Tecfluid FLOMID User Manual

Electromagnetic

sensor

instrumentation

for fluids

Series

FLOMID FX

Instructions Manual

Conforms with the Pressure Equipment Directive 97/23/EC.

This equipment is considered as being a pressure accessory and NOT a safety accessory as defined in

!

the 97/23/EC directive, Article 1, paragraph 2.1.3.

R-MI-FlomidFX Rev.: 0

English version

0830

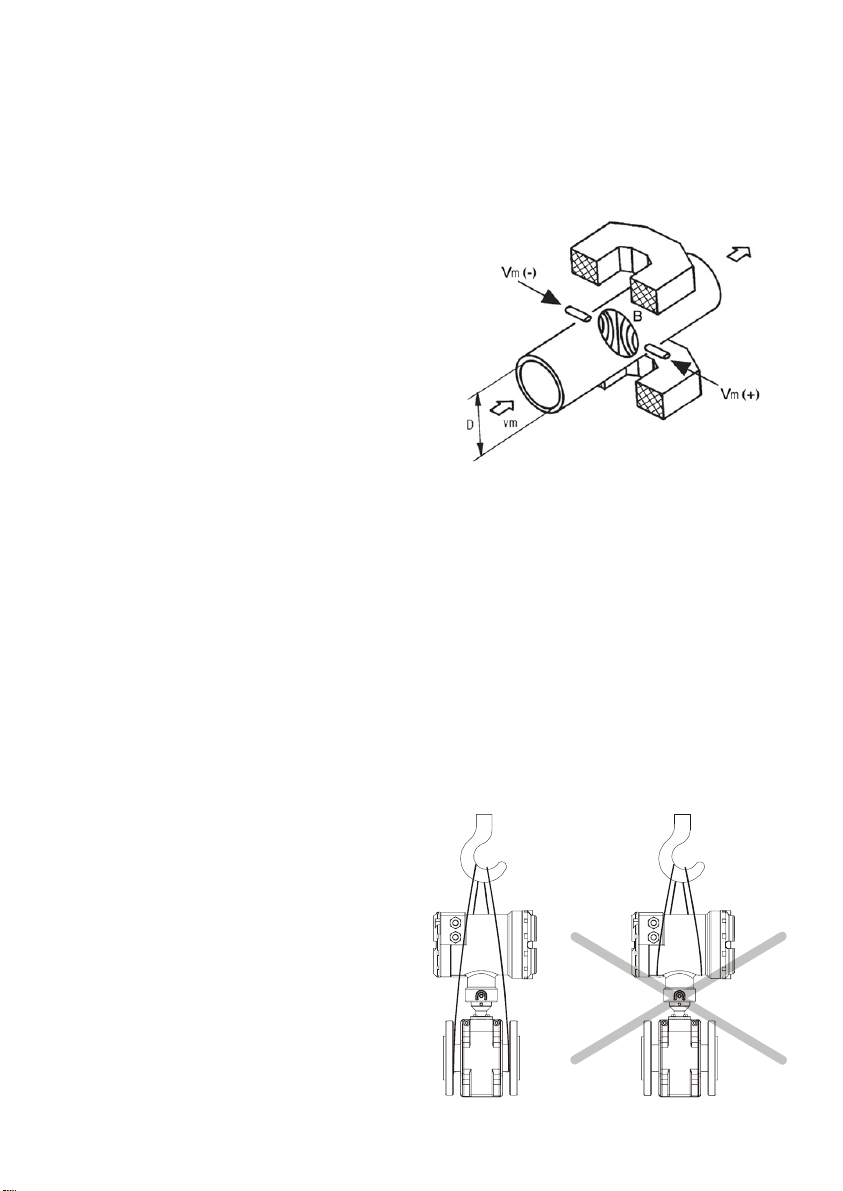

WORKING PRINCIPLE

The Flomid electromagnetic flowmeters , are based on Faraday’s induction law.

When an electrically conductive liquid flows through a magnetic field, perpendicular to the flow

direction, it induces a voltage V

, proportional to the liquid velocity.

m

Two electrodes in contact with the liquid and positioned perpendicular to the magnetic field, sense

this voltage V

.

m

Vm = B·vm·D

Where:

V

= Measured voltage in the electrodes.

m

B = Magnetic flux density

v

= Average liquid velocity

m

D = Pipe diameter.

RECEPTION

The FLOMID electromagnetic flowmeters are supplied conveniently packed for transport together

with their instruction manual for installation and operation.

All the flowmeters have been verified in our calibration rigs to obtain the factor Fc for each sensor.

Disassembly

Unpack the instrument carefully, removing any remains of the packing from the inside of the

sensor. Do not remove the grease from the neck that couples to the electronics housing.

Storage temperature

Sensors linings of : PTFE and PVDF -20ºC ...... +60ºC

PP and EBONITE -5ºC ...... +50ºC

HANDLING

It should always be done with care and

without knocks.

The large diameter sensors have rings

for holding the elevation elements. If the

flowmeter is held using slings, these

should hold on the sensor and not on the

electronics housing (see the drawing).

2

INSTALLATION

This should be made in a point that guarantees that the pipe is always completely full.

Avoid high points of the pipes where air pockets usually form, or pipes with falling flow where

vacuums can form.

Partially full pipes can produce important reading errors.

Flow rate measurement

with open discharge

makes it necessary to

install the flowmeter in a

pipe section with a siphon

which avoids stagnation of

air in the sensor.

Sensor position

The most adequate position is

with the electrodes in a

horizontal plane. In this way,

deposits of particles on the

electrodes are avoided.

Straight pipe sections

Are necessary before and after the

sensor. The minimum distances are

the following:

Upstream : 5 DN

Downstream : 3 DN

In installations with turbulent flow it

may be necessary to increase these

distances.

Mixtures

If liquids of different conductivities are mixed it is

necessary to install the sensor a minimum of 30 DN

from the point of mixture in order to obtain a uniform

conductivity of the liquid and stabilize the readings.

If this distance is less, the readings may be unstable.

3

Loading...

Loading...