Page 1

Gibbs and Associates

323 Science Drive

Moorpark, CA 93021

(805) 523-0004

March 1999

SolidSurfacer

USER MANUAL

Page 2

PROPRIETARY NOTICE

This document contains propriety information of Gibbs and Associates and is to be used only

pursuant to and in conjunction with the license granted to you with respect to the accompanying Gibbs

and Associates licensed software. Except as expressly permitted in the license, no part of this document

may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language

or computer language, in any form or by any means, electronic, magnetic, optical, chemical, manual or

otherwise, without the prior written permission from a duly authorized representative of Gibbs and

Associates.

It is strongly advised that you carefully review the license in order that you understand your

rights and obligations related to the licensed software and the accompanying user documentation.

Use of the computer software and the user documentation has been provided pursuant to a

Gibbs and Associates license agreement.

© Copyright 1998 Gibbs and Associates, Inc.

All Rights Reserved

Acknowledgements:

Written by Shannon McConville and Good Wil Gaffga.

Thanks to Bill Gibbs, Tim Alvord, Sean Canterbury, Gary Esser, Charles Haden, Tom Hubina, Kristin

Esser, Al Martins, Israel Klain, Jeff Myers for their input and assistance.

Trademarks:

Windows NT and Windows 95 are trademarks of Microsoft Corporation

Macintosh is a trademark of Apple Computer, Inc.

Printed in the United States of America

◆

SolidSurfacer User Manual #GFK-1709

Page 3

Table of Contents

INTRODUCTION 1

CHAPTER 1

:

INTERFACE 5

Level 2 Interface ...............................................................7

Taskbar ......................................................................7

Right Mouse Click .............................................................7

Body Bag ....................................................................8

History Dialog.................................................................8

Colors .......................................................................9

Slide Bars ....................................................................9

Pointer Markers................................................................9

CHAPTER 2

:

MODELING 11

Introduction to Modeling .......................................................13

Modeling Reference...........................................................20

Modifying Bodies ............................................................62

Modeling Tips and Techniques ..................................................67

CHAPTER 3

:

MODELING EXERCISES 69

Exercise #1: Phone ...........................................................71

Exercise #2: Hot Punch .......................................................85

Exercise #3: Teapot...........................................................91

Exercise #4: Plumbing........................................................113

Exercise #5: Remote Control Casing ............................................125

Exercise #6: Fish belt ........................................................141

CHAPTER 4: DATA EXCHANGE 161

Import .....................................................................163

Parasolids Files, ACIS (.sat) Files, IGES Surface Files

Exercise: Healing ............................................................169

Export .....................................................................183

File Extensions ..............................................................184

CHAPTER 5: MULTI-SURFACE MACHINING 187

Introduction To 3-Axis Machining...............................................189

Machining Palette ...........................................................190

Contouring Process...........................................................190

GFK-1709 T able of Contents

◆

i

Page 4

Roughing Process ...........................................................196

Surfacing Process ...........................................................200

CHAPTER 6: MACHINING EXERCISES 219

Exercise #1: Phone..........................................................221

Exercise #2: Hot Punch ......................................................245

Exercise #3: Plumbing .......................................................253

Exercise #4: 2D Contour .....................................................275

Exercise #5: Remote Control Casing............................................285

APPENDIX 1: GLOSSARY 309

APPENDIX 2: PART PRINTS 315

Part Print #1: Phone .........................................................317

Part Print #2: Hot Punch ......................................................319

Part Print #3: Plumbing.......................................................321

Part Print #4: Plumbing Views .................................................323

Part Print #5: Fish Belt .......................................................325

Part Print #6: Fish Belt Views..................................................327

INDEX 329

◆

SolidSurfacer User Manual GFK-1709

ii

Page 5

Introduction

The SolidSurfacer option allows users to define parts using solid and surface modeling tech-

niques. This manual is composed of two types of sections: reference and tutorial. It is recommended

that the user briefly review the reference material and then move on to the accompanying instructional exercises.

There are three primary methods of using the capabilities of SolidSurfacer to create part models that can be machined. The first method is creating solid models from part blueprints using the

solid modeling functions contained in the system. There are many powerful modeling functions

including adding, subtracting and intersecting solids, automatic chamfering and filleting, and several

methods for generating solid bodies from geometry.

Secondly, the system can directly read solid model formats generated by other CAD packages.

Parasolids and SAT files can be directly opened by the system. SAT files require the purchase of an

additional option. The system does not use an importation filter or any means of translation for these

solid files, but rather, directly reads them.

The final method is through the importation of 3D surface files. The system recognizes and

imports several surface entities. Once a surface file is brought into the system, it can either be made

into a solid, using the Solidify functions, or can be kept as a surface model and machined.

Regardless of the method used to define the part, the final model can be machined using the

3D surfacing capabilities. The standard Roughing and Contouring functions can be applied to solid

bodies and surfaces. There is also a Surfacing function that provides several methods for generating

3-axis toolpaths to efficiently cut complex solid and surface part models.

Users should familiarize themselves with the basics of the system which are outlined in the

Geometry Creation Manual, Mill Module Manual and Advanced Milling Manual before reviewing

this manual. This manual assumes a level of proficiency with geometry creation, coordinate systems

and basic machining.

GFK-1709 Introduction

◆

1

Page 6

CHAPTER 1

:

Interface

This chapter describes interface items that are specific to the system when the SolidSurfacer

option is installed. The Mill Module Manual and Geometry Creation Manual contain descriptions of

standard system interface items.

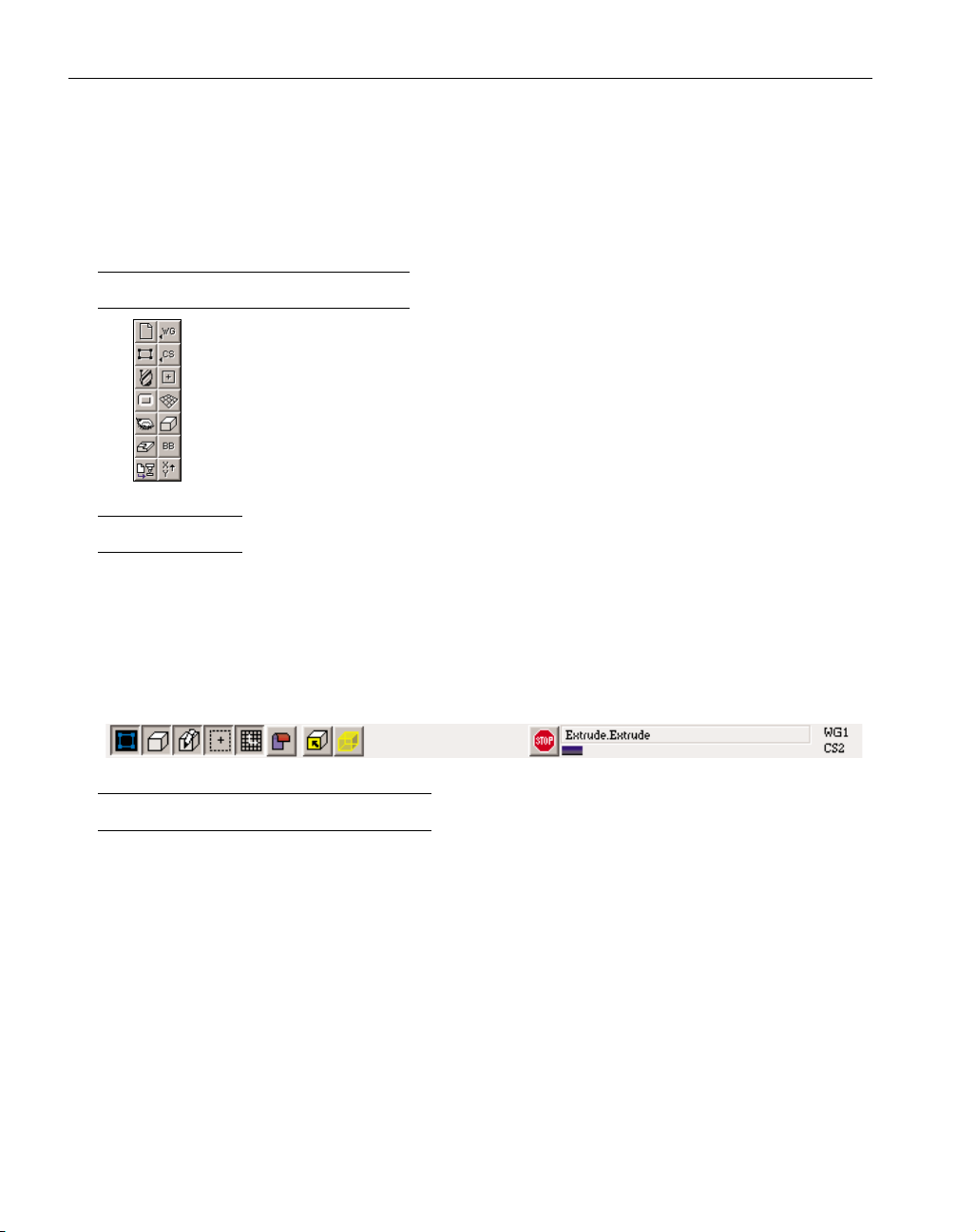

LEVEL 2 INTERFACE

The system has three different levels of functionality. Each level makes slight changes

to the interface. In order to use the SolidSurfacer capabilities, the user must be working

with the Level 2 interface. The interface level is specified in the Interface Preferences

accessed from the Preferences submenu under the File menu. The Level 2 interface is

characterized by a 14 button Top Level palette and a taskbar.

TASKBAR

The taskbar is located along the top of the drawing window, below the menu bar. The taskbar

contains a series of buttons which affect the drawing and selection of items in the drawing window.

Each of the buttons has two states, depressed (on) or raised (off). The taskbar also contains a

progress bar and message display. The progress messages indicate the function the system is performing and the progress bar gives the status of the function. The Stop button can be depressed to

stop the current function. The current workgroup and coordinate system are displayed next to the

progress bar.

RIGHT MOUSE CLICK

The mouse has two buttons that are used in different manners. The left mouse button

selects/deselects and accesses items: geometry, bodies, text boxes, buttons, etc. Clicking the right

mouse button on certain objects accesses context menus which contain items specific to the selected

objects. Right mouse click on the title bar of certain dialogs and a pull down menu containing items

specific to that dialog will appear. Also, right mouse clicking on a body or sheet accesses a menu

containing such functions as Recreate, History and Properties. The Modeling Chapter contains a section which lists all of the available context menus and the functionality of the items contained in

these menus.

◆

SolidSurfacer User Manual GFK-1709

2

Page 7

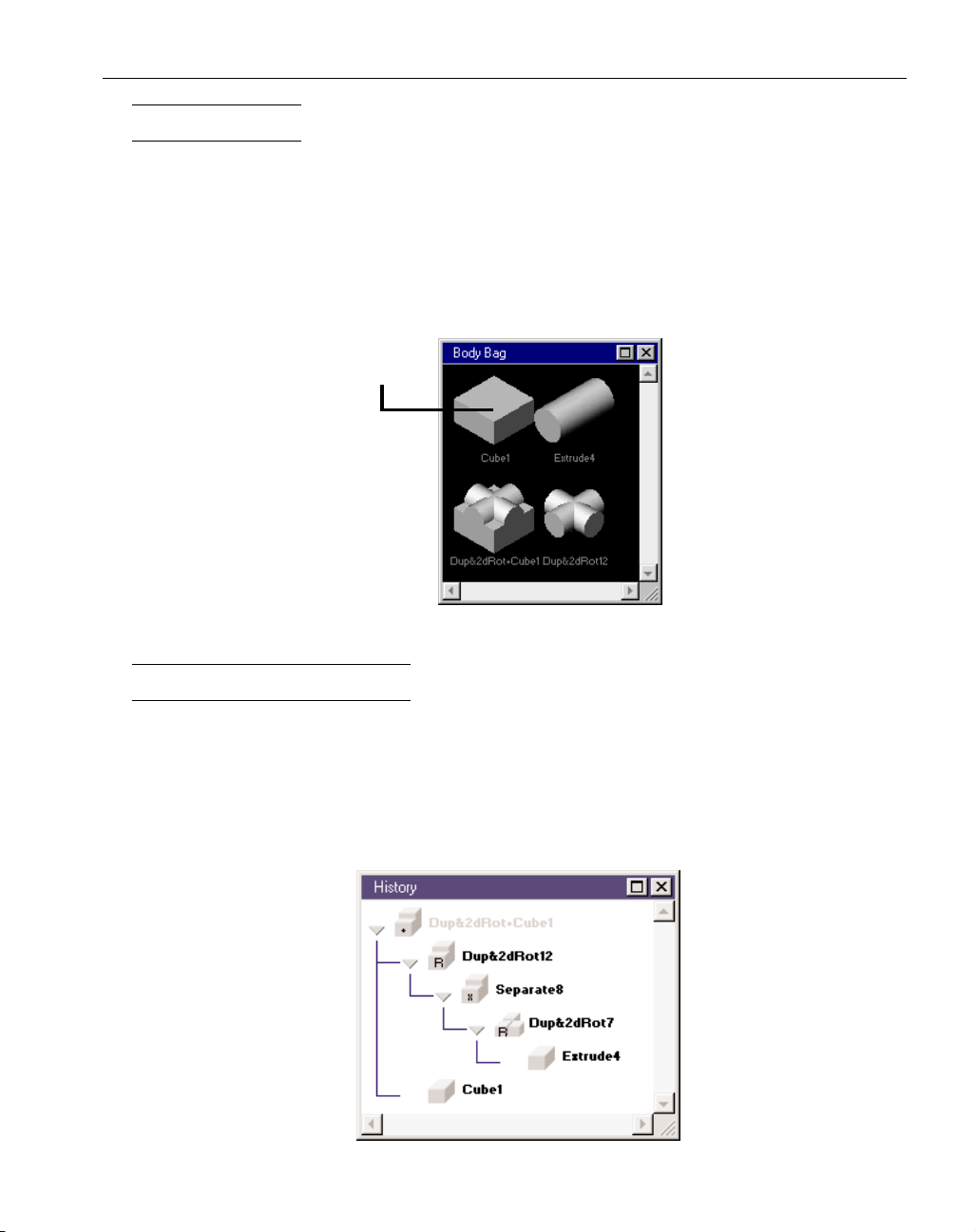

BODY BAG

Bodies and sheets can exist in the drawing window or the Body Bag. The Body Bag is used to

store bodies and surfaces in order to keep the main drawing window uncluttered. Double clicking on

a body or surface will place it in the Body Bag and remove it from the drawing window. The Body

Bag context menu also contains items for selecting and placing bodies and sheets in the Body Bag.

When bodies are in the Body Bag, they are represented as icons. These icons can be dragged, selected, re-sized, or renamed. They act very similar to standard system icons. The body and sheet icons

can either be double clicked or dragged out of the Body Bag in order to get the objects back in the

drawing window.

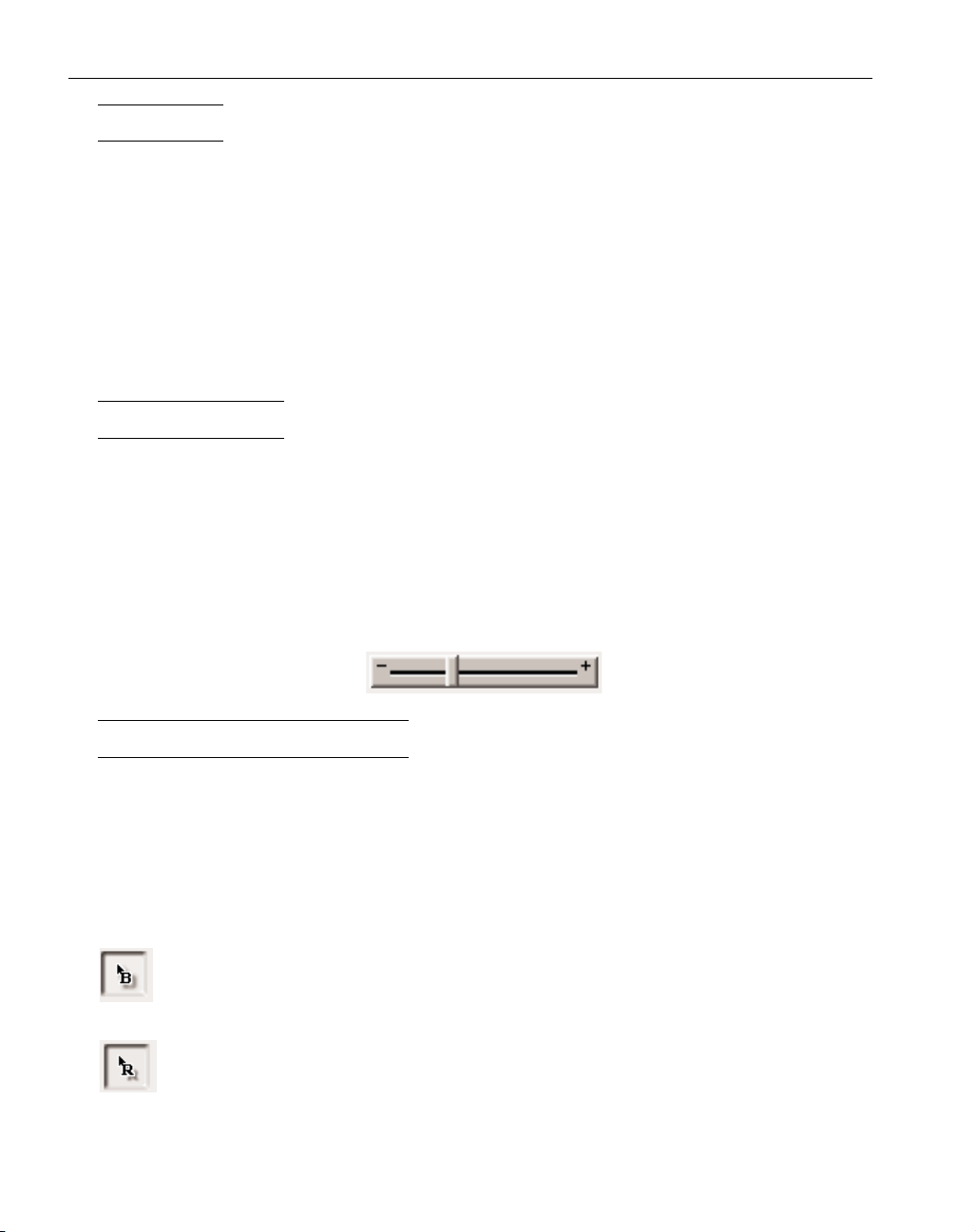

HISTORY DIALOG

The History dialog displays the history tree for any selected body. All of the bodies that were

used to create the selected solid or sheet will appear in the history tree, even if they are no longer

active bodies. Any of the bodies listed in black in the history tree can be brought back to the workspace and modified. To bring a body back into the workspace from the history tree, double-click on

the cube next to the name of the body. The arrows at the branches of the history tree can be clicked

on to expand that branch of the history. If a body is grayed out in the history tree, it is an active

body. Active bodies are in the workspace, either the main drawing window or the Body Bag.

GFK-1709 Interface

◆

3

Body Bag Icon

Page 8

COLORS

The system uses colors to graphically display different items. The color scheme listed below is

for the rendering of objects by the solid modeler. For a list of other colors used by the system, refer

to the Geometry Creation and Mill Module Manuals.

Object Rendering

Gray Unselected Bodies

Light Blue Unselected Sheets

Yellow Selected Bodies and Sheets

Dark Blue Stock Bodies

Red Constraint Bodies and Sheets; Fixtures; Inside of Sheets

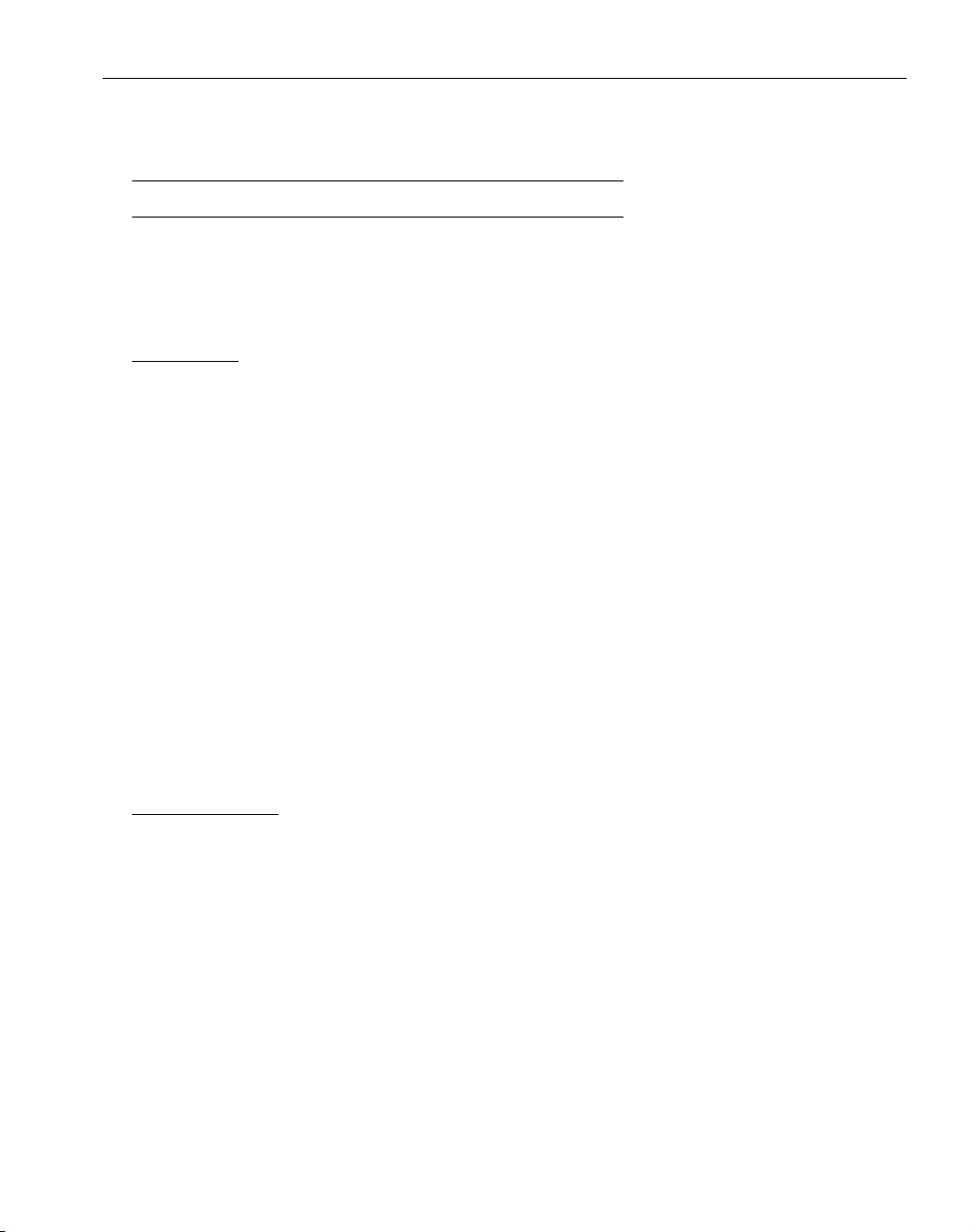

SLIDE BARS

Slide bars are an interface item used in a few of the dialogs when a specific value is not necessarily required. The user can either type in a value or use the slide bar. For example, when designating the chord height, either in the Graphics Preference dialog or the Properties dialog, the user may

simply want to make the rendered image of a solid finer or courser. Moving the slider left towards

the plus sign (+) will make the values larger by given increments. Likewise, moving the slider

towards the negative sign will make the values smaller. When the slider is moved, the numeric values are updated according to the movement. For the Chord Height, the slide bar's numeric values

range from .0001" to .1" and the metric equivalents.

POINTER MARKERS

Pointer markers are interface items that are used to designate particular items that are necessary to perform certain operations. The pointer markers are contained within a bounding box in each

of the dialogs. In order to place a marker, the user can drag the marker from its box in the dialog

and place it on an item, or at a particular location in the workspace. To remove a marker, select the

marker in the workspace and drag it back to its bounding box in the dialog.

These pointer markers are found in the Sweep dialog and the Variable Radius Rounding dialog.

B-pointer marker: The Sweep dialog contains a B-pointer marker, which allows the user to

designate the base curve of the swept body.

R-pointer marker: The Rounding dialog contains an R-pointer marker, which allows the user

to specify different radius values along a single edge when performing a variable radius

blending operation.

◆

SolidSurfacer User Manual GFK-1709

4

Page 9

CHAPTER 2

:

Modeling

INTRODUCTION TO MODELING

This chapter contains reference information on the modeling functions contained in the system.

This first section provides a brief introduction to terms and concepts used in solid modeling. There

is also a glossary which provides additional terms that are used throughout this manual and the software.

DEFINITIONS

The terms and definitions provided below are used to describe objects and elements used by

the solid modeler.

Body: A body is the term used for the solid objects created by the system. Each body is a single

object composed of faces and the area enclosed by the faces. Bodies have volume. Bodies are used

as the building blocks for creating part models.

Sheet: A sheet is the term used for surfaces created or imported by the system. A sheet is an object

composed of faces, but a sheet has no volume or thickness associated with it. It is only composed of

its surface faces.

Face: A face is one surface of a body or sheet. Faces are surfaces that have knowledge of the surfaces

that surround them. For example, one side of a cube would be considered a face. Each face is

bounded by loops. A simple face is bounded by 1 loop.

Loop: A loop is a series of connected edges that outline a face.

Edge: An edge is a curve/line between two faces. A body must have two faces connected at every

edge. [More than two faces at an edge produces a non-manifold solid. The solid modeler cannot perform the necessary calculations on non-manifold solids, and therefore will produce an error message

if operations create non-manifold solids.]

Vertex: A vertex is an endpoint of an edge.

SOLID MODELING

Modeling is the process of defining a part’s shape and dimensions on a computer. Common

types of modeling include wireframe modeling, both 2D and 3D, surface modeling and solid modeling. Solid Modeling is the method of defining a part as a solid object rather than as a wireframe or

collection of surfaces. The process of solid modeling involves using graphically disjunct objects

(bodies and sheets) and combining, modifying, and manipulating them to create the final part model.

A solid model completely identifies any point in space as inside or outside of the model.

The process of solid modeling starts with the creation of a simple body referred to as an atomic

or primitive body. A body is made up of faces and the space enclosed by those faces. A face is a single surface, but a surface that has knowledge of the other surfaces that are connected to it. Examples

of an atomic body include a sphere, a cube, a revolved or extruded 2D shape, etc.

The basic operations, often referred to as Boolean operations, are to add, subtract or intersect

these simple bodies to create a new, distinct body. Each time a Boolean operation is performed, the

result is always a single object. In this way solid modeling allows the user to work with single

objects rather than hundreds of surfaces. When solid modeling, no user input is required to determine the sections of the bodies to maintain or remove. The solid modeler automatically trims off

GFK-1709 Modeling

◆

5

Page 10

unneeded portions, or adds new portions, handling all faces. One Boolean operation may create any

number of new faces on the resulting solid.

Surfaces can also be created by the solid modeler. The solid modeler creates an object called a

sheet. A sheet is similar to a body in that it is made up of faces. A face is a single surface. However,

a sheet does not have any volume the way a body does. A sheet is only made up of faces, whereas a

body is composed of the faces as well as the space enclosed by the faces. One way to think of it is

that a sheet is similar to an infinitely thin gauge balloon while a body is more like a bowling ball.

BODIES

A body is the modeling entity that represents a solid. A body is represented as a single object,

not as a complex collection of surfaces. When a body is created, it is graphically displayed as a solid

object. The system allows the user to view the body as a wireframe, however the wireframe representation cannot be selected and acted upon using any of the functions in the system. It can simply

be viewed. In order to perform any type of operations on the body, such as Boolean operations or

rounding, the body must be viewed as a solid object. The system draws bodies in gray.

The operations of adding, subtracting and intersecting bodies require that two bodies be selected. When these operations are performed, the result is a new, single body composed of the two, previously distinct bodies.

When selected, bodies become yellow. Clicking on a body selects it. Selecting a body indicates what object(s) compose the single body. A single body may contain disjunct objects, which are

objects that are not connected or touching. Disjunct objects contained in a single body are called

lumps. Bodies containing lumps or multi-lump bodies can be separated to create multiple, separate

bodies. The easiest way to tell if disjunct objects are lumps or separate bodies is by selection.

The system defaults to create multi-lump bodies rather than multiple bodies. Creating multilump bodies rather than multiple bodies provides for more efficient part creation due to a shorter

history tree. Also, splitting multi-lump bodies into any number of multiple bodies is more efficient

than adding bodies because bodies can only be added two at a time.

SHEETS

A sheet is the modeling entity that represents a surface. A sheet contains more information than

a surface in that a sheet has knowledge of the neighboring surfaces that surround it. A sheet is represented as a single object. It is composed of faces. Sheets may have one face or several faces. A face

is a single surface. Sheets do not have any thickness or volume. A sheet is the graphical representation of a surface or collection of surfaces.

There are surface modeling tools contained in the system for creating sheets and modifying

sheets. These functions are located in the Surface Modeling palette. The sheet creation functions

include planar sheets, revolved sheets, lofted sheets, Coons patch sheets, swept sheets and sheets

created from selected faces. There are also functions such as Stitch, Unstitch and Trim/Untrim contained in the Surface Modeling palette that are very useful when working with sheets. The sheet creation tools are primarily intended to be used with surface files that are imported rather than creating

complete part models using sheets and surface modeling techniques. The recommended method for

modeling a part is using the solid modeling tools.

When surface files are imported, each surface entity is brought in as a single faced sheet.

These sheets can be modified as necessary to complete the part model or can be machined directly.

◆

SolidSurfacer User Manual GFK-1709

6

Page 11

PRIMITIVES/ATOMIC BODIES

A primitive or atomic body is a simple, non-divisible body; a body that is not built from other

bodies. Atomic bodies do not have a history tree. All solid models start from at least one atomic

body.

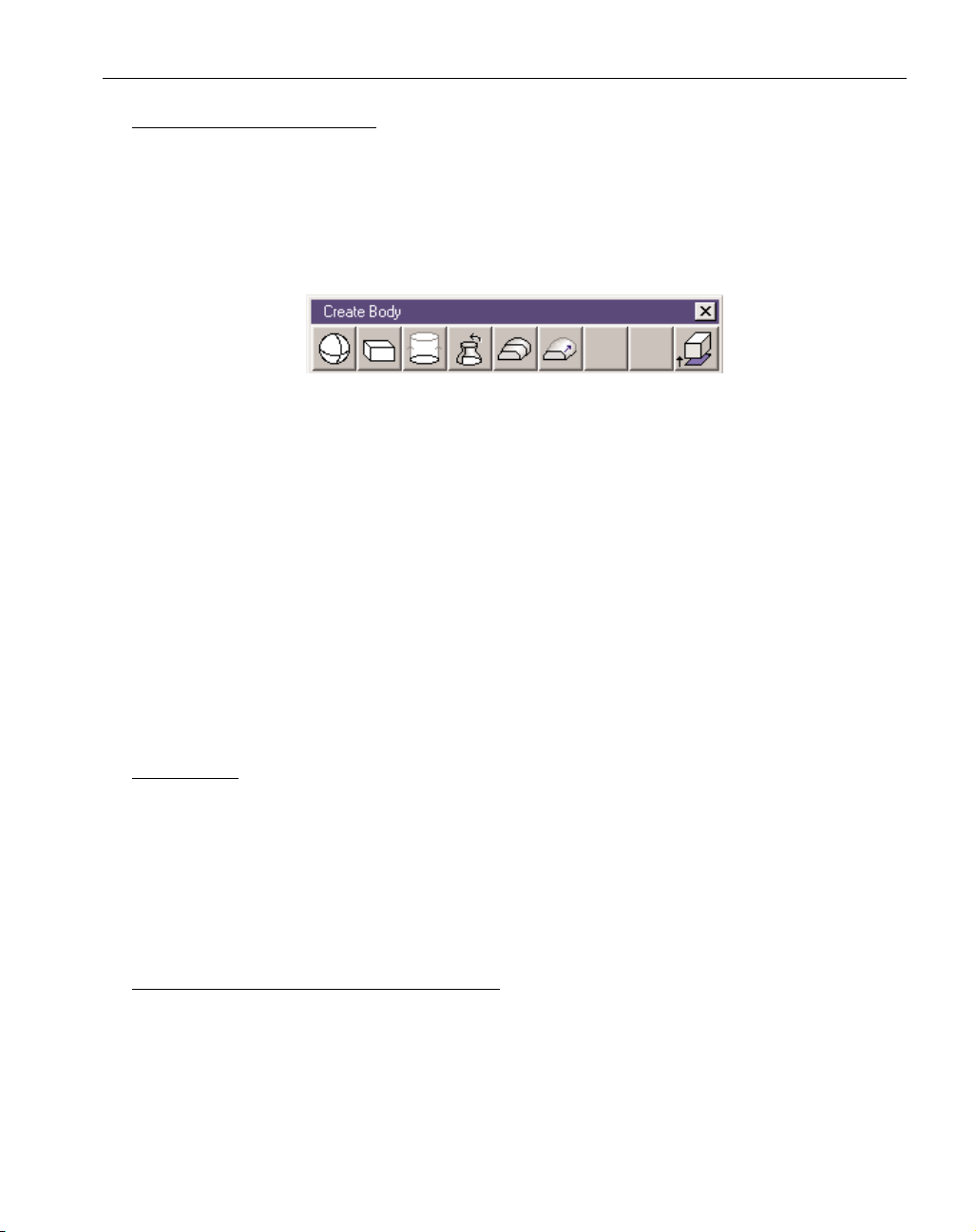

Atomic bodies are created using the functions contained in the Create Body palette which is

accessed by clicking on the Create Body button in the Solid Modeling palette. The Solidifying functions which convert sheets to solid bodies are also contained in the Create Body palette. Solidified

sheets are considered atomic bodies as they have no history tree associated with them.

1. Sphere: A ball or globular solid.

2. Cuboid: Any type of rectangular solid.

3. Extruded Body: A 2D (in HV) closed shape extruded along the depth axis.

4. Revolved Body: A 2D shape, either open or closed, revolved around either the horizontal or

vertical axis, a specified number of degrees.

5. Lofted Body: Lofted bodies are created by selecting a series of closed shapes that will be

blended together using selected alignment points. Lofting is also referred to as skinning or

blending.

6. Swept Body: Swept bodies are created by selecting base curve geometry and drive curve

geometry. The base curve acts as the spine determining the overall contour of the swept

body and the drive curve(s) designate the location and shape of the body.

7. Solidified Sheet: There are several options for solidifying sheets into bodies. They include:

Cap, Extrude, Offset and Solidify Closed Sheets.

WORKSPACE

Active bodies and sheets exist in the workspace. The workspace consists of the drawing window, which is the main portion of the screen and the Body Bag. Bodies and sheets must be active in

order to perform any modeling functions, such as Boolean operations. Bodies and sheets that only

exist in the history tree are considered dormant bodies. Because the solid modeler always creates

single bodies from any operation, the component bodies are removed and made dormant to simplify

the modeling process and control the file size. Dormant bodies can be retrieved using the History

dialog.

WORKGROUPS AND COORDINATE SYSTEMS

Bodies and sheets are NOT contained in workgroups. They are drawn in either the Body Bag

or the workspace, regardless of the current workgroup.

Bodies are assigned a coordinate system which is based on the current CS when the body was

created. Some of the modeling functions, such as extrusions and revolved bodies, are CS specific

meaning that the current coordinate system is used to create the body. Other modeling functions,

such as lofting, are not dependent on the current CS. Regardless, a body is assigned a coordinate

system.

1 2 3 4 5 6 7

GFK-1709 Modeling

◆

7

Page 12

Coordinate Systems can be modified into the proper orientation by selecting components of a

body or sheet. There are two categories of CS alignment, plane through geometry groups and plane

normal geometry groups. Planes can either be aligned through selected geometry or normal (perpendicular) to selected geometry. With bodies and sheets, the plane through geometry groups include

planar edges and planar faces; the plane normal geometry groups include an edge and a point, and a

face (planar or non-planar) and a point. For further information on these subjects, please refer to the

Advanced Milling manual.

BOOLEAN OPERATIONS

Boolean operations are used to combine two entities (either bodies or sheets or some combination of the two) to create a new, single body or sheet. The Boolean operations contained in the system are addition, subtraction and intersection. Boolean operations are destructive, in that the initial

two bodies selected for the Boolean operation are deleted, and only the resulting body remains

active in the workspace. The deleted bodies used in the Boolean operation become dormant bodies

and can be retrieved from the History tree. Non-destructive Booleans can be performed by holding

down a modifier key when performing the operation. The modifier key depends on the selection

made for keyboard shortcuts in the Interface Preferences. If the Alternate Shortcuts option is selected, hold down the Ctrl key to perform non-destructive Boolean operations. If the Windows Shortcuts

option is selected, hold down the Alt key. Non-destructive Booleans will generate the new body and

place the original two bodies used in the Boolean operation in the Body Bag. The following

Boolean operations are supported by the system.

• Addition (Union): Combine the volume of two bodies. Select two bodies and add them

together. The resulting body will be a new single body composed of the two selected bodies.

If the two selected bodies were disjunct (not touching), the resulting body will be a multi-lump

body.

• Subtraction (Difference): Remove the volume of one body from another body. Select two bod-

ies and subtract them. The resulting body will be the first body minus the second body. The

order of selection determines which body is kept and which is subtracted out. The first body

selected is kept and the second body selected is subtracted out.

• Intersection: Keep the common volume between two bodies. Select two bodies and intersect

them. The resulting body will be the volume that is common to the two bodies selected.

HISTORY OF SOLIDS AND SHEETS

The system maintains the history of all solid bodies and sheets that are created using the solid

modeling functions contained in the system. When models are imported in either the Parasolids or

SAT format, the history is not imported.

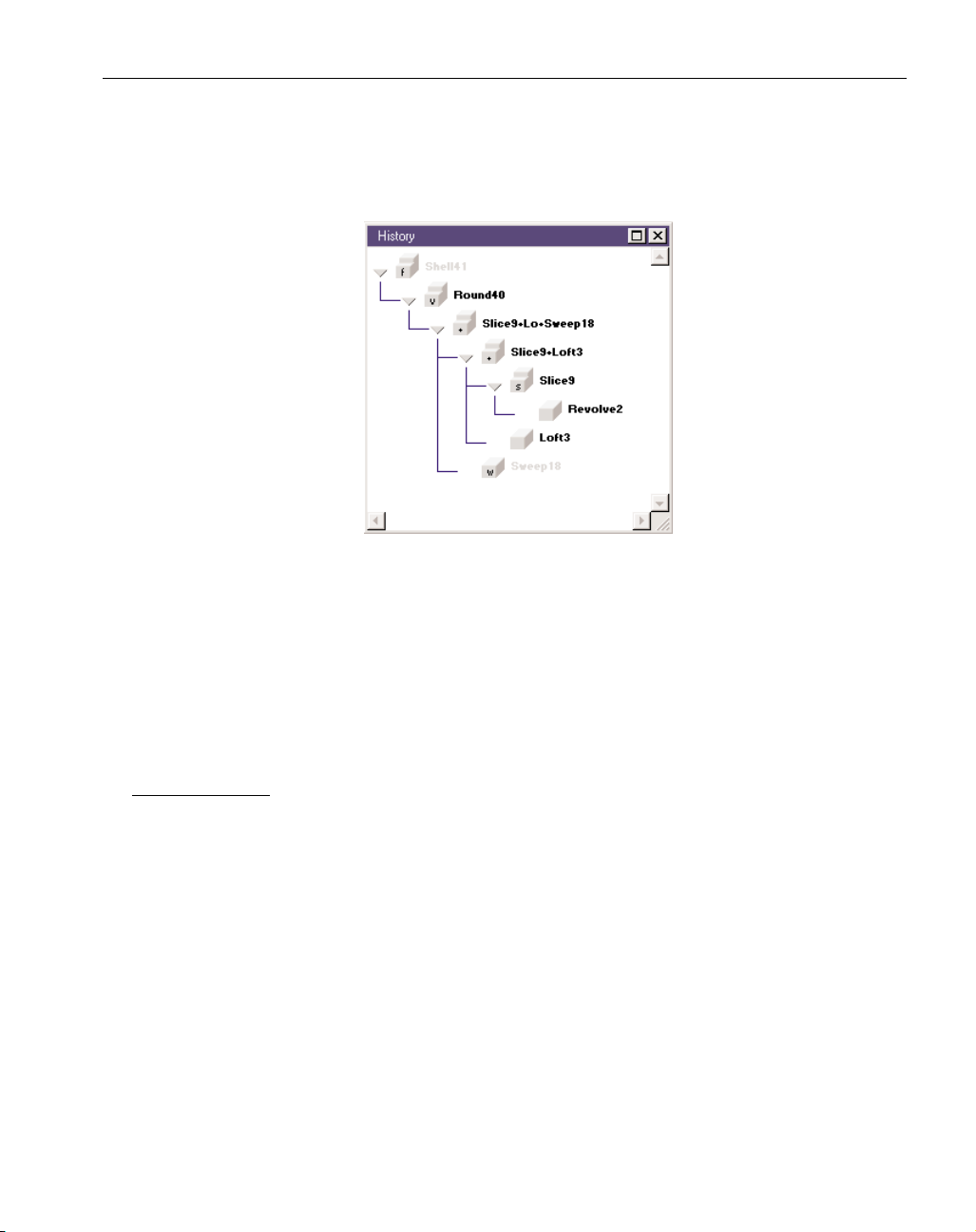

The History dialog allows the user to access any body that went into the construction of the

selected solid. By giving the user access to the history of a model, changes can be made to an earlier

step in the modeling process allowing for changes to easily be incorporated to the final model without having to start over from scratch.

Every solid except atomic bodies have history trees which contain information on the “parents”. "Parents" is the term used to describe the bodies or sheets that were used to create the select-

◆

SolidSurfacer User Manual GFK-1709

8

Page 13

ed body or sheet. Solids may have one parent, as in cases of rounding or slicing, or two parents as in

the case of Boolean operations. Bodies removed from the workspace as the result of a Boolean operation are maintained in the history tree. Bodies contained in the history tree are considered dormant

bodies, while bodies in the workspace are active bodies. Operations such as rounding or any of the

Boolean functions, can be performed on active bodies only.

The History dialog is structured in a hierarchical format where the selected body is at the top

and all other bodies used to create it are found below in steps or branches. Double clicking on the

cube icon next to the name of a body will make that body active; it will be brought back into the

drawing window. In order to make modifications to a body contained in the history tree and have

those changes be incorporated into the existing history tree, the Recreate function must be used. The

Recreate and Rebuild functions are described in the following section.

The History dialog is accessed from the Body/Sheet context menu by right mouse clicking on

the body or sheet.

RECREATE MODE

Rebuilding a solid incorporates any changes made to bodies that were used to create that solid.

These bodies are referred to as parent bodies. Recreate allows the user to change a parent body.

Recreate must be used for changes that the user wishes to incorporate into the rebuilding of a solid.

Bodies can be modified using the Recreate function of the software. The context menu

accessed when a body is right mouse clicked contains the Recreate item. When Recreate is selected,

the system goes into Recreate mode.

When in Recreate mode, the body selected to be recreated is drawn in red and placed in the

Body Bag. Recreate mode can be exited by selecting the body drawn in red, or selecting the Exit

Recreate item from the body context menu. If applicable, the parent body or bodies that were used

to create the body to be recreated become active and appear in the drawing window. The function

button originally used to create the body will be outlined in red. All original data will be restored.

Following are some examples of what can be done using the Recreate function.

• Change the data for an atomic body. For example, change the radius of a sphere.

• Recreate an atomic body from different geometry or modified geometry. The geometry

should be changed prior to entering Recreate mode.

GFK-1709 Modeling

◆

9

Page 14

• Change the type of atomic body that was created. For example, a sphere can be made into a

cuboid.

• Change the selected parents used in a Boolean operation.

• Change the type of Boolean operation that was performed.

Recreate only affects the creation of the selected body. To change its parents they must be

brought back from the History dialog and then the parent bodies can be recreated.

REBUILDING SOLIDS

Because the system maintains the history of solids and sheets, it is possible to modify earlier

steps during model creation and rebuild the final model. Any changes made can be incorporated into

the final model using the Rebuild function. This level of associativity is very useful when working

with complex models that would take considerable time to rebuild from scratch if changes are necessary.

To rebuild a model follow the steps outlined below.

1. Bring an earlier body back from the history tree.

2. Make modifications to that body using the Recreate function.

3. Rebuild the body by selecting the Rebuild item from the Solids menu.

The Rebuild function reprocesses the history tree. Any changes made to a body or sheet contained in the History tree will be incorporated into the rebuilt model. The only way to make a modification to an existing body without changing the name and reference of that body is to use the

Recreate function. The Rebuild function is not undoable which means that once a model has been

rebuilt, it cannot be changed back to its previous state.

Rebuild is useful when working with imported solid models. As an example, let's say you start

with an imported Parasolids file. You build a mold base body from this model. Changes are made to

the original model provided. The new model is imported into the system. To incorporate the new

changes, you would recreate the mold base by selecting the new body instead of the old one and

performing the Boolean operation. Then select the final body and rebuild it.

FACETING

Rendering is the process of displaying a picture of a model on the screen. When bodies and

sheets are rendered, they are faceted. Facets are small planar surfaces that compose the rendered

model. The more facets that are drawn, the closer the model resembles the actual mathematical

model and the more time it takes the system to render the model. Faceting affects the quality of the

rendered image of bodies and sheets. It also affects overall system performance and speed. The

faceting chord height should be set at a value that balances the quality of the model with system per-

formance. The faceting tolerance has NO affect on machining tolerances, only on the rendered image on the

screen. The tolerance used for surface machining is set in the Process dialogs and is labeled as the

Surface Tolerance. It is this specification which designates how closely the toolpath will follow the

surface.

The number of facets used to render a model is determined by the chord height. A chord is a

straight line that joins any two points on an arc or circle. The chord height is the distance from the

chord to the arc or circle (Figure 2.1). The smaller the chord height, the closer the facet will be to

the arc or circle resulting in a better rendered image of the body or sheet. (This is a 2D description

◆

SolidSurfacer User Manual GFK-1709

10

Page 15

of chord height, the system uses a 3D chord height for the faceting of bodies and sheets, but the

general idea is the same.)

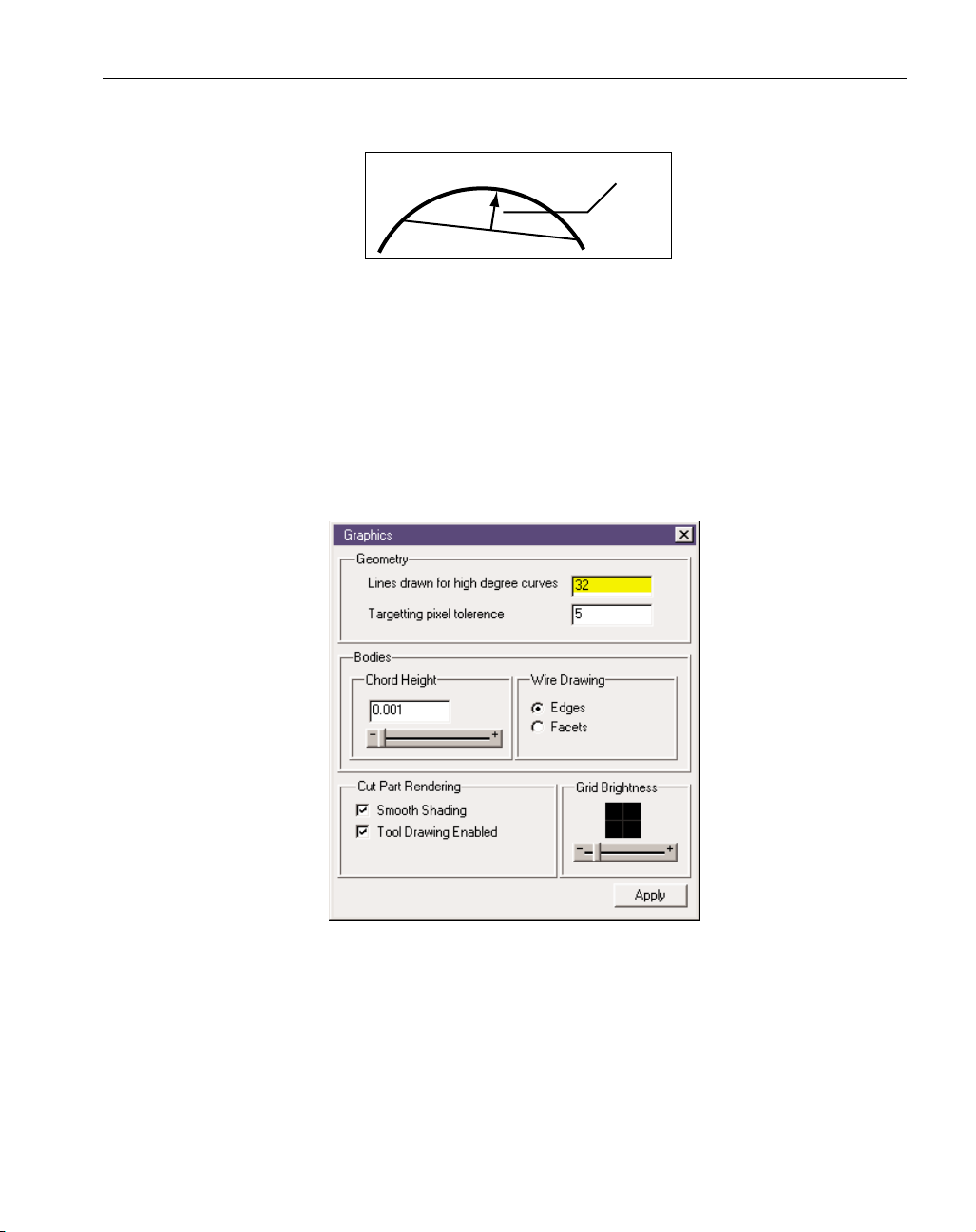

Figure 2.1

The system uses an overall faceting chord height which is applied to the entire part model. The

overall part chord height will be applied to all bodies and sheets that are created using the system’s

modeling functions, as well as any models that are imported. The overall part chord height is

entered in the Graphics Preference dialog (Figure 2.2) accessed from the Preferences submenu

under the File menu. The chord height is found in the Bodies section of the Graphics dialog. The

default chord height is .01". A number can be entered in the text box or the user can move the slider

in the + or - direction for a finer or coarser tolerance.

The Apply button must be depressed in order to change the facet tolerance for selected bodies

and sheets, as well as setting the value for new bodies.

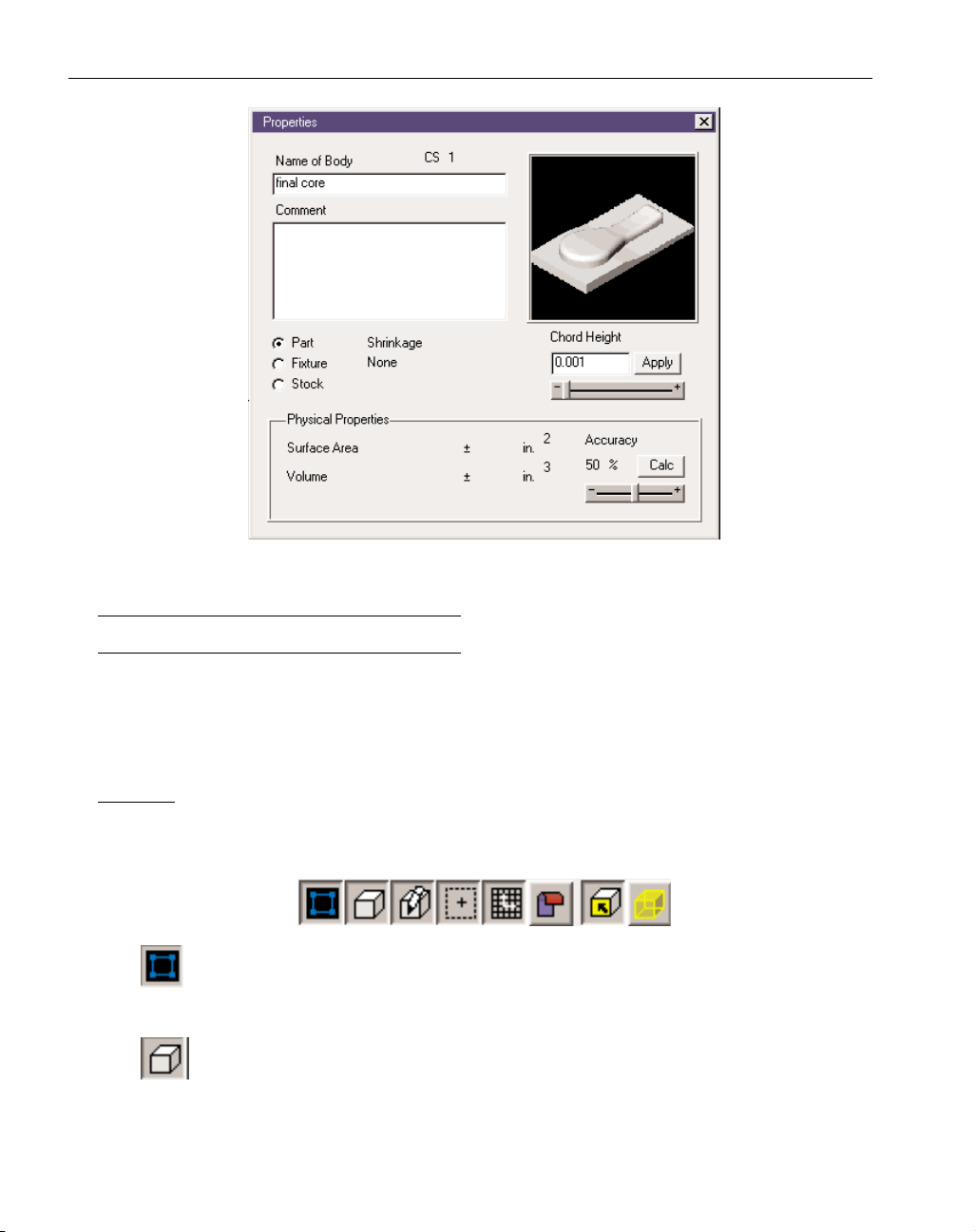

Figure 2.2: Overall Part Chord Height in Preferences Menu

A different faceting chord height can be applied to individual bodies and sheets. The Properties

dialog (Figure 2.3), accessed by right mouse clicking on a body or sheet, contains a chord height

value which will only be used to facet the selected body or sheet.

GFK-1709 Modeling

◆

11

Chord Height

Page 16

Figure 2.3: Individual Part Chord Height from Properties

MODELING REFERENCE

This section provides functional descriptions of the modeling capabilities contained in the system.

These modeling functions are put to practical application in the modeling exercises which provide

tutorial style learning. It may be best to start with the modeling exercises and refer to the reference

section when something is unclear.

TASKBAR

The taskbar is always displayed on the screen below the menu bar. The buttons in the taskbar

affect the drawing and selection of objects in the drawing window. Each button can either be turned

on or off; depressed is on, raised is off.

Show Geometry: When this button is depressed (on), geometry will be displayed in the

drawing window. If off, geometry will not be drawn. The geometry still exists, it is just

not displayed on the screen.

Show Solids: This button is very similar to the Show Geometry button, except it affects

bodies and sheets. When turned on, all bodies and sheets will be displayed in the workspace. If off, all body and sheets will not be displayed. This button does not affect the

drawing of objects in the Body Bag.

◆

SolidSurfacer User Manual GFK-1709

12

Page 17

Render/Wireframe: When this button is on, bodies and sheets will be rendered as solid

objects. If off, bodies and sheets will be displayed as wireframe drawings, not rendered

objects. The wireframe drawing will display either the edges or the facets of bodies and

sheets depending on the selection made in the Graphics Preference dialog.

Show Stock & Origin: When this button is on, the stock outline and origin will be drawn

on the screen. This button replaces the Show Stock & Origin in the View menu.

Show CS Grid: When this button is turned on, the CS grid and axis markers for the current coordinate system will be drawn on the screen. The CS grid will always be drawn

at the depth of 0. The axis markers will always be displayed on top of any body or

sheet. This button replaces the Show CS Grid item in the View menu.

Indicate Sheet Side: This button is for use with sheets. It differentiates the outside and

inside of a sheet by displaying it in different colors. The outside of the sheet will

remain the standard blue that is assigned to all sheets, while the inside will be dis-

played in red. The outside of a sheet is the side from which the positive direction of the

surface normal is projecting outward. The negative direction of the surface normals are projected out from the inside of the sheet. The sheet side is important when performing such functions as offsetting sheets or solidifying sheets using either the offset or extrude option. This is

due to the fact that sheets are offset or extruded in the positive direction of their surface normal. It is possible to toggle the inside and outside of a sheet, using the Toggle Sheet Side item

in the Modify menu.

Face Selection: When this button is depressed, the system will be in face selection mode,

which means that when bodies or sheets are clicked on to be selected, only the face

will be selected, not the entire body or sheet.

Edge Selection: When the Edge Selection button is depressed, the edges of all sheets and

bodies in the workspace will be displayed. These edges can be selected. An edge is the

curve between two faces. In order to select edges for such functions as blending, geometry

extraction, body unstitching, etc., the user must be in Edge Selection mode. Also, when using

the stitching function, Edge Selection mode is useful for viewing the external edges of a

model. If an edge is double-clicked, the system will attempt to select an entire loop that contains the selected edge. This edge selection will stop when it has more than one good choice at

a vertex. In some instances, it may take a few double clicks on different edges to select an

entire loop, but it is still much faster than attempting to select edges one at a time.

GFK-1709 Modeling

◆

13

Page 18

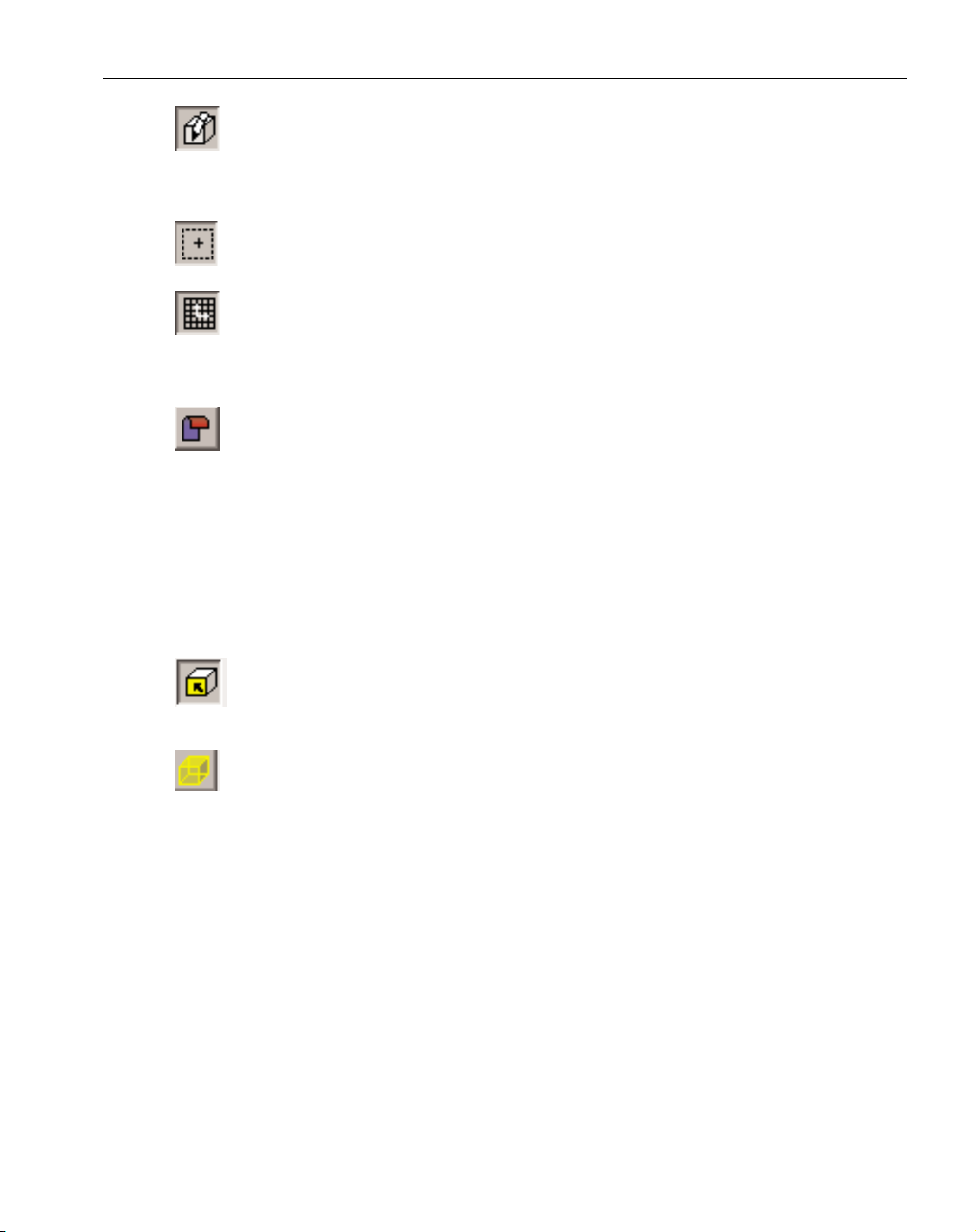

Top Level palette: The Top Level palette contains 14 buttons when the Level 2 interface

is in use. The Level 2 Interface must be used in order to access the SolidSurfacer functionality. All of the surface modeling and solid modeling functions contained in the system are accessed from the Top Level palette. The Body Bag, which is used as a storage

place for bodies and sheets, is also accessed from the Top Level palette. The other Top

Level palette buttons function as they do when using the Production Modules of the

software.

SURFACE MODELING

Surface Modeling button: Depressing this button brings up the Surface Modeling palette,

shown below, which is used to create sheets. Surface modeling and sheets are primarily for

working with imported surface files, and are not generally required for building bodies.

Surface Modeling palette: This palette provides

various methods for creating sheets, including planes, revolved sheets, lofted sheets,

Coons patch, and stitching separate sheets

together.

Plane button: This button is used to create planes. With no geometry selected, this function will create a flat, planar sheet based on the current coordinate system. Selecting a

closed, planar shape will create a sheet bounded by the selected geometry and based on

the plane of the selected geometry.

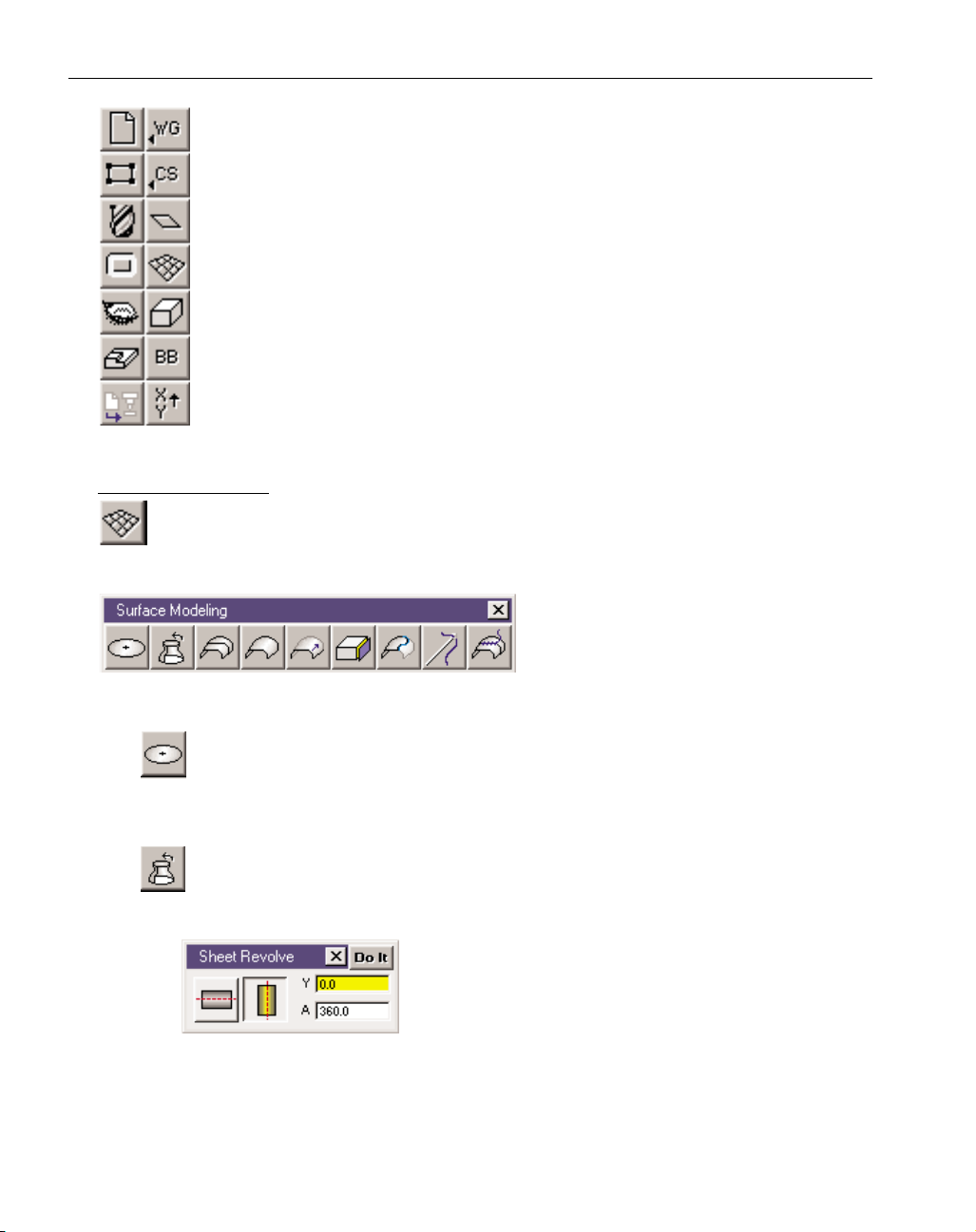

Revolve button: Depressing this button, brings up the Sheet Revolve dialog which allows

users to revolve a shape around the horizontal or vertical axis by a specified number of

degrees, creating a sheet.

Sheet Revolve dialog: Select an open, terminated shape or a

closed shape to be revolved. The axis buttons specify which

axis the selected shape will be revolved about. If the horizontal axis is selected for the axis of revolution, a vertical

value must be entered to specify the position of the revolution axis. Likewise, if the vertical axis is the axis of revolution, a horizontal value must

be entered to specify the position of the revolution axis. The value entered in the A text

box is the angle, specified in degrees, the selected shape will be revolved around the

selected axis. A positive angle value will revolve the shape in a counter clockwise

◆

SolidSurfacer User Manual GFK-1709

14

Page 19

direction and a negative angle in a clockwise direction based on the positive axis of

revolution.

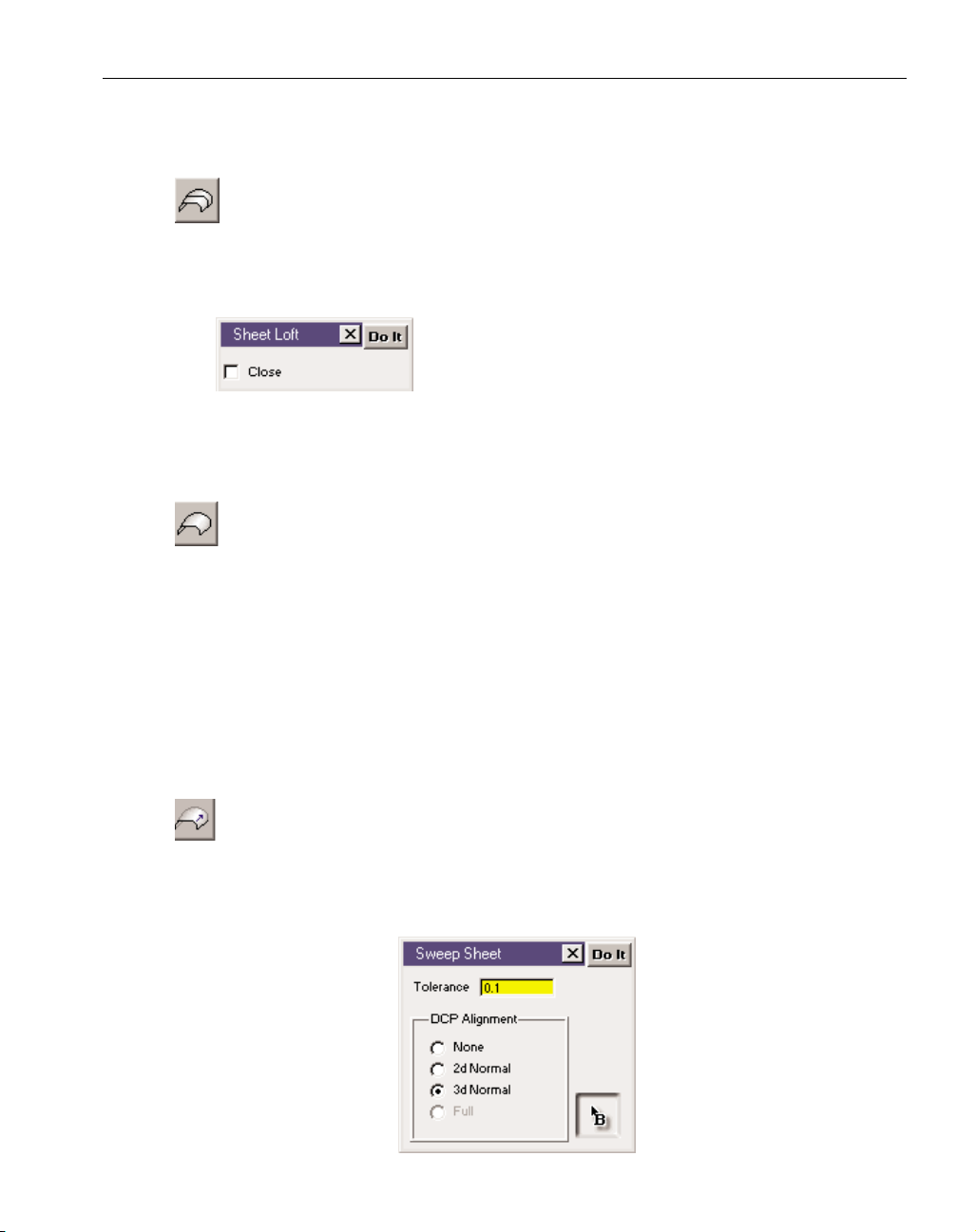

Loft button: Depressing this button accesses the Sheet Loft dialog which allows users to

create a sheet through a series of open or closed shapes. The system will blend all the

selected shapes into a smooth sheet. Sheet lofting produces ruled surfaces when

only two shapes are selected and sculptured surfaces when three or more shapes are

selected.

Sheet Loft dialog: Select a series of shapes to be blended into a

smooth sheet. These can be closed or open, terminated

shapes. The shapes act as the cross-sections through which

the final sheet will be created. The system will blend the

selected shapes into a sheet using C0 points (corners) as alignment points. If the Close

button is checked, the system will attempt to blend the first and last shapes together to

form a closed sheet.

Coons Patch button: This button creates a sheet called a Coons patch through either

three or four selected open, terminated shapes.A Coons patch is a surface type that

uses boundary shapes, typically splines, and blends a smooth surface between them.

Either three or four shapes must be designated as boundary shapes. Each shape can be any size

or orientation as long as the endpoints are coincident (in the exact same location in X, Y and

Z) and each shape is continuous and does not contain any sharp corners. The selected shapes

represent the boundary of the sheet.

In some cases, connected splines or features can be selected to create a Coons patch.

Also, if trimmed splines are imported that do not have coincident point at the edges, a Coons

patch can be created providing the ends of each trimmed spline are coincident. If there are

more than 3 or 4 line segments, but the connected splines have three or four distinct corners,

often times a Coons patch surface can be created.

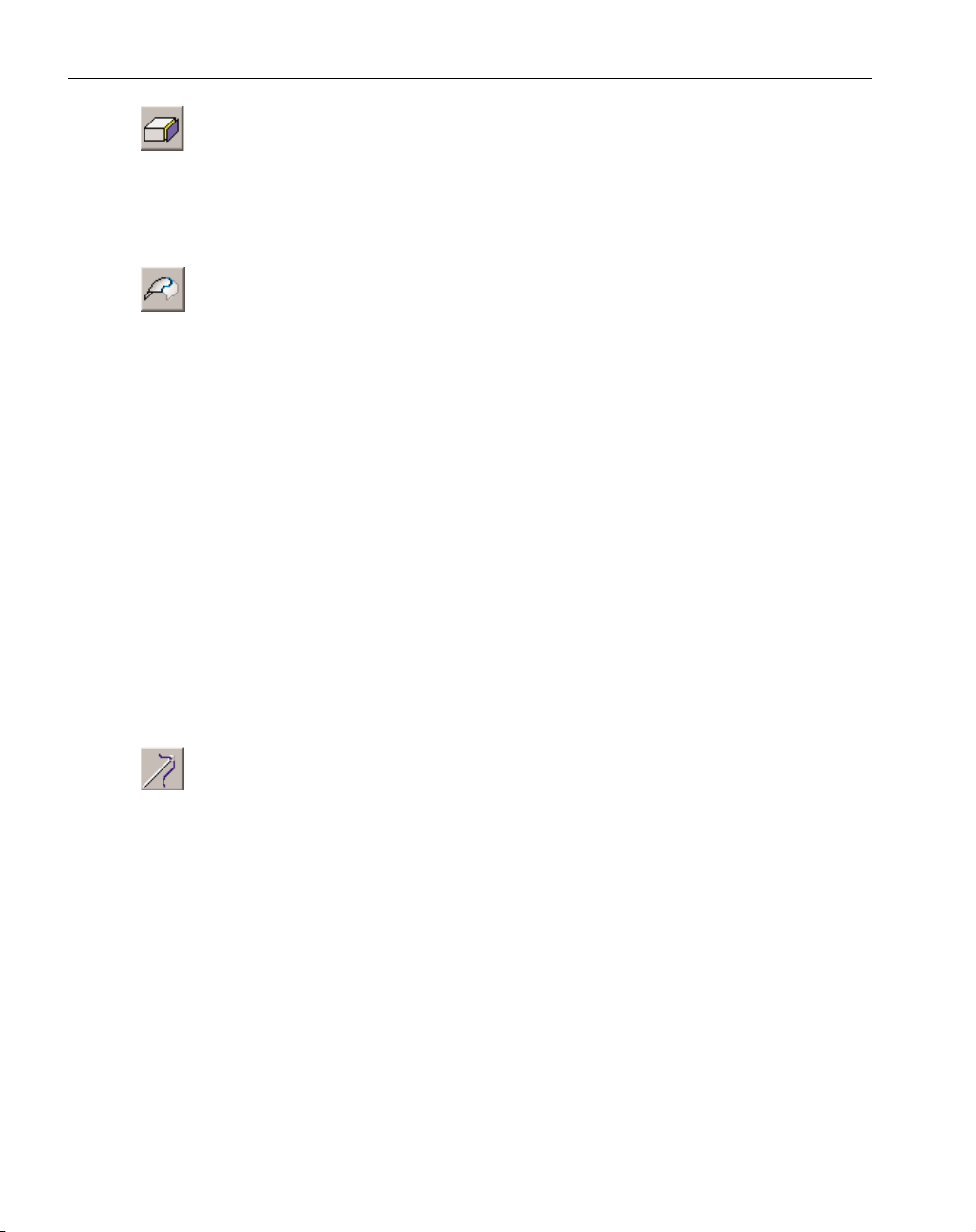

Sweep Sheet: The Sweep Sheet function is nearly identical to the Sweep Body function

which is described in the following Solid Modeling section. The only difference

involves the alignment rules for the drive curves. Swept sheets do not use alignment or synch

points, selected on the drive curves, to determine how the drive curves will be blended together. Only one alignment point per drive curve needs to be selected for the Sweep Sheet function.

Refer to the Sweep Body section for additional information.

GFK-1709 Modeling

◆

15

Page 20

Sheet from Face: This option creates a sheet from the face of a body or sheet. A face is

one surface of a body or sheet and is bounded by an edge loop. Using the Face

Selection mode accessed from the taskbar, users can select individual faces of either a

sheet or a body. Selecting a face or faces and clicking on this button will create a sheet based

on the face which will be bounded by the edge loop of the selected face. Neighboring faces

will produce stitched faces in the resulting sheet.

Trim/Untrim Sheets: The trim and untrim functions are both performed with this button

depending on the entities selected when the button is depressed. If a sheet and geome-

try are selected, the system will attempt to perform the trim operation. The trim function breaks a single sheet into two separate sheets at the selected trim geometry. The geometry

selected for the trim operation must completely cut the selected sheet into two pieces. If the

geometry does not lie on the selected sheet, the geometry will be projected onto the selected

sheet and the trim operation will be performed.

If only a sheet is selected, the system will attempt to untrim. The Untrim function

only works with single face sheets. The edge loop is what bounds the underlying surface definition into a finite bounded surface. The Untrim function, in essence, removes the bounding

edge loop so that the underlying surface definition replaces the selected surface. The

untrimmed surface will be bounded by the stock. This is useful when working with imported

IGES files that are not stitching or solidifying due to edge loops of neighboring surfaces not

joining within the specified tolerance. In that case, the user can select the problem sheet,

untrim it to create the underlying surface definition and then trim that surface with the extracted edges from neighboring sheets.

Holding down the Alt key when the Untrim/Trim button is depressed will perform

both the trim and untrim operations at once. The system will untrim the selected one face sheet

and trim that sheet to the selected geometry in one step, never attempting to create a valid face

from the untrimmed surface.

Stitch Sheets: The Stitch Utilities dialog, accessed by clicking on the Stitch Sheets but-

ton, provides different methods for stitching sheets together, as well as providing tools

to analyze stitched sheets. In order to stitch sheets, the user must select all the sheets to be

stitched, choose a stitching method from the Stitch dialog and click on the Stitch button.

Sheets are stitched at their edges. When surface files are imported into the system,

each surface is represented as a single faced sheet. A face is a trimmed surface with an edge

and knowledge of neighboring surfaces. An edge is the trim curve that bounds a face. For

sheets to successfully stitch to their neighbors, the edges of these sheets must align with each

other within a specified tolerance, otherwise there are holes or gaps and adjoining sheets that

are separated by a gap cannot be stitched.

In order to view edges, the system must be in Edge Selection mode which is accomplished by depressing the Edge Selection button in the taskbar. The Show Internal Edges

checkbox provides a method for only viewing the external edges of a part. The internal edges

are edges that can be viewed from the inside of the model looking out, while the external

edges are viewed from the outside. The external edges are the edges that need to be stitched

together. After performing a stitching operation, the only external edges that will be visible are

the edges that could not be stitched together because of the tolerance gap. All stitched edges

become internal edges.

◆

SolidSurfacer User Manual GFK-1709

16

Page 21

Once the problem edges have been identified, if the gap is large, the user can build a

sheet using Coons patch or another Surface Modeling tool to fill the hole. Often times the gaps

are small and can be solved by setting a different tolerance. The user can apply a looser tolerance to select edges. This is accomplished by selecting the problem edges, entering the looser

tolerance in the Edge Tolerance text box, and clicking on the Set Edge button. Applying a dif-

ferent edge tolerance to certain edges often aids the system in stitching together all of the

sheets.

There are three methods of stitching offered in this dialog: 1 Pass, Multiple Passes

and Multiple Tries. Each of these methods uses the tolerance value entered in the dialog. The

tolerance can be thought of as the maximum gap that can exist between the edges of two sheets

that the system will still stitch together. For example, the edges of two adjoining sheets are

.0001" apart. If the tolerance set is .0001" or greater, the two sheets will be stitched together

and the result will be a single sheet. If the tolerance is less than .0001", the two sheets will not

be stitched together and remain two separate entities. The minimum tolerance is set by the system and is .00002mm or .00000079". The tolerance specified by the user cannot be less than

this value.

1 Pass: When the 1 Pass option is selected, the system will attempt to stitch all selected

sheets at the given tolerance. The system will take one pass at the specified tolerance in

this attempt. The system will analyze each sheet, its neighbors and its edges and if they

fall within the tolerance, stitch the sheets together. If all edges stitch together at this tolerance into a single closed sheet, the system will solidify the sheets, creating a solid body.

Otherwise, the result will be a multi-faced sheet composed of all of the sheets that could

be stitched together.

Multiple Passes: When this option is selected, the system will attempt to stitch together all

selected sheets by performing a series of single passes. The system will begin at the minimum tolerance which is .00002mm and attempt to stitch the sheets at that tolerance. The

tolerance entered by the user provides the maximum tolerance that the system will go to

in its attempt to stitch the sheets. Multiple passes will be taken at incremental tolerance

steps ranging from the minimum tolerance (set by the system) to the maximum tolerance

(set by the user). On each pass the system will stitch together all the sheets it can at that

tolerance and then proceed to another pass at the next tolerance, attempting to stitch any

remaining sheets. The progress bar, located on the right side of the taskbar, displays the

number of sheets remaining to be stitched and the tolerance being used on the current

GFK-1709 Modeling

◆

17

Page 22

pass. When all of the passes have been completed, if the sheets stitched together into a

single closed sheet, the system will automatically solidify the sheets, resulting in a solid

body. Otherwise, the result will be a multi-faced sheet or sheets.

Multiple Tries: This option is similar to the Multiple Passes option in that it takes incremen-

tal passes ranging from the minimum tolerance, which is .00002mm, to the maximum tolerance, which is the Tolerance value entered in the Stitch dialog. The system will attempt

to stitch all the sheets together at each tolerance increment, starting over from scratch

after each pass that does not stitch together all the selected sheets. The system is looking

for the smallest single tolerance that will stitch the entire part. This is similar to taking a

series of one pass steps and undoing after each one. The stitching process will stop when

all the selected sheets have been stitched together into a single sheet even if this occurs

before the maximum tolerance is reached.

Face Check: Clicking on the Face Check button will perform a face validity check on the

selected sheets. This is identical to the face validity check that is run when the Check

Body Validity item is selected from the Solids Tools menu. Check Body Validity is

described in the Machining reference section. The face check produces an error message

for each invalid face and also deselects the problem faces. It is useful to run a face check

if stitching has failed to identify problem areas before attempting to stitch again. When a

face fails the check, it must be deleted and re-created in order for future stitching

attempts to be successful.

Unstitch Sheets: This function will unstitch selected faces of a sheet or unstitch faces of

a body to create sheets. A face is a single surface of a sheet or body which is bounded

by an edge loop. Multiple, adjoining faces can be selected to be unstitched. The faces will be

unstitched at the edge loop which bounds the selected face or faces. Faces can be selected

when the Face Selection button in the Taskbar is depressed. The following pictures illustrate an

example of an unstitching operation (Figure 2.4). The first row of pictures shows a single,

multi-faced sheet with the edges displayed to differentiate between the faces of the sheet. In

the second row multiple, adjoining faces are selected to be unstitched. Again the result will be

two sheets, unstitched at the edge separating the selected faces from the non-selected faces.

◆

SolidSurfacer User Manual GFK-1709

18

Page 23

Figure 2.4: Example of Unstitching Sheets

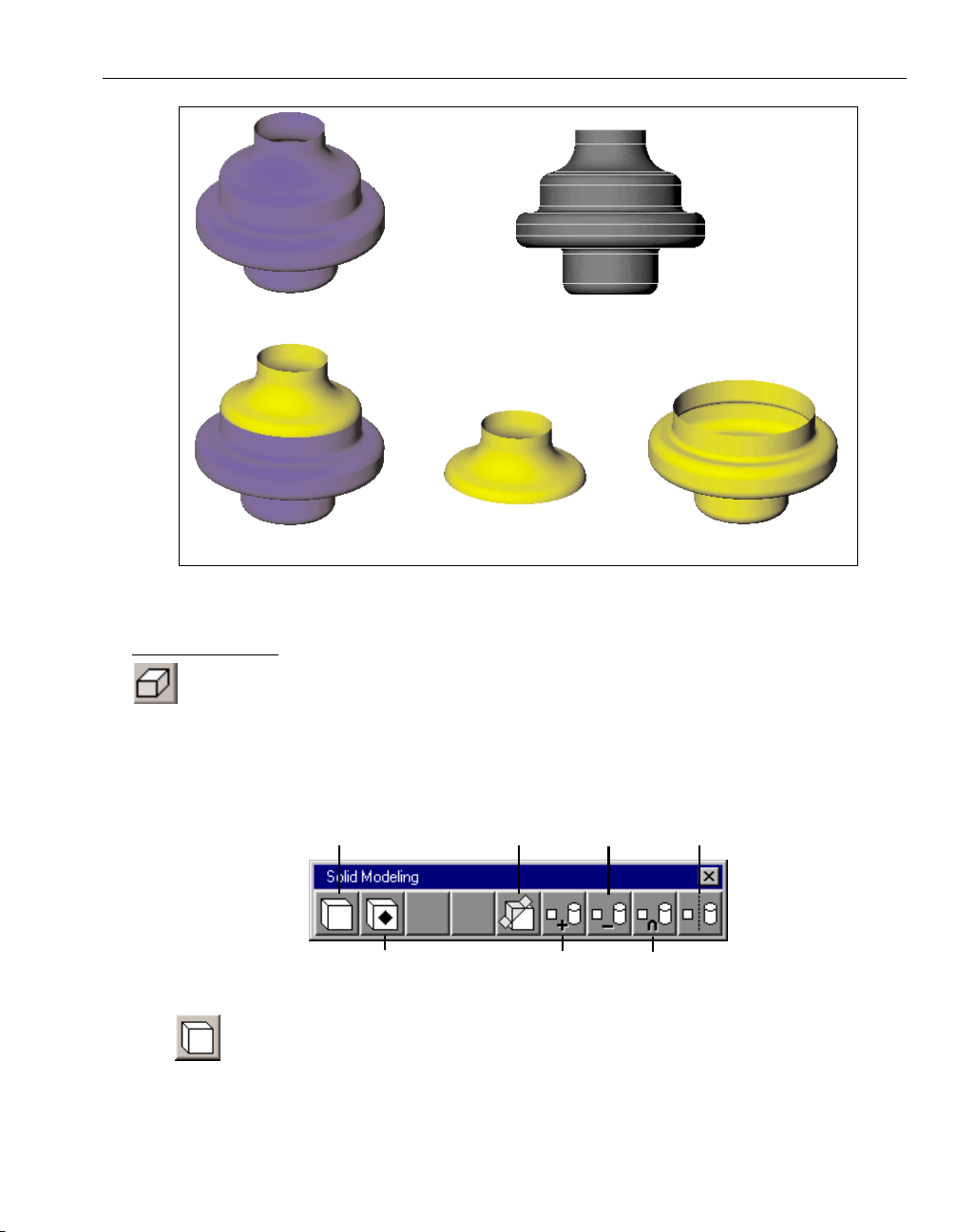

SOLID MODELING

The Solid Modeling palette is accessed by clicking on the Solid Modeling button in the Top

Level palette. All of the modeling functions that are used with solids are accessed from this

palette. The first button accesses the Create Body palette which provides options for creating atomic

or primitive bodies. The second button accesses the Advanced Solid Modeling palette which provides for such functions as offsetting and rounding. The remaining buttons in the Solid Modeling

palette, include Slicing, Adding, Subtracting, Intersecting and Separating which are all options that

provide for various interactions between solids and sheets.

Create Body button: Depressing this button accesses the Create Body palette which provides various methods for creating atomic bodies and solidifying sheets into bodies.

Atomic bodies or primitives are non-divisible bodies in that they were not created from

any other bodies. They are the starting blocks for creating solid models.

GFK-1709 Modeling

◆

19

Original Sheet Edges of sheet which separate the faces

Selected face to be unstitched Resulting Sheet Resulting Sheet

Create Body

Advanced Modeling

Slice

Subtraction

Addition

Seperate

Intersection

Page 24

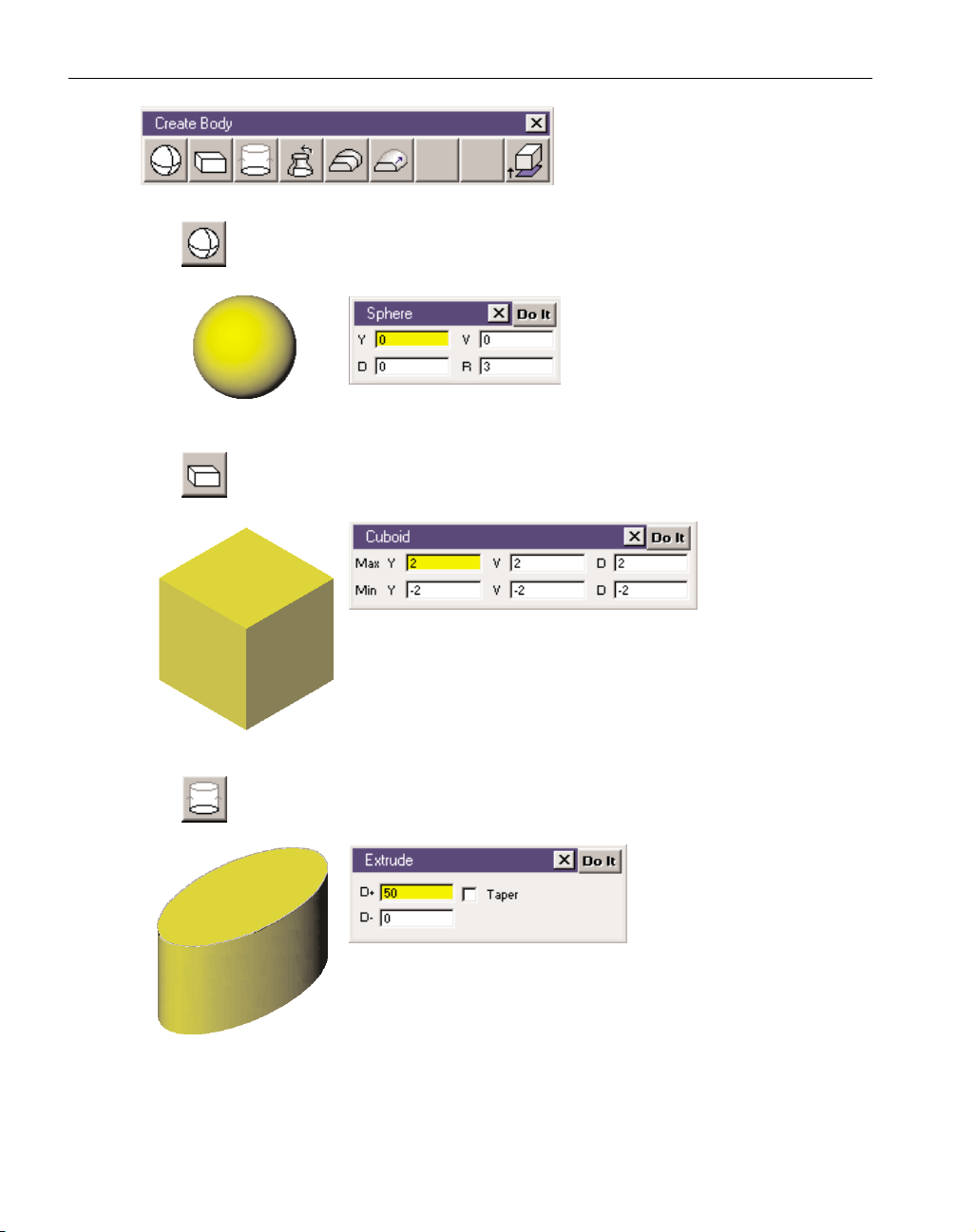

Create Body palette: This palette pro-

vides options for creating atomic bodies in a variety of methods. Each

method is described below.

Sphere button: Depressing this button brings up the Sphere dialog which allows

users to create spherical bodies.

Sphere dialog: Enter the H, V, D (hori-

zontal, vertical, and depth) coordinates of the centerpoint of the sphere

and a radius value. Click on the Do It

button to create the sphere.

Cuboid button: Depressing this button brings up the Cuboid dialog which allows

users to create cubes, rectangular bodies and slabs.

Cuboid dialog: Enter

a minimum and

maximum

horizontal, vertical

and depth value to define the volume of the cuboid. These values

will be measured from the origin of the current coordinate system.

The labels used in the dialog may vary when the current coordinate

system aligns with one of the primary planes. The labels X, Y and Z

will be used instead of H, V and D.Click on the Do It button to create the cuboid.

Extrude button: Depressing this button brings up the Extrude dialog which allows

users to create a body by selecting a closed shape and extruding it along the depth

axis.

Extrude dialog: Select a 2D (in

H and V) closed shape. The

shape can be extruded along

the depth axis of the current

coordinate system in the positive and/or negative direction based on the values entered in the D+

and D- text boxes. These text boxes may be labeled X, Y or Z if the

current coordinate system aligns with one of the primary planes.

The extrusion starts at the depth location of the geometry selected

to be extruded. Click on the Do It button to create the extruded

body.

◆

SolidSurfacer User Manual GFK-1709

20

Page 25

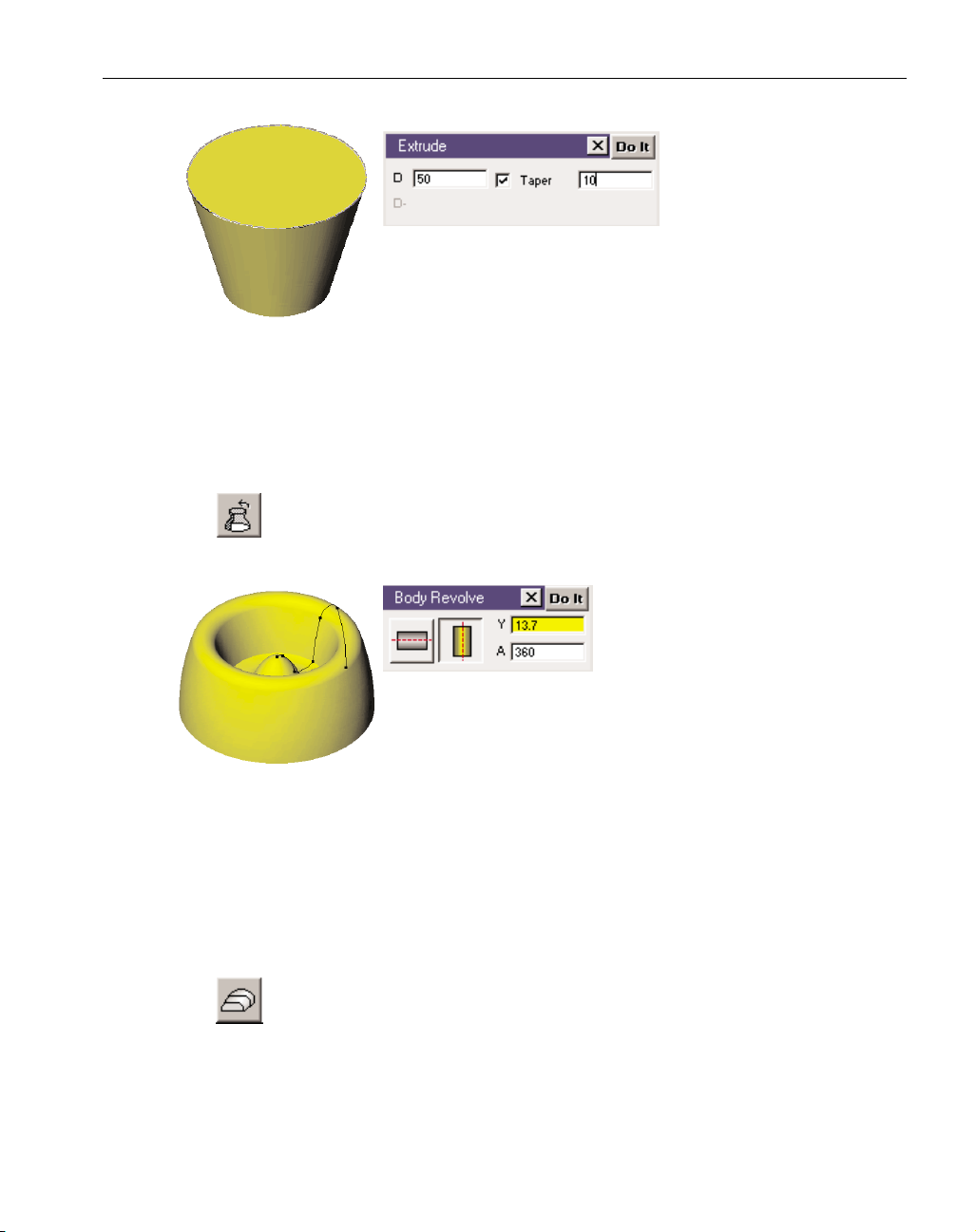

TAPERED EXTRUSIONS

A taper can be put on an

extruded body. The value

entered for the taper specifies the angle of the taper.

When doing an extrusion

with a taper, the extrusion can only be done in one direction along

the depth axis in order to properly calculate the taper on the body.

When the Taper box is activated, the negative depth specification

will become grayed out. A negative value can be entered for the Z+

value so that the shape can be extruded along the negative direction of the depth axis. Negative

angle values can also be entered for the taper amount. When extruding a body, the shape

selected to be extruded is duplicated along the depth axis by the amount specified. When doing

an extrusion with no taper, the offset shape is an exact duplicate of the original shape. When

creating an extrusion with a taper, the offset shape is going to be larger or smaller (depending

on if the taper is positive or negative) than the original shape.

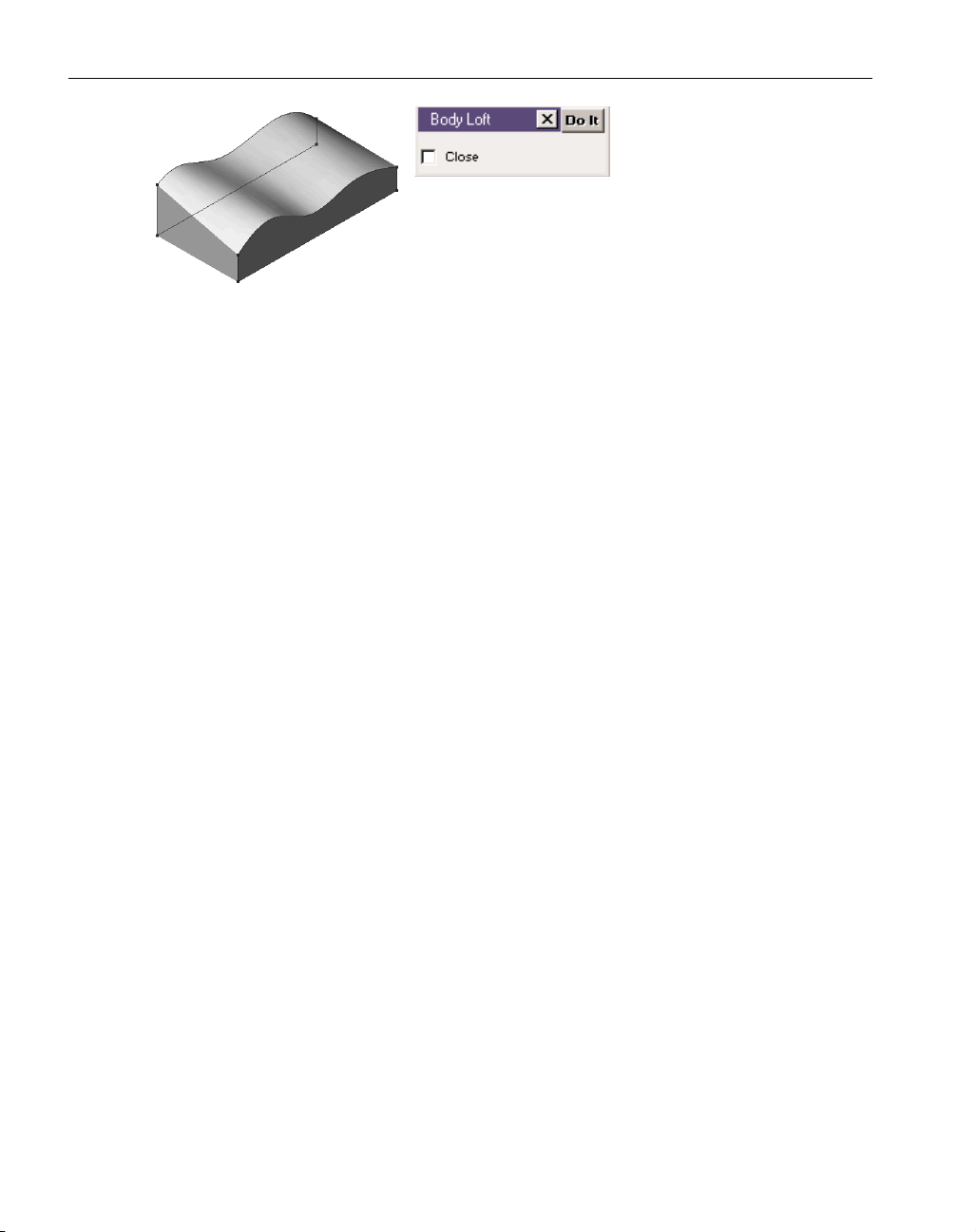

Revolve button: Depressing this button accesses the Body Revolve dialog which

allows users to revolve a shape a specified number of degrees around either the

horizontal or vertical axis to create a body.

Body Revolve dialog: Select an open,

terminated shape or a closed shape to

be revolved. The selected shape must

be an open, terminated shape, rather

than a closed shape, in order to revolve 360° about an axis position

of 0. In other words, there cannot be a line on the axis of revolution,

or revolving will fail because it will produce self intersecting edges.

The axis buttons designate whether the shape will be revolved

around the horizontal or vertical axis of the current coordinate system. If the horizontal axis is

selected for the axis of revolution, a vertical value must be entered to specify the position of

the revolution axis. Likewise, if the vertical axis is the axis of revolution, a horizontal value

must be entered to specify the position of the vertical axis that will be the revolution axis. The

value entered in the A text box is the angle, specified in degrees, the selected shape will be

revolved around the selected axis. A positive angle value will revolve the shape in a counter

clockwise direction and a negative angle in a clockwise direction based on the positive axis of

revolution.

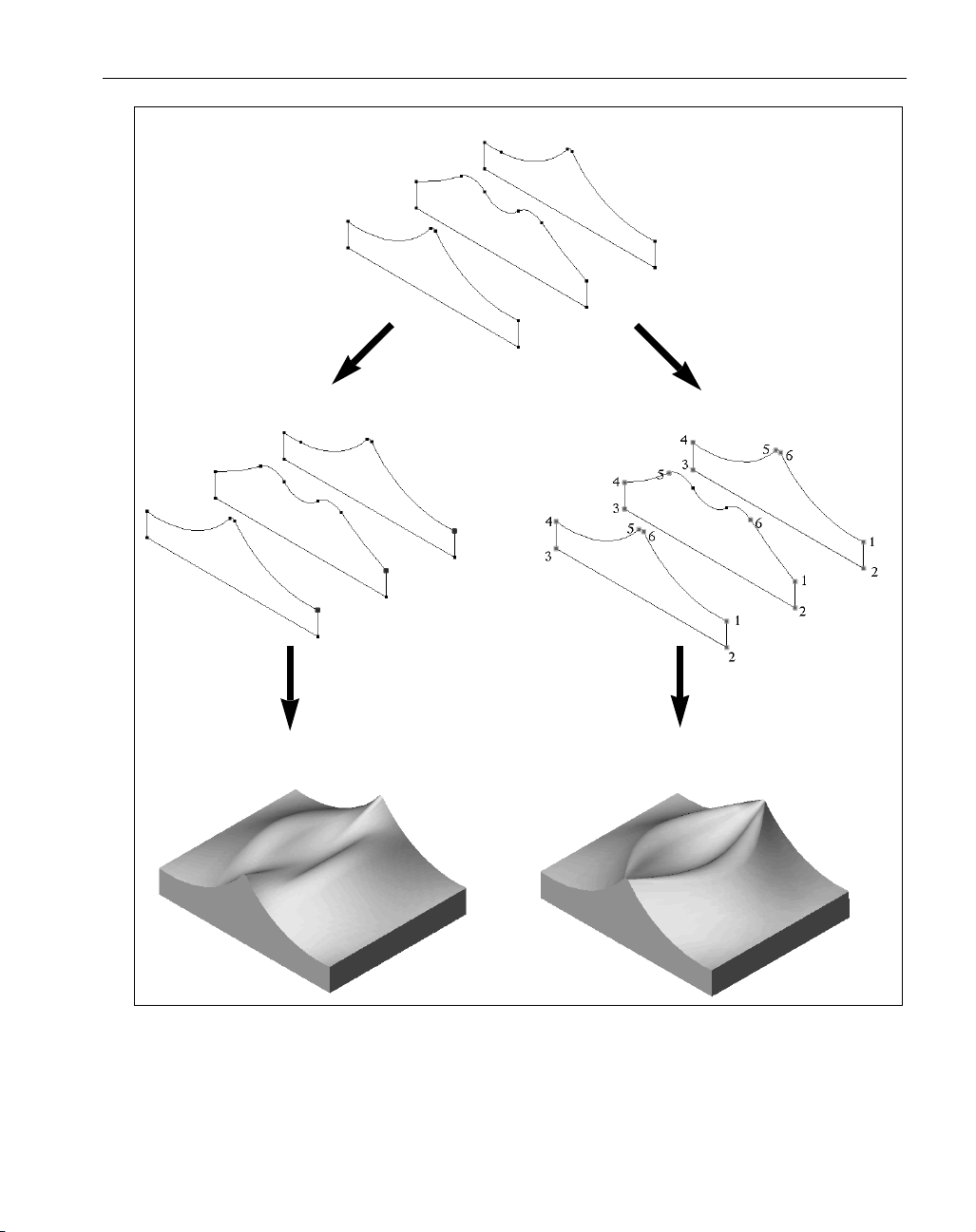

Loft button: Depressing this button brings up the Body Loft dialog. Lofting is also

referred to as blending or skinning.

GFK-1709 Modeling

◆

21

Page 26

Body Loft dialog: Select a series

of closed shapes to be blended

into a body. These selected

shapes define the crossections

of the resulting lofted body. The shapes should be selected

by choosing points on each shape that will act as alignment

or synchronization points. The system will break up the

section of the shape between synch points into an equal

number of segments and create a face (surface) by match-

ing each segment. The synch points on each shape will match up in the finished lofted body.

To achieve the best results when lofting, select all relevant points to act as synch points. If the

shapes selected have the same number of corners, one synch point per shape can be selected

and the system will blend the lofted body using the corners as synch points. A corner is defined

as the non-tangent intersection between two features. When selecting synch points on the

shapes, either select all synch points per shape in the same order or select the first synch point

on all shapes then the second, etc. The system looks at the selection order for each shape. If the

Close button is turned on, the system will attempt to blend the first and last shapes together

into a closed body. Click on the Do It button to create the lofted body.

In the Figure 2.5, three closed shapes are selected to be lofted. The top picture shows the

shapes selected to be lofted. The second set of pictures show synch points selected, one has

one synch point per shape, the other six synch points per shape. The third set of pictures show

the lofted bodies created from the shapes. The body created from the shapes with one synch

point selected blends the shapes using the four corners of each shape because the shapes have

the same number of corners. The body created from the shapes with six synch points selected

blends the body based on all of the synch points selected allowing the user more control over

the body that is generated.

◆

SolidSurfacer User Manual GFK-1709

22

Page 27

Figure 2.5: Example of the use of synch points in lofting

GFK-1709 Modeling

◆

23

Curves Selected for Lofting

1 Synch Point Selected

1

Lofted Body

6 Synch Points Selected

1

1

Lofted Body

Page 28

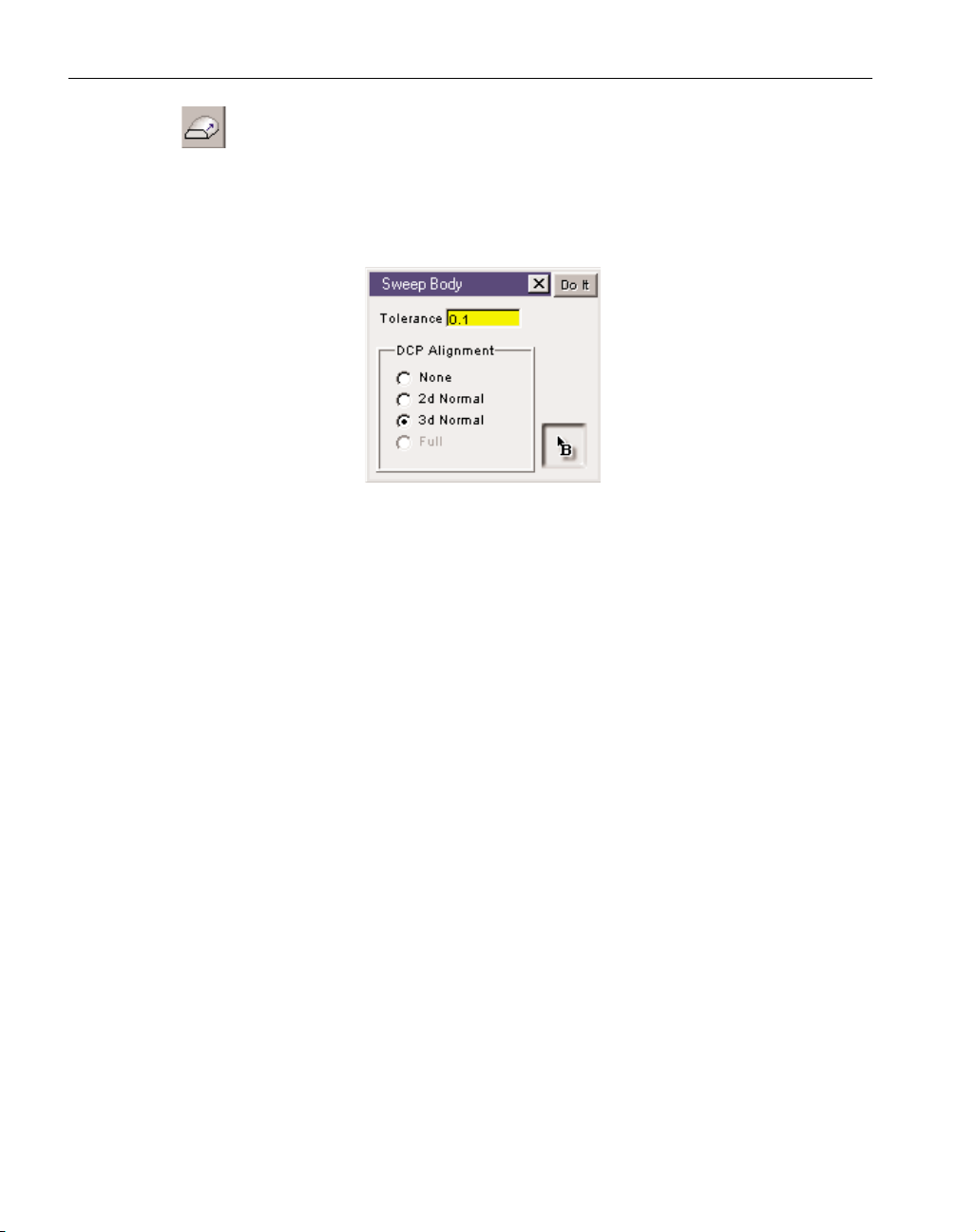

Sweep Body: The Sweep function is located in the Create Body palette. It pro-

vides options for creating swept bodies. A swept body is created by selecting a

base curve, which defines the spine or edge of the desired swept body, and a drive

curve(s) that designates the location and shape of the swept body by defining the cross

sections. The Sweep function supports one base curve and a maximum of two drive

curves. The tolerance value specifies how closely the generated swept body will be to the

"true" swept surface.

Base Curve: The base curve can be a 2D or 3D curve and must be either a closed shape or

an open, terminated shape. It should also be defined in the exact 3D location for the

desired swept body. The B-pointer marker, located in the Sweep Body dialog, is used to

designate the base curve. The B-pointer can be dragged from its box in the dialog and

dropped on the geometry to be used for the base curve. It can be removed in the same

manner, dragging it from geometry back to its box in the Sweep dialog. The location of

the B-pointer marker on the base curve has no affect on the resulting swept body.

Drive Curve: The drive curve(s) are 2D curves that define the cross sections of the swept

body. The drive curves must be defined in the correct 3D location for the desired swept

shape. The system supports a maximum of two drive curves. Following is a list of rules

regarding drive curve creation.

1. Drive curves must be planar.

2. All drive curves must be closed shapes and selected in the appropriate order for

the desired swept body. Open, terminated shapes can be used for the drive curves

when these open shapes can be capped by a single plane.

3. Select drive curves by choosing alignment points on each of the shapes.

• Alignment points must be connectors or terminators on the drive curves.

• A minimum of one alignment point must be selected for each drive curve.

• If more than one alignment point is selected, all corner connectors (non-tangent intersections) must be selected

• If only one alignment point is selected for each shape, corner connectors will

automatically be aligned. In this case, each shape must have the same number

of corner connectors or the sweeping operation will fail.

• The same number of alignment points must be selected on each shape.

• Full circles have a default alignment at 12:00, in their respective planes. This

allows the user to select circles for the drive curves without needing to create and

select alignment points. If full circles are selected for the drive curve without

alignment points selected and the resulting swept body is not the desired result,

create terminators or connectors on the circles in order to control alignment.

◆

SolidSurfacer User Manual GFK-1709

24

Page 29

Sweeping Plane: The Sweeping Plane is the current coordinate system when the Sweeping

function is performed. The Sweeping Plane affects the DCP Alignment options when the

2d Normal or 3d Normal choices are selected. The sweeping plane also determines the

CS to which the resulting swept body will be assigned.

DCP Alignment: The DCP Alignment options determine the alignment of the drive curve

plane in reference to the base curve; how the drive curve will be swept around the base

curve. There are three options: None, 2d Normal and 3d Normal.

None: The selected drive curve determines the orientation of the drive curve plane.

All the frames used for the drive curve plane will be parallel to the plane of the

selected drive curve. The drive curve is simply translated along the base curve, but

not rotated in any way.

2d Normal: The selected drive curve will be rotated around the sweeping plane normal vector so that it is perpendicular to the base curve in the sweeping plane.

However, the drive curve will not remain normal to the base curve as the base curve

moves in Z (or the depth of the current CS). Another way to think of this is that the

vertical axis of the drive curve plane always stays parallel to the depth axis of the

sweeping plane. The alignment is locked.

3d Normal: As in the 2d Normal case, the selected drive curve will be rotated around

the sweeping plane normal vector so that it is perpendicular to the base curve in the

sweeping plane, and it will follow the base curve as it changes in depth. Another

way of describing this is that the horizontal axis of the drive curve plane will lie in

the sweeping plane and be normal to the base curve at every point.

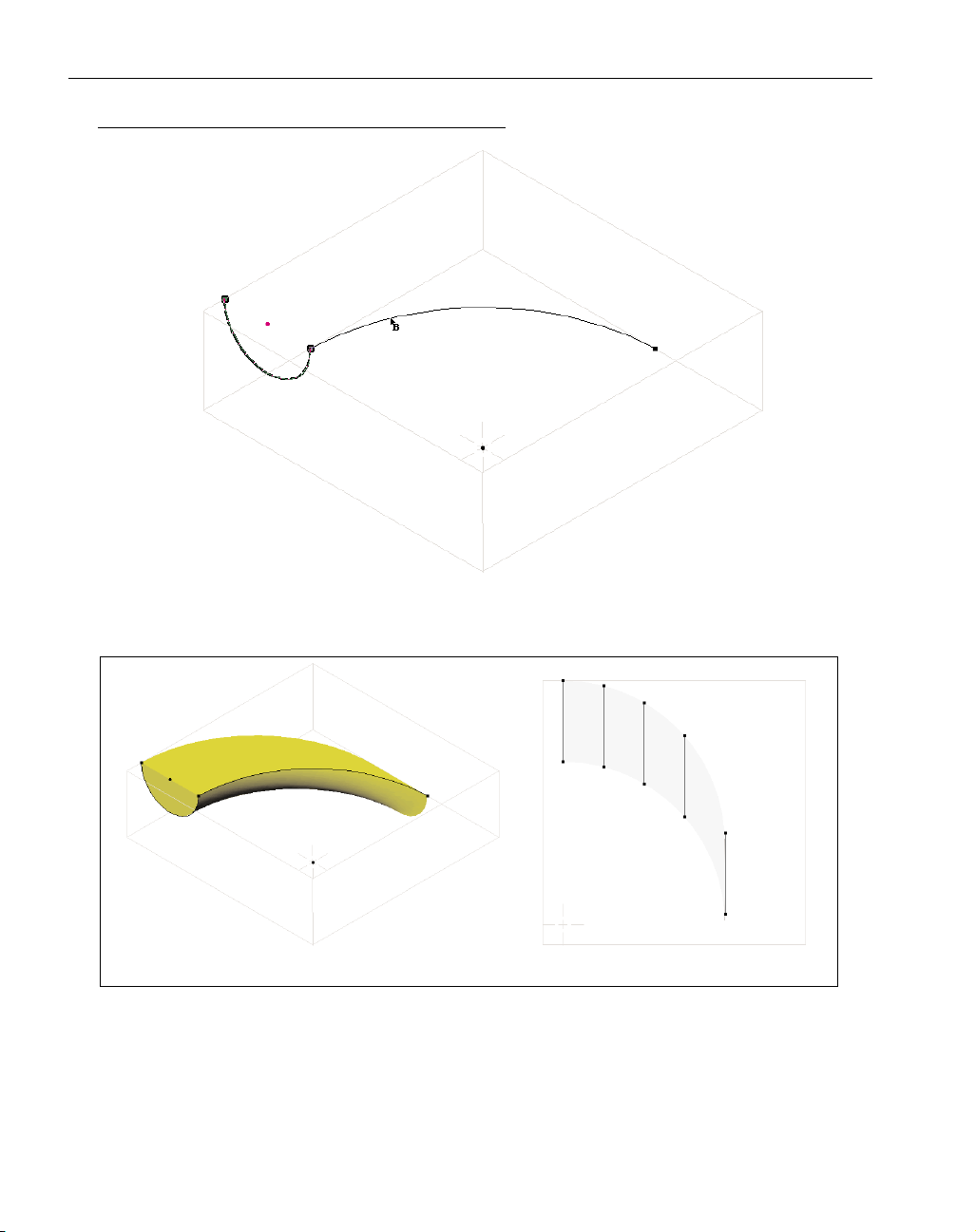

Following are examples that provide a series of pictures intended to illustrate the different

types of alignment and sweeping options. The first example (Figure 2.5a, b & c) illustrates the differences between the None and 2d Normal alignment options, while the second example (Figure

2.6a, b & c)deals with the difference between the 2d and 3d Normal options. The third example

(Figure 2.7a & b) provides an illustration of one base curve, which is acting as a spine, and two

drive curves.

GFK-1709 Modeling

◆

25

Page 30

EXAMPLE 1: NONE VS. 2D NORMAL ALIGNMENT

Figure 2.5a: Base curve and drive curve geometry

Figure 2.5b: DCP Alignment: None

Isometric View Top View with Drive Curve cross sections

◆

SolidSurfacer User Manual GFK-1709

26

Page 31

Figure 2.5c: DCP Alignment: 2d Normal

EXAMPLE 2: 2D VS. 3D NORMAL ALIGNMENT

Figure 2.6a: Base curve and drive curve geometry

Side View Isometric View

Isometric View Top View with Drive Curve cross sections

GFK-1709 Modeling

◆

27

Page 32

Figure 2.6b: DCP Alignment: 2d Normal

Figure 2.6c: DCP Alignment: 3d Normal

Side View Side View with Drive Curve cross sections

Side View Side View with Drive Curve cross sections

◆

SolidSurfacer User Manual GFK-1709

28

Page 33

EXAMPLE 3: ONE BASE CURVE AND TWO DRIVE CURVES

Figure 2.7a: Base Curve and Drive Curve Geometry

Figure 2.7b: Resulting Swept Body

Top View Isometric View

Top View Isometric View

GFK-1709 Modeling

◆

29

Page 34

Solidify button: This button accesses the Solidify dialog which provides options for creating bodies from sheets. It is often useful to solidify sheets into bodies to reduce part

complexity and so that solid modeling functions can be performed. However, it is not

necessary to solidify sheets in order to machine them. Sheets can be machined directly without

being solidified or stitched together.

Solidify dialog: This dialog contains four options for

converting sheets into solid bodies. To solidify a sheet,

select the desired option in this dialog, select the sheet

and click on the Do It button. The first three options

can only be used to change a single sheet into a body.

The Solidify Closed Sheets option can be used on mul-

tiple sheets. Each method is described below.

Cap: The Cap option creates a body from an open sheet by creating planar surfaces at any open

ends of the selected sheet. The enclosed area is filled in to create the solid body. In order to use

the cap option to solidify a sheet, the sheet selected to be capped must only require planar surfaces to provide closure of open ends of the sheet. Figure 2.8 illustrates the capping function to

solidify a sheet.

Figure 2.8 : Example of solidifying a sheet using the Cap option

Extrude: The Extrude option creates a solid body by extruding a selected sheet along the depth

axis of the current coordinate system. The sheet can be extruded in the positive or negative

direction along the depth axis. The user enters a value which specifies how far along the depth

axis to extrude the sheet. Entering a negative value will extrude the sheet along the negative

direction of the depth axis. When performing an extrusion, the sheet selected to be extruded is

duplicated along the depth axis by the amount specified and the area between these sheets is

filled in to create a solid body. In order to use the extrude option to solidify a sheet, the sheet

selected to be extruded cannot overlap itself or fold over. Also, the extrude axis (depth axis of

the current coordinate system) can not hit the sheet in more than one place and cannot be parallel to the edge of the sheet. Figure 2.9 illustrates extruding a sheet in order to solidify it.

◆

SolidSurfacer User Manual GFK-1709

30

Sheet Solidified Body

Page 35

Figure 2.9: Example of solidifying a sheet using the Extrude option

Offset: The Offset option creates a solid body by creating an offset sheet of the sheet selected to

be solidified at a specified distance and filling in the area between the original sheet and the

offset sheet to create a solid body. The definition of an offset is that every point on the offset

sheet will be normal (perpendicular) to a point on the original sheet. Offsetting can be thought

of as rolling a ball with a diameter the size of the offset amount along the sheet.

When using the Offset option, the user specifies a Max and/or Min value that acts as

the offset amount. The sheet selected to be solidified acts as the 0 reference point for the Max

and Min values. These values can be positive or negative. The sheet selected to be solidified

will be offset in one direction by the Max value and in the other direction by the Min value.

Figure 2.10 illustrates the offsetting function to solidify a sheet.

Figure 2.10: Example of solidifying a sheet using the Offset option

Solidify Closed Sheets: The Solidify Closed Sheets option creates a solid body by filling in the

volume enclosed by adjoining separate sheets. The sheets selected do not need to be stitched

together in order to use this solidify option. There can be no holes or gaps between the adjoining sheets to be solidified. The accuracy for closure must be .001" in order for Solidify Closed

Sheets to create a solid body. This option provides the same functionality as the stitching

options which are accessed from the Surface Modeling palette.

GFK-1709 Modeling

◆

31

Sheet Solidified Body

Sheet Solidified Body

Page 36

ADVANCED SOLID MODELING PALETTE

The Advanced Solid Modeling palette is accessed from the Solid Modeling palette by

depressing the Advanced Modeling button. The functions included in this palette include

Shelling and Offsetting, Blending/Rounding, Body Unstitch and Drafting a body. Each function is described below.

Offset/Shell button: This button is located in the Advanced Solid Modeling palette and

accesses the Offset-Shell dialog. Within the Offset-Shell dialog, there is an Offset button and a Shell button. Depressing one of these buttons accesses the respective function. Each

is described below.

Offset: The Offset function can be performed on bodies, sheets and individual

faces. The Offset function will grow or shrink a body or face by the specified

Offset amount. Positive offset values will make the selected entities larger; neg-

ative values, smaller. Both bodies and faces can be offset and multiple bodies

and faces can be offset at one time. To offset a body or face, select the body or face(s), enter an

offset amount and click on the Do It button. It should be noted that the original body selected

to be offset is replaced by the offset body. The original body can be brought back from the

History tree if necessary. Figure 2.11 provides an example of offsetting an entire body, while

Figure 2.12 illustrates offsetting only selection faces.

Figure 2.11: Offset Body

Original Body Offset Body

◆

SolidSurfacer User Manual GFK-1709

32

Offset

Shell

Page 37

In Figure 2.11, the original body is a solid canister and the offset body is enlarged by a given

offset amount. Note the change in the size of the fillet at the top of the bottle; it is a much

smaller fillet than on the original body due to the fact that the system must extend the unoffset

neighbors to intersect. This example would fail to offset if the offset amount was greater than

the size of the fillet. In Figure2.12, only selected faces are offset and the unselected faces

"grow" in order to provide for the offset.

Figure 2.12: Offset Selected Faces of a Body

The offset function can also be performed on sheets. A sheet has two sides, an inside

and an outside. The outside of a sheet is defined as the side from which the positive direction

of the surface normals are projecting outward. The negative direction of the surface normals

project to the inside of the sheet. When offsetting sheets, the location of the selected sheet will

be moved in the direction of its positive surface normals by the specified offset amount. Sheets

are offset to the outside of the sheet. The outside and inside of a sheet can be determined by

turning on the Indicate Sheet Side button in the taskbar. When this button is depressed the system will display the outside of sheets as blue and the inside of sheets as red.

Original Body Faces Selected to be Offset

Resulting body with Offset Faces

GFK-1709 Modeling

◆

33

Page 38

In certain instances, the offset function will not succeed because the specified offset

amount creates excessive topology changes. Topology is the term in solid modeling for the

manner in which specific faces of a body are positioned relative to each other. Modeling functions that change the shape of a face do not affect the topology, unless the function requires

that a change be made to the way faces connect to one another along their edges. An example

of offsetting that will require excessive topology changes, and therefore will fail, is if the offset

amount is greater than an inside (concave) fillet of the face or body to be offset. The offset

function attempts to extend the unoffset neighbor faces to intersect with the faces that are

being offset. When one or more of the unoffset neighbor faces is tangent to the offset face, no

amount of extension will intersect with the offset face. Therefore the offset function will fail in

this instance.

Shell: The Shelling function creates hollow bodies. The Offset amount entered

specifies the amount the body will be shelled, which is equivalent to the wall

thickness of the resulting hollow body. Entering a negative value for the offset

will shell the body to the inside, meaning that the outside face not be enlarged

to account for the shell amount, remaining in its original position. A positive value will offset

the body to the outside and the body itself will become larger as a result. In this case the inside

of the face of the shelled body is the same as the outside face of the original body. Deselecting

faces on the body to be shelled will create entry holes at those faces. Select a body, deselect

the faces to be removed for entry holes using face selection mode and click on the Do It button

to create the shelled body. It is not necessary to create entry holes, however, if there are no

entry holes on the shelled body it will need to be sliced or modified to see the results of the

shell. Figure 2.13 illustrates an example of a shelling operation which creates an entry hole by

deselecting a face.

Figure 2.13: Example of a Shelling operation

Original Body Body Selected with

Top Face Unselected

Results

◆

SolidSurfacer User Manual GFK-1709

34

Page 39

Blending: The Blending or Rounding function contains options for blending edges of

bodies. There are options for constant radius rounding, variable radius rounding and

constant width chamfering. Figure 2.14 shows which button is used for the different

blending options. The dialog will change slightly depending on the type of blending. In order

to use the blending functions, edges of bodies or sheets must be selected. The system must be

in Edge Selection mode for edges to be viewed and selected. Multiple edges can be rounded at

one time.

Figure 2.14: Blending Dialog