Page 1

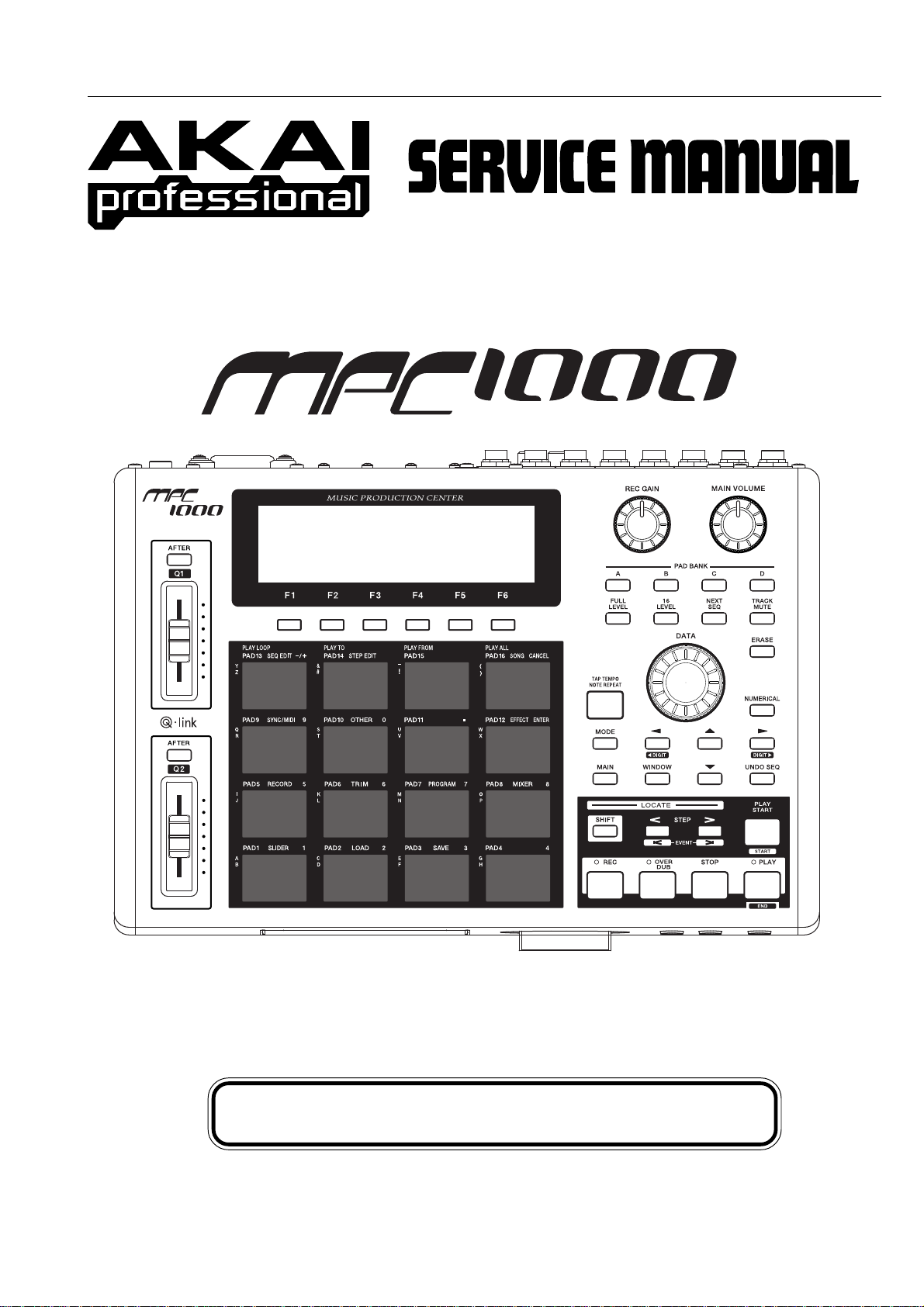

Music production Center

SERVICE MANUAL

1

Page 2

SAFETY INSTRUCTIONS

INFORMATIONS

1. Parts identified by the symbol are critical for safety.

Replace them only with the parts number specified.

2. In addition to safety, other parts and assemblies are

specified for conformance with such regulations as those

applying to spurious radiation.

These must also be replaced only with the specified

replacements.

Examples : Noise blocking capacitors, noise blocking filters,

etc.

3. Use specified internal wiring. Note especially :

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

4. Use specified insulating materials for hazardous live parts.

Note especially :

1) Insulation Tape

2) PVC tubing

3) Spacers (insulating barriers)

4) Insulation sheets for transistors

5) Plastic screws for fixing micro switches

5. When replacing AC primary side components (transformers, power cords, noise blocking capacitors, etc.),

wrap the ends of the wires securely around the terminals

before soldering.

SYMBOLS FOR PRIMARY DESTINATION

Unit destinations are indicated with letters as shown below.

Symbols Principal Destinations

A U.S.A

B England

E Europe

J Japan

V

X1

X4

MAKE YOUR CONTRIBUTION TO PROTECT THE

ENVIRONMENT

Used batteries with the ISO symbol for recycling as

well as small accumulators (rechargeable batteries),

mini-batteries (cells) and starter batteries should not

be thrown into the garbage can.

Please leave them at an appropriate depot.

PRECAUTIONS FOR LITHIUM BATTERY

The lithium battery may explode when

[OBSERVE THE FOLLOEING WHEN REPLACING]

Germany

Japan

Universal Area

incorrectly replaced.

6. Make sure that wires do not contact heat producing parts

(heat sinks, oxide metal film resistors, fusible resistors,

etc.).

7. Check that replaced wires do not contact sharp edged or

pointed parts.

8. Also check areas surrounding repaired locations.

9. Make sure that foreign objects (screws, solder droplets,

etc.) do not remain inside the set.

SAFETY CHECK AFTER SERVICING

After servicing, make measurements of leakage-current or

resistance in order to determine that exposed parts are

acceptably insulated from the supply circuit. The leakagecurrent measurement should be done between accessible

metal parts (such as chassis, ground terminal, microphone

jacks, signal input/output connectors, etc.) and the earth ground

through a resistor of 1500 ohms paralleled with a 0.15 F

capacitor, under the unit’s normal working conditions.

The leakage-current should be less than 0.5 mA rms AC. The

resistance measurement should be done between accessible

exposed metal parts and power cord plug prongs with the

power switch (if included) “ON”. The resistance should be

more than 2.2 M ohms.

Replace with the same make and type or equivalent recom

mended by manufacturer.

Place battery in correct polarity.

Do not short the terminals.

Do not charge battery.

Do not dispose of battery in fire.

SERVICE MANUAL

2

Page 3

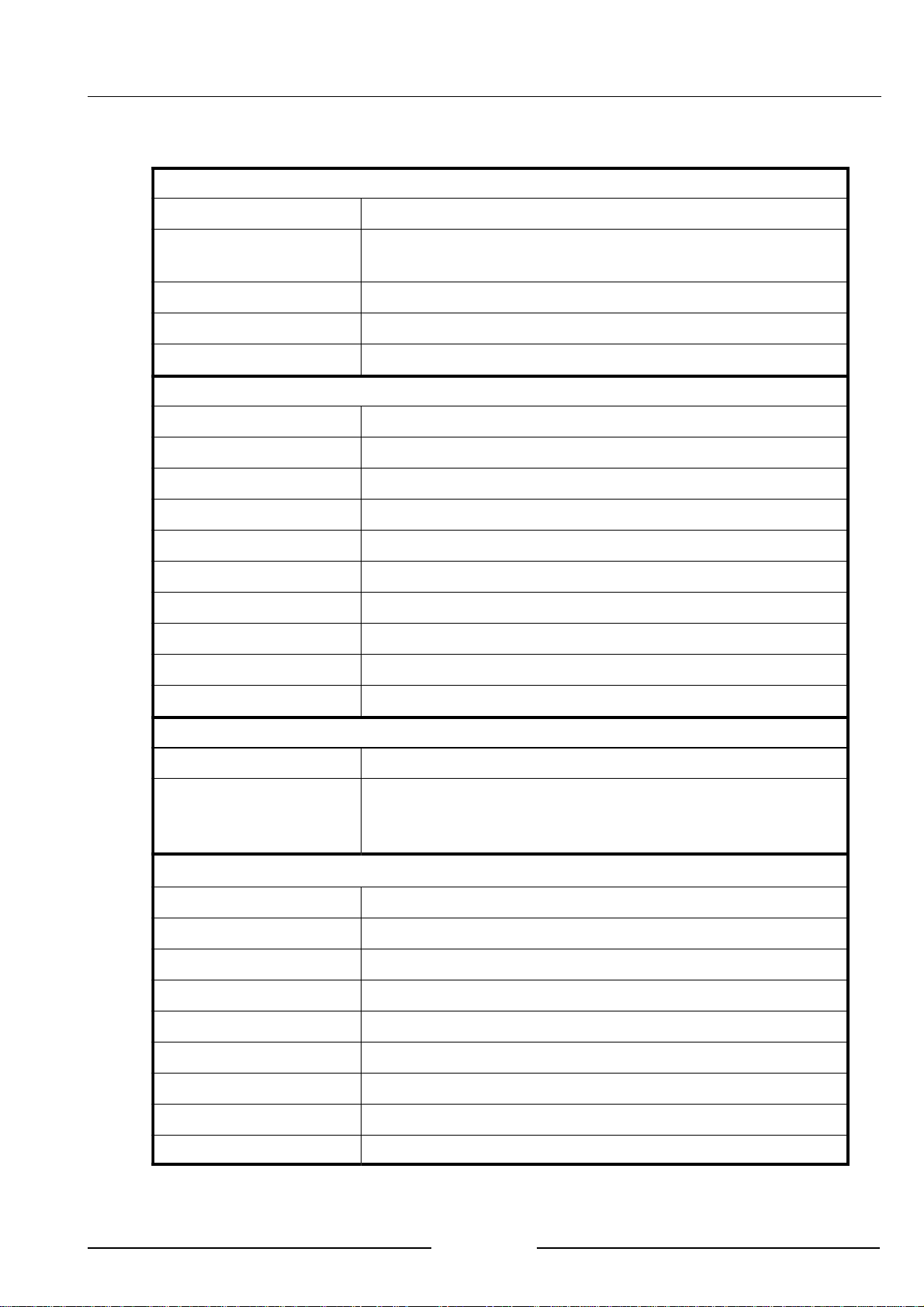

I. SPECIFICATIONS

General

Display

240 x 64 dot graphic LCD w/back light

Memory card slot

Compact Flash (The size of the compact flash card the MPC1000 can

handle is from 32MB to 2GB)

Dimentions (W x H x D)

330 x 75.5 x 228.2(Max 234.6)

Weight

3.45kg

Power reqirement

19W

Sound generator

Sampling rate

44.1kHz

Memory capacity

16MB standard (11.5MB for sound memory), expandable to 128MB

Recording time

136sec. (16MB, MONO), 24m28sec. (128MB, MONO)

Memory expansion slot

1 x for optional EXM128

Data format

16-bit linear

Polyphony

32

Dynamic filtering

2 x 2-pole filter per voice

Filter type

Low pass, Band pass, High pass

Preset sound memory

5MB

Number of programs

24

Effects

Effects

2 stereo effects and Master effect

Effect type

Chorus, Flanger, Bit grunger, 4 band EQ, Compressor, Phase shifter,

Tremolo, Flying pan, Reverb

Master effect: 4 band EQ, Compressor

Sequencer

Maximum events

100,000 notes

Resolution

96 parts per 1/4-note

Sequences

99

Tracks per sequence

64

MIDI output channels

32 (16 channels x 2 outputs)

Song mode

20 songs, 250 steps per song

Drum pad

16 (velocity and pressure sensitive)

Drum pad banks

4

Sync mode

MIDI clock

* The specifications are subject to change without the prior notice.

SERVICE MANUAL

3

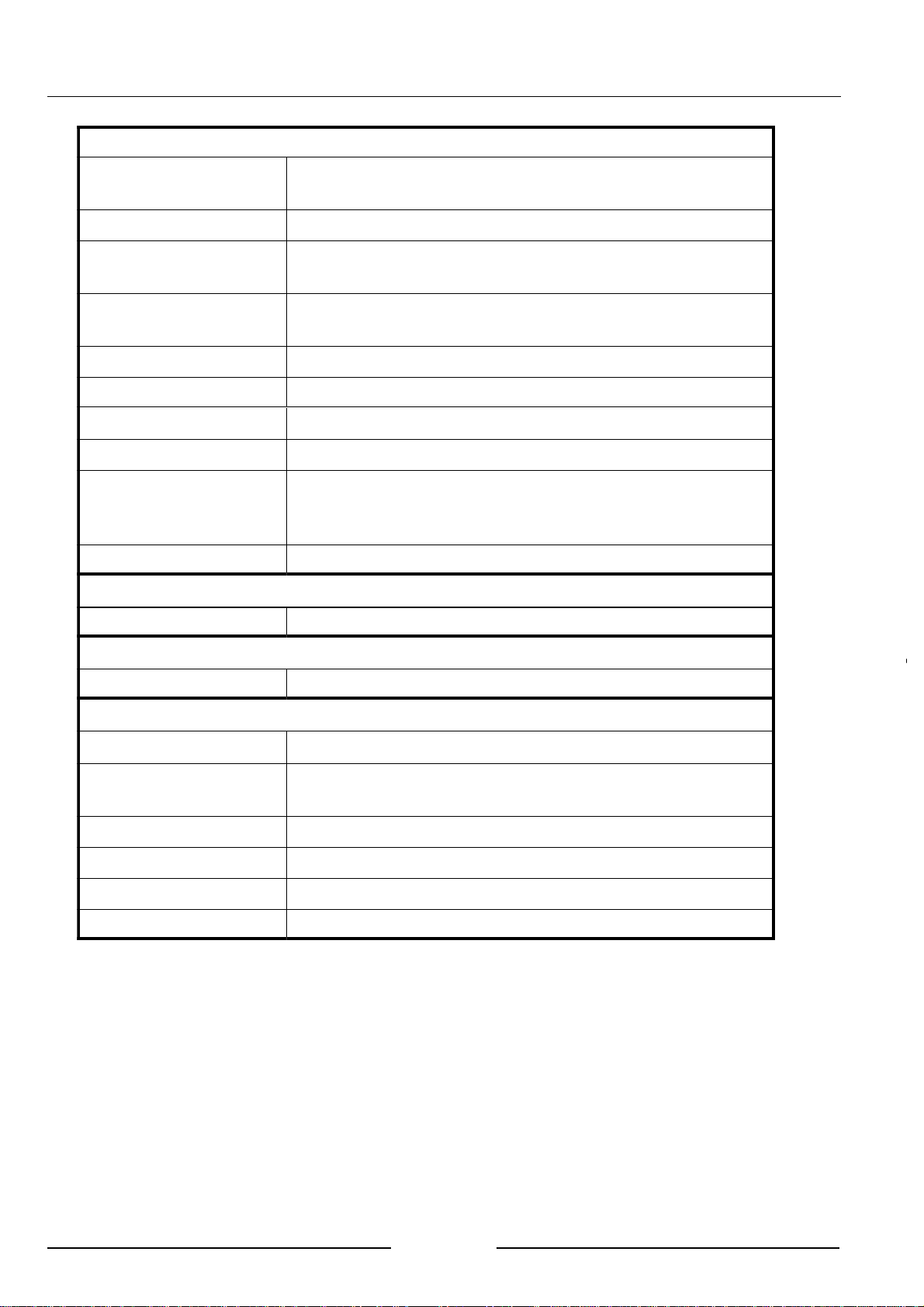

Page 4

* The specifications are subject to change without the prior notice.

Inputs / Outputs

Record input (L and R)

1/4-inch stereo phone x 2, balanced -40dBu, input impedance 11k ohms;

Max. Input level +10dBu

Digital input

RCA-pin x 1 S/PDIF

Stereo output (L and R)

1/4-inch phone x 2 unbalanced +11dBu, output impedance 1k Ohms, Max.

output level +17dBu

4 individual outputs

1/4-inch phone x 4 unbalanced +11dBu, output impedance 1k Ohms, Max.

output level +17dBu

Phones output

1/4-inch stereo phone x 1, 200mW / 100 ohms

Digital output

RCA-pin x 1 S/PDIF

MIDI inputs

5-pin DIN x 2

MIDI outputs

5-pin DIN x 2

USB

Slave connector x 1, USB MASS STORAGE CLASS support.

(You need Windows 2000/Me/XP or later version, or MacOS 9.x/10.x or later

version. )

Footswitches

1/4-inch phone x 2

Standard accessories

Standard accessories

32MB Compact Flash card, Power cable, Operator's manual

Options

EXM128

128MB expansion memory card

Data Compatibility (THRU Computer)

MPC2000XL

SEQ, WAV, PGM (Most parameters of PGM file can be loaded.)

MPC4000

SEQ, WAV , PGM (DRUM program only. Only note assign and tune are

loaded.)

MPC3000

No compatibility

Z4/Z8

WAV only

S5000/6000

WAV only

S1000/3000

No compatibility

4

SERVICE MANUAL

Page 5

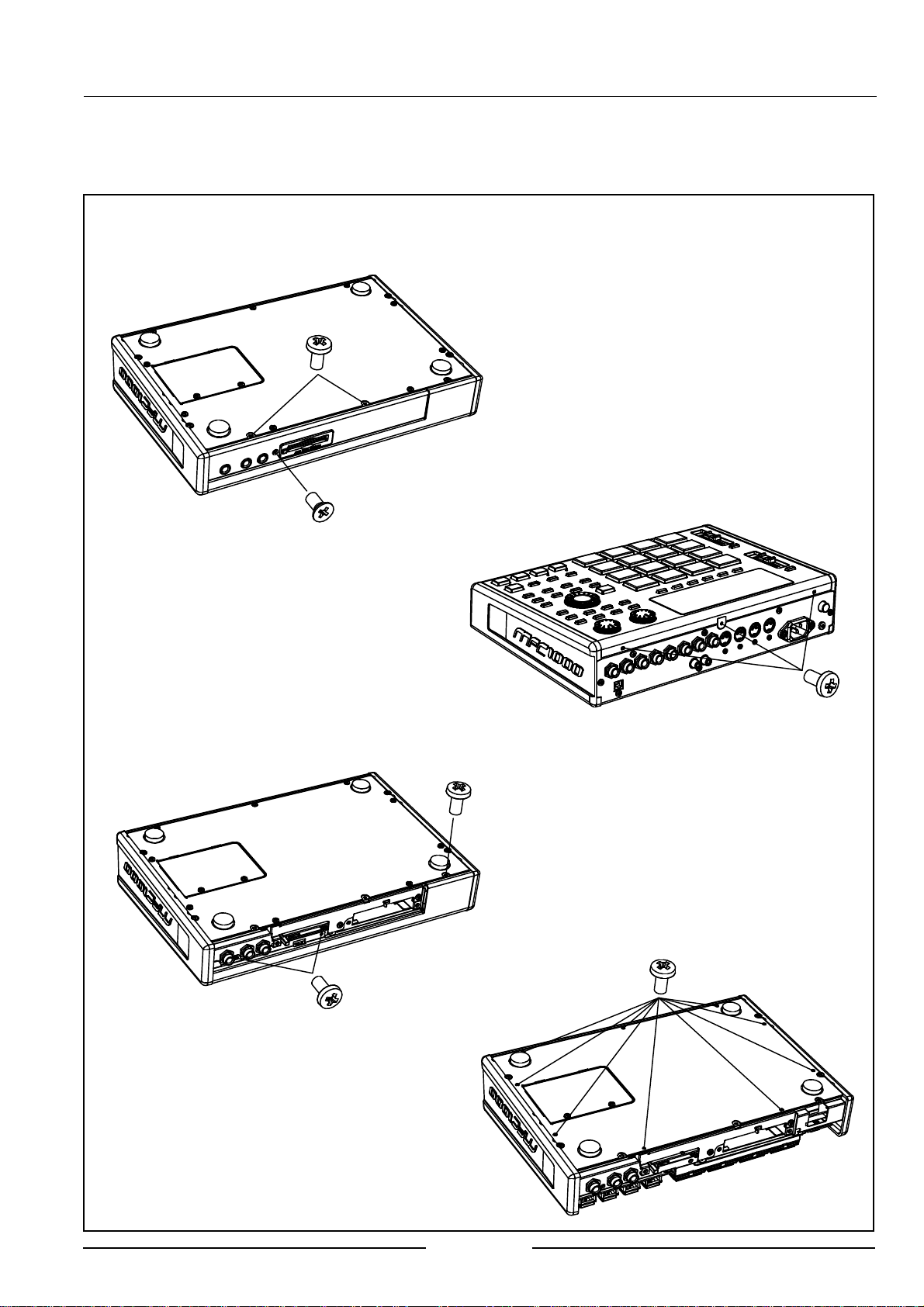

II. DISASSEMBLY

In case of trouble, etc., necessitating dismantling, please dismantle in the order shown in the illustrations. Reassemble in the

reverse order.

ZS-820454X

ZS-820455X

ZS-820454X

ZS-820454X

ZS-820454X

ZS-820454X

SERVICE MANUAL

5

Page 6

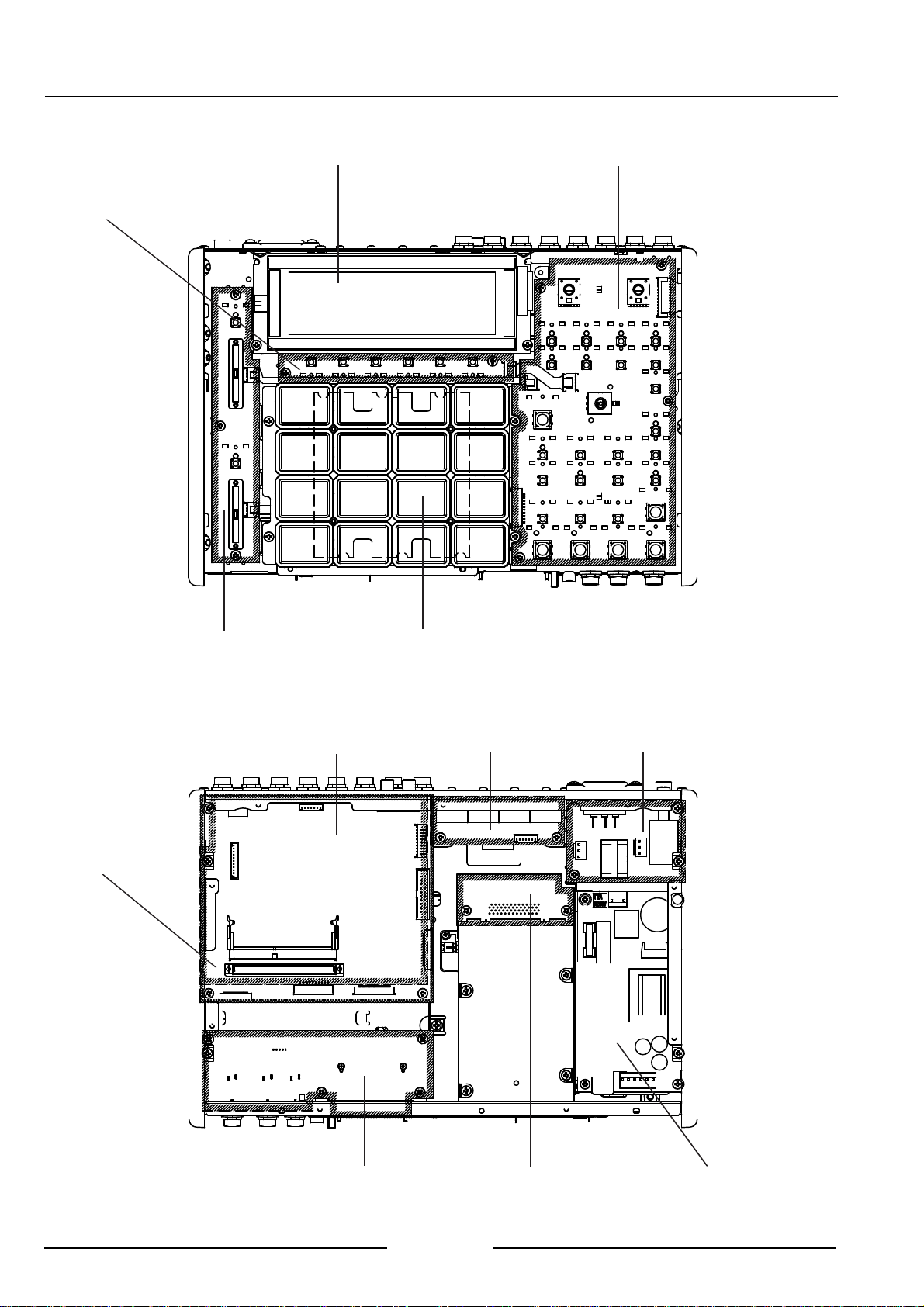

III. PRINCIPAL PARTS LOCATION

BA - L4033A502D

PC OPERATION - F BLK

EM - 821776X

IND LCD PS24064LRU - ETA - H03

BA - L4033A502A

PC OPERATION - R BLK

BA - L4033A501B

PC AD/DA BLK

BA - L4033A502C

PC OPERATION - L BLK

BA - L4033A501A

PC CPU BLK

BA - L4033A502B

PC PAD BLK

BA - L4033A502E

PC MIDI BLK

BA - L4033A501E

PC FILTER BLK

BA - L4033A501C

PC FRONT BLK

SERVICE MANUAL

6

BA - L4033A501D

PC HD CONNECT BLK

BP - 821839X

SW POW SNP - 9031

Page 7

IV. SUPPLEMENTARY INFORMATION

[Update procedure]

===How to copy the OS binary file to a CF card using a MPC1000 and a computer====

Below procedure will utilize the MPC1000 as a Compact flash writer.

Required Equipment :

Compact Flash (CF), Computer with USB mass storage class support (Windows

1. Copy/Download the OS data to a computer’s hard disc drive and extract it ’s data.

2. Insert a Compact Flash card into the MPC1000.

3. Turn on the power of the MPC1000.

4. Go to Load mode, then press USB (F4).

5. Connect a USB cable between the computer and the MPC1000. (Display will change

from “Status=Not Connected ” to “Status=Connected ”)

6. The CF in the MPC1000 will be mounted as a drive on the computer.

7. Copy the OS binary file to the CF in the MPC1000.

8. Disconnect the USB cable. (MPC1000 will not accept any user in put while a USB

XP/ME/2000 or Mac OSX, OS9.x)

cable is connected)

Note: The OS data can also be copied to a Compact Flash card using any other Compact

Flash card reader/writer. In this case it is not necessary to connect the MPC1000 to a

====How to update the MPC1000====

MPC1000 is updated using a Compact Flash card containing OS data.

1.

Insert a CF containing OS data into the MPC1000.

2.

Turn on the power of the MPC1000 while pressing down the “Window ” button.

3.

To start the update process, p ress the “REC” button. After the update process is

Note: The MPC1000 can not be updated from a computer via USB directly – updating is

====Hidden model====

( Note: V1.06 is not supported.)

computer.

finished the MPC1000 will re - boot automatically.

only possible using a CF card.

The MPC1000 has the following hidden modes, which can be accessed by certain input sequences or holding down a

key while powering on the unit. Currently these modes are not supported in OS Version 1.06.

[Owner Name]

1.

Mode > Other > F3/FOOTSW > F6 > Enter owner name

[Initialize parameter]

2.

in the startup screen, “Owner Name” will be displayed.

Hold down the ERASE button while powering on the unit.

[Memory Check]

3.

Hold down the PLAY button while powering on the unit.

[Demo mode ]

4.

Hold down the Bank “D” button while powering on the unit.

In this mode “Internal memory” on the Save page can not be selected . In the startup screen “Demo” will be displayed

instead of “MPC1000”. Once demo mode has been activated it will remain active even if power is turned off and on again.

To turn off the Demo mode, hold down the Bank “D” button while powering on the unit.

SERVICE MANUAL

7

Page 8

[Test program]

Test programs on the MPC1000 can be run either using a Test OS or a JIG PC Flash Rom.

[Running the test Program using a Test OS

]

A test program can be installed on the MPC1000 by updating it with a Test OS. The Test OS must be copied to a CF card

from which it will be written to the Flash ROM of the MPC1000. The installation procedure is the same as for a normal OS

update. For a description of the test mode functions, refer to the “MPC1000 Test Program list”.

Note: Once the Test OS is installed, the unit will always start up using the Test OS, until the regular OS is re-installed.

[Running the test Program using a JIG PC Flash ROM MPC1K (AJ - 771312J)]

The PC Flash ROM is used during repair for the testing jig and boot block recovery.

To access the test program on the PC Flash ROM MPC1K follow this procedure:

1. Turn off the MPC1000 and open the unit.

2. Insert the PC Flash MPC1K ROM into J110 on the CPU board.

3. Turn on the MPC1000 to start up the Test OS from the PC Flash ROM.

JOG,FADER1,FADER2,input,value,displyed

Each Pad No., and input value displayed. Plural input displayed "Error"

By Pressing Keys correspond 35 boxes change to negative.(#1)

-PAD-

-JOG-

-KEYF1F2F3F4F5

"PANEL TEST"

PANEL

F1

SDRAM simple check

All dot of LCD change to Black. Contrast adjusting by JOG

All LEDs light

-LED-

-LCD-

SDRAM all area READ/WRITE check

(#2)When press Keys with LED, LED light while pressing switches. (#1Press F6 twice = EXIT)

-----

FULL-

SIMPL

F1

F2F3F4F5F6F1F2F3F4F5F6F1F2F3F4F5F6

"SDRAM TEST"

EXIT-

F6

SDRAM

F1

-----

-----

EXIT-

CF card simple check

SIMPL

Delete CF card data

For development

Type of CF card display

CF card all area READ/WRITE check

EXIT-

ERASE

BACUP

DETEC

SECTR

"CF CARD TEST"

-CF-F2

Delete HDD dataHDD

HDD all area READ/WRITE check

HDD simple check

Type of HDD displayed

SIMPL

DETEC

SECTR

"HDD TEST"

-HDDF3

"MEMORY TEST"

MEMORY

F2

No function

For development

EXIT-

ERASE

BACUP

-DSPF4

No function

No function

Write Test OS to Flash ROM

Data (OS/Liblary) transport via USB

LIBH-

LIBC-

-USB-

P_OSF1F2F3F4F5

"FLASH WRITING"

FLASH

F5

A/D inputting signal output to all OUTPUT.

-----

EXITF6

-A/D-

EXITF6F1F2F3F4F5F6

SPDIF inputting signal output to all OUTPUT. (#3)

SPDIF

FULL bit signal output to all OUTPUT.

(#3)A/D-L > MAIN-L, 1,3 A/D-R >MAIN-R, 2,4

-----

-----

EXIT-

TONE-

"A/D selected"

"SPDIF selected"

"test tone"

AUDIO

F3

Start Loop back Test, MIDI OUT A --> MIDI IN 1, MIDI OUT B --> MIDI IN 2

-----

-----

-----

START

F1

F2F3F4F5F6

(Each connection result dislayed)

"OUTA > IN 1:OK OUTB > IN2 FAILED

MIDIF4

-----

EXIT-

-----

-----

-----

-----

F1

F2F3F4F5F6

"F.SW1 : ON F.SW2 : OFF"

F.SW-

F5

-----

EXIT-

(Foot SW status displayed)

-----

F6

MPC1000 TEST OS

8

Starting Display

SERVICE MANUAL

Page 9

V. PARTS LIST

ATTENTION

1. When placing an order for parts, be sure to list the Part No., Model No. and the description of each part.

Otherwise, the non-delivery of the part or the delivery of a wrong part may result.

2. Please make sure that Part No. is correct when ordering.

If not, a part different from the one you ordered may be delivered.

3. Since the parts shown in Parts List or Preliminary Service Manual may have been the subject of changes,

please use this Parts List for all future reference.

HOW TO USE THIS PARTS LIST

1. This Parts List lists those parts which are considered necessary for repairs.

2. Parts not shown in the Parts List will not in principle be supplied.

3. How to read the Parts List.

1. PC MAIN BOARD BLK

Ref. No. Part No. Description

D5 ED-431276C D SCHOT 1S30-J T05

D110 ED-431276C D SCHOT 1S30-J T05

:

:

IC5 EI-811073J ICTRC-6593

IC10 EI-811068J IC HD74HC157FP

Service parts classification

These reference symbols correspond with component

symbols in the Schematic Diagrams.

2. FINAL ASSEMBLY BLK

Ref. No. Part No. Description

1. SA-349332 FOOT

2. ZS-344754C ST PAN30x06STL CMT

:

:

44. SP-417333J COVER TOP

45. ZS-418385J BT BID30X06STL BNI EATRH LOCK

46-A EW-380905J AC CORD 250S KP300 KS16A

H B J [J]

46-B EW-368420J1 AC CORD 200SKP30KS B AC [A]

46-C EW-410608J AC CORD 250 KP4819D KS31A B E

[E,V]

Symbols for primary destination

[A] U.S.A. [J] Japan

[B] England [V] Germany

[E] Europe [x1] Japan

[X4] Universal Area

Safety critical component

This number corresponds with the individual parts index number

in the figure.

WARNING

INDICATES SAFETY CRITICAL COMPONENTS. FOR CONTINUED SAFETY, REPLACE SAFETY CRITICAL

COMPONENTS ONLY WITH MANUFACTURER'S RECOMMENDED PARTS.

AVERTISSEMENT

IL INDIQUE LES COMPOSANTS CRITIQUES DE SÉCURITÉ. POUR MAINTENIR LE DEGRÉ DE SÉCURITÉDE

L'APPAREIL, NE REMPLACER QUE DES PIÉCES RECOMMANDEES PAR LÉ FABRICANT.

SERVICE MANUAL

9

Page 10

Ref. No.

Part No.

Description

Ref. No.

Part No.

Description

IC203EI812479J

IC NJM5532M FPT1T32P

IC204EI812479J

IC NJM5532M FPT1T32P

1BAL4033A020A

PC(#) MAIN BLK MPC1000

IC301EI812479J

IC NJM5532M FPT1T32P

2BAL4033A030A

PC(#) OPERATION BLK MPC1000

IC302EI812479J

IC NJM5532M FPT1T32P

IC401EI812479J

IC NJM5532M FPT1T32P

PC(#) MAIN BLK CONSISTS OF FOLLOWING P.C. BOARDS.

IC402EI812479J

IC NJM5532M FPT1T32P

1BAL4033A501A

PC CPU BLK

IC501EI812479J

IC NJM5532M FPT1T32P

2BAL4033A501B

PC AD/DA BLK

IC502EI812479J

IC NJM5532M FPT1T32P

3BAL4033A501C

PC FRONT BLK

IC601EI821828X

IC AD1839AS QFTY

4BAL4033A501D

PC HD CONNECT BLK

IC602EI821830X

IC CS8427-CS FP

5BAL4033A501E

PC FILTER BLK

IC603EI438820J

IC TC74HCU04AF FPELT16E

IC901EI821826X

IC LM2575S-ADJ

PC(#) OPERATION BLK CONSISTS OF FOLLOWING P.C. BOARDS.

J101EJ821888X

SOCKET 32FLZ-SM1-R-TB 32P

1BAL4033A502A

PC OPERATION-R BLK

J201EJ821778X

PHONE J YKB22-5326 NUT 6.3

2BAL4033A502B

PC PAD BLK

J202EJ821778X

PHONE J YKB22-5326 NUT 6.3

3BAL4033A502C

PC OPERATION-L BLK

J301EJ821386X

PHONE J YKB22-5264 NUT 6.3

4BAL4033A502D

PC OPERATION-F BLK

J302EJ821386X

PHONE J YKB22-5264 NUT 6.3

5BAL4033A502E

PC MIDI BLK

J401EJ821386X

PHONE J YKB22-5264 NUT 6.3

J402EJ821386X

PHONE J YKB22-5264 NUT 6.3

J501EJ821386X

PHONE J YKB22-5264 NUT 6.3

J502EJ821386X

PHONE J YKB22-5264 NUT 6.3

Ref. No.

Part No.

Description

L1EO821758X

COIL FIX 1 PE-52627

L901EO821758X

COIL FIX 1 PE-52627

D1ED428998J

D SILICON C.1SS355TE-17 T08E

L902EO822001X

COIL FIX 1 LHL10NB 220K

D2ED428998J

D SILICON C.1SS355TE-17 T08E

L903EO822001X

COIL FIX 1 LHL10NB 220K

D3ED812338J

D ZENER C.UDZ4.7BTE-17 T08E

R904ER307565

R FUSE H S10 ERD2FC 1/4W 6R8J

D4ED812338J

D ZENER C.UDZ4.7BTE-17 T08E

R905ER307565

R FUSE H S10 ERD2FC 1/4W 6R8J

D5ED812338J

D ZENER C.UDZ4.7BTE-17 T08E

T601BT810651J

TRANS PULSE CIT0705S-35101TFP

D6ED812338J

D ZENER C.UDZ4.7BTE-17 T08E

TR10ET428249J

TR C.2SC2412K R,S T146T08E

IC1EI821832X

IC HD6417727F160 QFTY

TR301

ET

810831J

TR.CHIP 2SC3326 A,B TE85LT08E

IC2EI821835X

IC MBM29LV651UE90TN

TR302

ET

810831J

TR.CHIP 2SC3326 A,B TE85LT08E

IC3EI821837X

IC GAL20V8B-15QP L4033A

TR401

ET

810831J

TR.CHIP 2SC3326 A,B TE85LT08E

IC4EI821838X

IC GAL20V8B-15QP L4033B

TR402

ET

810831J

TR.CHIP 2SC3326 A,B TE85LT08E

IC5EI812979J

IC HD74LVC245ATELL FPELT16E

TR501

ET

810831J

TR.CHIP 2SC3326 A,B TE85LT08E

IC6EI812979J

IC HD74LVC245ATELL FPELT16E

TR502

ET

810831J

TR.CHIP 2SC3326 A,B TE85LT08E

IC7EI812979J

IC HD74LVC245ATELL FPELT16E

TR601

ET

429898J

TR C.DTA114EKA T146T08E

IC8EI812979J

IC HD74LVC245ATELL FPELT16E

TR602

ET

430868J

TR C.DTC114EKA T146T08E

IC9EI812979J

IC HD74LVC245ATELL FPELT16E

TR603

ET

428249J

TR C.2SC2412K R,S T146T08E

IC10EI812979J

IC HD74LVC245ATELL FPELT16E

TR604

ET

428248J

TR C.2SA1037AK R,S T146T08E

IC11EI820795X

IC HD74LVC14TELL FPELT12E

TR701

ET

810831J

TR.CHIP 2SC3326 A,B TE85LT08E

IC12EI820062J

IC HD74HCT541FP FPELT24

TR702

ET

810831J

TR.CHIP 2SC3326 A,B TE85LT08E

IC13EI821833X

IC HD74LVCC3245ATELL FPELT16E

X601EI821786X

OSC X'TAL C.DS0751SV 11.2896MHZ

IC14EI821827X

IC NJU7002M FPT1T08

IC15EI821836X

IC SI9706DY

IC16EI821831X

IC DS1811R-10

IC17EI821834X

IC HY57V641620HGT-H

Ref. No.

Part No.

Description

IC18EI821834X

IC HY57V641620HGT-H

IC19EI821889X

IC HD74LV1G32ACME FPT08E

IC701EI812705J

IC NJM4556AL

IC20EI821901X

IC GAL16V8D-15QP L4033C

J103EJ821779X

SOCKET 42FLZ-SM1-R-TB 42P

J1EJ821236X

SOCKET CONNECTER YKF45-0020 4P

J207EJ821782X

SOCKET CFMB50MTW1NL 50P

J2EJ820754X

PIN J YKC21-3079 P2P

J208EJ821386X

PHONE J YKB22-5264 NUT 6.3

J3EJ821781X

SOCKET DMM3-RS144A2B-13 144P

J209EJ821386X

PHONE J YKB22-5264 NUT 6.3

J101EJ821888X

SOCKET 32FLZ-SM1-R-TB 32P

J210EJ821386X

PHONE J YKB22-5264 NUT 6.3

J102EJ821842X

SOCKET 20FMZ-ST 20P

R707ER430691J

R OMF H S12 FS 1W 101J

J103EJ821779X

SOCKET 42FLZ-SM1-R-TB 42P

R708ER430691J

R OMF H S12 FS 1W 101J

J104EJ821779X

SOCKET 42FLZ-SM1-R-TB 42P

J110EJ419246J

SOCKET 128A-050S2A-S14A 50P

P105EJ821841X

PLUG SCP20GS3 20P

PH1ET821874X

DETECTOR HCPL-0701

Ref. No.

Part No.

Description

PH2ET821874X

DETECTOR HCPL-0701

SF1EF810572J

FUSE C.ICP-S2.3 50V 2.3A T08E

J104EJ821779X

SOCKET 42FLZ-SM1-R-TB 42P

TR1ET821788X

TR FET CHIP 2SK3065T100 T12E

P211EJ821777X

PLUG DHB-PA50-R131N 50P

TR2ET821788X

TR FET CHIP 2SK3065T100 T12E

TR3ET821788X

TR FET CHIP 2SK3065T100 T12E

TR4ET821788X

TR FET CHIP 2SK3065T100 T12E

TR5ET821788X

TR FET CHIP 2SK3065T100 T12E

Ref. No.

Part No.

Description

TR6ET821789X

TR CHIP DTB113ZKT146 T08E

TR7ET821789X

TR CHIP DTB113ZKT146 T08E

C951EC430824J

C MMY V CUT MKP3362 683M 275AC

TR8ET821789X

TR CHIP DTB113ZKT146 T08E

C952EC427562J

C MMY V CUT MKP3362 103M 275AC

TR9ET821789X

TR CHIP DTB113ZKT146 T08E

C953EC427562J

C MMY V CUT MKP3362 103M 275AC

X1EI821787X

OSC X'TAL C.DS0751SV 13.330MHZ

L901EO427223J

COIL LF HR-24-562

X2EI820989X

OSC X'TAL C.DS0751SV 48.0000MHZ

SW901

ES

812750J

SW PUSH SDKEC 02-1

Ref. No.

Part No.

Description

D7ED821790X

D SCHOT. RK44 40/3.0A

D901ED821790X

D SCHOT. RK44 40/3.0A

D902ED812354J

D ZENER C.RB081L-20 TE25T12E

D903ED812338J

D ZENER C.UDZ4.7BTE-17 T08E

IC21EI821826X

IC LM2575S-ADJ

IC201EI812479J

IC NJM5532M FPT1T32P

IC202EI812479J

IC NJM5532M FPT1T32P

1. PC BOARD BLK

2. PC CPU BLK

3. PC AD/DA BLK

4. PC FRONT BLK

5. PC HD CONNECT BLK

6. PC FILTER BLK

10

SERVICE MANUAL

Page 11

Ref. No.

Part No.

Description

Ref. No.

Part No.

Description

D301ED812087J

D LED L-934SRD-G RED

J317EJ427801J

DIN J TCS5084-45-4151 5P

D302ED812087J

D LED L-934SRD-G RED

J318EJ427801J

DIN J TCS5084-45-4151 5P

D303ED812086J

D LED L-934SGD GREEN

J319EJ427801J

DIN J TCS5084-45-4151 5P

D304ED813021J

D LED L-934SYD YELLOW

J320EJ427801J

DIN J TCS5084-45-4151 5P

D305ED812087J

D LED L-934SRD-G RED

D306ED812086J

D LED L-934SGD GREEN

D307ED812086J

D LED L-934SGD GREEN

D308ED812086J

D LED L-934SGD GREEN

Ref. No.

Part No.

Description

D309ED812086J

D LED L-934SGD GREEN

D310ED812086J

D LED L-934SGD GREEN

1BP821839X

SW POW SNP-9031

D311ED812086J

D LED L-934SGD GREEN

2EF822002X

FUSE 181 T 250V 2A

D312ED812086J

D LED L-934SGD GREEN

3ZW302909

RV NYL30X035 BL

D313ED812086J

D LED L-934SGD GREEN

4SP821814X

PANEL REAR MPC1000

J102EJ821842X

SOCKET 20FMZ-ST 20P

5EJ358632J2

SOCKET INLET SOT-16 3P

SW101

ES

821759X

SW R.ENCORDER SIM-026MT R66 5214

6ZS820481X

BT PAN30X08STL BZN C080

SW301

ES

415015J

SW TACT SKQEAD

7ZS411232

BID40X10STL BNI

SW302

ES

415015J

SW TACT SKQEAD

8ZS820454X

BT BID30X06STL BNI

SW303

ES

415015J

SW TACT SKQEAD

9SB810525J

BUTTON POWER

SW304

ES

415015J

SW TACT SKQEAD

9ES812750J

SW PUSH SDKEC 02-1

SW305

ES

349474

SW TACT SKHHAM004A

10EW821886X

CORD FFC P0.50 L90 32P

SW306

ES

349474

SW TACT SKHHAM004A

11ZS812478J

PAN26X06STL BNI

SW307

ES

349474

SW TACT SKHHAM004A

12SP821794X

HOLDER OPTION HD

SW308

ES

415015J

SW TACT SKQEAD

13EW821775X

CORD FFC P0.50 L180 42P

SW309

ES

349474

SW TACT SKHHAM004A

14ZS331182

BT BID30X08STL BNI

SW310

ES

349474

SW TACT SKHHAM004A

15ZS355511

BID30X06STL BNI

SW311

ES

349474

SW TACT SKHHAM004A

16ZS821572X

PAN30X04STL CMT SW

SW312

ES

349474

SW TACT SKHHAM004A

17BA821854X

SENSOR PAD L4033

SW313

ES

349474

SW TACT SKHHAM004A

18EW821770X

WIRE ASSY L4033 W301 2P

SW314

ES

349474

SW TACT SKHHAM004A

19ZS821573X

PAN25X04STL CMT SW

SW315

ES

349474

SW TACT SKHHAM004A

20EM821776X

IND LCD PS24064LRU-ETA-H03

SW316

ES

349474

SW TACT SKHHAM004A

21EW821760X

WIRE ASSY L4033 W105 20P

SW317

ES

415015J

SW TACT SKQEAD

22SZ821800X

SHIELD LCD (1)

SW318

ES

349474

SW TACT SKHHAM004A

23SZ821801X

SHIELD LCD (2)

SW319

ES

349474

SW TACT SKHHAM004A

24EW821887X

CORD FFC P1.00 L210 20P

SW320

ES

349474

SW TACT SKHHAM004A

25SB821820X

BUTTON PUSH(B)-6

[WHITE]

SW321

ES

349474

SW TACT SKHHAM004A

26SE821858X

MASK SLIDE

SW322

ES

349474

SW TACT SKHHAM004A

26EV821785X

VRSLIDE RS3011119018 B103

SW323

ES

349474

SW TACT SKHHAM004A

27ZW618884

N20STL CMT 1

SW324

ES

349474

SW TACT SKHHAM004A

28ZS608106

PAN20X06STL CMT

SW325

ES

349474

SW TACT SKHHAM004A

29EJ821861X

SOCKET ACCE EJECTOR CFE250M

SW326

ES

349474

SW TACT SKHHAM004A

30EW821885X

CORD FFC P0.50 L80 42P

SW327

ES

349474

SW TACT SKHHAM004A

31SB821806X

BUTTON PUSH S (A)

[CLEAR]

VR301

EV

821784X

VR ROTARY RK14K1230 L=15 C203X2

32SB821807X

BUTTON PUSH S (B)

[WHITE]

[REC GAIN]

33SB821808X

BUTTON PUSH S (C)

[PURPLE]

VR302

EV

821783X

VR ROTARY RK14K1230A1E L=15 A103X2

34SB430327J

BUTTON PUSH B(2)

[RED]

[MAIN VOLUME]

35SB821550X

BUTTON PUSH B(5)

[WHITE]

36SK821810X

KNOB VOLUME (A)

[MAIN]

36EV821783X

VR ROTARY RK14K1230A1E L=15 A103X2

37SK821811X

KNOB VOLUME (B)

[REC]

Ref. No.

Part No.

Description

37EV821784X

VR ROTARY RK14K1230 L=15 C203X2

38SK821812X

KNOB JOG

IC301EI821829X

IC CD74HCT4051M96

38ES821759X

SW R.ENCORDER SIM-026MT R66 5214

IC302EI821829X

IC CD74HCT4051M96

39SP821803X

PANEL TOP MPC1000

40SE810353J

LENS LED

41SE821804X

WINDOW LCD

42SP821815X

PANEL SIDE (R)

Ref. No.

Part No.

Description

43SP821816X

PANEL SIDE (L)

44SE821805X

COVER HD

D0314

ED

812086J

D LED L-934SGD GREEN

45SP821819X

PANEL SLOT

D0315

ED

812086J

D LED L-934SGD GREEN

46ZS820455X

BT CTS30X06STL BNI

SW328

ES

349474

SW TACT SKHHAM004A

47SP821798X

COVER BOTTOM

SW329

ES

349474

SW TACT SKHHAM004A

48SP821799X

COVER MEMORY

VR303

EV

821785X

VRSLIDE RS3011119018 B103

49SA812668J

FOOT B

VR304

EV

821785X

VRSLIDE RS3011119018 B103

50SK821813X

KNOB SLIDE

50EV821785X

VRSLIDE RS3011119018 B103

51EJ821386X

PHONE J YKB22-5264 NUT 6.3

52EJ821778X

PHONE J YKB22-5326 NUT 6.3

Ref. No.

Part No.

Description

53EJ427801J

DIN J TCS5084-45-4151 5P

54EJ820754X

PIN J YKC21-3079 P2P

SW330

ES

349474

SW TACT SKHHAM004A

55EJ821236X

SOCKET CONNECTER YKF45-0020 4P

SW331

ES

349474

SW TACT SKHHAM004A

56EW380905J

AC CORD 250S KP300 KS16A H B J

[J]

SW332

ES

349474

SW TACT SKHHAM004A

56EW368420J1

AC CORD200SKP30KS16 B AC

[A]

SW333

ES

349474

SW TACT SKHHAM004A

56EW403993J

AC CORD200SKP4819DKS31A B E

[E,V]

SW334

ES

349474

SW TACT SKHHAM004A

56EW419170J

AC CORD200S KP610 KS31A B

[B]

SW335

ES

349474

SW TACT SKHHAM004A

57EJ405424J

PLUG ADAPTOR KPR-25

[J]

7. PC OPERATION-R BLK

11. PC MIDI BLK

12. FINAL ASSEMBLY BLK

8. PC PAD BLK

9. PC OPERATION-L BLK

10. PC OPERATION-F BLK

SERVICE MANUAL

11

Page 12

FINAL ASSEMBL Y BLOCK

12

SERVICE MANUAL

Page 13

FINAL ASSEMBL Y BLOCK

SERVICE MANUAL

13

Page 14

FINAL ASSEMBL Y BLOCK

14

565

57

SERVICE MANUAL

Page 15

4-7-3, KITA-YAMATA, TSYZUKI-KU, YOKOHAMA, JAPAN

SERVICE SECT. PHONE : +81-45-914-8530 FAX : +81-45-914-8531

SERVICE MANUAL

35

Page 16

PC (#) OPERATION

(OPERATION - F)

FOOT SW

HEAD PHONE

PC (#)MAIN

(FRONT)

Page 17

SOUND / WORK

TO : OPERATION - R BLK

TO : PAD BLK

TO : FRONT BLK (CF)

TO : MIDI BLK

TO : USB

TO :HDD CONNECT BLK

TO : AD / DA BLK

SOUND / WORK

TO : DIGTAL BLK

TO : LCD

Page 18

Page 19

MPC1000 OPERATION-R BLK

PAD BLK

OPERATION-L BLK

OPERATION-F BLK

MIDI BLK

SCHEMATIC DIAGRAM

L4033A502A

L4033A502B

L4033A502C

L4033A502D

L4033A502E

Page 20

MPC1000 CPU BLK

SCHEMATIC DIAGRAM

L4033A501A

Page 21

MPC1000

CONNECTION DIAGRAM

Page 22

MPC1000 AD/DA BLK

SCHEMATIC DIAGRAM

L4033A501B

Loading...

Loading...