Canon LBP7750C, LBP5460 Service Manual

LBP7750C/5460 Series

Service Manual

Product Description

Technical Reference

Disassembly and Assembly

Maintenance and Inspection

Troubleshooting

Appendix

1 |

2 |

3 |

4 |

5 |

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair of products. This manual covers all localities where the products are sold. For this reason, there may be information in this manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or translated into another language, in whole or in part, without the written consent of Canon Inc.

(C) CANON INC. 2009

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation

Used to show permission.

Used to show prohibition.

The following rules apply throughout this Service Manual:

1.Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of operation.

In the diagrams,  represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow

represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow  indicates the direction of the electric signal.

indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit door, which results in supplying the machine with power.

2.In the digital circuits, '1' is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low". (The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations of the microprocessors used in the machines

are not discussed: they are explained in terms of from sensors to the input of the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service Information bulletins and be able to identify and isolate faults in the machine.

Contents

Operation Sequence---------------------------------------------------------- |

2-3 |

Overview------------------------------------------------------------------------------ |

2-3 |

Laser Exposure System------------------------------------------------------ |

2-4 |

1 Product Description

Characteristics------------------------------------------------------------------ |

1-2 |

System Configuration--------------------------------------------------------- |

1-2 |

System Configuration-------------------------------------------------------------- |

1-2 |

Product Specifications-------------------------------------------------------- |

1-3 |

Host Machine Specifications----------------------------------------------------- |

1-3 |

Detailed Specification--------------------------------------------------------- |

1-5 |

Printing Speed----------------------------------------------------------------------- |

1-5 |

Paper Type -------------------------------------------------------------------------- |

1-5 |

Paper Size---------------------------------------------------------------------------- |

1-6 |

Parts Name---------------------------------------------------------------------- |

1-7 |

External View------------------------------------------------------------------------ |

1-7 |

Cross Section View---------------------------------------------------------------- |

1-8 |

Operation------------------------------------------------------------------------ |

1-9 |

Control Panel------------------------------------------------------------------------ |

1-9 |

Job Menu---------------------------------------------------------------------------- |

1-11 |

Setup Menu------------------------------------------------------------------------- |

1-11 |

Utility Menu-------------------------------------------------------------------------- |

1-16 |

Reset Menu------------------------------------------------------------------------- |

1-17 |

Select Feeder Menu-------------------------------------------------------------- |

1-17 |

Safety Precautions---------------------------------------------------------- |

1-18 |

Overview------------------------------------------------------------------------------ |

2-4 |

Detecting a Failure in the Optical Assembly--------------------------------- |

2-4 |

Safety---------------------------------------------------------------------------------- |

2-4 |

Image Formation System---------------------------------------------------- |

2-5 |

Overview------------------------------------------------------------------------------ |

2-5 |

Image Formation Process-------------------------------------------------------- |

2-5 |

Controls------------------------------------------------------------------------------- |

2-9 |

Cartridge----------------------------------------------------------------------------- |

2-12 |

ITB Unit------------------------------------------------------------------------------ |

2-14 |

Fixing System----------------------------------------------------------------- |

2-17 |

Overview----------------------------------------------------------------------------- |

2-17 |

Various Controls------------------------------------------------------------------- |

2-17 |

Pickup Feeding System---------------------------------------------------- |

2-21 |

Overview----------------------------------------------------------------------------- |

2-21 |

Pickup Feeding Assembly------------------------------------------------------- |

2-22 |

Fixing/Delivery Assembly-------------------------------------------------------- |

2-28 |

Duplex Assembly------------------------------------------------------------------ |

2-29 |

Jam Detection---------------------------------------------------------------------- |

2-30 |

Controller System------------------------------------------------------------ |

2-32 |

Overview----------------------------------------------------------------------------- |

2-32 |

DC Controller PCB---------------------------------------------------------------- |

2-32 |

Low-voltage Power Supply------------------------------------------------------ |

2-35 |

Embedded RDS-------------------------------------------------------------- |

2-37 |

Laser Safety------------------------------------------------------------------------ |

1-18 |

Overview----------------------------------------------------------------------------- |

2-37 |

CDRH Regulation----------------------------------------------------------------- |

1-18 |

Settings Procedures-------------------------------------------------------------- |

2-37 |

Toner Safety------------------------------------------------------------------------ |

1-18 |

FAQ----------------------------------------------------------------------------------- |

2-40 |

How to Handle the Laser Scanner Unit-------------------------------------- |

1-18 |

Troubleshooting Guide----------------------------------------------------------- |

2-41 |

Points to Note when Replacing/Discarding a Lithium Battery---------- |

1-19 |

Service Cautions------------------------------------------------------------------- |

2-43 |

Points to Note when Performing Disassembly/Assembly--------------- |

1-19 |

3 Disassembly and Assembly |

|

2 Technical Reference |

|

|

|

|

Introduction---------------------------------------------------------------------- |

3-2 |

|

Basic Configuration----------------------------------------------------------- |

2-2 |

Points to Note During Disassembly and Assembly------------------------ |

3-2 |

Functional Configuration---------------------------------------------------------- |

2-2 |

Lay Out Drawing-------------------------------------------------------------------- |

3-3 |

External-related Issues------------------------------------------------------- |

3-9 |

Removing Left Cover-------------------------------------------------------------- |

3-9 |

Removing Rear Cover------------------------------------------------------------- |

3-9 |

Removing Right Rear Cover---------------------------------------------------- |

3-10 |

Removing the Control Panel Unit Right Cover----------------------------- |

3-10 |

Removing the Control Panel Unit Left Cover------------------------------- |

3-11 |

Removing Upper Front Cover Unit-------------------------------------------- |

3-11 |

Removing Control Panel Unit--------------------------------------------------- |

3-13 |

Removing Upper Rear Cover--------------------------------------------------- |

3-14 |

Removing the Front Cover Unit------------------------------------------------ |

3-14 |

Removing Front Right Cover--------------------------------------------------- |

3-15 |

Removing the Right Cover Unit------------------------------------------------ |

3-16 |

Main Units--------------------------------------------------------------------- |

3-17 |

Removing Secondary Transfer Unit------------------------------------------- |

3-17 |

Removing ITB Unit---------------------------------------------------------------- |

3-17 |

Removing Fixing Assembly----------------------------------------------------- |

3-18 |

Removing Waste Toner Container-------------------------------------------- |

3-19 |

Removing Waste Toner Full Sensor Unit------------------------------------ |

3-19 |

Removing Waste Toner Feed Motor Unit------------------------------------ |

3-20 |

Removing Registration Unit----------------------------------------------------- |

3-21 |

Removing Color Displacement/Density Sensor Unit--------------------- |

3-23 |

Removing Lifter Drive Unit------------------------------------------------------ |

3-24 |

Removing Laser Scanner Unit------------------------------------------------- |

3-25 |

Removing Cassette Pickup Drive Unit--------------------------------------- |

3-29 |

Removing Cassette Pickup Unit----------------------------------------------- |

3-31 |

Removing the Main Drive Unit------------------------------------------------- |

3-32 |

Removing the Fixing Drive Unit------------------------------------------------ |

3-35 |

Removing the Delivery Unit----------------------------------------------------- |

3-36 |

Removing the Duplex Drive Unit----------------------------------------------- |

3-38 |

Removing the Duplex Feed Roller Unit-------------------------------------- |

3-39 |

Removing the Multi-purpose Tray Pickup Unit----------------------------- |

3-40 |

Main Parts--------------------------------------------------------------------- |

3-43 |

Removing the Cassette Pickup Roller---------------------------------------- |

3-43 |

Removing the Cassette Separation Roller Assembly-------------------- |

3-44 |

Removing the Power Fan------------------------------------------------------- |

3-44 |

Removing the Fan Unit----------------------------------------------------------- |

3-46 |

|

Removing the Developing Disengagement Motor------------------------- |

3-47 |

|

Removing the Secondary Transfer Outer Roller Unit--------------------- |

3-48 |

|

Removing the Pickup Motor---------------------------------------------------- |

3-49 |

|

Removing the Drum Motor 1---------------------------------------------------- |

3-50 |

|

Removing the Drum Motor 2---------------------------------------------------- |

3-50 |

|

Removing the Drum Motor 3---------------------------------------------------- |

3-51 |

|

Removing the Fixing Motor----------------------------------------------------- |

3-51 |

|

Removing the Delivery Fan----------------------------------------------------- |

3-52 |

|

Removing the Cartridge Fan---------------------------------------------------- |

3-53 |

|

Removing the Multi-purpose Tray Pickup Roller--------------------------- |

3-54 |

|

Removing the Multi-purpose Tray Separation Pad------------------------ |

3-55 |

|

Removing the Controller Fan--------------------------------------------------- |

3-56 |

|

PCB-related Issures--------------------------------------------------------- |

3-58 |

|

Removing the ICB PCB---------------------------------------------------------- |

3-58 |

|

Removing the Main Controller PCB------------------------------------------- |

3-58 |

|

Removing the Low Voltage Power Unit-------------------------------------- |

3-60 |

|

Removing the DC Controller PCB--------------------------------------------- |

3-62 |

|

Removing the Lower High Voltage Power Supply PCB------------------ |

3-63 |

|

Removing the Upper High Voltage Power Supply PCB------------------ |

3-65 |

|

Removing the Environment Sensor------------------------------------------- |

3-66 |

4 |

Maintenance and Inspection |

|

|

Periodically Replaced Parts------------------------------------------------- |

4-2 |

|

Periodically Replaced Parts------------------------------------------------------ |

4-2 |

|

Consumable Parts------------------------------------------------------------- |

4-2 |

|

Consumable Parts Replaced by Users--------------------------------------- |

4-2 |

|

Consumable Parts Replaced by Service Engineers----------------------- |

4-2 |

|

Periodical Service------------------------------------------------------------- |

4-2 |

|

Periodical Service------------------------------------------------------------------ |

4-2 |

|

Cleaning-------------------------------------------------------------------------- |

4-3 |

|

Cleaning Item------------------------------------------------------------------------ |

4-3 |

5 |

Troubleshooting |

|

|

Corrective Actions------------------------------------------------------------- |

5-2 |

|

Image Failure------------------------------------------------------------------------ |

5-2 |

|

Standard/Adjustment--------------------------------------------------------- |

5-9 |

Test Print------------------------------------------------------------------------------ |

5-9 |

Adjustment of the Image Formation System--------------------------------- |

5-9 |

Adjustment of the Fixing Assembly------------------------------------------- |

5-10 |

Adjustment of Electrical Parts-------------------------------------------------- |

5-11 |

Outline of Electrical Components---------------------------------------- |

5-12 |

Sensor-------------------------------------------------------------------------------- |

5-12 |

Motor---------------------------------------------------------------------------------- |

5-13 |

Clutch/Solenoid-------------------------------------------------------------------- |

5-13 |

Fan------------------------------------------------------------------------------------ |

5-14 |

LED/Heater/Thermistor/Switch------------------------------------------------- |

5-14 |

PCB----------------------------------------------------------------------------------- |

5-15 |

Connector Layout Drawing------------------------------------------------ |

5-17 |

Connector List---------------------------------------------------------------------- |

5-17 |

Service Tools------------------------------------------------------------------ |

5-20 |

Standard Tools--------------------------------------------------------------------- |

5-20 |

List of Solvents/Greases--------------------------------------------------------- |

5-20 |

Error Code--------------------------------------------------------------------- |

5-21 |

Error Code Details----------------------------------------------------------------- |

5-21 |

Jam Code---------------------------------------------------------------------------- |

5-24 |

Alarm Code------------------------------------------------------------------------- |

5-25 |

Version Up--------------------------------------------------------------------- |

5-26 |

Overview----------------------------------------------------------------------------- |

5-26 |

Preparation-------------------------------------------------------------------------- |

5-26 |

Downloading the System Software------------------------------------------- |

5-27 |

Service Mode----------------------------------------------------------------- |

5-30 |

Service Mode List----------------------------------------------------------------- |

5-30 |

Special Administrator Mode----------------------------------------------- |

5-34 |

6 Appendix

General Timing Chart--------------------------------------------------------- |

6-2 |

General Circuit Diagram----------------------------------------------------- |

6-3 |

General Circuit Diagram (1/2)--------------------------------------------------- |

6-3 |

General Circuit Diagram (2/2)--------------------------------------------------- |

6-4 |

Signal Input/Output List------------------------------------------------------ |

6-5 |

1 |

Product Description |

■Characteristics |

■System Configuration ■Product Specifications ■Detailed Specification

■Parts Name ■Operation ■Safety Precautions

1 Product Description

1 Product Description > System Configuration > System Configuration

Characteristics

● High-Speed Color Printer

This machine is a high-speed color printer, realizing a speed of approximately 30 pages per minute in full-color printing with A4 vertical paper.

● Introducing Intermediate Transfer Method (ITB)

This machine introduced an intermediate transfer method, in which 4-color toner images are transferred into an intermediate transfer belt (ITB) and then simultaneously transferred into a printing sheet. This method enabled to realize stable color printing in various types of paper without receiving impact of paper at the time of primary transfer.

● Automatic Duplex Printing

This machine supports automatic duplex printing as standard function.

1-2

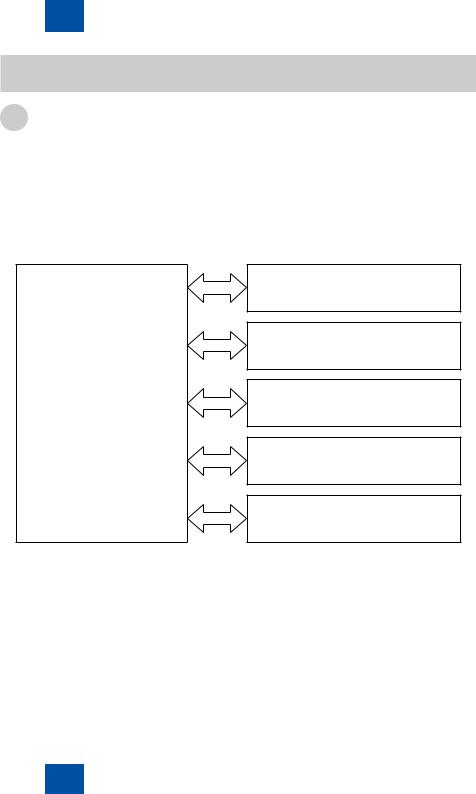

System Configuration

System Configuration

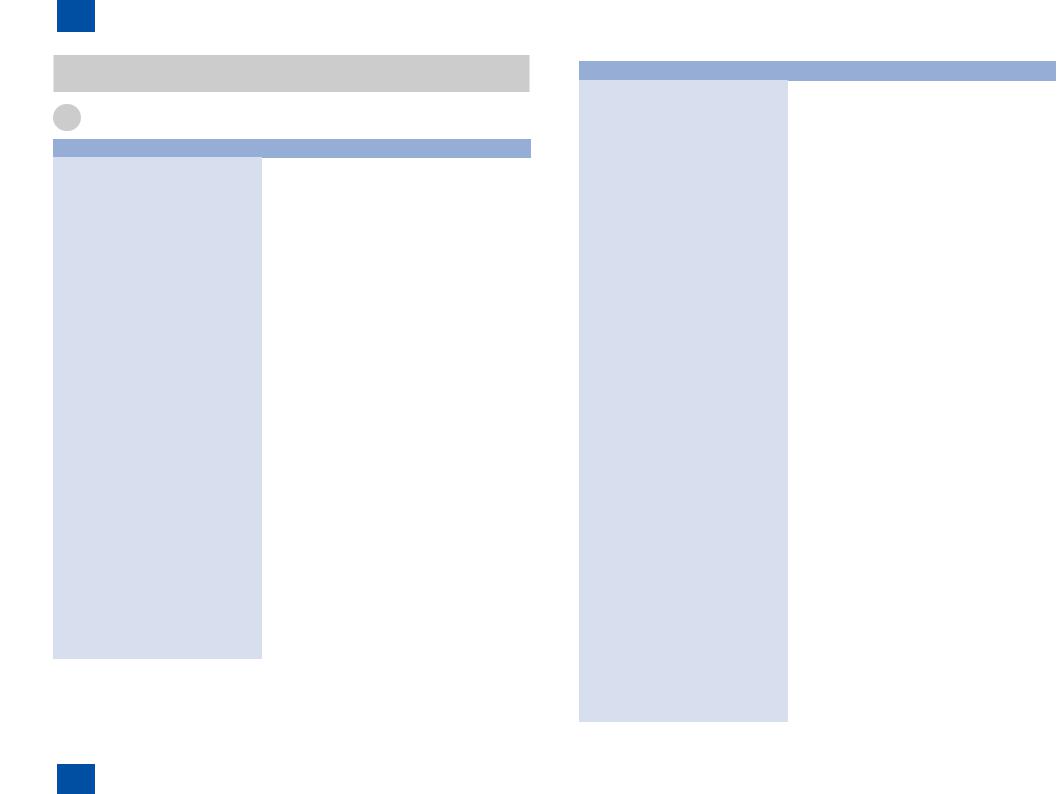

[2] |

[1] |

[3]

[4]

[5] |

F-1-1 |

|

Option |

Description |

[1] |

Paper Feeder |

1 extra cassette can be installed. |

|

PF-723 |

|

[2] |

Hard Disk Kit |

Hard disk with 40GB |

|

HD-14 |

|

[3] |

Extended RAM |

3 types are provided; 128MB, 256MB, and 512MB |

|

RD-128/256/512MW |

|

[4] |

Control ROM |

Emulation modes and fonts are contained. |

|

CR-HIX |

|

[5] |

Intelligent Controller |

Installation of the MEAP-Lite application, which is |

|

NB-J2 |

created with Java language, enables customization of |

|

|

printer function. SMS is mounted so that application |

|

|

can be controlled by a browser. |

[6] |

Self-contained Wireless Print Server |

This enables wireless LAN communication and |

|

NB-W2 |

security supported. |

|

|

|

T-1-1

1-2

1 Product Description > System Configuration > System Configuration

1 Product Description > Product Specifications > Host Machine Specifications

Product Specifications

Item |

Function / Method |

Installation of the host machine |

Desktop page printer |

Photoreceptor |

OPC drum |

Charging method |

Roller charging |

|

|

Exposure method |

Laser exposure |

|

|

Developing method |

Contact development |

Transfer method |

Intermediate transfer (ITB) |

Transfer (primary transfer) method |

Transfer belt |

|

|

Transfer (secondary transfer) method |

Transfer roller |

|

|

Separation method |

Curvature separation |

Feeding method |

Cassette / manual feeding |

Cassette feeding method |

Simple retard method |

Manual tray feeding method |

Pad separation method |

|

|

Drum cleaning method |

Blade |

Transfer cleaning method |

Blade |

Fixing method |

On-demand fixing |

Delivery method |

Face-down |

|

|

Contrast adjustment function |

Automatic |

|

|

Toner level detection |

Enabled (Optical detection) |

Toner type |

Nonmagnetic 1-component toner |

Toner supply method |

Replacement of the cartridge |

|

|

Warm-up time |

Less than approx. 60 sec. when the power is turned on |

|

(Room temperature: 20 degree C) |

Print quality guaranteed range |

Excluding 5.0mm from leading edge, trailing edge and |

|

right and left edge (10mm for envelope) |

Image gradation |

16 levels |

Print resolution |

600dpi x 600dpi |

First print time |

Black and white printing: 10.2 seconds or less |

|

Color printing: 10.4 seconds or less |

|

|

1-3

Item |

|

Function / Method |

Paper size for the cassette |

Standard sizes: |

|

|

A4, B5, A5, Letter, Executive, 16K |

|

|

Custom paper sizes: |

|

|

• |

Portrait orientation (when the short edges of the |

|

|

paper are parallel to the front side of the printer): |

|

|

Short edges 8.27 to 8.50 in.(210.0 to 215.9 mm); |

|

• |

Long edges 8.27 to 8.50 in.(210.0 to 215.9 mm) |

|

Landscape orientation (when the long edges of the |

|

|

|

paper are parallel to the front side of the printer): |

|

|

Short edges 5.85 to 8.50 in.(148.0 to 215.9 mm); |

|

|

Long edges 8.27 to 11.69 in. (210.0 to 297.0 mm) |

Paper size for the multi-purpose tray |

Standard sizes: |

|

|

A4, B5, A5, Legal, Letter, Executive, Statement, |

|

|

Foolscap, 16K, Envelope DL, Envelope No.10, |

|

|

Envelope ISO-C5, Envelope ISO-B5, Envelope |

|

|

Monarch |

|

|

Custom paper sizes: |

|

|

• |

Portrait orientation (when the short edges of the |

|

|

paper are parallel to the front side of the printer): |

|

|

Short edges 8.27 to 8.50 in.(210.0 to 215.9 mm); |

|

• |

Long edges 8.27 to 8.50 in. (210.0 to 215.9 mm) |

|

Landscape orientation (when the long edges of the |

|

|

|

paper are parallel to the front side of the printer): |

|

|

Short edges 3.87 to 8.50 in.(98.4 to 215.9 mm); |

|

|

Long edges 5.83 to 14.00 in. (148.0 to 355.6 mm) |

Paper type for the cassette |

Plain paper*1 (60 - 105g/m2), Thick paper (106 - 163g/ |

|

|

m2), Colored paper, Coated paper |

|

|

*1: Recycled paper can be used as plain paper. |

|

Paper type for the multi-purpose tray |

Plain paper*2 (60 - 105g/m2), Thick paper (106 - 163g/ |

|

|

m2), Label, Coated paper (100 - 220g/m2), Postcard, |

|

|

Envelope, OHP film (only for monochrome printing) |

|

|

Paper weight: 60 - 216g/m2 (Excl. coated paper) |

|

|

: 105 - 220g/m2 (Coated paper) |

|

|

*2: Recycled paper can be used as plain paper. |

|

Paper type for duplex printing |

Plain paper*3 (60 - 105g/m2), Thick paper (106 - 163g/ |

|

|

m2), Colored paper, Coated paper (120 - 220g/m2) |

|

|

*3: Recycled paper can be used as plain paper. |

|

Capacity of the cassette |

Cassette 1: Approx.250 sheets (80g/m2 paper) |

|

|

Cassette 2 (Option): Approx.500 sheets (80g/m2 paper) |

|

Capacity of the multi-purpose tray |

Cassette 1: Approx.100 sheets (80g/m2 paper) |

|

Duplex method |

Through-pass method |

|

Stack capacity of the delivery tray |

Approx.200 sheets (Plan paper, 80g/m2) |

|

Memory capacity |

256MB (Max. 768MB) |

|

|

|

|

HD capacity |

40GB (When an option is installed) |

|

|

|

1-3 |

1 Product Description > Product Specifications > Host Machine Specifications

|

1 |

Product Description > Product Specifications > Host Machine Specifications |

|||

|

|

|

|

1-4 |

|

|

|

|

|

|

|

|

|

Item |

|

Function / Method |

|

|

Automatic gradation correction |

Enabled |

|

||

|

Temperature range in the use environment |

10 - 30 degree C |

|

||

|

Humidity range in the use environment |

10 - 80%RH |

|

||

|

Operation noise |

Lwad (declared A-weighted sound power level |

|

||

|

|

|

(1B=10dB)) |

|

|

|

|

|

• |

During standby: 5B or less |

|

|

|

|

• |

During operation: 7B or less |

|

|

|

|

Sound pressure level (bysatander position) |

|

|

|

|

|

• |

During standby: 50dB or less |

|

|

|

|

• |

During operation: 53dB(A) or less |

|

|

Rated power voltage |

100V ± 10%, 110-127V ± 10%, 220-240V ± 10% |

|

||

|

|

|

(50/60Hz ± 2Hz) |

|

|

|

Maximum power consumption |

Less than 1305W |

|

||

|

Power consumption |

At standby: Approx. 47W |

|

||

|

|

|

Average during operation: Approx. 573W |

|

|

|

|

|

|

|

|

|

|

|

Average during deep sleep mode: Approx. 1.8W |

|

|

|

Dimension |

517 (W) x 530 (D) x 374 (H) mm |

|

||

|

Weight |

Approx. 31.0kg (Excl. cartridge) |

|

||

|

|

|

|

T-1-2 |

|

1-4

1 Product Description > Product Specifications > Host Machine Specifications

1 Product Description > Detailed Specification > Paper Type

Detailed Specification

Printing Speed

Printing speed of the LBP7750C/5460 machine is shown below. The machine provides the

|

|

Cassette 1 pickup |

Multi-purpose tray |

Cassette 2 pickup |

||||

|

|

|

|

|

|

(option) |

||

|

|

1-sided |

2-sided |

1-sided |

2-sided |

1-sided |

2-sided |

|

|

A4 vertical |

30.0 |

27.6 |

26.9 |

7.5 |

30.0 |

13.8 |

|

Plain paper |

A5 vertical |

31.0 |

- |

28.1 |

- |

31.0 |

- |

|

B5 vertical |

31.0 |

28.9 |

28.1 |

7.7 |

31.0 |

14.4 |

||

(60 to 105 g/m2) |

||||||||

LGL |

- |

- |

23.4 |

6.9 |

25.8 |

7.0 |

||

|

||||||||

|

LTR vertical |

31.0 |

28.9 |

28.1 |

7.7 |

31.0 |

14.4 |

|

|

EXE vertical |

31.0 |

28.9 |

28.1 |

7.7 |

31.0 |

14.4 |

|

|

A4 vertical |

15.0 |

13.7 |

15.0 |

3.7 |

15.0 |

6.8 |

|

Heavy paper |

A5 vertical |

15.8 |

- |

15.7 |

- |

15.8 |

- |

|

B5 vertical |

15.8 |

14.4 |

15.7 |

3.8 |

15.8 |

7.2 |

||

(106 to 120 g/m2) |

||||||||

Rough paper |

LGL |

- |

- |

12.8 |

3.4 |

12.8 |

3.5 |

|

(75 to 90 g/m2) |

|

|

|

|

|

|

|

|

LTR vertical |

15.8 |

14.4 |

15.7 |

3.8 |

15.8 |

7.2 |

||

|

||||||||

|

EXE vertical |

15.8 |

14.4 |

15.7 |

3.8 |

15.8 |

7.2 |

|

|

A4 vertical |

- |

- |

9.5 |

2.5 |

- |

- |

|

|

A5 vertical |

- |

- |

10.0 |

- |

- |

- |

|

Heavy paper |

B5 vertical |

- |

- |

10.0 |

2.5 |

- |

- |

|

(121 to 216 g/m2) |

LGL |

- |

- |

8.2 |

2.3 |

- |

- |

|

|

LTR vertical |

- |

- |

10.0 |

2.5 |

- |

- |

|

|

EXE vertical |

- |

- |

10.0 |

2.5 |

- |

- |

|

Label paper |

|

- |

- |

15.0 |

- |

- |

- |

|

Transparency film |

|

- |

- |

4.0 |

- |

- |

- |

|

Envelope |

|

- |

- |

15.7 |

- |

- |

- |

|

Postcard |

|

- |

- |

10.0 |

- |

10.0 |

- |

|

|

|

|

|

|

|

|

|

|

*1: 2 pages = 1 sheet (2 sided front and back page) |

|

|

|

T-1-3 |

||||

1-5

Paper Type

|

|

|

|

Setup Menu |

|

Paper Source |

|

|||

|

|

Paper Type |

|

[Cassette N (N = 1, 2) |

Multi-purpose |

Cassette 1 |

Cassette 2 |

|||

|

|

|

|

Type] |

|

tray |

|

(Optional) |

||

|

|

|

|

|

|

|

||||

|

|

16.0 to 19.8 lb Bond |

[Plain Paper L] |

*2 |

● |

|

● |

● |

||

Plain |

|

(60 to 74 g/m2) |

|

|

|

|||||

*1 |

|

|

[Plain Paper] |

|

|

|

|

|

||

paper |

18.6 to 27.9 lb Bond |

|

|

|

|

|

||||

|

(Default) |

*2*3 |

|

● |

|

● |

● |

|||

|

|

2 |

|

|

|

|

||||

|

|

(70 to 105 g/m |

) |

[Rough Paper]*6 |

|

|

|

|

||

|

|

26.6 lb Bond to 44.4 |

[Heavy Paper 1]*3*4 |

|

|

|

|

|||

|

|

lb Cover (100 to 120 |

● |

|

● |

● |

||||

|

|

g/m2) |

|

|

|

|

|

|

|

|

Heavy |

30.6 lb Bond to 60.3 |

[Heavy Paper 2]*4 |

|

|

|

|

||||

Paper |

lb Cover (115 to 163 |

○ |

|

○ |

○ |

|||||

|

|

g/m2) |

|

|

|

|

|

|

|

|

|

|

60.4 to 65.1 lb Cover |

[Heavy Paper 2] |

○ |

|

- |

○ |

|||

|

|

(164 to 176 g/m2) |

|

|||||||

Transparency |

|

[Transparencies] |

○ |

|

- |

- |

||||

(black-and-white printing only) |

|

|||||||||

Label |

|

|

|

[Label] |

|

|

○ |

|

- |

- |

Envelope |

|

[Envelope] |

|

○ |

|

- |

- |

|||

*1 Recycled paper can be used as plain paper.

*2 If you want to print paper of 18.6 to 19.8 lb Bond (70 to 74 g/m2), you can specify either of

[Plain Paper] or [Plain Paper L].*5

*3 If you want to print paper of 26.6 to 27.9 lb Bond (100 to 105 g/m2), you can specify either of [Plain Paper] or [Heavy Paper1].*5

*4 If you want to print paper of 30.6 lb Bond to 44.4 lb Cover (115 to 120 g/m2), you can specify either of [Heavy Paper 1] or [Heavy Paper 2].*5

*5 If either setting causes the following problems etc., specify the other setting to print.

•Output paper curls.

•Residual images apperar on non-printed areas.

•The toner does not fix onto paper well, and the printing comes out faint.

*6 Specify [Rough Paper] for this item when a paper jam occurs or when you want to improve the fixation on printing coarse paper (19.9 to 23.9 lb Bond(75 to 90 g/m2)) with [Plain Paper] selected.

1-5

1 Product Description > Detailed Specification > Paper Type

1 Product Description > Detailed Specification > Paper Size

Paper Size

This printer supports the following paper sizes.

|

Paper Size |

|

|

Paper Source |

|

|

||

|

Multi-purpose |

|

|

Cassette 2 |

||||

|

(short edge x long edge) |

Cassette 1 |

||||||

|

tray |

|

(Optional) |

|||||

|

|

|

||||||

A4 (8.27 in. x 11.69 in. (210.0 mm x 297.0 mm)) |

● |

|

● |

● |

||||

B5 (7.17 in. x 10.12 in. (182.0 mm x 257.0 mm)) |

● |

|

● |

● |

||||

A5 (5.83 in. x 8.27 in. (148.0 mm x 210.0 mm)) |

○ |

|

○ |

○ |

||||

|

|

|

|

|

|

|||

Legal (8.50 in. x 14.00 in. (215.9 mm x 355.6 mm)) |

● |

|

- |

● |

||||

|

|

|

|

|

|

|||

Letter (8.50 in. x 11.00 in. (215.9 mm x 279.4 mm)) |

● |

|

● |

● |

||||

Executive (7.25 in. x 10.50 in. (184.2 mm x 266.7 mm)) |

● |

|

● |

● |

||||

Statement (5.50 in. x 8.50 in. (139.7 mm x 215.9 mm)) |

○ |

|

- |

- |

||||

|

|

|

|

|

|

|||

Foolscap (8.50 in. x 13.00 in. (215.9 mm x 330.2 mm)) |

● |

|

- |

● |

||||

|

|

|

|

|

|

|||

16K (7.68 in. x 10.63 in. (195.0 mm x 270.0 mm)) |

● |

|

● |

● |

||||

Custom paper size |

○ |

*5 |

|

○ |

*6 |

○ |

*6 |

|

Portrait*1 *3 |

|

|

|

|

||||

Custom paper size |

● |

*7 |

|

● |

*8 |

● |

*9 |

|

Landscape*2 *4 |

|

|

|

|

||||

|

Envelope Monarch |

○ |

|

- |

- |

|||

|

(3.87 in. x 7.50 in. (98.4 mm x 190.5 mm)) |

|

||||||

|

|

|

|

|

|

|

|

|

|

Envelope No.10 |

○ |

|

- |

- |

|||

|

(4.12 in. x 9.50 in. (104.7 mm x 241.3 mm)) |

|

||||||

|

|

|

|

|

|

|

|

|

Envelope |

Envelope DL |

○ |

|

- |

- |

|||

(4.33 in. x 8.66 in. (110.0 mm x 220.0 mm)) |

|

|||||||

|

Envelope ISO-C5 |

○ |

|

- |

- |

|||

|

(6.38 in. x 9.02 in. (162.0 mm x 229.0 mm)) |

|

||||||

|

|

|

|

|

|

|

|

|

|

Envelope ISO-B5 |

○ |

|

- |

- |

|||

|

(6.93 in. x 9.84 in. (176.0 mm x 250.0 mm)) |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T-1-5 |

*1 Portrait: The short edges of the paper are parallel to the front side of the printer. *2 Landscape: The long edges of the paper are parallel to the front side of the printer. *3 Can be loaded only when the UFR II printer driver is used.

*4 Automatic 2-sided printing can be performed on the custom size paper whose short edges are 7.17 to 8.50 in. (182.0 to 215.9 mm) and long edges are 10.12 to 11.69 in. (257.0 to 297.0 mm).

1-6

*5 The custom size paper whose short edges are 5.83 to 8.50 in. (148.0 to 215.9 mm) and long edges are 5.83 to 8.50 in. (148.0 to 215.9 mm) can be loaded.

*6 The custom size paper whose short edges are 8.27 to 8.50 in. (210.0 to 215.9 mm) and long edges are 8.27 to 8.50 in. (210.0 to 215.9 mm) can be loaded.

*7 The custom size paper whose short edges are 3.87 to 8.50 in. (98.4 to 215.9 mm) and long edges are 5.83 to 14.00 in. (148.0 to 355.6 mm) can be loaded.

*8 The custom size paper whose short edges are 5.83 to 8.50 in. (148.0 to 215.9 mm) and long edges are 8.27 to 11.69 in. (210.0 to 297.0 mm) can be loaded.

*9 The custom size paper whose short edges are 5.83 to 8.50 in. (148.5 to 215.9 mm) and long edges are 8.27 to 14.00 in. (210.0 to 355.6 mm) can be loaded.

1-6

1 Product Description > Detailed Specification > Paper Size

1 Product Description > Parts Name > External View > Back View of the Printer

Caution :

Be sure not to cover the vent with a wall or an article. If it is covered, the inside of the printer becomes hot, which may cause a fire.

External View

■

[4] [5]

[1]

[6]

1-7

■ Back View of the Printer

[1] |

[10] |

|

|

||

[2] |

|

|

[3] |

|

|

[4] |

|

|

[5] |

|

|

[6] |

[8] |

|

[7] |

||

|

[8] |

[9] |

[11]

[12]

|

|

|

[7] |

|

[2] |

|

[8] |

|

[3] |

|

[9] |

|

|

|

|

|

|

|

F-1-2 |

[1] |

Power switch |

[6] |

Right cover |

[2] |

Front cover |

[7] |

Vent |

[3] |

Cassette |

[8] |

Multi-purpose tray |

[4] |

Control Panel |

[9] |

Grip |

[5]Delivery tray

F-1-3

[1] |

Slot cover |

[8] |

Grip |

[2] |

USB connector |

[9] |

Rated voltage label |

[3] |

LAN connector |

[10] |

Vent |

[4] |

LNK/ACT lamp (green) |

[11] |

Grounding wire terminal |

[5] |

10/100 lamp (green) |

[12] |

Power cord slot |

[6]Hard disk slot

[7]Extended board slot

1-7

1 Product Description > Parts Name > External View > Back View of the Printer

1 Product Description > Parts Name > Cross Section View

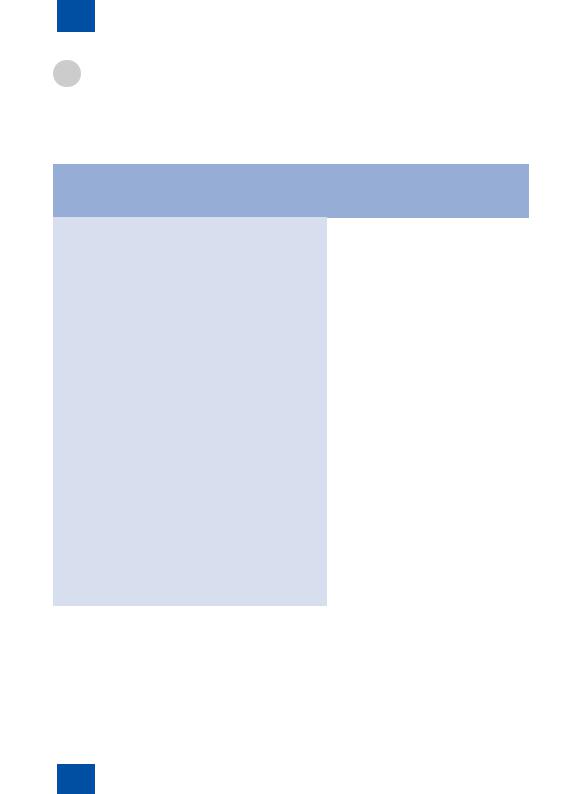

■ Inside of the Printer

[2] [3] [4] [5]

[6] |

[7] |

[1] |

[8] |

|

F-1-4

[1]Waste toner container

[2]Y (Yellow) toner cartridge

[3]M (Magenta) toner cartridge

[4]C (Cyan) toner cartridge

[5]K (Black) toner cartridge

[6]Fixing assembly

[7]ITB (Intermediate Transfer Belt) unit

[8]Secondary transfer external roller

1-8

Cross Section View

|

|

[1] [2] |

[3] [4] [5] [6] [7] [8] |

|

|

|

[9] |

|

|

|

[10] |

|

|

|

[11] |

|

|

|

[12] |

|

|

|

[13] |

|

|

|

[14] |

|

|

|

[15] |

|

|

|

[16] |

[25] |

[24] |

[23] |

[22][21][20][19][18] [17] |

|

|

|

F-1-5 |

[1]ITB unit

[2]Primary transfer roller

[3]Delivery roller 2

[4]Duplex reverse roller

[5]Duplex flapper

[6]Delivery roller 1

[7]Pressure roller

[8]Fixing assembly

[9]Fixing sleeve unit

[10]Duplex feed roller

[11]Secondary transfer outer roller

[12]ITB drive roller

[13]Color displacement/density sensor

[14]OHT sensor

[15]Registration shutter

[16]Multi-purpose tray pickup roller

[17]Multi-purpose tray separation pad

[18]Duplex re-pickup roller

[19]Registration roller

[20]Feed roller

[21]Cassette separation roller

[22]Cassette pickup roller

[23]Photosensitive drum

[24]Toner cartridge

[25]Laser scanner unit

1-8

1 Product Description > Parts Name > Cross Section View

1 Product Description > Operation > Control Panel > Lamp |

|

|

|

|

|

||||

Operation |

|

|

|

|

■ |

|

|

|

|

|

|

|

|

|

|

No. |

Name |

|

Condition |

Control Panel |

|

|

|

[1] |

Online |

Lighting |

The printer is in the on-line condition (Print data can be |

||

|

|

|

|

|

|

|

(Green) |

|

received from the computer in this condition). |

The control panel consists of lamps and displays showing the printer condition and operation |

|

|

When the printer is placed in the sleep mode, the on-line lamp |

||||||

keys. |

|

|

|

|

|

|

|

|

lights off even if the printer is in the on-line condition. |

|

|

|

|

|

[4] |

Pickup origination |

Lighting |

The pickup assembly is selected. |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

display (Green) |

Flashing |

No paper is set and printing cannot be performed. |

|

|

|

|

|

|

|

|

||

[1] |

[2] |

[4] |

[5] |

[11] |

[13] |

[16] |

|

|

The pickup cassette is not installed. |

|

|

|

|

|

|

|

|

|

(When the multi-purpose tray is used, the lamp lights up even |

|

|

|

|

|

|

|

|

|

when no paper is set.) |

|

|

Job |

|

[6] |

Printable |

Lighting |

Printing can be performed. |

Cancel Job |

|

|

|

|

|

|

|

Online |

|

Utility |

Settings |

Power |

|

Flashing |

Preparation for printing or calibration is performed. |

|

|

|

|

||||

Feeder Selection |

|

|

|

[7] |

Message |

Lighting |

A trouble occurred and printing cannot be performed. |

|

|

Back |

|

||||

|

|

|

Main Power |

(Orange) |

|

(When the printer is placed in the sleep mode in the off- |

|

Ready Message |

|

|

|

|

|||

Job |

Reset |

|

|

|

|

line condition, the message lamp lights up even if no trouble |

|

|

|

|

|

|

|

|

occurs.) |

[8] HDD (Green)

[3] |

[6] |

[7] |

[8] |

[9] |

[10] |

[12] |

[14] |

[15] |

[17] |

[9] |

Job |

Lighting Data is being received. |

|

|

|

|

|

|

|

|

|

|

|

(Green) |

Data remains in the printer memory. |

|

|

|

F-1-6 |

|

Flashing Data processing is being performed. |

|

[1] |

Online indicator / key |

[10] |

Utility key |

|

||

[17] Main power |

Lighting The power is turned on. |

|||||

[2] |

Job confirmation / cancel key |

[11] |

Job key |

|||

(Green) |

|

|||||

[3] |

Pickup selection key |

[12] |

Return key |

|

||

|

T-1-6 |

|||||

[4] |

Pickup origination display lamp |

[13] |

OK key |

|

||

|

|

|||||

[5] |

Control panel display |

[14] |

Reset key |

|

|

|

[6] |

Printable lamp |

[15] |

Setup key |

|

|

|

[7] |

Message lamp |

[16] |

Control panel power switch (Sub power) |

|

|

|

[8] |

HDD lamp |

[17] |

Main power lamp (Green) |

|

|

[9]Job lamp

1-9

1 Product Description > Operation > Control Panel > Lamp

1 Product Description > Operation > Control Panel > Control Panel Key

■ Control Panel Key

No. |

Name |

|

Function |

[1] |

On-line |

The on-line and off-line conditions are switched. When the key lights up, |

|

|

|

the printer is placed in the on-line condition. When the key lights off, the |

|

|

|

printer is in the off-line condition. |

|

[2] |

Job |

On-line |

When this key is pressed in the condition where |

|

confirmation/cancel |

Off-line |

the job lamp lights up or flashes (data processing |

|

|

|

being performed/data being received), a list of |

|

|

|

jobs is displayed. You can select a job from the |

|

|

|

list and cancel it. |

|

|

Displaying the menu |

Not available |

[3] |

Pickup selection |

On-line |

The pickup selection menu is displayed. The |

|

|

|

setting of whether printing is performed from the |

|

|

Off-line |

|

|

|

pickup cassette or the multi-purpose tray, or that |

|

|

|

|

|

|

|

|

of the paper size is made. |

|

|

Displaying the menu |

Not available |

[10] |

Utility |

On-line |

The utility menu is displayed. Internal information |

|

|

|

such as current setting of the printer, etc., is |

|

|

|

printed. |

|

|

Off-line |

Not available |

|

|

Displaying the menu |

The printer returns to the previous level. |

|

|

|

|

[11] |

Job |

On-line |

The job menu is displayed. Operation of jobs |

|

|

|

saved in Secure Print or Box and various list of |

|

|

|

operation history are printed. |

|

|

Off-line |

Not available |

|

|

|

|

|

|

Displaying the menu |

An upper item in the same level is selected. |

|

|

|

When a numeric value is selected, the value |

|

|

|

increases. When the key is kept pressed, the |

|

|

|

speed of increasing the value becomes faster for |

|

|

|

some items. |

[12] |

Return |

On-line |

Not available |

|

|

|

|

|

|

Off-line |

|

|

|

|

|

|

|

Displaying the menu |

The printer returns to the previous level. |

[13] |

OK |

On-line |

Not available |

|

|

Off-line |

|

|

|

|

|

|

|

Displaying the menu |

The selected item is executed. Or, the printer |

|

|

|

goes to the next level. |

1-10

No. |

|

Name |

|

Function |

[14] |

Reset |

|

On-line |

The reset menu is displayed. Printer reset |

|

|

|

|

operation, discharging of printing data, and |

|

|

|

Off-line |

|

|

|

|

shutdown operation are performed. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Displaying the menu |

The lower item in the same level is selected. |

|

|

|

|

When a numeric value is selected, the value |

|

|

|

|

decreases. When the key is kept pressed, the |

|

|

|

|

speed of decreasing the value becomes faster for |

|

|

|

|

some items. |

[15] |

Setup |

|

On-line |

The setup menu is displayed. The printing |

|

|

|

Off-line |

environment such as layout adjustment or |

|

|

|

enlargement/reduction can be set. |

|

|

|

|

|

|

|

|

|

Displaying the menu |

The selected item is executed. Or, the printer |

|

|

|

|

goes to the next level. |

[16] |

Power |

|

When "Sleep Mode" is set to other items than "Not used", the printer is |

|

|

|

|

placed in the sleep mode. |

|

|

|

|

|

T-1-7 |

1-10

1 Product Description > Operation > Control Panel > Control Panel Key

1 Product Description > Operation > Setup Menu > Control Menu Options

■

|

Setting |

Setting Value |

Job Menu |

Encrypted Print*1 |

- |

|

Secured Print*1 |

- |

|

Stored Job List*1 |

- |

|

Stored Job Print*1 |

- |

|

Job Print Log List |

- |

|

Stored Job Print Log*1 |

- |

|

Report Print Log |

- |

|

E-mail Print Log |

- |

|

|

|

T-1-8

• Items and setting values with "*1" may not be displayed depending on the model, presence/ absence of options, or contents of other setting items.

1-11

■

|

Setting |

|

Setting Value |

|

Power Save Mode |

[On]*, [Deep Sleep], [Off], [Panel Off] |

|||

Power Save in Error |

[On]*, [Off] |

|||

Power Save Time |

|

|

||

|

When not using a hard disk |

[1 minute]*, [5 minutes], [10 minutes], [15 minutes], |

||

|

[30 minutes], [60 minutes], [180 minutes] |

|||

|

|

|||

When using a hard disk |

[5 minutes]*, [10 minutes], [15 minutes], [30 minutes], |

|||

|

||||

|

[60 minutes], [180 minutes] |

|||

|

|

|||

|

|

|

|

|

Timer Settings |

|

|

||

|

|

|

||

|

Wake Up Timer |

[Off]*, [On] |

||

|

|

• |

When [AM/PM] is selected in [12/24 Hour Clock]: |

|

|

Wake Up Time |

• |

00:00:00 AM/PM to 11:59:59 AM/PM |

|

|

When [24 Hour] is selected in [12/24 Hour Clock]: |

|||

|

|

|||

|

|

|

00:00:00 to 23:59:59 |

|

|

Power Save Timer |

[Off]*, [On] |

||

|

|

• |

When [AM/PM] is selected in [12/24 Hour Clock]: |

|

Power Save Time |

• |

00:00:00 AM/PM to 11:59:59 AM/PM |

||

|

When [24 Hour] is selected in [12/24 Hour Clock]: |

|||

|

|

|||

|

|

|

00:00:00 to 23:59:59 |

|

|

|

|

||

|

Calibration Timer |

[Off]*, [On] |

||

|

|

• |

When [AM/PM] is selected in [12/24 Hour Clock]: |

|

|

Calibration Time |

• |

00:00:00 AM/PM to 11:59:59 AM/PM |

|

|

When [24 Hour] is selected in [12/24 Hour Clock]: |

|||

|

|

|||

|

|

|

00:00:00 to 23:59:59 |

|

Warning Step |

|

|

||

|

Check Toner |

[Continue Printing]*, [Stop Printing] |

||

Auto Error Skip |

[Off]*, [On] |

|||

Panel Language |

[English]*, [Español], [Français], [Italiano], [Deutsch] |

|||

Alarm |

|

[On]*, [Off] |

||

Show Warnings |

|

|

||

|

|

|

||

|

Check Toner |

[On]*, [Off] |

||

|

Check Waste Tnr Ctn |

[On]*, [Off] |

||

Cassette Empty |

[On]*, [Off] |

|||

|

||||

|

E-mail Trans. Error |

[On]*, [Off] |

||

1-11

1 Product Description > Operation > Setup Menu > Control Menu Options

1 Product Description > Operation > Setup Menu > Paper Source Menu Options

|

Setting |

|

Setting Value |

|

Date and Time |

|

|

||

|

|

|

||

|

Date Settings |

01/01/2001 to 31/12/2089 |

||

|

12/24 Hour Clock |

[AM/PM]*, [24 Hour] |

||

|

|

• |

When [AM/PM] is selected in [12/24 Hour Clock]: |

|

|

Time Settings |

• |

00:00:00 AM/PM to 11:59:59 AM/PM |

|

|

When [24 Hour] is selected in [12/24 Hour Clock]: |

|||

|

|

|||

|

|

|

00:00:00 to 23:59:59 |

|

|

|

|

||

|

[DST Settings]: [Off]*, [On] |

|||

|

|

|||

|

|

[Start Date and Time]: |

||

|

Daylight Saving Time |

<Month>, <Week>, <Day>, <Time Settings> |

||

|

|

[End Date and Time]: |

||

|

|

<Month>, <Week>, <Day>, <Time Settings> |

||

|

Time Zone |

GMT-12 to GMT+12 |

||

Hard Disk*1 |

[On]*, [Off] |

|||

Interrupt Print*1 |

[On]*, [Off] |

|||

Securing Time*1 |

[1 hour]*, [2 hours], [3 hours], [6 hours], [12 hours], |

|||

|

|

[24 hours] |

||

Secured Type*1 |

[Image]*, [PDL]*1 |

|||

RIP Once*1 |

[On]*, [Off] |

|||

Assure Job Log*1 |

[Off]*, [On] |

|||

PDL Select (PnP)*1 |

[UFR II]*, [PCL5C], [PCL6], [PS3]*1 |

|||

Adjust Screen |

|

|

||

|

Contrast |

-3 to 0* to +3 |

||

Backlight Brightness |

[Level 3]*, [Off], [Level 1], [Level 2] |

|||

|

||||

Animated Instruction |

[On]*, [Off] |

|||

Show Toner Gauge |

[On]*, [Off] |

|||

T-1-9

• Items and setting values with "*1" may not be displayed depending on the model, presence/ absence of options, or contents of other setting items.

• Setting values with "*" are factory setting values.

1-12

■ Paper Source Menu Options

|

Setting |

Setting Value |

MP Tray Paper Size |

[LTR]*, [LGL], [EXEC], [Mixed Sizes], [Custom Size], [Custom Size R], |

|

|

|

[ENV. ISOC5], [ENV. No.10], [ENV. C.G. No.8], |

|

|

[ENV. DL], [ENV. ISO-B5], [STMT], [FLSC], [16K], [A5], [B5], [A4] |

MP Tray Priority |

[Off]*, [On] |

|

Cassette 1 Size |

[LTR]*, [EXEC], [Mixed Sizes], [Custom Size], [Custom Size R], [16K], |

|

|

|

[A5], [B5],[A4] |

Cassette 2 Size*1 |

[Auto]*, [Custom Size], [Custom Size R], [16K], [Mixed Sizes] |

|

Standard Paper Size |

[LTR]*, [LGL], [EXEC], [ENV. ISO-C5], [ENV. No.10], [ENV. C.G. No.8], |

|

|

|

[ENV. DL], [ENV. ISO-B5], [STMT], [FLSC], [16K], [A5], [B5], [A4] |

Invalid Paper Tray |

[Off]*, [On] |

|

Auto Selection |

|

|

|

Multi-purpose Tray |

[On]*, [Off] |

|

Cassette 1 |

[On]*, [Off] |

|

Cassette 2*1 |

[On]*, [Off] |

Standard Paper Type |

[Plain Paper]*, [Plain Paper L], [Heavy Paper 1], [Heavy Paper 2], |

|

|

|

[Transparencies], [Envelope], [Coated Paper 1], [Coated Paper 2], |

|

|

[Coated Paper 3], [Label], [Rough Paper] |

MP Tray Paper Type |

[Mixed Types]*, [Plain Paper], [Plain Paper L], [Heavy Paper 1], |

|

|

|

[Heavy Paper 2], [Transparencies], [Envelope], [Coated Paper 1], |

|

|

[Coated Paper 2], [Coated Paper 3], [Label], [Rough Paper] |

Cassette 1 Type |

[Mixed Types]*, [Plain Paper], [Plain Paper L], [Heavy Paper 1], |

|

|

|

[Heavy Paper 2], [Coated Paper 1], [Coated Paper 2], [Rough Paper] |

|

|

|

Cassette 2 Type*1 |

[Mixed Types]*, [Plain Paper], [Plain Paper L], [Heavy Paper 1], |

|

|

|

[Heavy Paper 2], [Transparencies], [Coated Paper 1], [Coated Paper 2], |

|

|

[Coated Paper 3], [Label], [Rough Paper] |

Manual 2-Sided |

[1st Side]*, [2nd Side] |

|

2-Sided Printing |

[Off]*, [On] |

|

T-1-10

• Items and setting values with "*1" may not be displayed depending on the model, presence/ absence of options, or contents of other setting items.

• Setting values with "*" are factory setting values.

1-12

1 Product Description > Operation > Setup Menu > Paper Source Menu Options

1 Product Description > Operation > Setup Menu > Standard Network Menu Options

■ Standard Network Menu Options

|

Setting |

Setting Value |

|

TCP/IP Settings |

|

|

|

|

IP v.4 Settings |

IP Mode |

[Manual]*, [Auto] |

|

|

Protocol*1 |

Use DHCP: [Off]*, [On] |

|

|

|

Use BOOTP: [Off]*, [On] |

|

|

|

Use RARP: [Off]*, [On] |

|

|

IP Address Settings*1 |

IP Address: 0.0.0.0 |

|

|

|

Subnet Mask: 0.0.0.0 |

|

|

|

Gateway Address: 0.0.0.0 |

|

|

|

|

|

|

IP Address Range |

Reject Receive/Print: [Off]*, [On] |

|

|

|

Reject Address Set.*1: Reject IP address 1 to 8 |

|

|

|

Permit Receive/Print: [Off]*, [On] |

|

|

|

Permit Address Set.*1: Permit IP address 1 to 8 |

|

|

|

Reject Set/Browse: [Off]*, [On] |

|

|

|

Reject Address Set.*1: Reject IP address 1 to 8 |

|

|

|

Permit Set/Browse: [Off]*, [On] |

|

|

|

Permit Address Set.*1: Permit IP address 1 to 8 |

|

|

DNS |

Primary Address: 0.0.0.0 |

|

|

|

|

|

|

|

Secondary Address: 0.0.0.0 |

|

IP v.6 Settings |

|

IPv6: [Off]*, [On] |

|

WINS Resolution |

|

[Off]*, [On] |

|

ARP/PING |

|

[On]*, [Off] |

|

FTP |

FTP Print |

[Off]*, [On] |

|

|

FTP Settings |

[Off]*, [On] |

|

LPD Print |

|

[On]*, [Off] |

|

RAW Print |

|

[On]*, [Off] |

|

IPP Print |

|

[On]*, [Off] |

|

WSD |

WSD Print |

[On]*, [Off] |

|

|

WSD Browsing*1 |

[On]*, [Off] |

|

|

Multicast Discovery |

[On]*, [Off] |

|

HTTP |

|

[On]*, [Off] |

1-13

|

Setting |

Setting Value |

||

|

Proxy Settings*1 |

|

Proxy |

[Off]*, [On] |

|

|

|

Server Address |

- |

|

|

|

Port Number |

0 to 80* to 99999 |

|

|

|

Same Domain |

Do Not Use Proxy*, Use Proxy |

|

|

|

Proxy Authentication |

[Off]*, [On] |

|

|

|

User Name |

- |

|

|

|

Password |

- |

|

SNTP |

|

[Off]*, [On] |

|

|

Response |

|

[On]*, [Off] |

|

|

|

|

|

|

|

MAC Address |

|

Permit Receive |

[Off]*, [On] |

|

Settings |

|

|

|

|

|

Permit Address |

Permit MAC Add. 1 to Permit MAC Add. 50 |

|

|

|

|

||

|

|

|

Set.*1 |

|

|

NetWare Settings |

|

[NetWare]: [Off]*, [On] |

|

|

|

|

|

[Frame Type]: [Auto Detect]*, [Ethernet II], [Ethernet |

|

|

|

|

802.2], [Ethernet 802.3], [Ethernet SNAP] |

|

|

|

|

[Print Service]: [NDS PServer]*, [NPrinter], [Bindery |

|

|

|

|

PServer], [RPrinter] |

AppleTalk |

|

[Off]*, [On] |

||

SMB |

|

|

|

|

|

|

|

|

|

|

SMB Server |

|

[Off]*, [On] |

|

|

SMB*1 |

|

[Off]*, [On] |

|

SNMP v.1 |

|

[On]*, [Off] |

||

SNMP v.3 Settings |

|

|

||

|

SNMP v.3 |

|

[Off]*, [On] |

|

|

User Settings 1 to User Settings 5*1 |

Authent. Password |

||

|

|

|

|

Encryption Password |

Spooler*1 |

|

[Off]*, [On] |

||

Start Wait Time*1 |

|

0* to 300 |

||

Remote UI Settings |

|

|

||

|

|

|

|

|

|

Remote UI |

|

[On]*, [Off] |

|

|

SSL |

|

[Off]*, [On]*1 |

|

Ethernet Driver*1 |

|

|

||

|

Auto Detect |

|

[On]*, [Off] |

|

|

Communication Mode*1 |

[Half Duplex]*, [Full Duplex] |

||

|

Ethernet Type*1 |

|

[10 Base-T]*, [100 Base-TX] |

|

1-13

1 Product Description > Operation > Setup Menu > Standard Network Menu Options

1 Product Description > Operation > Setup Menu > Quality Menu Options

|

Setting |

Setting Value |

MAC Address*1 |

(Display only) |

|

E-Mail Print Set. |

|

|

|

POP3 Interval |

0* to 90 |

|

POP3 Receive |

[Off]*, [On] |

|

SMTP Receive |

[Off]*, [On] |

Initialize Network |

- |

|

T-1-11

• Items and setting values with "*1" may not be displayed depending on the model, presence/ absence of options, or contents of other setting items.

• Setting values with "*" are factory setting values.

■ Layout Menu Options

Setting |

Setting Value |

|

|

Copies |

1* to 9999 |

Offset Y |

-1.97 to 0.0* to 1.97 (in.) |

Offset X |

-1.97 to 0.0* to 1.97 (in.) |

Binding Location |

[Long Edge]*, [Short Edge] |

Gutter |

-1.97 to 0.0* to 1.97 (in.) |

Alternative Method |

[Off]*, [On] |

T-1-12

• Items and setting values with "*1" may not be displayed depending on the model, presence/ absence of options, or contents of other setting items.

• Setting values with "*" are factory setting values.

■ Quality Menu Options

Setting |

Setting Value |

Gradation Level |

[High 1]*, [High 2] |

Toner Save |

[Off]*, [On] |

Density: Cyan |

-8 to 0* to +7 |

Density: Magenta |

-8 to 0* to +7 |

Density: Yellow |

-8 to 0* to +7 |

Density: Black |

-8 to 0* to +7 |

Color Mode |

[Auto]*, [Color], [Black and White] |

1-14

|

Setting |

|

Setting Value |

Halftones |

|

|

|

|

|

|

|

|

B & W Halftones |

Text |

[Resolution]*, [Gradation], [Color Tone], |

|

|

|

[High Resolution], [Error Diffusion] |

|

|

Graphics |

[Gradation]*, [Color Tone], [High Resolution], |

|

|

|

[Error Diffusion], [Resolution] |

|

|

Image |

[Gradation]*, [Color Tone], [High Resolution], |

|

|

|

[Error Diffusion], [Resolution] |

|

Color Halftones |

Text |

[Resolution]*, [Gradation], [Color Tone], |

|

|

|

[High Resolution], [Error Diffusion] |

|

|

Graphics |

[Color Tone]*, [High Resolution], [Error Diffusion], |

|

|

|

[Resolution], [Gradation] |

|

|

Image |

[Color Tone]*, [High Resolution], [Error Diffusion], |

|

|

|

[Resolution], [Gradation] |

Gray Compensation |

|

|

|

|

|

|

|

|

Text |

|

[On]*, [Off] |

|

Graphics |

|

[On]*, [Off] |

|

Image |

|

[On]*, [Off] |

CMS |

|

|

|

|

CMS Selection |

|

[Printer]*, [Host] |

|

CMS/Gamma |

Text |

[CMS]*, [Gamma] |

|

|

Graphics |

[CMS]*, [Gamma] |

|

|

Image |

[CMS]*, [Gamma] |

|

RGB Source Profile |

Text |

[sRGB_v1.31]*, [HDTV_gamma_1.5], |

|

|

|

[HDTV_gamma_1.8], [HDTV_gamma_2.4], |

|

|

|

[Download Profile]*1 |

|

|

Graphics |

[sRGB_v1.31*, HDTV_gamma_1.5], |

|

|

|

[HDTV_gamma_1.8], [HDTV_gamma_2.4], |

|

|

|

[Download Profile]*1 |

|

|

Image |

[sRGB_v1.31]*, [HDTV_gamma_1.5], |

|

|

|

[HDTV_gamma_1.8], [HDTV_gamma_2.4], |

|

|

|

[Download Profile]*1 |

|

Output Profile |

Text |

[Normal]*, [Photo] |

|

|

Graphics |

[Normal]*, [Photo] |

|

|

Image |

[Photo]*, [Normal] |

|

Matching Method |

Text |

[Saturation]*, [Colorimetric], [Perceptual] |

|

|

Graphics |

[Perceptual]*, [Saturation], [Colorimetric] |

|

|

Image |

[Perceptual]*, [Saturation], [Colorimetric] |

1-14

1 Product Description > Operation > Setup Menu > Quality Menu Options

1 Product Description > Operation > Setup Menu > User Maintenance Options

|

Setting |

|

Setting Value |

|

Gamma |

Text |

[1.4]*, [1.8], [2.2], [1.0] |

|

|

Graphics |

[1.4]*, [1.8], [2.2], [1.0] |

|

|

Image |

[1.4]*, [1.8], [2.2], [1.0] |

Gradation Settings |

|

|

|

|

|

|

|

|

Gradation |

|

[Off]*, [Smooth 1], [Smooth 2] |

|

Graphics*1 |

|

[On]*, [Off] |

|

Image*1 |

|

[On]*, [Off] |

Advanced Smoothing |

|

|

|

|

Advanced Smoothing |

|

[Smooth 1]*, [Smooth 2], [Off] |

|

Graphics*1 |

|

[Off]*, [On] |

|

Text*1 |

|

[On]*, [Off] |

Toner Volume Adjust |

|

[Normal]*, [Gradation [Priority], [Text Priority] |

|

Line Control |

|

[Resolution [Priority]*, [Gradation Priority] |

|

Quality Change |

|

[Continue Printing]*, [Stop Printing] |

|

T-1-13

• Items and setting values with "*1" may not be displayed depending on the model, presence/ absence of options, or contents of other setting items.

• Setting values with "*" are factory setting values.

■ Interface Menu Options

|

Setting |

Setting Value |

|

Interface Connection |

|

USB |

[On]*, [Off] |

|

|

Network |

[On]*, [Off] |

Mode Timeout |

|

|

[On]*, [Off] |

Time*1 |

|

|

5 to 15* to 300 seconds |

Extension Card*1 |

|

|

- |

Connection Recog. |

|

|

[On]*, [Off] |

Extended RX Buffer*1 |

|

|

[Off]*, [On] |

T-1-14

• Items and setting values with "*1" may not be displayed depending on the model, presence/ absence of options, or contents of other setting items.

• Setting values with "*" are factory setting values.

1-15

■ User Maintenance Options

|

Setting |

Setting Value |

Adj. Start Position |

|

|

|

Offset Y (MP Tray) |

-0.20 to 0.0* to 0.20 (in.) |

|

Offset X (MP Tray) |

-0.09 to 0.0* to 0.09 (in.) |

|

Offset Y (Cass. 1) |

-0.20 to 0.0* to 0.20 (in.) |

|

Offset X (Cass. 1) |

-0.09 to 0.0* to 0.09 (in.) |

|

Offset Y (Cass. 2)*1 |

-0.20 to 0.0* to 0.20 (in.) |

|

Offset X (Cass. 2)*1 |

-0.09 to 0.0* to 0.09 (in.) |

|

Offset Y (Duplex) |

-0.20 to 0.0* to 0.20 (in.) |

|

Offset X (Duplex) |

-0.09 to 0.0* to 0.09 (in.) |

Recovery Printing |

[On]*, [Off] |

|

Check Paper Size |

[Off]*, [On] |

|

Substitute Size |

[Off]*, [On] |

|

Special Image Mode |

[Off]*, [Level 1], [Level 2] |

|

HDD Maintenance*1 |

|

|

|

HDD Data All Erase |

[Off]*, [On] |

|

Quick Format*1 |

- |

|

Standard Format |

- |

Special Print Mode |

|

|

|

Curl Adjustment |

[Off]*, [On] |

Update Firmware |

|

|

|

|

|

USB |

- |

|

|

Standard Network |

- |

1st Calibration |

[After Jobs]*, [Immediately] |

|

Paper Feed Method |

|

|

|

|

|

|

Multi-purpose Tray |

[Speed Priority]*, [Print Side Priority] |

|

Cassette 1 |

[Speed Priority]*, [Print Side Priority] |

|

Cassette 2*1 |

[Speed Priority]*, [Print Side Priority] |

Adjust Temp.Standby |

[Off]*, [On] |

|

T-1-15

• Items and setting values with "*1" may not be displayed depending on the model, presence/ absence of options, or contents of other setting items.

• Setting values with "*" are factory setting values.

1-15

1 Product Description > Operation > Setup Menu > User Maintenance Options

1 Product Description > Operation > Utility Menu

■ Print Mode Options

|

Setting |

Setting Value |

|

|

|

Mode Selection |

[Auto Selection]*, [PCL], [PS]*1, [PDF]*1 |

|

|

|

|

Auto Switch |

|

|

|

|

|

|

PCL |

[On]*, [Off] |

|

PS*1 |

[On]*, [Off] |

|

PDF*1 |

[On]*, [Off] |

Mode Priority |

[None]*, [PCL], [PS]*1, [PDF]*1 |

|

T-1-16

•Items and setting values with "*1" may not be displayed depending on the model, presence/ absence of options, or contents of other setting items.

•Setting values with "*" are factory setting values.

|

|

1-16 |

|

|

|

|

Setting |

Setting Value |

Configuration Page |

- |

|

Network Status Print |

- |

|

Calibration |

[Color Regis. Adjust.], [Density Control], [Density Median Cont.], |

|

|

|

[Full Calibration] |

PCL Utility |

[Fonts List] |

|

PS Utility*1 |

[Status Print], [Fonts List] |

|

Cleaning |

[A4]*, [LTR] |

|

Extension Card List*1 |

- |

|

E-mail Utility |

[Receive E-mails], [Receive Log List] |

|

Printing Pos. Print |

- |

|

Page Count List |

- |

|

Serial Number |

- |

|

|

|

|

Consumables |

[Paper Information], [Cartridge], [Remaining Toner], [Waste Toner |

|

|

|

cntnr], [Waste Toner Status] |

• |

|

T-1-17 |

Items and setting values with "*1" may not be displayed depending on the model, presence/ |

||

|

absence of options, or contents of other setting items. |

|

• |

Setting values with "*" are factory setting values. |

|

1-16

1 Product Description > Operation > Utility Menu

|

1 |

Product Description > Operation > Select Feeder Menu |

|

|

|

1-17 |

|