tekmar 369 Installation

- Data Brochure

- 01/09

01/09

D 369

Zone Control 369

01/09

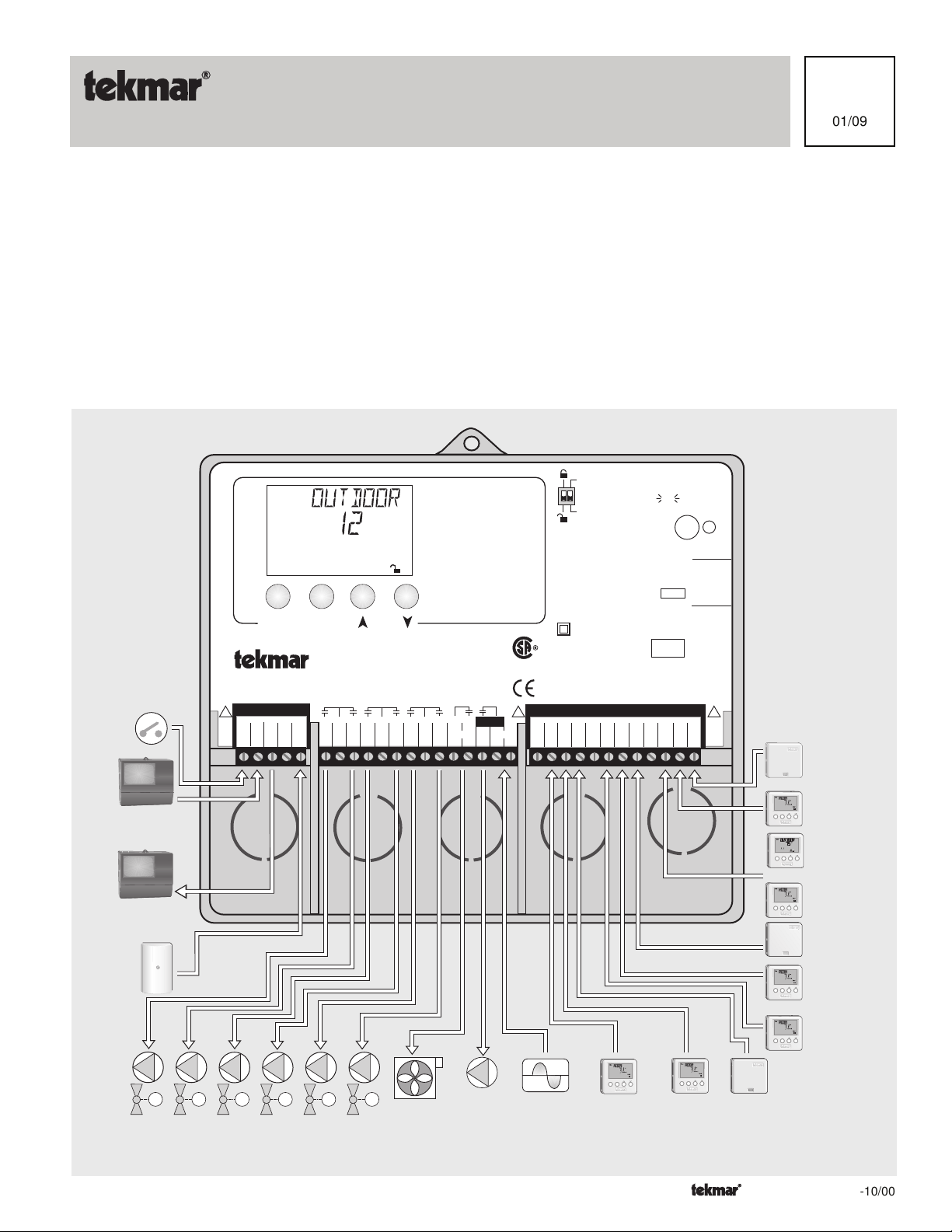

The Zone Control 369 is designed to control the temperature in up to six heating zones using Room Temperature Units (RTUs) or

indoor sensors. The 369 allows one stage heating zones, two stage heating zones, or a combination of one stage and two stage

heating zones. PID zoning logic allows for staggering and synchronization of multiple zones in order to minimize boiler short cycling.

The 369 is capable of operating a single cooling output and can provide automatic or manual heat / cool change over. When the 369

is used with a tekmar Reset or House Control, the 369 provides indoor temperature feedback that automatically adjusts the supply

water temperature in order to satisfy the zone with the highest heat load. A large Liquid Crystal Display (LCD) is incorporated in order

to view system status and operating information. The LCD and user key pad are used to set the control’s adjustments and to monitor

zone running times, outdoor high and low temperatures, minimum zone temperatures, and many other useful items.

Additional features include:

• Control Schedule • Slab Minimum and Slab Maximum Temperature Control

• Individual Zone Schedules • Remote Display and Adjustment Capabilities

• Optimum Start / Stop • Test Sequence to Ensure Proper Component Operation

• Cooling Control or Cooling Enable • 115 V (ac) Power Supply

• Manual Override • CE and CSA C US Certified (approved to applicable UL standards)

View

Setback

°

F

None

off

red

red

not testing

testing

testing paused

Test

Lithium Battery CR1620

POS (+) up

Press here

on battery to

remove it.

WARNING: Battery may explode

or cause burns if disassembled,

Input

Timer

tekmar Zone

Output

tekmar Reset

Control

Input

Outdoor

Sensor

Included

LR 58233

E150539

Input

Control

LR 58233

E150539

Menu

Zone Control 369

Six Zones

Do not apply power

12345

UnO

Zo

Sw

In

Item

Com

6

Zn

Out

1

Zo

Out

Com

INSTALLATION CATEGORY II

Made in Canada by

tekmar Control Systems Ltd.

C US

Power: 115 V 50/60 Hz 600 VA

Relays: 230 V (ac) 5 A

Signal wiring must be rated at least 300V.

7

8

9

10

11

12

13

Zn

Zn

Com

1-2

2

3

3-4

14

Zn

Zn

Com

Zn

4

5

5-6

6

15

Cooling

16 17

Sys

Pmp

18

Power

19

Com

NL

Do not apply power

20 21 22 23 24

tN1

tN1

Indr

1

2

2

Com

25

tN1

26

tN1

3

4

recharged or exposed to fire or

high temperatures.

27

28

30

Indr

Com29tN1/2

tN1

4

5

6

!!!

31

Indr

H1202B

6

70

ItemMenu

ItemMenu

or

ItemMenu

ItemMenu

ItemMenu

Input

Indoor

Sensor

Input

Room

Temperatue

Unit (RTU)

Input

WWSD

Remote

Display

Module

Input

Room

Temperatue

Unit (RTU)

Input

Indoor

Sensor

Input

Room

Temperatue

Unit (RTU)

Input

Room

Temperatue

Unit (RTU)

OR OR

M M

Zone Valves or Zone Pumps

OR

M

Output

ORMOR

M

OR

M

Output

Cooling

Output

System

Pump

Input

115 V (ac)

Power

Supply

ItemMenu

Input

Room

Temperatue

Unit (RTU)

1 of 32

ItemMenu

Input

Room

Temperatue

Unit (RTU)

70

Input

Indoor

Sensor

Copyright © D 369 -10/00

How To Use The Data Brochure

- 01/09

This brochure is organized into four main sections. They are: 1)

4)

Troubleshooting

Operation

The

displayed by the control. The control functions of each adjustable item are described in the

, as each one contains important information on the overall operation of the control.

Control Settings

. The Sequence of Operation has four subsections. We recommend reading each subsection of the

section (starting at the DIP Switch Settings) of this brochure describes the various items that are adjusted and

Sequence of Operation

, 2)

Installation

Sequence of Operation

, 3)

Control Settings

.

Table of Contents

User Interface ..................................................... Pg 2 Control Settings ............................................................ Pg 18

Description of Display Elements ...................... Pg 4 View Menu .................................................................. Pg 18

Sequence of Operation...................................... Pg 5 Adjust Menu ............................................................... Pg 18

Section A: Heating ......................................... Pg 5 Monitor Menu ............................................................. Pg 20

Section B: Cooling ......................................... Pg 7 Time Menu .................................................................. Pg 21

Section C: Setback (UnOccupied) ................ Pg 9 Schedule Menu .......................................................... Pg 22

Section D: tN 1 / 2 Devices ............................ Pg 11 Miscellaneous Menu.................................................. Pg 23

Installation .......................................................... Pg 12 RTU Menu ................................................................... Pg 23

Electrical Connections .................................. Pg 13 Testing and Troubleshooting ....................................... Pg 27

Testing the Wiring .......................................... Pg 15 Error Messages.......................................................... Pg 29

DIP Switch Settings ........................................... Pg 17 Technical Data ............................................................... Pg 32

, and

Sequence of

Access Levels .................................................... Pg 17 Limited Warranty ........................................................... Pg 32

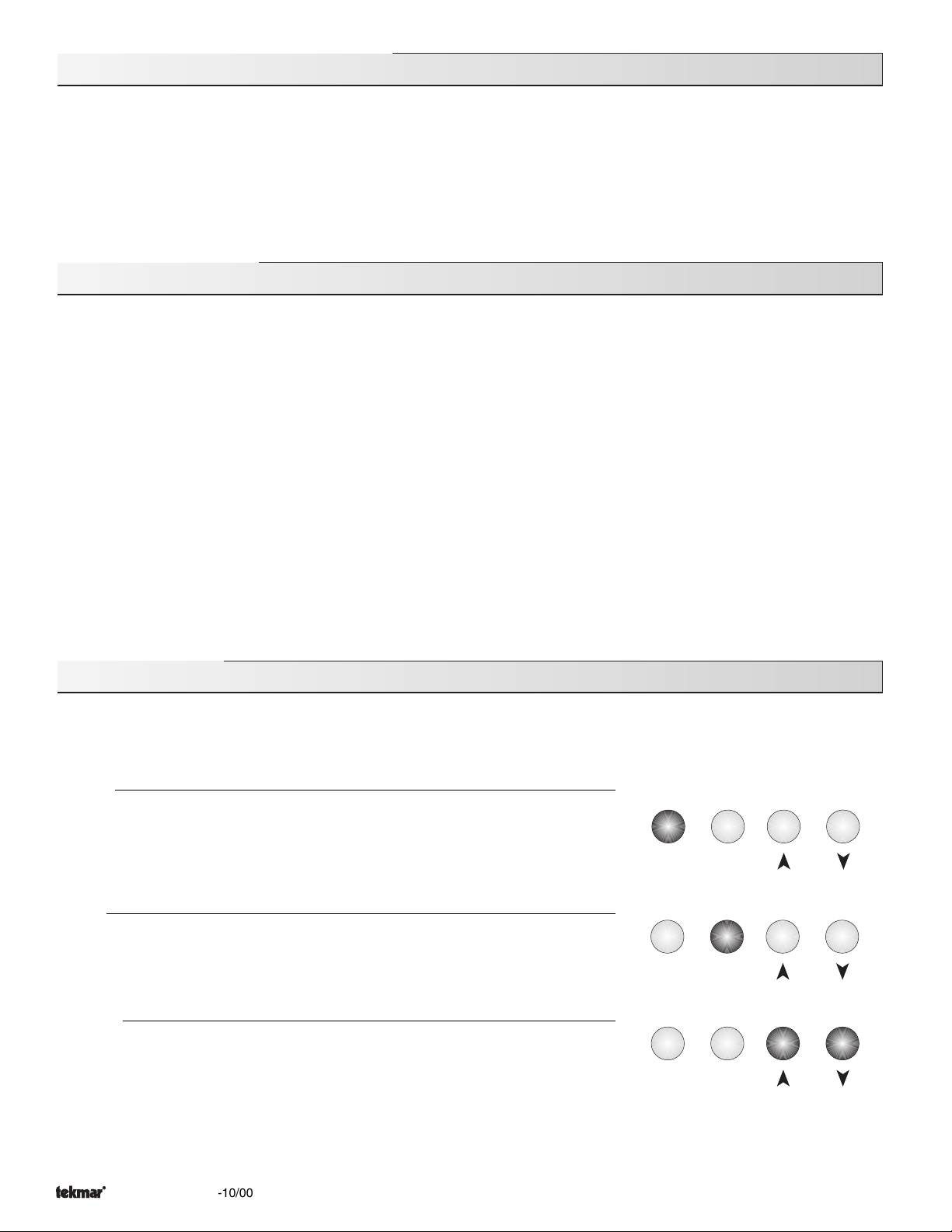

User Interface

The 369 uses a Liquid Crystal Display (LCD) as the method of supplying information. You can use the LCD in order to setup and

monitor the operation of your system. The 369 has four push buttons (Menu, Item, ▼, ▲) for selecting and adjusting settings. As you

program your control, record your settings in the Adjust Menu table which is found in the second half of this brochure.

Menu

All of the items displayed by the control are organized into various menus. These

menus are listed on the left hand side of the display (Menu Field). To select a menu,

use the

advance to the next available menu. Once a menu is selected, there will be a group of

items that can be viewed within that menu.

Item

The abbreviated name of the selected item will be displayed in the item field of the

display. To view the next available item, press and release the

have reached the last available item in a menu, pressing and releasing the

will return the display to the first item in the selected menu.

Adjust

To make an adjustment to a setting in the control, begin by selecting the appropriate

menu using the

Finally, use the ▼ and / or ▲ button to make the adjustment.

Menu

button. By pressing and releasing the

Menu

button, the display will

Menu

Item

Item

button. Once you

Item

button

Menu

Item

Menu

button. Then select the desired item using the

Item

button.

Menu

Item

Additional information can be gained by observing the Status field of the LCD. The status field will indicate which of the control’s

outputs are currently active. Most symbols in the status field are only visible when the View Menu is selected.

Copyright © D 369 -10/00 2 of 32

- 01/09

- 01/09

MENU FIELD

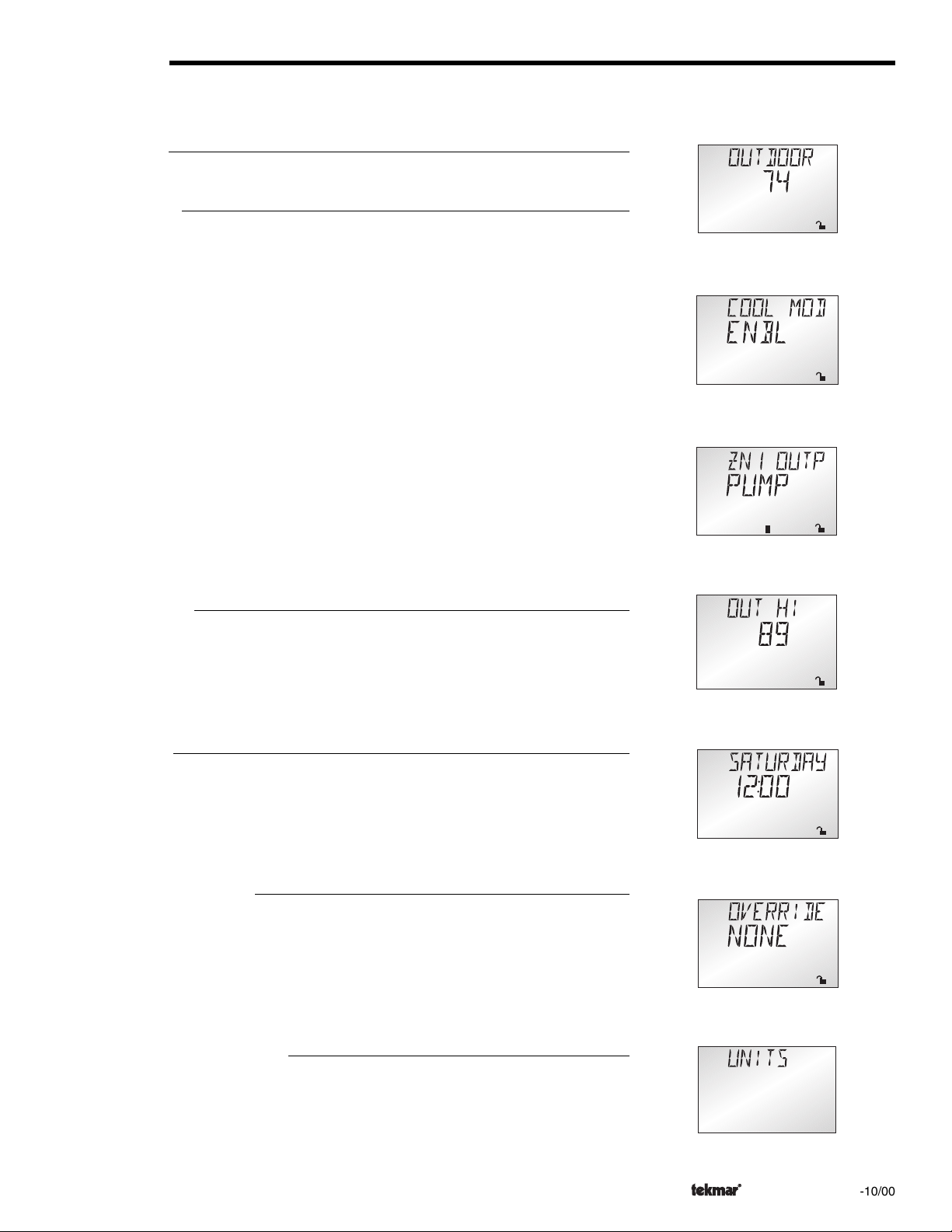

The 369 has a number of menus used to monitor system status and adjust settings in the control. The current menu will be displayed

in the left hand side of the display.

View Menu

The View menu is used to view the outdoor temperature and zone temperatures.

Adjust Menu

View

°

F

There are seven separate menus used to make adjustments to the control settings and

the zone settings. There is an Adjust menu for the control, and an Adjust menu for

each zone.

Control Adjust Menu

Adjust

The Control Adjust menu is used to make adjustments to the control settings. The

control settings affect every zone. To access the control settings, select the Adjust

menu by using the

Menu

button.

Adjust

will be displayed in the left hand side of

the display.

Zone Adjust Menu

The Zone Adjust menu is used to make adjustments to the zone settings. There is a

Zone Adjust menu for each zone that an RTU or indoor sensor is connected to. To

access the zone settings for a particular zone, select the Zone Adjust menu for that

zone by using the

display, and

Menu

button.

Zone

followed by the zone number will be displayed in the bottom of

Adjust

will be displayed in the left hand side of the

the display.

Note:

The Zone Adjust menu in the control is different than the Adjust menu in a

display RTU.

Adjust

Zone

1

Monitor Menu

The Monitor menu is used to monitor the system over a period of time. It is possible to

track system pump and zone running hours, and high and low zone temperatures.

Time Menu

The Time menu is used for setback purposes, and displays the time of day and the day

of the week. In order to access the Time menu, the

in the

Setback

Schedule (Schd) Menu

position. Refer to the Settings section on how to set the clock.

Setback / None

DIP switch must be

The Schd menu is used to set the control schedules. In order to access the control

schedules in the Schd menu, the

Setback / None

DIP switch must be in the

Setback

position. Schedule overrides are also available in the Schd menu. Refer to the Settings

section on how to set a schedule.

Miscellaneous (Misc) Menu

The Misc menu is used to select units, access levels, and backlite operation.

Monitor

Time

Schd

Misc

°

F

AM

°

F

3 of 32

Copyright © D 369 -10/00

- 01/09

- 01/09

Display

Item Field

Displays an abbreviated name

of the selected item

Menu Field

Displays the

current menu

Status Field

Displays the current

status of the control’s

inputs, outputs and

operation

View

Adjust

Monitor

Time

Schd

Misc

Menu

Item

Zone

Un

5 61 234

°

°

F

PM

Occ

C

min hrAM

sec

1

2

Ovr

Cool

Number Field

Displays the current value of

the selected item

Buttons

Selects Menu, Items

{

and adjusts settings

Symbol Description

Override

Displays when the control is in override

mode.

Cooling

Displays when the

Warning

Displays when an error exists or when a

limit has been reached.

Lock/UnLock

Displays whether control is locked or

unlocked.

Temperature

Displays the unit of measure that all of the

temperatures are to be displayed.

Time

Displays the unit of measure that all of the

times are to be displayed.

Cooling

relay is on.

Zone

UnOcc

Occ

Pump

Displays when the system pump is in

operation.

Zone

5 61 234

Displays when a zone is in operation.

Optimum Stop

Displays when a zone is in optimum stop.

Optimum Start

Displays when a zone is in optimum start.

Unoccupied Schedule

Displays when the control is in unoccupied

(Night) mode.

Occupied Schedule

Displays when the control is in occupied

(Day) mode.

Ovr

Cool

°

F, °C

AM,PM,sec,

min,hr

Definitions

The following defined terms and symbols are used throughout this manual to bring attention to the presence of hazards of various risk

levels, or to important information concerning the life of the product.

- Warning Symbol: Indicates presence of hazards which can cause severe personal injury, death or substantial

property damage if ignored.

- Double insulated

INSTALLATION

CATAGORY II

Copyright © D 369 -10/00 4 of 32

- Local level, appliances.

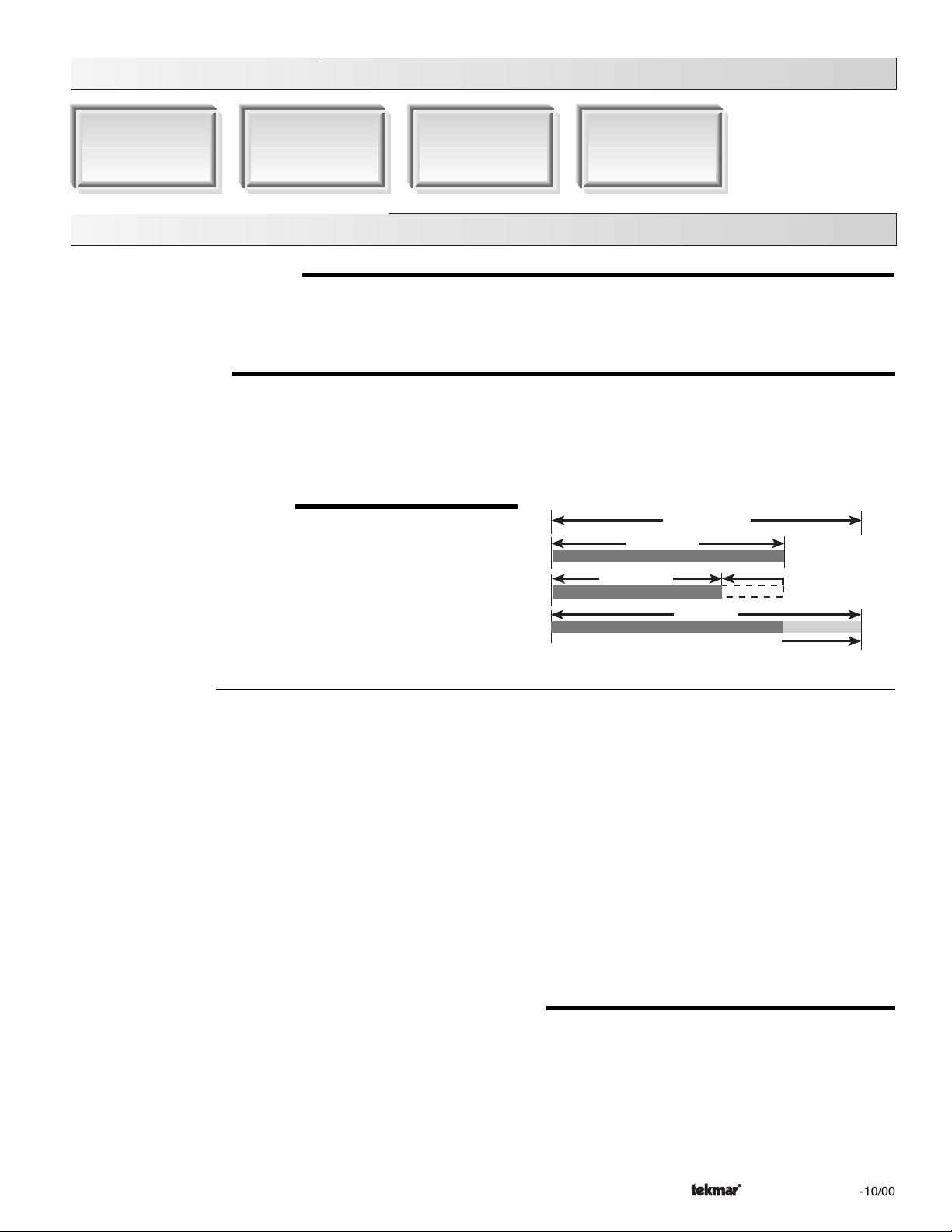

Relay On Time

less heat

Relay On Time

more heat

Cycle Length

Relay On Time

- 01/09

- 01/09

Sequence of Operation

Section A

Heating Operation

Section B

Cooling Operation

Section C

Setback

Section D

tN 1/2 Devices

(UnOccupied)

Page 5 - 7

Page 7 - 8

Page 9 - 10

Page 11

Section A1: General Heating

POWERING UP THE CONTROL

When the Zone Control 369 is powered up, the control displays the control type number in the LCD for 2 seconds. Next, the software

version is displayed for 2 seconds. Finally, the control enters into the normal operating mode and the LCD defaults to displaying the

current outdoor temperature.

ZONING OPERATION

The 369 can directly control the temperature in up to six one stage heating zones, three two stage heating zones, or a combination

of one stage and two stage heating zones. In order to measure the indoor temperature, each zone requires either an indoor sensor

or an RTU. With display RTUs, the desired zone temperature is set using the HEATING adjustment in the Adjust menu of the RTU.

With non-display RTUs, the desired zone temperature is set using the RTU dial. If an indoor sensor is used, the desired zone

temperature is set using the HEATING adjustment in the Zone Adjust menu of the control.

HEATING CYCLE (HEAT CYC)

The 369 operation is based on a cycle length which is adjustable

through the HEAT CYC setting in the Control Adjust menu of the control.

During every cycle, the control turns on each zone relay for a specific

on time. The required on time is calculated based on the PID response

of the zone during the previous cycle period. If the zone requires more

heat, the on time is increased, and if the zone requires less heat, the on

time is reduced. In order to prevent short cycling, the 369 ensures that

the zone relays remain on or off for a minimum amount of time.

PID Zoning Logic

Proportional (P)

Proportional control logic compares the actual zone temperature to the desired zone temperature. Zone relay on time is based on

the difference between the actual temperature and the desired temperature. As the zone temperature drops, the relay on time

increases, and as the zone temperature rises, the relay on time decreases.

Integral (I)

Integral control logic compares the actual zone temperature to the desired zone temperature over a period of time. The longer the

actual temperature is below the desired temperature, the longer the on time for the zone relay will be.

Derivative (D)

Determines how fast or how slow the actual temperature is changing.

P + I + D = PID

If proportional, integral and derivative (PID) control logic is used, the control is more able to prevent excessive temperature

swings and provide a stable room temperature under all conditions. It not only takes into account how much the room temperature

has dropped, but also how long there has been a droop and how fast the temperature is changing.

ZONE CONTROL LOAD STAGGERING AND SYNCHRONIZATION

The 369 staggers the operation of the zones in order to achieve a steady load on the boiler while preventing boiler short cycling.

Multiple Zone Controls can be daisy chained together to increase the number of zones. Each of the Zone Controls synchronizes

its zone operating cycles based on the

improved boiler operation. In order for Zone Control synchronization to work properly, the cycle length on each Zone Control must

be equal.

Note:

If a Zone Control 367/ 368 or House Control 370 / 371 is used with a Zone Control 369, the HEAT CYC adjustment in the 369

should be set to 15 minutes.

Zo In

input from the other Zone Controls. This results in a more stable system flow rate and

5 of 32

Copyright © D 369 -10/00

- 01/09

- 01/09

ZONE CONTROL OPERATION WITH A TEKMAR OUTDOOR RESET CONTROL

The 369 can provide indoor temperature feedback to a tekmar Reset Control. When multiple Zone Controls are used, each zone

control uses its

Zo Out

output to sequentially pass the information to the tekmar Reset Control. The ZO OUT item displayed in the

view menu represents the target from the zone with the highest heat requirement. The tekmar Reset Control uses this target to

determine the water temperature required to satisfy the zone with the highest heat requirement.

ZONE OUTPUT (ZN OUTP)

The ZN OUTP adjustment in the Zone Adjust menu of the control selects the zoning

device used for each zone, and affects the operation of the system pump.

Adjust

When PUMP is selected, the control assumes the device used to control the heat

delivery is a pump. When the zone turns on, the control does not operate the system

pump.

Zone

1

When VLV is selected, the control assumes the device used to control the heat delivery

is a fast acting spring return valve. When the zone turns on, the control turns on the

system pump.

When THRM is selected, the control assumes the device used to control the heat delivery is a slow acting zone valve with a

thermal actuating motor. When the zone turns on, the system pump is held off for a period of time to allow the thermal motor zone

valve to fully open. This time is adjustable through the thermal open (THRM OPEN) setting in the Control Adjust menu of the

control. The thermal close (THRM CLS) setting in the Control Adjust menu of the control sets the time required for the thermal

motor zone valve to close.

SYSTEM PUMP OPERATION

The system pump (

Sys Pmp

) contact is operated based on the zoning device(s) selected. Refer to the ZONE OUTPUT section for system

pump operation. The system pump is also operated based on the purge and exercise functions.

EXERCISING (EXERCISE)

The 369 has a built-in exercising function. The exercising period is adjustable and comes factory set at 70 hours. If the zoning devices

or the system pump has not been operated at least once during every exercising period, the control turns on the output for 10 seconds.

This minimizes the possibility of a pump or valve seizing during a long period of inactivity. The Test LED flashes anytime the control

is exercising.

Note:

The zone relay exercising time is increased to the THRM OPEN setting if THRM is selected as the zoning device.

PURGING (PURGE)

The 369 includes a purging function which allows for any excess heat available in the boiler to be purged into the zones. The 369 removes

the call for heat from the reset control some time before the zones are turned off. The purging time is adjustable based on the PURGE

setting in the Control Adjust menu of the control.

Section A2: One Stage Heating

ONE STAGE HEATING

A one stage heating zone has one RTU or indoor sensor controlling a

single heating terminal. One RTU or indoor sensor therefore controls

one output relay. If an RTU is used to control a one stage heating zone,

the RTU must be connected to a

to an even numbered

be selected through the STG NUM adjustment in the Zone Adjust menu

of the control. If an indoor sensor is used to control a one stage heating

zone, the sensor can only be connected to an

Indr 4 or Indr 6

adjustment in the Zone Adjust menu of the control.

Example:

tN1 1

terminals (20 and 21) is used to control the

output relay

Com

and

control the output relay

), and ONE must be selected through the STG NUM

An RTU connected between

Zn 1

, and an RTU connected between

tN1 2

terminals (20 and 22) is used to

tN1

terminal (i.e.

Zn 2

.

tN1

terminal. If an RTU is connected

tN1 2, tN1 4 or tN1 6

Indr

terminal (i.e.

Com

and

), ONE must

C

Indr 2,

M

21

22

View

°

F

Occ

1

Un

ItemMenu

7

8

6

Com

Zn

Zn

1-2

1

2

20

Com

View

ItemMenu

tN1

1

tN1

2

°

F

Occ

Un

1

23

Indr

2

R

Copyright © D 369 -10/00 6 of 32

M

Cycle Length

Lo Stage

Hi Stage

Lo Stage

Hi Stage

Lo Stage

Hi Stage

On

Off

On

Off

On

On

- 01/09

- 01/09

Section A3: Two Stage Heating

TWO STAGE HEATING

In cases where a one stage heating system can not provide sufficient heat, a second stage of heat from an

additional heating terminal can be provided to supplement the first stage. A two stage heating system

therefore has one RTU or indoor sensor controlling two output relays: a

Lo stage

If an RTU is used to control a two stage heating zone, the RTU must be connected to an even

(i.e.

tN1 2, tN1 4 or tN1 6

), and TWO must be selected through the STG NUM adjustment in the Zone Adjust

menu of the control. If an indoor sensor is used to control a two stage heating zone, the sensor must be

connected to an

terminal (i.e.

Indr 2, Indr 4 or Indr 6

), and TWO must be selected through the STG NUM

Indr

adjustment in the Zone Adjust menu of the control. The odd numbered zone relay becomes the Lo Stage

and the even numbered zone relay becomes the Hi Stage.

Example

and

control the output relays

Relay

relay

PID Staging Logic

: An RTU connected between

tN1 2

terminals (20 and 22) is used to

Zn 1

Zn 1

is the

Zn 2

is the

Lo stage

Hi stage

output relay and

output relay.

and

Com

Zn 2

View

°

F

Occ

1

.

Un

ItemMenu

The temperature within each two stage zone is controlled by varying the

on time of the output relays over a cycle length. During light loads, the

369 cycles the

stage

relay on time increases until it reaches the maximum of the cycle

length. The

Lo Stage

Hi stage

relay on and off. As the load increases, the

Lo

relay is then turned on and its on time is increased

as the load increases. When the heating load decreases again, the on

time of the

completely. The control then starts to reduce the on time of the

stage

relay.

Hi stage

relay is reduced until the

Hi stage

relay is turned off

Lo

relay and a

21

20

tN1

tN1

Com

1

Hi stage

tN1

terminal

22

23

Indr

2

2

C

R

relay.

Lo Stage

Adjust

M

M

Zn

1

Zone

6

2

7

Com

Zn

1-2

2

Hi Stage

8

Section B: Cooling Operation

Section B1

General Cooling

Section B2

Cooling Enable

Section B3

Cooling Control

Section B1: General Cooling

GENERAL COOLING

The Zone Control 369 is capable of operating a single cooling group to provide either cooling enable (ENBL)

or cooling control (CTRL). This is an adjustable item through the COOL MOD setting in the Control Adjust menu

of the control. In order to prevent short cycling of the mechanical cooling unit, the 369 ensures the

is operated for a minimum amount of time. The minimum run time (MIN RUN) and minimum off time (MIN OFF)

are adjustable settings in the Control Adjust menu of the control.

COOLING GROUP (CG)

A cooling group is a group of heating zones that are a part of a cooling zone. This function allows zones which

are assigned to the cooling group to be doing cooling, while zones which are not assigned to the cooling group

are heating. A heating zone can be assigned to the cooling group by selecting CG through the ZN COOL

adjustment in the Zone Adjust menu of the control. Zone 6 (

group; therefore, there is no option for removing this zone from the cooling group.

COOLING INTERLOCK (INTRLOCK)

In order to prevent simultaneous heating and cooling, the 369 provides a cooling interlock. Once all the heating zones assigned to the

cooling group have been satisfied for a period of time, the control will allow cooling operation to occur. This time is adjustable through

the INTRLOCK setting in the Control Adjust menu of the control. Once any zone assigned to the cooling group requires heat, cooling

operation is terminated.

Adjust

Cooling

relay

Adjust

tN1

6 or

Indr 6

) is always a member of the cooling

1

Zone

7 of 32

Copyright © D 369 -10/00

- 01/09

- 01/09

HEAT / COOL CHANGEOVER

The changeover between heating and cooling is based on whether or not a display RTU is connected to zone 6 (

RTU is connected to zone 6 (

tN1 6

). If a display

tN1 6

), the changeover between heating and cooling is selected at RTU 6. A pointer in the lower right

hand display of the RTU indicates that this RTU is the designated heat / cool RTU. Heat / cool changeover can be achieved

automatically or manually through the RTU. The MODE adjustment in the Adjust menu of RTU 6 allows the selection between HEAT,

COOL, AUTO or OFF. When HEAT is selected at RTU 6, the cooling system is locked out and only heating is allowed as required.

When COOL is selected at RTU 6, the heating system is locked out and all the heating zones assigned to the cooling group shut off.

Cooling is then allowed to operate as required. When AUTO is selected at RTU 6, the changeover between heating and cooling occurs

based on the Cooling Interlock function. Cooling is then allowed to operate as required. When OFF is selected at RTU 6, zone 6

becomes inactive and cooling operation is disabled. If a display RTU is not connected to zone 6 (

tN1 6

), the changeover between

heating and cooling is automatic.

COOLING WHILE FLOOR WARMING

The 369 can use a 063 display RTU to provide floor (slab) and air temperature control. The 063 RTU has a built-in air sensor which

is used to control the heating and cooling air temperature, while a slab sensor connected to the 063 RTU controls the floor (slab)

temperature. During mild conditions the floor (slab) is maintained at a minimum temperature, and as the outdoor temperature drops

the floor (slab) will rise above the minimum setting and the air sensor takes over. As the outdoor temperature rises and cooling is

required, the control targets the cooling setpoint and the floor (slab) is still maintained at a minimum temperature.

Note:

During mild conditions, it is possible to overheat the space if the floor (slab ) is maintained at a minimum temperature.

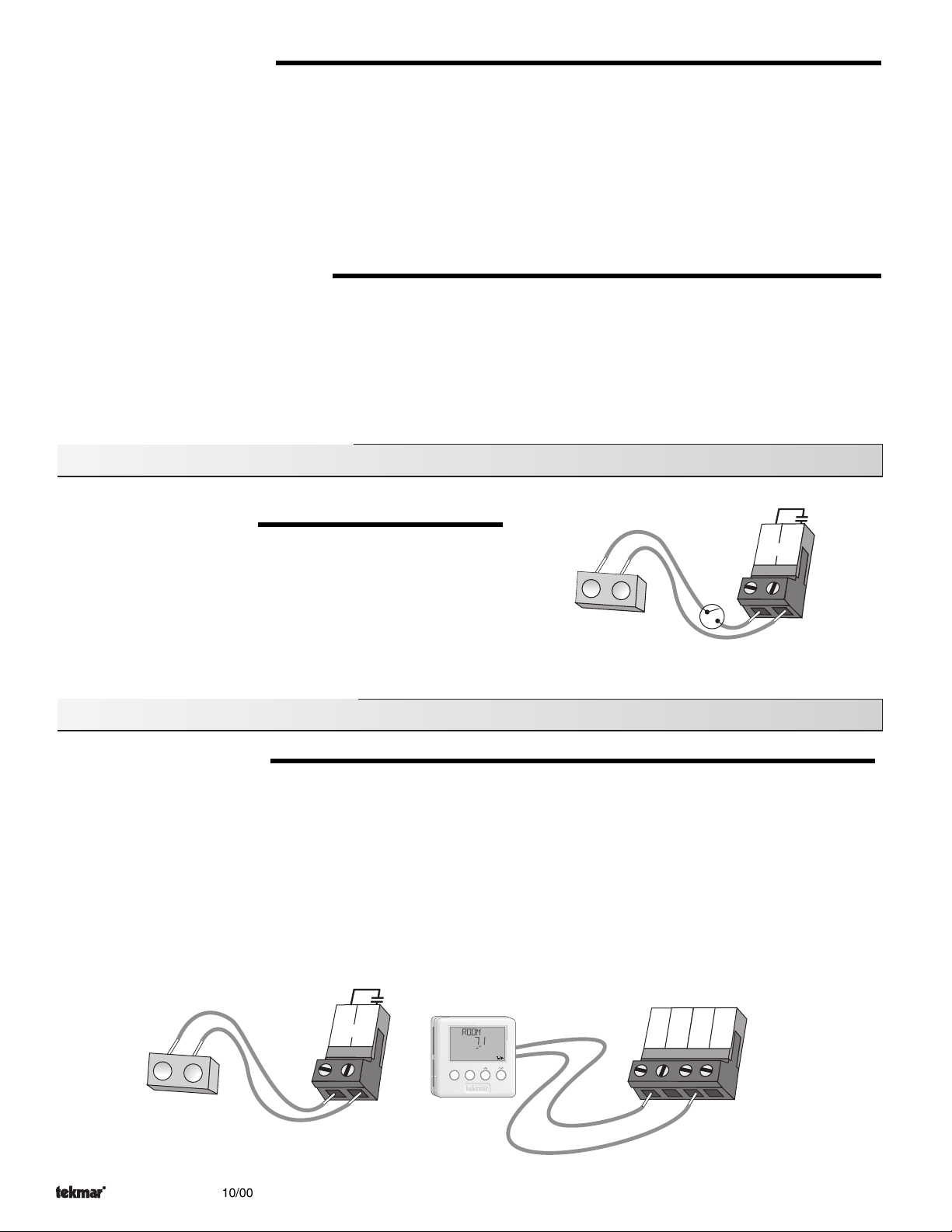

Section B2: Cooling Enable

COOLING ENABLE (ENBL)

The

Cooling

relay can be used to enable a cooling system, which can be

15

16

Cooling

controlled by a cooling thermostat. The changeover between heating

and cooling is described in the Heat / Cool Changeover section.

Cooling Unit

Cooling

Thermostat

Section B3: Cooling Control

COOLING CONTROL (CTRL)

A display RTU connected to zone 6 (

as the controlling device for the cooling system. The actual cooling “room” temperature is an average of the room temperature of all

the zones assigned to the cooling group. The desired cooling temperature is set using the COOLING adjustment in the Adjust menu

of RTU 6. When cooling, the 369 varies the on time of the

through the COOL CYC setting in the Control Adjust menu of the control. If COOL CYC is set to AUTO, the control automatically

calculates a cooling cycle length. During every cycle, the control turns on the

time is calculated based on the PID response of the cooling group during the previous cycle period. If the cooling group requires more

cooling, the on time is increased, and if the cooling group requires less cooling, the on time is reduced. The changeover between

heating and cooling is described in the Heat / Cool Changeover section.

Note:

If a non-display RTU is connected to

selected.

tN1 6

) can be used to control a heating zone as well as the cooling group. This RTU is designated

Cooling

tN1 6

or if an indoor sensor is connected to

relay based on a cycle length. The cooling cycle length is adjustable

Cooling

relay for a specific on time. The required on

Indr 6

, cooling control (CTRL) can not be

15

16

Cooling

Cooling Unit

Copyright © D 369 -10/00 8 of 32

View

ItemMenu

Display RTU

2

30

2

8

tN1/2

°

F

UnOcc1

Com

31

9

Indr

tN1

6

6

5

- 01/09

- 01/09

Section C: UnOccupied

SETBACK (UNOCCUPIED)

To provide greater energy savings, the 369 can lower the building temperature at night or when the building is unoccupied. The 369

has a built-in clock which allows for heating and cooling setback capabilities. As an option, an external timer may be connected to

provide a separate setback signal. When in the unoccupied mode, the

operates the zones based on the

temperature is set using the HEATING

the desired zone temperature is set using the HEATING

UnOcc

settings made in the control and / or display RTUs. With display RTUs, the desired zone

UnOcc

adjustment in the Adjust menu of the RTU. With non-display RTUs or indoor sensors,

UnOcc

(CTRL) is selected, the desired cooling temperature is set using the COOLING

setback feature is enabled by setting the

Setback / None

DIP switch to the

UnOcc

segment is displayed in the appropriate LCD. The 369

adjustment in the Zone Adjust menu of the control. If cooling control

UnOcc

adjustment in the Adjust menu of RTU 6. The

Setback

position, and selecting a desirable schedule. As

well, a schedule override or an external unoccupied override can enable the setback feature.

Clock

The clock in the 369 is used for setback purposes. In order to set the clock, the

Setback / None

DIP switch must be in the

Setback

position. The clock is accessed in the Time menu of the control. The clock displays the time of day and the day of the week. Setting

of the clock is described in the Settings section of this brochure.

SCHEDULE

The 369 provides a control schedule and a zone schedule. Non-display RTUs and indoor

sensors may only select the control schedule, while display RTUs have the option to select

either the control schedule or its own zone schedule. Each schedule allows two occupied

Schd

and two unoccupied events each day. During the first event, the 1 segment is displayed

in the appropriate LCD, and during the second event, the 2 segment is displayed. Setting

ItemMenu

of a schedule is described in the Settings section of this brochure.

Zone Schedule (ZONE)

The zone schedule allows each zone to have its own independent schedule. A zone

schedule is only available for zones using display RTUs. The ZONE schedule is

accessed through the HEAT SCHD adjustment in the schedule (Schd) menu of the RTU.

Control Schedule (CTRL)

The control schedule allows each zone to be on the same schedule. When using display

RTUs, the CTRL schedule is accessed through the HEAT SCH adjustment in the

schedule (Schd) menu of the RTU. When using non-display RTUs or indoor sensors,

the CTRL schedule is accessed through the HT SCHD adjustment in the Zone Adjust

menu of the control.

Cooling Schedule

The 369 allows the heat / cool RTU (

tN1 6

) to select a schedule for cooling. The COOL SCH adjustment in the schedule (Schd)

menu of the RTU may be set to CTRL to use the control schedule, or ZONE to use the zone schedule.

Note:

If cooling enable (ENBL) is selected and the control is in unoccupied mode, the control does not operate the

OPTIMUM START / STOP

The Optimum Start / Stop feature is used during transitions between

the unoccupied mode and the occupied mode. If Optimum Stop is

selected, the control turns off the zone valve or pump before the start

of the setback period. Therefore, the zone starts to cool down at the

beginning of the UnOccupied period. If Optimum Start is selected, the

Optimum Stop

369 raises the zone temperature during the final stages of the

unoccupied period. This ensures the zone is at the occupied temperature as soon as the occupied period begins.

The Optimum Start / Stop function may be selected for each zone to

provide optimum start (STRT), optimum stop (STOP), or optimum

start and stop (BOTH). For display RTUs this setting is selected

through the OPT STRT adjustment in the schedule (Schd) menu of

the RTU. For non-display RTUs or indoor sensors, the Optimum Start

10 P.M. 12 A.M. 2 A.M. 4 A.M. 6 A.M.

/ Stop setting is selected through the HEAT OPT adjustment in the

Zone Adjust menu of the control.

Adjust

Setback Period

Zone 1

Zone 2

Zone 3

Zone 4

2

Zone

Cooling

Optimum Start

relay.

If cooling control (CTRL) is selected, Optimum Start may be selected for cooling. If Optimum Start is selected, the control operates

the

Cooling

relay to ensure the cooling group is at the occupied temperature as soon as the occupied period begins. This function

is enabled by selecting STRT through the COOL OPT adjustment in the Control Adjust menu of the control.

9 of 32

Copyright © D 369 -10/00

- 01/09

- 01/09

SCHEDULE OVERRIDES

The 369 has a number of setback overrides that are selected through the schedule (Schd) menu. A system override and a zone override

are available. Any time an override is in effect, the

System Override

(OVERRIDE)

Ovr

segment is displayed in the appropriate LCD.

Schd

Occ

OvrUn

The system overrides affect every zone and are selected in the schedule (Schd) menu

of the control, remote display module (RDM), or display RTU. These setback overrides

have priority over any external setback signal.

Adjust

Zone Override

(ZONE OVR)

Schd

Occ

Ovr

Zone overrides are only available for zones using display RTUs. The zone overrides

only affect the respective zone, and are selected in the schedule (Schd) menu of the

ItemMenu

RTU or remote display module (RDM).

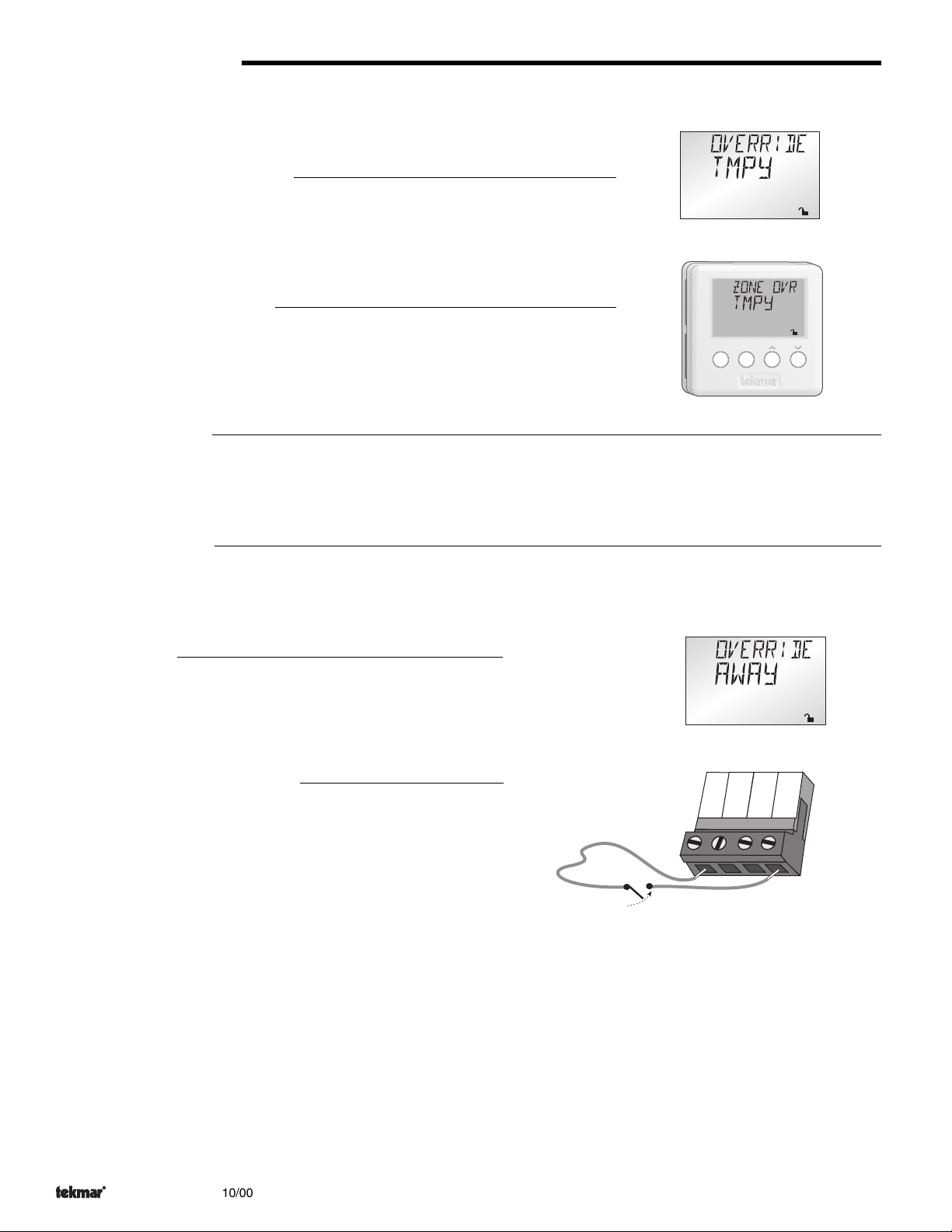

Temporary (TMPY)

If a temporary occupied or temporary unoccupied override is selected, the 369 operates the zone(s) in the selected override mode

for 3 hours from the time the selection is made. Once completed, the control reverts to the currently scheduled operation.

Permanent (PERM)

If a permanent occupied or permanent unoccupied override is selected, the 369 operates the zone(s) in the selected override mode

until a new override is selected.

Away (AWAY)

If the AWAY override is selected, the 369 reduces all the heating

Schd

setpoints to a maximum of 62°F (17°C), and increases the cooling

setpoint to at least 82°F (28°C). Also, slab minimum settings and all

existing schedules are ignored.

External UnOccupied Override

An external signal can place the 369 into unoccupied mode. Any time

the

UnO Sw

(1) and the

Com

(4) terminals are shorted together, the

1

UnO

Sw

Zo

In

3

2

Zo

Out

4

Com

control overrides the occupied mode and operates in the unoccupied

mode. The

UnOcc Ovr

segment is displayed in the appropriate LCD.

The control remains in the unoccupied mode as long as the signal is

present or until a system override is selected.

Timer Switch

Copyright © D 369 -10/00 10 of 32

Loading...

Loading...