Page 1

- Data Brochure

Constant

Room Temperature

Outdoor

Temperature

Drop

Heat

Loss

Increase

House Control 352

UnOcc.

Heat

Demand

WWSD

Min. Boiler /

Max. Supply

Pump

Heat

House Control 352

One Zone, Boiler /

Injection

Power

The House Control 352 is a microprocessor-based outdoor reset control designed to control the

temperature of a single zone hydronic heating system. The 352 regulates the supply water

temperature based on the outdoor air temperature and optionally the indoor air temperature. The

352 can either operate a boiler and a system pump, or an injection valve and a system pump. To

avoid boiler short cycling and large temperature swings, the 352 has a built in function which continuously adjusts the boiler differential.

The 352 includes features such as Warm Weather Shut Down (WWSD), system pump exercising,

Night Setback (UnOccupied period), minimum boiler supply temperature setting (Boiler mode) and

maximum supply water temperature setting (Injection mode). A Room Temperature Unit (RTU) 054 or

an Indoor Sensor 076 can be connected to the 352 to provide indoor temperature feedback.

Control Strategy . . . . . . . . . . . . pg. 1 Testing the Control . . . . . . . pg. 7

Sequence of Operation . . . . . . . pg. 3 Error Messages. . . . . . . . . . . pg. 7

Installation . . . . . . . . . . . . . . . . . pg. 4 Technical Data . . . . . . . . . . . pg. 8

Settings . . . . . . . . . . . . . . . . . . . pg. 6 Limited Warranty . . . . . . . . . pg. 8

Output

System Pump

(through back of control)

H11191

105 Off

Min. Boiler /

Max. Supply

House Control 352

One Zone, Boiler /

Injection

Power

140°F

Made in Canada by

tekmar Control

Systems Ltd.

170

Heat

Demand

0.2

Heating Curve

Pump

1

UnOcc.

WWSD

Min. Boiler /

Max. Supply

Heat

D 352

06/00

2

3

3.6

Aug 95

31000265

NRTL/C

Heat4Heat

LR 58223

UnOccupied

Signal wiring

must be rated

at least 300V

Input

24 V (ac)

Power Supply

M

or

Output

Boiler or Valve

Input

tekmar

Timer

Power:

24 V 50/60 Hz 3 VA

Relays:

120 V (ac) 10 A 1/3 hp

pilot duty 240 VA

1C2R3

Boiler / Injection

Power Relay

TIME

1

PRGM

AMPM

2

UNOCC

OVR

S

SMWTFT

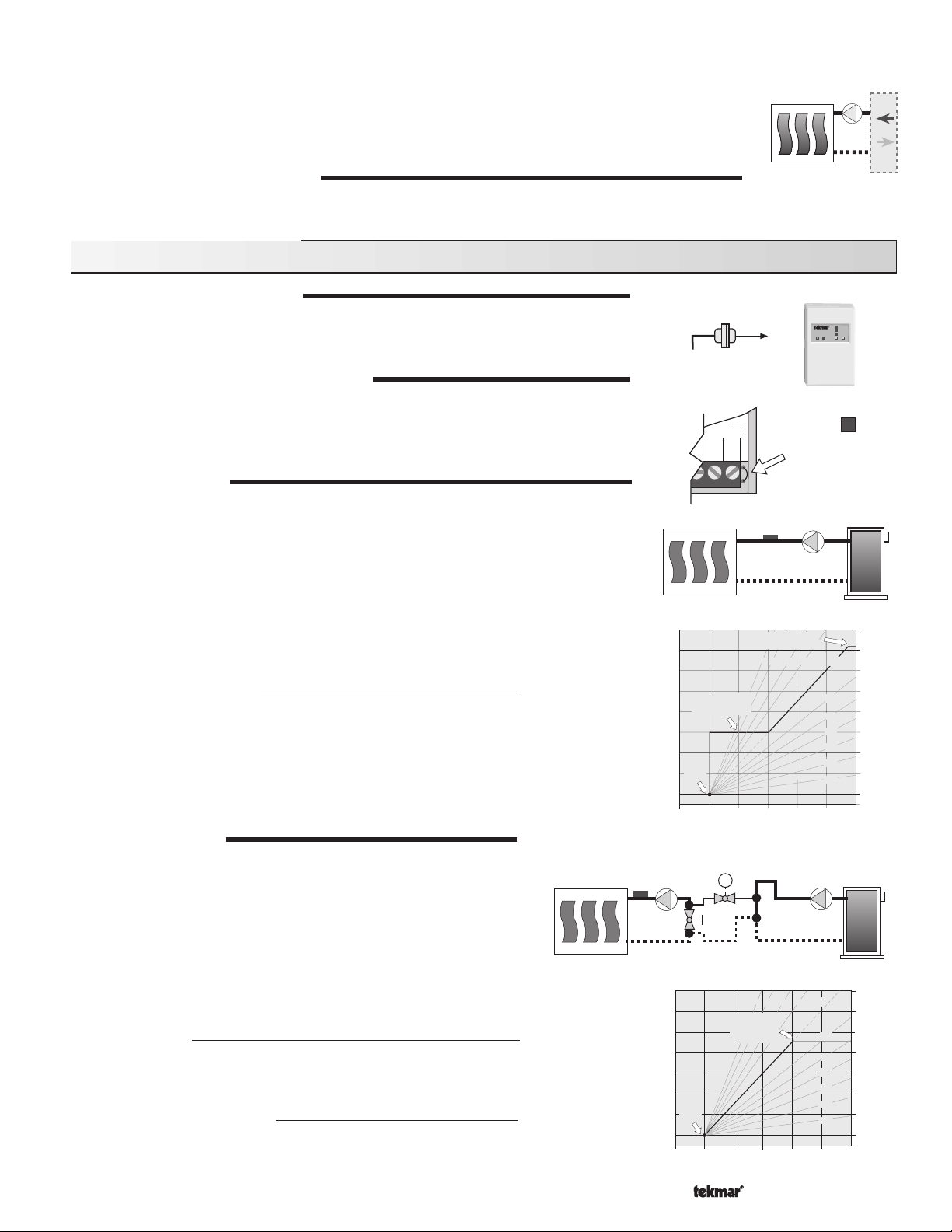

Control Strategy

OUTDOOR RESET

In order to properly control a hot water heating system, the heat supplied

to the building must equal the heat lost by the building.

• The heat supplied to a building is proportional to the temperature of the

water and the surface area of the heating element. A small surface area

such as baseboard radiators requires a higher water temperature than

a larger surface area such as radiant floors.

• The heat lost from a building is dependent on the outdoor temperature.

As the outdoor temperature drops, the building heat loss increases.

1 of 8

R

70°F (21°C)

40 (4) 100 (38)

Do not apply power

5

RTU

UnO

Sen

Sw

Test

Input

Outdoor Sensor

6

7

8

9

Com

Sup

Out

Sen

Sen

Sen

Included

Input

Supply Sensor

Included

70

Input

tekmar RTU or

Indoor Sensor

Copyright © D 352 - 06/00

Page 2

Heating Curve

Supply Water Temperature

Time

Differential = 10°F (5°C

)

165°F(74°C)

B

o

i

l

e

r

o

f

f

B

o

i

l

e

r

o

n

155°F (68°C)

160°F (71°C)

B

o

i

l

e

r

o

f

f

B

o

i

l

e

r

o

n

Mixing

Device

Boiler

Loop

System

Loop

A hot water heating system can be accurately controlled by modulating the supply water

temperature as the outdoor temperature changes. Using this approach the heat lost from

the building is exactly matched by the heat input to the building. A tekmar reset control

utilizes a heating curve to set the relationship between outdoor temperature and supply

water temperature. The heating curve determines the amount the supply water temperature is raised for every 1° drop in outdoor air temperature. The heating curve is sometimes

called an outdoor reset ratio.

Heating Curve Parallel Shift

All heating curves begin at the heating curve starting point. If the heating curve starting

point is adjusted, the heating curve will be parallel shifted. The heating curve starting point

is either set manually through a dial, or it is determined automatically by the control

through indoor temperature feedback.

Indoor Temperature Feedback

Most buildings have internal heat gains due to people, passive solar heating and

mechanical or electrical equipment. If only the outdoor temperature is measured, the

control cannot compensate for these internal heat gains and the building may overheat.

In order to prevent overheating, indoor temperature feedback should be combined with

the outdoor reset strategy. From this indoor temperature feedback, the control can

change the heating curve starting point in order to match the supply water temperature

to the heat loss of the building. If the indoor temperature is too warm, the control

automatically shifts the starting point and the heating curve down. If the indoor temperature is too cold, the control shifts the starting point and heating curve up.

Warm Weather Shut Down (WWSD)

When the outdoor temperature is equal to the heating curve starting point, no additional

heat is required in the building and therefore the heating system can be shut down. The

WWSD point is normally the same as the heating curve starting point.

BOILER OPERATION

The supply water temperature from a boiler can be controlled by cycling the boiler on and

off. Modulation of the boiler’s operating temperature in hot water heating systems not only

provides more comfort but also offers significant energy savings. The cooler the boiler runs,

the more efficient it is due to less heat losses up the flue and reduced boiler jacket losses.

Minimum Boiler Supply

Most boilers require a minimum supply water temperature in order to prevent corrosion

from flue gas condensation. The control should therefore only modulate the boiler supply

water temperature down to the boiler manufacturer’s minimum recommended operating

temperature. Some boilers are designed to condense and should be operated

water temperatures as much as possible for maximum efficiency.

at low

Heating

Curve

Starting

Point

70

90

(21)

(32)

70

90

(21)

(32)

Minimum Boiler

Supply Setting

WWSD

Point

70°F

70

90

(21)

(32)

3.0

3.6

2.4 2.0

50

(10)30(-1)10(-12)

Outdoor air temperature

3.0

3.6

2.4

Parallel Shift of Heating Curve

UP

DOWN

50

(10)30(-1)10(-12)

Outdoor air temperature

3.0

3.6

2.4

130°F

50

(10)30(-1)10(-12)

Outdoor air temperature

210

(99)

1.6

190

(88)

170

1.2

(77)

150

1.0

(65)

0.8

130

(54)

0.6

11 0

(43)

0.4

0.2

-10

(-23)

2.0

1.6

1.2

1.0

0.8

0.6

0.4

0.2

-10

(-23)

2.0

1.6

1.2

1.0

0.8

0.6

0.4

0.2

-10

(-23)

Supply water temperature

90

(32)

70

(21)

°F

(°C)

210

(99)

190

(88)

170

(77)

150

(65)

130

(54)

11 0

(43)

Supply water temperature

90

(32)

70

(21)

°

F

°C)

(

210

(99)

190

(88)

170

(77)

150

(65)

130

(54)

11 0

(43)

Supply water temperature

90

(32)

70

(21)

°F

(°C)

Boiler Differential

An on / off boiler must be operated with a differential in order to prevent

short cycling. When the supply water temperature drops below the

bottom rail of the differential, the boiler is turned on. The boiler is then

kept on until the supply water temperature rises above the top rail of

the differential. If the differential is too wide, there can be large supply

water temperature swings; however, if the differential is too narrow, the

boiler short cycles and operates inefficiently. Some controls automatically calculate the boiler differential in order to achieve an appropriate

balance between temperature swings and boiler efficiency. This also

permits the control to adapt to changing loads and conditions.

MIXING OPERATION

The full range of water temperatures required through a heating season

can be provided with a standard (non-condensing) boiler by incorporating a mixing device into the system. An On / Off Injection Valve or Pump

can be used to modulate the system supply water temperature to

improve comfort in the building and provide a maximum target supply

water temperature limit. For more detailed information on mixing methods consult Essay E 021.

Copyright © D 352 - 06/00

2 of 8

Page 3

Maximum System Supply

Jumper

6

Sen

RTU

7

Sen

Com

8

Sen

Sup

9

Sen

Out

Do not apply power

Some systems, such as hydronic radiant floor heating, usually operate at water temperatures that are below

the minimum boiler supply temperature. This is due to the large surface area of the floors which radiate a

significant amount of heat at low water temperatures. Floor heating systems and flat panel convectors also

have a maximum surface temperature limit for occupant health reasons. In such systems a mixing device

is normally required to limit the supply water temperature.

UNOCCUPIED (NIGHT SETBACK)

During the night, or at times when people are not within the building, energy can be saved by lowering the

building temperature for an UnOccupied (Night Setback) period.

Sequence of Operation

Mix

POWERING UP THE CONTROL

WARM WEATHER SHUT DOWN (WWSD)

BOILER OPERATION

MIXING OPERATION

After the 352 is powered up a certain combination of red LEDs are turned on for 2 seconds

indicating the software version. All red LEDs are then held on for 4 seconds. When the

control is powered up, the green

Power

light remains on continuously.

When the outdoor temperature rises above the heating curve starting point, the 352 turns

WWSD

the

If the control is in

light on and shuts down the system pump and the

Boiler

mode and the jumper is cut, the control ignores the WWSD feature

Heat

relay.

and keeps the boiler warm.

If the DIP switch is set to

the boiler on and off. The 352 calculates the target supply water temperature based on the

outdoor temperature and optionally the indoor air temperature. In order to prevent boiler

short cycling, the 352 has a minimum time delay of 30 seconds before turning the boiler on

or off. The 352 calculates the boiler differential automatically. The

whenever the boiler is on.

Maximum Boiler Supply

The 352 does not allow the target boiler supply water temperature to exceed 212°F

(100°C). If the supply water temperature approaches 212°F (100°C), the 352 turns off

the boiler.

Minimum Boiler Supply

The 352 has a

order to prevent corrosion from flue gas condensation. This dial has an

condensing and electric boilers. If an RTU or Indoor Sensor is connected to the 352 and

the required system supply temperature needs to be lower than the

setting, the 352 turns on the boiler until the minimum boiler temperature is reached. It then

keeps the boiler off for a calculated off time in order to prevent overheating of the zone.

The

Heat Demand

Boiler

, the system supply water temperature is controlled by turning

Min. Boiler

dial which sets a minimum target boiler supply temperature in

light turns on when operation of the boiler is required.

Heat

light turns on

Off

position for

Min. Boiler

dial

If the DIP switch is set to

is controlled by turning an injection device, such as a zone valve, on and

off. The 352 calculates the target supply water temperature based on the

outdoor temperature and optionally the indoor air temperature. To

prevent short cycling of the valve, the 352 uses a minimum time delay of

30 seconds. The

If the jumper beside the outdoor sensor terminal is cut, the control will

ensure the injection device and system pump are turned on for at least

17 minutes every 7 days. This flushing function prevents bacteria growth

in applications where a water heater is used for DHW and heating.

Boiler Control

During mixing operation the boiler can be enabled using the end switch of the zone valve.

The boiler aquastat should be set at least 20°F (11°C) above the system design water

temperature.

Maximum System Supply

The 352 has a

water temperature. If the system supply temperature approaches the

setting, the 352 turns on the

Max. Supply

Injection

Heat Demand

dial that can be used to set an upper limit to the system supply

, the system supply water temperature

light turns on when heat is required.

Max. Supply

light and closes the injection valve.

3 of 8

Max. Supply

dial

Minimum Boiler

Supply Setting

WWSD

Point

70°F

90

(32)

WWSD

Point

70°F

90

(21)

(32)

24 V (ac)

Temperature 212°F

130°F

50

70

(10)30(-1)10(-12)

(21)

Outdoor air temperature

M

3.6

Maximum

Temperature

(set on dial)

50

70

(10)30(-1)10(-12)

Outdoor air temperature

Copyright © D 352 - 06/00

Maximum Boiler

3.0

3.6

2.4

3.0

2.4

Supply

UnOcc.

WWSD

House Control 352

One Zone, Boiler /

Min. Boiler /

Injection

Max. Supply

Heat

Demand

Power

Pump

Heat

WWSD

230

(110)

210

2.0

(-23)

2.0

-10

(-23)

(99)

1.6

190

(88)

170

1.2

(77)

150

1.0

(65)

0.8

130

(54)

0.6

11 0

(43)

0.4

0.2

-10

1.6

1.2

1.0

0.8

0.6

0.4

0.2

90

(32)

70

(21)

°

F

°C)

(

210

(99)

190

(88)

170

(77)

150

(65)

130

(54)

11 0

(43)

Supply water temperature

90

(32)

70

(21)

°F

(°C)

Supply water temperature

Page 4

ZONING OPERATION

T

l

Single Zone with Indoor Temperature Feedback

The 352 can directly control the space temperature of one heating zone. In order to

measure the indoor temperature and provide indoor temperature feedback, the control

requires either a Room Temperature Unit (RTU) 054 or an Indoor Sensor 076. With an

RTU, the desired indoor temperature is set using the RTU dial; with an Indoor Sensor, the

desired zone temperature is fixed at 70°F (21°C).

Multiple Zones with no Indoor Temperature Feedback

For systems where no indoor temperature feedback is provided, zone valve end switches

may be used to power up the 352. Since no indoor temperature is available to the control,

the 352 sets the starting point of the heating curve at 70°F (21°C).

UNOCCUPIED MODE (NIGHT SETBACK)

The 352 can be switched into UnOccupied mode by closing an external switch or a timer

relay wired into the control. When the 352 is in UnOccupied mode and an RTU or Indoor

Sensor is connected, the

set using the

UnOccupied

the

UnOccupied

dial sets the heating curve starting point.

UnOcc

light turns on and the desired temperature in the zone is

dial on the control. If no indoor temperature feedback is provided,

70

Indoor SensorRTU

o contro

Zone Valve Motor

End Switches

M

M

C

R

SYSTEM PUMP OPERATION

The

Pump

light turns on every time the system pump relay at the back of the control closes. The system pump turns on whenever the

control is not in WWSD.

Pump Exercising

The system pump is exercised to help prevent corrosion from building up and subsequently jamming the equipment. Every three days

the 352 runs the pump for at least 10 seconds.

Installation

Caution

Improper installation and operation of this control could result in damage to the equipment and possibly even personal injury.

It is your responsibility to ensure that this control is safely installed according to all applicable codes and standards. This

electronic control is not intended for use as a primary limit control. Other controls that are intended and certified as safety

limits must be placed into the control circuit.

STEP ONE

GETTING READY

Check the contents of this package. If any of the contents listed are missing or damaged, please contact your wholesaler or tekmar sales

representative for assistance.

Type 352 includes:

• One Control 352 • One Outdoor Sensor 070

• One Universal Sensor 071

• Data Brochures D 352, D 070, D 001

• Application Brochures A 352

Other information available:

• Essays

Note Carefully read the details of the Sequence of Operation section in this brochure to ensure that you have chosen the proper control

for your application.

STEP TWO

MOUNTING

Install a 2” x 4” duplex electrical box in accordance with the instructions in the Data Brochure D 001. Determine whether the low voltage

wiring enters the wiring chamber through the back or the bottom of the control. Ensure the depth of the electrical box is enough to house

all the wiring that will be in it.

STEP THREE

ROUGH-IN WIRING

The system pump wiring terminates in the electrical box. All other electrical wiring terminates in the two wiring chambers on the control.

The wiring is roughed-in to the electrical box prior to installation of the control (See Brochure D 001). Standard 18 AWG solid wire is

recommended for all low voltage wiring.

Power must not be applied to any of the wires during the rough-in wiring stage.

• Install the system pump and run the wiring to the electrical box.

• Install the Outdoor Sensor 070 and the Supply Sensor 071 according to the instructions in the Data Brochure D 070 and run the wiring

back to the control mounting location. If indoor temperature feedback is desired, install the RTU 054 or Indoor Sensor 076 according

to the installation instructions provided in the Data Brochure D 054 or D 070 and run the wiring back to the control mounting location.

• Run the wiring from the other system components (boiler, injection valve, etc.) to the control mounting location.

Copyright © D 352 - 06/00

4 of 8

Page 5

• Run the wires from the 24 V (ac) power source or heat demand to the control mounting location.

Use a clean power source to ensure

proper operation.

• If a tekmar Timer 031 is used, follow the installation procedure provided in the Data Brochure D 031 and run the wiring back to the

control mounting location.

STEP FOUR

TESTING THE WIRING

No wires should be connected to the control during testing.

A good quality electrical test meter, capable of reading from at least 0 — 200 V (ac) and at least 0 — 2,000,000 Ohms, is essential to

properly test the wiring and sensors.

Test the Sensors

Test the sensors and RTU according to the testing procedure in Data Brochures D 070

Ω

and D 054.

Ω

Test the Power Supply

Make sure exposed wires and bare terminals are not in contact with other wires or

grounded surfaces. Turn on the power and measure the voltage across the 24 V (ac)

power supply. The voltmeter should read between 22 and 26 Volts.

Test the Outputs

• Short the system pump wires and power up the pump circuit; the system pump should turn on. Remove the power from the system

pump circuit.

• If the control is in

Boiler

mode, short the boiler wires and power up the boiler circuit; the boiler should fire. Remove the power from

the boiler circuit.

• If the control is in

Injection

mode, short the valve wires and power up the valve circuit; the valve should open. Remove the power

from the valve circuit and the valve should close.

STEP FIVE

ELECTRICAL CONNECTIONS TO THE CONTROL

The installer should confirm that no voltage is present at any of the wires.

Output Connections

System Pump

Connect one of the wires from the system pump to one of the wires from the back of

the control. Connect the second wire from the back to the live (L) side of the 120 V (ac)

power source. The other wire on the system pump must be connected to the neutral

(N) side of the 120 V (ac) power supply. Refer to application brochures A 352.

Insert the low voltage wiring into the wiring chambers on the control and mount the 352

lified

a

qu

g to

rvicin

r se

fe

g voids

e

in

R

n

pe

el. O

n

n

rso

e

p

ty.

STOP

rran

a

w

on the electrical box.

Heat Relay

If the DIP switch is set to

Heat

to the

relay (3 and 4) terminals.

Boiler

, connect the 120 V (ac) or 24 V (ac) boiler circuit directly

Pump

(black)

Live power

(black)

If an injection valve or pump is used, connect one of the wires from the valve or pump

Heat

to the

24 V (ac) or N for 120 V (ac)) of the power supply. Connect the

to the live (R for 24 V (ac) or L for 120 V (ac)) side of the power supply.

Powered Input Connections

relay (4) terminal and the other wire to the common or neutral side (C for

Heat Relay

(3) terminal

Power

C

Heat Heat

R

3412

Relay

24 V (ac) Power

Connect the 24 V (ac) power supply to terminals

Sensor and Unpowered Input Connections

Do not apply power to these terminals as this will damage the control.

Power C— R

(1 and 2) on the control.

Power

C

R

3412

Relay

Heat Heat

Outdoor Sensor

Connect the two wires from the Outdoor Sensor 070 to the terminals

(7 and 9). The Outdoor Sensor measures the outdoor air temperature.

Sen

Com Sen

Supply Sensor

Connect the two wires from the Supply Sensor 071 to the terminals

Sen

(7 and 8). The Supply Sensor measures the supply water temperature to the

system.

5 of 8

Com Sen — Sup

—

Out

68

5

7

9

UnO

Sw

5

UnO

Sw

RTU

Com

Sen

Sen

6 8

7

RTU

Com

Sen

Sen

Sup

Sen

Sup

Sen

Out

Sen

9

Out

Sen

Copyright © D 352 - 06/00

Page 6

Room Temperature Unit (RTU) and Indoor Sensor

2

Connect the two wires from either the RTU 054 or the Indoor Sensor 076 to the

(6 and 7) terminals. The RTU or Indoor Sensor provides indoor temperature feedback.

RTU Sen — Com Sen

5

UnO

Sw

6 8

7

RTU

Com

Sen

Sen

Sup

Sen

Unoccupied Switch

If an external timer or switch is used, connect the two wires from the external dry contact switch to the

Sw — Com Sen

(5 and 7) terminals. When these terminals short together, the control registers an

UnOccupied signal. For more information on the tekmar Timer 031 consult its Data Brochure D 031.

UnO

68

5

7

UnO

RTU

Com

Sw

Sen

Sen

Sup

Sen

Settings

Before adjusting the dial settings, read through the sequence of operation to ensure that you understand how the control operates.

STEP SIX

Minimum Boiler Supply

ESSENTIAL CONTROL SETTINGS

Most boilers require a minimum operating temperature to prevent corrosion from flue gas condensation. If the 352 is in

the

Min. Boiler

Supply dial should be set to the lowest supply water temperature at which the boiler can operate without causing the

boiler flue gases to condense. Consult the boiler manufacturer for recommended minimum boiler supply temperatures. Some typical

settings are given below. If a condensing or electric boiler is used, the

Typical settings:

• Steel fire tube boilers …..........140 to 160°F (60 to 71°C)

• Cast iron boilers …..................135 to 160°F (57 to 71°C)

• Copper tube boilers ….............135 to 150°F (57 to 66°C)

Maximum System Supply

If the 352 is used in

above the

Max. Supply

Injection

mode, the 352 helps prevent the mixed supply water temperature from rising

dial setting. The

Max. Supply

dial should be set to the maximum temperature allowed

in the system loop. There are many factors which may limit the allowable supply temperature in a radiant

floor heating system. A few of these are provided below.

• Some tubing manufacturers recommend that their products not be maintained at temperatures exceeding

140°F (60°C). Consult the tubing manufacturer for specific details.

• No where in the concrete should the temperature be maintained above 170°F (77°C).

• The surface temperature of a radiant floor heating slab should normally not exceed 85°F (29°C). The slab surface temperature is

affected by the slab thermal resistance, the heating load, and the supply water temperature to the slab.

Heating Curve

The Heating Curve setting determines the number of degrees the supply water temperature is raised for every one degree drop in outdoor temperature. The

position can be calculated from the following formula.

Heating Curve =

design supply temperature – desired room temperature

desired room temperature – design outdoor temperature

Example: A system is designed to supply 120°F water when the outdoor temperature is

10°F. The desired room temperature is 70°F.

Heating Curve =

=

120 °F - 70°F (49°C - 21°C) 50°F (28°C)

70°F - 10°F (21°C - (-12°C)) 60°F (33°C)

Min. Boiler

Heating Curve

= 0.8

Supply dial should be set to

3.0

3.6

dial

WWSD

Point

50

70

90

(32)

(10)30(-1)10(-12)

(21)

Outdoor air temperature

Boiler

Off

.

140°F

105 Off

Min. Boiler /

Max. Supply

140°F

105 Off

Min. Boiler /

Max. Supply

2.4 2.0

-10

(-23)

1.6

1.2

1.0

0.8

0.6

0.4

0.2

9

Out

Sen

9

Out

Sen

mode,

170

170

210

(99)

190

(88)

170

(77)

150

(65)

130

(54)

11 0

(43)

90

(32)

70

(21)

°

F

°C)

(

Supply water temperature

If the design supply water temperature is unknown, the

Heating Curve

dial can be set to

a trial value using the typical design supply temperatures given below.

Typical design supply temperatures:

• Hydronic radiant floors … 100 to 130°F (38 to 54°C)

• Baseboard convectors … 160 to 190°F (71 to 88°C)

• Fan coils ………………… 180 to 210°F (82 to 99°C)

Unoccupied Temperature

The

UnOccupied

dial sets the desired indoor temperature during UnOccupied (Night

Setback) mode. If no indoor temperature feedback is used, the dial determines the

heating curve starting point during the UnOccupied period.

DIP Switch Setting

Boiler — Injection

If boiler operation is required, the DIP switch must be set to

is required, the DIP switch must be set to

Copyright © D 352 - 06/00

Injection

.

Boiler

. If mixing operation

6 of 8

UnOccupied

1

3

0.2

Heating Curve

40 (4) 100 (38)

Injection

Boiler

3.6

70°F (21°C)

Page 7

Testing the Control

STEP SEVEN

OPERATIONAL TEST OF CONTROL FUNCTIONS

The main control functions on the 352 can be tested by pressing and holding the

While the

Test

button is pressed, the system pump and the

Heat

relay turn on. Once the

button is released the output relays return to normal operation. If an RTU is connected to

the control and the

Supply

lights will cycle on and off in an upward direction.

Indicator Lights "On"

Power

Heat Demand

UnOcc.

WWSD

Min. Boiler /

Max. Supply

Pump

Heat

STEP EIGHT

Test

button is pressed the

UnOcc., WWSD

, and the

Min. Boiler / Max.

• 24 V (ac) power is applied to the control and the control is energized.

• Heat is required in the system.

• The control is in UnOccupied (Night Setback) mode.

• Heat is not required in the heating system.

• The supply water temperature is approaching the

• The system supply water temperature is approaching the

• The system pump is on.

• The relay contacts between

TROUBLESHOOTING

Heat — Heat

(3 and 4) are closed.

Min. Boiler

Test

button.

Max. Supply

Test

dial setting.

Test

dial setting.

Pump

UnOcc.

WWSD

Min. Boiler /

Max. Supply

As in any troubleshooting procedure, it is important to isolate a problem as much as possible before proceeding. The Error Messages

and

Test

button greatly simplify troubleshooting of the 352. When the control is flashing an error message, identify the fault from the

look-up table below and follow standard testing procedures to confirm the problem. If you suspect a wiring fault, return to steps three,

four and five and carefully check all external wiring and wiring connections.

Sensor and Internal Faults

• If an outdoor sensor fault occurs, the 352 will assume a fixed outdoor temperature of 32°F (0°C), and will supply the appropriate

supply water temperature. An error message is displayed.

• If the RTU or Indoor Sensor short circuits, the 352 displays an error message and operates as if no RTU or Indoor Sensor is

connected.

Heat

• If a supply sensor fault occurs, the 352 displays an error message and turns the system pump and the

Test

• If an internal control fault occurs, the 352 displays an error message. Press the

button to clear the error message. If the error

relay off.

message remains, the control must be returned for repair.

Adjustment of Settings

• If the outdoor temperature is cold and the rooms are cold, increase the

STEP NINE

BEFORE YOU LEAVE

Heating Curve

dial setting by 0.1 per day.

• Install the wiring cover over the wiring chamber and secure it with the screw provided.

• Place the front cover on the control to cover the setting dials and snap it into place.

• Place this brochure, and all other brochures relating to the installation, in the protective plastic bag supplied with the control.

• Place the bag in a conspicuous location near the control for future reference.

• It is important to explain the operation of this control within the system to the end user, and to anyone else who may be operating

the system.

Heat

Error Messages

Whenever a fault is detected in any of the sensors, the indicator lights will flash in specific ways to indicate the location of the problem.

For detailed Sensor and RTU testing instructions see Data Brochures D 070 and D 054.

Light off

Light flashing

Light on

Supply sensor

open circuit

Heat

Power

Demand

Pump

UnOcc.

WWSD

Min. Boiler /

Max. Supply

Heat

Outdoor sensor

short circuit

Heat

Power

Demand

RTU 1

short circuit

Heat

Power

Demand

Pump

Pump

UnOcc.

WWSD

Min. Boiler /

Max. Supply

Heat

UnOcc.

WWSD

Min. Boiler /

Max. Supply

Heat

Outdoor sensor

Power

Power

7 of 8

open circuit

Heat

Demand

RTU 1

open circuit

Heat

Demand

Pump

Pump

UnOcc.

WWSD

Min. Boiler /

Max. Supply

Heat

UnOcc.

WWSD

Min. Boiler /

Max. Supply

Heat

Supply sensor

short circuit

Heat

Power

Demand

Internal

fault

Heat

Power

Demand

Copyright © D 352 - 06/00

Pump

Pump

UnOcc.

WWSD

Min. Boiler /

Max. Supply

Heat

UnOcc.

WWSD

Min. Boiler /

Max. Supply

Heat

Page 8

Technical Data

Test

Power

Min. Boiler /

Max. Supply

House Control 352

One Zone, Boiler /

Injection

Pump

WWSD

UnOcc.

1C2R3

Heat4Heat

6

Sen

RTU

7

Sen

Com

8

Sen

Sup

9

Sen

Out

Signal wiring

must be rated

at least 300V

H11191

Heat

Demand

Heat

Aug 95

31000265

R

NRTL/C

LR 58223

Made in Canada by

tekmar Control

Systems Ltd.

Power:

24 V (ac)

±

10% 50/60 Hz 3 VA

Relays:

120 V (ac) 10 A 1/3 hp

pilot duty 240 VA

5

Sw

UnO

Power Relay

Boiler / Injection

70°F (21°C)

40 (4) 100 (38)

UnOccupied

Do not apply power

0.223.6

1

3

Heating Curve

140°F

170

Min. Boiler /

Max. Supply

105 Off

House Control 352

Literature —

One Zone, Boiler / Injection

D 352, A 352’s, D 001, D 070.

Control — Microprocessor PID control; This is not a safety (limit) control.

Packaged weight — 1.0 lb. (450 g), Enclosure D, white PVC plastic

Dimensions — 4-3/4” H x 2-7/8” W x 1-7/8” D (120 x 74 x 48 mm)

Approvals — CSA NRTL / C, meets ICES & FCC regulations for EMI/RFI.

Ambient conditions — Indoor use only, 32 to 122°F (0 to 50°C), < 90% RH non-

condensing.

Power supply — Class 2, 24 V (ac) ±10% 50/60 Hz 3 VA

Relays — 120 V (ac) 10 A , 1/3 hp, pilot duty 240 VA

Sensors included — NTC thermistor, 10 kΩ @77°F (25°C ±0.2°C) ß=3892

Outdoor Sensor 070 and Universal Sensor 071

Optional devices — tekmar type #: 031, 054, 055.

UnOccupied

Heating Curve

Min. Boiler / Max. Supply

— 40 to 100°F (4 to 38°C)

— 0.2 to 3.6

— 105 to 170°F, Off (40 to 77°C, Off)

The installer must ensure that this control and its wiring are isolated and/or shielded from strong sources of electromagnetic noise.

Conversely, this Class B digital apparatus complies with Part 15 of the FCC Rules and meets all requirements of the Canadian

Interference-Causing Equipment Regulations. However, if this control does cause harmful interference to radio or television reception,

which can be determined by turning the control off and on, the user is encouraged to try to correct the interference by reorienting or

relocating the receiving antenna, relocating the receiver with respect to this control, and/or connecting the control to a different circuit

from that to which the receiver is connected.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Limited Warranty and Product Return Procedure

Limited Warranty The liability of tekmar Control Systems Ltd. and tekmar

Control Systems, Inc. (“tekmar”) under this warranty is limited. The purchaser,

by taking receipt of the tekmar product (“product”), acknowledges receipt of

the terms of the warranty and acknowledges that it has read and

understands same.

tekmar warrants each tekmar product against defects in workmanship and materials, if the product is installed and used in compliance with tekmar's instructions. The

warranty period is for a period of twenty-four (24) months from the production date

if the product is not installed during that period, or twelve (12) months from the

documented date of installation if installed within twenty-four (24) months from the

production date.

The liability of tekmar under this warranty shall be limited to, at tekmar's sole discretion: the cost of parts and labor provided by tekmar to repair defects in materials

and/or workmanship of the defective product; or to the exchange of the defective

product for a replacement product; or to the granting of credit limited to the original

cost of the defective product, and such repair, exchange or credit shall be the sole

remedy available from tekmar, and, without limiting the foregoing in any way,

tekmar is not responsible, in contract, tort or strict product liability, for any

other losses, costs, expenses, inconveniences, or damages, whether direct, indirect, special, secondary, incidental or consequential, arising from ownership or use

of the product, or from defects in workmanship or materials, including any liability

for fundamental breach of contract.

This warranty applies only to those products returned to tekmar during the

warranty period. This warranty does not cover the cost of the parts or labor

to remove or transport the defective product, or to reinstall the repaired or

Product design, software and literature are Copyright © 2000 by:

tekmar Control Systems Ltd. and tekmar Control Systems, Inc.

Control Systems

tekmar Control Systems Ltd., Canada

tekmar Control Systems, Inc., U.S.A.

Head Office: 5100 Silver Star Road

Vernon, B.C. Canada V1B 3K4

Tel. (250) 545-7749 Fax. (250) 545-0650

Web Site: www.tekmarcontrols.com

replacement product. Returned products that are not defective are not covered by this warranty.

This warranty does not apply if the product has been damaged by negligence

by persons other than tekmar, accident, fire, Act of God, abuse or misuse; or

has been damaged by modifications, alterations or attachments made subsequent to purchase which have not been authorized by tekmar; or if the

product was not installed in compliance with tekmar’s instructions and the

local codes and ordinances; or if due to defective installation of the product;

or if the product was not used in compliance with tekmar’s instructions.

This warranty is in lieu of all other warranties, express or implied, which the

Governing Law (being the law of British Columbia) allows parties to contractually exclude, including, without limitation, warranties of merchantability,

fitness for a particular purpose, durability or description of the product, its

non-infringement of any relevant patents or trademarks, and its compliance

with or non-violation of any applicable environmental, health or safety legislation; the term of any other warranty not hereby contractually excluded is

limited such that it shall not extend beyond twenty-four (24) months from the

production date, to the extent that such limitation is allowed by the Governing Law.

Product Return Procedure Products that are believed to have defects in work-

manship or materials must be returned, together with a written description of the

defect, to the tekmar representative for that territory. If the address of the representative is not known, please request it from tekmar at the telephone number

listed below

8 of 8

.

All specifications are subject to change without notice.

Printed in Canada. D 352 - 06/00.

Loading...

Loading...