Toshiba RAS-24SA-ES, RAS-18S2AH-ES, RAS-24SKP-ES, RAS-18SKP-ES, RAS-24S2AH-ES SERVICE MANUAL

...

FILE NO. SVM-09036

SERVICE MANUAL

AIR CONDITIONER

SPLIT WALL TYPE

RAS-18SKHP-ES / RAS-18S2AH-ES RAS-24SKHP-ES / RAS-24S2AH-ES RAS-18SKP-ES / RAS-18SA-ES RAS-24SKP-ES / RAS-24SA-ES

February, 2009

FILE NO. SVM-09036

CONTENTS

1.SPECIFICATIONS

2.CONSTRUCTION VIEWS

2-1 Indoor Unit

2-2 Outdoor Unit

3.WIRING DIAGRAM

3-1 RAS-18SKP-ES / RAS-18SA-ES, RAS-24SKP-ES / RAS-24SA-ES

3-2 RAS-18SKHP-ES / RAS-18S2AH-ES RAS-24SKHP-ES / RAS-24S2AH-ES

4.SPECIFICATION OF ELECTRICAL PARTS

4-1 Indoor Unit (RAS-18SKP-ES, RAS-24SKP-ES) 4-2 Outdoor Unit (RAS-18SA-ES)

4-3 Outdoor Unit (RAS-24SA-ES)

4-4 Indoor Unit (RAS-18SKHP-ES, RASP-24SKHP-ES) 4-5 Outdoor Unit (RAS-18S2AH-ES)

4-6 Outdoor Unit (RAS-24S2AH-ES)

5.REFRIGERATION CYCLE DIAGRAM

5-1 RAS-18SKP-ES / RAS-18SA-ES 5-2 RAS-24SKP-ES / RAS-24SA-ES 5-3 RAS-18SKHP-ES / RAS-18S2AH-ES 5-4 RAS-24SKHP-ES / RAS-24S2AH-ES

6.CONTROL BLOCK DIAGRAM

6-1 RAS-18SKP-ES / RAS-18SA-ES, RAS-24SKP-ES / RAS-24SA-ES

6-2 RAS-18SKHP-ES / RAS-18S2AH-ES RAS-24SKHP-ES / RAS-24S2AH-ES

– 1 –

FILE NO. SVM-09036

7.OPERATION DESCRIPTION

7-1 Remote control

7-2 Outline of Air Conditioner Control

7-3 Description of Operation Circuit

7-4 Description of Safety and Reliability Prevention Function 7-5 One-Touch Operation

7-6 Hi POWER Operation

7-7 QUIET Operation

7-8 ECO Operation

7-9 COMFORT SLEEP Operation

7-10 FILTER Check lamp

7-11 Auto Restart Function

7-12 Self-Cleaning Operation

8.INSTALLATION PROCEDURE

8-1 Safety Cautions

8-2 Installation Diagram of Indoor and Outdoor Units 8-3 Installation

8-4 Indoor Unit

8-5 Outdoor Unit

8-6 Test Operation

9.TROUBLESHOOTING CHART

9-1 Troubleshooting Procedure

9-2 Basic Check Items

9-3 Primary Judgement

9-4 Self-Diagnosis by Remote Control (Check Code) 9-5 How To Diagnose Faulty Parts

9-6 Troubleshooting for Indoor unit

9-7 Troubleshooting for Wiring (Interconnect cable and Serial Signal Wire) 9-8 Troubleshooting for P.C. Board

9-9 Troubleshooting for Remote Control

10.HOW TO REPLACE THE MAIN PARTS

10-1 Indoor Unit

10-2 Outdoor Unit

11.EXPLODED VIEWS AND PARTS LIST

11-1 Indoor Unit (E - Parts Assy)

11-2 Indoor Unit

11-3 Outdoor Unit (RAS-18SA-ES, RAS-24SA-ES)

11-4 Outdoor Unit (RAS-18S2AH-ES, RAS-24S2AH-ES)

− 2 −

FILE NO. SVM-09036

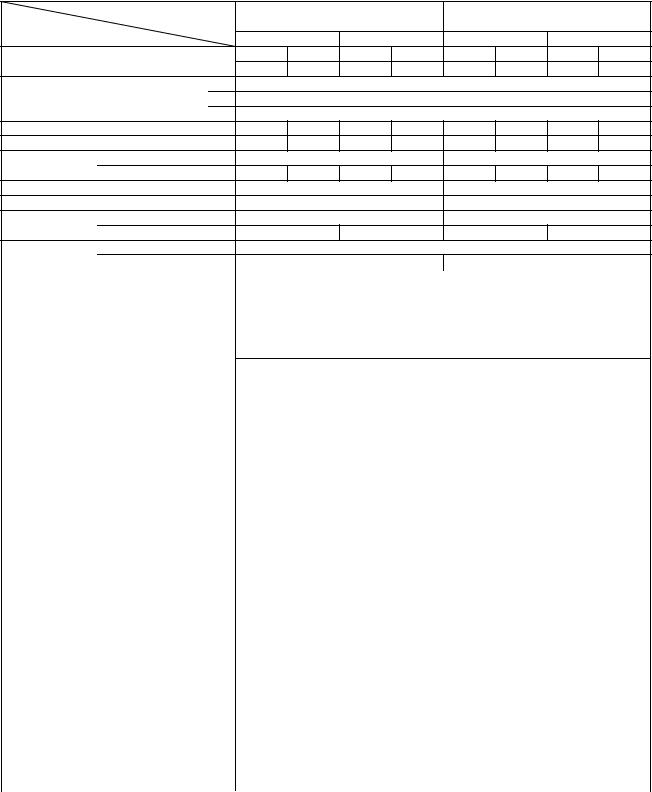

1. SPECIFICATIONS

|

MODEL |

|

RAS-18SKP-ES |

RAS-24SKP-ES |

|||

|

|

|

|

RAS-18SA-ES |

RAS-24SA-ES |

||

ITEM |

|

|

|

|

Cooling |

|

Cooling |

Capacity |

|

|

220V |

|

240V |

220V |

240V |

|

kW |

5.30 |

|

5.35 |

6.80 |

6.85 |

|

|

|

|

|||||

|

|

Phase |

|

|

|

1 |

|

Power source |

|

V |

|

|

|

220 - 240 |

|

|

|

Hz |

|

|

|

50 |

|

Power consumption |

|

W |

1640 |

|

1680 |

2410 |

2450 |

Power factor |

|

% |

98 |

|

97 |

98 |

93 |

Running |

|

A |

0.3/7.30 |

0.3/6.90 |

0.50/14.70 |

0.50/12.90 |

|

Current |

Indoor/Outdoor |

|

|||||

|

|

|

|

|

|

||

Starting current |

|

A |

|

|

31 |

|

44 |

Moisture removal |

|

lit/h |

|

|

2.0 |

|

2.7 |

Noise |

Indoor (H/M+/M/L+/L) |

dB |

|

44/42/39/37/35 |

45/43/41/39/37 |

||

|

Outdoor (220-240V) |

dB |

56 |

|

57 |

56 |

57 |

Refrigerant |

Name of refrigerant |

|

|

|

|

R410A |

|

|

Rated amount |

kg |

|

|

1.65 |

|

1.70 |

Refrigerant control |

|

|

|

|

|

Capillary tube |

|

||

Interconnection |

Gas side size |

mm |

|

|

|

12.7 |

|

||

pipe |

Connection type |

|

|

|

|

Flare connection |

|

||

|

Liquid side size |

mm |

|

|

|

6.35 |

|

||

|

Connection type |

|

|

|

|

Flare connection |

|

||

|

Maximum length |

m |

|

|

|

15*1 |

|

|

|

|

(One way) |

|

|

20*2 |

|

25*2 |

|

||

|

Maximum height |

m |

|

8 |

|

10 |

|

||

|

difference |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

INDOOR UNIT |

|

|

|

RAS-18SKP-ES |

|

RAS-24SKP-ES |

|

||

Dimensions |

Height |

mm |

|

|

|

320 |

|

|

|

|

Width |

mm |

|

|

|

1050 |

|

|

|

|

Depth |

mm |

|

|

|

228 |

|

|

|

Net weight |

|

kg |

|

|

|

13 |

|

|

|

Evaporator type |

|

|

|

|

|

Finned tube |

|

||

Indoor fan type |

|

|

|

|

|

Cross flow fan |

|

||

Airflow volume |

High fan |

m3/h |

|

1000 |

|

1100 |

|

||

|

Medium fan |

m3/h |

|

880 |

|

950 |

|

||

|

Low fan |

m3/h |

|

750 |

|

850 |

|

||

Fan motor output |

|

W |

|

|

|

30 |

|

|

|

Air filter |

|

|

|

|

Honeycomb woven filter with PP frame |

|

|||

OUTDOOR UNIT |

|

|

|

RAS-18SA-ES |

|

RAS-24SA-ES |

|

||

Dimensions |

Height |

mm |

|

|

|

715 |

|

|

|

|

Width |

mm |

|

|

|

780 |

|

|

|

|

Depth |

mm |

|

|

|

290 |

|

|

|

Net weight |

|

kg |

|

45 |

|

50 |

|

||

Condenser type |

|

|

|

|

|

Finned |

tube |

|

|

Outdoor fan type |

|

|

|

|

|

Propeller fan |

|

||

Airflow volume |

|

m3/h |

2400 |

|

2550 |

|

2450 |

|

2600 |

Fan motor output |

|

W |

|

|

|

42 |

|

|

|

Compressor |

Model |

|

PA200X2CS-4KU1 |

|

PA270X3CS-4MU2 |

||||

|

Output |

W |

|

1500 |

|

2000 |

|

||

Safety device |

|

|

|

|

|

Fuse |

, IOL |

|

|

Louver type |

|

|

|

|

|

Automatic louver |

|

||

Usable outdoor temperature range |

°C |

|

|

|

15 ~ 43 |

|

|

||

Note *1 Chargeless pipe *2 Maximum pipe

− 3 −

FILE NO. SVM-09036

|

MODEL |

|

RAS-18SKHP-ES |

|

|

RAS-24SKHP-ES |

|

|||

|

|

|

|

RAS-18S2AH-ES |

|

|

RAS-24S2AH-ES |

|

||

ITEM |

|

|

Cooling |

Heating |

Cooling |

Heating |

||||

Capacity |

|

|

220V |

240V |

220V |

240V |

220V |

240V |

220V |

240V |

|

kW |

5.10 |

5.12 |

5.45 |

5.56 |

6.30 |

6.35 |

6.80 |

6.90 |

|

|

|

|||||||||

|

|

Phase |

|

|

|

|

1 |

|

|

|

Power source |

|

V |

|

|

|

220 - 240 |

|

|

|

|

|

|

Hz |

|

|

|

|

50 |

|

|

|

Power consumption |

|

W |

1540 |

1580 |

1470 |

1530 |

2190 |

2250 |

2050 |

2140 |

Power factor |

|

% |

98 |

96 |

98 |

97 |

98 |

93 |

98 |

93 |

Running |

Indoor |

A |

|

|

0.30 |

|

|

|

0.30 |

|

Current |

Outdoor |

A |

6.85 |

6.55 |

6.55 |

6.30 |

9.90 |

9.80 |

9.20 |

9.30 |

Starting current |

|

A |

|

|

31 |

|

|

|

44 |

|

Moisture removal |

|

lit/h |

|

|

2.0 |

|

|

|

2.5 |

|

Noise |

Indoor (H/M+/M/L+/L) |

dB |

|

44/42/39/37/35 |

|

|

45/43/41/39/37 |

|

||

|

Outdoor (220-240V) |

dB |

|

56-57 |

57-58 |

|

|

56-57 |

57-58 |

|

Refrigerant |

Name of refrigerant |

|

|

|

|

R410A |

|

|

|

|

|

Rated amount |

kg |

|

|

1.53 |

|

|

|

1.62 |

|

Refrigerant control |

|

|

|

|

|

|

|

|

Capillary tube |

|

|

|

|

|

|

||

Interconnection |

Gas side size |

mm |

|

|

|

|

|

|

12.7 |

|

|

|

|

|

|

|

|

pipe |

Connection type |

|

|

|

|

|

|

|

Flare connection |

|

|

|

|

|

|

||

|

Liquid side size |

mm |

|

|

|

|

|

|

6.35 |

|

|

|

|

|

|

|

|

|

Connection type |

|

|

|

|

|

|

|

Flare connection |

|

|

|

|

|

|

||

|

Maximum length |

m |

|

|

|

20*2 |

|

15*1 |

|

|

|

25*2 |

|

|

|||

|

(One way) |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Maximum height |

m |

|

|

|

8 |

|

|

|

|

|

|

10 |

|

|

||

|

difference |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INDOOR UNIT |

|

|

|

|

RAS-18SKHP-ES |

|

|

|

|

RAS-24SKHP-ES |

|

||||||

Dimensions |

Height |

mm |

|

|

|

|

|

|

320 |

|

|

|

|

|

|

|

|

|

Width |

mm |

|

|

|

|

|

|

1050 |

|

|

|

|

|

|

|

|

|

Depth |

mm |

|

|

|

|

|

|

228 |

|

|

|

|

|

|

|

|

Net weight |

|

kg |

|

|

|

|

|

|

13 |

|

|

|

|

|

|

|

|

Evaporator type |

|

|

|

|

|

|

|

|

Finned tube |

|

|

|

|

|

|

||

Indoor fan type |

|

|

|

|

|

|

|

|

Cross flow fan |

|

|

|

|

|

|

||

Airflow volume |

High fan |

m3/h |

|

1000 |

|

1000 |

|

|

|

1100 |

|

1100 |

|

||||

|

Medium fan |

m3/h |

|

880 |

|

900 |

|

|

|

950 |

|

950 |

|

||||

|

Low fan |

m3/h |

|

750 |

|

770 |

|

|

|

850 |

|

850 |

|

||||

Fan motor output |

|

W |

|

|

|

|

|

|

30 |

|

|

|

|

|

|

|

|

Air filter |

|

|

|

|

|

|

Honeycomb woven filter with PP frame |

|

|

|

|

||||||

OUTDOOR UNIT |

|

|

|

|

RAS-18S2AH-ES |

|

|

|

|

RAS-24S2AH-ES |

|

||||||

Dimensions |

Height |

mm |

|

|

|

715 |

|

|

|

|

|

|

715 |

|

|

||

|

Width |

mm |

|

|

|

780 |

|

|

|

|

|

|

780 |

|

|

||

|

Depth |

mm |

|

|

|

290 |

|

|

|

|

|

|

290 |

|

|

||

Net weight |

|

kg |

|

|

|

47 |

|

|

|

|

|

|

53 |

|

|

||

Condenser type |

|

|

|

|

|

|

|

|

Finned |

tube |

|

|

|

|

|

|

|

Outdoor fan type |

|

|

|

|

|

|

|

|

Propeller fan |

|

|

|

|

|

|

||

Airflow volume |

|

m3/h |

2400 |

|

2550 |

|

2400 |

|

2550 |

|

2400 |

|

2550 |

|

2400 |

|

2550 |

Fan motor output |

|

W |

|

|

|

|

|

|

42 |

|

|

|

|

|

|

|

|

Compressor |

Model |

|

|

|

PA200X2CS-4KU1 |

|

|

|

|

PA270X3CS-4MU2 |

|

||||||

|

Output |

W |

|

|

|

1500 |

|

|

|

|

|

|

2000 |

|

|

||

Safety device |

|

|

|

|

|

|

|

Td sensor , |

Fuse , IOL |

|

|

|

|

||||

Louver type |

|

|

|

|

|

|

|

|

Automatic louver |

|

|

|

|

|

|

||

Usable outdoor temperature range |

°C |

15 ~ 43 |

|

-10 ~ 24 |

|

15 ~ 43 |

|

-10 ~ 24 |

|||||||||

Note *1 Chargeless pipe *2 Maximum pipe

− 4 −

FILE NO. SVM-09036

Note : 1

• Capacity is based on the following temperature conditions.

|

Condition |

|

JIS C9612 |

|

Temperature |

Cooling |

Heating |

||

|

||||

Indoor unit inlet air temperature |

(DB) |

27°C |

20°C |

|

(WB) |

19°C |

15°C |

||

|

||||

Outdoor unit inlet air temperature |

(DB) |

35°C |

7°C |

|

(WB) |

24°C |

6°C |

||

|

||||

Note : 2 |

|

|

|

• Charge refrigerant according to the table below.

|

Refrigerant |

RAS-18SKP-ES / RAS-18SA-ES |

RAS-24SKP-ES / RAS-24SA-ES |

|

RAS-18SKHP-ES / RAS-18S2AH-ES |

RAS-24SKHP-ES / RAS-24S2AH-ES |

|

|

|

||

|

|

|

|

*1 |

No need to charge |

15 m or less |

15 m or less |

|

extra refrigerant |

||

|

|

|

|

|

|

|

|

*2 |

Need to charge |

Over 15 m up to 20 m (20 g/m) |

Over 15 m up to 25 m (20 g/m) |

|

extra refrigerant |

||

|

|

|

– 5 –

FILE NO. SVM-09036

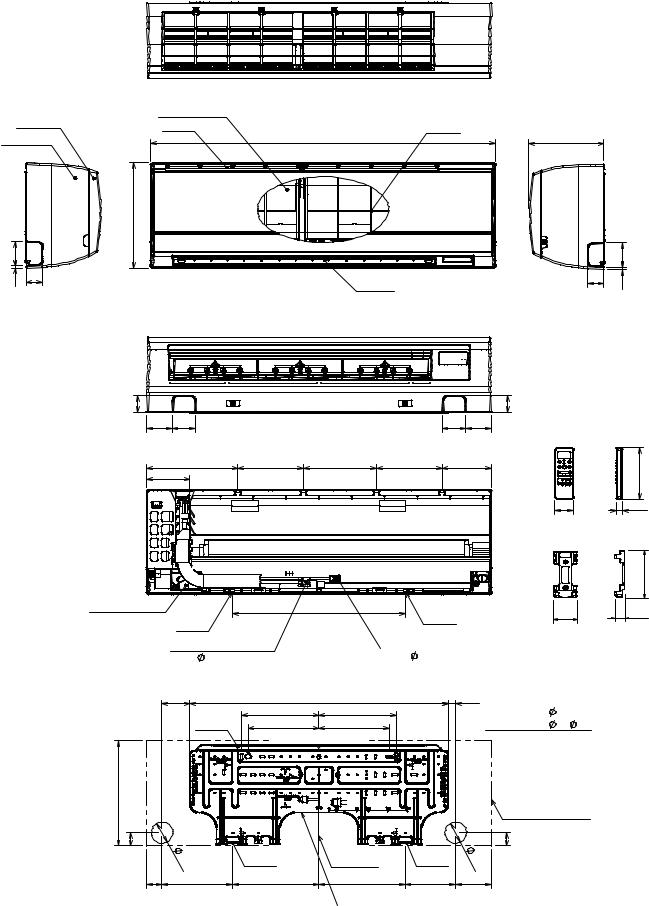

2. CONSTRUCTION VIEWS

2-1. Indoor Unit

Grille Inlet |

Heat exchanger |

|

|

|

Air inlet |

Air filter |

|||

Front Panel |

|

|

1050 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

320 |

73.5 |

|

7 |

50 |

|

Air outlet |

228

|

73.5 |

50 |

7 |

Knock out system |

|

|

|

|

|

Knock out system |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

|

|

|

|

|

50 |

|

78 |

72 |

|

|

|

72 |

78 |

|

132 |

278 |

200 |

222 |

200 |

150 |

157 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

56 |

19 |

Wireless remote controller

125

Drain hose (0.5m) |

|

525 |

Hanger |

63 |

26 |

|

|

|

|

||||

Hanger |

|

|

|

|

||

|

|

|

Remote controller holder |

|||

Connecting pipe (0.39m) |

Connecting pipe (0.49m) |

|||||

|

|

|||||

(Flare |

12.70) |

(Flare |

6.35) |

|

|

|

85

Hanger

320

40

6 5

47 215.5

|

|

|

786 |

|

|

|

|||||

235 |

235 |

||||||||||

215 |

215 |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hanger |

Center line |

Hanger |

262.5262.5 153.5

Installation plate outline

23

For stud bold ( |

6) |

For stud bold ( |

8~ 10) |

Outline of indoor unit

40

6 5

109

− 6 −

FILE NO. SVM-09036

2-2. Outdoor Unit

A

28 |

108 |

125 |

|

|

600 |

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

R15 |

|

|

|

|

|

|

|

|

|

|

|

|

36 |

|

|

|

|

|

|

|

|

|

|

|

320 |

306 |

R5.5 |

Ø6 hole |

320 |

86 |

|

|

|

|

320 |

306 |

|

|

|

|

|

|

|

|

|

|

|

Ø6 Hole |

|

36 |

R15 |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Ø11x14 Hole |

50 |

||

A Detail Drawing (Back leg) |

|

|

|

|

|

|

|

||||||

|

|

2 |

Ø11x14 Hole |

|

B |

|

|

||||||

|

|

|

|

Ø25 Drain outlet |

|

B |

Detail Drawing (Front leg) |

||||||

|

|

|

|

(For Ø 8-Ø 10 anchor bolt) |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

HANDLE |

FAN-GUARD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ø 436 |

|

|

|

|

|

|

|

HANDLE |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

COVER-PV |

|

|

|

715 |

|

|

|

|

|

|

|

|

|

Z |

|

|

|

|

|

275 |

|

|

|

|

|

|

|

|

|

|

290 |

|

|

90 |

|

600 |

90 |

69 |

|

320 |

|

|

|

|

|

|

|

|

342 |

|

|

|||||

129 |

84 |

54 |

Electrical part cover

Liquid side (Flare Ø 6.35)

Gas-side (Flare Ø 15.88)

|

|

Z View |

|

|

Service port |

|

|

600 |

100 or more |

|

Air inlet |

|

|

600 or more |

320 |

|

|

100 or more |

Air out let |

600 or more |

|

||

|

|

4xØ 11 Long holes(For Ø8Ø10 anchor bolt) |

Installation dimension

– 7 –

FILE NO. SVM-09036

3. WIRING DIAGRAM

3-1. RAS-18SKP-ES / RAS-18SA-ES, RAS-24SKP-ES / RAS-24SA-ES

|

|

|

1 |

2 |

3 |

|

|

|

|

POWER SUPPLY |

|

|

|

|

OUTDOOR |

|

|||

|

|

|

|

UNIT |

|

||||

220 − 240 V ~ 50 Hz |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|||

OUTDOOR |

L |

N |

1 |

2 |

3 |

|

|

|

|

TERMINAL |

|

|

|

|

|||||

BLOCK |

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

|

|

|

|

|

|

|

BLK |

RED |

|

|

|

|

|

|

|

|

|

|

|

CHASSIS |

|

|

|

||

|

|

RED |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

BLK |

|

GRY |

|

|

|

|

|

|

SPARK KILLER |

|

|

|

|

|

|

|

|

|

A2 52C A1 |

|

|

RED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RED |

|

|

|

|

CAPACITOR |

WHI |

BLK |

|

|

R |

U |

RED |

|

|

RED |

||

|

|

|

|

|

|

|

|

||

|

|

|

|

CAPACITOR |

WHI |

S |

FAN MOTOR |

||

|

|

|

|

PNK |

C |

BLK |

|

||

|

|

S |

V |

|

|

|

|||

|

|

|

|

|

R |

|

|

||

|

|

T |

W |

|

|

|

COMPRESSOR |

|

|

|

|

|

|

|

|

|

|

||

MAGNETIC CONTACTOR

– 8 –

FILE NO. SVM-09036

3-2. RAS-18SKHP-ES / RAS-18S2AH-ES, RAS-24SKHP-ES / RAS-24S2AH-ES

|

|

|

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

TRANSFORMER |

||

|

POWER SUPPLY |

|

|

|

|

BLK 1 1 |

||

|

220-240V~50Hz |

|

|

|

|

2 |

||

|

|

|

|

|

|

|

|

BLK 3 3 |

|

|

|

|

|

GRN&YEL |

|

|

RED 1 1 |

|

|

|

|

|

|

|

|

|

OUTDOOR |

L |

N |

1 |

2 |

3 |

|

|

RED 3 3 |

TERMINAL |

OUTDOOR |

|

||||||

|

|

|

|

|

|

|||

BLOCK |

|

FERRITE CORE |

|

|

BLK 1 1 |

|||

|

|

BLK |

|

|

|

UNIT |

|

|

|

|

|

|

i |

|

|

BLK 3 3 |

|

|

|

|

RED |

|

|

|

||

|

|

|

|

CHASSIS |

|

|

WHI 5 5 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RED 7 7 |

|

BLK |

RED |

|

|

|

|

|

GRY 9 9 |

|

|

|

MAGNETIC |

|

|

|

|

|

|

|

|

CONTACTOR |

|

|

|

|

BLU 1 1 |

|

|

|

|

|

|

|

|

|

|

|

R |

S |

T |

A1 |

|

|

YEL 3 3 |

|

|

|

|

|

||||

|

|

|

|

|

52C |

|

|

BLU 1 1 |

|

|

U |

V |

W |

A2 |

|

|

|

|

|

|

|

|

BLU 3 3 |

|||

|

|

|

|

|

|

|

COIL FOR |

|

|

|

|

|

|

|

|

4 WAY VALVE |

|

|

CAPACITOR |

|

CAPACITOR |

RED |

|

RED |

|

WHI |

S |

WHI |

|

PNK |

C BLK |

RED |

BLK |

R

MAIN P.C. BOARD (MCC-890)

CN06 |

|

|

|

DISCHARGE |

|

|

|

|

|

PIPE |

|

|

|

|

|

SENSOR (TD) |

|

CN05 |

|

|

1 |

1 |

BLU |

|

|

CN07 2 |

|

|

|

SG01 |

TNR |

|

3 |

3 |

BLU |

R74 |

|

|

|

|

|

F01 |

|

|

|

|

|

250VAC T6. 3A |

TNR |

1 |

1 |

BLK |

|

|

|

R73 |

CN08 2 |

|

|

CN01 |

|

|

3 |

3 |

BLK |

|

|

|

|

HEAT |

|

|

|

|

|

EXCHANGER |

|

|

|

|

|

SENSOR (TE) |

|

|

|

RY07 |

|

|

|

CN11 |

|

|

|

|

|

|

CR11 |

RY05 |

|

|

|

|

|

|

|

|

|

CN02 |

|

|

|

|

|

|

CR12 |

|

|

|

|

CR13 |

|

RY06 |

|

|

|

|

|

|

|

|

|

|

CN03 |

|

|

|

|

|

1 |

3 |

|

|

|

|

1 |

|

|

|

|

|

BLK |

|

|

|

|

COMPRESSOR |

FAN MOTOR |

– 9 –

FILE NO. SVM-09036

4. SPECIFICATION OF ELECTRICAL PARTS

4-1. Indoor Unit (RAS-18SKP-ES, RAS-24SKP-ES)

No. |

Parts name |

Type |

Specifications |

|

|

|

|

1 |

Fan motor (for indoor) |

ICF-340-30-2B |

DC 340V, 30W |

|

|

|

|

2 |

Thermo sensor (TA-sensor) |

——— |

10 kΩ at 25° C |

|

|

|

|

3 |

Switching Transformer (T01) |

SWT-77 |

DC7V, 12 V |

|

|

|

|

4 |

Microcontroller |

TMP87CM40ANG-6P68 |

|

|

|

|

|

5 |

Heat exchanger sensor |

——— |

10 kΩ at 25° C |

|

(TC-sensor) |

||

|

|

|

|

|

|

|

|

6 |

Line filter (L01) |

LC*SS11V-R06270 |

27mH, 600mA |

|

|

|

|

7 |

Diode (DB01) |

D3SBA60 |

4 A, 600 V |

|

|

|

|

8 |

Capacitor (C03) |

EKMH451VSN121MQ35S |

120 μF, 450 V |

9 |

Fuse (F01) |

BET 6.3A |

6.3 A, 250 V |

|

|

|

|

10 |

Varistor (R09, R10) |

SR561K14DL |

560 V |

11 |

Resistor (R01) |

RF-5TK1R8 |

1.8Ω , 5W |

12 |

Louver motor |

MP24Z3T |

Output (Rated) 2 W, 6 poles, 1-2 phase, |

|

|

|

DC 12 V |

13 |

Relay : (RY03) |

G5NB-1A-CA |

Coil DC 12V, 16.7mA, Contact AC 250V, 1A |

|

|

|

|

4-2. Outdoor Unit (RAS-18SA-ES)

No. |

Parts name |

Type |

Specifications |

|

|

|

|

|

Output (Rated) 1500W, 2poles, 1 phase, 220 − 240V, 50Hz |

||

1 |

Compressor |

PA200X2CS-4KU1 |

Winding resistance (Ω) |

Red-Black |

White-Black |

|

|

|

|

|

|

|

|

|

(at 20°C ) |

1.85 |

2.62 |

|

|

|

|

|

|

|

|

|

Output (Rated) 42W, 4poles, 1 phase, 220 − 240V, 50Hz |

||

2 |

Fan motor (for outdoor) |

FG-240-42A |

Winding resistance (Ω) |

Red-Black |

White-Black |

|

|

|

|

|

|

|

|

|

(at 20°C) |

128 |

126 |

|

|

|

|

|

|

3 |

Running capacitor |

DS451305NPQB |

AC 450V, 3.0µF |

|

|

(for fan motor) |

|

|

|||

|

|

|

|

|

|

4 |

Running capacitor |

B32332I5606J063 |

AC 450V, 50μF |

|

|

|

(for compressor) |

|

|

|

|

5 |

Magnetic contactor |

CLK-26J |

220 − 240V, 50Hz |

|

|

– 10 –

FILE NO. SVM-09036

4-3. Outdoor Unit (RAS-24SA-ES)

No. |

Parts name |

Type |

Specifications |

|

|

|

|

|

Output (Rated) 2000W, 2poles, 1 phase, 220 − 240V, 50Hz |

||

1 |

Compressor |

PA270X3CS-4MU2 |

Winding resistance (Ω) |

Red-Black |

White-Black |

|

|

|

(at 20°C) |

1.37 |

2.55 |

|

|

|

|

|

|

|

|

|

Output (Rated) 42W, 4poles, 1 phase, 220 − |

240V, 50Hz |

|

2 |

Fan motor (for outdoor) |

FG-240-42A |

Winding resistance (Ω) |

Red-Black |

White-Black |

|

|

|

|

|

|

|

|

|

(at 20° C) |

128 |

126 |

|

|

|

|

|

|

3 |

Running capacitor |

DS451355NPQB |

AC 450V, 3.5μF |

|

|

|

(for fan motor) |

|

|

|

|

4 |

Running capacitor |

B32332I5606J063 |

AC 450V, 60μF |

|

|

(for compressor) |

|

|

|||

|

|

|

|

|

|

5 |

Magnetic contactor |

CLK-35J |

220 − 240V, 50Hz |

|

|

|

|

|

|

|

|

4-4. Indoor Unit (RAS-18SKHP-ES, RAS-24SKHP-ES)

No. |

Parts name |

Type |

Specifications |

|

|

|

|

1 |

Fan motor (for indoor) |

ICF-340-30-2B |

DC 340V, 30W |

|

|

|

|

2 |

Thermo sensor (TA-sensor) |

——— |

10 kΩ at 25°C |

|

|

|

|

3 |

Switching Transformer (T01) |

SWT-77 |

DC 7V, 12V |

|

|

|

|

4 |

Microcontroller |

TMP87CM40ANG-6P68 |

|

|

|

|

|

5 |

Heat exchanger sensor |

——— |

10 kΩ at 25°C |

|

(TC-sensor) |

||

|

|

|

|

|

|

|

|

6 |

Line filter (L01) |

LC*SS11V-R06270 |

27mH, 600mA |

|

|

|

|

7 |

Diode (DB01) |

D3SBA60 |

4 A, 600 V |

|

|

|

|

8 |

Capacitor (C03) |

EKMH451VSN121MQ35S |

120 μF, 450 V |

9 |

Fuse (F01) |

BET 6.3A |

6.3 A, 250 V |

|

|

|

|

10 |

Varistor (R09, R10) |

SR561K14DL |

560 V |

|

|

|

|

11 |

Resistor (R01) |

RF-5TK1R8 |

1.8Ω , 5W |

12 |

Louver motor |

MP24Z3T |

Output (Rated) 2 W, 6 poles, 1-2 phase, |

|

|

|

DC 12 V |

– 11 –

FILE NO. SVM-08037

4-5. Outdoor Unit (RAS-18S2AH-ES)

No. |

Parts name |

Type |

Specifications |

|

|

|

|

|

Output (Rated) 1500W, 2poles, 1 phase, 220 − 240V, 50Hz |

||

1 |

Compressor |

PA200X2CS-4KU1 |

Winding resistance (Ω) |

Red-Black |

White-Black |

|

|

|

|

|

|

|

|

|

(at 20°C) |

1.85 |

2.62 |

|

|

|

|

|

|

|

|

|

Output (Rated) 42W, 4poles, 1 phase, 220 – 240V, 50Hz |

||

|

|

|

|

|

|

2 |

Fan motor (for outdoor) |

FG-240-42A-1 |

Winding resistance (Ω) |

Red-Black |

White-Black |

|

|

|

|

|

|

|

|

|

(at 20°C) |

128 |

126 |

|

|

|

|

|

|

3 |

Running capacitor |

DS451305NPQB |

AC 450V, 3.0µF |

|

|

(for fan motor) |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Running capacitor |

B32332I5606J063 |

AC 450V, 50µF |

|

|

(for compressor) |

|

|

|||

|

|

|

|

|

|

5 |

Solenoid coil |

VHV (STF) |

AC 220 − 240V |

|

|

|

(for 4-way valve) |

|

|

|

|

6 |

Thermo sensor |

TE / TD |

10kΩ at 25°C / 50kΩ at 25°C |

|

|

|

|

|

|

|

|

7 |

Magnetic contactor |

CLK-26J |

220 − 240V, 50Hz |

|

|

8 |

Transformer |

TT-05 |

220 − 240V |

|

|

9 |

Microcomputer |

TMP47C840N |

|

|

|

|

|

|

|

|

|

10 |

Varistor (R73, R74) |

15G471K |

470V |

|

|

|

|

|

|

|

|

11 |

Fuse (F01) |

TSCR |

T6.3A, 250V |

|

|

|

|

|

|

|

|

4-6. Outdoor Unit (RAS-24S2AH-ES)

No. |

Parts name |

Type |

|

Specifications |

|

||

|

|

|

|

Output (Rated) 2000W, 2poles, 1 phase, 220 − 240V, 50Hz |

|||

1 |

Compressor |

PA270X3CS-4MU2 |

|

Winding resistance (Ω) |

|

Red-Black |

White-Black |

|

|

|

|

|

|

|

|

|

|

|

|

(at 20°C) |

|

1.37 |

2.55 |

|

|

|

|

|

|

|

|

|

|

|

|

Output (Rated) 42W, 4poles, 1 phase, 220 – 240V, 50Hz |

|||

|

|

|

|

|

|

|

|

2 |

Fan motor (for outdoor) |

FG-240-42A-1 |

|

Winding resistance (Ω) |

|

Red-Black |

White-Black |

|

|

|

|

|

|

|

|

|

|

|

|

(at 20°C) |

|

128 |

126 |

|

|

|

|

|

|

|

|

3 |

Running capacitor |

DS451305NPQB |

|

AC 450V, 3.0µF |

|

|

|

(for fan motor) |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Running capacitor |

B32332I5606J063 |

|

AC 450V, 60µF |

|

|

|

(for compressor) |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

Solenoid coil |

VHV (STF) |

|

AC 220 ~ 240V |

|

|

|

(for 4-way valve) |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

Thermo sensor |

TE / TD |

|

10kΩ at 25°C / 50kΩ at 25°C |

|

|

|

|

|

|

|

|

|

|

|

7 |

Magnetic contactor |

CLK-35J |

|

220 ~ 240V, 50Hz |

|

|

|

|

|

|

|

|

|

|

|

8 |

Transformer |

TT-05 |

|

220 ~ 240V |

|

|

|

|

|

|

|

|

|

|

|

9 |

Microcontroller |

TMP47C840N |

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

Varistor (R73, R74) |

15G471K |

|

470V |

|

|

|

|

|

|

|

|

|

|

|

11 |

Fuse (F01) |

TSCR |

|

T6.3A, 250V |

|

|

|

|

|

|

|

|

|

|

|

– 12 –

FILE NO. SVM-09036

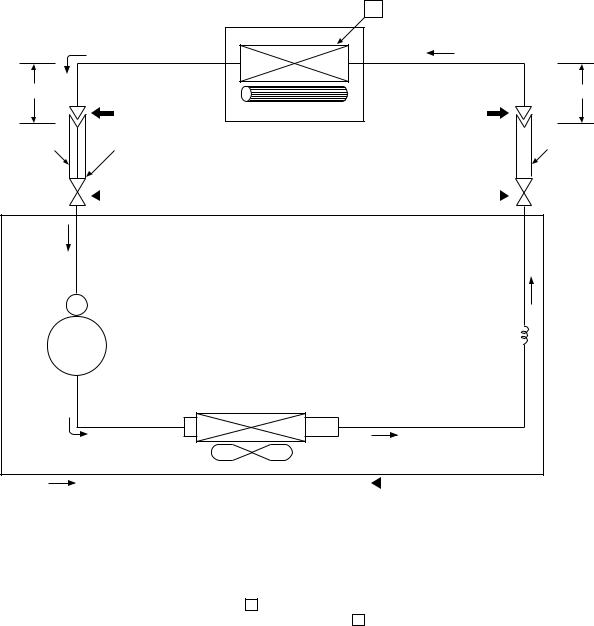

5. REFRIGERATION CYCLE DIAGRAM

5-1. RAS-18SKP-ES / RAS-18SA-ES

T

Heat exchanger

0.39 m (Connecting pipe)

(Connecting pipe)

12.7

Cross flow fan

0.49 m

(Connecting pipe)

6.35

O.D.:12.7 mm |

P |

|

O.D.:6.35 mm |

Packed valve |

|

Packed valve |

|

|

( 12.7) |

|

( 6.35) |

|

|

|

Capillary tube |

|

|

|

2.0x1100 s |

Compressor |

PA200X2CS-4KU1 |

|

|

|

|

Heat exchanger |

|

|

|

|

Refrigerant |

|

|

Propeller fan |

R410A 1.65 kg |

|

|

|

|

Outdoor unit |

Mark ( |

|

) means check points of Gas Leak |

|

|||

|

|

|

Standard |

Surface temp. of heat |

|

Ambient temp. |

||

|

50 Hz |

Fan speed |

conditions DB/WB |

||||

|

pressure P |

exchanger interchanging |

(indoor) |

|

(°C) |

||

|

|

(MPaG) |

pipe T (°C) |

|

|

|

|

|

|

|

Indoor |

|

Outdoor |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Standard |

0.94 |

10.6 |

High |

27/19 |

|

35/24 |

|

|

|

|

|

|

|

|

Cooling |

High temperature |

1.09 |

15.0 |

High |

32/23 |

|

43/26 |

|

|

|

|

|

|

|

|

|

Low temperature |

0.75 |

4.3 |

Low |

21/15 |

|

21/15 |

|

|

|

|

|

|

|

|

Note : Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor.)

– 13 –

FILE NO. SVM-09036

5-2. RAS-24SKP-ES / RAS-24SA-ES

Cooling

0.39 m (Connecting pipe)12.7

T

Indoor unit

Heat exchanger |

Cross flow fan |

0.49 m (Connecting pipe)6 .35

|

|

|

|

|

|

|

|

|

|

O.D.:12.7 mm |

|

|

P |

|

|

|

|

|

O.D.:6.35 mm |

|

Packed valve |

Packed valve |

|

|

|||||

|

|

||||||||

|

|

|

( 12.7 ) |

( 6.35) |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

Gas container connection (Reinstall etc.) |

|

|

|

|

|

||

Cooling |

|

|

|

|

Capillary tube |

Compressor |

PA270X3CS-4MU2 |

2.0x1000 s |

|

||

|

Heat exchanger |

|

|

|

Refrigerant |

|

Propeller fan |

R410A 1.70 kg |

Cooling |

Outdoor unit |

Mark ( |

|

) means check points of Gas Leak |

|

||||

|

|

|

Standard |

Surface temp. of heat |

|

Ambient temp. |

||

|

|

Fan speed |

conditions DB/WB |

||||

|

50 Hz |

pressure P |

exchanger interchanging |

||||

|

(indoor) |

|

(°C) |

||||

|

|

(MPaG) |

pipe T (°C) |

|

|

|

|

|

|

|

Indoor |

|

Outdoor |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Standard |

0.84 |

13.0 |

High |

27/19 |

|

35/24 |

|

|

|

|

|

|

|

|

Cooling |

High temperature |

1.01 |

17.0 |

High |

32/23 |

|

43/26 |

|

|

|

|

|

|

|

|

|

Low temperature |

0.65 |

5.0 |

Low |

21/15 |

|

21/15 |

|

|

|

|

|

|

|

|

Note : Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor.)

– 14 –

FILE NO. SVM-09036

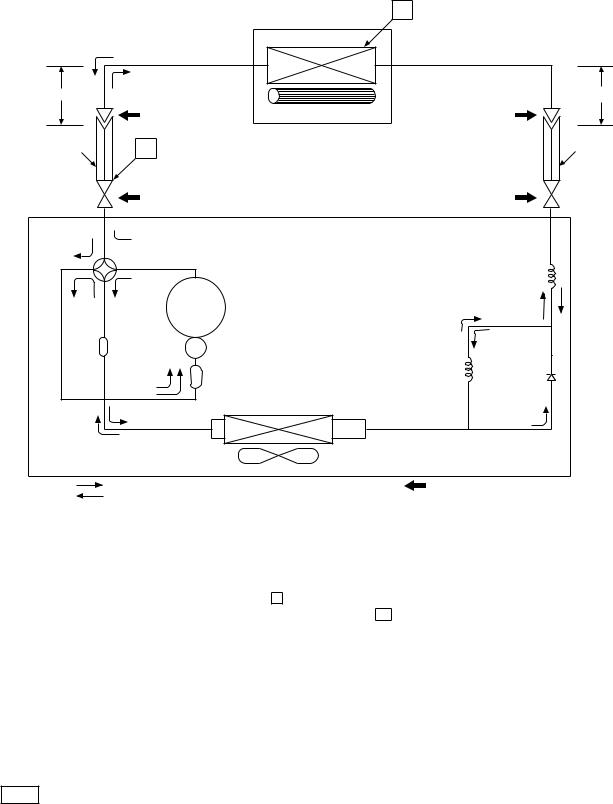

5-3. RAS-18SKHP-ES / RAS-18S2AH-ES

|

|

|

T1 |

|

|

|

Indoor unit |

|

Cooling |

Heat exchanger |

|

|

|

||

0.39 m |

|

Heating |

|

(Connecting pipe) |

|

||

|

|

||

Æ12.7 |

|

|

Cross flow fan |

|

|

|

|

O.D.:12.7 mm |

|

P |

|

|

|

Packed valve |

Packed valve |

|

|

(Æ12.7) |

(Æ6.35) |

Heating

Heating

Cooling 4-way valve

Heating |

Cooling |

Compressor |

PA200X2CS-4KU1 |

|

|

||

|

Discharge Muffler |

|

|

|

25x160L |

|

|

|

|

Accumulator |

|

Heat exchanger

Capillary tube Æ2.0 x 1000 l

Capillary tube Æ1.7 x 600l

0.49 m (Connecting pipe)

Æ6.35

O.D.:6.35 mm

|

|

|

Refrigerant |

|

Propeller fan |

|

R410A : 1.53 kg. |

Cooling |

Outdoor unit |

Mark ( |

) means check points of Gas Leak. |

Heating |

|

|

|

|

|

Standard |

Surface temp. of heat |

|

Ambient temp. |

||

|

|

Fan speed |

conditions DB/WB |

||||

|

50Hz |

pressure P |

exchanger interchanging |

(indoor) |

|

(°C) |

|

|

|

(MPaG) |

pipe T1 (°C) |

|

|

|

|

|

|

|

Indoor |

|

Outdoor |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Standard |

2.53 |

44.0 |

High |

20/15 |

|

7/6 |

|

|

|

|

|

|

|

|

Heating |

Overload*1 |

3.30 ~ 3.65 |

51.0 ~ 55.0 |

Low |

27/- |

|

24/18 |

|

|

|

|

|

|

|

|

|

Low temperature |

1.75 |

32.0 |

High |

20/- |

|

-10/-10 |

|

|

|

|

|

|

|

|

|

Standard |

0.54 |

11.0 |

High |

27/19 |

|

35/24 |

|

|

|

|

|

|

|

|

Cooling |

Overload |

1.12 |

15.0 |

High |

32/23 |

|

43/26 |

|

|

|

|

|

|

|

|

|

Low temperature |

0.72 |

4.2 |

Low |

21/15 |

|

21/15 |

|

|

|

|

|

|

|

|

Note

· Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor)

*1 · During heating overload operation, a value for the high temperature limit control operation is included.

- 15 -

FILE NO. SVM-09036

5-4. RAS-24SKHP-ES / RAS-24S2AH-ES

|

|

|

T1 |

|

|

|

Indoor unit |

|

Cooling |

Heat exchanger |

|

|

|

||

0.39 m |

|

Heating |

|

(Connecting pipe) |

|

||

|

|

||

Æ12.7 |

|

|

Cross flow fan |

|

|

|

|

O.D.:12.7 mm |

|

P |

|

|

|

Packed valve |

Packed valve |

|

|

(Æ12.7) |

(Æ6.35) |

Heating

Heating

Cooling 4-way valve

Heating |

Cooling |

Compressor |

PA270X3CS-4MU2 |

|

|

||

|

Discharge Muffler |

|

|

|

25x160L |

|

|

|

|

Accumulator |

|

Heat exchanger

Capillary tube Æ2.0 x 900 l

Capillary tube Æ2.0 x 700l

0.49 m (Connecting pipe)

Æ6.35

O.D.:6.35 mm

|

|

|

Refrigerant |

|

Propeller fan |

|

R410A 1.62 kg. |

Cooling |

Outdoor unit |

Mark ( |

) means check points of Gas Leak. |

Heating |

|

|

|

|

|

Standard |

Surface temp. of heat |

|

Ambient temp. |

||

|

|

Fan speed |

conditions DB/WB |

||||

|

50Hz |

pressure P |

exchanger interchanging |

(indoor) |

|

(°C) |

|

|

|

(MPaG) |

pipe T1 (°C) |

|

|

|

|

|

|

|

Indoor |

|

Outdoor |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Standard |

2.86 |

45.6 |

High |

20/15 |

|

7/6 |

|

|

|

|

|

|

|

|

Heating |

Overload*1 |

3.54 ~ 3.91 |

53.6 ~ 57.6 |

Low |

27/- |

|

24/18 |

|

|

|

|

|

|

|

|

|

Low temperature |

2.19 |

33.9 |

High |

20/- |

|

-10/-10 |

|

Standard |

0.84 |

10.0 |

High |

27/19 |

|

35/24 |

|

|

|

|

|

|

|

|

Cooling |

Overload |

1.12 |

16.1 |

High |

32/23 |

|

43/26 |

|

|

|

|

|

|

|

|

|

Low temperature |

0.74 |

2.3 |

Low |

21/15 |

|

21/15 |

|

|

|

|

|

|

|

|

Note

· Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor)

*1 · During heating overload operation, a value for the high temperature limit control operation is included.

- 16 -

FILE NO. SVM-09036

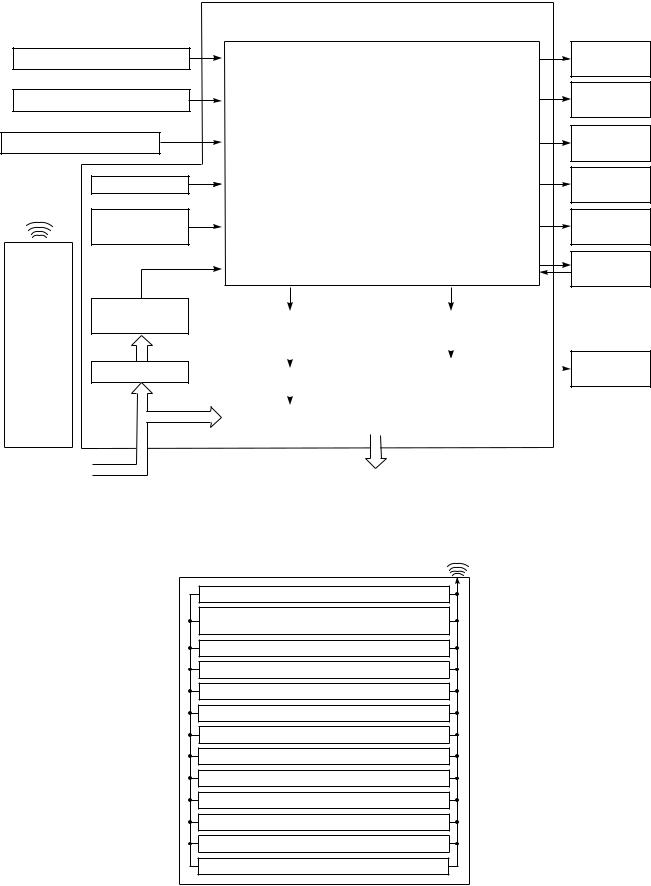

6.CONTROL BLOCK DIAGRAM

6.1RAS-18SKP-ES / RAS-18S2A-ES, RAS-24SKP-ES / RAS-24S2A-ES

Heat Exchanger Sensor

Temperature Sensor

Infrared Rays Signal Receiver

Initiallizing Circuit

Infrared

Rays

Clock Frequency

Oscillator Circuit

Power Supply

Circuit

Remote

Control

Noise Filter

From Outdoor Unit

240 V AC 50 Hz

REMOTE CONTROL

Indoor Unit Control Panel

M.C.U.

Functions

•Louver Control

• 3-minute Delay at Restart for Compressor

• Motor Revolution Control

• Processing

(Temperature Processing)

• Timer

Outdoor unit |

|

|

Louver ON/OFF Signal |

|

||

ON/OFF Signal |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Louver Driver |

|

|

|

|

|

|

|

||

Relay Driver |

|

|

|

|||

|

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Relay RY03 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor Unit |

|

|||

|

|

|

|

|

|

|

Infrared Rays

Remote Control

Operation ( )

)

Operation Mode Selection

AUTO, COOL, DRY, FAN ONLY

Temperature Setting

Fan Speed Selection

ON TIMER Setting

OFF TIMER Setting

Louver Auto Swing

Louver Direction Setting

ECO

Hi power

TIMER 1.3.5.9H

COMFORT SLEEP

QUIET

Operation

Display

Timer

Display

Filter Sign

Display

Fan Only

Sign Display

Hi Power

Sign Display

Indoor

Fan Motor

Louver Motor

– 17 –

FILE NO. SVM-09036

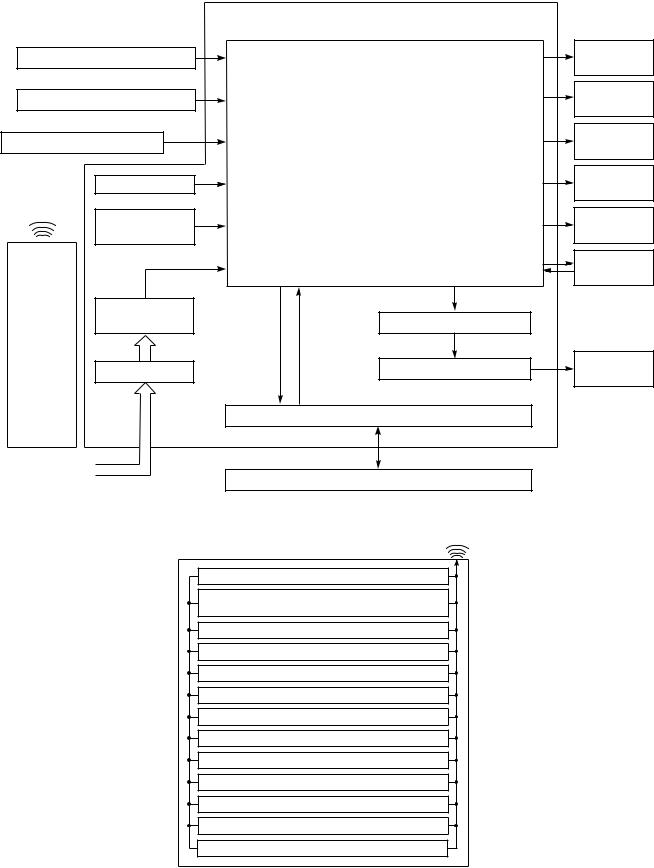

6.2 RAS-18SKHP-ES / RAS-18S2AH-ES, RAS-24SKHP-ES / RAS-24S2AH-ES

Heat Exchanger Sensor

Temperature Sensor

Infrared Rays Signal Receiver

Initiallizing Circuit

Infrared

Rays Clock Frequency

Oscillator Circuit

Power Supply

Circuit

Remote

Control

Noise Filter

From Outdoor Unit

240 V AC 50 Hz

REMOTE CONTROL

Indoor Unit Control Panel

M.C.U.

Functions

• Louver Control

• 3-minute Delay at Restart for Compressor

• Motor Revolution Control

• Processing

(Temperature Processing)

• Timer

• Serial Signal Communication

Louver ON/OFF Signal

Louver Driver

Serial Signal Transmitter/Receiver

Serial Signal Communication

Infrared Rays

Remote Control

Operation ( )

)

Operation Mode Selection

Operation

Display

Timer

Display

Filter Sign

Display

PRE DEF.

Sign Display

Hi Power

Sign Display

Indoor

Fan Motor

Louver Motor

AUTO, COOL, DRY, HEAT, FAN ONLY

Temperature Setting

Fan Speed Selection

ON TIMER Setting

OFF TIMER Setting

Louver Auto Swing

Louver Direction Setting

ECO

Hi power

TIMER 1.3.5.9H

COMFORT SLEEP

QUIET

– 18 –

FILE NO. SVM-0936

7. OPERATION DESCRIPTION

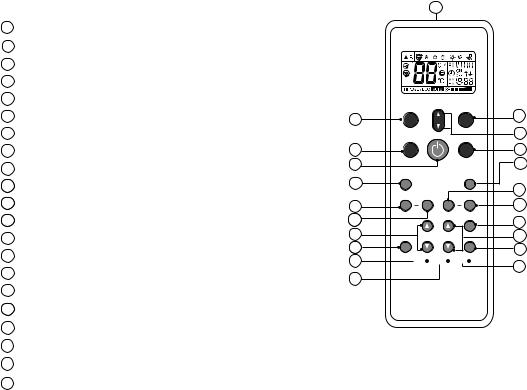

7-1. Remote control

7-1-1. Function of Push Putton

1Infrared signal emitter

2Start/Stop button

3Mode select button (MODE)

4Temperature button (TEMP)

5Fan speed button (FAN)

6Swing louver button (SWING)

7Set louver button (FIX)

8On timer button (ON)

9Off timer button (OFF)

108 Sleep timer button (SLEEP)

119 Timer setup button (SET)

2012 Timer clear button (CLR)

13Memory and Preset button (PRESET)

14One Touch button (ONE-TOUCH)

15High power button (Hi-POWER)

16Economy button (ECO)

17Quiet button (QUIET)

18Comfort sleep button (COMFORT SLEEP)

19Filter reset button (FILTER)

20Clock Reset button (CLOCK)

21 Check button (CHK)

1

13 |

PRESET |

FAN |

5 |

|

TEMP |

||

|

ONE-TOUCH |

MODE |

4 |

|

|

||

14 |

|

|

3 |

2 |

|

COMFORT |

18 |

|

QUIET |

SLEEP |

|

17 |

|

|

15 |

|

SWING FIX |

Hi-POWER ECO |

|

|

16 |

||

6 |

|

|

|

7 |

TIMER |

CLR |

12 |

8 |

ON |

OFF |

9 |

10 |

SLEEP |

SET |

11 |

21 |

CHK |

FILTER CLOCK |

20 |

|

|

|

19

− 19 −

FILE NO. SVM-09036

7-1-2. Display of Remote Control

All indications, except for the clock time indicator, are displayed by pressing the  button.

button.

1. Transmission mark |

5. TIMER and clock time indicator |

This transmission mark  indicates when the remote controller transmits signals to the indoor unit.

indicates when the remote controller transmits signals to the indoor unit.

2. Mode indicator

The time setting for timer operation or the clock time is indicated.

The current time is always indicated except during TIMER operation.

Indicates the current operation mode.

(A : Auto,  : Cool,

: Cool, : Dry,

: Dry,  : Heat,

: Heat, : Fan only)

: Fan only)

3. Temperature indicator

Indicates the temperature setting. (17°C to 30°C)

4. FAN speed indicator

Indicates the selected fan speed. AUTO or five fan speed levels

(LOW  , LOW+

, LOW+  , MED

, MED  , MED+

, MED+  ,

,

HIGH |

) can be shown. |

Indicate Auto will be appear with Dry operation ( : Dry) only.

: Dry) only.

9 |

12 |

|

2 |

13 |

|||||||||

1 |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

||||

10 |

|

|

10 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

5 |

||

6 |

|

4 |

|||||||

|

|

|

|

|

|||||

|

|

|

|

||||||

3 |

|

7 |

|

|

|

|

|||

6. Hi-POWER indicator

Indicates when the Hi-POWER operation starts.

Press the Hi-POWER button to start and press it again to stop the operation.

7.  (PRESET) indicator

(PRESET) indicator

Flashes for 3 seconds when the PRESET button is pressed during operation.

The mark is shown when holding down the button for more than 3 seconds while the mark is blinks.

Press another button to turn off the mark.

8. ECO indicator

Indicates when the ECO is in activated.

Press the ECO button to start and press it again to stop operation.

9. A, B change indicator remote controller

When the remote controller switching function is set, “B” appears in the remote controller display. (When the remote controller setting is “A”, there is no indication at this position.)

10. Comfort sleep

Indicates when comfort sleep is activaled. Press comfort sleep button to selectter

11. Quiet

Indicates when quiet is activated.

Press quiet button to start and press it again to stop operation.

12. One-Touch

Indicates when one touch comfort is activated. Press one-touch button to start the operation.

13. Swing

Indicates when louver is swing.

Press swing button to start the swing operation and press it again to stop the swing operation.

− 20 −

7-2. Outline of Air Conditioner Control

This is a fixed capacity type air conditioner, which uses a DC motor for an indoor fan. The DC motor drive circuit is mounted in the indoor unit. And electrical parts which operate the compressor and the outdoor fan motor, are mounted in the outdoor unit.

The air conditioner is mainly controlled by the indoor unit controller. The controller operates the indoor fan motor based upon commands transmitted by the remote control and transfers the operation commands to the outdoor unit.

The outdoor unit receives operation commands from the indoor unit, and operates the outdoor fan motor and the compressor.

(1)Role of indoor unit controller

The indoor unit controller receives the operation commands from the remote control and executes them.

∙Temperature measurement at the air inlet of the indoor heat exchanger by the indoor temperature sensor

∙Temperature measurement of the indoor heat exchanger by the heat exchanger sensor

∙Louver motor control

∙Indoor fan motor operation control

∙LED display control

∙Transferring of operation commands to the outdoor unit

∙Receiving of information of the operation status and judging of the information or indication of error

(2)Role of outdoor unit controller

The outdoor unit controller receives the operation commands from the indoor controller and executes them.

∙ Compressor operation control

∙ Operation control of outdoor fan motor

Table 7-2-3 Indoor fan and air flow rate

|

OPERATION |

|

Cooling |

UH |

|

|

|||

|

|

Fan only |

|

|

|

MODE |

|

|

|

|

|

Dry |

1100 |

|

Model |

RAS-18SKP-ES |

|

rpm |

|

|

Air flow volume (m3/h) |

1000 |

||

RAS-24SKP-ES |

|

rpm |

1200 |

|

|

|

Air flow volume (m3/h) |

1100 |

FILE NO. SVM-09036

∙Turning off the compressor and outdoor fan when the outdoor unit receives the shutdown command

∙Defrost control in heating operation (Temperature measurement by the Indoor heat exchanger, control the four-way valve and outdoor fan motor control)

7-2-1. Louver control

(1)Vertical air flow louver

Position of veritcal air flow louver is automatically controlled according to the operation mode. Besides, position of vertical air flow louver can be arbitrarily set by pressing [FIX] button.

The louver position which is set by [FIX] button is stored in the microcomputer, and the louver is

automatically set at the stored position for the next operation.

(2)Swing

If [SWING] button is pressed when the indoor unit is in operation, the vertical air flow louver starts swinging. When [SWING] button is pressed, it stops swinging.

7-2-2. Indoor Fan Control

The operation controls the fan speed at indoor unit

side. The indoor fan (cross flow fan) is operated by the phase control induction motor. The fan rotates in 5

stages in MANUAL mode, and in 5 stages in AUTO mode, respectively. (Table 7-2-3)

1)When setting the fan speed to L, L+,M, M+ or H

on the remote controller, the operation is performed with the constant speed shown in Table 7-2-1 and Table 7-2-2

Table (7-2-1) Cooling

Indication |

Fan speed |

L |

Low |

L+ |

(L + M) / 2 |

M |

Med |

M+ |

(M + H) / 2 |

H |

High |

Table (7-2-2) Heating

Indication |

Fan speed |

L |

Low |

L+ |

(L + M) / 2 |

M |

Med |

M+ |

(M + H) / 2 |

H |

High |

2)When setting the fan speed to AUTO on the remote controller, revolution of the fan motor is controlled to the fan speed level show in Table 7-2-3

according to the setup temperature, room temperature, and heat exchanger temperature.

|

|

FAN TAP |

|

|

|

|

|

H |

M+ |

M |

L+ |

L |

L- |

UL |

SL |

H |

M+ |

M |

L+ |

L |

L- |

|

|

|

M+ |

M |

L+ |

L |

L- |

UL |

SL |

|

1050 |

980 |

900 |

850 |

750 |

650 |

550 |

|

950 |

880 |

800 |

800 |

650 |

550 |

450 |

|

1125 |

1050 |

1000 |

950 |

850 |

700 |

600 |

|

1025 |

950 |

900 |

850 |

750 |

600 |

500 |

Model

|

Cooling |

|

|

|

|

|

|

|

FAN TAP |

|

|

|

|

|

|

|

|

|

|

UH |

H |

M+ |

|

M |

|

L+ |

L |

L- |

UL |

SL |

|

OPERATION |

Fan only |

|

|

|

|

H |

M+ |

|

M |

|

L+ |

L |

L- |

|

|

MODE |

Dry |

|

|

|

|

|

M+ |

|

M |

|

L+ |

L |

L- |

UL |

SL |

|

Heat |

UH |

H |

|

M+ |

|

|

M |

L+ |

L |

L- |

|

UL |

|

SL |

RAS-18SKHP-ES |

rpm |

|

|

1100 |

|

1000 |

1000 |

940 |

870 |

850 |

850 |

750 |

640 |

550 |

|

Air flow volume (m3/h) |

|

|

1000 |

|

900 |

900 |

840 |

770 |

750 |

750 |

650 |

540 |

450 |

||

RAS-24SKHP-ES |

rpm |

|

|

1200 |

|

1050 |

1050 |

1050 |

950 |

950 |

950 |

850 |

700 |

600 |

|

Air flow volume (m3/h) |

|

|

1100 |

|

950 |

950 |

950 |

850 |

850 |

850 |

750 |

600 |

500 |

||

- 21 -

FILE NO. SVM-09036

7-3. Description of Operation Mode

(1)When turning on the breaker, the operation lamp blinks. This means that the power is on (or the power supply is cut off.)

(2)When pressing [ ] button on the

] button on the

remote control, receiving beep sounds from the indoor unit, and the next operation is performed together with opening the vertical air flow louver.

(3)Once the operation mode is set, it is memorized in the microcomputer so that the previous operation can be effected thereafter simply by pressing

[ ] button.

] button.

7-3-1. Fan only operation

([MODE] button on the remote control is set to the fan only operation.)

(1)When [FAN] button is set to AUTO, the indoor fan motor operates as shown in Fig. 7-3-1. When [FAN] button is set to LOW, LOW+, MED, MED+ or HIGH, the motor operates with a constant air flow.

temp.) |

|

° C |

|

|

|

|

+3 |

|

|

|

|

||

(Preset− |

|

M+ |

||||

+2 |

|

|||||

|

+2.5 |

|

|

|

|

|

|

|

*1 |

|

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

temp.) |

+1.5 |

|

*2 |

|

||

|

*3 |

|

||||

(Room |

+1 |

|

|

|

|

|

|

|

|

|

|||

+0.5 |

|

|

|

|

||

|

|

|

|

|||

Preset |

|

0 |

|

|

|

|

|

|

|

|

|

||

temp. |

|

|

|

|

|

|

|

|

|

(Preset temp.: 24 °C) |

|

||

|

|

|

|

|

|

|

NOTE 1 : *1 : Fan speed = (M + −L) x 3/4 + L *2 : Fan speed = (M + −L) x 2/4 + L *3 : Fan speed = (M + −L) x 1/4 + L

2 : The Hi Power, ECO and COMFORT SLEEP operation can not be set

(Linear approximation from M+ and L)

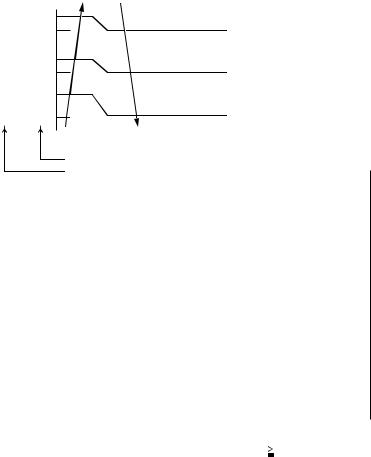

Fig. 7-3-1 Setting of air flow [FAN:AUTO]

7-3-2. Cooling operation

([MODE] button on the remote control is set to the cooling operation.)

(1)The compressor, 4-way valve, (Heat pump model only) outdoor fan and operation display lamp are controlled as shown in Fig. 7-3-2.

temp.) |

° C |

|

|

|

||

|

|

|

|

|||

(Preset |

0.5 |

ON |

|

ON |

|

|

|

|

|||||

|

|

|

|

|

||

temp.) |

|

|

|

|

|

|

|

|

OFF |

OFF |

OFF |

ON |

|

(Room |

|

|

||||

|

|

|

|

|

|

|

Preset |

|

0 |

|

|

|

|

temp. |

|

|

Compressor |

way-4valve |

Outdoorfan |

OPERATION |

|

|

|

||||

|

|

|

|

|

|

displaylamp |

|

|

|

|

|

|

|

Fig. 7-3-2

(2)When [FAN] button is set to AUTO, the indoor fan motor operates as shown in Fig. 7-3-3. When [FAN] button is set to LOW, LOW+, MED, MED+ or HIGH, the motor operates with a constant air flow.

temp.) |

|

° C |

|

|

|

+3 |

M+ |

||||

|

|||||

(Preset |

+2.5 |

||||

*1 |

|||||

|

|||||

|

+2 |

||||

− |

*2 |

||||

|

|

||||

temp.) |

+1.5 |

*3 |

|||

|

|

|

|||

(Room |

+1 |

|

|

||

+0.5 |

|

|

|||

Preset |

|

|

|||

|

0 |

|

|

||

|

|

|

|||

temp. |

-0.5 |

|

|

||

|

|

|

|||

NOTE1 : *1 : Fan speed = (M + −L) x 3/4 + L *2 : Fan speed = (M + −L) x 2/4 + L *3 : Fan speed = (M + −L) x 1/4 + L

(Linear approximation from M+ and L)

Fig. 7-3-3 Setting of air flow [FAN:AUTO]

- 22 -

FILE NO. SVM-09036

7-3-3. Dry operation

([MODE] button on the remote control is set to the dry operation.)

(1)The compressor, 4-way valve, (Heat pump model only) outdoor fan and operation display lamp are controlled as shown in Fig. 7-3-4.

7-3-4. Heating operation *Heat pump model only ([MODE] button on the remote control is set to the heating operation.)

(1)The compressor, 4-way valve, outdoor fan and operation display lamp are controlled as shown in Fig. 7-3-6.

temp.) |

° C |

|

(Preset |

+3 |

|

|

||

temp.) |

+2 |

|

|

|

|

(Room |

+1 |

|

|

|

|

Preset |

|

0 |

|

||

temp.

ON:6min. OFF:4min. |

|

ON:6min. OFF:4min. |

|

ON:5min. OFF:5min. |

OFF |

ON:5min. OFF:5min. |

ON |

|

|

||

OFF |

|

OFF |

|

|

|

|

|

Compressor |

way-4valve |

Outdoorfan |

OPERATION |

|

|

|

displaylamp |

|

|

|

|

Fig. 7-3-4

(2)The microprocessor turns the compressor on and off at the regular intervals (4 to 6 minutes). While the compressor is turning off, the indoor fan motor operates in the SUPER LOW position.

The pattern of operation depending on the relation between room temperature and preset temperatures is shown in Fig. 7-3-5.

Room temp.

Preset temp.+1

Preset temp.

Compressor |

ON |

ON |

ON |

|

ON |

||

|

|

|

|

|

|

|

|

Outdoor fan |

|

OFF |

|

OFF |

|

OFF |

|

|

|

|

|

||||

|

|

|

|

|

|

||

Indoor fan L. |

*S.L. |

L. |

S.L. |

L. |

S.L. |

L. |

|

|

*Super Low |

|

|

|

|

|

|

Fig. 7-3-5

(3)[FAN] button on the remote control is set to AUTO only.

(4)The ECO, COMFORT SLEEP, QUIET and Hi POWER operations can not be set.

|

|

° C |

|

|

|

|

|

Preset |

|

0 |

|

|

|

|

|

temp. |

|

|

|

|

|

|

|

temp.) |

|

|

|

OFF |

ON |

OFF |

ON |

(Preset |

0.5 |

|

|

|

|

|

|

|

|

|

|

|

|

||

(Roomtemp.) |

|

ON |

|

ON |

|

||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Compressor |

way-4valve |

Outdoorfan |

OPERATION |

|

|

|

|

|

|

|

|

displaylamp |

|

|

|

|

|

|

|

|

Fig. 7-3-6

(2)When [FAN] button is set to AUTO, the indoor fan motor operates as shown in Fig. 7-3-7. When [FAN] button is set to LOW, LOW+, MED, MED+ or HIGH, the motor operates with a constant air flow.

° C

Preset  0 L temp. -0.5

0 L temp. -0.5

temp.) |

-1 |

*2 |

|

-2 |

|||

|

-1.5 |

*1 |

|

|

|

||

(Preset |

|

M+ |

|

− |

|

|

|

temp.) |

-5.0 |

|

|

(Room |

-5.5 |

H |

|

[FAN AUTO] |

|||

|

|||

|

|

*1 : Fan speed = (M + −L) x 1/4 + L *2 : Fan speed = (M + −L) x 2/4 + L *3 : Fan speed = (M + −L) x 3/4 + L

(Calculated with Linear approximation from M+ and L+)

Fig. 7-3-7

- 23 -

FILE NO. SVM-09036

(3)The indoor heat exchanger restricts revolving speed of the fan motor to prevent a cold draft. The upper limit of the revolving speed is shown in Fig. 7-3-8

|

Tc |

46 |

34 |

45 |

33 |