Tecfluid LC Series User Manual

Float Level Switch

English Version

Series

instrumentation

for fluids

LC-30 / LC-31 / LC-M11 / LC-M12

User’s Manual

RECEPTION

Check that the level instrument is mechanically correct by means of the

following inspection:

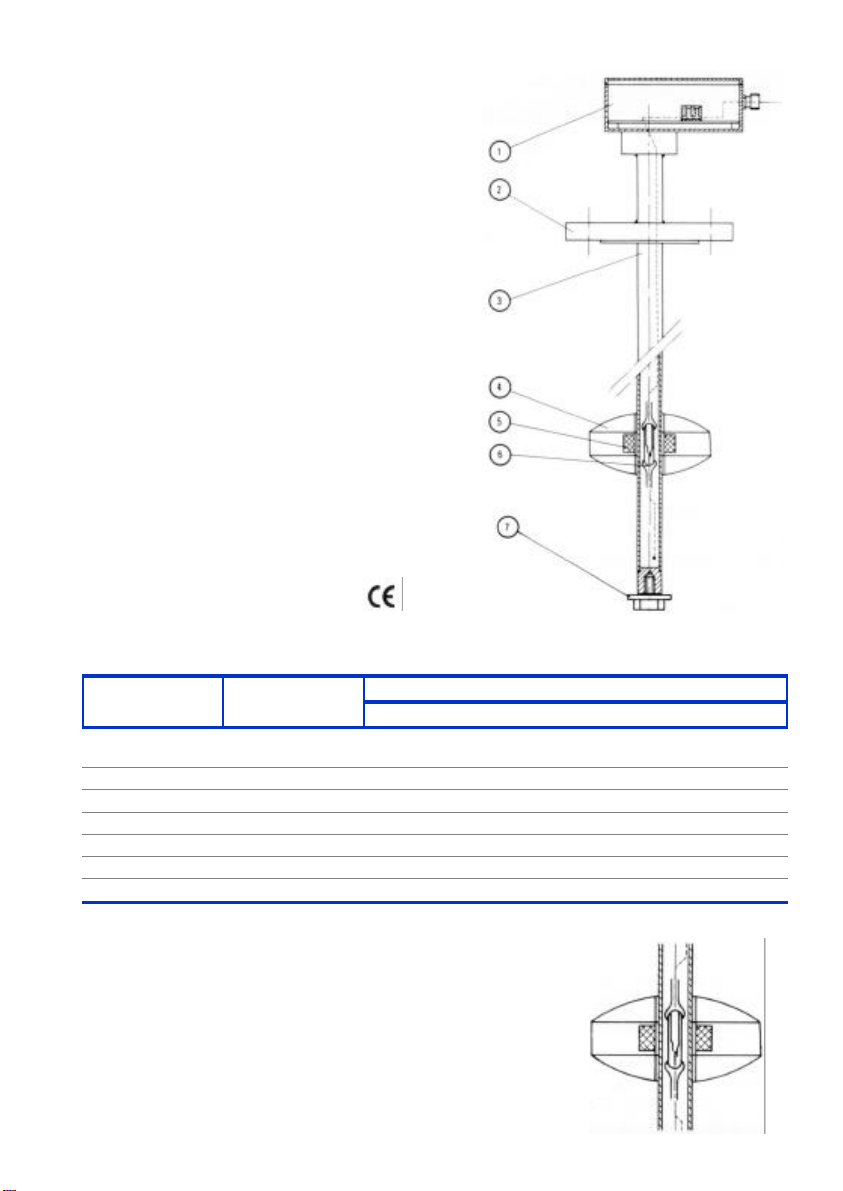

− The float (4) slides smoothly along the rod (3) (do it carefully by hand

in moving the float up and down).

− The rod (3) does not have any shock and is not bent.

− The bottom float stop (7) at the rod is in place.

Check with a multimeter that when the float slides along the rod, the

reed switch is activated in changing the output from NO to NC or vice

versa (depending on the wiring according to attached diagram).

Check that the switching points correspond to the required ones.

Check that the float density is inferior than the density of the liquid and

that the float is in the correct position (the mark UP engraved at the top

of the float indicates that this side of the float must be up).

INSTALLATION

The mounting of the level switch is vertical. The float level varies

accordingly with the level of the liquid.

Mount the seal on the flange or the coupling thread.

Introduce with care the float through the mounting hole until the flange

or coupling thread couples with the tank. Fix the flange with the

appropriate nuts & bolts.

You could mount, if the installation so require, the float by the inside of

the tank, in removing the bottom float stop (7).

In the case of a coupling thread, turn until tight. Do not apply torques

greater than 60 Nm.

REED SWITCHES

The LC’s series has two types of contacts for

level indication, RSC and Bi-stable RBC. The

difference is in the status of the contact once

the float has passed the contact.

Series RSC

The RSC is a reed switch without “memory”. It

is only activated in presence of the magnetic

field of the float. If the float moves away from

position of the switch, the switch returns to it’s

non-active position, which is the same for the

float being above or below the switch.

This system provides an indication of when the

level is at the same position as the reed switch

but will not provide an indication of the level

away from this point. That is, it provides an

indication of actual level but not high or low

level.

Series Bi-stable RBC

The bi-stable RBC reed switch remains in it’s

switched position after the float has passed. It

will remain in one position when the float is

below and remains in the opposite position

while the float is above the reed switch. This

provides a High/Low indication but not indicate

the exact position of the level.

C-MI-LC30 Rev.: 0

Technical Data

• Mounting: Vertical.

• Connection: DN-40 PN-16 DIN 2501 Flange.

R 1½” BSP thead.

(Others available on request).

• Maximum length: AISI-316 ... 6000 mm.

PVC, PTFE ... 2500 mm.

PVC, PTFE ... 6000 mm

(internal AISI-316).

• Precision: ± 2 mm.

• Hysteresis: ± 4 mm.

• Working pressure:

PN-16 AISI-316.

PVC, PTFE with internal AISI-316 tube.

PN-10 PVC, PTFE.

• Liquid temperature:

-20ºC...+150ºC en AISI-316, PTFE.

0ºC...+50ºC PVC.

• Ambient temperature:

-20ºC...+60ºC AISI-316, PTFE.

0ºC...+50ºC PVC.

• Liquid density: From 0,45 to 3 kg/l.

• Liquid viscosity: Maximum 1500 cSt.

• Contacts: Reed 1 A 220 V.

(maximum 9 with minimum separation

of 20 mm)

Conforms with Directive 73 / 23 / CEE

CONSTRUCTION

No. Piece Materials

1 Enclosure

2 Connection AISI-316 PVC PTFE

3 Rod AISI-316 PVC PTFE

4 Float AISI-316 PVC PTFE

5 Magnet Alnico Alnico Alnico

6 Reed switch - - 7 Float stop AISI-316 PVC PTFE

LC-.../INOX LC-.../PVC LC-.../PTFE

DIN 43650/

Aluminium

OPERATION

Inside the guide tube, reed switches are mounted at the

alarm/control points..

As the float passes the position where a reed switch is

located, the magnetic field from the float actives the switch.

The maximum number of alarm or control points is 9.

2

DIN 43650/

Aluminium

DIN 43650/

Aluminium

Loading...

Loading...