Tektronix 2225 schematic

SERVICE |

070-6299-00 |

TEK MANUAL |

Product Group 46 |

OSCILLOSCOPE

SERVICE

THE FOLLOWING SERVICING INSTRUCTIONS ARE

FOR USE BY QUALIFIED PERSONNEL ONLY. TO

AVOID PERSONAL INJURY, DO NOT PERFORM ANY

SERVICING OTHER THAN THAT CONTAINED IN

OPERATING INSTRUCTIONS UNLESS YOU ARE

QUALIFIED TO DO SO. REFER TO OPERATORS

SAFETY SUMMARY AND SERVICE SAFETY SUM-

MARY PRIOR TO PERFORMING ANY SERVICE.

Please Check for

CHANGE INFORMATION at the Rear of This Manual

First PrintingOCT 1987

RevisedAPR 1990

Scansby ARTEK MEDL4 ==-

DIGITALY REMASTERED

OUT OF PRINTMANUAL SCANS

By

ArtekMedia

P.O. BOX 175

Welch, MN 55089-0175

Phone: 651-269-4265

www.artekmedia.com

“High resolution scans of obsolete technical manuals”

If you are looking for a quality scanned technical manual in PDF format please visit our WEB site at www.artekmedia.com or drop us an email at manuals@artekmedia.com

If you don’t see the manual you need on the list drop us a line anyway we may still be able to obtain the manual you need or direct you to other sources. If you have an existing manual you would like scanned please write for details. This can often be done very reasonably in consideration for adding your manual to our library.

Typically the scans in our manuals are done as follows;

1)Typed text pages are typically scanned in black and white at 300 dpi.

2)Photo pages are typically scanned in gray scale mode at 600 dpi

3)Schematic diagram pages are typically scanned in black and white at 600 dpi unless the original manual had colored high lighting (as is the case for some 70’s vintage Tektronix manuals).

4)Most manuals are text searchable

5)All manuals are fully bookmarked

All data is guaranteed for life (yours or mine … whichever is shorter). If for ANY REASON your file becomes corrupted, deleted or lost, ArtekMedia will replace the file for the price of shipping, or free via FTP download.

Thanks

Dave & Lynn Henderson

ArtekMedia

Copyright O 1987 Tektronix, Inc. All rights reserved. Contents of this publication may not be reproduced in any form without the written permission of Tektronix, Inc.

Products of Tektronix, Inc. and its subsidiaries are covered by W.S. and foreign patents issued and pending.

TEKTRONIX, TEK, SCOPE-MOBILE, and |

are registered trade- |

|

marks of Tektronix, |

Inc. |

|

Printed in U.S.A. |

Specification and price |

change privileges are |

reserved. |

|

|

INSTRUMENT SERIAL NUMBERS

Each instrument has a serial number on a panel insert, tag, or stamped on the chassis. The first number or letter designates the country of manufacture. The last five digits of the serial number are assigned sequentially and are unique to each instrument. Those manufactured in the United States have six unique digits. The country of manufacture is identified as follows:

BOO0000 Tektronix, Inc., Beaverton, Oregon, U.S.A.

HKOOOOl Hong Kong

100000 Tektronix Guernsey, Ltd., Channel Islands

200000 Tektronix United Kingdom, Ltd., London

300000 SonyITektronix, Japan

700000 Tektronix Holland, NV, Heerenveen,

The Netherlands

Scam by ARTEK MEDIA 3

2225 Service

TABLE OF CONTENTS

|

Page |

LIST OF ILLUSTRATIONS ................... |

iv |

LIST OF TABLES ........................... |

v |

OPERATORS SAFETY SUMMARY ............ |

vi |

SERVICING SAFETY SUMMARY ............. |

vii |

Section 1 SPECIFICATION

INTRODUCTION . . . . . . . . . . . . . . 1-1

ACCESSORIES . . . . . . . . . . . . . . 1-1

FOR MORE INFORMATION . . . . . 1-1

RECOMMENDED RECALIBRATION

SCHEDULE . . . . . . . . . . . . . . . |

. . 1-1 |

PERFORMANCE CONDITIONS |

. . 1-1 |

|

Page |

TRIGGER . . . . . . . . . . . . . . . . . . |

2-6 |

REAR PANEL . . . . . . . . . . . . . . . |

2-7 |

OPERATING CONSIDERATIONS . . |

2-8 |

GRATICULE . . . . . . . . . . . . . . . . |

2-8 |

GROUNDING . . . . . . . . . . . . . . . |

2-8 |

SIGNAL CONNECTIONS . . . . . . |

2-8 |

INPUT-COLIPLING |

|

CAPACITOR PRECHARGING . . . |

2-9 |

OPERATOR'S CHECKSAND |

|

ADJUSTMENTS . . . . . . . . . . . . . . |

2-10 |

INITIAL SETUP . . . . . . . . . . . . . |

2-10 |

TRACE ROTATION |

|

ADJUSTMENT . . . . . . . . . . . . . |

2-10 |

PROBE COMPENSATION . . . . . |

2-10 |

Section 3 THEORY OF OPERA'I'ION

Section 2 OPERATING INSTRUCTIONS

PREPARATION FOR USE . . . . . . . . |

2-1 |

SAFETY . . . . . . . . . . . . . . . . . . . . |

2-1 |

LINE VOLTAGE SELECTION . . . . |

2-1 |

LINE FUSE . . . . . . . . . . . . . . . . . |

2-2 |

POWER CORD . . . . . . . . . . . . . . |

2-2 |

INSTRUMENT COOLING . . . . . . . |

2-2 |

INITIAL START-UP . . . . . . . . . . . |

2-2 |

REPACKAGING . . . . . . . . . . . . . . |

2-3 |

CONTROLS. CONNECTORS. |

|

AND INDICATORS . . . . . . . . . . . . . . |

2-4 |

POWER AlVD DISPLAY . . . . . . . . |

2-4 |

VERTICAL . . . . . . . . . . . . . . . . . . |

2-4 |

HORIZONTAL .............. . |

2-5 |

SECTION ORGANIZATION . . . . . |

3-1 |

INTEGRATED ClRClJlT |

|

DESCRIPTIONS . . . . . . . . . . . . . |

3-1 |

GENERAL DESCRIPTION . . . . . . . . |

3-1 |

DETAILED CIRCUIT |

|

DESCRIPTION . . . . . . . . . . . . . . . . |

3-3 |

VERTICAL . . . . . . . . . . . . . . . . . |

3-3 |

TRIGGER . . . . . . . . . . . . . . . . . . |

3-7 |

SWEEP AND SWEEP |

|

GENERATOR LOGIC . . . . . . . . |

3-10 |

HORIZONTAL . . . . . . . . . . . . . . |

3-12 |

FRONT PANEL . . . . . . . . . . . . . |

3-14 |

Z-AXIS AMPLIFIER . . . . . . . . . |

3-14 |

POWER SUPPLY . . . . . . . . . . . |

3-16 |

Scamby ARTEK MEDIA =>

2225 Service

TABLE OF CONTENTS (cont)

Page |

Page |

Section 4 PERFORMANCE CHECK PROCEDLIRE |

Section 5 ADJUSTMENT PROCEDLIRE |

INTRODUCTION ............... |

.4-1 |

PERFORMANCE CHECK |

|

INTERVAL . . . . . . . . . . . . . . . . . |

.4-1 |

STRUCTURE . . . . . . . . . . . . . . . . |

4-1 |

TEST EQUIPMENT |

|

REQUIRED . . . . . . . . . . . . . . . . . |

.4-1 |

LIMITS AND TOLERANCES . . . . |

. 4-1 |

PREPARATION FOR |

|

CHECKS .................. |

.4-1 |

INDEX TO PERFORMANCE |

|

CHECK STEPS ............. |

.4-3 |

VERTICAL . . . . . . . . . . . . . . . . . . . |

.4-4 |

INITIAL CONTROL |

|

SETTINGS ................. |

.4-4 |

PROCEDURE STEPS . . . . . . . . . |

.4-4 |

HORIZONTAL ................ |

.4-8 |

INITIAL CONTROL |

|

SETTINGS . . . . . . . . . . . . . . . . . |

.4-8 |

PROCEDURE STEPS . . . . . . . . . |

.4-8 |

TRIGGER .................... |

4-12 |

INITIAL CONTROL |

|

SETTINGS . . . . . . . . . . . . . . . . . |

4-1 2 |

PROCEDURE STEPS . . . . . . . . . |

4-1 2 |

EXTERNAL Z-AXIS AND |

|

PROBE ADJUST ............. . |

4-1 5 |

INITIAL CONTROL |

|

SETTINGS ................. |

4-1 5 |

PROCEDURE STEPS ........ . |

4-1 5 |

INTRODUCTION . . . . . . . . . . . . . . . |

5-1 |

PURPOSE . . . . . . . . . . . . . . . . . . |

5-1 |

STRUCTURE .............. . |

5-1 |

TEST EQUIPMENT |

|

REQUIRED . . . . . . . . . . . . . . . . . |

5-1 |

LIMITS AND TOLERANCES . . . . |

5-1 |

ADJUSTMENTS AFFECTED BY |

|

REPAIRS . . . . . . . . . . . . . . . . . . |

5-1 |

PREPARATION FOR

ADJUSTMENT . . . . . . . . . . . . . . 5-1

INDEX TO ADJUSTMENT PROCEDURE STEPS . . . . . . . . . 5-3

POWER SLIPPLY AND

CRT DISPLAY . . . . . . . . . . . . . . . . 5-4

INITIAL CONTROL |

|

SETTINGS ................ . |

5-4 |

PROCEDURE STEPS . . . . . . . . . |

5-4 |

VERTICAL . . . . . . . . . . . . . . . . . . . |

5-6 |

INITIAL CONTROL |

|

SETTINGS . . . . . . . . . . . . . . . . . |

5-6 |

PROCEDURE STEPS ........ . |

5-6 |

HORIZONTAL . . . . . . . . . . . . . . . . |

5-13 |

INITIAL CONTROL |

|

SETTINGS . . . . . . . . . . . . . . . . |

5-13 |

PROCEDURE STEPS . . . . . . . . |

5-13 |

TRIGGER . . . . . . . . . . . . . . . . . . . |

5-18 |

INITIAL CONTROL |

|

SETTINGS . . . . . . . . . . . . . . . . |

5-18 |

PROCEDURE STEPS . . . . . . . . |

5-18 |

EXTERNAL Z-AXIS AND |

|

PROBE ADJUST . . . . . . . . . . . . . |

5-22 |

INITIAL CONTROL |

|

SETTINGS ................ |

5-22 |

PROCEDURE STEPS . . . . . . . . |

5-22 |

Scam by ARTEK MEDL4 *

2225 Service

TABLE OF CONTENTS (cont)

Page

Section 6 MAINTENANCE

STATIC-SENSITIVE

COMPONENTS .. .. . . . . .... . . . . 6-1

. . . . . 6-2

INTRODUCTION ... . . ... . . . . .. 6-2

GENERAL CARE . . . . ... . . . . .. 6-2

INSPECTION AND

CLEANING ... . ... . . . . . . . . . . . 6-2

LUBRICATION . ... . .... . . . ... 6-4

. . . . 6-4

PERIODIC READJUSTMENT . . . . 6-4 TROUBLESHOOTING . . . . . .. . . . . . 6-4

INTRODUCTION . . .. . . . ... . . . . 6-4

.... . 6-4

RIBBON-CABLE |

|

CONNECTORS . .. . . . ... . |

. . . . 6-6 |

TROUBLESHOOTING |

|

EQUIPMENT .... . ... . .... |

. . . . 6-6 |

TROLIBLESHOOTING |

|

TECHN~QL~ES, .. .. . ... , , . .. 6-7 |

|

CORRECTIVE MAINTENANCE |

... 6-10 |

INTRODUCTION . ... . . . ... |

. . . 6-1 0 |

MAINTENANCE |

|

PRECAUTIONS .. . ... . . . . |

... 6-10 |

Page

OBTAINING REPLACEMENT

PARTS . . . ... . . .. . . .. . . . . . 6-1 0

. . . . . . . 6-1 1

. . . . . .. 6-1 1

TRANSISTORS AND

INTEGRATED CIRCUITS . . . .. 6-1 1 SOLDERING TECHNIQLIES . . . 6-12

REMOVAL AND REPLACE- |

|

MENT INSTRUCTIONS . . . .. .. |

6-1 3 |

Section 7 OPTIONS AND ACCESSORIES

INTRODUCTION . . . . ... . . . . . . 7-1

. . . 7-1

OPTIONS . . . .. . . ... . . ...... 7-1

Section 8 |

REPLACEABLE ELECTRICAL PARTS |

Section 9 |

DIAGRAMS |

Section 10 |

REPLACEABLE MECHANICAL PARTS |

APPENDIX |

|

CHANGE INFORMATION

iii

Scam by ARTEK MEDIA =>

2225 Service

LIST OF ILLUSTRATIONS

Figure |

|

Page |

|

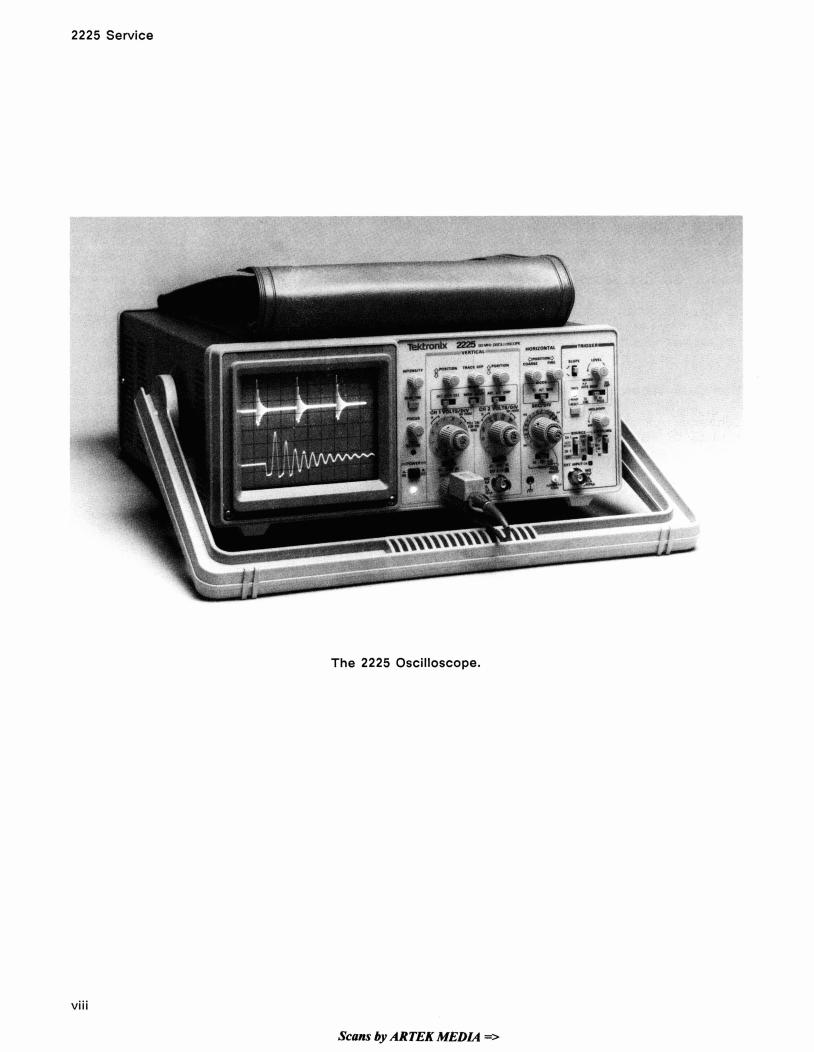

The 2225 Oscilloscope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .viii |

1-1 |

Max Input Voltage Vs Frequency Derating Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 1-7 |

1-2 |

Instrument dimensional drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 1-8 |

2-1 |

Voltage Selector switch. fuse. and power-cord receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

2-2 |

Power-cord and line-voltage data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-2 |

2-3 |

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-7 |

2-4 |

Graticule measurement markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.2-8 |

2-5 |

Probe compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-11 |

2-6 |

Probe compensation locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-11 |

3-1 |

Block diagram of the Channel 1 Attenuator circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-3 |

3-2 |

Block diagram of the Channel Switching circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.3-5 |

3-3 |

Block diagram of the Sweep Generator and Logic circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-10 |

3-4 |

Block diagram of the Horizontal Amplifier circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-13 |

3-5 |

Simplified diagram of the DC Restorer circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-15 |

5-1 |

Attenuator trimmer adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-9 |

6-1 |

Multi-connector operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-6 |

Scamby ARTEK MEDIA *

2225 Service

OPERATORS SAFETY SUMMARY

The safety information in this summary is for operafing personnel. Warnings and cautions will also be found throughout the manual where they apply.

Terms in this Manual

CAUTION statements identify conditions or practices that could result in damage to the equipment or other property.

WARNING statements identify conditions or practices that could result in personal injury or loss of life.

Grounding the Product

This product is grounded through the grounding conductor of the power cord. TOavoid electrical shock, plug the power cord into a properly wired receptacle before making any connections to the product input or output terminals. A protective ground connection, by way of the grounding conductor in the power cord, is essential for safe operation.

Terms as Marked on Equipment

CAUTION indicates a personal injury hazard not immediately accessible as one reads the markings, or a hazard property, including the itself'

DANGER indicates a personal injury hazard immediately accessible as one reads the marking.

Symbols in this Manual

This symbol indicates where applicable cautionary or other information is to be found. For maximum input voltage see Table 1-1 .

Danger Arising From Loss of Ground

Upon loss of the protective-ground connection, all

accessible conductive parts, including knobs and controls that may appear to be insulating, can ,-en-

der an electric shock.

Use the Proper Power Cord

Use only the power cord and connector specified for your product.

Use only a power cord that is in good condition.

For detailed information on power cords and connectors, see Figure 2-2.

Symbols as Marked on Equipment

1 DANGER-High voltage.

@Protective ground (earth) terminal.

A ATTENTION-Refer to manual.

Power Source

This product is intended to operate from a power source that does not apply more than 250 V rms between the supply conductors or between either supply conductor and ground. A protective ground connection, by way of the grounding conductor in the power cord, is essential for safe operation.

Use the Proper Fuse

To avoid fire hazard, use only a fuse of the correct type, voltage rating and current rating as specified in the parts list for your product.

Do Not Operate in an Explosive

To avoid explosion, do not operate this instrument in an explosive atmosphere unless it has been specifically certified for such operation.

DO Not Remove Covers or Panels

To avoid personal injury, do not remove the product covers or panels. Do not operate the product without the covers and panels properly installed.

Scans by ARTEK MEDU =>

2225 Service

SERVICING SAFETY SUMMARY

FOR QUALIFIED SERVICE PERSONNEL ONLY

Refer also to the preceding Operators Safety Summary

Do Not Service Alone

Do not perform internal service or adjustment of this product unless another person capable of rendering first aid and resuscitation is present.

Use Care When Servicing With Power On

Dangerous voltages exist at several points in this product. To avoid personal injury, do not touch exposed connections or components while power is on.

Disconnect power before removing protective panels, soldering, or replacing components.

Power Source

This product is intended to operate from a power source that does not apply more than 250 volts rms between the supply conductors or between either supply conductor and ground. A protective ground connection by way of the grounding connetor in the power cord is essential for safe operation.

Scam by ARTEK M E N =>

Section 1-2225 Service

SPECIFICATION

INTRODUCTION |

ACCESSORIES |

The TEKTRoNIX 2225 oscillosco~eis a lightweight, dual-channel, 50 MHz instrumentthat features a

bright* defined traceOn an 80 de-ray tube (crt).

The low-noisevertical systemof the2225 hascalibrated deflection factors from 5 mV to 5 V per division at full bandwidth. A vertical ma~nificationfeature extends the vertical sensitivity to 506 FV per division. This same magnification feature permits independent bandwidth limiting for each channel. With it, a user can limit the bandwid'hof one channel'05 MHzwi'houtaffectingthe bandwidth of the other channel.

Stable triggering is achieved over the full bandwidth of the vertical system. The very flexible trigger system of the 2225 features hands-free triggering with the peak- to-peak automatic mode, independent selection of TV LineandTV Fieldtriggering at any sweep speed, singlesweep triggering, and a variable holdoff control to facilitate triggering on complex waveforms. Along with the standard AC and DC signal coupling methods,the 2225 provides HF REJ and LF REJ trigger coupling. These added coupling features give the user the ability to filter outthe high-frequency or low-frequency componentsof a trigger signal that can interfere with stable triggering. An externaltrigger signal may be suppliedto the trigger system via a front-panel connector. That front-panel connectormay also be usedto supply an externalZ-axis signal for intensity modulationof the displayed signals.

The horizontal'ystem provides calibratedsweep 'peedsfrom0'5 to 50 ns perdivision'For greatermeasurement accuracy, a horizontal magnifier circuit extends the maximum sweep speed to 5 ns per division. Magnification is selected in three levels-X5, XlO, and X50-and the magnified trace can be displayed either alone or together with its associated unmagnifiedtrace.

Displaying both the magnified and unmagnified traces together -called Alternate Magnification modelets the user performtypes of timing measurementsthat pre-

viously were only possible on oscilloscopes havingdual time bases.

The instrument is shipped with the following accessories: operators manual, two probe kits, a power cord, and a power-cord clamp. The probes suppliedwith the

2225 have sturdy replaceabletips. Probecompensation is accomplished through a closeable window on the

probe body. Part numbersfor the standard accessories and for the suggested optional accessories are located in Section 7, Options and Accessories.

FOR MORE INFORMATION

Shouldyou need additional infonation about your 2225

Oscilloscope or about other TeMronix products, contact the nearest Tektronix Sales Office or Distributor or con- suit the TeMronix product catalog. infieUnited States you may call theTektronix National Marketing Centertoll free at 1-800-426-2200.

RECOMMENDED RECALIBRATION

SCHEDULE

To ensure accurate measurements, check the performance of this instrument every 2000 hoursof operation, or, if used infrequently, once each year. Replacement of components in the instrument may also necessitate readjustment of the affected circuits.

PERFORMANCE CONDITIONS

The electrical characteristicsgiven inTable 1-1 arevalid when the instrument has been adjusted at an ambient temperature between +20°C and +30°C, has had a warm-up period of at least 20 minutes, and is operating at an ambient temperature between O°C and +40°C (unless otherwise noted).

Items listed in the Performance Requirements column ,a verifiable qualitative or quantitative limitsthat define the measurement capabilities of the instrument.

Environmental characteristics are given in Table 1-2.

This instrument meets |

the requirements of |

MIL- |

~ - 2 8 8 0 0 ~ ,paragraphs |

4.5.5.1.3, 4.5.5.1 -4, |

and |

4.5.5.1.2.2 for Type Ill, Class 5 equipment, exceptwhere noted otherwise.

Physical characteristics of the instrument are listed in Table 1-3.

R N APR 1990

Scam by ARTEK MEDIA ==-

Specification-2225 Service

|

Table 1-1 |

Electrical Characteristics |

|

Characteristics |

Performance Requirements |

VERTICAL DEFLECTION SYSTEM |

|

Deflection Factor |

|

Range |

5 mV per division to 5 V per division in a 1-2-5 sequence |

|

of 10 steps. Sensitivity increases to 500 pV per division |

|

with X I 0 vertical magnification. |

Accuracy |

|

Without vertical magnification |

2 3%. |

With X I 0 vertical magnification |

2 5%. |

Variable Control Range |

Continuously variable between settings. Increases |

|

deflection factor by at least 2.5 to 1. |

Step Response |

Rise time is calculated from: Tr = -0 35 |

Rise Time |

BW |

|

|

+5" C to +35" C |

7 ns or lessa |

0°C to +5"C and |

|

+35OC to +40°C |

8.8 ns or lessa |

Aberrations |

|

5 mV per division |

+6%, -6%, 6% p-p. |

10 mV per division to 0.2 V per division |

+4%, -4%, 4% p-p. |

0.5 V per division |

+6%, -6%, 6% p-p. |

Bandwidth (-3 dB) |

|

+5OC to +35OC |

50 MHz or more. |

0°C to +5OC and |

|

+35'C to +40°C |

40 MHz or more.a |

X I 0 Vertical Magnification |

5 MHz or more. |

Ac Coupled Lower Cutoff Frequency (-3dB) |

10 Hz or lessa |

CHOP Mode Switching Rate |

500 kHz ?30%.a |

Input Characteristics |

|

Resistance |

1 Mi2 ?2%.a |

Capacitance |

25 pF +2 pFa |

aPerformance requirement not checked in manual.

REV APR 1990

Scans by ARTEK MEDLQ =>

Characteristics

Maximum Safe Input Voltage

(DC or AC Coupled)

Common-mode Rejection Ratio (CMRR)

Without Vertical Maanification

With X I 0 Vertical Magnification

Trace Shift with VOLTSIDIV

Switch Rotation

Trace Shift as the VOLTSIDIV Variable

Control is rotated.

Trace Shift with CH 2 INVERT

Trace Shift with X I 0 Vertical Magnification

Channel Isolation

Position Control Range

Trace Separation Range

Trigger Sensitivity

P-P AUTOITV LINE and

NORM Modes

Internal Signal

External Signal

TV FIELD

Lowest Usable Frequency in

P-P AUTO Mode

Specification-2225 Service

Table 1-1 (cont)

Performance Requirements

400 V (dc + peak ac) or 800 V ac p-p at 10 kHz or lessa (See Figure 1-1 for frequency derating curve.)

At least 10 to 1 at 10 MHz.

I At least 10 to 1 at 1 MHz.

0.75 division or less; VOLTS/DIV Variable control in the CAL detent?

1 division or lessa

1.5division or lessa

2.0divisions or less?

I |

Greater than 100:l at 10 MHz. |

|

10.5 divisions above and below the center graticule |

||

line at 25OC with the cabinet installed. |

||

I |

At least 23 divisions. |

|

|

TRIGGERING |

|

|

5 MHz I |

50 MHz |

|

I |

|

|

0.3 div |

1.0 div |

|

40 mV |

200 mV |

I 1 division of composite synca I

A 1.0 division internal signal or 100 mV external signal of 20 Hz or higher frequency will trigger.

External Input |

I |

Input Resistance |

1 M a |

Input Capacitance |

1 25 PF 22.5 PFP |

|

I |

Maximum Input Voltage |

400 V (dc + peak ac) or 800 V ac p-p at 10 kHz or lessa |

|

(See Figure 1-1 for frequency derating curve.) |

AC Coupled Lower Cutoff |

|

Frequency (-3dB) |

|

Internal Signal |

10 Hz or less? |

External Signal |

20 Hz or less.a |

aPerformance requlrement not checked in manual.

I

I

I

i

Scam by ARTEK MEDL4 =>

Specification-2225 Service

Table 1-1 (cont)

Characteristics

Trigger Level Range

NORM Mode

EXT Source

EXTI10 Source

Variable Holdoff Range

LF REJ Lower 3 dB point

HF REJ 3 dB point

Sweep Rates

Calibrated Range

Sweep

Accuracy

SECIDIV Variable Range

Performance Requirements

Level may be set to any point of trace that can be displayed.

At least 21.2 V, 2.4 V p-p.

At least 212 V, 24 V p-p.

Increases sweep holdoff time by at least a factor of 8 at maximum holdoff?

30 kHz ?25%.a

30 kHz 225%.a

HORIZONTAL DEFLECTION SYSTEM

0.5 s per division to 0.05 ~s per division in a 1-2-5 sequence of 22 steps. The X I 0 magnifier extends maximum sweep speed to 5 ns per d i ~ i s i o n . ~

Unmagnified |

|

Magnified |

|

X1 |

X5 |

X I 0 |

X50 |

Sweep accuracy applies over the center eight divisions. Exclude the first 25 ns of the sweep for magnified sweep speeds and anything beyond the 100th magnified division.

Continuously variable and uncalibrated between calibrated step settings of the SECIDIV switch. Decreases calibrated sweep speeds by at least a factor of 2.5.

Sweep Linearity

POSITION Control Range

Unmasnified |

|

Magnified |

|

X I |

X5 |

X I 0 |

X50 |

Start of sweep to 10th division in X I , |

to 50th division |

||

in X5, to 100th in X10, and to 500 division in X50 will position past the center vertical graticule line.

Registration between Magnified and |

0.2 division or less (measuredwhen switching from Magnified to |

Unmagnified traces |

Unmagnified), aligned to center vertical graticule 1ine.a |

Trace Shift between ALT and MAG |

Less than 1 divisiona |

Modes |

|

aPerformance requirement not checked in manual.

REV APR 1990

Scans by ARTEK MEDIA =>

|

Specification-2225 Service |

|

|

Table 1-1 (cont) |

|

Characteristics |

Performance Requirements |

|

|

Z-AXIS |

|

Sensitivity |

5 V causes noticeable modulation. Positive-going |

|

|

input decreases intensity. |

|

Usable frequency range |

DC to 5 MHZP |

|

Maximum Safe Input Voltage |

400 V (dc + peak ac) or 800 V p-p |

ac at 10 kHz or less.a |

|

(See Figure 1-1 for frequency derating curve.) |

|

X-Y |

OPERATION (XI MODE) |

|

Deflection Factors |

Same as vertical deflection system with variable controls |

|

|

in the CAL detent.a |

|

Accuracy |

+5%. |

|

X- Axis |

|

|

Y-Axis |

Same as vertical deflection systema |

|

Bandwidth (-3 dB) |

|

|

X-Axis |

Dc to at least 2 MHz. |

|

Y-Axis |

Same as vertical deflection systema |

|

Phase difference between X-Axis and |

+3O from dc to 150 kHz with DC input coup1ing.a |

|

Y-Axis Amplifiers |

|

|

PROBE ADJUST SIGNAL OUTPUT |

|

|

Voltage into 1 MR Load |

0.5 V +5%. |

|

Repetition Rate |

1 kHz -+5%.a |

|

|

POWER SUPPLY |

|

Line Voltage Ranges |

|

|

115 V Setting |

95 Vac to 128 Vaca |

|

230 V Setting |

185 Vac to 250 Vacaa |

|

Line Frequency |

48 Hz to 440 H Z . ~ |

|

Maximum Power Consumption |

70 watts (80 VA) .a |

|

Line Fuse |

UL 198.6 3AG (1I4 X 1 1/4 inch) |

IEC127 (5 x 20 mm) |

115 Setting |

1.0 A, Slow. |

0.8 A, Slow. |

230 Setting |

0.5 A, Slow. |

0.4 A, Slow. |

|

CATHODE-RAY TUBE |

|

Display Area |

8 X 10 c m a |

|

Standard Phosphor |

GH (P31) .a |

|

Nominal Accelerating Voltage |

1 12,600 V +60 V.a |

|

a~erformancerequirement not checked in manual.

REV APR 1990

Specification-2225 Service

Table 1-2

Environmental Characteristics

Characteristics

Temperature

Operating

Nonoperating

Altitude

Operating

Performance Requirements

0°C to +40°C (+32"F to +104"F)?

-55°C to t 7 5 " C (-67" F to +I67 " F) .a

To 4,570 meters (15,000 feet). Maximum operating temperature decreased 1°C per 300 m (1000 feet) above 1500 m (5,000 feet) .a

Nonoperating

Relative Humidity

Operating (+30°C to +40°C) Nonoperating (+30°C to +60°C)

Vibration

Operating

Shock

Operating and Nonoperating

Radiated and conducted emission requirements

To 15,250 meters (50,000 feet) .a

5 cycles (120 hours) referenced to MIL-T-28800C para 4.5.5.1.2.2 for type Ill, Class 5 instruments. Operating and nonoperating at 95% -5% to +0% relatiave humidity.

15 minutes along each of three major axes at a total displacement of 0.015 inch p-p (2.4 g at 55 Hz) with frequency varied from 10 Hz to 55 Hz to 10 Hz in one minute sweeps. Hold for 10 minutes at 55 Hz in each of three major axes. All major resonances must be above 55 Hz.a

30 g, half-sine, 11-ms duration, three shocks per axis each direction, for a total of 18 shocks.=

Meets VDE 0871, Class B and FCC Docket 20870, part 15, subpart J.a

aPerformance requirement not checked in manual.

REV APR 1990

Scansby ARTEK MEDLQ =>

Specification-2225 Service

|

Table 1-3 |

|

Physical Characteristics |

Characteristics |

Description |

Weight |

|

With Power Cord |

6.9 kg (15.2 Ibs) or less. |

Domestic Shipping Weight |

9.0 kg (19.8 Ibs) or less. |

Height |

138 m m (5.42 in). (See Figure 1-2 for a dimensional |

|

drawing). |

Width |

|

With Handle |

385 rnm (15.2 in). |

|

|

Without Handle |

327 m m (12.9 in). |

Depth |

|

Without Front Cover |

443 m m (17.3 in). |

With Handle Extended |

511 m m (20.1 in). |

400

300

-200

0

u

Y 4

w 100 a

+

-0

0

m 50

I-

-I

0

>

20

10

10 kHz |

50 kHz 100 kHz |

500 kHz I MHz |

50 MHz |

6299-21

Figure 1-1. Max Input Voltage Vs Frequency Derating Curve.

Scam by ARTEK MEDIA =>

Specification-2225 Service

Figure 1-2. Instrument dimensional drawing.

Section 2-2225 Service

OPERATING INSTRUCTIONS

This section is divided into four subsections. The first subsection, Preparation for Use, provides instructions for the user to follow before turning the instrument on, especially for the first time. Subsection two; Controls, Connectors, and Indicators; provides details on the operation of the front-panel

controls. Subsection three, Operating Considerations, provides the user with some of the more general information on measurement techniques. The last subsection, Operators Checks and Adjustments, provides simple checks and adjustments to be made on a routine basis by the user.

PREPARATION FOR USE

SAFETY

LINE (MAINS) |

POWER-CORD |

FUSE |

RECEPTACLE |

This subsection tells how to prepare for and to proceed with the initial start-up of the TEKTRONIX 2225 Oscilloscope.

Refer to the Safety Summary at the front of this manual for power source, grounding, and other safety considerations pertaining to the use of the instrument. Before connecting the oscilloscope to a power source, read both this subsection and the Safety Summary.

This instrument may be damaged i f operated with the LlNE VOLTAGE SELECTOR switch (on the rear panel) set for the wrong applied ac source voltage or i f the wrong fuse is installed.

LlNE VOLTAGE SELECTION

The oscilloscope operates from either a 115-V or a 230-V nominal ac power line with any frequency from 48 Hz to 440 Hz. Before connecting the power cord to a power source, verify that the LlNE VOLTAGE SELECTOR switch, located on the rear panel, is set correctly and that the proper line fuse is installed. Refer to Figure 2-1 and the instrument rear panel.

REPLACING FUSE

SELECTOR (MAINS) |

ATTACH POWER- |

SWITCH |

CORD CLAMP |

6299-23

Figure 2-1. Voltage Selector switch, fuse, and power-cord receptacle.

To convert the 2225 for operation on another line voltage range, set the LlNE VOLTAGE SELECTOR switch to the required position and install the appropriate fuse (listed on the rear panel). The detachable power cord may need to be replaced to match the particular power source. Power-cord option numbers are given in Figure 2-1 ; fuse part numbers are listed in Options and Accessories (Section 7).

Scans by ARTEK MEDLQ=>

Operating Instructions-2225 Service

LlNE FUSE

The instrument fuse holder is located on the rear panel and contains the line (main) fuse. Use the following procedure to verify that the proper fuse is installed or to install a replacement fuse.

1.Unplug the power cord from the power-input source (if plugged in).

2.Press in the fuse-holder cap and release it with a slight counterclockwise rotation.

3.Pull the cap (with the attached fuse inside) out of the fuse holder.

NOTE

The two types of fuses listed on the rear panel are not directly interchangeable; they require different types of fuse caps.

4.Verify that the fuse is the same type listed on the back of the instrument.

5.Reinstall the fuse (or replacement fuse) in the fuse-holder cap.

6.Reinstall the fuse and cap in the fuse holder by pressing in and giving a slight clockwise rotation of the cap.

POWER CORD

A detachable three-wire power cord with a threecontact plug is provided with each instrument for connecting to both the power source and protective ground. The protective-ground connector in the plug connects (through the protective-ground conductor) to the accessible metal parts of the instrument. For electrical-shock protection, insert this plug only into a power-source outlet that has a properly grounded protective-ground contact.

After plugging the power cord into its receptacle, secure it to the rear panel using the plastic clamp, screw, and washer provided.

Instruments are shipped with the power cord ordered by the customer. Available power-cord information is presented in Figure 2-2. Contact your Tektronix representative or local Tektronix Field Office for additional power-cord information.

Plug |

|

Line |

Reference |

Option |

Configuration |

Usage |

Voltage |

Standards |

Number |

Z |

|

North |

|

|

|

|

|

|

%\ 1 |

|

1 |

|

1 |

ANSI C 7 3 1 1 |

1 |

;; 1 |

|

|

1 0 - 1 6 A |

|

||||||

|

r |

a n |

|

1 2 0 ~ |

|

5 . 1 5 . ~ |

|

Standard |

|

|

1 2 0 v / |

|

|

|

IEC 8 3 |

|

|

|

|

1 5 A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Un~versal |

|

|

|

|

|

|

|

|

|

2r |

|

240v |

|

CEEIEC8F'Lll,lV3.Vll |

|

|

|

|

|

|

|

|

8 s 1 3 6 3 |

|

|

|

|

240v' |

|

"''IEC 8 3 |

|

|

||

|

|

1 3 A |

|

|

|

|

|

|

North |

|

ANSl C 7 3 2 0 |

|

|

Amerncan |

2 4 0 V |

A 4 |

||

N E M A 6 - 1 5 P |

||||

240V/ |

||||

|

IEC 8 3 |

|

||

1 5 A |

|

|

||

|

|

|

||

Sw~tzerland |

|

SEV |

A 5 |

|

2 2 0 V / |

2 2 0 V |

6 A

Abbreviations:

ANSl - American National Standards Institute

AS - Standards Association of Australia

BS - British Standards Institution

CEE - International Commiss~onon Rules for the

Approval of Electrical Equ~pment

IEC - International Electrotechnical Comm~ssion

N E M A - National Electrical Manufacturer'sAssociation

(2931-21)6083-35

Figure 2-2. Power-cord and line-voltage data.

INSTRUMENT COOLING

To prevent instrument damage from overheated components, adequate internal airflow must be maintained at all times. Before turning on the power, verify that the air-intake holes on the sides and rear panel are free from any obstructions to airflow.

INITIAL START-UP

Up to now, you should have made the following preparations:

1.Read the safety information.

2.Verified that the LlNE VOLTAGE SELECTOR switch is set for the source voltage to be used.

3.Verified the fuse for correct type and rating.

4. Attached the power cord.

5.Ensured that there is adequate ventilation around the instrument.

Scans by ARTEK MEDCQ =>

6.Plugged the power cord into the appropriate power-source outlet.

Now turn on your oscilloscope by pressing in the POWER button. Observe that the POWER-ON indicator, located below the button, is lit.

REPACKAGING

If this instrument is shipped by commercial transportation, use the original packaging material. Unpack the instrument carefully from the shipping container to save the carton and packaging material for this purpose.

If the original packaging is unfit for use or is not available, repackage the instrument as follows:

1.Obtain a corrugated cardboard shipping carton having inside dimensions at least six inches greater than the instrument dimensions and having a carton test strength of at least 275 pounds.

Operating Instructions-2225 Service

2.If the instrument is being shipped to a Tektronix Service Center for repair or calibration, attach a tag to the instrument showing the following: owner of the instrument (with address), the name of a person at your firm who may be contacted if additional information is needed, complete instrument type and serial number, and a description of the service required.

3.Wrap the instrument with polyethylene sheeting or equivalent to protect the outside finish and prevent entry of packing materials into the instrument.

4. Cushion the instrument on all sides by tightly packing dunnage or urethane foam between the carton and the instrument, allowing for three inches of padding on each side (including top and bottom).

5.Seal the carton with shipping tape or with an industrial stapler.

6.Mark the address of the Tektronix Service Center and your return address on the carton in one or more prominent locations.

Scans by ARTEK MEDLA =r>

Operating Instructions-2225 Service

CONTROLS, CONNECTORS, AND INDICATORS

The following descriptions are intended to familiarize the operator with the location and function of the instrument'scontrols, connectors, and indicators.

Refer to Figure 9-14 in the foldout pages for the location of all controls mentioned.

POWER AND DISPLAY

@ INTENSITY Control-Adjusts the brightness of all displayed waveforms.

@ BEAM FIND Button-Compresses the vertical and horizontal deflection to within the graticule area and intensifies the display to aid the user in locating traces that are overscanned or deflected outside of the crt viewing area.

@FOCUS Control-Adjusts for optimum display definition. Once set, proper focusing is maintained over a wide range of display intensity.

@TRACE ROTATION Control-Permits alignment of the trace with the horizontal graticule line. This control is a screwdriver adjustment that, once set, should require little attention during normal operation.

@ POWER Switch-Turns instrument power on or off.

@Power On Indicator-Lights up while instrument is operating.

VERTICAL

@Channel 1 Vertical POSITION Control-Con- trols the vertical display position of the Channel 1 signal. In X-Y mode the control is inactive.

@TRACE SEP Control-Permits the magnified traces that appear in Horizontal MAG Mode to be positioned up to three divisions above the associated Channel 1 or Channel 2 traces.

Trace separation between the magnified and unmagnified traces is independent of the Channel POSITION control settings. In other Horizontal modes, the TRACE SEP control is inoperative.

@Channel 2 Vertical POSITION Control-Con- trols the vertical display position of the Channel 2 signal. In X-Y mode the control vertically positions the display.

@ Vertical MODE Switch CH 1-BOTH- CH 2-Selects either a single channel for display or the dual-channel display mode.

CH 1-Selects only the Channel 1 input signal for display.

BOTH-Selects a combination of Channel 1 and Channel 2 input signals for display. The CH 1-BOTH-CH 2 switch must be in the BOTH position for ADD, ALT, and CHOP operation.

CH 2-Selects only the Channel 2 input signal for display.

@CH 2 INVERT Switch-Inverts the Channel 2 display when in the CH 2 INVERT position. With CH 2 inverted, the oscilloscope may be operated as a differential amplifier when the BOTH-ADD vertical mode is selected.

@Vertical MODE Switch ADD-ALT-CHOP-Sets the dual-channel vertical display mode.

ADD-Displays the sum of Channel 1 and Channel 2 input signals when BOTH is also selected. The difference of the Channel 1 and Channel 2 input signals is displayed when the Channel 2 signal is inverted.

ALT-Alternately displays the Channel 1 and Channel 2 input signals. The alternation occurs during retrace at the end of each sweep. ALT vertical mode is most useful for viewing both channel input signals at sweep rates of 0.5 ms per division and faster.

I

I

I

Scansby ARTEK MEDLQ=>

CHOP-Switches the display between the Channel 1 and Channel 2 vertical input signals during the sweep. The chopped switching rate (CHOP frequency) is approximately 500 kHz.

@ CH 1 and CH 2 VOLTSIDIV Switches-Select the vertical channel deflection factors from 5 mV to 5 V per division in a 1-2-5 sequence.

1X-Front-panel marking that indicates the deflection factor set by the VOLTSIDIV switch when a 1X probe or a coaxial cable is attached to the channel input connector.

1OX PROBE-Front-panel marking that indicates the deflection factor set by the VOLTSIDIV switch when a 10X probe is attached to the channel input connector.

@Variable VOLTSlDlV and X I 0 Vertical Magnification Controls-Provide continuously variable deflection factors between calibrated positions of the VOLTSIDIV controls and X1 or X I 0 vertical magnification of the displayed signal. The VOLTSIDIV sensitivity may be reduced by up to at least 2.5 times at the fully counterclockwise rotation of the variable (CAL) knob. A detent position at full clockwise rotation indicates the calibrated VOLTSIDIV position of the variable knob.

X I 0 vertical magnification of a displayed signal is obtained by pulling the variable (CAL) knob to the out position. A yellow ring is visible on the knob in the X I 0 Vertical Magnification position.

@AC-GND-DC (Input Coupling) SwitehesSelect the method of coupling the input signal from the CH 1 OR X and CH 2 OR Y connectors to the vertical amplifiers.

AC-Capacitively couples the input signal to the vertical deflection system. The dc component of the input signal is blocked. The lower -3 dB bandpass is 10 Hz or less.

GND-Grounds the input of the vertical deflection channel; provides a zero (ground)

Operating Instructions-2225 Service

reference voltage display (does not ground the input signal).

DC-All frequency components of the input signal are coupled to the vertical deflection and signal acquisition systems.

@CH 1 OR X and CH 2 on Y Input ConnectorsProvide for application of signals to the inputs of the deflection systems.

In X-Y mode, the signal connected to the CH 1 OR X input controls the horizontal deflection, and the signal connected to the CH 2 OR Y input controls the vertical deflection.

HORIZONTAL

@COARSE Horizontal POSITION Control-Po- sitions all the waveforms horizontally over a

one-sweep-length range (for X I , X5, X10, or X50 Magnified) .

@ FINE Horizontal POSITION Control-Allows for fine adjustment of the horizontal ~ositionof displayed waveforms.

@Horizontal MODE Switch-Selects the horizontal mode of operation.

X1-This is the normal mode of operation with the waveform being unmagnified horizontally.

ALT-Displays the unmagnified waveform and the horizontally magnified waveform alternately.

MAG-Displays only the horizontally magnified waveform.

The amount of horizontal magnification is set by the Horizontal MAG switch (X5, X10, X50).

@SEClDlV Switch-Selects calibrated sweep rates from 0.5 s to 0.05 bs per division in a 1-2-5 sequence of 22. steps. The X-Y position selects the X-Y mode; the CH 1 OR X input signal produces horizontal deflection for X-Y displays, and the CH 2 OR Y input signal produces vertical deflection.

Scam by ARTEK MEDL4 =>

Operating Instructions-2225 Service

@Variable SEClDlV Control-Continuously varies the uncalibrated sweep time per division to at least 2.5 times the calibrated time per division set by the SECIDIV switch. Full ccw rotation of the variable (CAL) knob increases the slowest sweep time per division to at least two seconds.

@Horizontal MAG Switch-Sets the amount of horizontal magnification to X5, X10, or X50 when the Horizontal MODE switch is set to either ALT or MAG.

@GND Connector (h)-provides an auxiliary ground connection directly to the instrument chassis via a banana-tip jack.

PROBE ADJUST Terminal-Provides an approximately 0.5-V, negative-going , square-wave signal (at about 1 kHz) for use in compensating voltage probes and checking the vertical deflection system. The PROBE ADJUST output signal is not intended as a reference for checking either the vertical or the horizontal accuracy of the instrument.

TRIGGER

@Trigger SLOPE Switch-Selects either the positive (I)or negative (I) slope of the trigger signal to start the sweep.

@Trigger LEVEL Control-Selects the amplitude point on the trigger signal that produces triggering.

@TRIG'DIREADY Indicator-A dual-function LED indicator. In P-P AUTO and NORM trigger modes, the indicator is turned on when triggering occurs. In SGL SWP trigger mode, the indicator turns on when the trigger circuit is armed, awaiting a triggering event; it turns off again as soon as the single sweep is triggered.

@Trigger MODE Switch-Determines the sweep triggering mode.

P-P AUTO-TV LINE-Triggering occurs on trigger signals having adequate amplitude and a repetition rate of about 20 Hz or faster. In the absence of a proper trigger

signal, an autotrigger is generated, and the sweep freeruns.

NORM-Permits triggering at all sweep rates (an autotrigger is not generated in the absence of an adequate trigger signal). NORM trigger mode is especially useful for low-frequency and low-repetition-rate signals.

TV FIELD-Permits stable triggering on a television field signal (vertical sync). In the absence of an adequate trigger signal, the sweep freeruns. The instrument otherwise behaves as in P-P AUTO.

SGL SWP-Selects single sweepoperation.

@SGL SWP RESET Button-Arms the trigger circuit for a single sweep. Triggering requirements are the same as in NORM trigger mode. After the completion of a triggered sweep, pressing in the SGL SWP RESET button rearms the trigger circuitry to accept the next triggering event.

@HOLDOFF Control-Adjusts the variable holdoff time. Variable holdoff starts at the end of the sweep.

@Trigger SOURCE Switches-Determine the source of the internal and external trigger signal for the trigger generator circuits.

CH 1-Trigger signal is obtained from the CH 1 OR X input connector.

VERT MODE-Trigger signals are automatically obtained alternately from the CH 1 OR X and CH 2 OR Y input signals in ALT vertical mode. In CHOP vertical mode, the trigger signal source is the sum of the Channel 1 and Channel 2 input signals.

CH 2-Trigger signal is obtained from the CH 2 OR Y input. The CH 2 INVERT switch also inverts the polarity of the internal Channel 2 trigger signal when the Channel 2 display is inverted.

EXT-Selects external trigger source. The actual form these triggers take is selected by the second SOURCE switch.

Scans by ARTEK MEDU =>

LINE-Routes a sample of the ac-power- line signal to the trigger circuit.

EXTI10-Divides the external signal applied to the EXT INPUT OR Z connector by a factor of ten before applying it to the trigger circuit.

EXT-Routes an external signal applied to the EXT INPUT OR Z connector to the trigger circuit.

EXT=Z-Routes the signal applied to the EXT INPUT OR Z connector to the z-axis amplifier rather than the trigger circuit.

@ COUPLING Switch-Determines the method of coupling the signal applied to the trigger circuit.

AC-Capacitively couples the input signal; the dc component of the signal is blocked.

HF REJ-Rejects (attenuates) the highfrequency components (above 30 kHz).

LF REJ-Rejects (attenuates) the lowfrequency components (below 30 kHz).

DC-Directly couples all frequency components of the external signal to the trigger circuit.

@EXT INPUT O R Z Connector-Provides for connection of external signals either to the trigger circuit for external triggering or to the z-axis amplifier for intensity modulation of the crt display.

Operating Instructions-2225 Service

REAR PANEL

@Fuse Holder-Contains the ac-power-source fuse. See the rear-panel nomenclature for fuse rating and line-voltage range.

@Detachable Power Cord Receptacle-Pro- vides the connection point for the ac-power source to the instrument.

@Line Voltage Selector (Mains Switch)-Se- lects the line voltage operating range of either 115 Vac or 230 Vac.

Figure 2-3. Rear Panel.

Scans by ARTEK MEDLQ =>

Operating Instructions-2225 Service

OPERATING CONSIDERATIONS

This part contains basic operating information and techniques that should be considered before attempting to make any measurements with the instrument.

GRATICULE

The graticule is internally marked on the faceplate of the crt to eliminate parallax-viewing errors and to enable measurements (see Figure 2-4). The graticule is marked with eight vertical and ten horizontal major divisions. In addition, each major division is divided into five subdivisions. The vertical deflection factors and horizontal timing are calibrated to the graticule so that accurate measurements can be made directly from the crt. Also, percentage marks for the measurement of rise and fall times are located on the left side of the graticule.

1ST OR LEFT |

1 l T H OR RIGHT |

VERTICAL |

VERTICAL |

GRATICULE |

GRATICULE |

FALL TIME |

CENTER |

HORIZONTAL |

|

MEASUREMENT |

GRATICULE |

||

VERTICAL |

|||

PERCENTAGE |

LlNE |

||

GRATICULE |

|||

MARKERS |

|

||

LlNE |

|

||

|

|

||

|

|

4207-09 |

Figure 2-4. Graticule measurement markings.

GROUNDING

The most reliable signal measurements are made when the 2225 and the unit under test are connected by a common reference (ground lead) in addition to the signal lead or probe. The probe'sground lead provides the best grounding method for signal interconnection and ensures the maximum amount of signal-lead shielding in the probe cable. A separate ground lead can also be connected from the unit under test to the ground connector (h)located on the oscilloscope's frontpanel.

SIGNAL CONNEC'I'IONS

Probes

Generally, the accessory probes supplied with the instrument provide the most convenient means of connecting a signal to the vertical inputs of the !instrument. The probe and probe lead are shielded to prevent pickup of electromagnetic interference. The 1OX attenuation factor of the probe offers a high input impedance that minimizes signal loading in the circuitry under test.

Both the probe itself and the probe accessories should be handled carefully at all times to prevent damage to them. Avoid dropping the probe body. Striking a hard surface can cause damage to both the probe body and the probe tip. Exercise care to prevent the cable from being crushed or kinked. Do not place excessive strain on the cable by pulling.

The standard-accessory probe is a compensated 10X voltage divider. It is a resistive voltage divider for low frequencies and a capacitive voltage divider for high-frequency signal components. Inductance introduced by either a long signal or ground lead forms a series-resonant circuit. This circuit will affect system bandwidth and will ring if driven by a signal containing significant frequency components at or near the circuit's resonant frequency. Oscillations (ringing) can then appear on the oscilloscope waveform display and distort the true signal waveshape. Always keep both the ground lead and the probe signal-input connections as short as possible to maintain the best waveform fidelity.

I

Scans by ARTEK MEDIA =>

Operating Instructions-2225 Service

Misadjustment of probe compensation is a common source of measurement error. Due to variations in oscilloscope input characteristics, probe compensation should be checked and adjusted, if necessary, whenever the probe is moved from one oscilloscope to another or between channels. See the Probe Compensation procedure in Operator's Checks and Adjustments, or consult the instructions supplied with the probe.

Coaxial Cables

Coaxial cables may also be used to connect signals to the vertical input connectors, but they may have considerable effect on the accuracy of a displayed waveform. To maintain the original frequency characteristics of an applied signal, only highquality, low-loss coaxial cables should be used. Coaxial cables should be terminated at both ends in their characteristic impedance. If this is not possible, use suitable impedance-matching devices.

INPUT-COUPLING CAPACITOR

PRECHARGING

When the Input Coupling switch is set to the GND position, the input signal is connected to ground through the input-coupling capacitor and a high value resistance. This series combination forms a precharging circuit that allows the input-coupling capacitor to charge to the average dc voltage level of the signal applied to the input connector. Thus, any large voltage transients that may accidentally be generated are not applied to the vertical amplifier

when the input coupling is switched from GND to AC. The precharging network also provides a measure of protection to the external circuitry by reducing the current level that is drawn from the external circuitry while the input-coupling capacitor is charging.

If AC input coupling is in use, the following procedure should be followed whenever the probe tip is connected to a signal source having a different dc level than that previously applied. This procedure becomes especially useful if the dc-level difference is more than ten times the VOLTS/DIV switch setting.

1.Set the AC-GND-DC (input coupling) switch to GND before connecting the probe tip to a signal source.

2.Touch the probe tip to the oscilloscope ground

(A)connector.

3.Wait several seconds for the input-coupling capacitor to discharge.

4. Connect the probe tip to the signal source.

5.Wait several seconds for the input-coupling capacitor to charge to the dc level of the signal source.

6.Set the AC-GND-DC switch to AC. A signal with a large dc component can now be vertically positioned within the graticule area, and the ac component of the signal can be measured in the normal manner.

Scans by ARTEK MEDL4 -

Operating Instructions-2225 Service

OPERATOR'SCHECKS AND ADJUSTMENTS

To verify the operation and basic accuracy of your instrument before making measurements, perform the following checks and adjustment procedures. If adjustments are required beyond the scope of these operator's checksand adjustments, refer the instrument to qualified service personnel.

For new equipment checks, before proceeding with these instructions, refer to Preparation for Use in this manual to prepare the instrument for the initial start-up before applying power.

INITIAL SETUP

1.Verify that the POWER switch is OFF (switch is in the out position), and the Line Voltage Selector switch is set for the correct source voltage. Then plug the power cord into the ac power outlet.

2.Press in the POWER switch (ON) and set the instrument controls to obtain a baseline trace:

Display

INTENSITY |

Midrange |

FOCUS |

Best defined display |

Vertical (Both Channels) |

|

VERTICAL MODE |

CH 1 |

POSITION (both) |

Midrange |

VOLTSIDIV (both) |

10 mV |

AC-GND-DC (both) |

DC |

VOLTSIDIV Variable |

CAL (in detent) |

(both) |

|

Magification (both) |

X I (CAL knobs |

|

in) |

Horizontal |

|

SECIDIV |

0.5 ms |

SECIDIV Variable |

CAL (in detent) |

POSITION |

Midrange |

MODE |

X I |

Trigger |

|

HOLDOFF |

MIN (fully counter- |

|

clockwise) |

SOURCE |

VERT MODE |

MODE |

P-P AUTO |

SLOPE |

Positive (1) |

COUPI-ING |

AC |

LEVEL |

For a stable display (with |

|

signal applied) |

3.Adjust the INTENSITY and FOCUS controls for the desired display brightness and best focused trace.

4. Adjust the Vertical and Horizontal POSITION controls to position the trace within the graticule area.

5.Allow the instrument to warm up for 20 minutes before commencing the adjustment procedures. Reduce the INTENSITY level during the waiting time.

'TRACEROTATION ADJUSTMENT

NOTE

Normally, the trace will be parallel to the center horizontal graticule line, and TRACE ROTATION adjustment is not required.

1.Preset the instrument controls and obtain a baseline trace as described in Initial Setup.

2.Use the CH 1 POSITION control to move the baseline trace to the center horizontal graticule line.

3.If the baseline trace is not parallel to the center horizontal graticule line, use a small-bladed screwdriver or alignment tool to adjust the TRACE ROTATION control and align the trace with the graticule line.

PROBE COWIPENSATION

Misadjustment of probe compensation is a source of measurement error. The attenuator probes are equipped with a compensation adjustment. To ensure optimum measurement accuracy, always check probe compensation before making

Scans by ARTEK MEDL4 ==.

measurements. Probe compensation is accomplished by the following steps:

1.Preset the instrument controls and obtain a baseline trace as described in the Initial Setup.

2.Connect the two 10X probes (supplied with the instrument) to the CH 1 OR X and CH 2 OR Y input connectors.

3.Connect the Channel 1 probe tip to the PROBE ADJUST terminal.

4. Use the CH 1 POSITION control to vertically center the display. If necessary, adjust the Trigger LEVEL control to obtain a stable display on the positive (1)SLOPE.

NOTE

Refer to the instruction manual supplied with the probe for more complete information on the probe and probe compensation.

5.Check the waveform display for overshoot and rounding (see Figure 2-5); if necessary adjust the probe'scompensation. Rotate the sleeve on the probe head to expose the adjustments (see Figure 2-6). Use a low-reactance alignment tool to adjust the LF comp capacitor for a square front corner on the waveform.

CORRECT

(FLAT)

1

OVER

COMPENSATED (OVERSHOOT)

UNDER

COMPENSATED (ROLLOFF)

4207-1 1A

Figure 2-5. Probe compensation.

Operating Instructions-2225 Service

LF COMP ROTATING

SLEEVE

\ J

0 )

R1 R2

6299-25

Figure 2-6. Probe compensation locations.

6.Disconnect the Channel 1 probe tip from the PROBE ADJUST terminal.

7.Connect the Channel 2 probe tip to the PROBE ADJUST terminal.

8.Set the Vertical MODE to CH 2.

9.Use the CH 2 POSITION control to vertically center the display.

10. Repeat step 5 for the Channel 2 probe.

Scans by ARTEK MEDL4 *

Loading...

Loading...