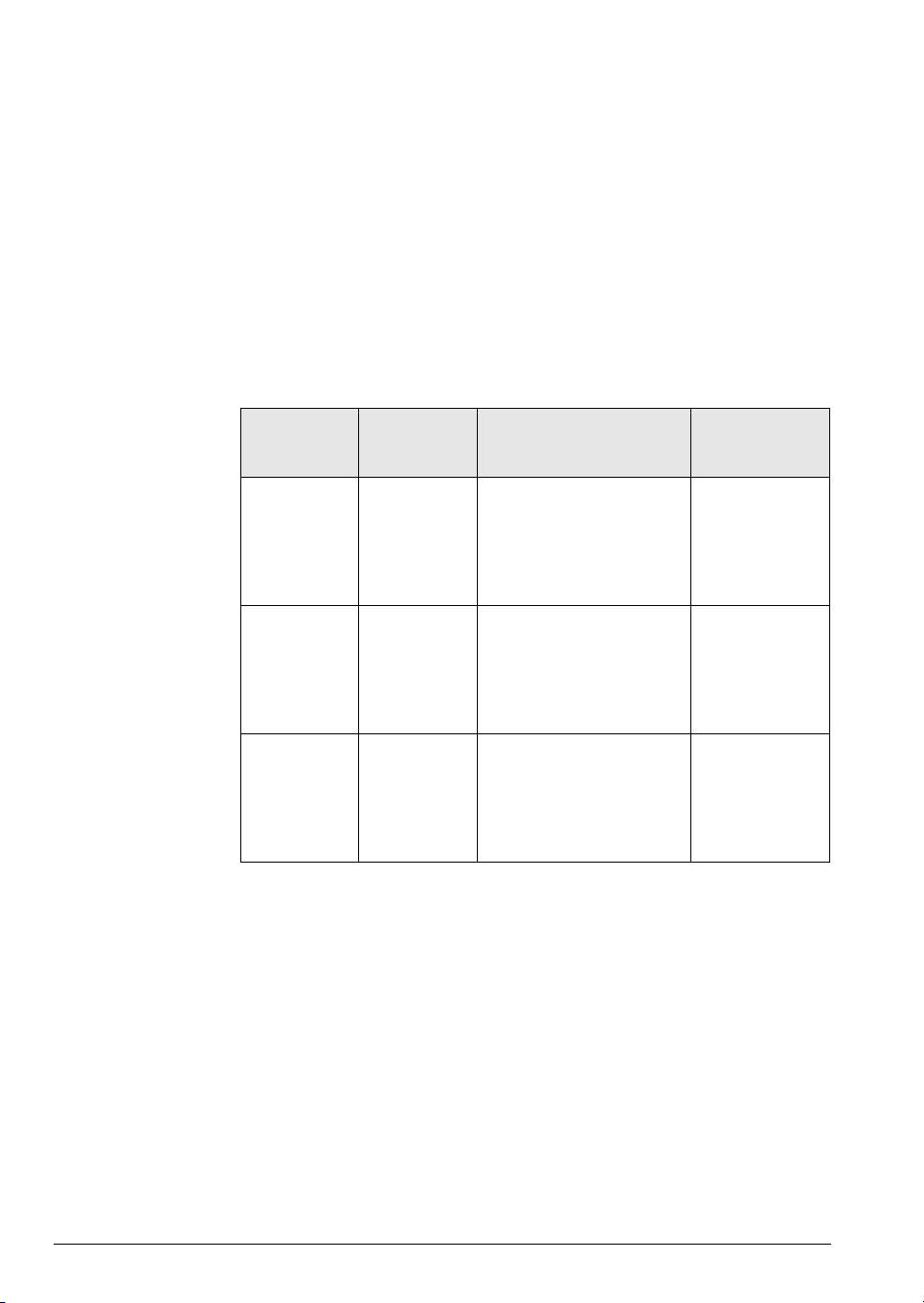

Page Change Remove

Page

Title New date of issue August 99 April 2000

Chapter 1 Update Information – Update Info. 1

Chapter 2 Printing errors corrected

Documentation of changes in the

variants

UE 211B, UE 241B have been added

UV 120, KDR 120 have been added

New line filter

UP 110 has been added

Chapter 3 First issue of the chapter Entire chapter Entire chapter

Chapter 4 Printing errors corrected Entire chapter Entire chapter

Chapter 5 Printing errors corrected

UE 211B, UE 241B have been added

Chapter 6 Printing errors corrected

UV 120, KDR 120 have been added

New line filter

UP 110 has been added

Chapter 7 Description changed

QSY 96G, QSY 112D, QSY 116 series

and QSY 155 have been added

QAN 164B has been added

New input values for current controller

Chapter 8 Subject Index Entire chapter Entire chapter

Entire chapter Entire chapter

Entire chapter Entire chapter

Entire chapter Entire chapter

Entire chapter Entire chapter

Insert

Page

1 – 2 HEIDENHAIN Technical Manual for Inverter Systems and Motors

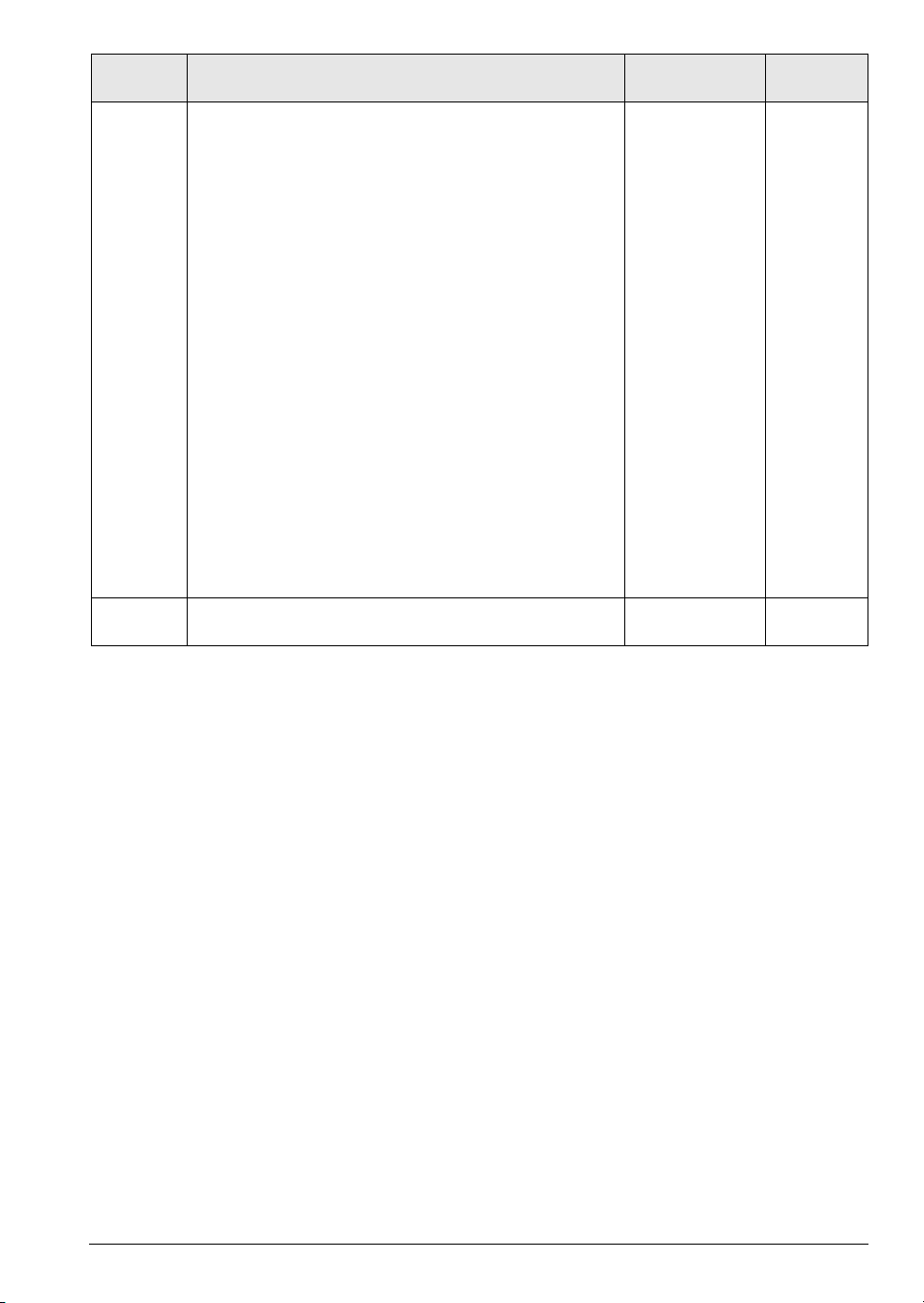

1 Update Information No. 2

1.1 Compact inverter

Length of ribbon cable delivered with the UE 2xxB changed

1.2 Modular Inverters

New EPCOS 35 A line filter added for the regenerative UV 120 power supply

unit

New connections on the bottom of the UM 1xx power module. These

connections are reserved for future applications and must not be wired.

If disturbances in the line power supply net occur with the regenerative

power supply units even though HEIDENHAIN commutating reactors and

line filters are being used, the new three-phase current capacitor must be

used.

1.3 Motors

QSY 96A has been added

Power and torque characteristic for QAN 134D has been added

Machine parameters for the current controller for QAN 134D have been

added

New power cable with UL certification

February 2001 Update Information No. 2 1 – 1

1.4 Replacing Instructions

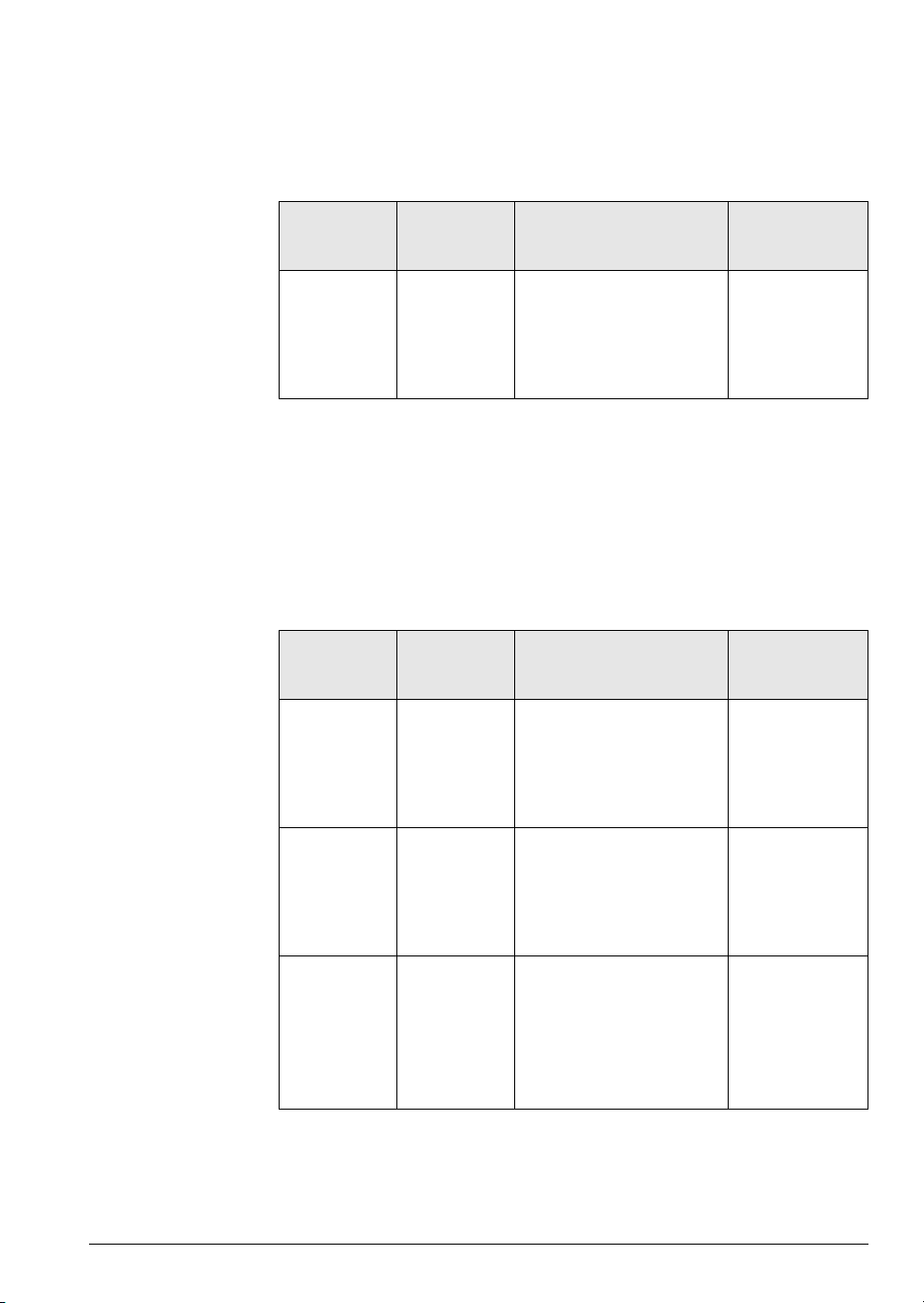

Page Change Remove

Page

Title New date of issue August 99 February 2001

Chapter 1 Update Information – Update Info. 2

Chapter 2 Printing errors corrected

New Id. Nr. for the UE 2xxB ribbon

cable

UE 2xxB power consumption corrected

EPCOS 35 A line filter added,

FINMOTOR removed

Selection tables for ribbon cables and

covers revised

Chapter 3 Printing errors corrected

Selection of the braking resistor

Chapter 4 Printing errors corrected

Demands of the line power supply

New three-phase current capacitor

PW 210 mounting instructions modified

Chapter 5 Printing errors corrected Entire chapter Entire chapter

Chapter 6 Printing errors corrected

EPCOS 35 A line filter added,

FINMOTOR removed

Notes for connecting the motor brake

New connections for the power

modules

Chapter 7 Printing errors corrected

Notes for connecting the motor brake

New power cable with UL certification

QSY 96A has been added

Terminal box illustration corrected

Rotatable flange sockets modified

Power and torque characteristic for

QAN 134D has been added

Input values for the current controller

on the QAN 134D have been added

Chapter 8 Subject Index Entire chapter Entire chapter

Entire chapter Entire chapter

Entire chapter Entire chapter

Entire chapter Entire chapter

Entire chapter Entire chapter

Entire chapter Entire chapter

Insert

Page

1 – 2 HEIDENHAIN Technical Manual for Inverter Systems and Motors

1 Update Information No. 3

1.1 General Information

New SM 110 voltage protection module for use with synchronous spindle

motors

Temperature sensor on the PW 1x0

Double-row configuration of the HEIDENHAIN inverter system

1.2 Compact Inverters

UE 241B no longer available

New regenerative compact inverters

• UR 230: Continuous load on axes: 2 x 7.5 A

• UR 240: Continuous load on axes: 3 x 7.5 A

• UR 242: Continuous load on axes: 3 x 7.5 A; 1 x 25 A

New connections for controlling the motor brakes: X344, X392 and X393

1.3 Modular Inverter

New UV 150 regenerative power supply unit with KDR 150 commutation

reactor

UV 150: DC-link full-load power: 50 kW

New UM 115 power module

New variants of the UV 1xx power units

Current consumptions from the 15-V and 24-V power supply of the inverter

system must be inspected

New connections for controlling the motor brakes: X344 and X392

Continuous load on spindle: 25 A

Continuous load on spindle: 35 A

Continuous load on spindle: 35 A

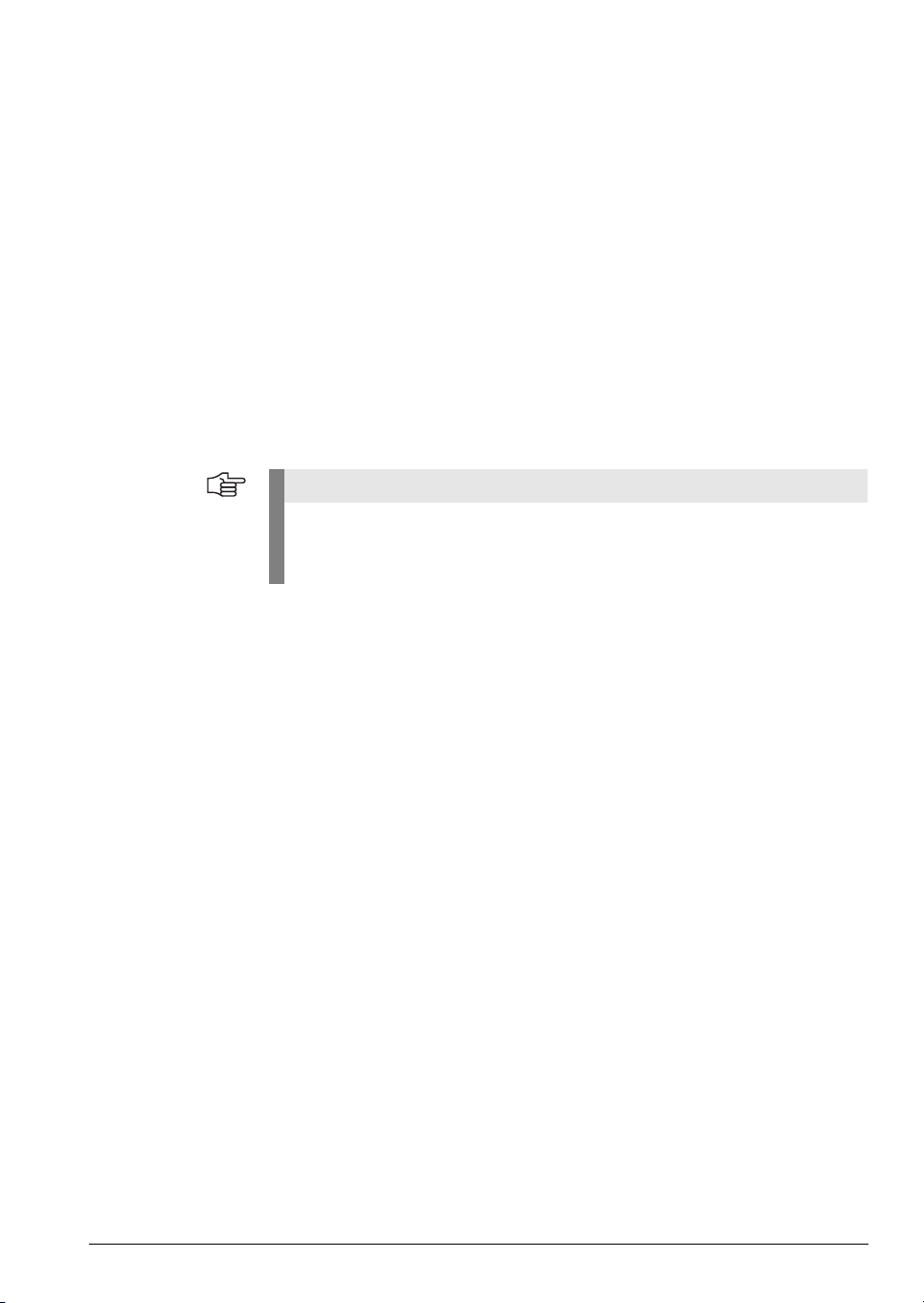

1.4 Motors

QSY 96, QSY 116, QSY 155 with EQN 1325 absolute multiturn rotary

encoder

New QSY 155B synchronous motors with n

Designation Stall torque M

QSY 155B 13 Nm 2000 rpm

QSY 155C 17.7 Nm 3000 rpm

Input values for the digital current controller

July 2002 Update Information No. 3 1 – 1

0

= 2000 rpm and QSY 155C

N

Rated speed n

N

1.5 Replacing Instructions

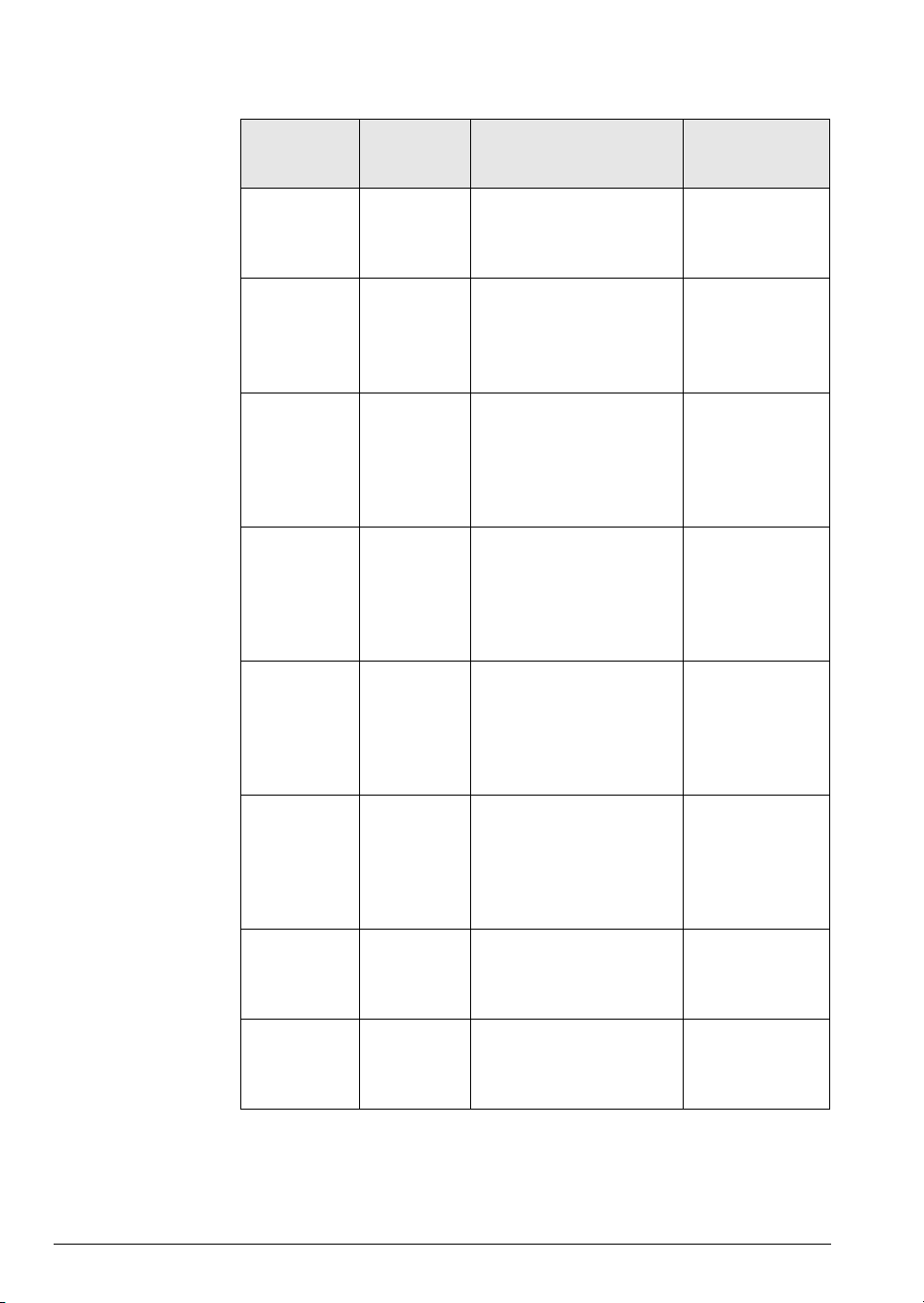

Page Change Remove

Page

Title New date of issue February 99 July 2002

Chapter 1 Update Information – Update

Chapter 2 Printing errors corrected

UE 241 B removed

UR 2xx, UV 150, KDR 150 and UM 115 added

Continuous load and short term rating for different

PWM frequencies

Peak performances for 0.2 s

Current consumption of the 15-V and 24-V supply

Covers included in the items supplied with the

compact inverters

Selection tables for ribbon cables and covers revised

SM 110 voltage protection module added

Double-row configuration of inverter systems

Chapter 3 Performance overview of a drive system added Entire chapter Entire

Chapter 4 Note on radio interferences

Cross sections of the power cables

HEIDENHAIN recommends use of the three-phase

current capacitor

Note on leakage current

Chapter 5 Printing errors corrected

UE 241B removed

UR 2xx added

New connections for controlling the motor brakes:

X344, X392 and X393

Line fuse for UE 2xx, UV 102, UE 2xxB

Temperature switch on the PW 110B

Additional voltage to X70, X71, X72

Tightening torque of the electrical screw connections

added

Dimensions only in mm

Chapter 6 New connections for controlling the motor brakes:

X344 and X392

Printing errors corrected

Line fuse for UV 1x0

Temperature switch on the PW 110B

Additional voltage to X70, X71, X72

Tightening torque of the electrical screw connections

added

Dimensions only in mm

Entire chapter Entire

Entire chapter Entire

Entire chapter Entire

Entire chapter Entire

Insert

Page

Info. 3

chapter

chapter

chapter

chapter

chapter

1 – 2 HEIDENHAIN Technical Manual for Inverter Systems and Motors

Page Change Remove

Page

Chapter 7 Printing errors corrected

Entire chapter Entire

Bend radii of the power and encoder cables

Insert

Page

chapter

Calculation of the maximum torque of a drive

Pin layout for speed encoders with EnDat interface

Note on differences between internal connections, ID

label and motor tables of QAN 30 and QAN 4S

Power modules for QAN 3M: UM 111B, UM 121B

Turning radius for connectors changed

Incorrect assignment for the fan connection on QAN

104 and QSY 112D

QSY 96, QSY 116, QSY 155 with EQN 1325 absolute

multiturn rotary encoder added

QSY 155B (n

= 2000 rpm) and QSY 155C added

N

Specifications for QSY 155B revised

Characteristic curves revised

Bearing service life for QSY 041B, QSY 071B,

QSY 090B, QSY 093B and QSY 112 series

Bearing service life for QAN 104, QAN 134 and

QAN 164B

Dimensions only in mm

Input values for the digital current controller

Chapter 8 Keyword index Entire chapter Entire

chapter

July 2002 Update Information No. 3 1 – 3

1 – 4 HEIDENHAIN Technical Manual for Inverter Systems and Motors

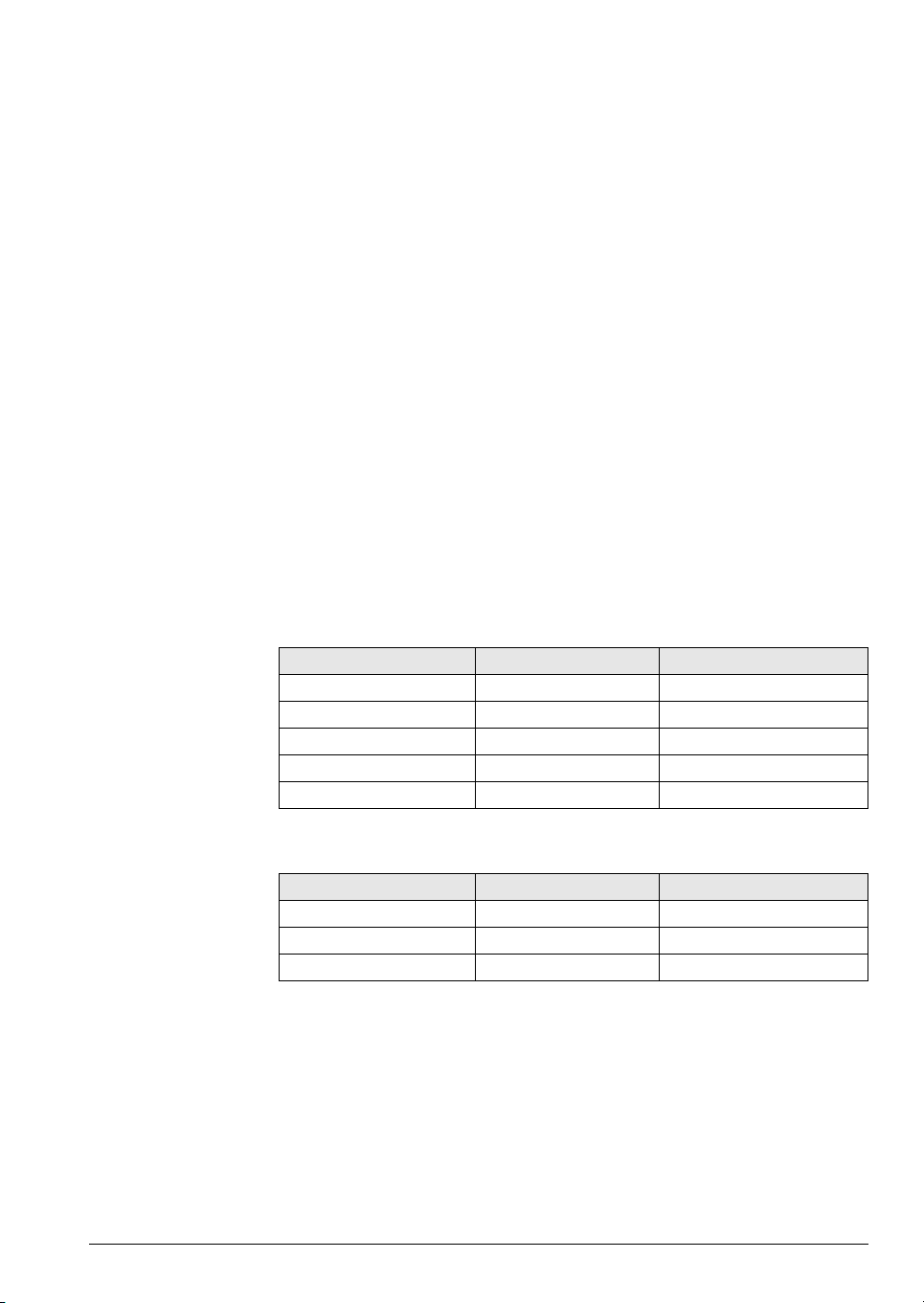

1 Update Information No. 4

1.1 General Information

New axis-enabling module (Id. Nr. 341 518-01) that allows you to switch off

power modules in modular inverter systems group-by-group. The axisenabling module is mounted onto the power module and separates the unit

bus. All power modules that are connected after the axis-enabling module

to the unit bus are switched of via X72 of the unit bus, and no longer via X72

of the UV(R) 1x0.

1.2 Modular Inverter

New variant of the UV 140 power supply unit (Id. Nr. 335 009-04) with

improved PCB and improved housing.

New UVR 150 power supply unit (Id. Nr. 384 708-01) with new power supply

unit and additional connections for supplying the CC 42x with +5 V and 0 V.

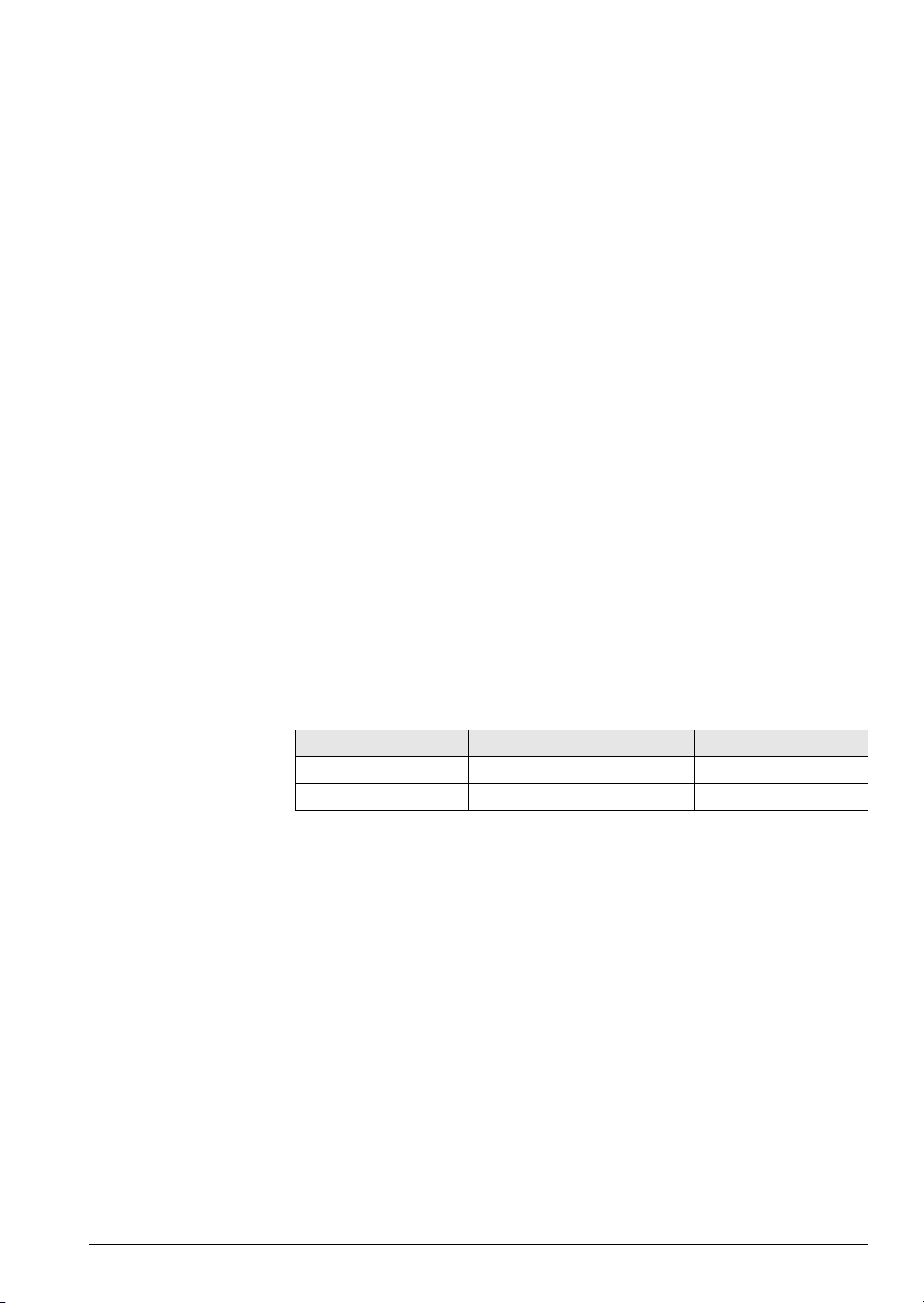

1.3 Motors

New QSY 116J EcoDyn, QSY 155B EcoDyn, QSY 155C EcoDyn, QSY 155F

EcoDyn synchronous motors

The following NC software versions are required for controlling these

motors in the EcoDyn operating mode:

• iTNC 530: 340 420-06 and later

• MANUALplus 4110: 354 809-11 and later

• CNC PILOT 4290: 340 460-14, 362 796-10 and later

Designation Stall torque M

QSY 116J EcoDyn 10.0 Nm 3000 rpm

QSY 116J EcoDyn 13.0 Nm 3000 rpm

QSY 155C EcoDyn 17.7 Nm 3000 rpm

QSY 155C EcoDyn 21.6 Nm 3000 rpm

QSY 155C EcoDyn 26.1 Nm 3000 rpm

New QAN 200M, QAN 200L, QAN 200U asynchronous motors

Designation Rated speed n

QAN 200M 1500 rpm 5.5 kW

QAN 200M 1500 rpm 7.5 kW

QAN 200M 1500 rpm 10 kW

0

N

Rated speed n

Rated power output P

N

N

March 2003 Update Information No. 4 1 – 1

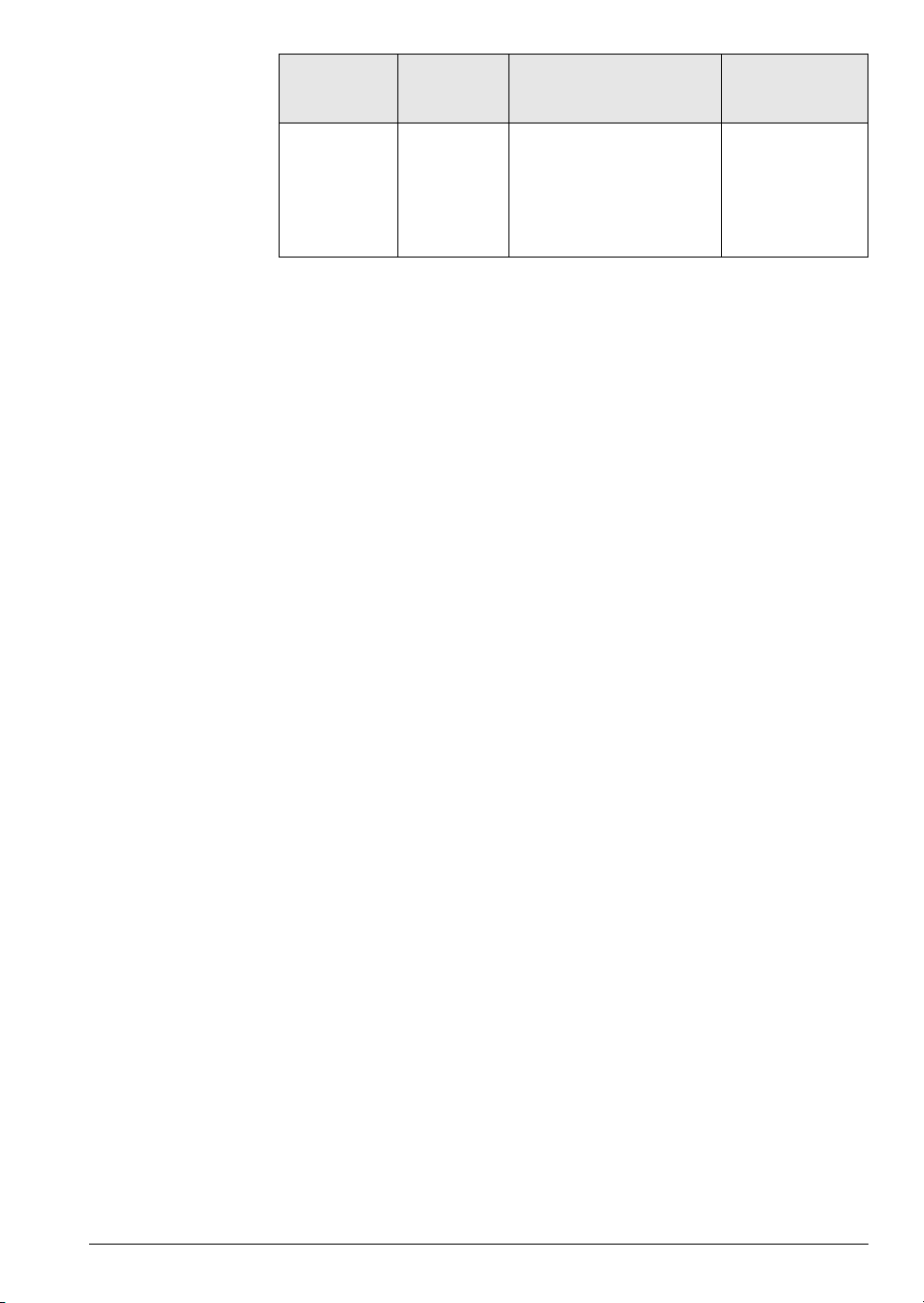

1.4 Replacing Instructions

Page Change Remove

Page

Title New date of issue May 2002 March 2003

Chapter 1 Update Information – Update Info. 4

Chapter 2 Corrective action, UVR 150 has been added, new

UV 140 variant, cover length has been added ,

axis-enabling module has been added

Chapter 3 UVR 150 has been added Entire chapter Entire chapter

Chapter 4 UVR 150 has been added,

corrective action

Chapter 5 Corrective action, PW 210 dimension drawing has

been revised

Chapter 6 Corrective action, UVR 150 has been added,

PW 210 dimension drawing has been revised

Chapter 7 Corrective action,

QAN 200, QSY 116J, QSY 155B EcoDyn,

QSY 155C EcoDyn, QSY 155D EcoDyn,

QSY 155F EcoDyn have been added

Chapter 8 Keyword index Entire chapter Entire chapter

Entire chapter Entire chapter

Entire chapter Entire chapter

Entire chapter Entire chapter

Entire chapter Entire chapter

Entire chapter Entire chapter

Insert

Page

1 – 2 HEIDENHAIN Technical Manual for Inverter Systems and Motors

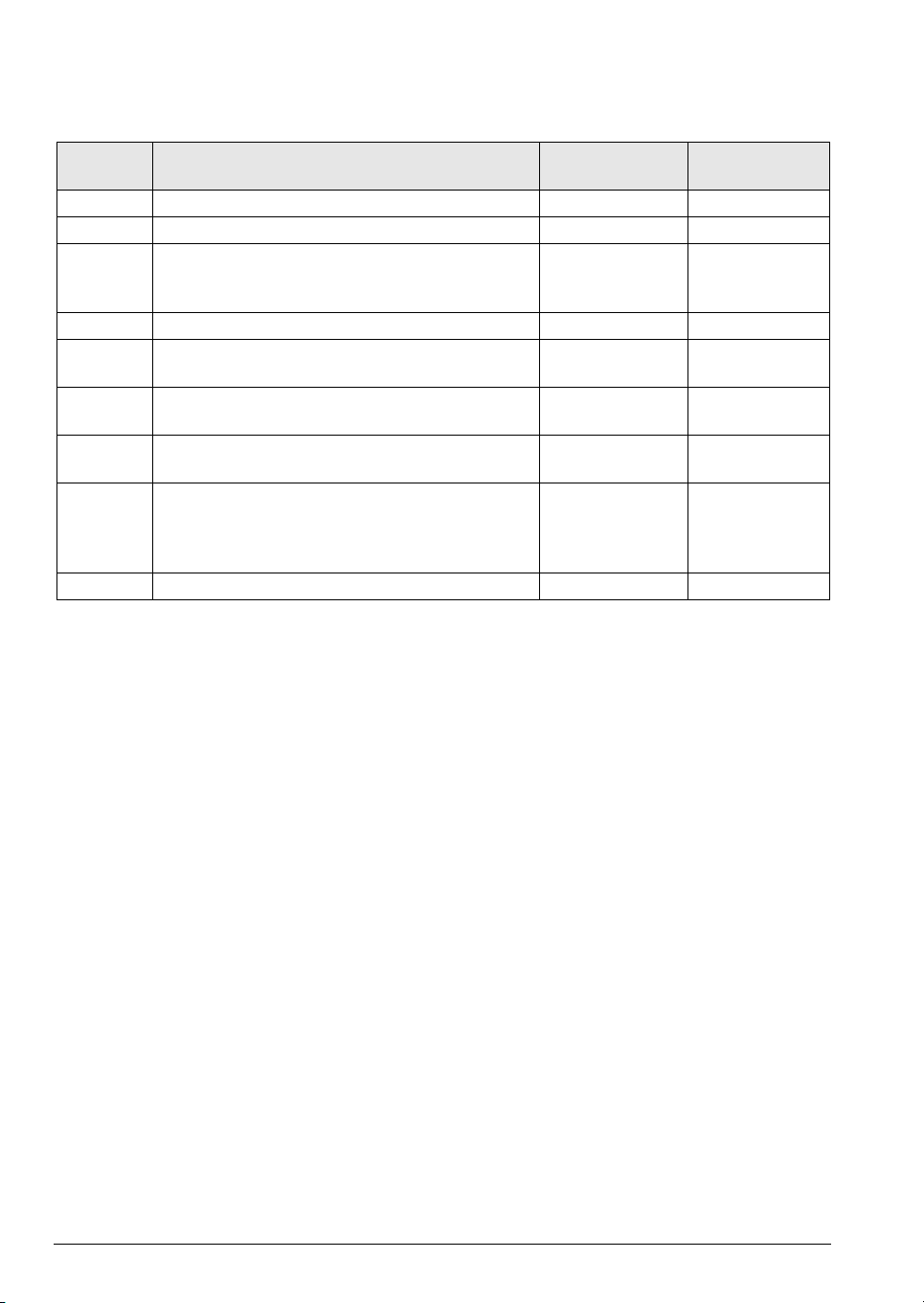

1 Update Information No. 5

1.1 Overview

New diagnosable compact inverters, power supply units and modular

inverters.

Improvement of various compact inverters, power supply units and modular

inverters.

Possibility of coupling power supply units for increasing the dc-link power

(separate dc-links).

New motors.

Diagnosability of motors with EnDat interface.

Improvement of the navigation through the Manual by QuickLinks for the

overviews of inverter systems, accessories and motors.

March 2005 Update Information No. 5 1 – 1

1.2 Compact Inverters

1.2.1 Non-Regenerative Compact Inverters

New compact inverter UE 110, rated power output 10 kW

• Continuous load on axes (at f

• Continuous load on spindle (at f

New compact inverter UE 112, rated power output 10 kW

• Continuous load on axes (at f

• Continuous load on spindle (at f

1.2.2 Regenerative Compact Inverters

The following compact inverters were improved:

= 3.3 kHz): 3 x 6 A

PWM

= 3.3 kHz): 24 A

PWM

= 3.3 kHz): 3 x 6 A, 1 x 9 A

PWM

= 3.3 kHz): 24 A

PWM

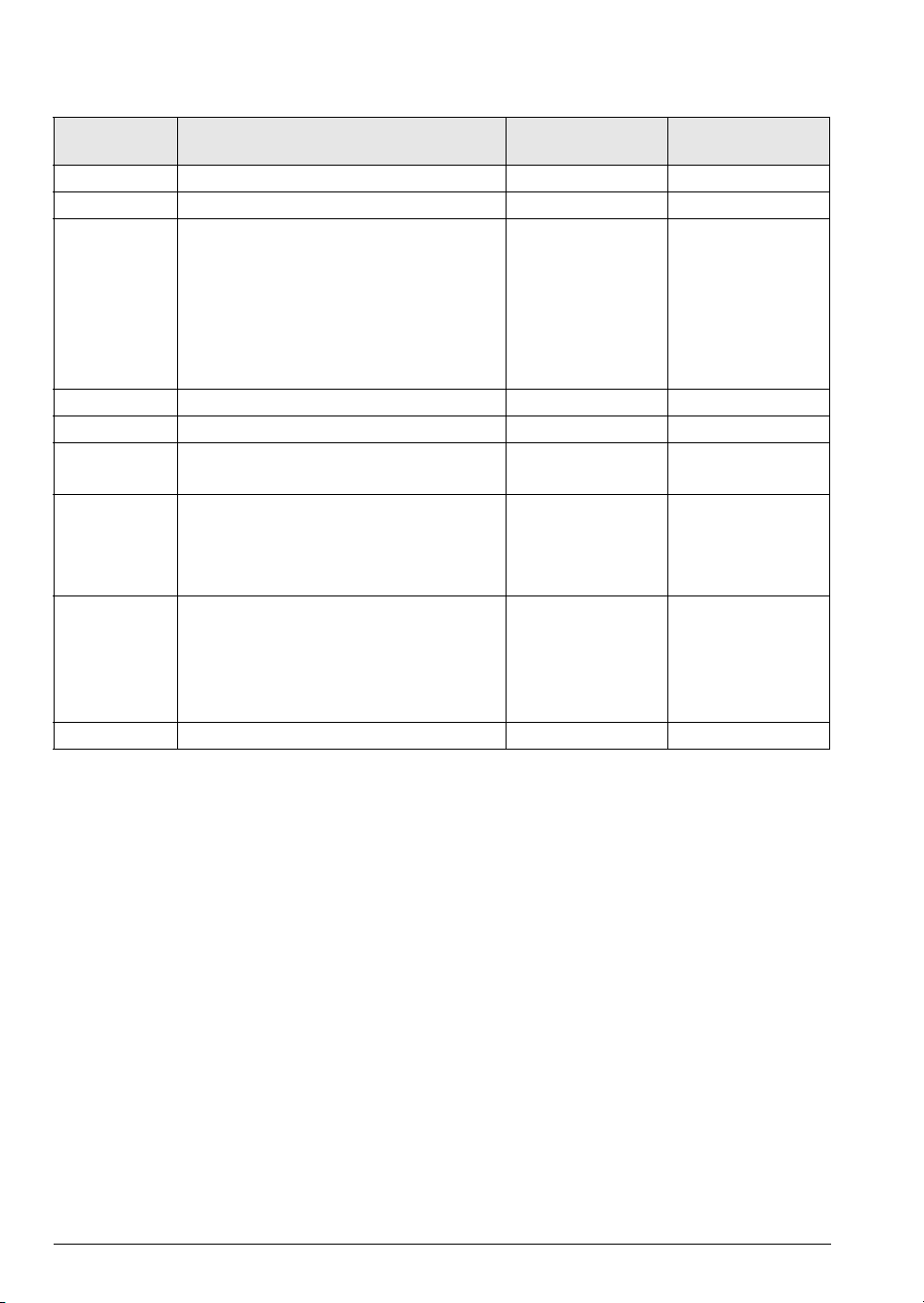

Designation

(new)

Designation

(old)

Improvement Rated power

UR 230D UR 230 New, more powerful

power supply unit with

separate 5-V connection

on the front panel (X74).

Additional features for

diagnostic functions.

UR 240D UR 240 New, more powerful

power supply unit with

separate 5-V connection

on the front panel (X74).

Additional features for

diagnostic functions.

UR 242D UR 242 New, more powerful

power supply unit with

separate 5-V connection

on the front panel (X74).

Additional features for

diagnostic functions.

output of

dc-link

22 kW

22 kW

22 kW

1 – 2 HEIDENHAIN Technical Manual for Inverter Systems and Motors

1.3 Modular Inverters

1.3.1 Non-Regenerative Power Supply Units

The following non-regenerative power supply units were improved:

Designation

(new)

UV 130D UV 130 New, more powerful

1.3.2 Regenerative Power Supply Units

New power supply unit UVR 130D, rated power output 30 kW

• Diagnosable

• Load capacity of 5 V = 20 A, with separate connecting terminals (X74)

• Load capacity of 15 V = 2.0 A

• Load capacity of 24 V = 4.0 A

The following regenerative power supply units were improved:

Designation

(new)

UVR 120D

UVR 140D

UVR 150D

a

a

a

a. Available as of the beginning of 2005.

Designation

Improvement Rated power

(old)

power supply unit with

separate 5-V connection

on the front panel (X74).

Additional features for

diagnostic functions.

Designation

Improvement Rated power

(old)

UV 120 New, more powerful

power supply unit with

separate 5-V connection

on the front panel (X74).

Additional features for

diagnostic functions.

UV 140 New, more powerful

power supply unit with

separate 5-V connection

on the front panel (X74).

Additional features for

diagnostic functions.

UVR 150 New, more powerful

power supply unit with

separate 5-V connection

on the front panel (X74).

Additional features for

diagnostic functions.

Increased rated power.

output of dclink

30 kW

output of dclink

22 kW

45 kW

55 kW

(up to now

50 kW)

March 2005 Update Information No. 5 1 – 3

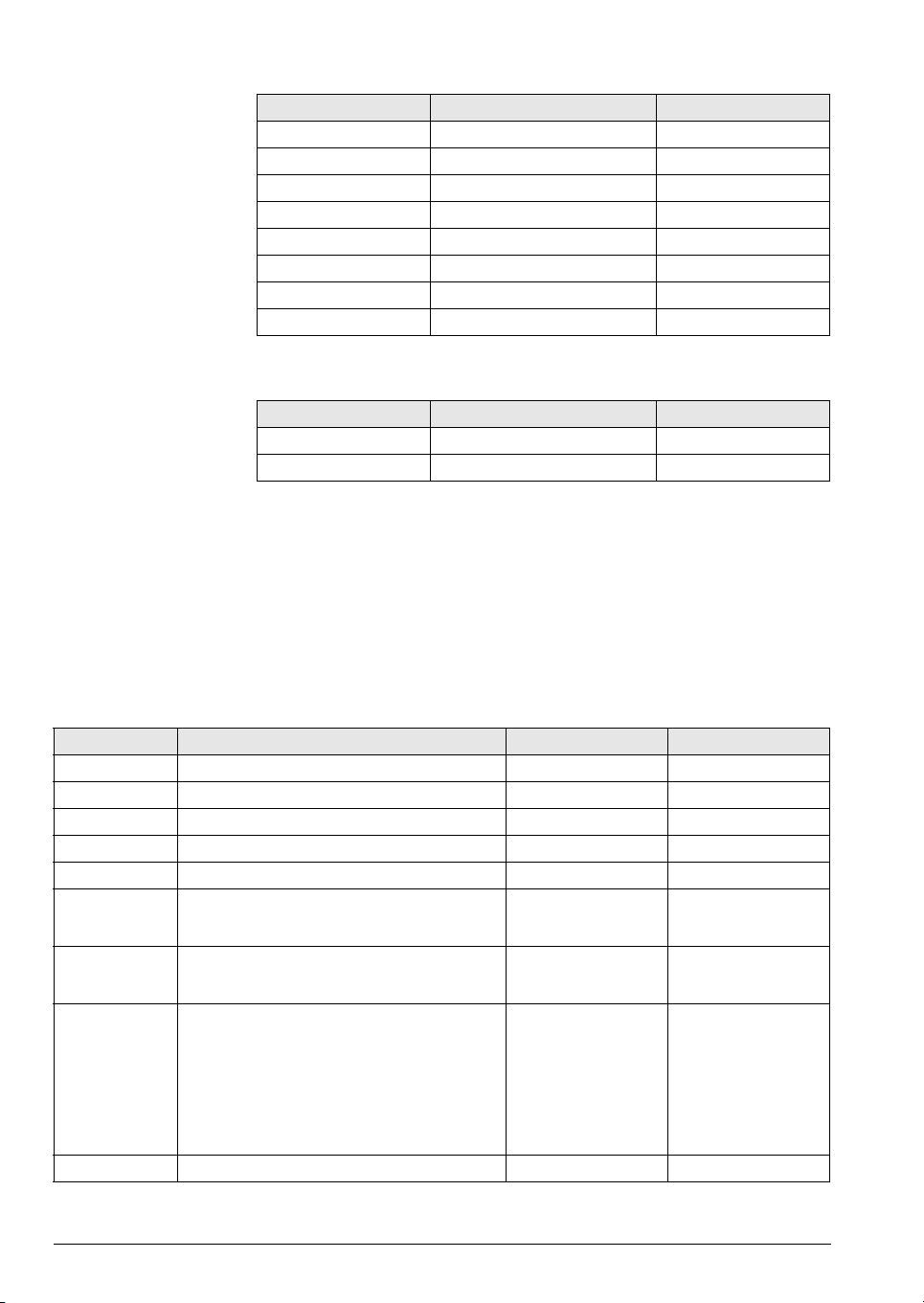

1.3.3 Inverters

The following inverters were improved:

Designation

(new)

UM 111D UM 111

Designation

(old)

Improvement Continuous load

Additional features for

diagnostic functions.

UM 111BD UM 111B

Higher maximum

current values.

Module width only 50 mm.

a

Additional features for

diagnostic functions.

Higher maximum

current values.

a

UM 112D UM 112 Additional features for

diagnostic functions.

Higher rated current

values.

Higher maximum

current values.

a

UM 113D UM 113 Additional features for

diagnostic functions.

Higher rated current

values.

Higher maximum

current values.

a

UM 114D UM 114 Additional features for

diagnostic functions.

Higher rated current

values.

Higher maximum

current values.

a

UM 115D UM 115 Additional features for

diagnostic functions.

Higher rated current

values.

Higher maximum

current values.

a

UM 121D UM 121 Additional features for

diagnostic functions.

Higher maximum

current values.

a

UM 121BD UM 121B Additional features for

diagnostic functions.

Higher maximum

current values.

a

at f

PWM

= 5 kHz

(axis/spindle)

7.5 A

15 A/20 A

25 A/34 A

(up to now 23 A/

31 A)

40 A/56 A

(up to now 32 A/

50 A)

60 A/90 A

(up to now 48 A/

75 A)

96 A/125 A

(up to now 70 A/

100 A)

2x 7.5 A

2x 15 A/1x 20 A

1 – 4 HEIDENHAIN Technical Manual for Inverter Systems and Motors

1.4 Accessories

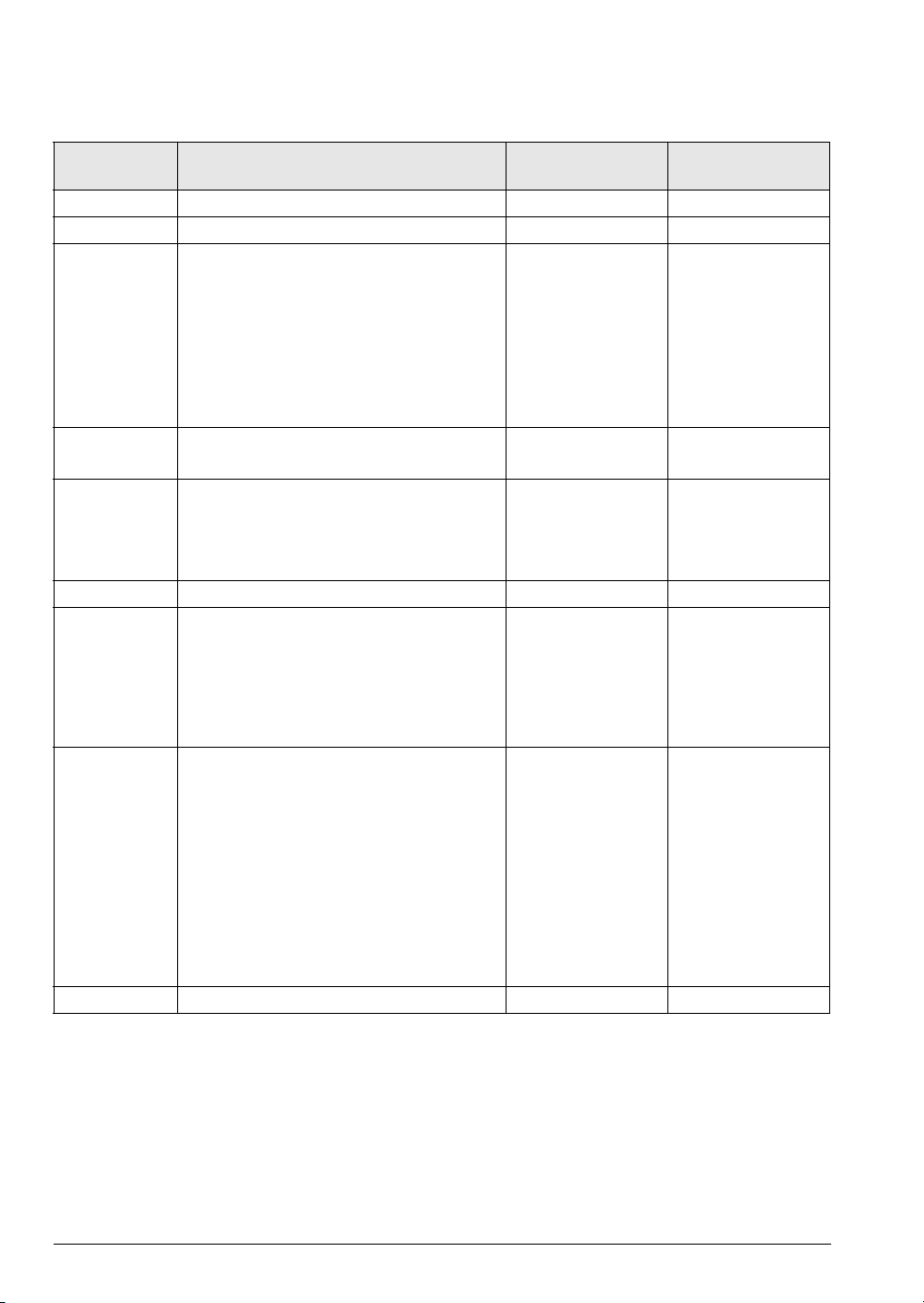

Designation

(new)

Designation

(old)

Improvement Continuous load

PWM

= 5 kHz

at f

(axis/spindle)

UM 122D UM 122 Additional features for

diagnostic functions.

Higher rated current

values.

Higher maximum

current values.

a

2x 25 A/1x 34 A

(up to now

2x 23 A/

1x 31 A)

a. As of mid-2005 (depending on software). Information available

from HEIDENHAIN.

New ZKF 110 dc-link filter for use with linear motors or torque motors

• Rated power: 30 kW

• Max. power during S6-20% cycle: 67 kW

• Max. leakage current < 1.3 A

New ZKF 120 dc-link filter for use with linear motors or torque motors

• Rated power: 30 kW

• Max. power during S6-20% cycle: 67 kW

• Max. leakage current < 6 A

• Modular design

New ZKF 130 dc-link filter for use with linear motors or torque motors

• Rated power: 55 kW

• Max. power during S6-20% cycle: 100 kW

• Max. leakage current< 6 A

• Modular design

• Integrated cooling (fan)

• Unit bus interface (X79)

New adapter module for coupling the power supply units

• Modular design

• Integration of the supply bus (X69) in the monitoring system

New KDR 130B commutating reactor

• Rated current: 3 x 40.5 A

• Thermally permissible continuous current: 3 x 45 A

March 2005 Update Information No. 5 1 – 5

1.5 Motors

1.5.1 Synchronous Motors

Designation Stall torque M

QSY 130C EcoDyn 6 Nm 3000 rpm

QSY 130E EcoDyn 9 Nm 3000 rpm

QSY 190C EcoDyn 28 Nm 3000 rpm

QSY 190D EcoDyn 38 Nm 3000 rpm

QSY 190F EcoDyn 47.6 Nm 3000 rpm

QSY 190K EcoDyn 62.5 Nm 3000 rpm

1.5.2 Asynchronous Motors

Designation Rated speed n

QAN 260M 1500 rpm 15.5 kW

QAN 260L 1500 rpm 20.0 kW

QAN 260U 1500 rpm 24 kW

QAN 260W 750 rpm 12 kW

QAN 320M 1500 rpm 32 kW

QAN 320W 750 rpm 18 kW

0

N

Rated speed n

N

Rated power output P

N

1 – 6 HEIDENHAIN Technical Manual for Inverter Systems and Motors

1.6 Technical Manual Documentation

Overviews with brief information and QuickLinks for accessing the following

subjects:

• Inverter Systems (Chapter 2.2)

• Motors (Chapter 7.2)

Introduction of QuickLinks in the component specifications in Chapter 2,

"Introduction," for accessing the respective subjects.

Expansion of Chapter 4, "Mounting and Operating Conditions."

Various connection overviews for inverter systems were added to

Chapter 4, "Mounting and Operating Conditions."

Expansion of connection overviews and dimensional drawings. Similar

components are illustrated in separate overviews.

Some changes were made to the structure of the Technical Manual.

1.7 Replacing Instructions

Note

Due to the comprehensive changes to the Technical Manual for Inverter

Systems and Motors, it is not possible to replace the old pages with the

new.

March 2005 Update Information No. 5 1 – 7

1 – 8 HEIDENHAIN Technical Manual for Inverter Systems and Motors

1 Update Information No. 6

1.1 General Information

Chapter 4 – Mounting and Operating Conditions – was expanded:

Connection and adjustment to different types of networks

Use of climate control units

Connection requirements when water cooling is used

The power connection of regenerative and non-regenerative inverter

systems was revised

Requirements for supply lines and bus cable

1.2 Power Supply Units

New regenerative power supply units

• UVR 160D: Rated power output of 80 kW

• UVR 160DW: Rated power output of 80 kW

UV 106B power supply unit as a replacement for the UV 106

1.3 Power Modules

New power module

• UM 116DW: Water cooling

Air cooling

Water cooling

1.4 Motors

New QAN 200UH and QAN 260 UH hollow-shaft motors

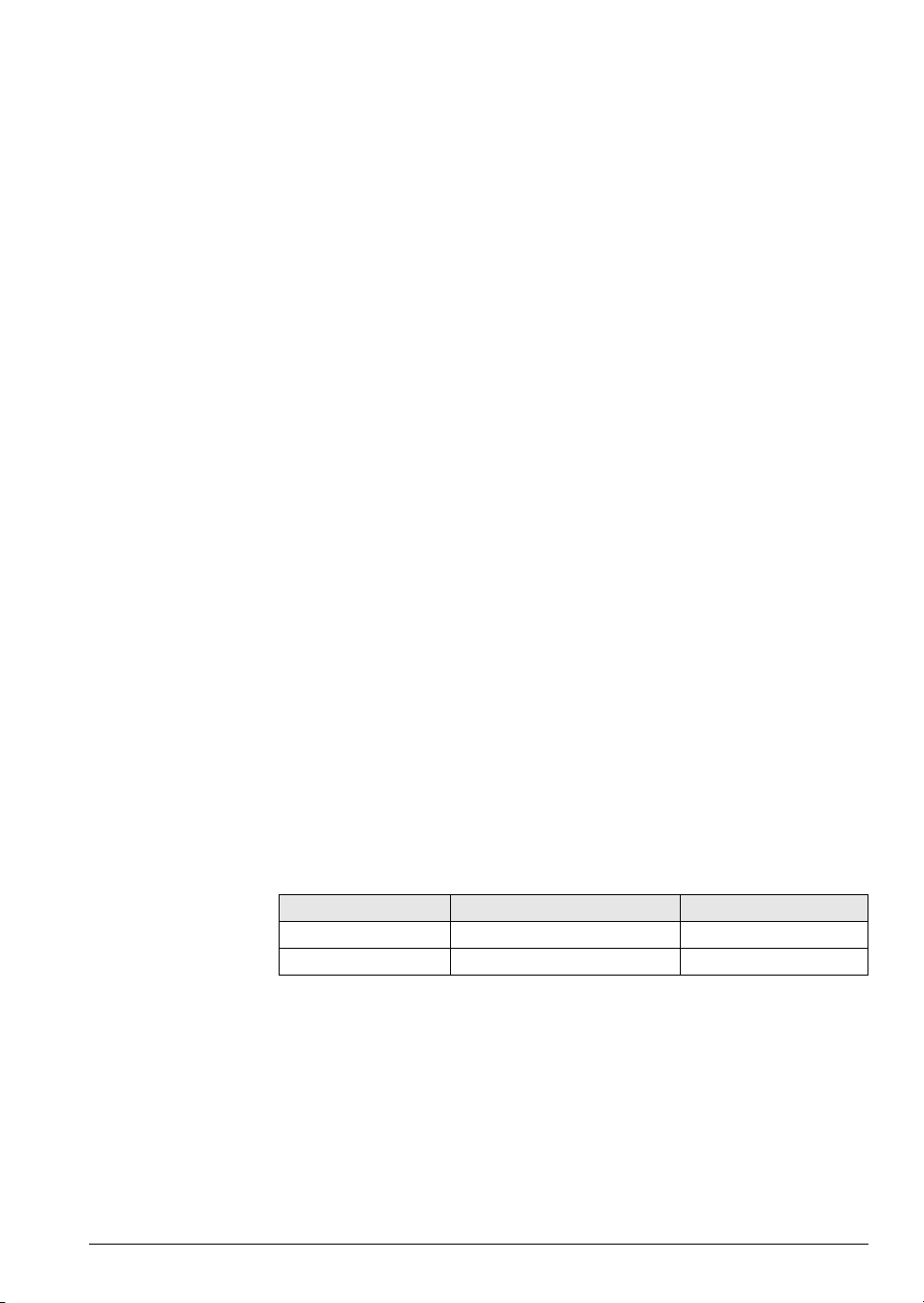

Designation Rated power output P

QAN 200UH 10 kW 1500 rpm

QAN 260UH 22 kW 1500 rpm

New QAN 320L asynchronous motor

• Rated speed n

• Rated power output P

Terminal box of the motors of the QAN 320 series revised since

August 2006.

: 1500 rpm

N

N

: 40 kW

Rated speed n

N

N

April 2007 Update Information No. 1 1 – 1

Siemens synchronous motors added

1.5 Accessories

Designation Rated power output P

Rated speed n

N

N

1FK7042-5AF71 0.82 kW 3000 rpm

1FK7060-5AF71 1.48 kW 3000 rpm

1FK7063-5AF71 2.30 kW 3000 rpm

1FK7080-5AF71 2.14 kW 3000 rpm

1FK7083-5AF71 3.30 kW 3000 rpm

1FK7100-5AF71 3.77 kW 3000 rpm

1FK7101-5AF71 4.87 kW 3000 rpm

1FK7103-5AF71 4.40 kW 3000 rpm

Siemens motors with hollow shaft added

Designation Rated power output P

Rated speed n

N

N

1PM6105-2DF81 7.50 kW 1500 rpm

1PM6133-2DF81 11.0 kW 1500 rpm

EPCOS 120 A line filter with integrated three-phase capacitor

KDR 160 commutating reactor with a rated current of 3 x 117 A

SM 130 voltage protection module for maximum phase currents of 300 A

Coolant connection for components with water cooling

1.6 Replacing Instructions

Page Change Remove Page Insert Page

Title New date of issue November 2004 April 2007

Chapter 1 Update Information – Update Info. 6

Chapter 2 Revised completely Entire chapter Entire chapter

Chapter 3 Page numbering changed Entire chapter Entire chapter

Chapter 4 Revised completely Entire chapter Entire chapter

Chapter 5 Description changed

UV 106B

Chapter 6 Description changed

UVR 160DW, UVR 160D, UM 116DW

Chapter 7 Description changed

QAN 200UH, QAN 260UH

QAN 320L

1FK7042, 1FK7060, 1FK7063,

1FK7080, 1FK7083, 1FK7100, 1FK7103

1PM6105, 1PM6133

Chapter 8 Keyword index Entire chapter Entire chapter

Entire chapter Entire chapter

Entire chapter Entire chapter

Entire chapter Entire chapter

1 – 2 HEIDENHAIN Technical Manual for Inverter Systems and Motors

1 Update Information No. 7

1.1 General Information

Chapter 4 – Mounting and Operating Conditions – was expanded:

Check list

Anyone connecting a machine with a HEIDENHAIN inverter system must

take note of the information presented there. The revised version of Chapter

4 is available for downloading from the FileBase.

1.2 Accessories

New axis-release module

An axis-release module is used to switch a group of axes on and off

independently of other axes. The new axis-release module makes it possible

to address both axes and spindles as “axis groups.” The selection is made

using jumpers.

ID number of the new axis-release-module: ID 573 732-02

It replaces the previous axis-release module (ID 341 518-02). The new axisrelease module is compatible in its functions to its predecessor, but the

installation differs. Comprehensive mounting instructions are included with

the new axis-release module.

VAL-MS surge voltage arrester

The VAL-MS 230/FM single-pole surge voltage protector from Phoenix

serves to protect the machine from overvoltages on the conductors, and

separates the protection element from the mains when it has become

overloaded due to high-energy surge voltages. Three surge arresters are

necessary for a machine tool connected to three-phase line power. The

surge arrester is also equipped with a double-throw switch as a remote

indicator switch.

Specifications Surge voltage arrester

Phoenix VAL-MS 230/FM

IEC test class II

EN type T2

Rated voltage 230 V

Rated frequency 50 Hz/60 Hz

Arrester rated voltage

(L-N)

Nominal discharge surge current 20 kA

Max. discharge surge current 40 kA

Module width Approx. 17.7 mm

ID 648 720-xx

Note

Please also refer to the manufacturer’s data sheet. There you will find

further specifications and information regarding the surge voltage arrester.

April 2008 Update Information No. 7 1 – 1

275 Vac

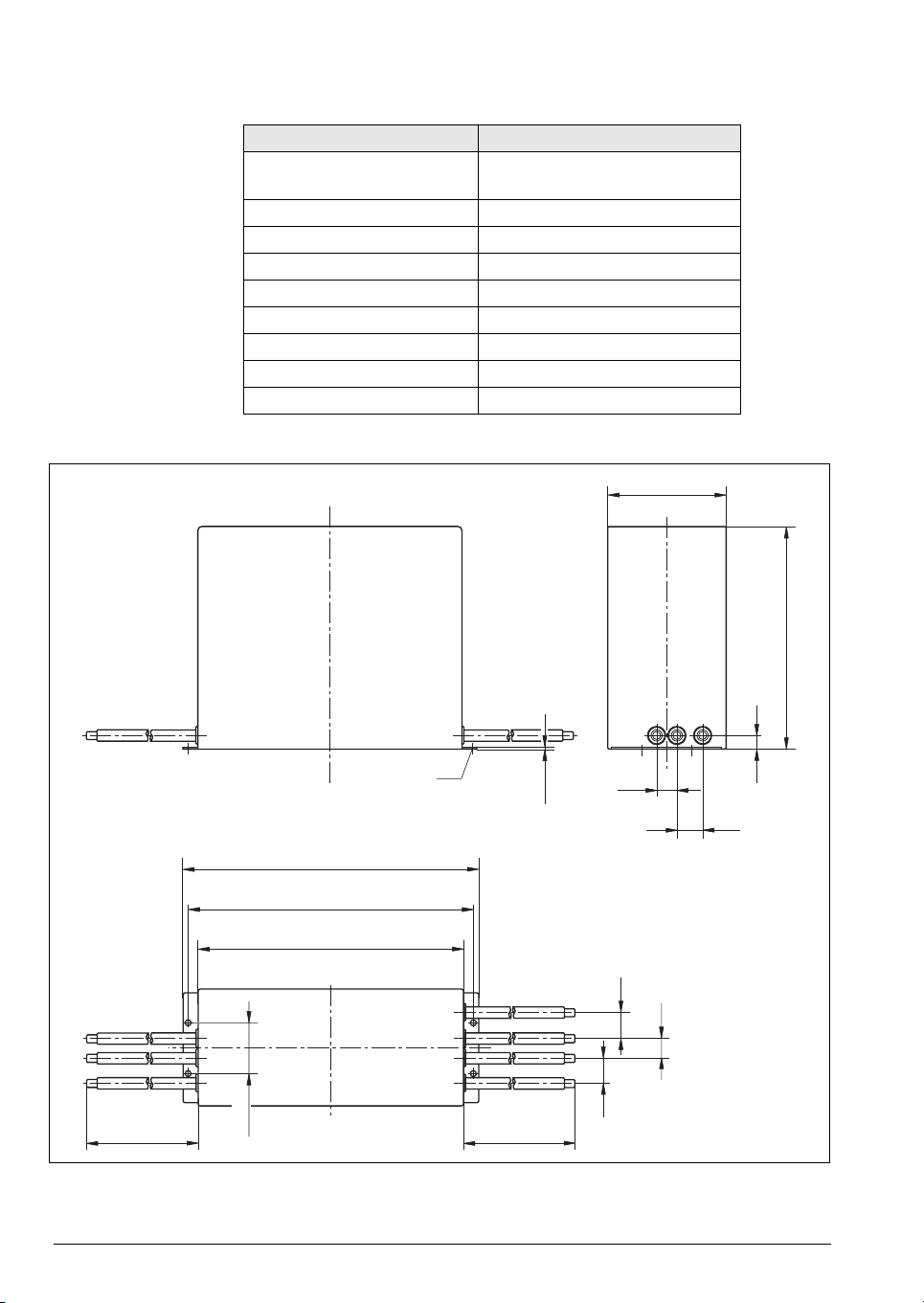

EPCOS 80 A line filter with integrated three-phase capacitor

Specifications EPCOS 80 A line filter

Suitable for UV 140, UVR 150, UVR 130 D,

UVR 140D, UVR 150D

Rated voltage 3 x 480 V

Rated frequency 50 Hz/60 Hz

Rated current 3 x 80 A

Power loss Approx. 75 W

Degree of protection IP 20

Weight 11 kg

Capacity 3 x 32 µA

ID 640 908-xx

116.5

Load

630±10

50±0.2

290

280±0.3

261

M5

Line

330±10

1±0.1

25

25

20

220.5

14

25

20

1 – 2 HEIDENHAIN Technical Manual for Inverter Systems and Motors

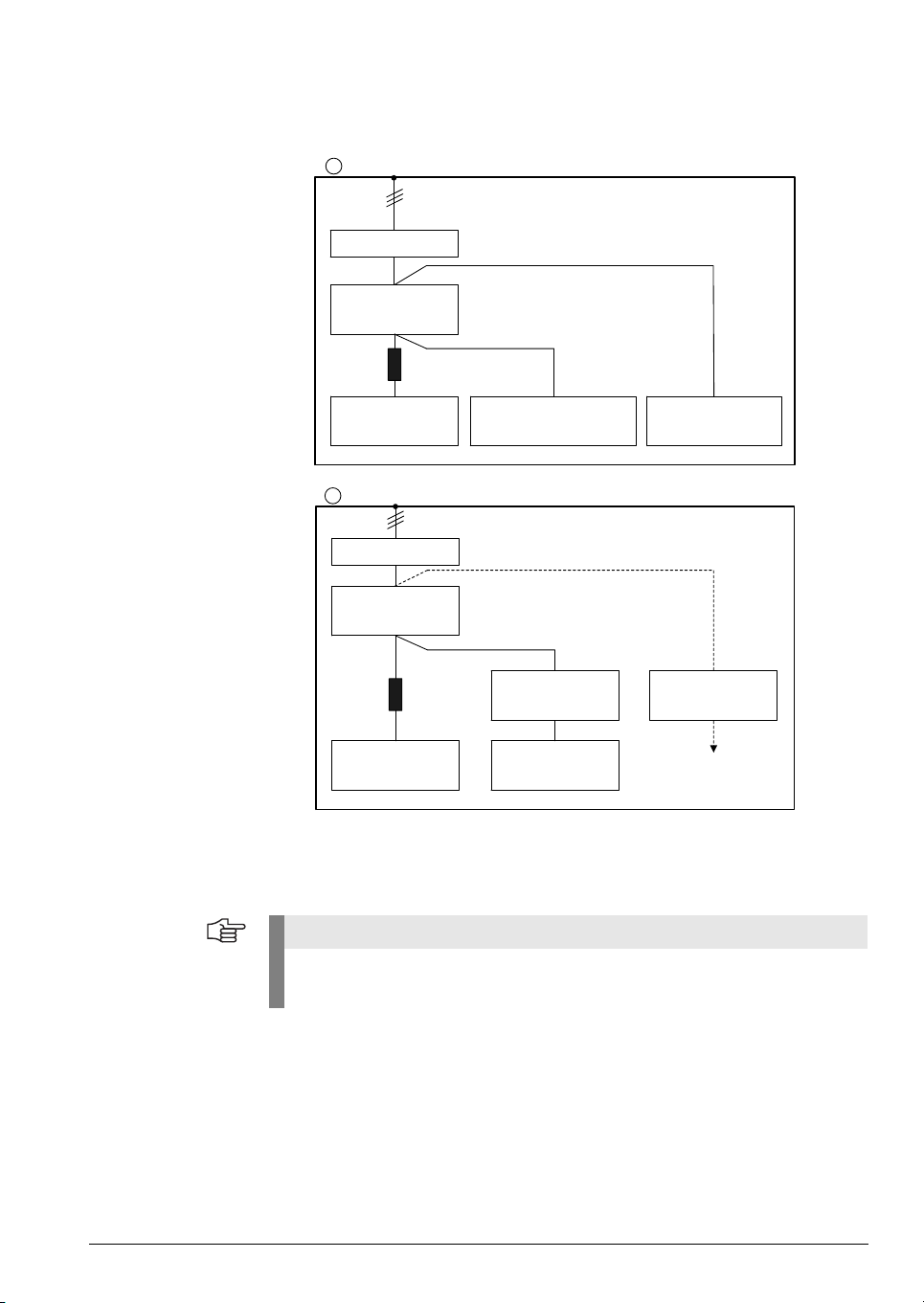

Line filters HEIDENHAIN offers Epcos line filters with integrated three-phase capacitor.

The following filter arrangements are allowed when using these filters and for

connecting other devices:

1

Power connection

Machine tool

Main switch

EPCOS filter with

integrated

three-phase capacitor

Regenerative

HEIDENHAIN

inverter system

2

Power connection

Main switch

EPCOS filter with

integrated

three-phase capacitor

Regenerative

HEIDENHAIN

inverter system

Equipment in accordance with

IEC 61000-6-2 (immunity for industrial

environments)

(also possible)

Line filter for

inverter operation

Any other equipment

in accordance with

IEC 6100-6-1, 2

Equipment in accordance with

IEC 61000-6-2 (immunity for

residential, commercial and

light-industrial environments)

Machine tool

Line filter

The illustrated filter arrangements comply with all environment requirements

for radio interference suppression as per EN 55011 Limit Class A for industrial

networks.

Note

If you want to connect additional consumers, you must ensure that the line

filters are designed for correspondingly high currents.

April 2008 Update Information No. 7 1 – 3

CMH 120 capacitor module

For maintaining the dc-link voltage during a power failure. This is necessary,

for example, to perform LIFTOFF completely even if direct drives are used.

Several CMH modules can be connected in parallel in order to increase

capacitance.

Specifications CMH 120

DC-link voltage Max. 850 V

Capacitance 10.0 mF

Module width 50 mm

Degree of protection IP 20

ID 591 116-xx

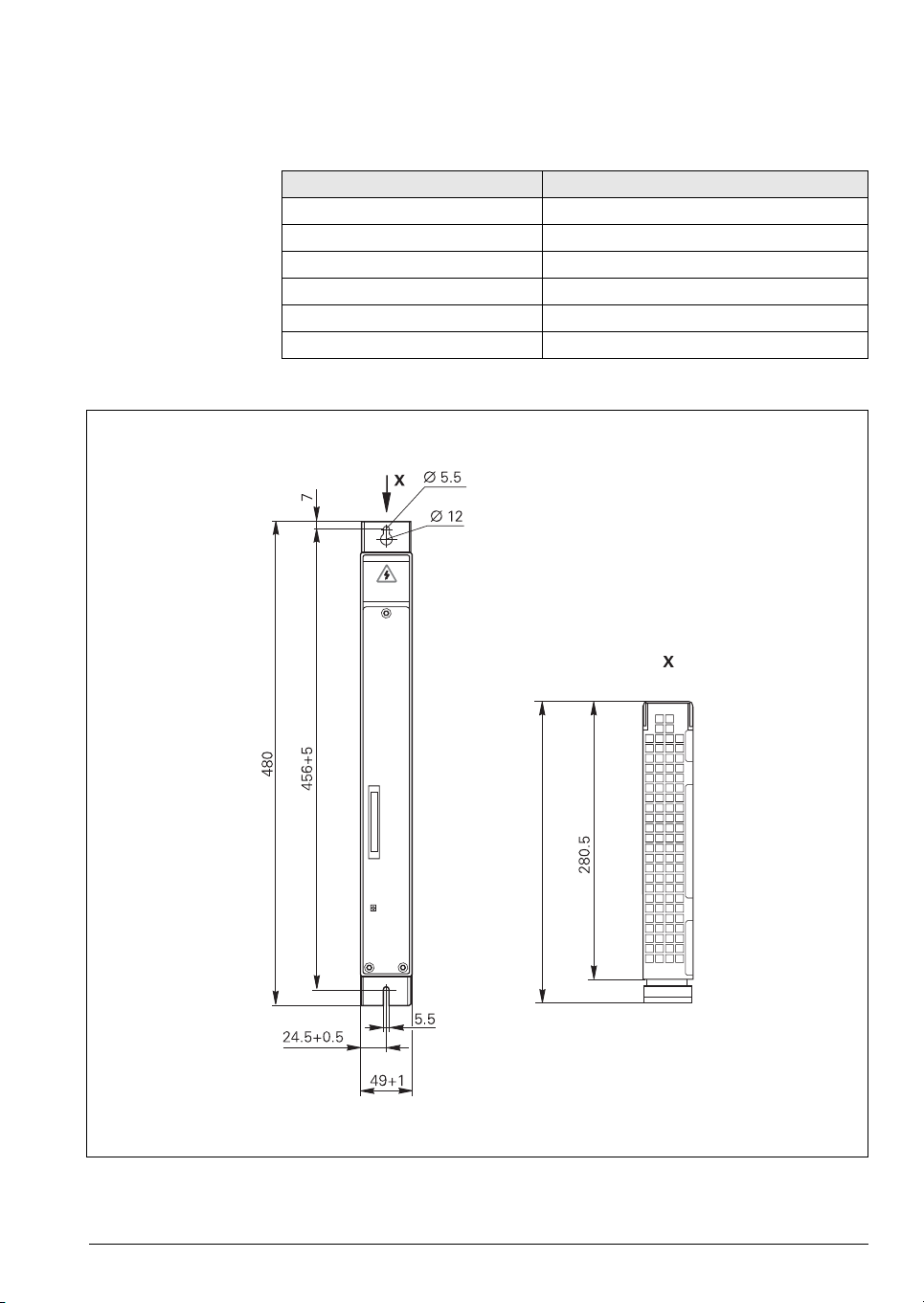

300+1

280.5+1

30

420

456±0.2

24.75

50

1 – 4 HEIDENHAIN Technical Manual for Inverter Systems and Motors

UP 120 braking resistor module

For powerful, regenerative inverter systems that use a UVR 160D (W)

supply unit, usually two UP 110 were connected in parallel. With the UP 120,

there is a powerful braking resistor module available now that can replace

the two UP 110.

Specifications UP 120

Switching voltage 740 V

Power 150 kW (for 2 s)

Resistance 3.6 Ω

Degree of protection IP 20

Weight 7.2 kg

ID 605 731-xx

300+1

April 2008 Update Information No. 7 1 – 5

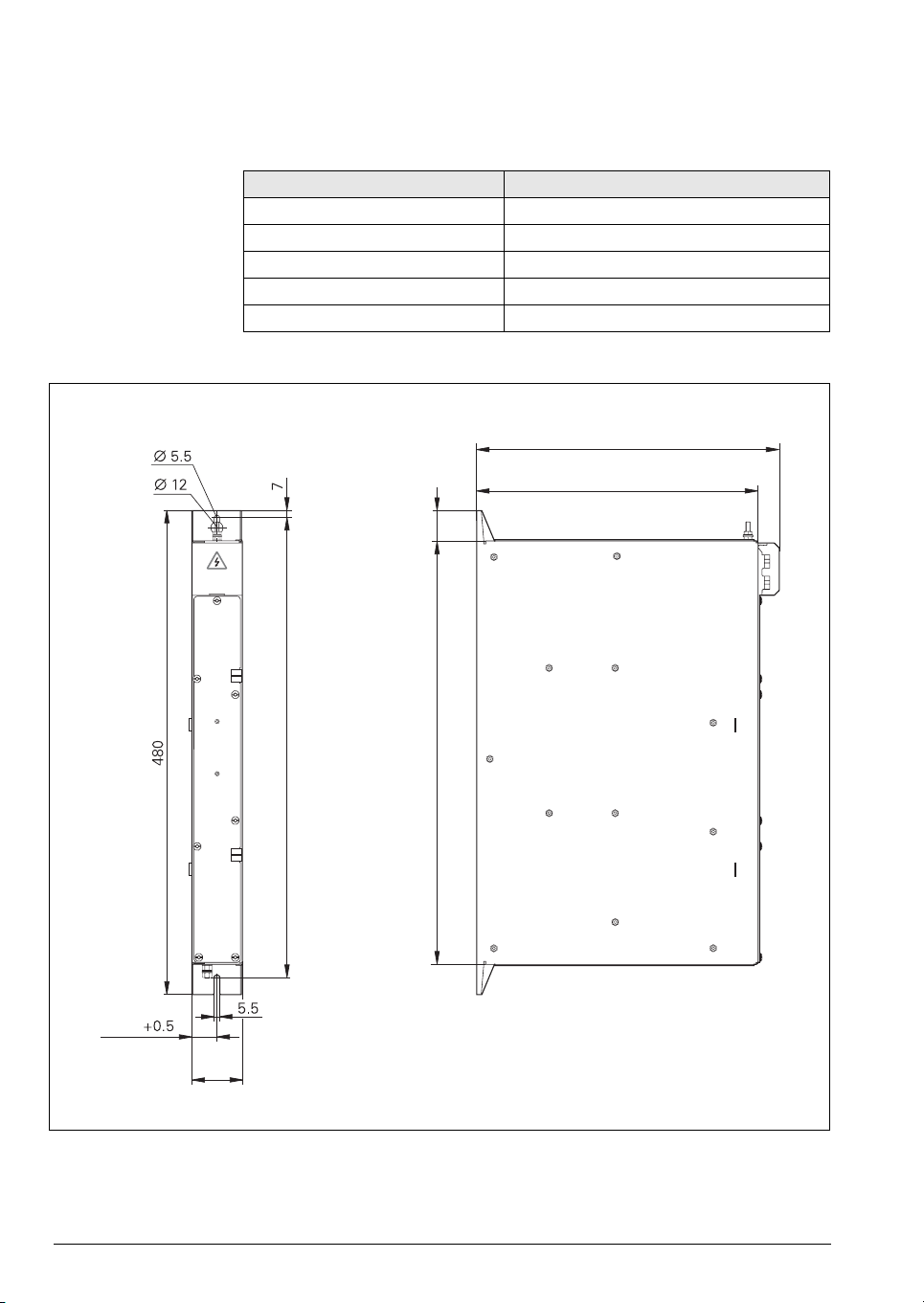

KDR 130C commutating reactor

In contrast to the KDR 130B, the primary and secondary connecting lines are

now placed on terminals and separate lines are used for further connection.

The terminals are suitable for lines with a cross section up to 16 mm

2

specifications are the same as for the KDR 130B.

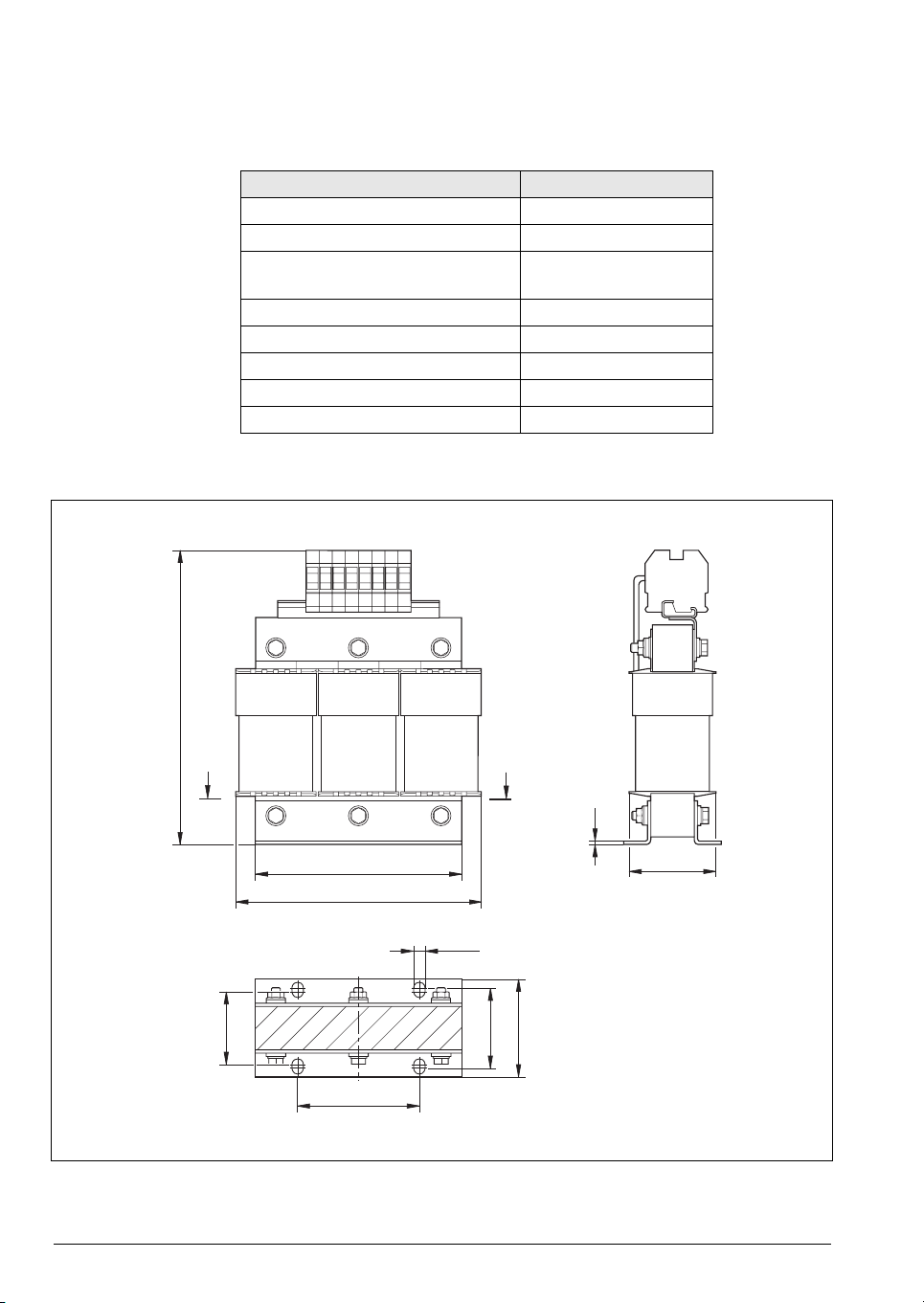

Specifications KDR 130 C

Rated voltage 3 x 400 V

Rated frequency 50 Hz/60 Hz

Thermally permissible continuous

3 x 45 A

current

Rated current 3 x 40.5 A

Power loss Approx. 250 W

Degree of protection IP 00

Weight Approx. 15 kg

ID 646 271-xx

. The

271

A

190

226

10.5

67

112±0.2

A

3

80

74

90

1 – 6 HEIDENHAIN Technical Manual for Inverter Systems and Motors

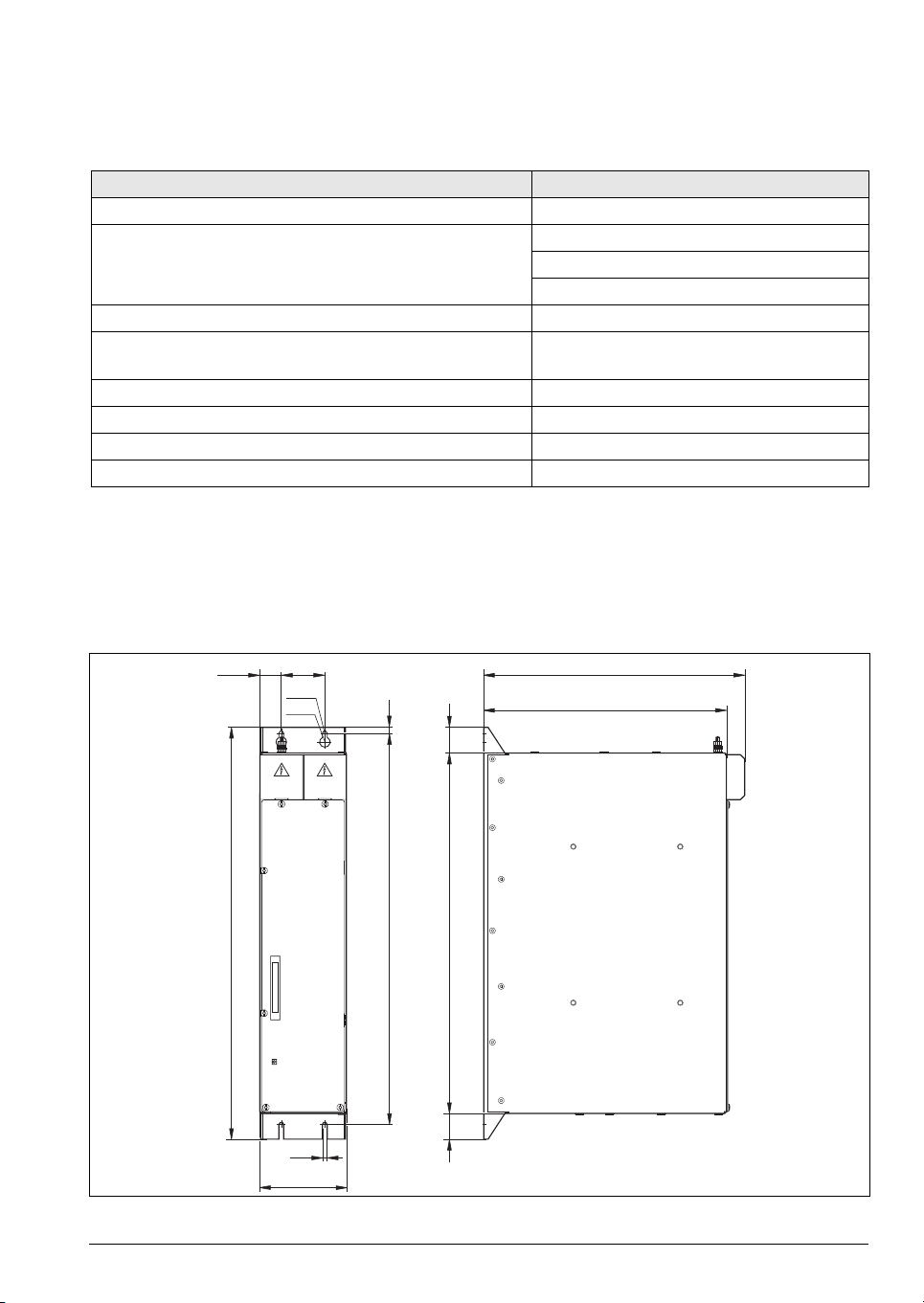

ZKF 140 dc-link filter

The ZKF 140 must be connected with the UVR 1xxD supply unit via the X79

unit bus. When choosing the ZKF, ensure that its rated power is at least as

high as the connected torque or linear motors.

Specifications ZKF 140

Rated power 80 kW

Peak power S6-40% 110 kW

Peak power S6-20% 140 kW

Peak power 160 kW

a

b

c

Max. leakage current < 6.0 A

24 V

d

440 mA

Current consumption

Integral cooling Yes

Degree of protection IP 20

Weight Approx. 15 kg

ID 597 954-01

a. 40% cyclic duration factor for duty cycle time of 10 minutes (S6-40%)

b. 20% cyclic duration factor for duty cycle time of 10 minutes (S6-20%)

c. 4 s cyclic duration factor for duty cycle time of 20 s

d. After making your selection, check the current consumption of the 15 V

supply of the entire modular inverter system. See page 2 – 54.

*1

and the 24 V*1

24.75

480

50±0.2

¬ 5.5

¬ 12

5.5

99.5+0.5

7

456+5

300+1

280.5

30

420

30

April 2008 Update Information No. 7 1 – 7

1.3 Compact Inverters

New UE 21xD diagnosable compact inverters

These compact inverters are equipped with a 5-V power pack for supplying

the MC/CC. The power pack provides up to 16 A. The X74 connecting

terminal for an additional supply of 5 V to the MC/CC is new.

The UV 105 power supply unit for MC/CC is no longer necessary in

combination with these compact inverters!

1 – 8 HEIDENHAIN Technical Manual for Inverter Systems and Motors

Loading...

Loading...