AEG PROTECT C. 6000, PROTECT C. 10000 User Manual

OPERATING INSTRUCTIONS UPS

PROTECT C.

PROTECT C. 6000 (S) PROTECT C. 10000 (S)

Thank you for purchasing the AEG UPS PROTECT C. from AEG Power Supply Systems.

Safety information and operating instructions are included in this manual. To ensure correct use of the UPS, please read this manual thoroughly before operating it. Save this manual properly.

3

1Notes on these Operating Instructions

Duty to Provide Information

These operating instructions will help you to install and operate the Uninterruptible Power Supply (UPS) PROTECT C. 6000 (S) or PROTECT C. 10000 (S) as well as the associated external battery units PROTECT C. 6000BP or PROTECT C. 10000BP – all referred to as PROTECT C. in this document – safely and properly, and for its intended purpose. These operating instructions contain important information necessary to avoid dangers during operation.

Please read these instructions carefully prior to commissioning!

These operating instructions are a composite part of the PROTECT C.

The owner of this unit is obliged to communicate the full content of these operating instructions to all personnel transporting or starting the PROTECT C. or performing maintenance or any other work on the unit.

Validity

These operating instructions comply with the current technical specifications of the PROTECT C. at the time of delivery. The contents do not constitute a subject matter of the contract, but serve for information purposes only.

Warranty and Liability

We reserve the right to alter any specifications given in these operating instructions, especially with regard to technical data and operation, prior to start-up or as a result of service work.

Claims in connection with supplied goods must be submitted within one week of receipt, along with the packing slip. Subsequent claims cannot be considered.

The warranty does not apply to damage caused by noncompliance with these instructions (such damage also includes damaging the warranty seal). AEG will accept no

4

liability for consequential damage. AEG reserves the right to rescind all obligations such as warranty agreements, service contracts, etc. entered into by AEG and its representatives without prior notification in the event of maintenance and repair work being carried out with anything other than original AEG spare parts or spare parts purchased by AEG.

Handling

PROTECT C. is designed and constructed so that all necessary steps for start-up and operation can be performed without any internal manipulation of the unit. Maintenance and repair work may only be performed by trained and qualified personnel.

Illustrations are provided to clarify and facilitate certain steps.

If danger to personnel and the unit cannot be ruled out in the case of certain work, it is highlighted accordingly by pictograms explained in chapter 3.

Hotline

If you still have questions after having read these operating instructions, please contact your dealer or our "Hotline":

Tel.: |

++49 (0)180 5 234 787 |

Fax: |

++49 (0)180 5 234 789 |

Internet: www.aegpss.de

Copyright

No part of these operating instructions may be transmitted, reproduced and/or copied by any electronic or mechanical means without the express prior written permission of AEG.

© Copyright AEG 2007. All rights reserved.

5

Table of Contents

1 Notes on these Operating Instructions............................. |

4 |

|||

2 |

General Information.......................................................... |

8 |

||

|

2.1 |

Technology................................................................ |

8 |

|

|

2.2 |

System Description ................................................... |

9 |

|

|

2.3 |

Technical Data ........................................................ |

12 |

|

3 |

Safety |

............................................................................. |

16 |

|

|

3.1 |

General .....................................Safety Instructions |

16 |

|

|

3.2 |

Accident ..............................prevention regulations |

16 |

|

|

3.3 |

Qualified ...................................................personal |

17 |

|

|

3.4 |

Safety . .....................Instructions for PROTECT C |

17 |

|

|

3.5 |

Certification ............................................................. |

20 |

|

4 |

Set-Up ....................................................and Operation |

21 |

||

|

4.1 |

Unpacking .......................................and Inspection |

21 |

|

|

4.2 |

Transportation ........................................to the site |

22 |

|

|

4.3 |

Point ..................................................of Installation |

23 |

|

|

4.4 |

Overview: ...Connections, Operating / Display Elements |

24 |

|

|

4.4.1 ........................................................ |

Front View |

24 |

|

|

4.4.2 ............................................................. |

Display |

25 |

|

|

4.4.3 ................................. |

Rear view (connections): |

26 |

|

5 |

Commissioning............................................................... |

28 |

||

|

5.1 |

Protection ....................................for the personnel |

29 |

|

|

5.2 |

Mains .....................................connection (general) |

29 |

|

|

5.2.1 .................................. |

Checklist for connectors |

29 |

|

|

5.2.2 ................ |

Connection diameter and protection |

30 |

|

|

5.3 |

One ...................................phase mains connector |

30 |

|

|

5.3.1 ..... |

Preparation for the one phase mains connector |

30 |

|

|

5.3.2 ....... |

Connection of the one phase mains connector |

31 |

|

|

5.3.3 ................. |

Preparation for the load connection |

31 |

|

|

5.3.4 ................................... |

Connection of the loads |

32 |

|

|

5.4 |

External ...................................Battery Expansions |

32 |

|

|

5.5 |

Mechanic . .................blocking of the PROTECT C |

33 |

|

6

6 |

Electrical Start-Up .......................................................... |

34 |

||

|

6.1 |

Operating ................................................................ |

36 |

|

|

6.1.1 |

Normal Operation ............................................ |

36 |

|

|

6.1.2 |

Battery Operation / Autonomy Operation ........ |

37 |

|

|

6.1.3 |

Bypass Operation ............................................ |

38 |

|

|

6.1.4 |

Manual bypass................................................. |

39 |

|

|

6.1.5 |

Unit Overload................................................... |

39 |

|

7 |

Interfaces and communication ....................................... |

41 |

||

|

7.1 |

Computer interfaces RS232.................................... |

41 |

|

|

7.2 |

Communication Slot................................................ |

41 |

|

|

7.3 |

Shutdown and UPS management software............ |

41 |

|

8 |

Signalling and Error Correction ...................................... |

43 |

||

|

8.1 |

Signalling................................................................. |

43 |

|

8.1.1Table overview of LED display / alarm signals 45

8.2 Fault Diagnosis / Fault Rectification........................ |

47 |

||

|

8.2.1 |

Error Messages................................................ |

47 |

9 |

Parallel operation ........................................................... |

49 |

|

9.1 Functionality ............................................................ |

49 |

||

9.2 Setup / connection of the parallel operation field.... |

50 |

||

9.3 Operation in parallel compound .............................. |

51 |

||

|

9.3.1 |

Activation ......................................................... |

51 |

|

9.3.2 |

Modification in parallel compound ................... |

53 |

10 |

Maintenance ............................................................... |

55 |

|

10.1 |

Charging the Battery ........................................... |

55 |

|

10.2 |

Maintenance ........................................................ |

55 |

|

|

10.2.1 |

Visual Check.................................................... |

55 |

|

10.2.2 |

Checking the Battery ....................................... |

56 |

|

10.2.3 |

Fan Checking................................................... |

56 |

11 |

Storage, Dismantling and Disposal ............................ |

57 |

|

11.1 |

Storage ................................................................ |

57 |

|

11.2 |

Dismantling.......................................................... |

57 |

|

11.3 |

Disposal............................................................... |

57 |

|

12 |

Glossary...................................................................... |

58 |

|

|

|

7 |

|

2 General Information

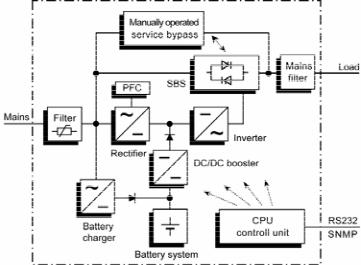

2.1Technology

i |

PROTECT C. |

is |

an |

Uninterruptible |

Power |

|

Supply (UPS) for essential loads such as PCs, |

||||||

workstations, |

servers, |

network |

components, |

|||

telecommunication |

equipment |

and |

similar |

|||

devices. It consists of:

♦Mains filter with overvoltage protection (appliance protection/class D) and mains energy backfeed protection

♦Rectifier section with PFC logic (power factor correction unit)

♦Separate battery charger with switch mode power supply technology

♦Integrated sealed, maintenance-free battery system (PROTECT C.6000 / C.10000) as energy storage medium with downstream DC/DC converter unit

♦IGBT inverter for continuous supply of connected loads with sinusoidal AC voltage

♦Automatic electronic bypass (SBS = Static Bypass Switch) as additional passive redundancy

♦Manual bypass for maintenance and service purposes (with SBS activation when activated)

♦Digital signal processor controlled control unit

8

View of the PROTECT C. components

2.2System Description

The UPS is connected between the public utility's mains and the loads to be protected.

The power section of the rectifier converts the mains voltage to DC voltage for supplying the inverter. The circuit technology used (PFC) enables sinusoidal current consumption and therefore operation with little system disturbance. A separate, second rectifier (charging REC set up using switch mode power supply technology) is responsible for charging or trickle-charging the battery connected in the intermediate circuit. The configuration of this charging REC means the harmonic content of the charging current for the battery is almost zero, so the service life of the battery is increased even more. The inverter is responsible for converting the DC voltage into a sinusoidal output voltage. A microprocessor-controlled control system based on pulsewidth modulation (PWM) in conjunction with digital signal processor technology and extremely quickly pulsating IGBT power semiconductors of the inverter guarantee that the

9

voltage system on the protected busbar is of the highest quality and availability.

In the event of mains faults (e.g. current failures), the voltage continues to be supplied from the inverter to the load without any interruption. From this point onwards, the inverter draws its power from the battery instead of the inverter. No switching operations are necessary; this means there is no interruption in the supply to the load.

The automatic electronic bypass serves to increase the security of supply further. It switches the public mains directly through to the load if there is an inverter malfunction. As a result, the automatic bypass represents an extra passive redundancy for the load.

The integrated manual bypass ensures in case of service and/or maintenances a complete power supply of all connected loads. The internal electronic circuit (with exception of the protected manual bypass) can be enabled by the input fuse.

The maximum security of supply for connected loads is achieved by switching up to three PROTECT C. UPS appliances parallel. The n+x technology provides the highest possible availability by a single or double redundancy. On the other hand the power can be raised by using the single redundancy. In case of no redundancy the highest power is reached with the UPS. The relation between available power and active redundancy is explained in the following table.

10

Parallel system with PROTECT C. 6000 (S)

Available Power |

Number of UPS units |

||||

|

|

|

|||

1 |

2 |

3 |

|||

|

|

||||

|

|

|

|

|

|

Active |

0 |

6 kVA |

12 kVA |

18 kVA |

|

|

|

|

|

||

redundancy |

1 |

--- |

6 kVA |

12 kVA |

|

level |

|

|

|

|

|

2 |

--- |

--- |

6 kVA |

||

|

|||||

|

|

|

|

|

|

Parallel system with PROTECT C.10000 (S)

Available Power |

Number of UPS units |

||||

|

|

|

|||

1 |

2 |

3 |

|||

|

|

||||

|

|

|

|

|

|

Active |

0 |

10 kVA |

20 kVA |

30 kVA |

|

|

|

|

|

||

redundancy |

1 |

--- |

10 kVA |

20 kVA |

|

level |

|

|

|

|

|

2 |

--- |

--- |

10 kVA |

||

|

|||||

|

|

|

|

|

|

11

2.3 |

Technical Data |

|

|

Type power |

|

|

PROTECT C. 6000 (S) |

6000 VA (cos ϕ = 0.7 lag.) |

|

|

4200 W |

|

PROTECT C. 10000 (S) |

10000 VA (cos ϕ = 0.7 lag.) |

|

|

7000 W |

|

UPS Input (single phase) |

1ph~ / N / PE |

|

Rated connection voltage |

220 / 230 / 240 Vac |

|

Voltage tolerance range |

176 Vac – 276 Vac ± 3 % |

|

without battery operation |

|

|

Nominal frequency |

50 Hz / 60 Hz |

|

|

(automatic detection) |

|

Frequency tolerance range |

± 4 Hz |

|

Curr. consumption (full load) |

|

|

PROTECT C. 6000 (S) |

31 A |

|

PROTECT C. 10000 (S) |

50 A |

|

Input power factor |

λ ≥ 0.98 |

|

UPS Output (single phase) |

|

|

Rated output voltage |

220 / 230 / 240 Vac ±1 % |

|

|

(configuration via software |

|

|

“CompuWatch”) |

|

Nominal frequency |

50 Hz / 60 Hz ± 0.1 % |

|

|

(depending on mains) |

|

Voltage waveform |

Harmonic distortion |

|

|

≤ 2% THD (linear load) |

|

|

≤ 6% THD (non-linear load) |

|

Current Crest Ratio |

3:1 |

|

Overload behaviour |

until 105 % continuous; |

|

with existing mains |

> 105 % - < 130 % for 10 min.; |

|

|

130 % for 1 s |

Gapless automatic switch to SBS. Cutoff after 1 minute at persisting overload (backswitch at damping overload = load < 90%).

12

Overload behaviour |

up to 105 % continuous; |

in battery mode |

> 105 % for 10 s |

Short circuit behaviour |

3 x IN for 300 ms |

Battery

Autonomy time (full load with internal battery)

PROTECT C. 6000 |

8 min. |

PROTECT C. 10000 |

5 min. |

Autonomy times with external optional battery expansions (only for PROTECT C. models):

Coupled |

Autonomy times (full load) |

|

|

|

|

battery modules |

C.6000 |

C. 10000 |

|

||

|

|

|

1 |

25 min. |

15 min. |

|

|

|

2 |

45 min. |

25 min. |

3 |

60 min. |

33 min. |

Rated direct voltage (intermediate circuit) |

||

PROTECT C. 6000 (S) |

240 Vdc |

|

PROTECT C. 10000 (S) |

240 Vdc |

|

Battery charging current |

|

|

PROTECT C. 6000 |

|

2.0 A |

PROTECT C. 6000 S |

4.2 A |

|

PROTECT C. 10000 |

2.0 A |

|

PROTECT C. 10000 S |

4.2 A |

|

Recharge time |

|

~ 7 h (UPS with internal |

to 90% of rated capacity |

battery only) |

|

(PROTECT C. – models) |

~ 11 h (with 1 battery |

|

|

|

expansion) |

~ 16 h (with 2 battery expansions)

~ 24 h (with 3 battery expansions)

13

Type |

Sealed, maintenance-free |

|

PROTECT C. 6000 |

12 V 7.2 Ah x 20 |

|

PROTECT C. 10000 |

12 V 9 Ah x 20 |

|

PROTECT C. 6000 BP |

12 V 7.2 Ah x 20 |

|

PROTECT C. 10000 BP |

12 V 9 Ah x 20 |

|

|

“S” versions with boosted battery |

|

|

charger for charging external |

|

|

battery (no integrated battery) |

|

Communication |

|

|

Ports |

RS232 |

|

|

SUB-D (9-pole) |

|

|

Communication slot for expansion |

|

|

(e.g. AS/400 / USB / SNMP, ...) |

|

Shutdown Software on CD |

“CompuWatch” for all popular |

|

|

operating systems like |

|

|

Windows, Linux, Mac OS X, |

|

General Data |

Unix, FreeBSD, Novell, Sun |

|

|

|

|

Classification |

VFI SS 111 to IEC 62040–3 |

|

Overall efficiency (full load) |

double-conversion technology |

|

|

|

|

PROTECT C. 6000 (S) |

> 88 % |

|

PROTECT C. 10000 (S) |

> 88 % |

|

Noise level (1m distance) |

|

|

PROTECT C. 6000 (S) |

< 55 dB(A) |

|

PROTECT C. 10000 (S) |

< 55 dB(A) |

|

Type of cooling |

Forced cooling |

|

|

by variable speed fans |

|

Operating temperature range |

0°C to +40°C |

|

|

Recommendation |

|

|

+15°C to +25°C (due to |

|

|

battery system) |

|

Storage temperature range |

0°C to +40°C |

|

Relative humidity |

< 95%, non-condensing |

|

14

Max. site altitude |

up to 1000m at rated power; |

||||||

|

|

if the UPS is used above than |

|||||

|

|

1000m, decreasing as follows: |

|||||

|

|

|

|

|

|

|

|

|

Altitude (m) |

|

1000 |

1500 |

2000 |

2500 |

3000 |

|

|

|

|

|

|

|

|

|

Power |

|

100% |

95% |

90% |

85% |

80% |

|

|

|

|

|

|

|

|

Colour |

Blackline |

||||||

Weight: |

|

|

|

|

|

|

|

PROTECT C. 6000 |

90 kg |

||||||

PROTECT C. 6000 S |

35 kg |

||||||

PROTECT C. 6000 BP |

65 kg |

||||||

PROTECT C. 10000 |

93 kg |

||||||

PROTECT C. 10000 S |

38 kg |

||||||

PROTECT C. 10000 BP |

68 kg |

||||||

Dimension W x H x D: |

|

|

|

|

|

|

|

PROTECT C. 6000 (S / BP) |

260 mm x 717 mm x 570 mm |

||||||

PROTECT C. 10000 (S / BP) |

260 mm x 717 mm x 570 mm |

||||||

Guidelines

The PROTECT C. complies with the product norm EN 50091.

The CE symbol on the unit certifies the compliance to the EG guidelines for 73/23 EEC low voltage and for 89/336 EEC electromagnetic compatibility (EMC), when following the installation instructions in the manual.

For the 73/23 EEC low voltage guidelines

Reference number |

EN 62040-1-1 : 2003 |

For 89/336-EMV guidelines |

|

Reference number |

EN 50091-2 : 1995 |

|

EN 61000-3-2 : 1995 |

|

EN 61000-3-3 : 1995 |

i |

Warning: |

This is a UPS product for restricted sales for |

|

users only with appropriate knowledge. To avoid |

|

|

interference, restrictions according installation |

|

or additional measures may be required. |

15

3 Safety

3.1General Safety Instructions

Canonical operation and maintenance as well as the complying with afffiliated security regulations are imminent for the protection of personal and the readiness to use of the unit. The personnel that sets up, activates, operates and maintains the unit has to be aware and has to stick to the security regulations. Any activity may only be performed by qualified personnel with designated and intact tools, appliances, measuring units and expandable items.

The following pictograms are used in these operating instructions to identify danger, attention and information content:

Danger!

This instruction defines work and operation methods, which are to follow, to prevent fatal injury to the operator and other persons.

Attention!

This instruction defines work and operation methods, which are to follow, to prevent damage to the unit and parts of the unit.

Information!

i Useful and important hints for the operation of the UPS and its external battery modules (special accessories).

3.2Accident prevention regulations

The local regulation for accident prevention and the general security regulations according IEC 364 have to be followed unconditionally. Before working with PROTECT C. the following security rules must be adhered.

♦Disconnect the unit from the mains

♦Protect against reconnection

16

♦Assure for no power

♦Ground and short circuit system

♦Cover or seals adjacent components still under power

3.3Qualified personal

The PROTECT C. may only be transported, setup, connected and maintained by qualified personnel, that is aware do the legal security and installation regulations and knows how to apply them. All executions have to be supervised by responsible qualified personnel.

The qualified personnel have to be authorised by the responsible person for security rights affairs to execute the necessary tasks.

Qualified personnel have

♦an education and experience in the relevant area of operation,

♦know the applicable norms, rules, regulations and accident preventions rules,

♦are educated in the functionality and the operation of the PROTECT C.,

♦can identify and prevent dangers.

Regulations and definitions for qualified personnel are included in DIN 57105 / VDE 0105, part 1.

3.4Safety Instructions for PROTECT C.

The UPS carries high voltage. The unit may only be opened by trained and qualified personnel. Repairs may only be carried out by qualified customer service staff!

The output may be live, even if the UPS is not connected to the mains, since the UPS has its own internal power supply (battery)!

For health and safety reasons, the unit must be earthed correctly!

17

PROTECT C. may only be operated with or connected to a 220 V / 230 V / 240 V mains with protective grounding using a CE marked mains connection cable with PE conductor that has been tested in accordance with national standards.

Danger! Risk of burning!

The battery has powerful short circuit currents. Incorrect connection or isolation faults can lead to melting of the plug connections, sparking potential and severe burns!

The unit has a warning signal that sounds when the battery voltage of PROTECT C. is exhausted or when the UPS is not working in its normal mode (chapter 8, page 45).

Observe the following safety instructions to ensure permanent operational safety of and safe work with the UPS and the battery modules (special accessories):

♦Do not dismantle the UPS!

The UPS does not contain any parts that require regular maintenance. Bear in mind that the warranty will be invalidated if the unit is opened!

♦Do not install the unit in direct sunshine or in close proximity of heaters!

♦The unit is designed to be installed inside in heated rooms. Never install the housing in the vicinity of water or in an excessively damp environment!

♦Condensation may occur if the UPS is brought from a cold environment into the room where it is to be installed. The UPS must be absolutely dry prior to start-up. As a result, leave it to acclimatise for at least two hours.

♦Never connect the mains input to the UPS output, and vice versa!

♦Ensure that no fluids or foreign bodies can penetrate the housing!

18

♦Do not block the air vents of the unit! Keep children away from the unit and ensure that objects are never inserted through the air vents!

♦Do not connect household appliances such as hairdryers to the UPS! Also take care when working with motor loads. It is essential to avoid back-feeding the inverter, e.g. if the load is intermittently operated in regenerative mode.

Danger! Electric shocks!

Even after the mains voltage has been disconnected, the components within the UPS remain connected to the battery and can thus cause electric shocks. It is therefore imperative to disconnect the battery circuit before carrying out any maintenance or repair work!

If it is necessary to replace the battery or carry out maintenance work, this must be done by or under the supervision of a specialist familiar with

batteries and the necessary safety precautions!

Only authorised persons are allowed in the vicinity of the batteries!

When replacing the batteries, the following must be observed: Only ever use identical maintenance-free sealed lead batteries with the same data as the original batteries.

Danger! Explosive!

Never throw batteries into open fire.

Never open or damage batteries. (Electrolyte may leak out and damage skin and eyes. It may be toxic!)

Batteries can cause electric shocks and high short-circuit currents.

Take the following safety precautions when working with the batteries:

♦Take off watches, rings and other metallic objects!

♦Always use tools with insulated handles!

19

Loading...

Loading...