Page 1

USER GUIDE

Gateway® E-824R/E-826R SuperLoader™ 3

Page 2

Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Gateway E-824R DLT-V4 SuperLoader 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Gateway E-826R LTO-3 SuperLoader 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Bar code reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Enclosure components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

External Backup CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gateway Web site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 2: Installing and Setting Up your Autoloader . . . . . . . . . . . . . . . . . . . . . . . . . .9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Choosing a location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

UL requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unpacking the autoloader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Rack mounting the autoloader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General preparation for rack mount installation . . . . . . . . . . . . . . . . . . . . . 14

Installing and removing the V-rail kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connecting the SCSI and power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Preparing the host and making sure the connection is correct . . . . . . . 22

Installing the device drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Configuring the autoloader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Setting the time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Setting the Change mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 3: Operating your Autoloader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Using the operator's panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Entering the passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Logging out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Using cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Inserting a single cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Moving a single cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Ejecting a single cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Using magazines and magazine blanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Magazine Load/Unload command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Installing a magazine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

i

Page 3

Contents www.gateway.com

Installing a magazine blank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Removing a magazine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Removing a magazine blank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Changing the orientation of a magazine or magazine blank . . . . . . . . . .44

Manually operating the magazine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Replacing a magazine or magazine blank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Viewing status information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Viewing the autoloader status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Viewing the firmware version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Viewing the status of the magazine slots . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Viewing the tape drive status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Viewing the tape drive version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Viewing Ethernet information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Running an inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Data compression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Chapter 4: Managing and Monitoring your Autoloader . . . . . . . . . . . . . . . . . . . . . . .53

On-board Remote Management overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Opening On-board Remote Management . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Viewing status information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Feedback on pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Using the Configuration page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

System Operations options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Setting security options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Using the Updates page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Using the Diagnostics page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Running diagnostic tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Viewing Error or History logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Performing a System Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Using the Commands page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Set to Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Sequential operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Chapter 5: Troubleshooting your Autoloader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Safety guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Understanding POST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Performing a POST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Interpreting the POST results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Running diagnostic tests from the front panel . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Setting the security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Stopping a diagnostic test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Front panel diagnostic tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

ii

Page 4

www.gateway.com

Running diagnostic tests remotely . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Diagnostics using On-board Remote Management . . . . . . . . . . . . . . . . . . 70

Checking for errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Hard error log display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Error code field description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Before contacting Gateway Customer Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Telephone support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Tutoring and training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Returning the autoloader for service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Preparing the autoloader for shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Removing the autoloader from a rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Packing the autoloader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Contents

Appendix A: Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Basic information logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Log descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Autoloader logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Soft logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Update logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Boot logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Tape drive logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Tape drive error logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

SCSI check condition error logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

POST failure logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Appendix B: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Autoloader performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Autoloader power specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Autoloader vibration specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Autoloader shock specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Tape drive specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

LTO-3 drive specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

DLT-V4 drive specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Appendix C: Safety, Regulatory, and Legal Information . . . . . . . . . . . . . . . . . . . . . 101

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

iii

Page 5

Contents www.gateway.com

iv

Page 6

CHAPTER 1

Introduction

•Introduction

•Features

•Enclosure components

•Getting Help

1

Page 7

CHAPTER 1: Introduction www.gateway.com

Introduction

This guide provides information on the installation, configuration, and general

use of the Gateway® E-824R and E-826R autoloaders.

These autoloaders are compatible with most operating systems and

environments that support the SCSI interface, but require either direct support

from the operating system or a compatible backup application to take full

advantage of their many features.

Features

Each autoloader is an automated system that includes a tape drive and one or

two magazines for tape cartridges. Your application can automatically load and

unload tape cartridges as required for data backup or data retrieval. The

autoloaders provide a compact, high capacity, low-cost method for unattended

data backup.

Each SuperLoader 3™ contains either a DLT-V4 tape drive (E-824R), or an LTO-3

tape drive (E-826R) and one or two magazines containing as many as eight

cartridges each. A single cartridge can be inserted directly through a

password-protected mailslot (front loading slot). From the mailslot, the

cartridge can be inserted into the tape drive (if there is no cartridge already in

the drive), or you can load the cartridge into a magazine slot (if there is no

cartridge already in the slot).

The front panel on the autoloader includes a liquid crystal display (LCD) screen

and four function keys. A scrolling menu on the LCD screen lets you get

information from the autoloader and enter commands. The front panel also

includes two LEDs, which indicate the autoloader's status and error condition.

The SuperLoader 3 connects to your host server through a SCSI connection,

letting the host send data and commands automatically. You can also connect

to the autoloader using an Ethernet connection, to perform administrative

functions and download system updates.

Gateway E-824R DLT -V4 SuperLoader 3

The Gateway E-824R DLT-V4 SuperLoader 3 is SCSI-3 compatible and operates

as a single SCSI ID/two LUN data storage device. It is equipped with a DLT-V4

tape drive and can hold as many as sixteen DLT VS1 data cartridges, when using

two magazines. This provides a compressed capacity of 5.1 Terabytes of data

and a sustained data transfer rate of 36 GB per hour (native) or as high as 72

GB per hour compressed (assuming 2:1 compression).

2

Page 8

www.gateway.com

Gateway E-826R LTO-3 SuperLoader 3

The Gateway E-826R LTO-3 SuperLoader 3 is SCSI-3 compatible and operates as

a single SCSI ID/two LUN data storage device. It is equipped with an LTO-3 tape

drive and contains as many as sixteen Ultrium 3 data cartridges, when using two

magazines, which provides a compressed capacity of 6.4 Terabytes of data and

a sustained data transfer rate of 245 GB per hour (native), or as high as 490 GB

per hour compressed (assuming 2:1 compression).

Bar code reader

A bar code reader is enclosed within the body of the autoloader. The bar code

reader automatically scans each cartridge in the magazine when the power is

turned on, after a reset, after an import or export, or when a re-inventory

command is issued (see “Running an inventory” on page 50). Other than that,

there is no user interface with the bar code reader through the front panel

operator controls or LCD screen. The information from each label is stored in

memory and is available through SCSI and On-board Remote Management to

the computer's operating system or backup application upon request.

If you use the bar code reader, you must apply or slide the bar code labels into

the appropriate slot on the right side of each cartridge. The labels must conform

to ANSI/AIM BC1 -1995 Uniform Symbology Specification Code 39. A set of bar

code labels is included with the autoloader.

Features

Accessories

The following accessories are shipped with the autoloader:

■ SCSI host cable

■ SCSI terminator

■ Hardware to rack mount the autoloader

■ T8 and T10 TORX

■ One magazine blank

■ Power cable

■ Documentation CD containing all of the documentation

■ Bar code labels

®

L-Key drivers

3

Page 9

CHAPTER 1: Introduction www.gateway.com

Enclosure components

Front

Left magazine or blank

Power switch

Front panel LCD screen

Mailslot (front

loading slot)

Front panel LEDs

Right magazine or blank

Function keys

4

Page 10

www.gateway.com

Back

Power

switch

Power

connector

Enclosure components

Fan vent

RJ-45 Ethernet

connector

68-pin HD SCSI

connectors

Fan vent

5

Page 11

CHAPTER 1: Introduction www.gateway.com

Product components

Getting Help

# Accessory

1 SCSI cable

2SCSI terminator

3 Power cable

4 Setup poster

5 CD (documentation)

6 Magazine blank

7 Bar code labels

8 TORX T8 and T10 L-key drivers

In addition to your autoloader’s documentation, you can use the following

information resources to help you use your autoloader.

External Backup CD

6

Use the External Backup CD to access file utilities, Windows 2003 Server drivers,

and documentation for your autoloader and its components.

Page 12

www.gateway.com

Gateway Web site

Getting Help

Gateway provides a variety of information on its Web site to help you use your

autoloader.

Visit the Gateway Web site at support.gateway.com

■ Technical documentation and product guides

■ Technical tips and support

■ Updated hardware drivers

■ Order status

■ Frequently asked questions (FAQs)

for:

7

Page 13

CHAPTER 1: Introduction www.gateway.com

8

Page 14

CHAPTER 2

Installing and Setting Up your Autoloader

•Overview

• Preparation

•Installation

•Setup

9

Page 15

Chapter 2: Installing and Setting Up your Autoloader www.gateway.com

Overview

Preparation

1 Prepare to install your new E-824R or E-826R (see “Preparation” on

page 10).

2 Identifying the correct SCSI bus types (see “SCSI bus requirements” on

page 10).

Installation

1 Install the autoloader in a computer rack. (see “Rack mounting the

autoloader” on page 13

2

Connect the autoloader to the server. (see “Connecting the SCSI and

power cables” on page 20).

3 Set the SCSI ID for the autoloader (see “Setting the SCSI ID” on page 25).

4 Turn on the autoloader on to make sure that it passes the Power-on Self

Test (PO ST ).

).

Whenever you power cycle the

autoloader, allow 10 seconds before

turning the power back on. The power

supply requires at least two to three

seconds for the capacitors to discharge.

This ensures a complete system reset on

power down and may avoid system

Caution

Preparation

The autoloader is not compatible with a

High-voltage Differential (HVD) SCSI bus.

Important

Setup and configuration

Set up the host and make sure that the connection is correct (see “Preparing

the host and making sure the connection is correct” on page 22).

errors.

Before you install your new Gateway autoloader, unpack it carefully and inspect

it for any damage that might have occurred during shipping.

Make sure that the work area is free from conditions that could cause

electrostatic discharge (ESD). Discharge static electricity from your body by

touching a known grounded surface, such as your computer's metal chassis.

SCSI bus requ iremen ts

You must connect the autoloader to one of the following SCSI bus types:

■ Ultra 160 SCSI-3, LVD/MSE SCSI bus

■ Ultra 320 SCSI-3, LVD/MSE SCSI bus

The maximum number of autoloaders

supported per SCSI bus is two.

10

Important

Your SCSI host adaptor card must also support the SCSI bus type used to

connect the autoloader.

Page 16

www.gateway.com

Choosing a location

Preparation

Choose a location that meets the following criteria. The autoloader uses

standard rack mounting hardware and must be flat and level.

Criteria Description

Rack requirements Standard 19-inch rack with 2U (3.5 inches) of available rack space.

Room temperature 50–95° F (10–35° C)

Power source AC power voltage: 100–127 VAC; 200–240 VAC

Line frequency: 50–60 Hz

Locate the AC outlet near the autoloader. The AC power cable is the product’s

main disconnect device and must be easily accessible at all times.

Weight 31 lb. (14.1 kg) unloaded

38 lb. (17.2 kg) loaded with 2 magazines, 16 cartridges

Air Quality Minimize sources of particulate contamination. Avoid areas near frequently

used doors and walkways, cooling or exhaust vents, stacks of supplies that

collect dust, printers, and smoke-filled rooms.

Excessive dust and debris can damage tapes and tape drives.

UL requirements

Humidity 20–80% RH (non-condensing)

Clearance Back: Minimum of 17 inches (43.2 cm)

Front: Minimum of 27 inches (68.6 cm)

Sides: Minimum of 2 inches (5.08 cm)

Elevated operating ambient temperature

When installed in a closed multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than the room ambient

temperature. Therefore, consideration should be given to installing the

equipment in an environment compatible with the manufacturer’s maximum

recommended ambient temperature.

Reduced air flow

When you install the autoloader in a rack, make sure that there is adequate air

flow for safe operation.

Mechanical loading

When you install the autoloader in a rack, make sure that you do not load the

rack unevenly (for example, all of the equipment in the top section of the rack).

11

Page 17

Chapter 2: Installing and Setting Up your Autoloader www.gateway.com

Overloading the circuit

When you connect the autoloader to the electrical supply circuit, do not

overload the circuit.

Reliable grounding

Make sure that the electrical circuit providing power to your autoloader has a

reliable ground. Pay particular attention to supply connections other than direct

connections to the branch circuit, such as the use of power strips.

Unpacking the autoloader

If the room in which you are working

differs from the temperature in which the

autoloader was shipped or stored by

30°F (15°C) or more, let the autoloader

environment for at least 12 hours before

acclimate to the surrounding

opening the shipping carton.

Important

If your autoloader was ordered as a

one-magazine autoloader, be sure to

remove the plastic shipping insert from

the magazine bay before connecting or

operating your autoloader. Insert either a

magazine or a magazine blank into the

bay. The autoloader does not function

without both magazine bays equipped

Important

with either a magazine or a magazine

blank.

Before you begin, clear a desk or table so that you can unpack the autoloader.

You also need to select an open 2U computer rack location near the server that

will host the autoloader.

To unpack and inspect the autoloader:

1 Clear a table or desk so that you have room to unpack the autoloader.

2 Inspect the shipping box for damage. If you notice any damage, report it

to the shipping company immediately.

3 Open the shipping box and remove the accessories package. Set the

accessories package aside for now.

4 Lift the autoloader and padding out of the box and place it on the work

surface, top facing up. Do not set the autoloader on the front, back, or

either side.

5 Carefully remove the shipping padding from the left and right sides of the

autoloader. Then remove the autoloader from the bag. Save the packing

materials in case you need to move or ship the autoloader in the future.

6 Remove the shipping filler block and replace it with the right magazine

or magazine blank.

12

Page 18

www.gateway.com

Installation

Rack mounting the autoloader

The autoloader can be rack mounted using the V-rail kit (included).

The following illustration shows minimum clearances for rack mount

installation:

Tap e

magazine

Installation

27.0” (686 mm)

Minimum clearance to load

or unload a magazine from

the system

Clearance to door inside a rack

2.0” (51 mm)

Minimum side

clearance (both sides)

1.0” (25 mm)

Minimum cle arance to load

a tape through the mailslot

6.0” (152 mm)

Tap e

Front

Autoloader

Minimum clearance between the

back of the autoloader and the

inside of the rack (using standard

mounting brackets adjusted to

their closest setting)

Back

3.4” (86 mm)

13

Page 19

Chapter 2: Installing and Setting Up your Autoloader www.gateway.com

General preparation for rack mount installation

To prepare for rack mount installation:

Failure to take these safety steps may

result in personal injury or equipment

Warnin g

damage.

1 Lower the cabinet feet.

2 Extend the cabinet’s anti-tip device, if available.

An anti-tip device may be extendable legs or similar equipment used to

stabilize the cabinet. This anti-tip equipment is to help avoid

over-balancing the cabinet when installing or removing equipment.

Do not remove the top cover of the

autoloader during the installation

process. Removing the top cover could

result in damage to the autoloader.

Caution

3 Make sure that the cabinet and all rack mounted equipment have a

reliable ground connection.

4 Make sure that the total current of all rack mounted components

(including the autoloader) does not exceed the current rating of the power

distribution unit or outlet receptacles.

5 Secure the help of at least one other person. At least two people are

required to safely install the autoloader into a rack cabinet.

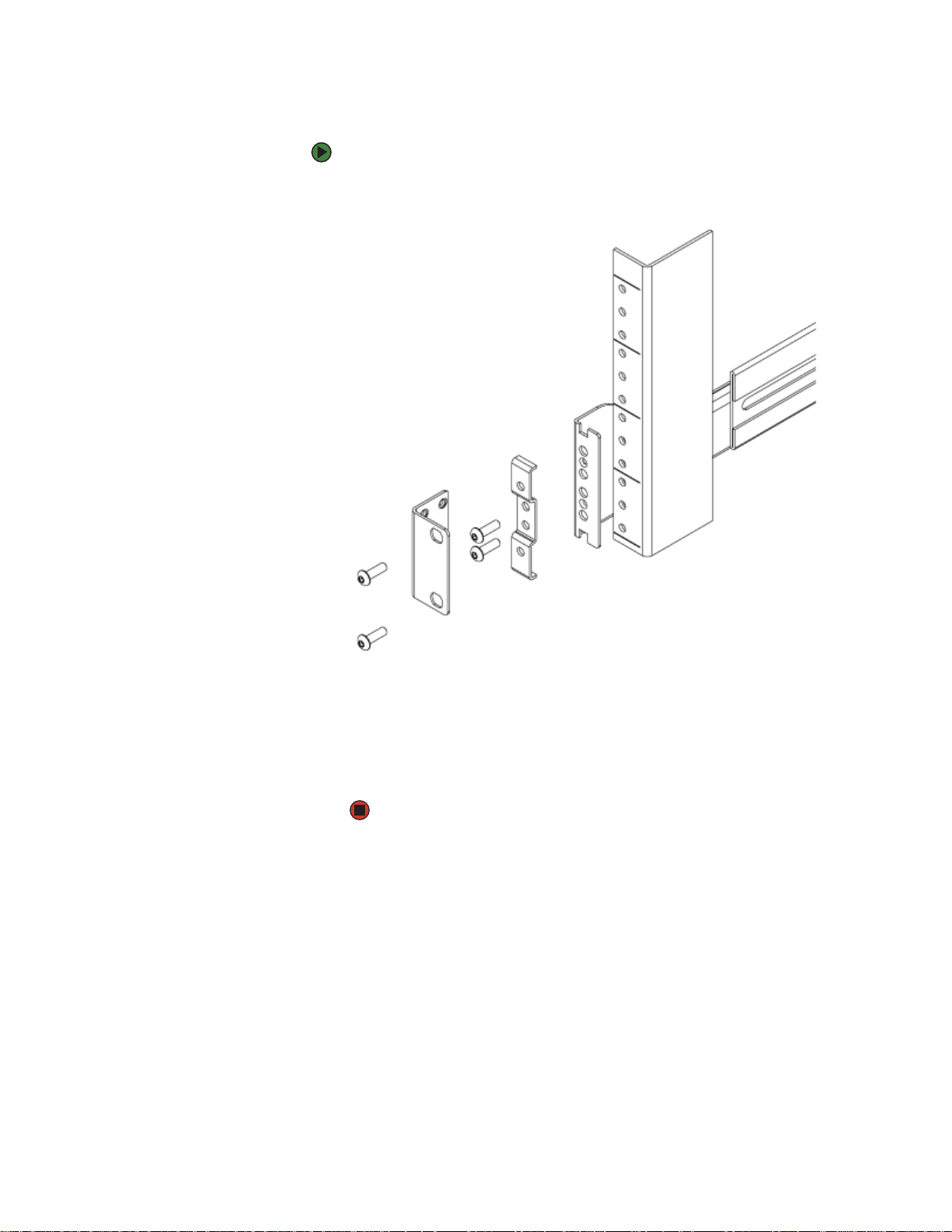

Installing and removing the V-rail kit

The V-rail is a set of rails, plates, and mounting hardware that lets you install

the autoloader into a rack. This is not a slide rail kit, but allows some movement

from the rack cabinet for easier access or removal of the autoloader.

The V-rails come already mounted to the chassis of your SuperLoader3.

Requirements

The V-rail can be used in many rack cabinet structures.

Front to rear rail spacing range is 25.75 – 34.50 inches (654.05 – 876.30 mm).

This range accommodates varying cabinet depths. The vertical rail thickness is

either 0.080 inch (2.03 mm) or .105 inch (7.14 mm).

Vertical rail hole types

The V-rail can be used with the following rack hole types:

■ .375 inch (9.53 mm) square through-holes

■ .281 inch (7.14 mm) diameter through-holes

■ 10-32 UNF-2B threaded holes

■ M6–1-6H threaded holes

14

Page 20

www.gateway.com

Installation

Left rail assembly

Right rail assembly

Accessory pieces

Besides the rail parts themselves, there are two plates included with the rail kit.

These plates are used for various rack mountings. The front cover plate is used

on all rack rails. The 10-32 inside nut plate is used on the .375 inch square-hole

rails, the .280 diameter rails, and the M6 rails.

Front cover

plate used on

all rack rails

10-32 inside

nut plate used

on .375

square-hole

rails, and .280

and M6 rails

15

Page 21

Chapter 2: Installing and Setting Up your Autoloader www.gateway.com

Installation in a .375 square-hole rack

To install the rail in a .375 square-hole rack:

1 Identify the correct mounting holes on the vertical rail, making sure that

the selected holes are on the same level as the mounting holes on the

other three vertical rails.

Vertical rail

Front cover

Autoloader tab

(autoloader not

shown)

2 Mount the front cover plate to the vertical rail in the identified holes by

plate

10-32 inside

nut plate

Rail

assembly

using 10-32 x .625 bolts in the center two holes of the plate.

3 Install the chassis into the rack by aligning the chassis-mounted rails with

the mounted rail assemblies, then pushing the chassis into the rack.

4 Secure the chassis into the rack by bolting the autoloader tabs to the

upper and lower holes in the front cover plate using 10-32 x .625 bolts.

16

Page 22

www.gateway.com

Installation

Installation in a .280 Diameter thru-hole rack

To install the rail in a .280 diameter thru-hole rack:

1 Identify the correct mounting holes on the vertical rail, making sure that

the selected holes are on the same level.

The upper and lower tabs of the inside

plate do not enter the holes of the rack.

They deform when secured.

Important

Vertical rail

Front cover

Autoloader tab

(autoloader not

shown)

2 Mount the front cover plate to the vertical rail in the identified holes by

plate

10-32 inside

nut plate

Rail

assembly

using M6 (.200”) threaded bolts in the center two holes of the plate.

3 Install the chassis into the rack by aligning the chassis-mounted rails with

the mounted rail assemblies, then pushing the chassis into the rack.

4 Secure the chassis into the rack by bolting the autoloader tabs to the

upper and lower holes in the front cover plate using M6 (.200”) threaded

bolts.

17

Page 23

Chapter 2: Installing and Setting Up your Autoloader www.gateway.com

Installation in a 10-32 threaded-hole rack

To install the rail in a 10-32 threaded-hole rack:

1 Identify the correct mounting holes on the vertical rail, making sure that

the selected holes are on the same level.

Vertical rail

Front cover

Autoloader tab

(autoloader not

shown)

plate

Rail

assembly

2 Mount the front cover plate to the vertical rail in the identified holes by

using 10-32 x .625 bolts in the center two holes of the plate.

3 Install the chassis into the rack by aligning the chassis-mounted rails with

the mounted rail assemblies, then pushing the chassis into the rack.

4 Secure the chassis into the rack by bolting the autoloader tabs to the

upper and lower holes in the front cover plate using 10-32 x .625 bolts.

18

Page 24

www.gateway.com

Installation

Chassis-m ounted r ails

The following illustrations show various views of the chassis-mounted rail

system.

Rail parts

Chassis rail

close-up

Rails installed

on a chassis

19

Page 25

Chapter 2: Installing and Setting Up your Autoloader www.gateway.com

Using long

autoloader brackets.

The chassis mounted

on a rack.

Using short

autoloader brackets.

Connecting the SCSI and power cables

To connect the SCSI and power cables:

1 Shut down and turn off the selected server. Turn off all attached accessory

devices, such as printers and other SCSI devices.

2 Attach one end of the SCSI cable (included in the accessory kit) to one of

the connectors on the back panel of the autoloader.

Back view of

mounted chassis.

20

Page 26

www.gateway.com

Installation

If the supplied SCSI cable does not fit the

connector on your SCSI host adapter, you

have an incompatible SCSI host adapter.

Contact your Gateway representative or

your SCSI host adapter manufacturer for

Important

information.

3 Attach the other end of the SCSI cable to the connector on the SCSI host

adapter or to the connector on the previous device on the SCSI bus.

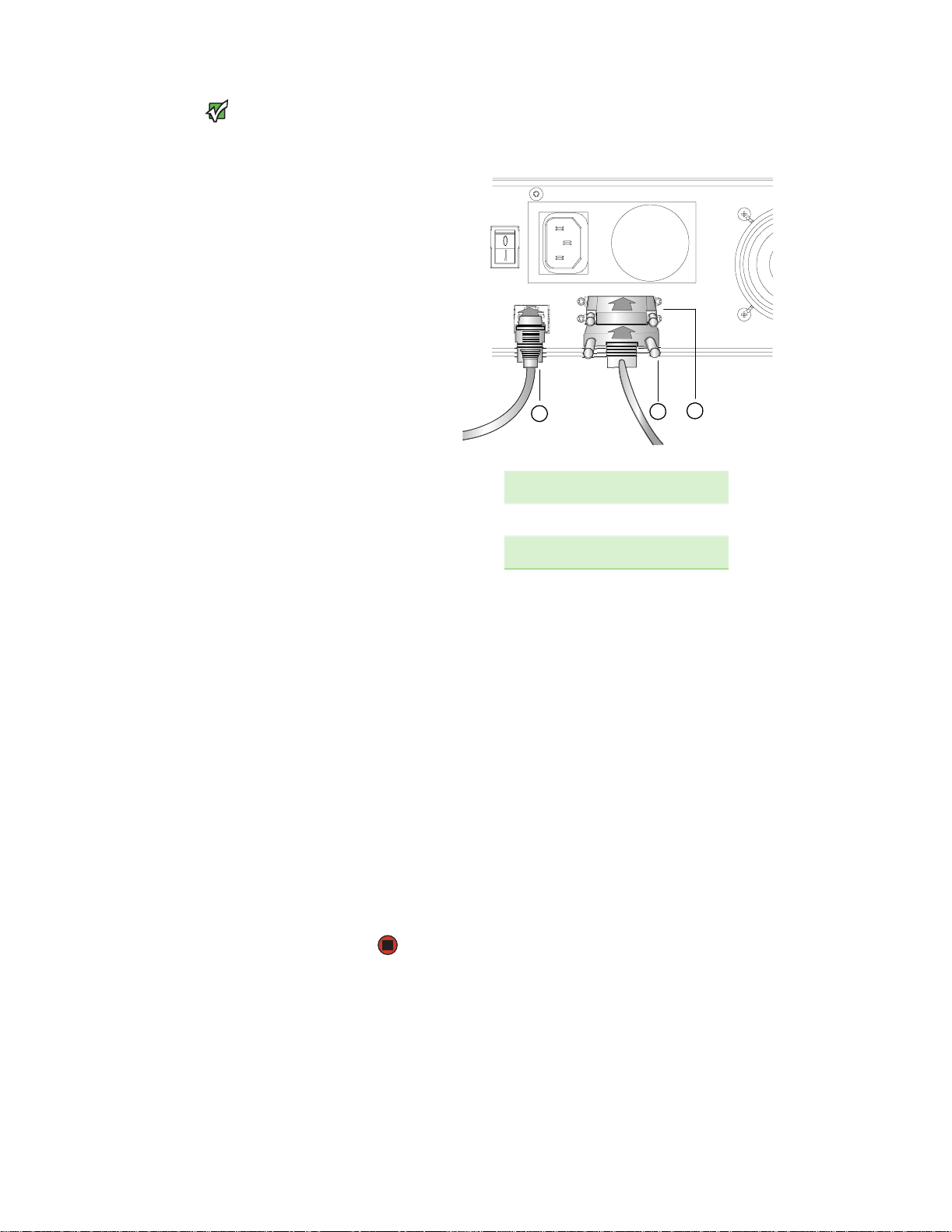

3

1

2

1 Ethernet cable

2SCSI cable

3 SCSI terminator

4 Attach the terminator to the remaining SCSI connector on the back panel

of the autoloader (if the autoloader is the last or only device on the SCSI

bus). Otherwise, attach the cable to the next device on the SCSI bus. Make

sure that the last device on the SCSI bus is correctly terminated.

5 Plug the power cable into the power connector on the back panel of the

autoloader.

6 Plug in the power cable to the nearest correctly grounded power outlet.

7 Turn on the autoloader by setting the power switch on the front panel to

the ON position. Check the LCD screen to make sure the autoloader is

receiving power. If it is not, check the power connections and your power

source.

8 Turn on any other devices you turned off earlier.

9 During the Power-on Self Test (POST), both LEDs are illuminated briefly,

followed by only the Ready/Activity LED flashing. When the initialization

sequence is complete, the LCD screen displays the Home screen.

10 Turn on the server.

21

Page 27

Chapter 2: Installing and Setting Up your Autoloader www.gateway.com

Preparing the host and making sure the connection is correct

If necessary, install a SCSI host adapter, software, and compatible drivers. Refer

to the manuals for the host computer and SCSI host adapter for detailed

instructions. In addition, follow these general guidelines:

■ When the host server is powered on, install software or drivers that are

compatible with the autoloader (see “Installing the device drivers” on

page 22). Most backup software packages require an additional module

to communicate with the autoloader robotics.

■ If the host server is connected to a network, check with the system

administrator before turning off power.

■ Use correct procedures to prevent electrostatic discharge (ESD). Use

wrist-grounding straps and anti-static mats when handling internal

components.

■ Make sure that the host server has an open expansion slot.

■ Make sure that your backup application supports the SCSI host adapter.

■ Depending on the server configuration, you may need to change the

SCSI ID of the autoloader (see “Setting the SCSI ID” on page 25).

■ Make sure that the autoloader is correctly terminated. If the autoloader is

the only SCSI device other than the SCSI host adapter on the selected SCSI

bus, it must be terminated. Likewise, if the autoloader is physically the last

SCSI device on the SCSI bus, it must be terminated. Only the devices

physically at the beginning and end of the SCSI bus should be terminated.

If the host is located at the beginning of the SCSI bus, the host HBA is

usually terminated internally.

Installing the device drivers

Device drivers are required if you intend

to use the Microsoft Windows 2003

native backup application. Commercial

backup applications provide all

necessary device driver support.

Microsoft Windows NT

native support for autoloaders. You must

use a backup application with Microsoft

No drivers are needed for Redhat 3.0,

Solaris 8, Solaris 9, and Solaris 10.

Commercial backup applications

provide all necessary device driver

Important

®

does not include

Windows NT.

support.

There are two device drivers associated with the autoloader. One for the

autoloader itself, and a second for the tape drive within the autoloader.

Tape drive device driver

To install the tape drive device driver for Microsoft Windows 2003:

1 Make sure that you are logged on to the host server with administrator

privileges.

2 Download the latest drivers. Save the drivers to your host computer.

■ For the either model, go to support.gateway.com.

■ Open the device manager (refer to your specific OS documentation

for instructions). For example, right-click the My Computer icon on

the Windows desktop, click Manage, then click Device Manager.

■ The drive should be listed under the ? Other Devices item as

Unknown Medium Changer Device.

3 Right-click the appropriate listing, click Uninstall, then click OK to confirm

that you want to remove the device.

4 Click Action in the upper-left corner of the Computer Management dialog

box.

22

Page 28

www.gateway.com

Installation

5 Click Scan for Hardware Changes. Windows 2003 scans for the

SuperLoader 3 drive. The drive appears under ?Other Devices again.

6 Right-click the appropriate listing, then click Properties.

7 Select the Driver tab, then click Update Driver.

8 When the Upgrade Device Driver Wizard appears, click Next.

9 Click Display a list..., then click Next.

10 Scroll down and click Tape Drive, then click Next.

11 Select the appropriate directory for your drive.

12 Click the SuperLoader 3 (drive) entry, then click Next.

13 Click Next to install the driver.

14 Click Finish.

15 Click Device Properties to make sure that the driver has been installed.

The drive now appears in Device Manager under Tape Dri ves as a (drive

type) SCSI Sequential Device and is ready to use.

The autoloader uses the SuperLoader 3

Important

Windows drivers.

Autoloader device driver

To install the autoloader device driver for Microsoft Windows 2003:

1 Make sure that you are logged on to the host server with administrator

privileges.

2 Download the latest drivers from support.gateway.com. Save the drivers

to your host computer.

3 Right-click the My Computer icon on the Windows desktop, then click

Manage, Device Manager.

The autoloader should be listed under Medium Changers as Unknown

Medium Changer Device.

4 Right-click the Unknown Medium Changer Device listing, click

Uninstall, then click OK to confirm that you want to remove the device.

5 Click Action in the upper-left corner of the Computer Management dialog

box.

6 Click Scan for Hardware Changes.

Windows 2003 scans for the autoloader. The autoloader appears under

Medium Changers again.

7 Right-click the Unknown Medium Changer Device listing, then click

Properties.

8 Select the Driver tab.

9 When the Upgrade Device Driver Wizard appears, click Next.

10 Click Display a list..., then click Next.

23

Page 29

Chapter 2: Installing and Setting Up your Autoloader www.gateway.com

11 Browse to the location where you saved the drivers on the host computer,

then click OK.

12 Click the SuperLoader 3 entry, then click Next.

13 Click Next again to install the driver.

14 Click Finish.

15 Close the Device Properties dialog box.

The autoloader now appears in Device Manager under Medium Changers

and is ready to use.

Setup

When you first power on the autoloader, it automatically runs a POST (Power-on

Self Test). During the POST, the left (green) LED flashes. After the POST, the left

(green) and right (amber) LED flash alternately back and forth. Do one of the

following:

The front panel requires a six-digit

password to change the configuration

(see “Setting passwords” on page 33). The

LCD front panel default password for the

Administrator is 000000. The default

password for the Operator is 111111.

Important

Configuring the autoloader

■ If the autoloader powers on successfully, continue configuring the

autoloader (see “Configuring the autoloader” on page 24).

■ If the autoloader does not power on successfully, make sure that:

■ The power switch is on.

■ The power cable is inserted correctly.

■ The SCSI bus is terminated.

■ The SCSI cable is connected to the autoloader and host computer.

■ No error code appears on the autoloader LCD.

■ If you cannot resolve the problem yourself, contact Gateway Customer

Care (see “Getting Help” on page 6).

When you first power on the autoloader, the setting for the Internet Protocol

(IP) address is static with the address 192.168.20.128. If you want to use

Dynamic Host Configuration Protocol (DHCP) to change the IP address, see

“Setting the IP address” on page 26. To determine the IP address when using

DHCP, view the Ethernet status information (see “Setting Ethernet” on page 26).

To configure the autoloader, start with the Main menu on the front panel. If the

Main menu is not already visible on the LCD, press E

NTER.

24

When you first power on the autoloader, the default is set with no password

protection. However, after you set the security option, all the configuration

functionality is password-protected. You need an administrator-level password

to configure the autoloader (see “Default username and password” on page 55

for On-board Remote Management or “Setting security options” on page 59 for

the front panel).

Page 30

www.gateway.com

Setup

The front panel menu has the following options:

To configure the autoloader, you must make sure that the setup includes the

following:

■ SCSI ID(s). For the autoloader, there is a single SCSI ID.

■ Magazine(s).

■ Ethernet IP address (if you are not using DHCP).

■ SNMP server IP address only if SNMP is being used.

■ Time server IP address (or the time zone, date, and time, if configuring

manually)—only if a time server is being used.

■ Control mode.

■ Security option.

Setting the SCSI ID

Each SCSI device attached to a server or workstation must have a unique SCSI

ID. For the autoloader, you need one SCSI ID.

To set the SCSI ID:

1 If the Main menu is not already visible, press ENTER. The Main menu opens.

2 Click Configuration, then press ENTER. The Configuration submenu opens.

3 Scroll to SCSI ID, then press ENTER.

25

Page 31

Chapter 2: Installing and Setting Up your Autoloader www.gateway.com

4 Scroll to the number you want to set as the autoloader's SCSI ID, then press

NTER. “Cycle Power new SCSI ID” appears on the LCD.

E

5 Press and hold the power button on the front panel until “System

Shutdown wait 60 sec” appears on the LCD, then release the button.

“Power Off” then appears on the LCD and the autoloader shuts off.

6 Press the power button again to turn on the autoloader. The new SCSI ID

is now in effect.

Setting Ethernet

Ethernet is the method used by the autoloader to access a network. With an

Ethernet connection, you can remotely access the autoloader over the network.

To use the Ethernet connection, you must define the following:

■ A dynamic or static IP address for the autoloader (required)

■ A subnet mask (required)

■ An IP gateway (optional)

■ A Simple Network Management Protocol (SNMP) server (optional)

■ A time server, or set the time and time zone manually (optional)

Setting the IP address

An IP address is the address of any device attached to a network. Each device

must have a unique IP address. IP addresses are written as four sets of numbers

separated by periods ranging from 0.0.0.0 up to and including 255.255.255.255.

IP addresses are either permanent or dynamically assigned. A permanent, or

static, address remains the same each time the device connects to the network

server. A dynamic address may change each time the device connects to the

network server using Dynamic Host Configuration Protocol (DHCP).

To set a dynamic IP address:

1 From the Main menu, click Configuration, then press ENTER. The

Configuration submenu opens.

2 Scroll to Ethernet, then press ENTER. The Ethernet submenu opens.

3 Scroll to Set IP, then press ENTER. The Set IP screen opens.

4 Scroll to DHCP, then press ENTER. “Please reboot to use DHCP” appears on

the LCD screen.

5 Press and hold the power button on the front panel until “System

Shutdown wait 60 sec” appears on the LCD, then release the button.

“Power Off” appears on the LCD, then the autoloader shuts off.

6 Press the power button again to turn on the autoloader. The IP address is

changed.

26

Page 32

www.gateway.com

Setup

To set a static IP address:

1 From the Main menu, click Configuration, then press ENTER. The

Configuration submenu opens.

2 Scroll to Ethernet, then press ENTER. The Ethernet submenu opens.

3 Scroll to Set IP, then press ENTER. The Set IP screen opens.

4 Scroll to Static IP, then press ENTER. The cursor automatically appears at

the first digit.

5 At each position of the IP address, use the up and down arrows to change

the value of each digit. Press E

When you have advanced through all of the digits of the IP address, the

autoloader displays “Enter to save.”

NTER to advance the cursor to the next digit.

If you make a mistake, press ESC to

backspace to the digit you want to

Important

change.

6 Press ENTER. The Configuration submenu appears and the static IP is now

in effect. You do not need to reboot the autoloader.

7 Press ESC or Enter to return to the Ethernet submenu.

Setting the subnet mask

Creating a subnet mask is a method of splitting IP networks into a series of

subgroups, or subnets, to improve performance or security.

To set a subnet mask:

1 From the Main menu, click Configuration, then press ENTER. The

Configuration submenu opens.

2 Scroll to Ethernet, then press ENTER. The Ethernet submenu opens.

3 Scroll to Set Subnet Mask, then press ENTER. The cursor automatically

appears at the first digit.

4 At each position of the Subnet Mask address use the up and down arrows

to change the value of each digit. Press E

next digit.

When you have advanced through all of the digits of the subnet mask

address, the autoloader displays “Enter to save.”

NTER to advance the cursor to the

If you make a mistake, press ESC to

backspace to the digit you want to

Important

change.

5 Press ENTER. “New Subnet Mask xxx.xxx.xxx” appears on the LCD. You do

not need to reboot the autoloader.

6 Press ESC or ENTER to return to the Ethernet submenu.

27

Page 33

Chapter 2: Installing and Setting Up your Autoloader www.gateway.com

Setting an IP gateway

A gateway is a node on a network that allows access to another network.

To set an IP gateway:

1 From the Main menu, click Configuration, then press ENTER. The

Configuration submenu opens.

2 Scroll to Ethernet, then press ENTER. The Ethernet submenu opens.

3 Scroll to Set Gateway, then press ENTER. The cursor automatically appears

at the first digit.

4 At each position of the gateway address use the up and down arrows to

change the value of each digit. Press E

next digit.

When you have advanced through all of the digits of the gateway address,

the autoloader displays “Enter to save.”

NTER to advance the cursor to the

If you make a mistake, press ESC to

backspace to the digit you want to

Important

change.

5 Press ENTER. “New Gateway is xxx.xxx.xxx” appears on the LCD. You do not

need to reboot the autoloader.

6 Press ESC or ENTER to return to the Ethernet submenu.

Setting the SNMP server

An SNMP server monitors a network by processing reporting activity in each

network device (hub, router, bridge, and so on). The server uses this information

to define what is available from each device and what can be controlled (turned

off, on, and so on).

To set an SNMP server:

1 From the Main menu, click Configuration, then press ENTER. The

Configuration submenu opens.

2 Scroll to Ethernet, then press ENTER. The Ethernet submenu opens.

3 Scroll to Set SNMP Server, then press ENTER. The cursor automatically

appears at the first digit.

4 At each position of the SNMP server address use the up and down arrows

to change the value of each digit. Press E

next digit.

NTER to advance the cursor to the

28

If you make a mistake, press ESC to

backspace to the digit you want to

Important

change.

When you have advanced through all of the digits of the SNMP server

address, the autoloader displays “Enter to save.”

5 Press ENTER. “New SNMP Server xxx.xxx.xxx” appears on the LCD. You do

not need to reboot the autoloader.

6 Press ESC or ENTER to return to the Ethernet submenu.

Page 34

www.gateway.com

Setting the time

Setup

The system time is displayed by On-board Remote Management and is used

internally when logging events and errors. The system time is either regular time

or power-on time. Regular time is Month/Date/Year Time, such as Nov/21/2004

19:28. Power-on time is Power On Cycles/Power On Hours. For example, POC:

00121, POH: 00002:07:45 where POC is the number of times the system has

booted since it was manufactured, and POH is the number of hours, minutes,

and seconds since the last system boot. If regular time is known, it is used,

otherwise power-on time is used.

The system time setting on the autoloader must be reset after each power up.

The time can be reset automatically if a time server is configured.

Setting the time server

You can connect the autoloader to a SNTP-compatible time server to supply the

correct date and time. The autoloader uses this information to time-stamp

information in its memory.

To set a time server:

1 From the Main menu, click Configuration, then press ENTER. The

Configuration submenu opens.

If you make a mistake, press ESC to

Important

backspace to the digit you want to

change.

2 Scroll to Ethernet, then press ENTER. The Ethernet submenu opens.

3 Scroll to Set Time Server, then press ENTER. The cursor automatically

appears at the first digit.

4 At each position of the time server address use the up and down arrows

to change the value of each digit. Press E

NTER to advance the cursor to the

next digit.

When you have advanced through all of the digits of the time server

address, the autoloader displays “Enter to save.”

5 Press ENTER. “New Time Server xxx.xxx.xxx” appears on the LCD. You do not

need to reboot the autoloader.

6 Press ESC or ENTER to return to the Ethernet submenu.

To set the time zone:

1 From the Main menu, click Configuration, then press Enter. The

Configuration submenu opens.

2 Scroll to Time, then press ENTER. The Time submenu opens.

3 Scroll to Set Timezone, then press ENTER. The Time Zone screen appears,

letting you set the hours. The cursor automatically appears at the first digit.

4 Scroll to set the number of hours difference between your local time and

Greenwich Mean Time (GMT).

29

Page 35

Chapter 2: Installing and Setting Up your Autoloader www.gateway.com

5 Scroll to set the number of minutes difference between your local time

and GMT, then press E

6 Press ESC or ENTER to return to the Main menu.

NTER. The new time zone is set.

To set the date and time:

1 From the Main menu, click Configuration, then press ENTER. The

Configuration submenu opens.

2 Scroll to Time, then press ENTER. The Time submenu opens.

3 Scroll to Set Date/Time, then press ENTER. The Date/Time screen appears,

letting you set the date and time. The cursor automatically appears at the

first digit.

4 The first four digits represent the current year. At each position of the year,

use the up and down arrows to change the value of each digit. Press E

to advance the cursor to the next digit.

5 The next two digits represent the current month. At each position of the

month, use the up and down arrows to change the value of each digit.

Enter a leading 0 if the month is a single digit. Press E

NTER to advance the

cursor to the next digit.

NTER

Setting the Change mode

6 The next two digits represent the current day. At each position of the day,

use the up and down arrows to change the value of each digit. Enter a

leading 0 if the day is a single digit. Press E

NTER to advance the cursor to

the next digit.

7 The next two digits represent the current hour. At each position of the

hour, use the up and down arrows to change the value of each digit. Enter

a leading 0 if the hour is a single digit. Press E

NTER to advance the cursor

to the next digit.

8 The last two digits represent the current minute. At each position of the

minute, use the up and down arrows to change the value of each digit.

Enter a leading 0 if the minute is a single digit. Press E

NTER to advance the

cursor to the next digit.

9 Press ENTER to save.

10 Press ESC to return to the Main menu.

You can set the autoloader Change mode to either Random or Sequential. The

default change mode is Random.

In Random mode either you or the backup software can specify which cartridge

you want to use and where you want it to go. You will probably use this mode

the most.

30

Page 36

www.gateway.com

Setup

The Sequential mode supports certain backup applications that do not manage

media. During backup, when one cartridge is read or written to the end of the

tape the autoloader, automatically returns that cartridge to its slot and loads

the cartridge from the next higher numbered slot to the tape drive to be read

or written to. This continues until the backup has sequentially accessed and

used all available cartridges. The autoloader does not move the media until the

host requests the tape drive to unload the tape through a SCSI unload

command.

In Sequential mode, the medium changer

does not appear in the Device Manager.

The medium changer reappears in

Device Manager if you return the system

to Random mode. This is to allow for

operating systems that do not support

Important

multiple LUNS.

In Seq Cycle mode, which is an option of the Sequential mode, the autoloader

automatically starts over with magazine slot 1 when the last cartridge is used

(slot 16 or the highest filled slot). If this change mode is not set, the autoloader

stops when the last cartridge available has been used. In Seq Cycle mode the

autoloader continues to cycle until you stop it.

To set the Change mode:

1 From the Main menu, click Configuration, then press ENTER. The

Configuration submenu opens.

2 Scroll to Change Mode, then press Enter. The mode options appear. A

check mark appears next to the currently enabled mode.

3 Do one of the following:

■ To leave the mode the same, press Esc.

■ To modify the change mode, scroll to the mode to you want, then

press Enter. “Reboot to enable new mode” appears on the LCD.

4 Press and hold the power button on the front panel until “System

Shutdown wait 60 sec” appears on the LCD, then release it. “Power Off”

then appears on the LCD and the autoloader shuts off.

5 Press the power button again to turn on the autoloader. The new change

mode is now in effect.

Sequential mode operations

If you enable Sequential mode, you must use the Sequential Ops submenu under

the Commands menu to operate the autoloader after you reboot.

■ The Start command lets you load the first cartridge.

■ The Resume command lets you continue from the next unused slot, if you

stopped the cycle.

■ The Stop command lets you stop the cycle.

To start Sequential mode operation:

1 From the Main menu, scroll to Commands, then press ENTER. The

Commands submenu opens.

2 Scroll to Sequential Ops, then press ENTER. The Sequential Ops submenu

opens.

3 Scroll to Start, then press ENTER. “Moving first tape to drive” appears on

the LCD.

31

Page 37

Chapter 2: Installing and Setting Up your Autoloader www.gateway.com

To stop Sequential mode operation:

1 From the Main menu, scroll to Commands, then press ENTER. The

Commands submenu opens.

2 Scroll to Sequential Ops, then press ENTER. The Sequential Ops submenu

opens.

3 Scroll to Stop, then press ENTER. “Ejecting tape from drive” appears on the

LCD.

To resume Sequential mode operation:

1 From the Main menu, scroll to Commands, then press ENTER. The

Commands submenu opens.

2 Scroll to Sequential Ops, then press ENTER. The Sequential Ops submenu

opens.

3 Scroll to Resume, then press ENTER. “Moving next tape to drive” appears

on the LCD.

Setting security

You can add security to the front panel by password-protecting the autoloader's

functionality. The security setting only protects the front panel functionality.

The default setting is Off, meaning that no password is required. However, you

can enable the security option so that users must enter a password to access

functionality.

Security option

When you first turn on the autoloader, the security option is set to Off. Use the

following procedure to enable the security option. You must have an

administrator-level password to set passwords.

To set the Security option:

1 From the Main menu, scroll to Configuration, then press ENTER. The

Configuration submenu opens.

2 Scroll to Security. If a check mark appears after the word Security, the

security option is On. If no check mark appears, the security option is Off.

3 To change the option, press ENTER. For example, if the security option was

set to On, it is now set to Off, and no check mark appears.

Setting magazines

32

In some cases, autoloader owners have been charged Independent Software

Vendor (ISV) licensing fees for two-magazine SuperLoader 3s, even though only

one magazine was configured. This happened because the ISV software

registered the autoloader as a two-magazine device, regardless of the number

of magazines actually configured. You can set the number of magazines in the

autoloader.

Page 38

www.gateway.com

Setup

To set the number of magazines:

1 From the Main menu, scroll to Configuration, then press ENTER. The

Configuration submenu opens.

2 Scroll to Magazines, then press ENTER. The Magazines submenu opens.

3 Select either Right, Left, or Both to indicate the magazines installed in the

autoloader.

Setting passwords

Many operations on the autoloader are password-protected to make sure that

data integrity is safe. You can set passwords to the Administrator level and to

the Operator level. Operator-level users have access to the Commands and

Status menus. Administrator-level users have access to all functionality.

To set a password:

1 From the Main menu, scroll to Configuration, then press ENTER. The

Configuration submenu opens.

If you make a mistake, press ESC to

Important

backspace to the digit you want to

change.

2 Scroll to Set Password, then press ENTER.

3 To set a password to the operator level, scroll to Operator. To set a

password to the administrator level, scroll to Administrator. Press ENTER.

The Set Password screen opens.

4 Press ENTER. If you are not logged in as Administrator, press ENTER again

to log in. A text box appears above the first asterisk.

5 The cursor automatically appears at the first character of the password.

6 At each position of the password, use the up and down arrows to change

the value of each character. Press E

NTER to enter the character and advance

the cursor to the next number. The text box above the asterisk disappears

and another text box appears above the next asterisk.

7 Repeat step Step 6 to enter the remaining digits of the password. When

you have entered six numbers, the autoloader displays “Submit Password”

below the asterisks.

8 Press ENTER to submit the password. “Password Successfully changed”

appears on the LCD.

9 Press ENTER. The Operator and Administrator options reappear. You can

either enter another password, or press E

SC or ENTER, as necessary, to

return to the Main menu.

33

Page 39

Chapter 2: Installing and Setting Up your Autoloader www.gateway.com

Getting lost passwords

You can reset front panel passwords to

the factory defaults from On-board

Remote Management. However, if the

On-board Remote Management

passwords are lost, you must contact

Customer Care. If you must contact

Customer Care, be at the host computer

with On-board Remote Management on

line. From the Main screen, click

Configuration. The User name and

Password screen opens. The Customer

Care representative needs the number

surrounded by asterisks to locate and

reset your password. This is your “realm

Important

If you forget the administrator-level password, you cannot access the

autoloader's functionality to enter a new password. In this case, you must call

Customer Care (see “Getting Help” on page 6). When you call, have the

autoloader connected to the Ethernet and On-board Remote Management

open.

number.”

34

Page 40

CHAPTER 3

Operating your Autoloader

• Using the operator's panel

• Using cartridges

• Using magazines and magazine blanks

• Replacing a magazine or magazine blank

• Viewing status information

• Running an inventory

• Data compression

35

Page 41

CHAPTER 3: Operating your Autoloader www.gateway.com

Using the operator's panel

The operator's panel consists of two LEDs, four buttons, and a 2-line by

16-character LCD screen. The operator's panel provides everything you need to

monitor autoloader status and to control all of its functions.

If security is enabled and you try to

execute a command without entering a

password, the autoloader displays the

Enter Password screen until you enter a

password. Once you enter a password

(see “Default username and password”

on page 55 for On-board Remote

Management or “Setting passwords” on

page 33 for the front panel), the

autoloader takes you back to the

command screen that you were at before

you entered a password.

Important

Entering the passwords

1 Power switch 5 Scroll down button

2 Front panel LCD screen 6 Escape

3 Front panel LEDs 7 Enter

4 Scroll up button

All of the functionality accessed from the scrolling menu is password-protected.

Two levels of security are built into the menu. The lower-level security is the

operator level and the higher-level security is the administrator level. There is

one password for each level. (See “Default username and password” on page 55

for On-board Remote Management or “Setting passwords” on page 33 for the

front panel.)

The administrator password allows access to all of the functionality available.

The operator password allows access to all of the functionality in the Command

and Status submenus.

Many functions on the autoloader may be password-protected to make sure

that data remains safe. To access the menu items necessary to execute these

functions, you must first enter your password (see “Setting passwords” on

page 33). All passwords for the front panel are six numeric digits long.

36

Page 42

www.gateway.com

Logging out

Using cartridges

When you enter a password, all password-protected functionality is available

until you close your browser session. If you do not use the front panel for 10

minutes, the Main screen reappears on the LCD. When the Main screen

reappears, the autoloader has automatically logged you out. You must re-enter

your password again to access the menu functionality.

To log out of the autoloader:

1 From the Main menu, scroll to Commands, then press ENTER. The

Commands submenu opens.

You can also press ESCAPE to log out.

Continue pressing E

SCAPE until the Main

screen appears.

Using cartridges

Tips & Tricks

Whenever you see Enter or Eject on the

front panel menu, it means the tape

enters and leaves the autoloader through

the mailslot. Whenever you see Load or

Unload, it means the tape is loaded into

or unloaded from the tape drive.

If a tape cartridge is holding the mailslot

door open on power up, the robot cannot

move. The system detects that the

mailslot door is open but cannot detect

the presence of the tape. If the mailslot

door is open, the bar code scanner laser

light may shine out the door and

potentially cause physical injury.

With the mailslot door open, do not insert

your hand through the mailslot door. This

is to prevent bodily injury from the robot.

Precautions are in place to prevent the

robotic mechanism functioning in this

Tips & Tricks

Warnin g

circumstance.

2 Scroll to Log Out, then press ENTER. “Session Complete” appears on the

LCD.

Typically, when you first install the autoloader, you load your cartridges into the

magazines, then load the magazines into the autoloader. However, you can

insert and eject cartridges individually using the mailslot, or you can eject a

magazine, manually load and unload cartridges, then load the magazine back

into the autoloader. The autoloader automatically detects the presence of a

cartridge in the magazine slot.

If you try to perform an illegal operation, the autoloader refuses to perform the

operation. For example, if you try to load a cartridge through the mailslot to the

drive but the drive already contains a cartridge, the mailslot does not unlock.

If you try to unload a cartridge from the drive while the autoloader is writing

to the tape, the command is not initiated until the write command is completed.

37

Page 43

CHAPTER 3: Operating your Autoloader www.gateway.com

If the tape cartridge is holding the

mailslot door open during operation, the

system keeps track of the tape movement

and continues robotic motion. This can

occur if the robot ejects the cartridge out

through the mailslot door.

Important

Inserting a single cartridge

When you want to load a single cartridge into the autoloader, you can use the

mailslot. However, if the Security option is turned on, you have to enter a valid

password to unlock the mailslot before you can load a cartridge (see “Default

username and password” on page 55 for On-board Remote Management or

“Setting passwords” on page 33 for the front panel). When you insert a cartridge

through the mailslot, you can load it into the tape drive or store it in a magazine

slot.

To insert a cartridge into the tape drive:

1 From the Main menu, scroll to Commands, then press ENTER. The

Commands submenu opens.

2 Scroll to Enter, then press ENTER. The Enter submenu opens.

3 Scroll to To Drive, then press ENTER. The message “Insert Tape, Push Until

Prompted” appears on the LCD.

For the autoloader, push in the cartridge

until it stops. The cartridge should be

about 3 inches (7.5 cm) inside the

mailslot. This may require that you push

and have your fingers well within the

mailslot opening. After insertion, the end

of the cartridge should be visible at the

back of the mailslot opening.

Important

4 Insert the cartridge into the mailslot. After approximately five seconds, the

system automatically verifies that a cartridge is inserted and continues the

process. The message “Tape Loaded” appears when the process is

successfully completed.

5 After you have inserted the cartridge, press ENTER.

If the insert cartridge function fails, the cartridge ejects, the message

“Missed Tape” appears, and you must perform Step 3 and Step 4 again.

38

Page 44

www.gateway.com

Using cartridges

To insert a cartridge into a magazine slot:

1 From the Main menu, scroll to Commands, then press ENTER. The

Commands submenu opens.

2 Scroll to Enter, then press ENTER. The Enter submenu opens.

3 Scroll to To Locat i o n , then press ENTER. The message “Insert Tape, Push

Until Prompted” appears on the LCD.

For the autoloader, push in the cartridge

until it stops. The cartridge should be

about 3 inches (7.5 cm) inside the

mailslot. This may require that you push

and have your fingers well within the

mailslot opening. After insertion, the end

of the cartridge should be visible at the

back of the mailslot opening.

Important

Moving a single cartridge

4 Insert the cartridge. After approximately five seconds, the system

automatically verifies that a cartridge is inserted and continues the

process. The message “Tape Loaded” appears when the process is

successfully completed.

5 After you have inserted the cartridge, press ENTER.

If the load cartridge function fails, the cartridge ejects, the message

“Missed Tape” appears, and you must perform Step 3 and Step 4 again.

6 Scroll through the magazine slots and view their status until you find the

appropriate slot. Slots that are occupied by a data cartridge are indicated

by an asterisk (*). Scroll to the slot where you want to store the cartridge,

then press E

NTER.

You can move a single cartridge from one location to another inside the

autoloader.

To move a single cartridge:

1 From the Main menu, scroll to Commands, then press ENTER. The

Commands submenu opens.

2 Scroll to Move, then press ENTER. The Move screen appears under From:.

If you select an empty From: location, “No Source Tape” appears on the

LCD. Choose a different location.

3 Scroll to the current location of the cartridge you want to move. Slots that

are occupied by a data cartridge are indicated by an asterisk (*).

4 From To : , scroll to the location to which you want to move the cartridge.

Slots that are occupied by a data cartridge are indicated by an asterisk (*).

Press E

NTER.

If you select a To : location that is already occupied, “Destination Full”

appears on the LCD. Choose a different location.

39

Page 45

CHAPTER 3: Operating your Autoloader www.gateway.com

Ejecting a single cartridge

When you want to remove a single cartridge from the autoloader, you can

specify the cartridge you want by bar code or location, or choose the cartridge

currently in the tape drive.

To eject a cartridge by bar code:

1 From the Main menu, scroll to Commands, then press ENTER. The

Commands submenu opens.

2 Scroll to Eject, then press ENTER. The Eject submenu opens.

3 Scroll to Tape , Mailslot, then press ENTER.

4 Scroll to By Barcode. A bar code label appears.

5 Scroll to the label that corresponds to the cartridge you want to eject, then

press E

To eject a cartridge by location:

1 From the Main menu, scroll to Commands, then press ENTER. The

Commands submenu opens.

NTER.

2 Scroll to Eject, then press ENTER. The Eject submenu opens.

3 Scroll to Tape , Mailslot, then press ENTER.

4 Scroll to By Location.

Slots that are occupied by a data cartridge are indicated by an asterisk (*).

If Auto Clean is enabled, the slot that is occupied by a cleaning tape is

indicated with an “at” (@) sign. Scroll to the slot containing the cartridge

you want to eject.

5 Press ENTER. The cartridge you want is ejected from the mailslot.

To eject a cartridge from the tape drive:

1 From the Main menu, scroll to Commands, then press ENTER. The

Commands submenu opens.

2 Scroll to Eject, then press ENTER. The Eject submenu opens.

3 Scroll to Cartridge, then press ENTER.

4 Scroll to From Drive, then press ENTER. The cartridge you want is ejected

from the mailslot.

40

Page 46

www.gateway.com

Using magazines and magazine blanks

Magazine - right side (with

left side handle installed)

Using magazines and magazine blanks

Magazines are not interchangeable

between drive types. Order the

appropriate part numbers when

Important

replacing these items.

Magazine - left side (with

left side handle installed)

The autoloader cannot run unless both magazine openings are correctly closed.

One way you can close the openings is to use two magazines. If you use only

one magazine, then you must fill the other magazine opening with a magazine

blank for the autoloader to become operational.

41

Page 47

CHAPTER 3: Operating your Autoloader www.gateway.com

Ejecting a magazine

When you want to remove several cartridges at once, eject the magazine(s) first.

To eject a magazine:

1 From the Main menu, scroll to Commands, then press ENTER. The

Commands submenu opens.

2 Scroll to Eject, then press ENTER. The Eject submenu opens.

3 Scroll to Right Magazine or Left Magazine, then press Enter.