AEG PROTECT B. 1500, PROTECT B. 3000, PROTECT B. 2000, PROTECT B. 1000, PROTECT B. 750 User Manual

...

OPERATING INSTRUCTIONS UPS

PROTECT B.

750

PROTECT B.

PROTECT B. 1000

PROTECT B. 1500

PROTECT B. 2000

1

PROTECT B. 3000

Thank you for purchasing a PROTECT B. UPS from

AEG Power Solutions.

The following security advices are an important

component of the manual and will prevent any operation

errors and protect you against possible dangers. Read

the manual thoroughly before you first use the appliance.

2

1 Notes on these Operating

Instructions

Duty to Provide Information

These operating instructions will help you to install

and operate the U

PROTECT B. 750, PROTECT B. 1000, PROTECT B. 1500,

PROTECT B. 2000 or PROTECT B. 3000 as well as the

associated external battery units PROTECT B. 1500 BP,

PROTECT B. 2000 BP or PROTECT B. 3000 BP – all referred

to as PROTECT B. in this document – safely and properly,

and for its intended purpose. These operating instructions

contain important information necessary to avoid dangers

during operation.

Please read these instructions carefully prior to

commissioning!

These operating instructions are a composite part of

PROTECT B.

The operator of this unit is obliged to communicate these

operating instructions to all personnel transporting or starting

up PROTECT B. or performing maintenance or any other

work on the unit.

ninterruptible Power Supply (UPS),

Validity

These operating instructions comply with the current technical

specifications of PROTECT B. at the time of publication. The

contents do not constitute a subject matter of the contract, but

serve for information purposes only.

Warranty and Liability

Our goods and services are subject to the general conditions

of supply for products of the electrical industry, and our

general sales conditions. We reserve the right to alter any

specifications given in these operating instructions, especially

with regard to technical data and operation.

3

Claims in connection with supplied goods must be submitted

within eight days of receipt, along with the packing slip.

Subsequent claims cannot be considered.

The warranty does not apply for damage caused by noncompliance with these instructions (such damage also includes

damaging the warranty seal). AEG will accept no liability for

consequential damage. AEG will rescind all obligations such

as warranty agreements, service contracts, etc. entered into

by AEG and its representatives without prior notification in the

event of maintenance and repair work being carried out with

anything other than original AEG spare parts or spare parts

purchased by AEG.

Handling

PROTECT B. is designed and constructed so that all

necessary steps for start-up and operation can be performed

without any internal manipulation of the unit. Maintenance and

repair work may only be performed by trained and qualified

personnel.

Illustrations are provided to clarify and facilitate certain steps.

If danger to personnel and the unit cannot be ruled out in the

case of certain work, it is highlighted accordingly by

pictograms explained in Chapter 3.

Hotline

If you still have questions after having read these operating

instructions, please contact your dealer or our "Hotline":

Tel.: +49 (0)180 5 234 787

Fax: +49 (0)180 5 234 789

Internet: www.AEGpartnernet.com

Copyright

No part of these operating instructions may be transmitted,

reproduced and/or copied by any electronic or mechanical

means without the express prior written permission of AEG.

© Copyright AEG 2009. All rights reserved.

4

Table of Contents

1 Notes on these Operating Instructions.............................3

2 System Description ..........................................................7

2.1 Overview ...................................................................7

2.2 Functionality..............................................................8

3 Safety .............................................................................10

3.1 General Safety Instructions.....................................10

3.2 Safety Instructions for PROTECT B........................10

3.3 Certification .............................................................14

3.4 Technical Data........................................................15

4 Set-Up and Operation ....................................................20

4.1 Unpacking and Inspection.......................................20

4.2 Point of installation..................................................21

4.3 Connections, Operation / Display Elements............22

4.3.1 Front view:........................................................22

4.3.2 Operating panel ...............................................23

4.3.3 Rear view (connections): .................................24

5 Commissioning...............................................................26

5.1 Deployment.............................................................26

5.1.1 Tower (Stand alone deployment).....................26

5.1.2 19” Rack Mount Setup.....................................28

5.2 Additional battery installation setup.........................32

5.3 Emergency Power Off (EPO) set up.......................33

5.4 Electric start-up.......................................................34

5.4.1 Connection.......................................................34

5.4.2 Configuration....................................................35

5.5 Operation.................................................................36

5.5.1 Normal Operation.............................................36

5.5.2 Battery Operation / Autonomous Operation.....36

5.5.3 Unit Overload...................................................37

5.5.4 System Diagnosis / Battery Test......................38

5

5.6 Interfaces and communication................................39

5.6.1 Data line protection RJ11 and RJ45

(modem / telephone / fax / network).................39

5.6.2 Computer interfaces RS232 and USB.............40

5.6.3 Communication slot

(PROTECT B.1500 / B.2000 / B.3000):............40

5.6.4 Shutdown and UPS management software.....40

6 Signalling and failure solution.........................................42

6.1 LED display.............................................................42

6.2 Audible Alarm Trouble Shooting: ............................44

6.3 General Fault Diagnosis and Fault Rectification.....44

7 Maintenance...................................................................46

7.1 Battery replacement................................................47

8 Storage, Dismantling and Disposal................................52

9 Glossary.........................................................................53

9.1 Technical terms.......................................................53

6

2 System Description

PROTECT B. is an Uninterruptible Power Supply

(UPS) for essential loads such as PCs,

i

The PROTECT B. series is a compact, interactive, sinusoidaly

operating USP, available with an output power rate of 750,

1000, 1500, 2000 and 3000 VA.

The design of the USP allows horizontal / lying operation

(Rack/19" with 2U) and vertical / standing operation (Tower).

2.1 Overview

The front of the UPS provides several LEDs and four push

buttons for easy configuration, control and management. The

panel also informs about the state of the power in the

alternating current (AC) branch, indications on net failures and

the charging state of the Output of the UPS. You will find two

LED bars for output load and battery capacity, two state

indicators (net available, battery active) and four alarm

indicators (power failure, failure, battery discharged, overload).

With the push button the acoustic alarm can be deactivated

and the self test of the UPS will be started.

workstations, servers, network components,

telecommunication equipment and similar devices.

Power connectors, communication interfaces and connections

for telephone and network are located on the rear of the

PROTECT B. Important UPS parameters and data are

constantly monitored and are transmitted via USB or serial

RS232 to the “CompuWatch” Software on the management

computer. The optional SNMP adapter allows remote

monitoring via SNMP connector and multi server shutdown

(starting with B.1500).

The main features of the PROTECT B. are:

♦ VI (Line Interactive) protection technology

with sinusoidal output voltage

♦ AVR control system

(automatic voltage regulation with mains operation)

7

♦ Micro processor control for high availability,

suited for generator mode

♦ Easy extension of battery capacity using external

batteries (starting with B.1500)

♦ Advanced battery management with integrated

protection against extreme discharge and overcharge

♦ Overload and short circuit proof

♦ Maintenance free, sealed lead batteries,

hot swappable (starting with B.1500)

♦ User friendly display

for optimal readability / configuration

♦ Intelligent monitoring system

with USB and RS232 interface

♦ Surge protection (RJ11 / RJ45)

for phone, fax, modem and network (10/100MBit/s)

♦ Expansion slot for extension cards, i.e. SNMP

(starting with B.1500)

♦ “CompuWatch” software for shutdown, state report

and measurement for all popular operating systems

(among others Windows, Mac, Linux)

♦ Compact design / variable deployment

due to combination design as tower / rack

(19” kit available optionally for all models)

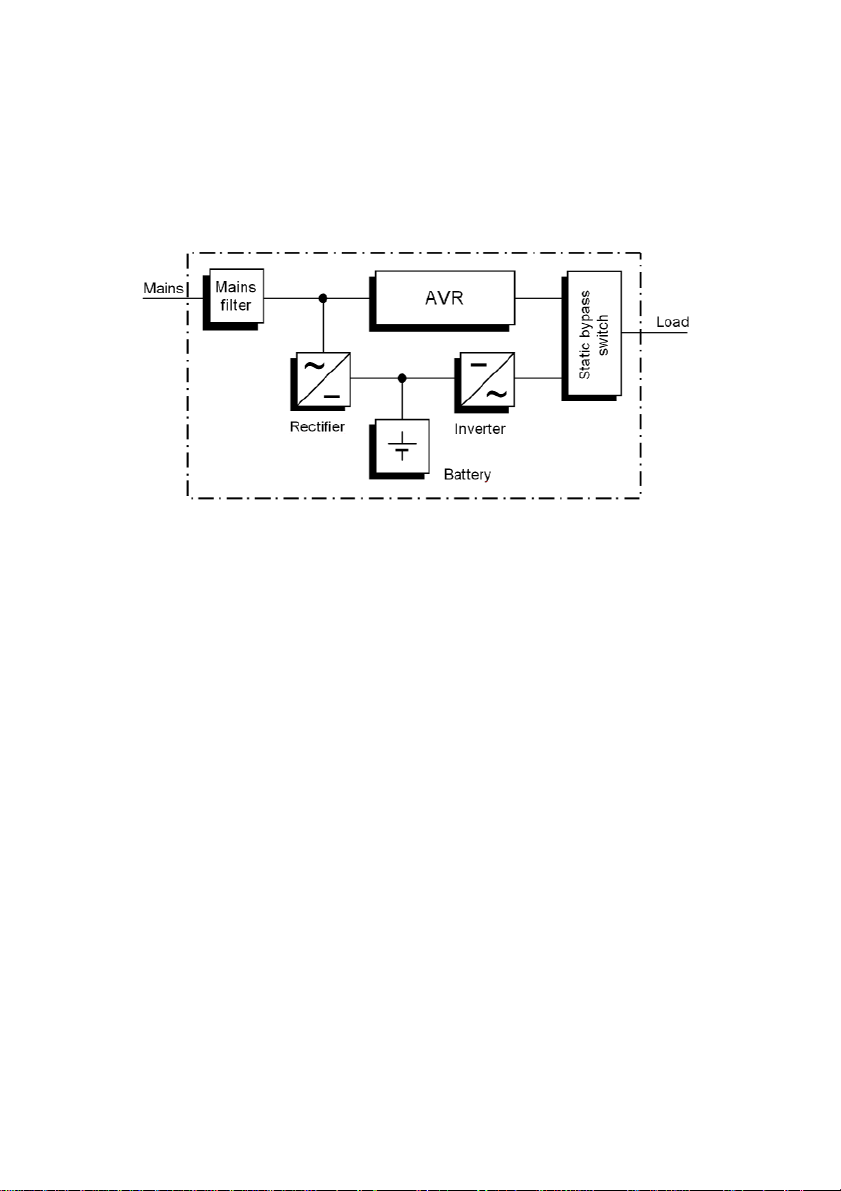

2.2 Functionality

The UPS is connected to a shockproof socket between the

public utility's mains and the loads to be protected.

Under normal operating conditions, i.e. if PROTECT B. is

supplied with mains voltage, the battery charger will ensure

that the battery is always completely charged.

During this operating status, the loads connected to

PROTECT B. are supplied with voltage via mains filters which

provide effective protection against mains voltage peaks and

high-frequency faults.

In case of sustained mains undervoltage or overvoltage within

defined ranges, the automatic voltage regulator (AVR) further

8

stabilizes the load voltage. As a result, voltage fluctuations in

the public utility's mains are reduced to a level which is

acceptable for the loads. This is performed without recourse

to the internal energy storage, something which in turn has a

positive effect on battery availability.

UPS block diagram PROTECT B.

The static bypass switch is activated in the event of a mains

failure. The inverter then takes over the voltage supply of the

connected loads, in order to prevent the risk of data loss or

damage to the loads. PROTECT B. supplies voltage until the

battery is discharged, allowing you to shut down your IT

system properly and switch it off. The standby time mainly

depends on the connected loads. If the mains power supply is

back to normal values, the UPS will switch back the loads to

mains supply. The battery charger will then recharge the

battery.

For safety reasons (as required by German standards, VDE),

the mains input in the unit will be disconnected by a two-pole

switch in the event of a mains failure. Energy backfeed to the

mains and voltage supply to the pins of the mains connector

are thus reliably avoided.

Furthermore, additional protective measures ensure effective

protection for the data/network interface.

9

3 Safety

The unit

may only be opened by trained and qualified

Repairs may only be carried out by

3.1 General Safety Instructions

Read these operating instructions carefully prior to

commissioning of the PROTECT B. UPS and observe the

safety instructions!

Only use the unit if it is in a technically perfect condition and

always in accordance with its intended purpose, while being

aware of safety and danger aspects, and in accordance with

the operating instructions! Immediately eliminate any faults

which could be detrimental to safety.

The following pictograms are used in these operating

instructions to identify dangers and important information:

Danger!

Identifies risk of fatal injury to the operator.

Attention!

Identifies risk of injury and risk of damage to the

unit and parts of the unit.

Information!

i

Useful and important information for operating

the UPS.

3.2 Safety Instructions for PROTECT B.

This chapter contains important instructions for the

PROTECT B. UPS. These must be followed during assembly,

operation and maintenance of the uninterruptible power supply

and the batteries.

The UPS carries high voltage. Danger!

personnel.

qualified customer service staff!

10

The output may be live, even if the UPS is not

connected to the mains supply,

as the UPS has

For health and safety reasons, the unit must be

circuit currents.

Incorrect connection or isolation faults can lead

connections, sparking

The unit has a warning signal that sounds when

the battery voltage of PROTECT B. is exhausted

or when the UPS is not working in its normal

Observe the following safety instructions to

manent operational safety of and safe

its own internal power supply (battery)!

earthed correctly!

PROTECT B. may only be operated with or connected to a

230 Vac mains with protective grounding using a mains

connection cable with PE conductor (included in the delivery)

that has been tested in accordance with German standards

(VDE).

Danger! Risk of burning!

The battery has powerful shortto melting of the plug

potential and severe burns!

mode.

ensure per

work with the UPS:

♦ Do not dismantle the UPS! (The UPS does not contain

any parts which require regular maintenance. Bear in

mind that the warranty will be invalidated if the unit is

opened!)

♦ Do not install the unit in direct sunshine or in close

proximity of heaters!

♦ The unit is designed to be installed inside in heated

rooms. Never install the UPS in the vicinity of water or in

an excessively damp environment!

♦ Condensation may occur if the UPS is brought from a cold

environment into the room where it is to be installed. The

UPS must be absolutely dry prior to start-up. As a result,

leave it to acclimatize for at least two hours.

11

♦ Never connect the mains input to the UPS output.

Even after the mains voltage has been

disconnected, the components within the UPS

remain connected to the battery and can thus

hocks. It is therefore imperative

to disconnect the battery circuit before carrying

If it is necessary to replace the battery or carry

out maintenance work, this must be done by or

t familiar with

Only authorised persons are allowed in the

♦ Ensure that no fluids or foreign bodies can penetrate the

UPS!

♦ Do not block the air vents of the unit! Keep children away

from the unit and ensure that objects are never inserted

through the air vents!

♦ Do not connect household appliances such as hairdryers

to the UPS!

♦ The mains connection should be near the unit and easily

accessible to facilitate disconnecting the AC input or

pulling out the plug!

♦ During operation, do not disconnect the mains connection

cable from the UPS or from the socket outlet in the

building (shockproof socket), otherwise the protective

grounding of the UPS and all the loads connected to it will

be cancelled.

Danger! Electric shocks!

cause electric s

out any maintenance or repair work!

under the supervision of a specialis

batteries and the necessary safety precautions!

vicinity of the batteries!

When replacing the battery/batteries, the following must be

observed: Only ever use identical maintenance-free sealed

lead batteries with the same data as the original battery/

batteries.

12

Danger! Explosive!

Never open

or damage batteries. (Electrolyte may leak out

lectric shocks and high

Never throw batteries into open fire.

and damage skin and eyes. It may be toxic!)

Batteries can cause e

short-circuit currents.

Therefore, take the following safety precautions

when working with batteries:

♦ Take off watches, rings and other metallic

objects!

♦ Only use tools with insulated handles!

For personal safety reasons, never switch on the

main switch when the mains connector of

PROTECT B. is disconnected!

13

3.3 Certification

14

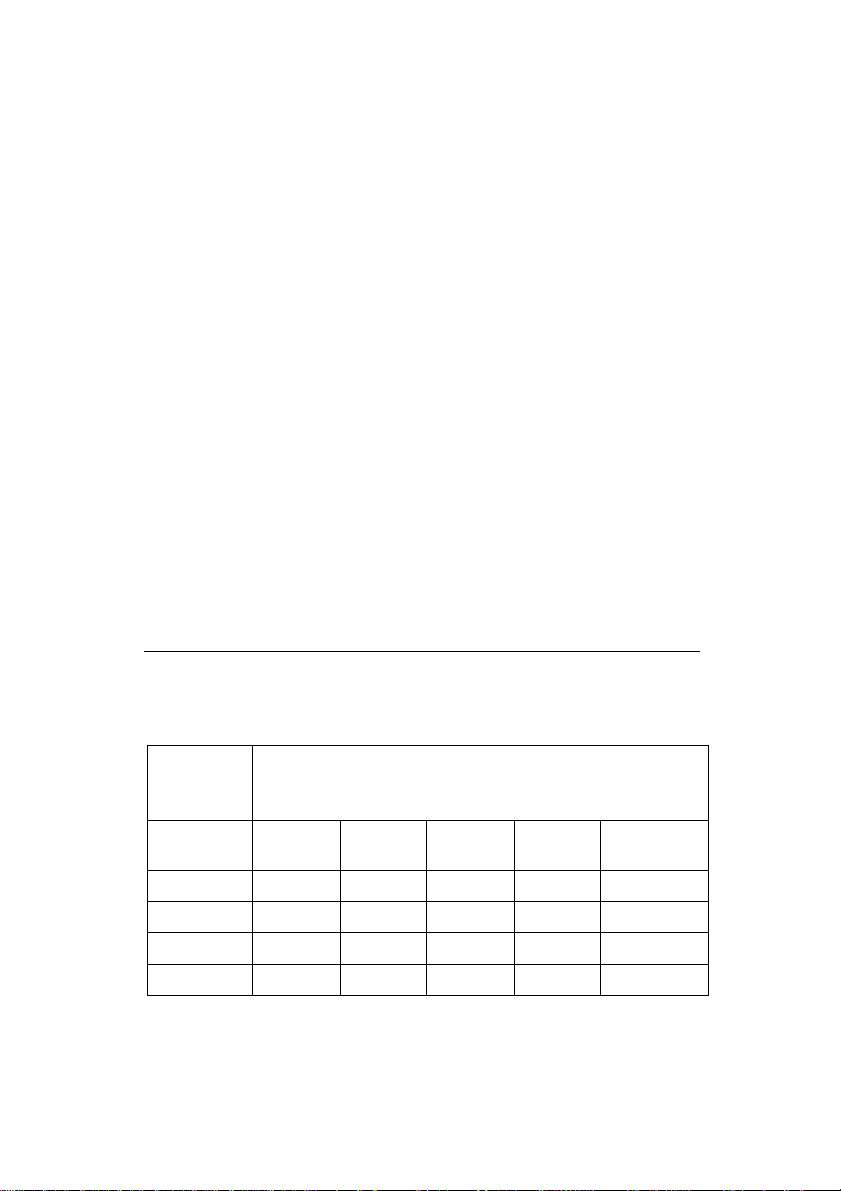

3.4 Technical Data

Model power

PROTECT B. 750 750 VA / 500 W

PROTECT B. 1000 1000 VA / 700 W

PROTECT B. 1500 1500 VA / 1050 W

PROTECT B. 2000 2000 VA / 1340 W

PROTECT B. 3000 3000 VA / 2100 W

UPS Input

Rated output voltage 220 / 230 / 240 Vac

Input voltage range 154 / 161 / 168 Vac ± 4%

Frequency (autom. detection) 50 / 60 Hz ± 5 Hz

Curr. consumption (full-load)

PROTECT B. 750 5 A

PROTECT B. 1000 8 A

PROTECT B. 1500 10 A

PROTECT B. 2000 10 A

PROTECT B. 3000 16 A

Connection IEC power connector

(wide)

176 / 184 / 192 Vac ± 4%

(standard) until

264 / 276 / 288 Vac ± 4%

> 40 Hz (generator mode)

(IEC 320)

USP output

Rated output voltage / 220 / 230 / 240 Vac

AVR-technology

Rated output voltage in ± 5 %

battery mode

Frequency in battery mode 50 Hz / 60 Hz ± 0.1 Hz

15

Output current power (at 230 Vac)

PROTECT B. 750 3.2 A

PROTECT B. 1000 4.3 A

PROTECT B. 1500 6.5 A

PROTECT B. 2000 8.7 A

PROTECT B. 3000 13 A

Transfer time at mains outage 2-4 ms (typical),

6 ms max.

13 ms max.

in generator operation

Voltage waveform sinusoidal

Outlets Non-heating appliance

connectors acc. to IEC 320

Overload response 110% for 3 min. /

at mains operation 150% for 200 ms

Overload response 110% for 30 s /

at battery operation 120% for 100ms

Overheat and short circuit protection Yes

Battery

Autonomy time at rated load 5 min.

Extendable from B.1500

Rated time with external battery packs

Number of

connected

battery

packs

1 15 min. - - - 15 min. - - - 24 min.

2 30 min. 30 min. 27 min. 27 min. 45 min.

3 50 min. - - - 40 min. - - - 55 min.

4 65 min. 65 min. 50 min. 50 min. 75 min.

Autonomy time at rated load

1500 VA

Tower

1500 VA

Rack

2000 VA

Tower

2000 VA

Rack

3000 VA

Tower/Rack

Deep discharge protection / yes

Overload protection

16

Recharge time 3 h (UPS in

(to 90 % of rated capacity) standard configuration)

7 h (UPS with 1 add. battery

pack)

12 h (UPS with 2 add.

battery packs)

18 h (UPS with 3 add.

battery packs)

24 h (UPS with 4 add.

battery packs)

Type Sealed, maintenance free,

hot swappable (from B.1500)

PROTECT B. 750 12 V / 7 Ah x 2

PROTECT B. 1000 12 V / 9 Ah x 2

PROTECT B. 1500 / B. 1500BP 12 V / 7 Ah x 4

PROTECT B. 2000 / B. 2000BP 12 V / 9 Ah x 4

PROTECT B. 3000 12 V / 5 Ah x 8

PROTECT B. 3000 BP 12 V / 5 Ah x 8 x 2

Communication

Interfaces USB and RS232

Additionally from

PROTECT B.1500:

Communication slot

for i.e. SNMP as well as

input contact for

emergency shutdown

Shutdown-Software on CD For all typical operating

systems, e.g. Windows,

Linux, Mac, Unix, FreeBSD,

Novell, Sun

Physical data

Noise (1 m distance) < 45 dB(A)

Operation temperature range 0°C - 40°C

Humidity 0 - 90% (without condens.)

Installation height up to 1000 m at rated power

17

Number of outlets

PROTECT B. 750 4 x IEC 320

PROTECT B. 1000 6 x IEC 320

PROTECT B. 1500 6 x IEC 320 (sep. module)

PROTECT B. 2000 6 x IEC 320 (sep. module)

PROTECT B. 3000 8 x IEC 320-10 A

1 x IEC 320-16 A

Equipment colour Black line

Size W x H x D (mm) Standard model

(Size in horizontal / lying view)

PROTECT B. 750 235 x 88 x 383

PROTECT B. 1000 235 x 88 x 383

PROTECT B. 1500 + B.1500BP (2 x 217) x 88 x 414

PROTECT B. 2000 + B.2000BP (2 x 217) x 88 x 414

PROTECT B. 3000 438 x 88 x 582

PROTECT B. 1500BP 217 x 88 x 414

PROTECT B. 2000BP 217 x 88 x 414

PROTECT B. 3000BP 438 x 88 x 582

Weight (kg)

PROTECT B. 750 8.6 kg

PROTECT B. 1000 9.6 kg

PROTECT B. 1500 + B.1500BP 18.5 kg

PROTECT B. 2000 + B.2000BP 18.5 kg

PROTECT B. 3000 31.5 kg

PROTECT B. 1500BP 12.0 kg

PROTECT B. 2000BP 12.0 kg

PROTECT B. 3000BP 40.5 kg

Cooling boosted self cooling

Store temperature range -15°C - +50°C

(UPS electronic)

Battery / UPS with integr. battery 0°C - +35°C

Certification CE

18

Guidelines

The PROTECT B. complies with the product norm EN 50091.

The CE symbol on the unit certifies the compliance to the EG

guidelines for 73/23 EEC low voltage and for 89/336 EEC

electromagnetic compatibility (EMC), when following the

installation instructions in the manual.

For the 73/23 EEC low voltage guidelines

Reference number EN 62040-1-1 : 2003

For the 89/336 EMC guidelines

Reference number EN 50091-2 : 1995

EN 61000-3-2 : 1995

EN 61000-3-3 : 1995

Warning:

i

This is a class A – UPS product. In a domestic

environment, this product may cause radio

interference, in which case, the user may be

required to take additional measures.

19

4 Set-Up and Operation

Claims for damage during transport must always

4.1 Unpacking and Inspection

The unit has been fully tested and inspected. Although the unit

has been packed and shipped with the usual degree of care,

damage during transport cannot be ruled out completely.

be made with the transport company!

i

Check the shipping container for damage on arrival. If

necessary, ask the transport company to check the goods and

make a record of the damage in the presence of the member

of staff from the transport company and register the damage

with the AEG representative or dealer within eight days of

delivery.

Check the delivery is complete:

♦ PROTECT B. with 700, 1000, 1500, 2000 or 3000 VA

♦ Two plastic feet plus two fixing bras (for B.3000)

♦ Mains connection cable with shockproof plug

♦ Two load connection cables

♦ USB / RS232 communication cable

♦ CD with "CompuWatch" shutdown software

♦ Operating instructions

Check for complete delivery of ordered options like additional

battery modules, 19” mounting kits or communication options

like a SNMP card etc.

Please contact our hotline (see page 4) in case of any

discrepancy.

The original packaging provides effective protection against

mechanical shocks and should be retained so the unit can be

transported safely later on.

20

Please keep the plastic packaging bags away

from babies and children in order to safeguard

against suffocation accidents.

Handle the components with care. Please take

into account their weights. It may be necessary to

engage the help of a second person, particularly

in the case of the PROTECT B. 3000 model.

4.2 Point of installation

PROTECT B. is designed to be installed in a protected

environment. When installing the unit, pay attention to such

factors as sufficient ventilation and suitable ambient

conditions.

PROTECT B. is air-cooled. Do not obstruct the

air vents!

The UPS should preferably be operated at room

temperature (between 15°C and 25°C).

Install the UPS in a room that is dry, relatively dust-free and

free of chemical vapours.

Make sure that no magnetic storage media are stored and/or

operated close to PROTECT B.

Check the nameplate to make sure the voltage

and frequency data correspond to the values

applicable to your loads.

21

4.3 Connections, Operation / Display Elements

wit

with type rating detail

with type rating details

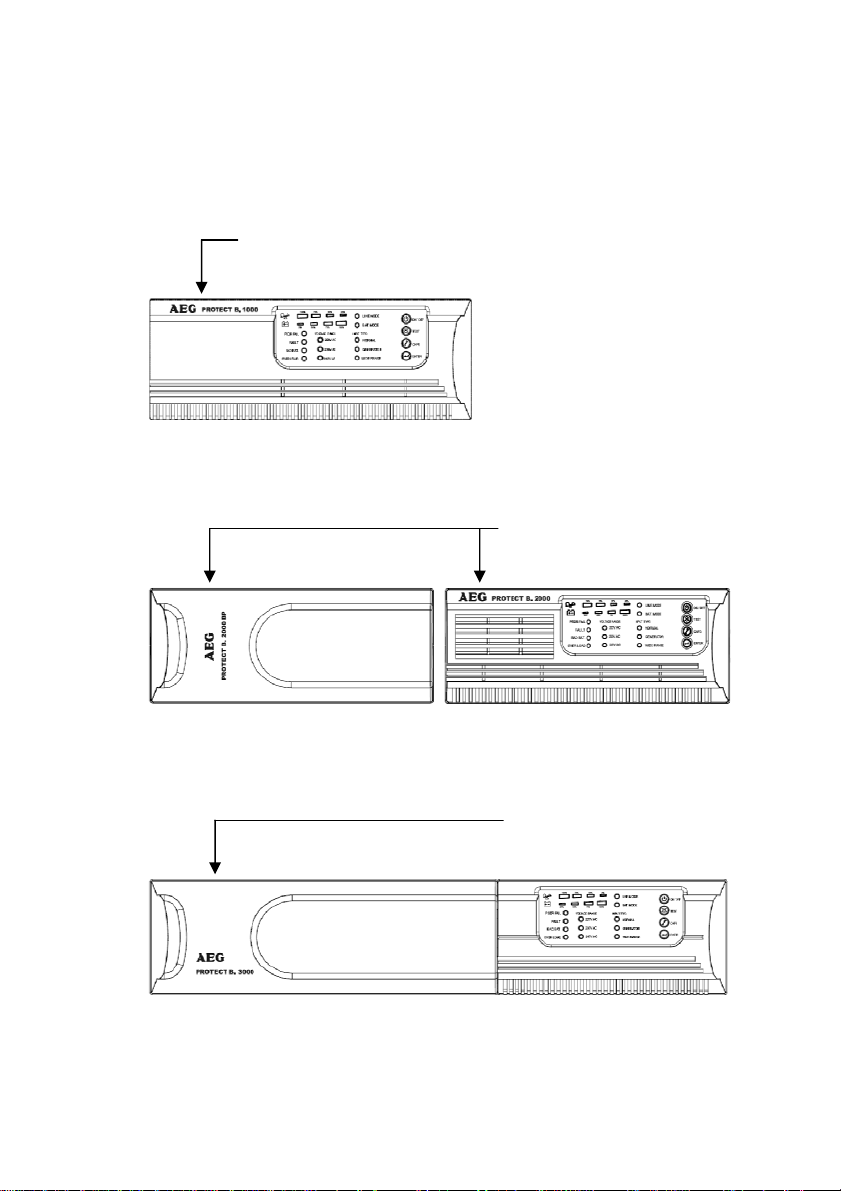

4.3.1 Front view:

Model designation

h type rating details

PROTECT B.750 and B.1000

Model designation

PROTECT B.1500 and B. 2000 (Battery module and UPS)

Model designation

PROTECT B. 3000

s

22

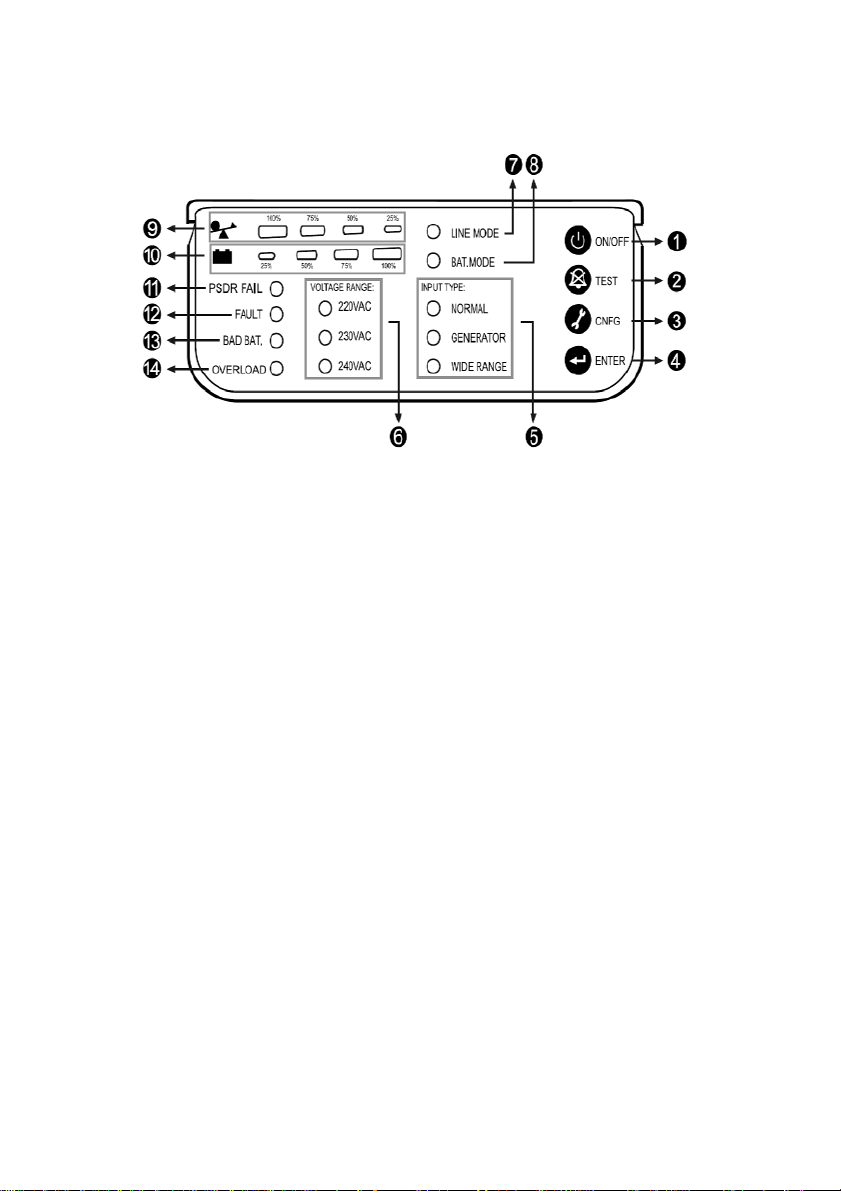

4.3.2 Operating panel

Explanations (see also chapter 6)

1. Main switch of the UPS (mains switch)

2. Pushbutton for system test (manually triggering) or

switching off the buzzer

3. Pushbutton to view the configuration

4. Enter button

5. LED for operating mode (details on page 42)

6. LED for current output rate voltage

7. LED for line mode

8. LED for battery mode

9. Bar graph LEDs for load level

10. Bar graph LEDs for battery capacity

(remaining autonomy time)

11. LED for rectifier failure

12. LED error display

(e.g. UPS overtemperature, short circuit)

13. LED for battery problem (e.g. discharged)

14. LED for fails/overload is timed out /or short output

23

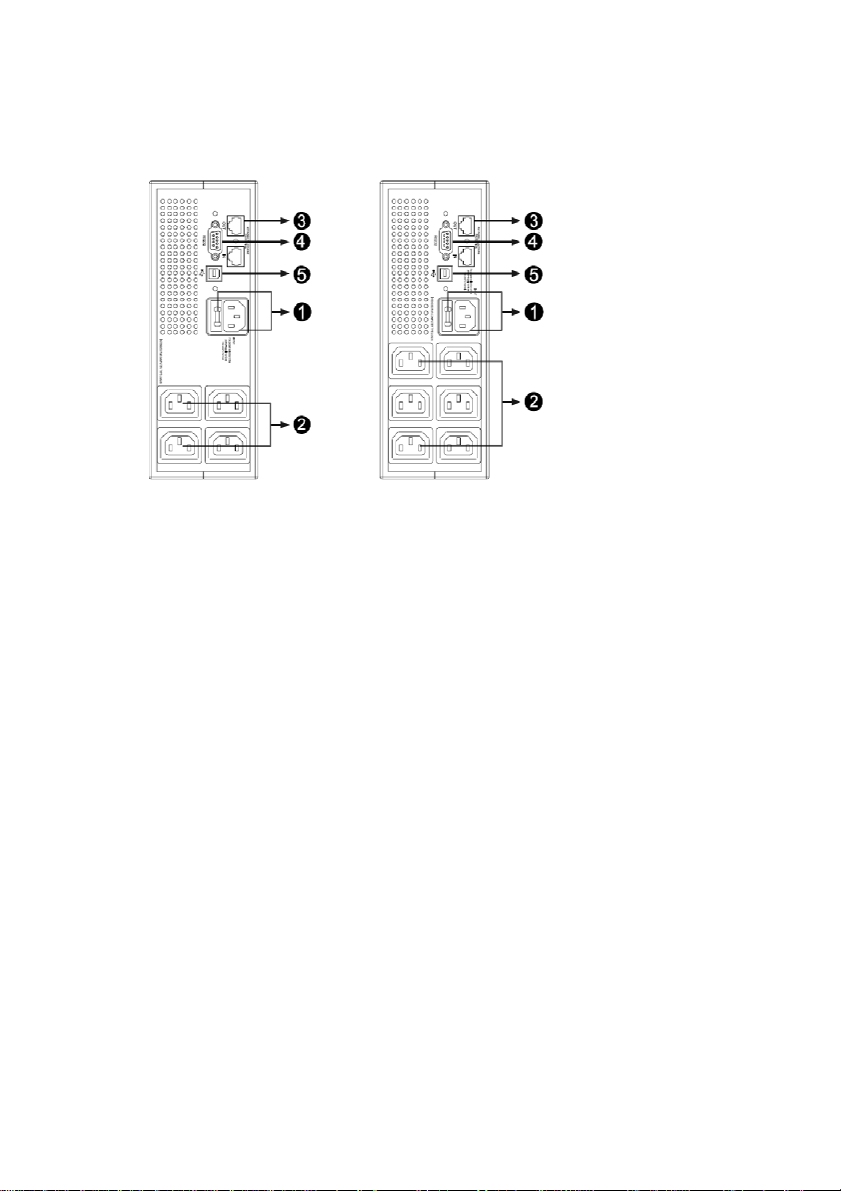

4.3.3 Rear view (connections):

PROTECT B. 750 und 1000

Comments:

1. Mains connection (UPS input) with electric fuse and

integrated spare fuse

2. Load connections (UPS outputs)

3. Surge protection (RJ11/RJ45) for data interface

for phone, fax, modem or network (10/100MBit/s)

4. Communication interface RS232

(9pin SUB-D socket)

5. USB communication interface

24

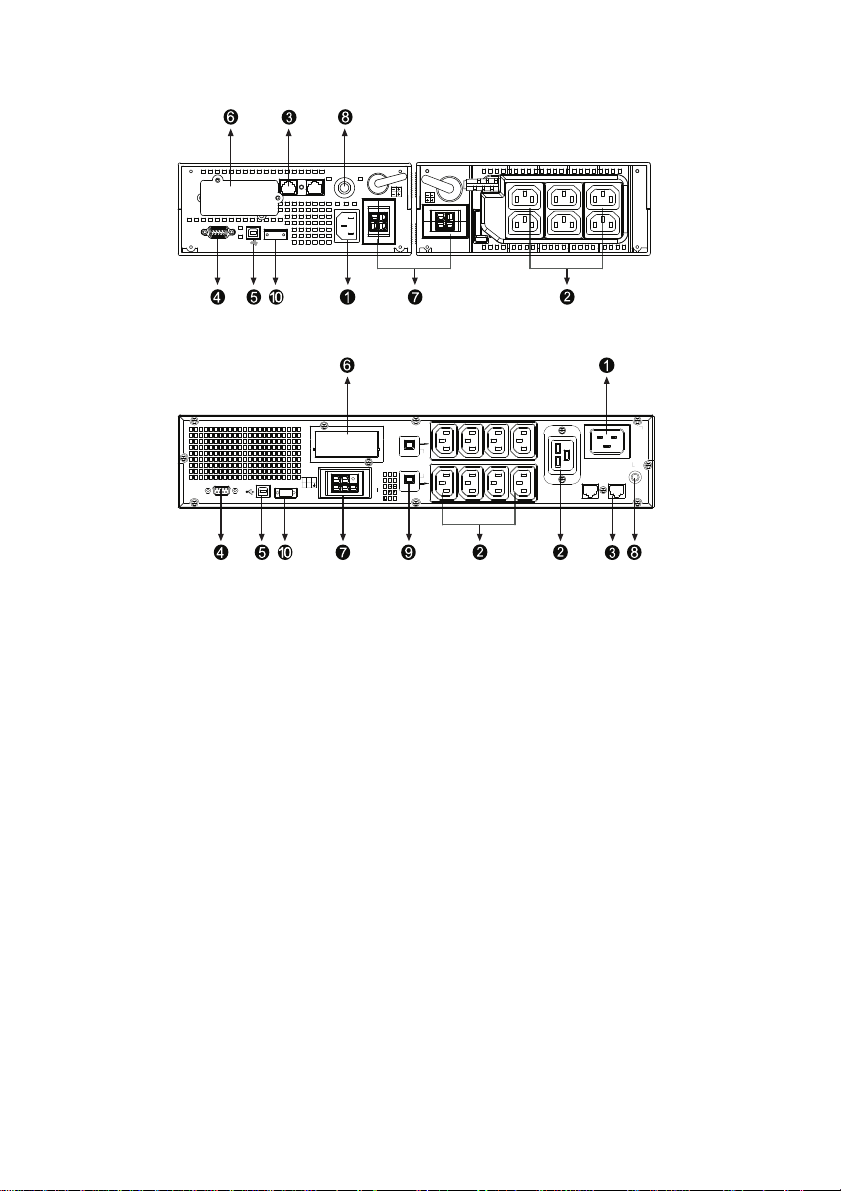

Comments:

SNMP

COM.PORT

EPO

OUT

IN

INPUT

10A MAX

INPUT :48VDC 50A(NOM)

TO/FROM EXTERNAL BATTERY

BREAKER 250VAC/13A

PUSH

TO RESET

10A MAX

OUTPUT

TO/FROM EXTERNAL BATTERY

INPUT

:48VDC 50A(NOM)

+

RS232

_

_

+

EPO

USB

SNMP

TO/FROM EXTERNAL BATTERY

INPUT : 96VDC 24A£¨NOM£©

OUT

IN

Us/Out/Ausg 16A

Max

Us/Out/Ausg 10A

Max

Ue/In/Eing 16A Max

INPUT PROTECTION

120A

/ 250VA

344-00128-00

( 10 A max / Outlet )

OUTPUT PROTECTION

1. Mains connection (UPS input)

2. Load connections (UPS outputs)

PROTECT B. 3000 with additional load connection

(IEC 320-16A)

3. Surge protection (RJ11/RJ45) for data interface

for phone, fax, modem or network (10/100MBit/s)

4. Communication interface RS232

(9pin SUB-D socket)

5. USB communication interface

6. Communication slot for optional expansion cards

7. Connection for external battery module

(battery extension)

8. Mains input circuit breaker

9. Circuit breaker for load connections (only for

PROTECT B. 3000)

10. Input contact for emergency shutdown (EPO)

25

5 Commissioning

5.1 Deployment

The UPS was constructed for both horizontal / flat (rack/19")

operation and vertical / standing (tower) operation.

Operation the unit for longer time above an

ambient temperature of 25° C reduces the lifetime

of the batteries.

Position the UPS unit at least 20 cm away of any

other electronic equipment to prevent

interference.

After deployment and assembly of the UPS follow the steps

for activation as explained in chapter 5.4

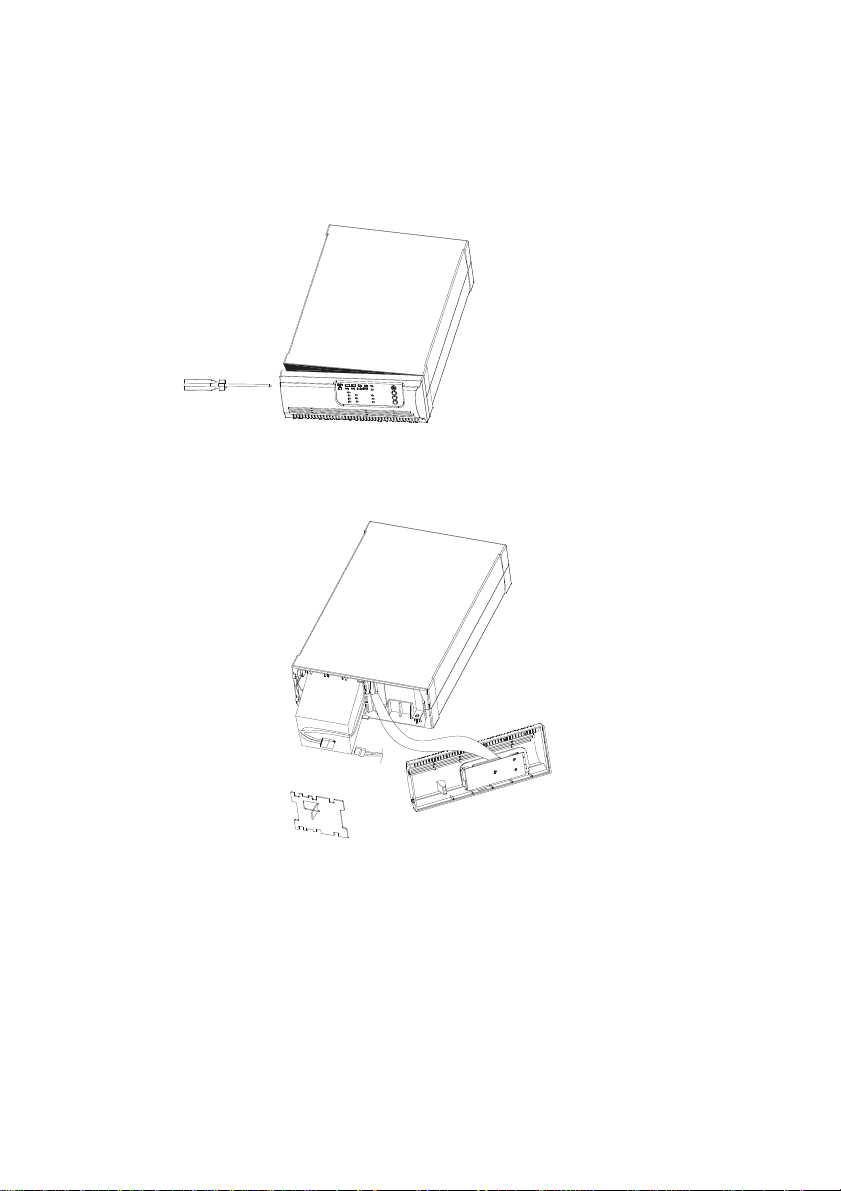

5.1.1 Tower (Stand alone deployment)

All models are qualified for stand alone use. PROTECT B. 750

and 1000 consist each of only one component and can be set

up either standing or lying position

PROTECT B. 750 / 1000 standing and lying

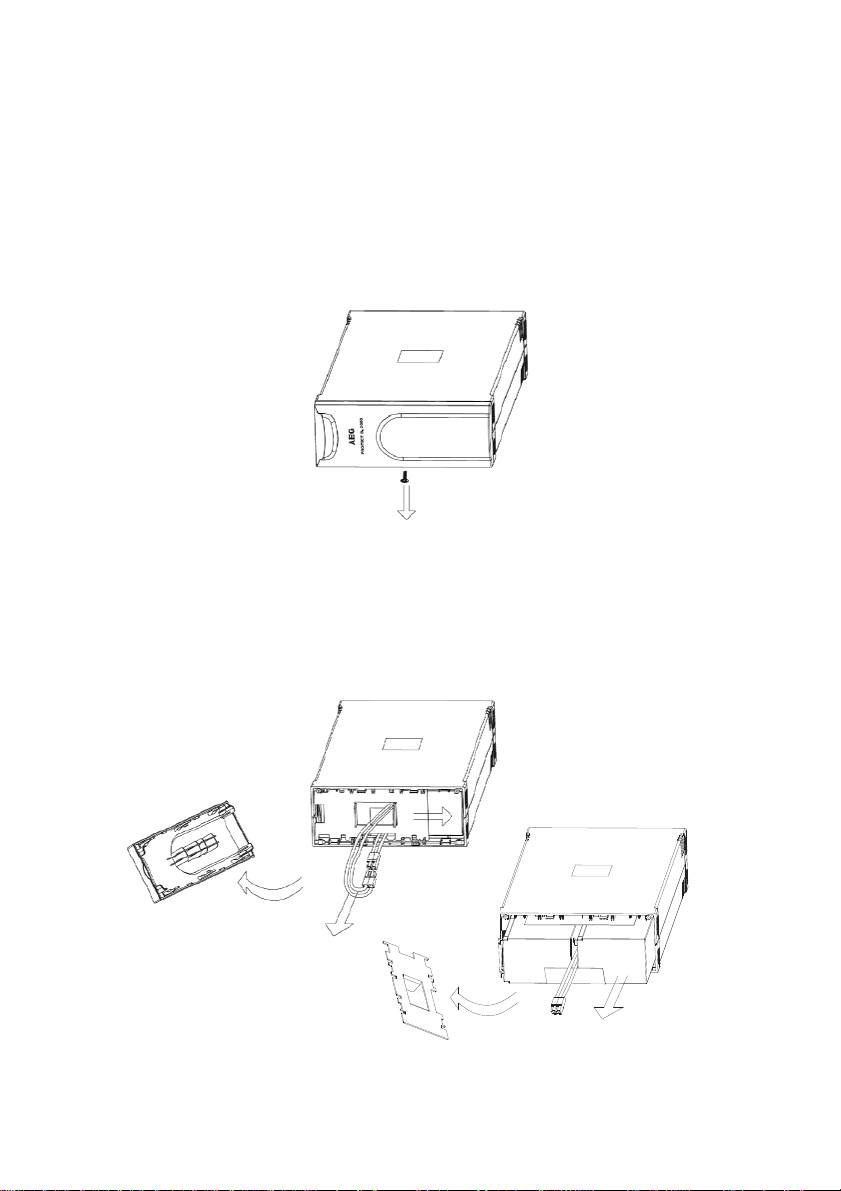

PROTECT B. 1500 and B. 2000 are operated always in

combination with at least one additional battery module.

Because of the air intake in the front and the rear there is a

variety of deployment positions.

26

When operating the system with more than one battery

module, the UPS can be positioned between the modules.

The following graphic displays the possibilities:

PROTECT B. 1500 / 2000 standing and lying (standard version)

PROTECT B. 3000 can be operated in the standing and lying

position as well. Putting up the UPS upright requires the use

of the two provided supports. The supports have to be

positioned in the front third and rear third of the unit.

PROTECT B.3000 standing

Please consider for the location of setup also the guidelines

on page 21 of the manual.

27

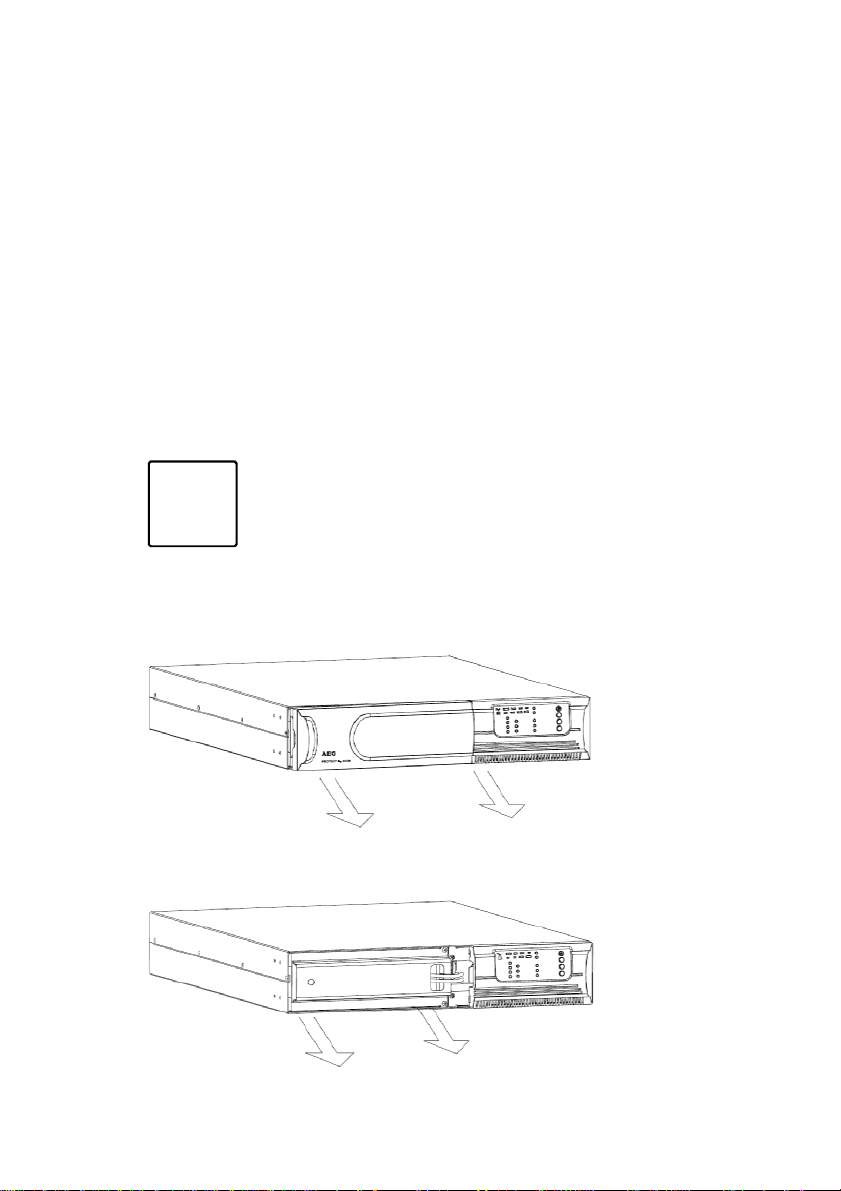

5.1.2 19" Rack Mount Setup

ROTECT B. 750, 1000, 1500, 2000 and 3000 can be installed

in 19” racks. The UPS and external battery enclosure need 2U

of valuable rack space. Mount the UPS preferable in the lower

third of the rack with respect to the mass centre and sufficient

ventilation.

Use the optional 19” mounting kit for the installation in the

rack.

PROTECT B. 750 und B.1000

1. Fix the mounting ears on the side of the UPS

according to the following figure.

2. Mount these subsequently to the slide assemblies.

3. Insert UPS into the slide assemblies and lock it in the

rack enclosure.

28

4. Add up the front panels for both sides. The

mechanical installation of the UPS is completed now.

PROTECT B. 1500 und B. 2000

This model is designed such that the UPS and the battery

module can be mounted beside each other into the rack.

29

1. Place the UPS on a flat and in a clean place that the

front side of the UPS is facing to you.

2. Loosen the screws in the middle of the cover and

remove the covers from both units.

3. Fix the (wide) mounting bracket to the open front.

Rack mounting holes stand out on each side of the

units.

4. Secure the bracket with the supplied screws to the

UPS and the battery module.

5. Reinstall the covers.

30

6. Align the second (smaller) mounting bracket at the rear

of both units and mount them with the enclosed screws.

7. Install Plug of the battery module with the socket at

the rear panel of the USP. Fix the output module to

the notch of the battery module.

The setup of the rack-mount is completed.

PROTECT B. 1500 BP / B. 2000 BP

If you want to install optional external battery modules in a 19”

rack use two of the units together and follow the steps 1 to 7

as described above.

31

PROTECT B. 3000 / B. 3000 BP

For mounting the 3000 VA UPS in a 19” rack fix the mounting

ears to the UPS and install the unit to the rails. Do the same

for the optional battery module.

100%

25%

50%75%

LINE MODE

ON / OFF

BAT. MODE

100%

25%

75%50%

TEST

TAGE RANGE:

VOL

INPUT

TYPE:

PSDR F

AIL

220V AC

NORMAL

F

AULT

CNFG

230V

AC

TOR

GENERA

BAD BA

T.

ENTER

240V AC

WIDE RANGE

OVER LOAD

5.2 Additional battery installation setup

PROTECT B. 1500, 2000 und 3000 include external battery

ports that allow connecting additional battery modules. This

provides additional battery runtime.

Caution:

Connect the battery connectors quickly and

check for a tight fit of the connections.

PROTECT B. 1500 und B. 2000

There is one external battery port on the UPS and on the

battery pack.

1. Connect the battery cable to the external battery

port of the rear of UPS.

2. Then connect the supplied battery cable from

extended battery module to the external battery

port on the rear of the UPS.

If continuing to add up extended battery packs, repeat

above step.

32

PROTECT B. 3000

After pressing the EPO all outputs of the UPS are

ting the system you have

to quit / reset the EPO and manually restart the

Connect the supplied battery module cable from extended

battery module to the external battery port of the rear of UPS.

If continuing to add up extended battery module, repeat above

steps.

5.3 Emergency Power Off (EPO) set up

PROTECT B. 1500, 2000 and 3000 include EPO port that

allows power to be shut down the protected equipment

immediately and does not follow the shutdown procedure from

any power management software.

Note:

i

Follow the procedure to install the EPO switch as below.

1. Check the UPS is turned off.

2. Remove the power supply from the EPO cradle

3. Connect isolated, normally-open, dry contacts

4. Use non-shield wiring, size 0,3 mm² - 0.75

5. Verify that the externally-connected EPO switch

6. Plug in the UPS, then pressing power switch

without power. For restar

UPS by pressing the on / off button.

on the rear of the UPS by loosening the two

outer screws.

(rated to handle 60Vdc maximum, 30Vac RMS

maximum, and 20mA maximum) across the

EPO device to Pin 1 and Pin 2.

mm². Plug the connector into the socket and fix

it by screwing the two outer screws tight.

is not activated to enable power to the UPS

output receptacles.

button to turn on the UPS.

33

7. Activate the external EPO switch to test the

EPO function

8. De-activate the external EPO switch and restart

the UPS.

5.4 Electric start-up

First compare the setting with the rated voltage valid in your

country. The factory default setting is 230 V

Make any changes in accordance with the description in

chapter 5.4.2 “Configuration”.

5.4.1 Connection

Now connect the input of the UPS (pos. 1 fig. p. 24/25) to the

mains connection cable provided and plug the mains

connector into a suitable shockproof socket.

1. Avoid using extension cables and/or

adapters. In particular in the case of highcapacity types, ensure that the fusing in your

sub-distribution is adequately dimensioned:

The PROTECT B. 3000 for example requires

its own connection with a 16 A fuse. No other

loads should be connected to this circuit!

2. Then connect the outputs of your UPS (pos.

2 fig. p. 24/25) to your loads. Use the load

connection cables provided for this. Don’t

switch on the loads yet. Please contact your

dealer if you require additional load

connection cables.

3. Now switch on the UPS. To do this, press

and hold the UPS main switch for about 3

seconds until the display goes on.

4. The UPS acknowledges your command by

starting a self test. During this automatically

running procedure a periodically audible

signal can be heard The green "Mains" LED

is permanently illuminated when the normal

34

operating stag has been reached (pos. 7 p. 3).

Please shut down the entire system if you cannot

solve any problems which occur. Please contact

In case anything different occurs, please

follow the instructions in Chapters 6.2 / 6.3.

i

In particular, bear in mind the considerable power

consumption of loads such as laser printers, large CRT

monitors and the like which can quickly lead to a UPS

overload.

5.4.2 Configuration

To reconfigure the internal UPS setup options, follow the

procedure as below:

1. Press the Configure

2. Press the Configure

3. After selecting the mode, press the Enter

our hotline (see page 4).

5. When the LINE MODE display is lit, switch

seconds. Then UPS will transfer from configure mode

to “output voltage mode” showing the value by a

flashing LED at 220 Vac, 230 Vac or 240 Vac.

second, the UPS allows you to select the “output

voltage mode” one by one.

more than three seconds, the “output voltage mode”

is configured.

on your loads one after the other. Note the

maximum permitted UPS load when doing

this (pos. 9 fig. p. 42).

button more than three

button more than one

button

4. UPS will automatically transfer from configure mode

to “operating mode” displayed by a flashing LED

beside NORMAL, GENERATOR or WIDE RANGE.

5. Press the Configure

second; the UPS will allow you to select the “operating

mode” one by one.

button more than one

35

6. After selecting the mode, press the confirmation

button

configuation.

5.5 Operation

Once you have connected the UPS to a suitable mains

connection, you can start operation using the UPS main

switch.

On and Off switch

♦ To switch on the USP press the button for about 3

sec. (until the display goes on).

♦ To switch off the UPS press the button until the UPS

signal stops.

Normally, the UPS operates continuously. The UPS now supplies

the output with voltage, this being signaled by the green LED

LINE MODE which lights up permanently (pos. 7 p. 42).

5.5.1 Normal Operation

During normal operation, i.e. when mains voltage is available,

the built-in battery charger keeps the battery fully charged and

the mains voltage monitoring system switches the inverter to

standby mode.

The connected loads are powered using the monitored and

filtered mains voltage, which is additionally stabilised by the

integrated AVR control unit.

more than three seconds to complete the

The UPS capacity utilisation can be read off the bar chart of

the operating panel (pos. 9, fig. p. 42).

5.5.2 Battery Operation / Autonomous Operation

When there is a mains failure or if the input voltage moves

outside the tolerance range, the inverter automatically

switches over to autonomous mode and supplies the loads

with voltage from the battery. This drains the capacity of the

battery and it is discharged. This status is signalled by the

yellow LED BAT.MODE flashing as well as an intermittent

acoustic signal (s. p. 42)

36

If the UPS does not automatically return to normal operation

If the LED BAT.MODE flashes every second, it is

ystem and all connected

loads! Shut down the UPS as well using the main

after a few minutes, close all jobs as usual and switch off your

loads (e.g. PC) before the battery is fully discharged. This

lengthens the service life of the battery! Switch OFF the UPS

by pressing the main switch .

During the discharge process as the battery capacity

consistently drops, the LED BAT.MODE flashes, accompanied

by an intermittent double acoustic signal (once every four

seconds). When the battery undervoltage limit is reached

(acoustic signal every second), the electronic of the UPS

switches off the power supply for the loads.

Never store the unit in this condition! The discharged battery

system should be recharged within a week.

time shut down the s

switch.

When the mains voltage comes back, the UPS must be

switched on again using the main switch (only applies if it

was previously switched off manually), in order to recharge the

battery and thus store sufficient battery capacity for any

possible future mains failures.

The batteries will be charged automatically when connected to

the mains, independently of the mode set. The charging time

after longer discharge of the batteries depends especially of

the number of connected external battery units.

The charging time up to 90% of the rate capacity for a

standard UPS is about 3 hours.

5.5.3 Unit Overload

If the unit is overloaded (load > 110 %), an intermittent signal

is heard. The power supply to the connected loads is

maintained, however the connected total load must be

reduced immediately.

Non-observance of the "Unit overload" condition may cause

the total loss of all UPS functions!

37

Also avoid short-term unit overloads, which may, for example,

Never connect any additional loads to the UPS

if there is a mains failure, i.e. if the UPS is

occur when connecting a laser printer or laser fax machine.

Do not connect any household appliances to the UPS.

working in emergency power operation.

The UPS output is de-energised if there is an overload of 150 %

for longer than 200 ms during normal operation. During

emergency power operation, an instant shutdown additionally

takes place if there is a unit overload of > 120 % (see Chapter

3.4). As a rule, if there has never been an overload during

normal operation, there will not be one during battery

operation either.

5.5.4 System Diagnosis / Battery Test

It is possible to press the "TEST" button

perform a manual check on the major hardware components

of the UPS. This test can only be initiated if the unit is

operating normally, and it involves switching the loads over to

UPS inverter supply for a few seconds. As well as checking

the procedures and the functional capability of the static

bypass switch, this check also involves drawing current from

the battery for a short time. The inverter has to provide the

entire load supply, which means the entire process chain is

tested with this function. Normal operation is restored after the

check.

(pos. 2 p. 42) to

38

Executing the Test:

ection supports networks with

♦ To execute the manual check press the button

about five seconds until the UPS acoustic signal fades

out.

♦ Additionally the button has the function to deactivate

the acoustic alarm signal. Press the button

the acoustic alarm it audible for about 1 second. The

tone stops. Any new error that is reported by a signal

activates the alarm signal again.

Note:

The acoustic signal can not be switched off in

the following situations:

Battery weak, overload, fan failure, fan error,

time cutout, overheat.

If the monitoring electronics detect an irregularity during the

procedure described above, the load is immediately switched

back onto the mains and is thus supplied with voltage. At the

same time, an acoustic fault signal and the corresponding

signals from LEDs in acc. with Chapter 6 "Signalling" are

output.

Faults detected and signalled during diagnosis

must be rectified; otherwise there is a risk of

load voltage loss if a mains failure occurs!

for

when

5.6 Interfaces and communication

5.6.1 Data line protection RJ11 and RJ45

(modem / telephone / fax / network)

The incoming data lines are connected to the “IN” line at the

rear of the UPS. The “OUT” line is connected via data line with

your terminal.

The data line prot

transfer rates between 10 and 100 MBit/s.

i

39

5.6.2 Computer interfaces RS232 and USB

The UPS offers various interfaces to manage the system and

to comfortable readout state information and important

parameters. The protocol is optimized for operation with the

shutdown and UPS management software “CompuWatch”

from AEG. To connect to the UPS use the provided RS232 or

USB cable by attaching them to a free port of your pc.

RS232 interface: The interface is connected via a 9 pole Sub-D

connector on the back of the unit (pos. 4 p. 24 / 25).

PIN configuration: 2 = RxD; 3 = TxD; 5 = GND.

USB interface: The connection via USB is recognized

automatically (pos 5 p. 24 / 25).

USB- and RS232 interfaces can not be used at

the same time.

i

5.6.3 Communication slot

(PROTECT B. 1500 / 2000 / 3000):

If the cover on the rear of the UPS is removed, additional

optionally available communication components can be

installed there.

SNMP board: Slot card for direct connection of the UPS to

the Ethernet network with RJ 45 (TCP/IP)

Details can be found in the description enclosed with the

particular optional component. Other boards are in

preparation.

Using the communication slot deactivates the

RS232 interface of chapter. 5.6.2.

i

5.6.4 Shutdown and UPS management software

Especially for monitoring the state of the UPS and the supply

of power AEG developed the software “CompuWatch”.

40

In combination with the intelligent UPS the software ensures

high availability of all IT components and full data integrity.

The shutdown software “CompuWatch” supports most popular

operating systems like Windows 98/ME, WindowsNT/2000/

XP, Linux, Novell Netware, IBM AIX, HP-UX, SUN Solaris,

Mac OS X, ...

Details concerning installation on diverse operating systems

can be found in the manual on the CD.

Download of updates via www.AEGpartnernet.com >>

PRODUCTS >> Software >> CompuWatch

41

6 Signalling and failure solution

6.1 LED display

1. Main switch of the UPS (mains switch)

2. Push button for manually triggering the system test or

switching off the buzzer

3. Push button to view the configuration

4. Acknowledgement button

5. INPUT TYPE: LED for preselected operation state

and output voltage

NORMAL: (Normal mode) The LED indicator will

illuminate during normal mode, the UPS accepts AC

input voltage range from +/-20%.

GENERATOR: (Generator mode) No change to

voltage window. However, the low frequency transfer

point is changed to 40Hz and there is no limitation for

high frequency transfer point.

WIDE RANGE: (Extended UPS)

AC input voltage ranges from -30% / +20%.

6. VOLTAGE RANGE: LED for current output rate

voltage 220Vac / 230Vac (ex factory) / 240Vac.

7. LINE MODE: Green LED for power mode. The line

LED indicator illuminates when the AC source is

present.

8. BAT. MODE: Yellow LED for battery mode. The LED

indicator will flash every four seconds when the UPS

42

is providing battery power to your equipment. On the

other hand, the LED indicator gives you a warning

which will flash every two seconds when the battery is

low.

9.

LED: Bar chart LEDs showing UPS utilization.

The LED indicator and the load level indicator will

illuminate to show the load level; linearly subdivided in

25% steps.

10.

11. PSDR FAIL: LED error display for corrupt inverter.

12. FAULT: Central error LED display, e.g. when UPS is

13. BAD BAT.: LED for battery problem (e.g.

14. OVERLOAD: LED for violation of overload time limit.

LED: Bar chart LEDs showing battery capacity

(remaining standby time). The

battery level indicator will illuminate to show battery

level. Each LED indicator displays a 25% capacity

level.

overloaded or encounters a short circuit on the output.

discharged). The LED indicator will flash every two

seconds when the battery failes or if the battery is

disconnected. Please check your battery connection;

replace the battery or contact your local dealer for a

battery replacement kit.

The LED indicator will light on when the UPS overload

timeout. (Information concerning the time limit is

available in chapter 3.4).

LED indicator and

43

6.2 Audible Alarm Trouble Shooting:

Problem Cause Solution

Sounding every 4

seconds

Sounding every

second

Continuously

sounding

The UPS is on battery Check the input voltage,

The battery is running low Save your work and turn

Output overload Check load level indicator

The UPS fails Please contact your local

Battery may need to

charge or service

the input fuse resp. the

circuit breaker

off your equipment

and remove some load

dealer

Charge or replace the

battery

6.3 General Fault Diagnosis and Fault Rectification

Problem Cause Solution

The UPS is not on

when power switch is

pressed

The power cord is

not connected

correctly

The wall outlet may

be faulty

Check the power cord

connection, especially the fit

of the plug in the socket of the

UPS

Please contact your local

qualified electrician

The UPS output

may short-circuit or

overload

Internal fuse may be

blown

44

1. Disconnect all loads and

restart UPS. Connect loads

again one by one.

2. Ensure loads are not

detective or shorted internally

Please contact your local

dealer

UPS could not

provide power to the

load

Output fuse it

released

UPS output

recognizes overload

or short circuit

Check the output fuse

(B. 3000)

Check the connected cable

Ensure the load does not

exceed the maximum rating of

UPS

Battery has reduced

backup time

.

Connected equipment

lose power while

connected to the UPS

The UPS fault LED

lights on

Battery is not

charged

Battery may not

able to hold a full

charge due to age.

The UPS may be

over- loaded

The UPS may be

failed

The UPS fails Save your work and turn off

Re-charge the battery at least

24 hours

Replace Battery

Check the load status on the

bar graph, reduce the load if

necessary

Please contact your local

dealer

equipment. Please contact

your local dealer

If you cannot solve the problem which has occurred, stop the

entire procedure, switch off the UPS and disconnect the

connector from the socket. Please contact our hotline in this

case (see page 4).

Please have the serial number of the unit as well as the

purchase date to hand in this case. The hotline will provide

you with technical support and can inform you about further

procedures once you have described the problem.

45

7 Maintenance

The PROTECT B. consists of advanced and resistant

components. To guarantee a continuous and high availability it is

recommended to check the unit (especially the batteries and the

fans) in regular intervals (at least every 6 months).

CAUTION:

Follow safety and security regulations

unconditionally!

Visual control

When going through the visual control check whether:

♦ mechanical defects or foreign matter is visible in the

system

♦ conducting dirt or dust sediments are in the unit and

♦ dust sediments prevent optimal ventilation in and out

the unit.

CAUTION:

Before going through the next step disconnect

the PROTECT B. from the mains.

If the unit is very dusty it is recommended to clean the UPS

with compressed air to enable optimal ventilation.

The time intervals for the visual control depend mainly on the

local situation at the deployment site.

Battery control

The aging process can be detected by regular capacity

probes. Make comparison measurements every 12 month e.g.

by simulating a power failure and check how long the standby

time lasts. The load should always be the same for each

simulation. Dramatic changes compared to the last

measurements require a change of batteries. Contact your

local dealer or call our hotline (see page 4).

46

Fan control

A battery can present a risk of electrical shock

.

The following precautions should be observed

f you are not qualified service personnel to

replace the battery, do not attempt to open the

battery door. Please call local dealer or

The fan has to be checked on a regular basis for dust

intrusion and strange untypical sounds. Clogged ventilation

has to be cleaned. If the fan makes a strange noise or runs

irregular contact the hotline (see page 4).

7.1 Battery replacement

CAUTION:

and can be very dangerous if handled improperly

before replacing the batteries.

♦ Turn off the UPS and disconnect the utility power cord

from the wall outlet.

♦ Remove rings, watches, and other metal objects.

♦ If the battery replacement kit is damaged in anyway or

shows signs of leakage, contact your dealer

immediately.

♦ Properly recycle or dispose of used battery. Do not

dispose of batteries in a fire. The batteries may

explode.

Note:

i

I

distributor immediately.

47

PROTECT B. 750 and B.1000

1. Unscrew the two screws on the side and remove the

front panel carefully on both ends. Make sure that the

panel does not tilt too much.

2. Disconnect the battery cable from the UPS and remove

the battery retaining battery bracket to the right so that

the battery can be pulled out to the front.

3. Withdraw the new batteries from the transport container

an put into the right position. Fix both blocks together

and connect the electric connections of the extracted

battery system.

4. Slide the new battery carefully into shaft of the UPS until

the end. Mount the bracket for fixing the battery pack

and connect the system electrically. Push the contact

together quickly and firmly. Take care of the right

polarity ( red - red / black - black)

48

5. Close and reinstall the front panel. Take care to push it

in firmly and fix the front panel with the two screws from

the beginning.

PROTECT B. 1500 und B. 2000

1. Unscrew the two screws from the battery case and

remove front panel by pulling on both ends.

2. Disconnect the battery cable from the battery

module and remove the bracket by sliding it to the

side. (Remember the position of the bracket for

the reassembly. The notches are good for

orientation).

49

3. Withdraw the new batteries from the transport

container and put into the right position. Fix both

blocks together and connect the electric

connections of the extracted battery system.

4. Slide the new battery carefully into shaft of the

UPS until the end.

5. Mount the bracket for fixing the battery pack and

connect the cable joint between the battery packs

(red-red / black-black). Close and reinstall the

front panel. Take care to push it in firmly and fix

the front panel with the two screws from the

beginning.

The battery exchange is completed.

Alternatively a complete battery module can be

provided ex factory as a spare part. Ask your

i

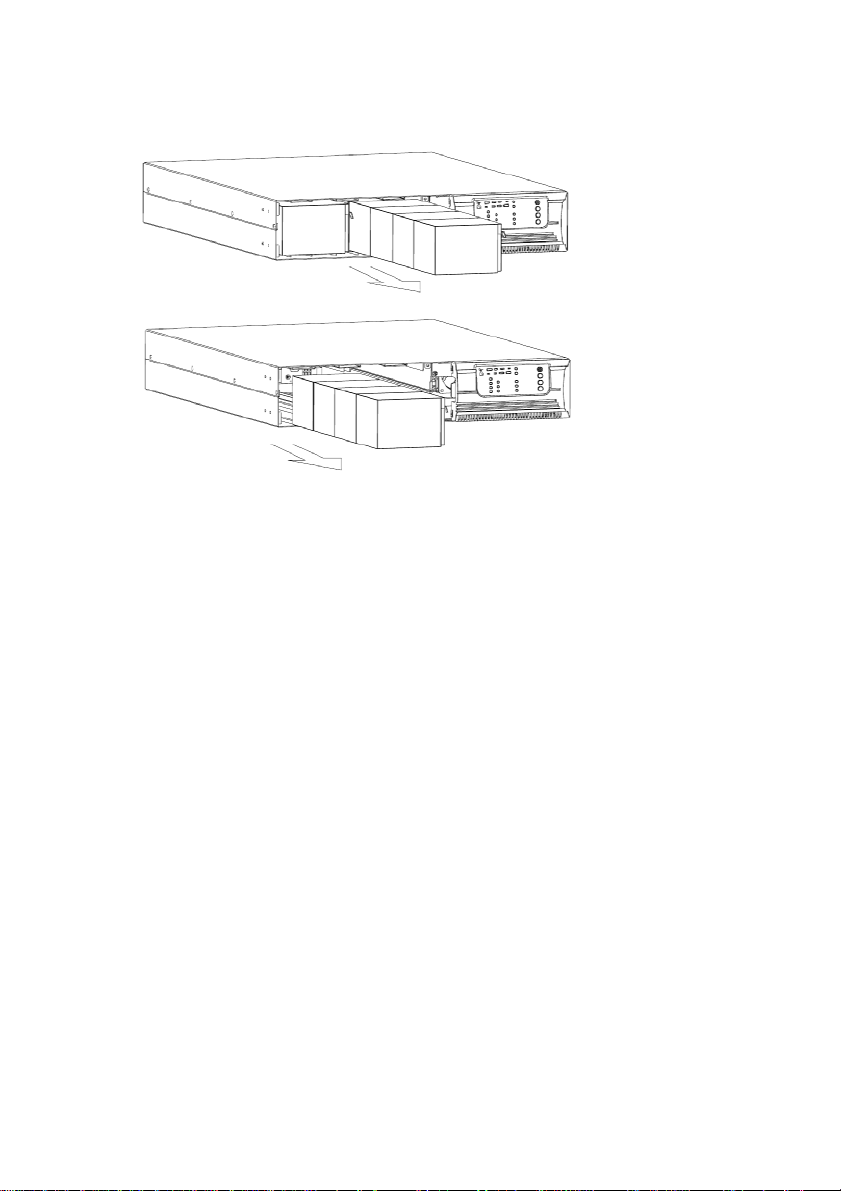

PROTECT B. 3000

1. Remove the left front panel carefully by pulling on

local dealer or call the hotline (see page 4).

both ends.

2. Disconnect the battery cable and remove the battery

bracket.

50

3. Pull first the right battery out and then the left one.

4. Withdraw the new batteries from the transport

container and put into the right position. Fix both

blocks together and connect the electric connections

with the junction line of the extracted battery system.

5. Slide the new batteries into battery module carefully

into the shaft.

6. Mount the bracket for fixing the battery pack and

connect the system electrically ( red - red / black black).

7. Close and reinstall the previously removed front

panel.

The battery exchange is completed.

51

8 Storage, Dismantling and Disposal

Long storage times without charging or

discharging the battery at regular intervals may

Connect PROTECT B. to the mains without load

ing it into storage, in order to make

The charging time should be at least as long as

Storage

lead to permanent damage of the battery.

If the battery is stored at room temperature (20

will automatically discharge at a rate of 3-6 % per month due

to internal reactions. Storing the battery at temperatures

above room temperature should be avoided. A high storage

temperature also means greater battery self-discharge.

Batteries that are stored at room temperature should be

recharged every six months to maintain their full capacity and

service life.

before putt

i

sure that the battery is fully charged.

recommended in chapter 3.4 “Technical Data”.

Dismantling

0

C to 300C) it

The system is dismantled in reverse order of the installation

instructions.

Disposal

In the interest of environmental protection and recycling,

please dispose condemned components in accordance with

the regulations and legal guidelines when permanently taking

the system out of operation.

52

9 Glossary

9.1 Technical terms

AVR Automatic Voltage Regulation

DC/DC Booster Circuit technology to boost the direct voltage

EPO E

PFC P

Appliance protection Surge technology term

Class D see appliance protection

LED L

SNMP S

VFD Output V

VI Output V

VFI Output V

against mains voltage variations

on a higher voltage level

mergency Power Off

device for emergency shut down

ower Factor Correction

Circuit technology to minimize circuit

backfeed (important for non linear loads)

The conventional mains surge protection

consists of an mains earthwire (class B),

an overvoltage protection (class C) and an

appliance protection (class D) – see also

e.g. under http://www.phoenixcontact.de

(topic „TRABTECH“)

ight Emitting Diode

Electronic semiconductor component,

commonly called light diode. Used for optical

signaling.

imple Network Management Protocol

common protocol in networks to manage /

control appliances

oltage and Frequency Dependent

from mains supply

The UPS output depends of mains voltage

and frequency variations. Former notation:

OFFLINE

oltage Independent from mains supply

The UPS output is independent of mains

voltage and frequency variations. The mains

voltage however is rectified by electronic /

passive voltage regulators. Former notation:

LINE-INTERACTIVE

oltage and Frequency Independent

from mains supply

The UPS output is independent of mains

voltage and frequency variations. Former

notation: ONLINE

53

Guarantee certificate

Type: …….…………………......................................................

Serial-no.: ……………………..……………...............................

Date of purchase: …………….............……………………........

Trading stamp / Signature

Specifications are subject to change without notice.

AEG Power Solutions GmbH

Emil-Siepmann-Straße 32

59581 Warstein-Belecke

Germany

Operating Instructions UPS

BAL 8000015758_01 EN

54

Loading...

Loading...