Tektronix TDS 380, TDS 360, TDS 340A Service Manual

Service Manual

TDS 340A, TDS 360 & TDS 380

Digital Real-Time Oscilloscopes

070-9435-03

This document applies to firmware version 1.05 and above.

Warning

The servicing instructions are for use by qualified personnel only. To avoid personal injury, do not perform any servicing unless you are qualified to do so. Refer to all safety summaries prior to performing service.

Copyright Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

Tektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070±1000

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

WARRANTY

Tektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship for a period of three (3) years from the date of purchase from an authorized Tektronix distributor. If any such product proves defective during this warranty period, Tektronix, at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the defective product. Batteries are excluded from this warranty.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for packaging and shipping the defective product to the service center designated by Tektronix, shipping charges prepaid, and with a copy of customer proof of purchase. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

Table of Contents

General Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

vii |

Service Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xi |

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xiii |

Specifications |

|

Warranted Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1±1 |

Typical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1±5 |

Nominal Traits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1±7 |

Operating Information |

|

Display and Power Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±1 |

Vertical Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±2 |

Horizontal Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±2 |

Trigger Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±3 |

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±3 |

Miscellaneous Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±4 |

Display Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±5 |

Rear-Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±6 |

Using the Menu System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±7 |

Theory of Operation |

|

Logic Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±1 |

Module Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±1 |

Performance Verification |

|

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±1 |

Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±3 |

Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±4 |

Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±5 |

Functional Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±7 |

Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±11 |

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±11 |

Signal Acquisition System Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±11 |

Time Base System Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±16 |

Trigger System Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±18 |

Sine Wave Generator Leveling Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±20 |

TDS 340A, TDS 360 & TDS 380 Service Manual |

i |

Contents

Adjustment Procedures

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5±1 |

The System Calibration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5±2 |

Attenuator Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5±4 |

Monitor Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5±6 |

Maintenance |

|

Preventing ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±1 |

General Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±2 |

Inspection and Cleaning Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±2 |

Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±5 |

Preparation Ð Please Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±5 |

Line Fuse and Line Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±8 |

Front Panel Knobs and Shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±10 |

Rear Cover, Cabinet, and Cabinet Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±11 |

Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±13 |

Trim Ring, Menu Elastomer, Menu Buttons, and Front EMI Gaskets . . . . . . . . |

6±14 |

Front Panel Assembly and Menu Flex Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±16 |

Main Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±18 |

Monitor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±21 |

Power Supply Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±23 |

Option 14 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±25 |

Fan and Fan Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±27 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±29 |

Onboard Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±29 |

Enabling Calibration Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±31 |

Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±32 |

Repackaging Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±43 |

Options |

|

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7±1 |

Standard Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7±3 |

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7±3 |

Accessory Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7±4 |

Accessory Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7±4 |

Electrical Parts List |

|

Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8±1 |

Diagrams |

|

Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9±1 |

Mechanical Parts List |

|

Parts Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10±1 |

Using the Replaceable Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10±2 |

ii |

TDS 340A, TDS 360 & TDS 380 Service Manual |

Contents

List of Figures

Figure 1±1: TDS 340A, TDS 360, & TDS 380 dimensions . . . . . . . . . . |

1±11 |

Figure 2±1: A pop-up menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±8 |

Figure 2±2: Using menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±9 |

Figure 3±1: TDS 340A, TDS360, & TDS380 block diagram . . . . . . . . |

3±2 |

Figure 3±2: TDS 340A, TDS360, & TDS380 |

|

block diagram with Option 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±3 |

Figure 4±1: Menu locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±2 |

Figure 4±2: Verifying adjustments and signal path |

|

compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±6 |

Figure 4±3: Hookup for functional test . . . . . . . . . . . . . . . . . . . . . . . . . |

4±7 |

Figure 4±4: Hookup for file system functional test . . . . . . . . . . . . . . . |

4±9 |

Figure 4±5: Hookup for DC voltage measurement |

|

accuracy check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±12 |

Figure 4±6: Hookup for analog bandwidth check . . . . . . . . . . . . . . . . |

4±14 |

Figure 4±7: Measuring analog bandwidth . . . . . . . . . . . . . . . . . . . . . . |

4±15 |

Figure 4±8: Hookup for sample rate check . . . . . . . . . . . . . . . . . . . . . . |

4±16 |

Figure 4±9: Hookup for trigger sensitivity check . . . . . . . . . . . . . . . . . |

4±18 |

Figure 4±10: Measuring trigger sensitivity . . . . . . . . . . . . . . . . . . . . . . |

4±19 |

Figure 4±11: Hookup for sine wave generator leveling . . . . . . . . . . . . |

4±21 |

Figure 5±1: The system calibration menu . . . . . . . . . . . . . . . . . . . . . . . |

5±2 |

Figure 5±2: Timing compensation waveform . . . . . . . . . . . . . . . . . . . . |

5±4 |

Figure 5±3: Attenuator adjustment setup and locations . . . . . . . . . . . |

5±5 |

Figure 5±4: Monitor adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5±7 |

Figure 6±1: Oscilloscope orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±6 |

Figure 6±2: Line cord removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±8 |

Figure 6±3: Line fuse removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±9 |

Figure 6±4: Knob and shaft removal . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±10 |

Figure 6±5: Rear cover, cabinet, and cabinet handle |

|

and feet removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±12 |

Figure 6±6: Removing the disk drive . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±13 |

Figure 6±7: Trim ring, menu elastomer, and |

|

menu buttons removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±14 |

TDS 340A, TDS 360 & TDS 380 Service Manual |

iii |

Contents

Figure 6±8: EMI gasket removal and installation . . . . . . . . . . . . . . . . |

6±16 |

Figure 6±9: Front panel assembly and menu |

|

flex circuit removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±17 |

Figure 6±10: Removing the floppy interface board . . . . . . . . . . . . . . . |

6±19 |

Figure 6±11: Removing the main board . . . . . . . . . . . . . . . . . . . . . . . . |

6±20 |

Figure 6±12: Monitor assembly removal . . . . . . . . . . . . . . . . . . . . . . . . |

6±22 |

Figure 6±13: Low voltage power supply removal . . . . . . . . . . . . . . . . . |

6±24 |

Figure 6±14: Option 14 assembly removal . . . . . . . . . . . . . . . . . . . . . . |

6±26 |

Figure 6±15: Fan and fan mount removal . . . . . . . . . . . . . . . . . . . . . . . |

6±27 |

Figure 6±16: The diagnostics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±29 |

Figure 6±17: The error log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±31 |

Figure 6±18: Main board cal jumper . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±32 |

Figure 6±19: Primary troubleshooting procedure . . . . . . . . . . . . . . . . |

6±33 |

Figure 6±20: Module isolation troubleshooting |

|

procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±34 |

Figure 6±21: Front panel/processor troubleshooting |

|

procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±35 |

Figure 6±22: Monitor troubleshooting procedure . . . . . . . . . . . . . . . . |

6±36 |

Figure 6±23: J901 pin 7 signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±37 |

Figure 6±24: J901 pin 2 signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±37 |

Figure 6±25: J901 pin 5 signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±38 |

Figure 6±26: Power supply troubleshooting procedure . . . . . . . . . . . . |

6±39 |

Figure 6±27: Power supply connector locations . . . . . . . . . . . . . . . . . . |

6±40 |

Figure 6±28: Power supply overload troubleshooting |

|

procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±41 |

Figure 6±29: Option 14 I/O interfaces troubleshooting |

|

procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±42 |

Figure 10±1: Cabinet and front panel assembly . . . . . . . . . . . . . . . . . . |

10±6 |

Figure 10±2: CRT, power supply, and circuit boards . . . . . . . . . . . . . |

10±8 |

Figure 10±3: Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10±10 |

iv |

TDS 340A, TDS 360 & TDS 380 Service Manual |

Contents

List of Tables

Table 1±1: Warranted characteristics Ð signal acquisition |

|

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1±1 |

Table 1±2: Warranted characteristics Ð time base system . . . . . . . . |

1±2 |

Table 1±3: Warranted characteristics Ð triggering system . . . . . . . . |

1±3 |

Table 1±4: Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1±3 |

Table 1±5: Warranted characteristics Ð environmental . . . . . . . . . . |

1±4 |

Table 1±6: Typical characteristics Ð signal acquisition system . . . . . |

1±5 |

Table 1±7: Typical characteristics Ð triggering system . . . . . . . . . . . |

1±6 |

Table 1±8: Typical characteristics Ð probe compensator output . . . |

1±6 |

Table 1±9: Typical characteristics Ð data handling . . . . . . . . . . . . . . |

1±7 |

Table 1±10: Nominal traits Ð signal acquisition system . . . . . . . . . . |

1±7 |

Table 1±11: Nominal traits Ð time base system . . . . . . . . . . . . . . . . . |

1±8 |

Table 1±12: Nominal traits Ð triggering system . . . . . . . . . . . . . . . . . |

1±8 |

Table 1±13: Nominal traits Ð display system . . . . . . . . . . . . . . . . . . . |

1±9 |

Table 1±14: Nominal traits Ð Option 14 I/O interface option |

|

(TD3F14A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1±9 |

Table 1±15: Nominal traits Ð power distribution system . . . . . . . . . |

1±9 |

Table 1±16: Nominal traits Ð mechanical characteristics . . . . . . . . . |

1±10 |

Table 1±17: Certifications and compliances . . . . . . . . . . . . . . . . . . . . . |

1±12 |

Table 4±1: Test equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±3 |

Table 4±2: DC accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±11 |

Table 5±1: Adjustment equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5±1 |

Table 6±1: External inspection check list . . . . . . . . . . . . . . . . . . . . . . . |

6±3 |

Table 6±2: Internal inspection check list . . . . . . . . . . . . . . . . . . . . . . . |

6±4 |

Table 6±3: Tools required for module removal . . . . . . . . . . . . . . . . . . |

6±6 |

Table 6±4: Power supply secondary voltages . . . . . . . . . . . . . . . . . . . . |

6±40 |

TDS 340A, TDS 360 & TDS 380 Service Manual |

v |

Contents

Table 7±1: VGA output connector pins . . . . . . . . . . . . . . . . . . . . . . . . |

7±1 |

Table 7±2: International power cords . . . . . . . . . . . . . . . . . . . . . . . . . . |

7±2 |

Table 7±3: Language options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7±2 |

Table 7±4: Standard accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7±3 |

Table 7±5: Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7±3 |

Table 7±6: Accessory cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7±4 |

Table 10±1: Certifications and compliances . . . . . . . . . . . . . . . . . . . . . |

10±1 |

vi |

TDS 340A, TDS 360 & TDS 380 Service Manual |

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to this product or any products connected to it. To avoid potential hazards, use the product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read the General Safety Summary in other system manuals for warnings and cautions related to operating the system.

Injury Precautions Use Proper Power Cord. To avoid fire hazard, use only the power cord specified for this product.

Avoid Electric Overload. To avoid electric shock or fire hazard, do not apply a voltage to a terminal that is outside the range specified for that terminal.

Avoid Overvoltage. To avoid electric shock or fire hazard, do not apply potential to any terminal, including the common terminal, that varies from ground by more than the maximum rating for that terminal.

Avoid Electric Shock. To avoid injury or loss of life, do not connect or disconnect probes or test leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor of the power cord. To avoid electric shock, the grounding conductor must be connected to earth ground. Before making connections to the input or output terminals of the product, ensure that the product is properly grounded.

Do Not Operate Without Covers. To avoid electric shock or fire hazard, do not operate this product with covers or panels removed.

Use Proper Fuse. To avoid fire hazard, use only the fuse type and rating specified for this product.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not operate this product in wet or damp conditions.

Do Not Operate in an Explosive Atmosphere. To avoid injury or fire hazard, do not operate this product in an explosive atmosphere.

Avoid Exposed Circuitry. To avoid injury, remove jewelry such as rings, watches, and other metallic objects. Do not touch exposed connections and components when power is present.

Keep Probe Surface Clean and Dry. To avoid electric shock and erroneous readings, keep probe surface clean and dry.

TDS 340A, TDS 360 & TDS 380 Service Manual |

vii |

General Safety Summary

Wear Eye Protection. To avoid eye injury, wear eye protection if there is a possibility of exposure to high-intensity rays.

Product Damage

Precautions

Use Proper Power Source. Do not operate this product from a power source that applies more than the voltage specified.

Provide Proper Ventilation. To prevent product overheating, provide proper ventilation.

Do Not Operate With Suspected Failures. If you suspect there is damage to this product, have it inspected by qualified service personnel.

Do Not Immerse in Liquids. Clean the probe using only a damp cloth. Refer to cleaning instructions.

Symbols and Terms Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the marking.

WARNING indicates an injury hazard not immediately accessible as you read the marking.

CAUTION indicates a hazard to property including the product.

viii |

TDS 340A, TDS 360 & TDS 380 Service Manual |

General Safety Summary

Symbols on the Product. The following symbols may appear on the product:

Certifications and

Compliances

DANGER |

Protective Ground |

ATTENTION |

Double |

High Voltage |

(Earth) Terminal |

Refer to Manual |

Insulated |

Refer to the specifications section for a listing of certifications and compliances that apply to this product.

TDS 340A, TDS 360 & TDS 380 Service Manual |

ix |

General Safety Summary

x |

TDS 340A, TDS 360 & TDS 380 Service Manual |

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this product unless another person capable of rendering first aid and resuscitation is present.

Disconnect Power. To avoid electric shock, disconnect the main power by means of the power cord or, if provided, the power switch.

Use Caution When Servicing the CRT. To avoid electric shock or injury, use extreme caution when handling the CRT. Only qualified personnel familiar with CRT servicing procedures and precautions should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off. Before attempting any servicing, discharge the CRT by shorting the anode to chassis ground. When discharging the CRT, connect the discharge path to ground and then the anode. Rough handling may cause the CRT to implode. Do not nick or scratch the glass or subject it to undue pressure when removing or installing it. When handling the CRT, wear safety goggles and heavy gloves for protection.

Use Care When Servicing With Power On. Dangerous voltages or currents may exist in this product. Disconnect power, remove battery (if applicable), and disconnect test leads before removing protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

X-Radiation. To avoid x-radiation exposure, do not modify or otherwise alter the high-voltage circuitry or the CRT enclosure. X-ray emissions generated within this product have been sufficiently shielded.

TDS 340A, TDS 360 & TDS 380 Service Manual |

xi |

Service Safety Summary

xii |

TDS 340A, TDS 360 & TDS 380 Service Manual |

Preface

This service manual provides service information for the TDS 340A, TDS 360, and TDS 380 Digitizing Oscilloscopes.

Manual Structure

This manual is divided into Chapters such as Specifications and Theory of Operation. Further, it is divided into subsections such as Product Description and Removal and Installation Procedures.

Sections containing procedures also contain introductions to those procedures. Be sure to read these introductions because they provide information needed to do the service correctly and efficiently. The following is a brief description of each manual chapter.

Specifications contains a product description of the digitizing oscilloscope and tables of the characteristics and descriptions that apply to it.

Operating Information includes general information and operating instructions at the level needed to safely power on and service this oscilloscope.

Theory of Operation contains circuit descriptions that support general service and fault isolation down to the module level.

Performance Verification contains a collection of procedures for confirming that this digitizing oscilloscope functions properly and meets warranted limits.

Adjustment Procedures contains a collection of procedures for adjusting this digitizing oscilloscope to meet warranted limits.

Maintenance contains information and procedures for doing preventive and corrective maintenance of the digitizing oscilloscope. Instructions for cleaning, for module removal and installation, and for fault isolation to a module are found here.

Options contains information on the factory-installed options that may be present in your oscilloscope.

Electrical Parts List contains a statement referring you to the Mechanical Parts List, where both electrical and mechanical modules are listed.

TDS 340A, TDS 360 & TDS 380 Service Manual |

xiii |

Preface

Diagrams contains a statement referring you to the Theory of Operation Chapter, where module-level block diagrams are listed.

Mechanical Parts List includes a table of all replaceable modules, their descriptions, and their Tektronix part numbers.

Manual Conventions

This manual uses certain conventions which you should become familiar with before doing service.

Modules Throughout this manual, any replaceable component, assembly, or part of this digitizing oscilloscope is referred to generically as a module. In general, a module is an assembly, like a circuit board, rather than a component, like a resistor or an integrated circuit. Sometimes a single component is a module; for example, the chassis of the oscilloscope is a module.

Safety Symbols and terms related to safety appear in the General Safety Summary and Service Safety Summary found at the beginning of this manual.

Symbols Besides the symbols related to safety, this manual uses the following symbols:

STOP. This ªstop signº labels information which you must read in order to correctly do service and to avoid incorrectly using or applying

service procedures.

Related Manuals

These other manuals are available for the TDS 340A, TDS 360, and TDS 380

Digitizing Oscilloscopes.

The Reference Manual gives you a quick overview of how to operate your oscilloscope.

The User Manual provides instructions on how to operate your oscilloscope.

The Programmer Manual provides complete information on programming and remote control of the oscilloscope through the GPIB or RS-232 interface (optional accessory).

xiv |

TDS 340A, TDS 360 & TDS 380 Service Manual |

Specifications

This appendix contains complete specifications for the TDS 340A, TDS 360, and TDS 380. The specifications are divided into three subsections, one for each of three classes of traits: Warranted Characteristics, Typical Characteristics, and Nominal Traits.

Warranted Characteristics

Warranted characteristics are described in terms of quantifiable performance limits that are warranted. This subsection lists only warranted characteristics.

NOTE. In these tables, those warranted characteristics that are checked in the

Performance Tests, starting on page 4±11, appear in boldface type under the column Name.

Performance Conditions The electrical characteristics found in these tables of warranted characteristics apply when the oscilloscope has been adjusted at an ambient temperature between +20_ C and +30_ C, has had a warm-up period of at least 20 minutes, and is operating at an ambient temperature between ±10_ C and +55_ C (unless otherwise noted).

Table 1±1: Warranted characteristics Ð signal acquisition system

Name |

Description |

|

|

|

|

|

|

Accuracy, DC Voltage Measurement, |

Measurement type |

DC accuracy |

|

Average Acquisition Mode |

|

|

|

Average of ≥ 16 waveforms |

±(2.0% ×|(reading ± Net Offset1)| + Offset |

||

|

|||

|

|

Accuracy + 0.1 div) |

|

|

|

|

|

|

Delta volts between any two averages of |

±(2.0% ×|reading| + 0.15 div + 0.3 mV) |

|

|

≥ 16 waveforms acquired under the same |

|

|

|

setup and ambient conditions |

|

|

Accuracy, DC Gain, Sample or |

±2% |

|

|

Average Acquisition Modes |

|

|

|

|

|

|

|

Pulse Response, Peak Detect and |

Sec/Div setting |

Minimum pulse width |

|

Envelope Mode |

|

|

|

5 s/div ± 25 s/div |

10 ns |

||

|

|||

|

|

|

|

|

TDS 340A: 10 s/div ± 5 ns/div |

The greater of 10 ns or |

|

|

TDS 360: 10 s/div ± 2.5 ns/div |

.02 ×sec/div setting |

|

|

TDS 380: 10 s/div ± 1 ns/div |

|

TDS 340A, TDS 360 & TDS 380 Service Manual |

1±1 |

Specifications

Table 1±1: Warranted characteristics Ð signal acquisition system (Cont.)

Name |

Description |

|

|

|

|

Accuracy, Offset |

Volts/Div setting |

Offset accuracy |

|

|

|

|

2 mV/div ± 99.5 mV/div |

±(0.4% ×|Net Offset1| |

|

|

+ 3 mV + 0.1 div ×V/div setting) |

|

100 mV/div ± 995 mV/div |

±(0.4% ×|Net Offset1| |

|

|

+ 30 mV + 0.1 div ×V/div setting) |

|

1 V/div ± 10 V/div |

±(0.4% ×|Net Offset1| |

|

|

+ 300 mV + 0.1 div ×V/div setting) |

Analog Bandwidth, DC Coupled |

TDS 340A: DC ± ≥ 100 MHz |

|

|

TDS 360: DC ± ≥ 200 MHz; DC ± ≥ 180 MHz for 2 mV/div |

|

|

TDS 380: DC ± ≥ 400 MHz; DC ± ≥ 250 MHz for 2 mV/div |

|

Cross Talk (Channel Isolation) |

≥ 100:1 at 50 MHz with equal Volts/Div settings on each channel |

|

Input Impedance, DC-Coupled |

TDS 340A: 1 MW ±1% in parallel with 20 pF ±2.0 pF |

|

|

TDS 360: 1 MW ±1% in parallel with 20 pF ±2.0 pF |

|

|

TDS 380: 1 MW ±1% in parallel with 12 pF ±2.0 pF |

|

Input Voltage, Maximum |

±300 V (DC or AC) CAT II; derate at 20 dB/decade above 100 kHz to 13 V peak AC at |

|

|

3 MHz and above |

|

|

|

|

Lower Frequency Limit, AC Coupled2 |

≤10 Hz |

|

1Net Offset = Offset ± (Position ×Volts/Div). Net offset is the voltage level at the center of the A-D converter dynamic range. Offset Accuracy is the accuracy of this voltage level.

2The AC Coupled Lower Frequency Limits are reduced by a factor of 10 when 10X, passive probes are used.

Table 1±2: Warranted characteristics Ð time base system

Name |

Description |

Accuracy, Long Term Sample Rate and |

±100 ppm over any ≥ 1 ms interval |

Delay Time |

|

|

|

Accuracy, Delta Time Measurements1, 2 |

For single-shot acquisitions using sample acquisition mode and a bandwidth limit setting |

|

of FULL: |

|

±(1 WI + 100 ppm ×|Reading| + 0.6 ns) |

|

For repetitive acquisitions using average acquisition mode with ≥ 16 averages and a |

|

bandwidth limit setting of FULL: |

±(1 WI + 100 ppm ×|Reading| + 0.4 ns)

1For input signals ≥ 5 divisions in amplitude and a slew rate of ≥ 2.0 divisions/ns at the delta time measurement points. Signal must be acquired at a volts/division setting ≥ 5 mV/division.

2The WI (waveform interval) is the time between the samples in the waveform record. Also, see the footnotes for Sample Rate Range and Equivalent Time or Interpolated Waveform Rates in Table 1±11 on page 1±8.

1±2 |

TDS 340A, TDS 360 & TDS 380 Service Manual |

Specifications

Table 1±3: Warranted characteristics Ð triggering system

Name |

Description |

|

|

|

|

|

|

Accuracy, Trigger Level, DC Coupled |

Trigger source |

Sensitivity |

|

|

|

|

|

|

CH1 or CH2 |

±(3% of |Setting ± Net Offset1| + 0.2 div × |

|

|

|

volts/div setting + Offset Accuracy) |

|

|

|

|

|

|

External |

±(6% of |Setting| + 20 mV) |

|

|

External/10 |

±(6% of |Setting| + 200 mV) |

|

Sensitivity, Edge-Type Trigger, DC |

Trigger source |

Sensitivity |

|

Coupled |

|

|

|

CH1 or CH2 |

TDS 340A: 0.35 division from DC to 20 |

||

|

|||

|

|

MHz, increasing to 1 div at 100 MHz |

|

|

|

TDS 360: 0.35 division from DC to 50 MHz, |

|

|

|

increasing to 1 div at 200 MHz |

|

|

|

TDS 380: 0.35 division from DC to 50 MHz, |

|

|

|

increasing to 1 div at 400 MHz |

|

|

|

|

|

|

External |

TDS 340A: 50 mV from DC to 20 MHz, |

|

|

|

increasing to 150 mV at 100 MHz |

|

|

|

TDS 360: 50 mV from DC to 50 MHz, |

|

|

|

increasing to 150 mV at 200 MHz |

|

|

|

TDS 380: 50 mV from DC to 50 MHz, |

|

|

|

increasing to 500 mV at 400 MHz |

|

|

|

|

|

|

External/10 |

TDS 340A: 500 mV from DC to 20 MHz, |

|

|

|

increasing to 1.5 V at 100 MHz |

|

|

|

TDS 360: 500 mV from DC to 50 MHz, |

|

|

|

increasing to 1.5 V at 200 MHz |

|

|

|

TDS 380: 500 mV from DC to 50 MHz, |

|

|

|

increasing to 5.0 V at 400 MHz |

|

|

|

|

|

Input Impedance, External Trigger |

1 MW ±2% in parallel with 20 pF ±2 pF |

|

|

Maximum Input Voltage, |

±300 V (DC or AC) CAT II; derate at 20 dB/decade above 100 kHz to 13 V peak AC at |

||

External Trigger |

3 MHz and above |

|

|

|

|

|

|

1Net Offset = Offset ± (Position ×Volts/Div). Net Offset is the voltage level at the center of the A-D converter dynamic range. Offset Accuracy is the accuracy of this voltage level.

Table 1±4: Power Requirements

Name |

Description |

|

|

Source Voltage and Frequency |

90 to 132 VACRMS, continuous range, for 47 Hz through 440 Hz |

|

132 to 250 VACRMS, continuous range, for 47 Hz through 63 Hz |

Power Consumption |

≤65 Watts (120 VA) |

TDS 340A, TDS 360 & TDS 380 Service Manual |

1±3 |

Specifications

Table 1±5: Warranted characteristics Ð environmental

Name |

Description |

|

|

Atmospherics (TDS 340A, TDS 360 or |

Temperature without diskette in floppy disk drive: |

TDS 380) |

+4_ C to +50_ C, operating; |

|

|

|

±22_ C to +60_ C, non-operating |

|

Temperature with diskette in floppy disk drive: |

|

+10_ C to +50_ C, operating or non-operating |

|

Relative humidity without diskette in floppy disk drive: |

|

to 80% at or below +29_ C, or to 20% from +30_ C to +50_ C, operating; |

|

to 90% at or below +40_ C, or to 5% from +41_ C to +50_ C, non-operating; |

|

Relative humidity with diskette in floppy disk drive: |

|

to 80% at or below +29_ C, or to 20% from +30_ C to +50_ C, operating or |

|

non-operating |

|

Altitude: |

|

To 15,000 ft (4570 m), operating; |

|

to 40,000 ft (12190 m), non-operating |

|

|

Dynamics |

Random vibration without diskette in floppy disk drive: |

|

0.31 g RMS, from 5 to 500 Hz, 10 minutes each axis, operating; |

|

2.46 g RMS, from 5 to 500 Hz, 10 minutes each axis, non-operating |

1±4 |

TDS 340A, TDS 360 & TDS 380 Service Manual |

Specifications

Typical Characteristics

Typical characteristics are described in terms of typical or average performance. |

||||

Typical characteristics are not warranted. |

|

|

||

Table 1±6: Typical characteristics Ð signal acquisition system |

|

|

|

|

|

|

|

|

|

Name |

Description |

|

|

|

|

|

|

|

|

Accuracy, DC Gain, Envelope |

±3% for sec/div settings from 5 Sec/Div to 25 sec/div; |

|

||

Acquisition Mode |

±2% for sec/div settings from 10 s/div to 5 ns/div (TDS 340A); |

|

||

|

±2% for sec/div settings from 10 s/div to 2.5 ns/div (TDS 360); |

|

||

|

±2% for sec/div settings from 10 s/div to 1 ns/div (TDS 380) |

|

||

Accuracy, DC Voltage Measurement, |

Measurement type |

|

DC accuracy |

|

Sample Acquisition Mode |

|

|

|

|

Any Sample |

|

±(2.0% ×(|reading ± Net Offset1|) + Offset |

||

|

|

|||

|

|

|

Accuracy + 0.13 div + 0.6 mV) |

|

|

|

|

|

|

|

Delta Volts between any two samples2 |

±(2.0% ×|reading| + 0.26 div + 1.2 mV) |

||

|

acquired under the same setup and |

|

|

|

|

ambient conditions |

|

|

|

|

|

|

|

|

Frequency Limit, Upper, 20 MHz Band- |

20 MHz |

|

|

|

width Limited |

|

|

|

|

|

|

|

|

|

Step Response Settling Error |

Volts/Div |

Step |

Settling error (%)3 |

|

|

setting |

amplitude |

|

|

|

100 ns |

20 ms |

||

|

|

|

||

|

|

|

|

|

|

2 mV/div ± 99.5 mV/div |

≤2 V |

≤1.0 |

≤0.1 |

|

100 mV/div ± 995 mV/div |

≤20 V |

≤1.5 |

≤0.2 |

|

1 V/div ± 10 V/div |

≤200 V |

≤2.5 |

≤0.2 |

Common Mode Rejection Ratio (CMRR) |

100:1 at 60 Hz, reducing to 20:1 at 50 MHz, with equal Volts/Div and Coupling settings |

|||

|

on each channel. |

|

|

|

|

|

|

|

|

1Net Offset = Offset ± (Position ×Volts/Div). Net Offset is the voltage level at the center of the A-D converter dynamic range. Offset Accuracy is the accuracy of this voltage level.

2The samples must be acquired under the same setup and ambient conditions.

3The values given are the maximum absolute difference between the value at the end of a specified time interval after the mid-level crossing of the step, and the value one second after the mid-level crossing of the step, expressed as a percentage of the step amplitude.

TDS 340A, TDS 360 & TDS 380 Service Manual |

1±5 |

Specifications

Table 1±7: Typical characteristics Ð triggering system

Name |

Description |

|

|

|

|

|

|

Error, Trigger Position, Edge Triggering |

Acquire mode |

Trigger-position error1,2 |

|

|

Sample, Average |

±(1 WI + 2 ns) |

|

|

Peak Detect, Envelope |

±(2 WI + 2 ns) |

|

|

|

|

|

Sensitivity, Video-Type Trigger |

Source |

Typical sensitivity |

|

|

|

|

|

|

CH1 or CH2 |

0.6 division of video sync signal |

|

|

External |

75 mV of video sync signal |

|

|

External/10 |

750 mV of video sync signal |

|

|

|

|

|

Lowest Frequency for Successful Operation |

50 Hz |

|

|

of ªSet Level to 50%º Function |

|

|

|

|

|

|

|

Sensitivity, Edge Type Trigger, Not DC |

Trigger coupling |

Typical signal level for stable triggering |

|

Coupled3 |

|

|

|

AC |

Same as DC-coupled limits4 for frequencies above |

||

|

|||

|

|

60 Hz. Attenuates signals below 60 Hz. |

|

|

|

|

|

|

Noise Reject |

Three and one half times the DC-coupled limits.4 |

|

|

High Frequency Reject |

One and one half times times the DC-coupled limits4 |

|

|

|

from DC to 30 kHz. Attenuates signals above 30 kHz. |

|

|

|

|

|

|

Low Frequency Reject |

One and one half times the DC-coupled limits4 for |

|

|

|

frequencies above 80 kHz. Attenuates signals below |

|

|

|

80 kHz. |

|

|

|

|

1The trigger position errors are typically less than the values given here. These values are for triggering signals having a slew rate at the trigger point of ±0.5 division/ns.

2The waveform interval (WI) is the time between the samples in the waveform record. Also, see the footnote for the characteristics Sample Rate Range and Equivalent Time or Interpolated Waveform Rates in Table 1±11 on page 1±8.

3The minimum sensitivity for obtaining a stable trigger. A stable trigger results in a uniform, regular display triggered on the selected slope. The trigger point must not switch between opposite slopes on the waveform, and the display must not ªrollº across the screen on successive acquisitions. The TRIG'D LED stays constantly lighted when the SEC/DIV setting is 2 ms or faster but may flash when the SEC/DIV setting is 10 ms or slower.

4See the characteristic Sensitivity, Edge-Type Trigger, DC Coupled in Table 1±3, which begins on page 1±3.

Table 1±8: Typical characteristics Ð probe compensator output

Name |

Description |

|

|

|

|

|

|

Output Voltage and Frequency, |

Characteristic |

|

|

Probe Compensator |

|

|

|

Voltage |

5.0 V (low-high) into a 1 MW load |

||

|

|||

|

|

|

|

|

Frequency |

1 kHz |

|

|

|

|

1±6 |

TDS 340A, TDS 360 & TDS 380 Service Manual |

Specifications

Table 1±9: Typical characteristics Ð data handling

Name |

Description |

|

|

Time, Data-Retention, Nonvolatile |

≥ 5 Years |

Memory1,2 |

|

1The time that reference waveforms, stored setups, and calibration constants are retained when there is no power to the oscilloscope.

2Data is maintained by a lithium poly-carbon monofluoride battery.

Nominal Traits

Nominal traits are described using simple statements of fact such as ªTwo, identicalº for the trait ªInput Channels, Number of,º rather than in terms of limits that are performance requirements.

Table 1±10: Nominal traits Ð signal acquisition system

Name |

Description |

|

|

|

|

|

|

Bandwidth Selections |

20 MHz and FULL |

|

|

|

|

|

|

Digitizers, Number of |

Two, identical, digitized simultaneously |

|

|

|

|

|

|

Digitized Bits, Number of |

8 bits1 |

|

|

Input Channels, Number of |

Two, identical, called CH 1 and CH 2 |

|

|

|

|

|

|

Input Coupling |

DC, AC, or GND |

|

|

|

|

|

|

Ranges, Offset, All Channels |

Volts/Div setting |

Offset range |

|

|

|

|

|

|

2 mV/div ± 99.5 mV/div |

±1 V |

|

|

|

|

|

|

100 mV/div ± 995 mV/div |

±10 V |

|

|

|

|

|

|

1 V/div ± 10 V/div |

±100 V |

|

|

|

|

|

Range, Position |

±5 divisions |

|

|

Range, Sensitivity2 |

2 mV/div to 10 V/div |

|

|

Rise Time |

TDS 340A: 3.5 ns |

|

|

|

TDS 360: 1.75 ns |

|

|

|

TDS 380: 875 ps |

|

|

TekProbe Interface |

Level one probe coding |

|

|

|

|

|

|

1Displayed vertically with 25 digitization levels (DLs) per division and 10.24 divisions dynamic range with zoom off. A DL is the smallest voltage level change that the 8-bit A-D Converter can resolve, with the input scaled to the volts/division setting of the channel used. Expressed as a voltage, a DL is equal to 1/25 of a division times the volts/division setting.

2The sensitivity ranges from 2 mV/div to 10 V/div in a 1±2±5 sequence of coarse settings. Between consecutive coarse settings, the sensitivity can be finely adjusted with a resolution of 1% of the more sensitive setting. For example, between 50 mV/div and 100 mV/div, the volts/division can be set with 0.5 mV resolution.

TDS 340A, TDS 360 & TDS 380 Service Manual |

1±7 |

Specifications

Table 1±11: Nominal traits Ð time base system

Name |

Description |

|

|

Range, Sample-Rate1,2 |

TDS 340A: 10 Samples/s to 500 MSamples/s in a 1±2±5 sequence |

|

TDS 360: 10 Samples/s to 1 GSamples/s in a 1±2±5 sequence |

|

TDS 380: 10 Samples/s to 2 GSamples/s in a 1±2±5 sequence |

|

|

Range, Seconds/Division |

TDS 340A: 5 ns/div to 5 s/div in a 1±2.5±5 sequence |

|

TDS 360: 2.5 ns/div to 5 s/div in a 1±2.5±5 sequence |

|

TDS 380: 1 ns/div to 5 s/div in a 1±2.5±5 sequence |

Range, Time Base Delay Time |

16.5 ns to 50 seconds |

|

|

Record Length |

1,000 samples |

|

|

1The range of real-time rates, expressed in samples/second, at which a digitizer samples signals at its inputs and stores the samples in memory to produce a record of time-sequential samples

2The Waveform Rate (WR) is the equivalent sample rate of a waveform record. For a waveform record acquired by real-time sampling of a single acquisition, the waveform rate is the same as the real-time sample rate; for a waveform created by interpolation of real-time samples from a single acquisition or by equivalent-time sampling of multiple acquisitions, the waveform rate is faster than the real time sample rate. For all three cases, the waveform rate is 1/(Waveform Interval) for the waveform record, where the waveform interval (WI) is the time between the samples in the waveform record.

Table 1±12: Nominal traits Ð triggering system

Name |

Description |

|

|

|

|

|

|

Range, Hold Off |

500 ns minimum to 10 seconds maximum |

|

|

|

|

|

|

Ranges, Trigger Level |

Source |

Range |

|

|

|

|

|

|

Any Channel |

±12 divisions from center of screen |

|

|

|

|

|

|

External |

±1.5 Volts |

|

|

|

|

|

|

External /10 |

±15 Volts |

|

|

Line |

±300 Volts |

|

Formats and Field Rates, Video Trigger |

Triggers from sync-negative composite video, 525 to 625 lines, 50 Hz to 60 Hz, interlaced |

||

|

or noninterlaced systems with scan rates from 15 kHz to 65 kHz ± such as NTSC, PAL, or |

||

|

SECAM |

|

|

TekProbe Interface, External Trigger |

Level one probe coding |

|

|

1±8 |

TDS 340A, TDS 360 & TDS 380 Service Manual |

Specifications

Table 1±13: Nominal traits Ð display system

Name |

Description |

|

|

CRT Type |

7-inch (17.95 cm) diagonal, magnetic deflection; horizontal raster-scan; P31 green |

|

phosphor |

|

|

Video Display Resolution |

640 pixels horizontally by 480 pixels vertically |

|

Display area is 5.04 inch (12.92 cm) horizontally by 3.78 inch (9.69 cm) vertically |

|

|

Waveform Display Graticule |

A single graticule 401 ×501 pixels (8 ×10 divisions, with divisions that are approximately |

|

1 cm by 1 cm) |

|

|

Intensity Levels |

Dim and Bright, with adjustable Overall Intensity and Contrast |

Table 1±14: Nominal traits Ð I/O interface option

Name |

Description |

|

|

GPIB |

Part of Option 14 I/O interface or TD3F14A I/O interface field upgrade kit; complies with |

|

IEEE Std 488±1987 |

|

|

RS-232 |

Part of Option 14 I/O interface or TD3F14A I/O interface field upgrade kit; a 9-pin male |

|

DTE RS-232 interface that complies with EIA/TIA 574±90 |

|

|

Centronics |

Part of Option 14 I/O interface or TD3F14A I/O interface field upgrade kit; a 25-pin, IBM |

|

PC-type, parallel printer interface that complies electrically with Centronics C332±44, |

|

Rev A |

|

|

Video Signal Output |

DB-9 rear panel Video connector; non-interlaced, with levels that comply with ANSI |

(Option 14 Only) |

RS343A |

|

VGA compatible at a 30.6 kHz sync rate |

|

|

Power Supply, Printer |

Power supply connector to supply power to the Option 3P Printer Pack |

(Option 14 Only) |

|

|

|

Table 1±15: Nominal traits Ð power distribution system

Name |

Description |

|

|

Fuse Rating |

5 mm ×20 mm, 3.15 A (T), 250 V; or 1.25 in ×0.25 in, 3 A (T), 250 V |

|

|

TDS 340A, TDS 360 & TDS 380 Service Manual |

1±9 |

Specifications

Table 1±16: Nominal traits Ð mechanical characteristics

Name |

Description |

||

|

|

|

|

Weight |

|

|

|

|

Standard |

7.0 kg (15.5 lbs) stand-alone instrument; |

|

|

|

8.6 kg (19 lbs) with front cover, accessories, and accessories pouch installed; |

|

|

|

12.9 kg (28.5 lbs) when packaged for domestic shipment |

|

|

Rackmount |

6.6 kg (14.5 lbs), plus weight of rackmount parts (Option 1R); |

|

|

|

14.7 kg (32.5 lbs) when the oscilloscope is packaged for domestic shipment |

|

|

|

|

|

|

Rackmount conversion kit |

4.5 kg (10 lbs); 7.5 kg (17.5 lbs) when kit is packaged for domestic shipment |

|

|

|

|

|

Overall Dimensions |

|

|

|

|

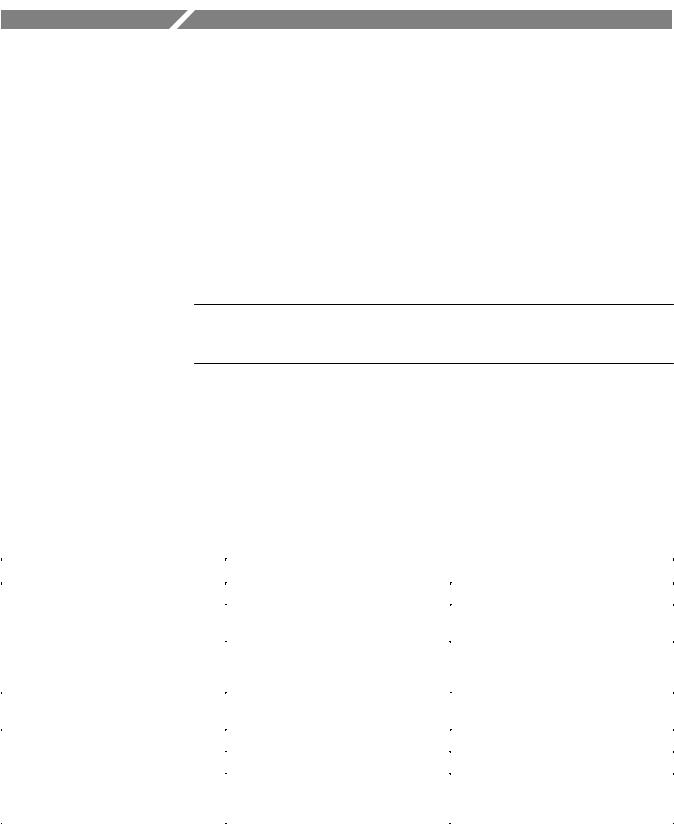

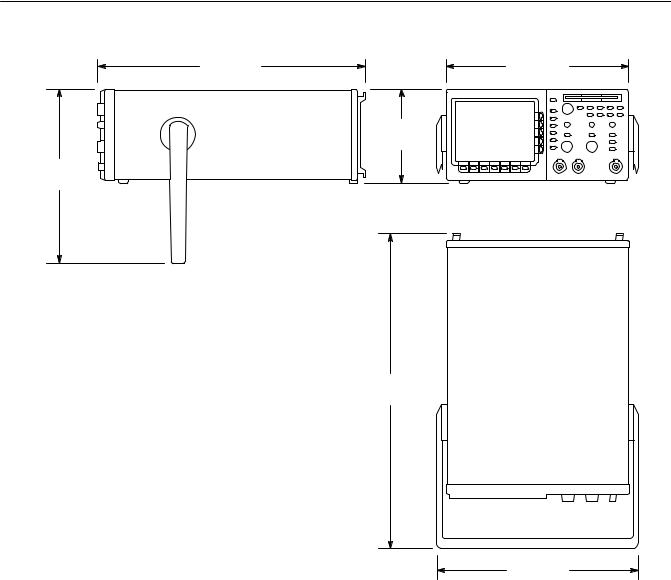

Standard Instrument (Figure 1±1) |

Height: |

191 mm (7.5 in) with feet and accessories pouch installed |

|

|

|

165 mm (6.5 in) without the accessories pouch installed |

|

|

Width: |

362 mm (14.25 in) with handle |

|

|

Depth: |

471 mm (18.55 in) stand-alone instrument |

|

|

|

490 mm (19.28 in) with front cover installed |

|

|

|

564 mm (22.2 in) with handle extended |

|

|

|

|

|

Rackmount Instrument |

Height: 178 mm (7 in) |

|

|

|

Width: 483 mm (19 in) |

|

|

|

Depth: 472 mm (18.6 in) without handles; 517 mm (20.35 in) including handles |

|

1±10 |

TDS 340A, TDS 360 & TDS 380 Service Manual |

Specifications

471 mm |

327.2 mm |

(18.55 in.) |

(12.88 in.) |

165 mm

(6.5 in.)

308.1 mm

(12.13 in.)

569 mm

(22.4 in.)

381 mm

(15 in.)

Figure 1±1: TDS 340A, TDS 360, & TDS 380 dimensions

TDS 340A, TDS 360 & TDS 380 Service Manual |

1±11 |

Loading...

Loading...