Fluke 734A, 732B Service manual

®

732B/734A

DC Reference Standard

Instruction Manual

PN 869321

March 1992 Rev.3, 11/97

© 1993, 1994, 1997 Fluke Corporation, All rights reserved. Printed in U.S.A. All product names are trademarks of their respective companies.

LIMITED WARRANTY & LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and service. The warranty period is one year and begins on the date of shipment. Parts, product repairs and services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of a Fluke authorized reseller, and does not apply to fuses, disposable batteries or to any product which, in Fluke’s opinion, has been misused, altered, neglected or damaged by accident or abnormal conditions of operation or handling. Fluke warrants that software will operate substantially in accordance with its functional specifications for 90 days and that it has been properly recorded on non-defective media. Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is available if product is purchased through a Fluke authorized sales outlet or Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for importation costs of repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price, free of charge repair, or replacement of a defective product which is returned to a Fluke authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or send the product, with a description of the difficulty, postage and insurance prepaid (FOB Destination), to the nearest Fluke authorized service center. Fluke assumes no risk for damage in transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke determines that the failure was caused by misuse, alteration, accident or abnormal condition of operation or handling, Fluke will provide an estimate of repair costs and obtain authorization before commencing the work. Following repair, the product will be returned to the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER ARISING FROM BREACH OF WARRANTY OR BASED ON CONTRACT, TORT, RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court of competent jurisdiction, such holding will not affect the validity or enforceability of any other provision.

Fluke Corporation |

Fluke Europe B.V. |

P.O. Box 9090 |

P.O. Box 1186 |

Everett, WA 98206-9090 |

5602 BD Eindhoven |

U.S.A. |

The Netherlands |

5/94

Declaration of the Manufacturer or Importer

We hereby certify that the Fluke Models 732B and 734A are in compliance with BMPT Vfg 243/1991 and is RFI suppressed. The normal operation of some equipment (e.g. signal generators) may be subject to specific restrictions. Please observe the notices in the users manual. The marketing and sales of the equipment was reported to the Central Office for Telecommunication Permits (BZT). The right to retest this equipment to verify compliance with the regulation was given to the BZT.

Bescheinigung des Herstellers/Importeurs

Hiermit wird bescheinigt, daβ Fluke Models 732B und 734A in Übereinstimmung mit den Bestimmungen der BMPT-AmtsblVfg 243/1991 funk-entstört ist. Der vorschriftsmäßige Betrieb mancher Geräte (z.B. Meßsender) kann allerdings gewissen Einschränkungen unterliegen. Beachten Sie deshalb die Hinweise in der Bedienungsanleitung. Dem Bundesamt für Zulassungen in der Telekcommunikation wurde das Inverkehrbringen dieses Gerätes angezeigt und die Berechtigung zur Überprüfung der Serie auf Einhaltung der Bestimmungen eingeräumt.

Fluke Corporation

Electromagnetic Compatibility

This instrument is designed to operate in Standards Laboratory environments where the radio frequency (RF) environments is highly controlled. If used in areas of high RF, there could be errors in measurements.

Safety Summary

Safety Terms in this Manual

Instrument models described in this manual (Models 732B and 734A) have been designed and tested in accordance with IEC Publication 348, Safety Requirements for Electronic Measuring Apparatus. This Instruction Manual contains information, warnings, and cautions that must be followed to ensure safe operation and to maintain the instrument in a safe condition. Use of these instruments in a manner mot specified herein may impair the protection by the instrument.

Warning statements identify conditions or practices that could result in personal injury or loss of life.

Caution statements identify conditions or practices that could result in damage to the equipment.

Symbols Marked on Equipment

Power Off Switch Position

Power On Switch Position

Ground (Earth) Terminal

Attention — refer to the manual. This symbol indicates that information about the use of a feature is contained in the manual.

Power Source

The instruments are intended to operate from a power source that will not apply more than 264V ac rms between the supply conductors or between either supply conductor and ground. A protective ground connection by way of the grounding conductor in the power cord is essential for safe operation.

Use the Proper Fuse

To avoid fire hazard, use only a fuse identical in type, voltage rating, and current rating as specified on the rear panel fuse rating label. Never bypass a fuse by shorting across the fuse terminals.

Grounding the Standard

These are Safety Class I (grounded enclosure) instruments as defined in IEC 348. To avoid electrical shock, plug the power cord into a properly wired earth grounded receptacle, or ground the GROUND binding post before connecting anything to any of the instrument binding posts. A protective ground connection by way of the grounding conductor in the power cord is essential for safe operation when using ac line power.

Use the Proper Power Cord

Use only the power cord and connector appropriate for the voltage and plug configuration in your country.

Use only a power cord that is in good condition.

Refer cord and connector changes to qualified service personnel.

Do Not Operate in Explosive Atmospheres

To avoid explosion, do not operate the instrument in an atmosphere of explosive gas.

Do Not Attempt to Operate if Protection May be Impaired

If the instrument appears damaged or operates abnormally, protection may be impaired. Do not attempt to operate it. When is doubt, have the instrument serviced.

Use Care When Servicing with Power On

High voltages exist at several points inside the instrument. To avoid personal injury, do not touch exposed connections and components while power is on. Disconnect line cord and battery power before removing protective panels, soldering, or replacing components.

Table of Contents

Chapter |

|

Title |

Page |

1 |

Introduction and Specifications.......................................................... |

1-1 |

|

|

1-1. |

Introduction ........................................................................................... |

1-3 |

|

1-2. |

Hardware Options .................................................................................. |

1-4 |

|

1-3. |

734A-7001 Instrument Enclosure ..................................................... |

1-4 |

|

1-4. |

723B-7001 External Battery and Charger ......................................... |

1-4 |

|

1-5. |

Accessory Y734 Rack Mount Kit ..................................................... |

1-4 |

|

1-6. |

Calibration Options ............................................................................... |

1-5 |

|

1-7. |

732B-000 Special Calibration ........................................................... |

1-5 |

|

1-8. |

732B-100 Special Calibration and Drift Characterization ................ |

1-5 |

|

1-9. |

732B-200 On-Site Calibration .......................................................... |

1-5 |

|

1-10. |

Warranty Information ............................................................................ |

1-5 |

|

1-11. Service and Reshipment Information .................................................... |

1-6 |

|

|

1-12. |

Specifications ........................................................................................ |

1-6 |

2 |

Installation............................................................................................ |

2-1 |

|

|

2-1. |

Introduction ........................................................................................... |

2-3 |

|

2-2. |

Unpacking and Inspection ..................................................................... |

2-3 |

|

2-3. |

Selecting Line Voltage and Accessing the Fuse ................................... |

2-4 |

|

2-4. |

Connecting to Line Power ..................................................................... |

2-5 |

|

2-5. |

Installing a 732B or 732B-7001 in a 734A-7001 Instrument Enclosure |

2-5 |

3 |

Operation.............................................................................................. |

3-1 |

|

|

3-1. |

Introduction ........................................................................................... |

3-3 |

|

3-2. |

Summary of the Features ....................................................................... |

3-3 |

|

3-3. |

732B DC Standard Front Panel ......................................................... |

3-3 |

|

3-4. |

732B DC Standard Rear Panel .......................................................... |

3-3 |

|

3-5. |

732B-7001 External Battery and Charger Front Panel ..................... |

3-3 |

|

3-6. |

732B-7001 External Battery and Charger Rear Panel ...................... |

3-3 |

|

3-7. |

734A-7001 Instrument Enclosure Front Panel ................................. |

3-3 |

|

3-8. |

734A-7001 Instrument Enclosure Rear Panel .................................. |

3-3 |

|

3-9. |

Powering the Standard .......................................................................... |

3-11 |

|

3-10. |

Setting the BAT Switch .................................................................... |

3-12 |

|

3-11. |

Charging the Internal Battery ........................................................... |

3-12 |

i

732B/734A

Instruction Manual

|

3-12. |

Powering the Standard from a 732B-7001 ........................................ |

3-12 |

|

3-13. |

Replacing the Internal Battery .......................................................... |

3-13 |

|

3-14. |

Connecting Cables to the Output .......................................................... |

3-14 |

|

3-15. |

Connecting the GUARD and GROUND .......................................... |

3-15 |

|

3-16. |

Monitoring Oven Temperature .............................................................. |

3-16 |

|

3-17. |

Resetting the IN CAL Indicator ............................................................ |

3-16 |

|

3-18. |

Monitoring The IN CAL Indicator State Remotely .............................. |

3-16 |

|

3-19. |

Monitoring Long-Term Stability ........................................................... |

3-17 |

|

3-20. |

Minimizing Error Sources ..................................................................... |

3-18 |

|

3-21. |

Mechanically Induced Errors ............................................................ |

3-18 |

|

3-22. |

Thermal EMFs .................................................................................. |

3-18 |

|

3-23. |

Output Cable Loading ....................................................................... |

3-18 |

4 |

Theory of Operation............................................................................. |

4-1 |

|

|

4-1. |

Introduction ........................................................................................... |

4-3 |

|

4-2. |

Overall Functional Description ............................................................. |

4-3 |

|

4-3. |

Model 734A Functional Description ................................................ |

4-5 |

|

4-4. |

Model 732B-7001 External Battery/Power Supply .......................... |

4-5 |

|

4-5. |

732B Circuit Description ...................................................................... |

4-5 |

|

4-6. |

10V Reference Circuit ...................................................................... |

4-5 |

|

4-7. |

Generating the 1.018V Output ...................................................... |

4-7 |

|

4-8. |

Biasing the Refamp for Low Temperature Coefficient ................ |

4-7 |

|

4-9. |

Sense Current Cancellation .......................................................... |

4-7 |

|

4-10. |

Buffering of the 10V Output ........................................................ |

4-8 |

|

4-11. |

Oven Temperature Controller A4 ..................................................... |

4-8 |

|

4-12. |

A1 Front Panel Assembly ................................................................. |

4-8 |

|

4-13. |

Power Supplies and Battery Charger Assembly A5 ......................... |

4-9 |

|

4-14. |

Overvoltage Protection Circuitry ................................................. |

4-9 |

|

4-15. |

Raw DC Power Supply ................................................................. |

4-11 |

|

4-16. |

Battery Charger ............................................................................. |

4-11 |

|

4-17. |

+11.5V Preregulator ..................................................................... |

4-11 |

|

4-18. |

+11.5V Low-Dropout Regulator .................................................. |

4-12 |

|

4-19. |

-6V Power Supply ......................................................................... |

4-12 |

|

4-20. |

IN CAL Logic ............................................................................... |

4-12 |

|

4-21. |

LED Drive Logic .......................................................................... |

4-12 |

|

4-22. |

AC Power to Battery Power Switching Circuitry ......................... |

4-13 |

|

4-23. |

Battery Circuit .............................................................................. |

4-13 |

|

4-24. |

Rear Panel Connections ................................................................ |

4-13 |

|

4-25. |

Low-Battery Shutdown Circuitry ................................................. |

4-14 |

5 |

Maintenance ......................................................................................... |

5-1 |

|

|

5-1. |

Introduction ........................................................................................... |

5-3 |

|

5-2. |

Service Information ............................................................................... |

5-3 |

|

5-3. |

Replacing the Fuse ................................................................................ |

5-3 |

|

5-4. |

Cleaning the External Surfaces ............................................................. |

5-3 |

|

5-5. |

Calibration ............................................................................................. |

5-3 |

|

5-6. |

Preparing for Calibration .................................................................. |

5-4 |

|

5-7. |

Preparing for 10V Calibration with Adjustment ............................... |

5-4 |

|

5-8. |

Calibration with Adjustment ............................................................. |

5-6 |

|

5-9. |

Calibration Without Adjustment ....................................................... |

5-8 |

|

5-10. |

Access Procedures ................................................................................. |

5-9 |

|

5-11. |

Initial Access Procedure ................................................................... |

5-9 |

|

5-12. |

Replacing the Battery ........................................................................ |

5-9 |

|

5-13. |

Replacing the Oven Assembly .......................................................... |

5-13 |

ii

|

|

|

Contents (continued) |

|

5-14. |

Accessing the A5 Battery Charger .................................................... |

5-13 |

|

5-15. |

Removing the Power Transformer Assembly ................................... |

5-13 |

|

5-16. |

Troubleshooting .................................................................................... |

5-14 |

|

5-17. |

10V Reference Performance Test ..................................................... |

5-14 |

|

5-18. |

Troubleshooting the A5 Battery Charger Assembly ......................... |

5-14 |

|

5-19. |

Transformer/Rectifier/Filter ......................................................... |

5-15 |

|

5-20. |

Battery Charger ............................................................................. |

5-15 |

|

5-21. |

+11.5V DC Preregulator ............................................................... |

5-15 |

|

5-22. |

+11.5V DC Regulator ................................................................... |

5-16 |

|

5-23. |

-6V DC Supply ............................................................................. |

5-16 |

|

5-24. |

IN CAL LED Logic ...................................................................... |

5-16 |

6 |

List of Replaceable Parts .................................................................... |

6-1 |

|

|

6-1. |

Introduction ........................................................................................... |

6-3 |

|

6-2. How to Obtain Parts .............................................................................. |

6-3 |

|

|

6-3. |

Manual Status Information .................................................................... |

6-3 |

|

6-4. |

Newer Instruments ................................................................................ |

6-3 |

|

6-5. |

Service Centers ..................................................................................... |

6-4 |

|

6-6. |

Parts ....................................................................................................... |

6-4 |

7 |

Schematic Diagrams............................................................................ |

7-1 |

|

|

A1 Front Panel PCA............................................................................................ |

7-3 |

|

|

A2 Flex Circuit PCA ........................................................................................... |

7-5 |

|

|

A3 BCD Switch PCA .......................................................................................... |

7-6 |

|

|

A4 Oven Control PCA......................................................................................... |

7-7 |

|

|

A5 Power Supply PCA........................................................................................ |

7-8 |

|

Index

iii

732B/734A

Instruction Manual

iv

List of Tables

Table |

|

Title |

Page |

2-1. |

Standard Equipment................................................................................................. |

2-3 |

|

2-2. |

AC Line Cords Available for Fluke Instruments..................................................... |

2-3 |

|

3-1. |

732B |

DC Standard Front Panel Features................................................................. |

3-5 |

3-2. |

732B |

DC Standard Rear Panel Features .................................................................. |

3-7 |

3-3. |

732B-7001 External Battery/Charger Front Panel Features.................................... |

3-8 |

|

3-4. |

732B-7001 External Battery/Charger Rear Panel Features..................................... |

3-9 |

|

3-5. |

734A-7001 Instrument Enclosure Front Panel Features ......................................... |

3-10 |

|

3-6. |

734A-7001 Instrument Enclosure Rear Panel Features........................................... |

3-11 |

|

5-1. |

Equipment Required for Calibration ....................................................................... |

5-4 |

|

6-1. |

734A DC Reference Standard ................................................................................. |

6-4 |

|

6-2. |

732B |

DC Standard ................................................................................................... |

6-8 |

6-3. |

A1 Front Panel PCA ................................................................................................ |

6-15 |

|

6-4. |

A5 Power Supply PCA ............................................................................................ |

6-17 |

|

v

732B/734A

Instruction Manual

vi

List of Figures

Figure |

Title |

Page |

1-1. |

Mechanical Specifications ....................................................................................... |

1-11 |

2-1. |

Line Power Cords Available for Fluke Instruments................................................ |

2-4 |

2-2. |

Line Power Label and Fuse Location ...................................................................... |

2-7 |

2-3. |

Installing a 732B or 732B-7001 in a 734A-7001 Instrument Enclosure................. |

2-8 |

3-1. |

732B DC Standard Front Panel Features................................................................. |

3-4 |

3-2. |

732B DC Standard Rear Panel Features .................................................................. |

3-6 |

3-3. |

732B-7001 External Battery/Charger Front Panel Features.................................... |

3-8 |

3-4. |

732B-7001 External Battery/Charger Rear Panel Features..................................... |

3-9 |

3-5. |

734A-7001 Instrument Enclosure Front Panel Features ......................................... |

3-10 |

3-6. |

734A-7001 Instrument Enclosure Rear Panel Features........................................... |

3-11 |

3-7. |

732B MONITOR/EXT BAT IN Connector Pinout ................................................. |

3-13 |

3-8. |

732B-7001 BAT OUT Connector Pinout ................................................................ |

3-14 |

3-9. |

Typical 732B Cable Connections ............................................................................ |

3-15 |

3-10. |

IN CAL Status Output Circuit ................................................................................. |

3-17 |

3-11. |

Loading Error Example ........................................................................................... |

3-19 |

4-1. |

732B Overall Block Diagram .................................................................................. |

4-4 |

4-2. |

10V Reference Circuit Block Diagram ................................................................... |

4-6 |

4-3. |

A5 Power Supply/Battery Charger Block Diagram ................................................ |

4-10 |

5-1. |

10V Output Calibration Connections ...................................................................... |

5-5 |

5-2. |

Location of 732B Calibration Adjustment Switches............................................... |

5-7 |

5-3. |

Accessing Internal Components .............................................................................. |

5-10 |

5-4. |

Replacing the Battery .............................................................................................. |

5-12 |

6-1. |

734A DC Reference Standard ................................................................................. |

6-5 |

6-2. |

732B DC Standard ................................................................................................... |

6-10 |

6-3. |

A1 Front Panel PCA ................................................................................................ |

6-16 |

6-4. |

A5 Power Supply PCA ............................................................................................ |

6-20 |

vii

732B/734A

Instruction Manual

viii

Chapter 1

Introduction and Specifications

|

Title |

Page |

1-1. |

Introduction ............................................................................................ |

1-3 |

1-2. |

Hardware Options................................................................................... |

1-4 |

1-3. |

734A-7001 Instrument Enclosure ...................................................... |

1-4 |

1-4. |

723B-7001 External Battery and Charger.......................................... |

1-4 |

1-5. |

Accessory Y734 Rack Mount Kit ...................................................... |

1-4 |

1-6. |

Calibration Options ................................................................................ |

1-5 |

1-7. |

732B-000 Special Calibration............................................................ |

1-5 |

1-8. |

732B-100 Special Calibration and Drift Characterization................. |

1-5 |

1-9. |

732B-200 On-Site Calibration ........................................................... |

1-5 |

1-10. |

Warranty Information............................................................................. |

1-5 |

1-11. Service and Reshipment Information..................................................... |

1-6 |

|

1-12. |

Specifications ......................................................................................... |

1-6 |

1-1

732B/734A

Instruction Manual

1-2

Introduction and Specifications 1

Introduction

Introduction |

1-1. |

Caution

Set the rear panel BAT switch to (on) before connecting AC power. This is required for proper instrument operation. If your 732B was shipped cold, you will need to calibrate it against a traceable standard as described in Section 5 before you begin using it. For best results, leave the standard powered for a minimum of 14 days before you calibrate and begin using it.

Model 732B is a dc voltage laboratory standard that produces reference voltages of 10V and 1.018V. Model 734A contains four 732B DC Standards in a chassis. The 732B is highly stable, rugged and transportable. Its 10V output excels in stability, and can be used as your direct link in the traceability chain to national standards. You can use the 732B 1.018V output to transfer the "volt" at the 1.018V level from one set of saturated standard cells to another. You can also use the 1.018V output as a working standard with older equipment that requires a standard cell voltage input.

The 10V output’s long-term stability, predictable drift rate, low uncertainty, convenient level, and immunity to accidental damage make the 732B or 734A the preferred artifact for maintaining a local standard of voltage. With time characterization (Calibration Option 732B-100) the drift rate for the 10V output is given. This reduces the 10V output uncertainty from 2 ppm/year to 1 ppm/year.

All outputs of the 732B can withstand short circuit indefinitely, without damage to the instrument or disruption of the state of calibration. Recovery time for a momentary short is less than 2 minutes; for an extended short, recovery time is less than 2 hours.

To maintain calibration as a traceable standard, the 732B must continue to receive uninterrupted operating voltage from ac line power or from the internal battery. If battery voltage drops too low, the front panel IN CAL indicator goes out and recalibration is required.

The internal rechargeable battery (if switched on) protects the standard from line power interruption and provides power for hot shipment (shipment under power). The 732B outputs are unaffected as you change between battery or ac line power. Battery operation with a fully charged battery lasts at least 72 hours. You can extend battery operation by connecting an external 12V battery such as Model 732B-7001 to the rear panel MONITOR/EXT BAT IN connector. Plugging the 732B into ac line power for 24 hours fully recharges the internal battery.

Four front panel indicators show operating status. Model 732B-7001 External Battery and Charger has all but the IN CAL indicator.

∙AC PWR lights when the 732B is connected to ac line power.

∙IN CAL goes out to warn you when the 732B may have lost its calibration. This indicator responds to an excessively large drop in battery voltage or a large change in oven temperature. If battery voltage falls below the level needed to keep the 732B working normally, the IN CAL indicator extinguishes, indicating a loss of the state of calibration. Once power is restored and the output has been verified, you can reset the IN CAL indicator.

Note

An illuminated IN CAL indicator is not sufficient by itself to indicate the 732B satisfies the specifications of section 1-12. See Calibration label on front of the 732B for calibration due date.

1-3

732B/734A

Instruction Manual

∙LOW BAT blinks to warn you to plug the line cord into ac power when only a few hours of battery operation remain.

∙CHARGE lights when the battery is being recharged in constant-current charge mode, and is off when the battery is charged to the 90% level. At 90% of full charge, a float charge completes and maintains full charge.

You can monitor the oven temperature by measuring the resistance of the oven temperature thermistor through the rear panel MONITOR/EXT BAT IN connector. Instructions for using this connector are in Section 3.

Hardware Options |

1-2. |

Table 1-1 summarizes hardware options for the 732B DC Standard. Calibration Options are described further on in this section.

Table 1-1. 732B/734A Hardware Options and Accessories

Model Number

734A-7001

732B-7001

732B-7002

Y734

Name

Instrument Enclosure

External Battery and Charger

Transit Case for two 732Bs or 732B-7001s

Rack Mount Kit for 734A or 734A-7001

734A-7001 Instrument Enclosure |

1-3. |

The Model 734A DC Reference Standard is made up of one 734A-7001 Instrument Enclosure and four 732B DC Standards. The Model 734A-7001 can be purchased separately as needed for your application. The enclosure securely holds up to four 732B DC Standards and/or 732B-7001 External Battery/Chargers (described next).

An ac power bus inside the 734A-7001 enclosure powers up to four 732B units with only one ac line cord. Using the enclosure allows you to rack mount 732Bs. (See Y734 Rack Mount Kit.)

723B-7001 External Battery and Charger |

1-4. |

The Model 732B-7001 External Battery and Charger is contained in the same enclosure as the 732B. This means it fits into and is powered by the 734A-7001 Instrument Enclosure just like a 732B DC Standard.

When the external battery is completely charged and connected to a completely charged 732B, it increases 732B battery operating time from 72 to 130 hours. Just as in the 732B, the charger in the 732B-7001 takes 36 hours to completely charge the battery (with no load on the battery). Refer to Section 3 for information about interconnecting 732Bs and 732B-7001s.

Accessory Y734 Rack Mount Kit |

1-5. |

To rack mount a 732B, use the 734A-7001 Instrument Enclosure (standard equipment with Model 734A). Use Accessory Y734 Rack Mount Kit to mount the enclosure in a rack. Outside dimensions of the 732B and 734A are shown in the specifications at the end of this section. Instructions for rack mounting the 734A-7001 Instrument Enclosure are packed with the kit.

1-4

Introduction and Specifications 1

Calibration Options

Calibration Options |

1-6. |

Unless requested at time of order, the 732B is shipped cold (not under battery power) and will need to be calibrated on receipt. A procedure to calibrate a 732B using a reference 732B as a transfer standard is provided in Section 5. After calibration, the 732B must be kept powered by ac power or battery, even during shipment. Fluke calibration services that are available for the 732B are described next.

Note

Contact a Fluke Sales or Service Center for price and delivery information about 732B calibration options. Addresses for Fluke Service Centers are provided following the parts lists in Section 6.

732B-000 Special Calibration |

1-7. |

If you ordered Option 732B-000, the standard is shipped to you hot with a calibration report that assigns a value to the 10V output. This calibration meets or exceeds the requirements of MIL-STD-45662A.

732B-100 Special Calibration and Drift Characterization |

1-8. |

If you ordered Option 732B-100, the standard is shipped to you hot with a calibration report that assigns a value to the 10V output. This calibration meets or exceeds the requirements of MIL-STD-45662A. In addition, a calibration report shows the predicted output on the 1st of each month for the 12 months following shipment.

732B-200 On-Site Calibration |

1-9. |

Option 732B-200 is the Fluke Direct Volt Maintenance Program, as has been applied to other Fluke dc standards equipment. This program works as follows:

1.Fluke hot-ships a Fluke-owned transfer standard with all the necessary interconnecting cables and clear instructions.

2.You make a series of comparisons over five days and send your data to Fluke.

3.Fluke sends you a calibration report that assigns a value to your 732B 10V output relative to the Fluke Volt. The Fluke Volt is maintained by means of a Josephson Junction array in the Fluke Primary Standards laboratory. Periodic transfers to NIST also maintain traceability to the U.S. Legal Volt (at greater uncertainty) for those who are required to maintain NIST traceability.

Warranty Information |

1-10. |

The warranty that applies to your Fluke product appears at the front of this manual.

1-5

732B/734A

Instruction Manual

Service and Reshipment Information |

1-11. |

Warning

Warning

Service procedures, including replacing the batteries, are to be done by qualified service personnel only. To avoid electric shock or fire, do not service the 732B unless you are qualified to do so.

If your standard ever needs service, you may return it to Fluke for Warranty or afterwarranty repair. Addresses for authorized service centers are in Section 6. If you are qualified to troubleshoot electronic equipment, you can refer to Section 5 for theory, troubleshooting, and calibration information. Schematic diagrams are in Section 7.

The 732B and 734A are designed to withstand the shock and vibration of air and ground shipment, provided that you protect the equipment with a proper shipping container. When you return a 732B or 734A to Fluke for service or calibration, use the original shipping carton, a replacement carton obtained from Fluke, or the accessory transit case. Transit Case Model 732B-7002 holds two 732B DC Standards or 732B-7001 External Battery/Chargers.

Caution

Do not charge a 732B or 732B-7001 while it is in the transit case. Doing so can cause overheating and possible equipment damage, and in the case of the 732B, loss of the state of calibration.

Specifications |

1-12. |

Output Voltages

10V and 1.018V are provided at separate binding post pairs with the following characteristics:

Note

A potential difference of approximately <200 μV exists between the floating 1.018V LO and 10V LO terminals. Consequently, buck measurements cannot be made between these sources without taking this into account.

1-6

Introduction and Specifications 1

Specifications

Stability

Stability for a given period of time is defined as the output uncertainty minus the calibration uncertainty at the 99% Confidence Level. When the output voltage is characterized by a regression model, stability is given by the following equation:

æ |

P ö |

+ 2.65S |

|

b ç |

|

÷ |

|

|

|||

è |

365 ø |

1 |

|

|

|

ù2 |

|

|

|

|

é |

( |

|

+ P - x1)2 |

ù |

|||

é Sra |

|

|

|

êê |

|

úú |

||||||||

æ |

1 ö |

|

x |

|||||||||||

ê |

|

ú |

+ ç |

|

÷ |

+ |

ê |

|

|

|

|

|

2 ú |

|

|

|

|

|

|

|

|

||||||||

ê S |

ú |

è n ø |

|

æ |

|

ö |

||||||||

ë 1 û |

|

|

|

|

ê |

|

|

ú |

||||||

|

|

|

|

åçX |

j |

- x÷ |

|

|||||||

|

|

|

|

|

|

|

ê |

è |

ø |

|

ú |

|||

|

|

|

|

|

|

|

ë |

|

|

|

|

|

|

û |

where b = slope of regression in ppm/year

S1 = standard deviation about the regression (SDEV)

Sra = SDEV of data filtered with 7-day moving average filter (MAF) P = Period of time under consideration in days

x = mean time for regession data

n = 180 period (typically 2 meassurements per day) Xj = jth period

X1 = time at beginning of data

Each data point for the computation of the regression parameters is the average voltage of 50 readings taken in a 50-second measurement period.

Stability for the 732B outputs at 23 ±1°C is specified as follows:

Output Voltage |

|

Stability (± ppm) |

|

|

30 Days |

90 Days |

1 Year |

|

|

|

|

10V |

0.3 |

0.8 |

2.0 |

|

|

|

|

1.018V |

0.8 |

NA |

NA |

|

|

|

|

Noise at the Output Terminals

Output noise is specified for both day-to-day observations and for short-term observations. The former is given by the standard deviation of a 90-day regression model. The latter is in terms of its rms value in a bandwidth as follows:

Output Voltage |

S1 (± ppm) |

Sra (± ppm) |

Noise (0.01 Hz to 10 |

Hz (± ppm rms) |

|||

10V |

0.068 |

0.05 |

0.06 |

|

|

|

|

1.018V |

0.1 |

NA |

0.03 |

|

|

|

|

Output Current and Limits

Output Voltage |

Output Current Limit |

Output Impedance |

|

|

|

10V |

12 mA (Note) |

≤ 1 mΩ |

1.018V |

20 pA |

≤ 1 kΩ |

Note: Limit output current to ≤ 0.1 mA to realize 72 hour battery operation.

1-7

732B/734A

Instruction Manual

Output Adjustability

-10V: 0.15 ppm resolution

-1.018V: Set at nominal ±1 mV. No adjustment is provided.

The 10V adjustment is done with a set of four decade-control switches with a range of at least 4 mV.

Retrace (Hysteresis) Error

The following table shows the change in 10V output voltage following a power outage (with the battery turned off) with temperature held constant in the normal operating range.

Period that Power is Turned Off

10 minutes or less

10 minutes to 24 hours

Change in 10V Output Value

≤±0.1 ppm

≤±0.25 ppm

Stabilization Time Requirements

The following information specifies the warmup times required after ac line and battery power has been turned off. The IN CAL indicator will be off, and recalibration will be necessary. The previously specified retrace error specification can be used in the case of brief power interruptions.

With no power interruption: |

No stabilization time is required after moving into |

|

another environment. |

Power off for less than 1 hour: |

1-hour warmup required |

Power off for 1 to 24 hours: |

24-hour warmup required |

Electromagnetic Compatibility

This instrument is designed to operate in Standards Laboratory environments where the radio frequency (RF) environment is highly controlled. If used in environments with field strengths >0.18 V/m, there could be errors in measurements.

Temperature Coefficient (TC) of Output

In the temperature range of 15°C to 35°C, the magnitude of the TC is bounded by the following:

-10V Output: TC ≤ 0.04 ppm/°C

-1.018V Output: TC ≤ 0.1 ppm/°C

Load Regulation

10V Output Load Change

0 mA to 12 mA (no load to full load)

0 mA to 2 mA

Maximum 10V Output Change

±1 ppm

±0.1 ppm

1-8

Introduction and Specifications 1

Specifications

Line Regulation

The outputs will change no more than 0.05 ppm for any 10% line voltage change or for the entire operating range of the battery.

Output Protection

All outputs can be shorted indefinitely without damage to the instrument. The 10V output can withstand voltages from other sources as follows:

1.For voltages ≤ 220V dc, the unit is protected for up to 50 mA continuous current.

2.For voltage ≤ 1100V dc, the unit is protected for up to 25 mA continuous current or up to 0.6 joules for short periods of time.

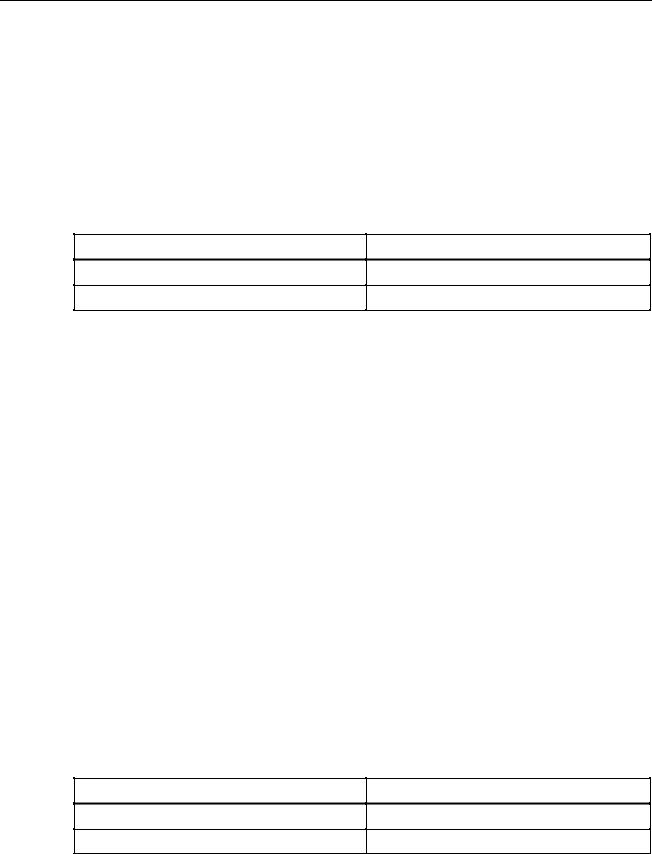

Environment

|

Temperature Range |

Relative Humidity |

Altitude |

|

|

|

|

Normal Operation |

15°C to 35°C |

15% to 80% |

0 to 6,000 ft |

Safe Operation |

0°C to 50°C |

15% to 90% |

0 to 10,000 ft |

Storage (With battery |

-49°C to 50°C |

Noncondensing |

0 to 40,000 ft |

removed) |

|

|

|

|

|

|

|

Compliance to Standards

ANSI/ISA-S82

CSA C22.2 #231

IEC348

IEC 1010

UL 1244

Line Power Requirements

Line voltage is accepted in the two ranges 90 to 132V and 180 to 264V, at 47 to 63 Hz as shown in the table below. AC line current at 120V ac is 0.13A.

732B Line Voltage Setting |

Line Voltage Accepted |

Frequency Accepted |

|

|

|

100V |

90 to 110V |

47 to 63 Hz |

|

|

|

120V |

108 to 132V |

47 to 63 Hz |

|

|

|

220V |

180 to 235V |

47 to 63 Hz |

|

|

|

240V |

225 to 264V |

47 to 63 Hz |

|

|

|

Battery Operation

When fully charged, the internal batteries will operate the 732B for a minimum of 72 hours at 23 ±5°C, with 0 to 0.1 mA current drain at the 10V output. Model 732B-7001

contains the same battery and charger as Model 732B.

1-9

732B/734A

Instruction Manual

Charging Time

The batteries are rechargeable in less than 36 hours with a self-contained automatic battery charger.

External DC Input

A rear panel input for external 12 to 15V dc allows for powering the 732B indefinitely. The dc source must be rated for 300 mA or more.

Isolation

The resistance from any of the 732B binding posts to earth (chassis) ground or to ac line power is greater than 10,000 MΩ shunted by less than 1000 pF.

Guard and Ground Terminals

Chassis ground connections are provided on both the front and rear panels. Access to the internal guard is provided by a front panel binding post.

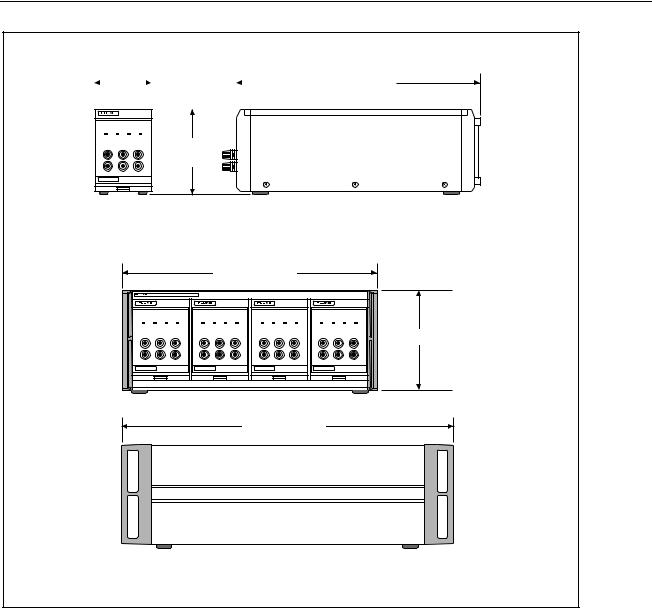

Mechanical Specifications

|

Model 734A* |

Model 732B* |

Model 732B-7001 |

|

|

|

|

Height |

17.8 cm (7.0 in) |

13.4 cm (5.28 in) |

13.4 cm (5.28 in) |

|

|

|

|

Width |

43.2 cm (17.0 in) |

9.8 cm (3.85 in) |

9.8 cm (3.85 in) |

|

|

|

|

Depth |

50.3 cm (19.8 in) including handles |

40.6 cm (16.0 in) |

40.6 cm (16.0 in) |

|

|

|

|

Weight |

30.4 kg (67 lb) |

5.91 kg (13 lb) |

5.91 kg (13 lb) |

|

|

|

|

Refer to Figure 1-1.

1-10

Introduction and Specifications 1

Specifications

|

9.8 cm |

|

|

|

|

40.6 cm (16.0 in) |

|

|

|

||||

|

(3.85 in) |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DC STANDARD

AC PWR |

IN CAL |

CHARGE |

LOW BAT |

10V |

|

1.018V |

CHASSIS |

10V COM |

1.018V COM |

GUARD |

|

SERIAL NUMBER

13.4 cm

(5.28 in)

|

|

|

|

|

|

|

|

|

732B |

|

|

|

|

|

||

|

|

|

|

|

43.2 cm (17.0 in) |

|

|

|

|

|

||||||

|

734A DC REFERENCE STANDARD |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

732B DC STANDARD |

|

732B DC STANDARD |

|

|

732B DC STANDARD |

|

732B DC STANDARD |

|

|

|

||||||

AC PWR |

IN CAL |

CHARGE |

LOW BAT |

AC PWR |

IN CAL |

CHARGE |

LOW BAT |

AC PWR |

IN CAL |

CHARGE |

LOW BAT |

AC PWR |

IN CAL |

CHARGE |

LOW BAT |

17.8 cm (7.0 in) |

10V |

|

1.018V |

CHASSIS |

10V |

1.018V |

CHASSIS |

10V |

|

1.018V |

CHASSIS |

10V |

1.018V |

CHASSIS |

|||

10V COM |

1.018V COM |

GUARD |

10V COM |

1.018V COM |

GUARD |

10V COM |

1.018V COM |

GUARD |

10V COM |

1.018V COM |

GUARD |

|

||||

SERIAL NUMBER |

|

|

SERIAL NUMBER |

|

|

|

SERIAL NUMBER |

|

|

SERIAL NUMBER |

|

|

|

|

||

50.3 cm (19.8 in)

734A

k1i.eps

Figure 1-1. Mechanical Specifications

1-11

732B/734A

Instruction Manual

1-12

Chapter 2

Installation

|

Title |

Page |

2-1. |

Introduction ............................................................................................ |

2-3 |

2-2. |

Unpacking and Inspection ...................................................................... |

2-3 |

2-3. |

Selecting Line Voltage and Accessing the Fuse .................................... |

2-4 |

2-4. |

Connecting to Line Power...................................................................... |

2-5 |

2-5. |

Installing a 732B or 732B-7001 in a 734A-7001 Instrument Enclosure |

2-5 |

2-1

732B/734A

Instruction Manual

2-2

Installation 2

Introduction

Introduction |

2-1. |

This section provides instructions for the following:

∙Unpacking

∙Installation

∙Selecting line voltage

∙Checking or replacing the fuse

∙Connecting to line power

Because this section explains fusing and operating environment requirements, you should read this section before operating the standard. Section 3 contains instructions for operating your standard.

Unpacking and Inspection |

2-2. |

The 732B and 734A are shipped in a container that is specially designed to prevent damage during shipping. However, you should inspect the standard carefully for damage, and immediately report any damage to the shipper. Instructions for inspection and claims are included in the shipping container. If you need to reship the 732B, refer to Service and Reshipment Information in Section 1.

If you ordered your 732B with calibration option 732B-000 or 732B-100, the standard is shipped hot (under battery power) to maintain the state of calibration. Verify that the IN CAL indicator is lit. Immediately refer to the fusing and line voltage instructions in this section, and plug the standard into ac line power.

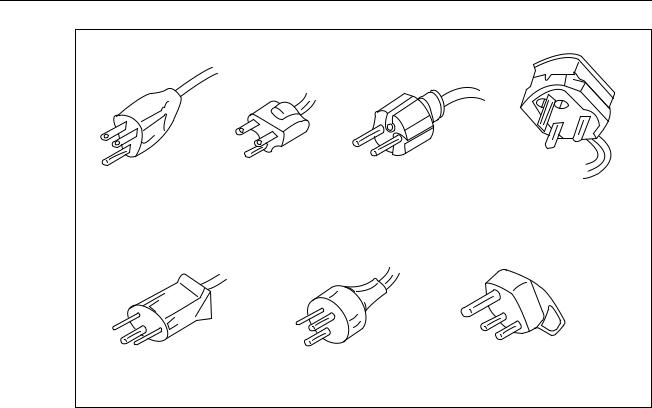

Accompanying the standard should be an ac line power cord appropriate for your country. Line power cords available from Fluke are listed in Table 2-2 and illustrated in Figure 2-1. If you have any questions about the contents of the carton you are unpacking, contact the nearest Fluke Service Center. (A List of Service Centers is located in Appendix A of this manual.)

For more information about calibration options, refer to Section 1. If a verification test is required for your acceptance procedures, refer to Section 5 for instructions.

Table 2-1. Standard Equipment

Item

AC Line Cord

732B/734A Instruction Manual

Model or Part Number

(See Table 2-2 and Figure 2-1)

871723

Table 2-2. AC Line Cords Available for Fluke Instruments |

|

||

|

|

|

|

Type |

Voltage/Current |

|

Fluke |

|

|

|

|

North American |

120V/15A |

|

LC-1 |

North American |

240V/15A |

|

LC-2 |

Universal Euro |

220V/16A |

|

LC-3 |

United Kingdom |

240V/13A |

|

LC-4 |

Switzerland |

220V/10A |

|

LC-5 |

Australian |

240V/10A |

|

LC-6 |

South African |

240V/5A |

|

LC-7 |

2-3

732B/734A

Instruction Manual

LC-1 |

LC-2 |

LC-3 |

LC-4 |

LC-5 |

|

LC-6 |

LC-7 |

|

|

|

k2f.eps |

Figure 2-1. Line Power Cords Available for Fluke Instruments

Selecting Line Voltage and Accessing the Fuse |

2-3. |

Caution

To avoid blowing the ac line fuse, verify the position of the line voltage selection drum before plugging in the line cord. Rotate the drum if necessary to match local line power.

Caution

To prevent instrument damage, verify that a 1/4A, 250V FAST BLOW fuse is installed. No other rating or type of fuse is acceptable.

The ac input module on the rear panel has four line voltage settings: 100V, 120V, 220V, and 240V. Each voltage setting has a voltage tolerance of ±10% and accepts line frequencies of 50 or 60 Hz.

To select line voltage and verify the fuse, or to replace the fuse, refer to Figure 2-2, and proceed as follows:

1.Disconnect the ac line cord from the wall outlet and the rear panel.

2.Using a small screwdriver, pop open the line voltage selection module door from the top.

3.Using the screwdriver, pry the tab of the fuse holder to slide out the fuse holder.

4.Verify the fuse type and rating using the data on the rear panel or Figure 2-2, and replace it.

2-4

Loading...

Loading...