suzuki GSF1200, GSF1200S Service Manual

GSF1200/GSF1200S

9 9 5 0 0 - 3 9 2 8 0 - 0 1 E

Downloaded from www.Manualsbooks.com manuals search

FOREWORD

This manual contains an introductory description on the SUZUKI GSF1200/GSF1200S and procedures for its inspection/service and overhaul of its main components.

Other information considered as generally known is not included.

Read the GENERAL INFORMATION section to familiarize yourself with the motorcycle and its maintenance. Use this section as well as other sections to use as a guide for proper inspection and service.

This manual will help you know the motorcycle better so that you can assure your customers of fast and reliable service.

*This manual has been prepared on the basis of the latest specifications at the time of publication. If modifications have been made since then, differences may exist between the content of this manual and the actual motorcycle.

*Illustrations in this manual are used to show the basic principles of operation and work procedures. They may not represent the actual motorcycle exactly in detail.

*This manual is written for persons who have enough knowledge, skills and tools, including special tools, for servicing SUZUKI motorcycles. If you do not have the proper knowledge and tools, ask your authorized SUZUKI motorcycle dealer to help you.

!WARNING

Inexperienced mechanics or mechanics without the proper tools and equipment may not be able to properly perform the services described in this manual.

Improper repair may result in injury to the mechanic and may render the motorcycle unsafe for the rider and passenger.

© COPYRIGHT SUZUKI MOTOR CORPORATION 2005

Downloaded from www.Manualsbooks.com manuals search

TABLE OF CONTENTS

Precautions................................................................... |

.. 00-i |

|

Precautions.................................................................... |

00-1 |

|

General Information...................................................... |

..0-i |

|

General Information............................................... |

0A-1 |

|

Maintenance and Lubrication................................. |

0B-1 |

|

Service |

Data........................................................... |

0C-1 |

Engine............................................................................... |

|

..1-i |

Precautions...................................................................... |

1-1 |

|

Engine General Information and Diagnosis........... |

1A-1 |

|

Emission Control Devices...................................... |

1B-1 |

|

Engine Mechanical................................................. |

1D-1 |

|

Engine Lubrication System .................................... |

1E-1 |

|

Engine Cooling System.......................................... |

1F-1 |

|

FuelSystem........................................................... |

1G-1 |

|

Ignition |

System....................................................... |

1H-1 |

Starting System....................................................... |

1I-1 |

|

Charging |

System..................................................... |

1J-1 |

ExhaustSystem..................................................... |

1K-1 |

|

Suspension...................................................................... |

..2-i |

|

Precautions...................................................................... |

2-1 |

|

Suspension General Diagnosis.............................. |

2A-1 |

|

Front Suspension................................................... |

2B-1 |

|

RearSuspension.................................................... |

2C-1 |

|

Wheels and Tires................................................... |

2D-1 |

|

Driveline / Axle................................................................ |

.. 3-i |

|

Precautions...................................................................... |

3-1 |

|

Drive Chain / Drive Train / Drive Shaft................... |

3A-1 |

|

Brake................................................................................. |

|

..4-i |

Precautions...................................................................... |

4-1 |

|

Brake Control System and Diagnosis.................... |

4A-1 |

|

Front Brakes........................................................... |

4B-1 |

|

RearBrakes........................................................... |

4C-1 |

|

Transmission / Transaxle............................................ |

.. 5-i |

|

Precautions...................................................................... |

5-1 |

|

Manual Transmission............................................. |

5B-1 |

|

Clutch ..................................................................... |

|

5C-1 |

Steering............................................................................ |

|

.. 6-i |

Precautions...................................................................... |

6-1 |

|

Steering General Diagnosis................................... |

6A-1 |

|

Steering / Handlebar.............................................. |

6B-1 |

|

Body and Accessories.................................................. |

.. 9-i |

|

Precautions...................................................................... |

9-1 |

|

Wiring Systems...................................................... |

9A-1 |

|

Lighting Systems.................................................... |

9B-1 |

|

Combination Meter / Fuel Meter / Horn.................. |

9C-1 |

|

Exterior Parts......................................................... |

9D-1 |

|

BodyStructure....................................................... |

9E-1 |

|

00

0

1

2

3

4

5

6

9

Downloaded from www.Manualsbooks.com manuals search

Downloaded from www.Manualsbooks.com manuals search

|

|

Table of Contents 00- i |

||

|

|

|

|

|

|

Section 00 |

|

|

|

|

Precautions |

00 |

||

|

|

|

||

|

CONTENTS |

|

|

|

Precautions.................................................... |

00-1 |

General Precautions................................................. |

00-1 |

|

Precautions |

00-1 |

Precautions for Electrical Circuit Service.............. |

00-2 |

|

|

|

|

||

Warning / Caution / Note..................... |

00-1 |

|

|

|

Downloaded from www.Manualsbooks.com manuals search

00-1 Precautions:

Precautions

Precautions

Warning / Caution / Note

B649G10000001

Please read this manual and follow its instructions carefully. Toemphasize special information, the symbol and the words WARNING, CAUTION and NOTE have special meanings. Pay special attention to the messages highlighted by these signal words.

! WARNING

Indicates a potential hazard that could result in death or injury.

! CAUTION

Indicates a potential hazard that could result in motorcycle damage.

NOTE

Indicates special information to make maintenance easier or instructions clearer.

Please note, however, that the warnings and cautions contained in this manual cannot possibly cover all potential hazards relating to the servicing, or lack of servicing, of the motorcycle. In addition to the WARNINGS and CAUTIONS stated, you must use good judgement and basic mechanical safety principles. If you are unsure about how to perform a particular service operation, ask a more experienced mechanic for advice.

General Precautions

B649G10000002

!WARNING

•Proper service and repair proceduresare important for the safety of the service mechanic and the safety and reliabilityof the motorcycle.

•When 2 or more persons work together, pay attention to the safety of eachother.

•When it is necessary to run the engine indoors, make sure that exhaust gasis forced outdoors.

•When working with toxic or flammable materials, make sure that the area you work in is well-ventilated and that you follow all of the materialmanufacturer’s instructions.

•Never use gasoline as a cleaning solvent.

•Toavoid getting burned, do not touch the engine, engine oil, oil cooler and exhaust system until they have cooled.

•After servicing the fuel, oil, exhaust or brake systems, check all lines andfittings related to the system for leaks.

!CAUTION

•If parts replacement is necessary,replace the parts with Suzuki Genuine Parts or their equivalent.

•When removing partsthat are to be reused, keep them arranged in an orderly manner so that they may be reinstalled in the proper order and orientation.

•Be sure to use special toolswhen instructed.

•Make sure that all parts used in reassembly are clean. Lubricatethem when specified.

•Use the specified lubricant, bond,or sealant.

•When removing the battery, disconnect the negative (–) cable first and then the positive cable.

•When reconnecting the battery, connect the positive cable first and then the negative (–) cable, and replace the terminal cover on the positive terminal.

•When performing service to electrical parts, if the service procedures not require use of battery power, disconnect the negative (–) cable the battery.

•When tightening the cylinder head and case bolts and nuts, tighten the larger sizes first. Always tighten the bolts and nuts diagonally from the inside working out and to the specified tighteningtorque.

•Whenever you remove oil seals, gaskets, packing, O-rings, locking washers, selflocking nuts, cotter pins, circlips and certain other parts as specified, be sureto replace them with new ones. Also, before installing these new parts, be sure to remove any left over material from the mating surfaces.

•Never reuse a circlip. When installing a new circlip, take care not to expand the end gap larger than required to slip the circlip over the shaft. After installing a circlip, always ensure that it iscompletely seated in its groove and securely fitted.

Downloaded from www.Manualsbooks.com manuals search

Precautions: 00-2

•Use a torque wrench to tightenfasteners to the specified torque. Wipe off grease and oil if a thread is smeared withthem.

•After reassembling, check partsfor tightness and proper operation.

•Toprotect the environment, do not unlawfully dispose of used motor oil, engine coolant and other fluids:batteries, and tires.

•Toprotect Earth’s natural resources, properly dispose of used motorcycleand parts.

Precautions for Electrical Circuit Service

B649G10000003

When handling the electrical parts or servicing the ABS system, observe the following points for the safety of the system.

Electrical Parts

Connector / Coupler

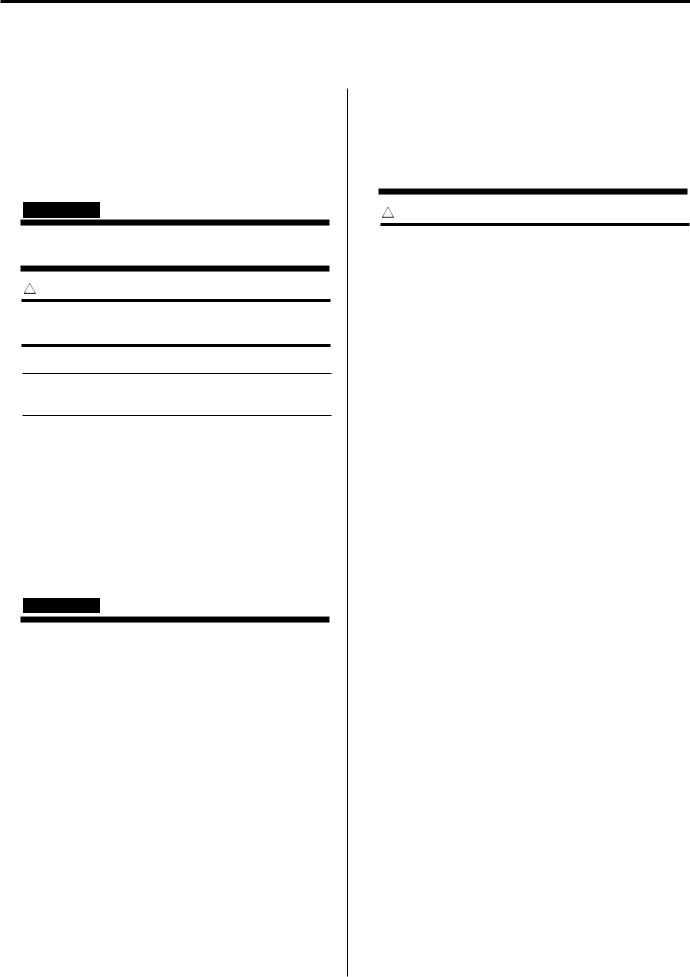

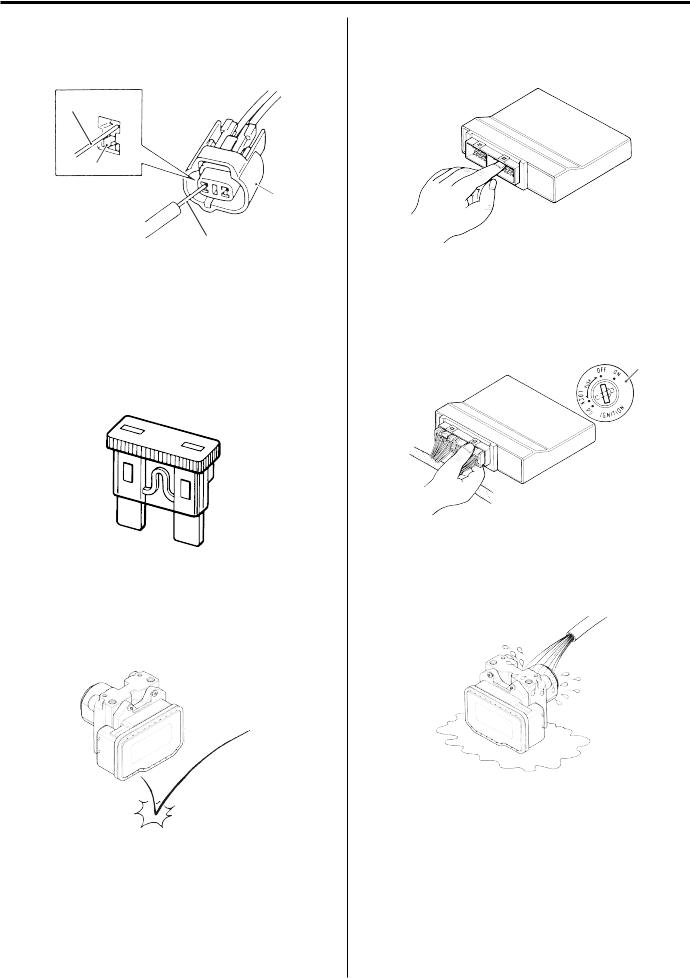

•When connecting a connector, be sure to push it in until a click is felt.

I310G1000001-01

•With a lock type coupler, be sure to release the lock when disconnecting, and push it in fully till the lock works when connecting it.

•When disconnecting the coupler, be sure to hold the coupler body and do not pull the lead wires.

•Inspect each terminal on the connector/couplerfor looseness or bending.

•Inspect each terminal for corrosion and contamination. The terminals must be clean andfree of any foreign material which could impede proper terminal contact.

I310G1000002-01

•Inspect each lead wire circuit for poor connection by shaking it by hand lightly. If any abnormal condition is found, repair or replace.

I310G1000003-01

•When taking measurements at electrical connectors using a tester probe, be sure to insert the probefrom the wire harness side (backside) of the connector/ coupler.

2

1

I649G1000013-01

1. Coupler |

2. Probe |

|

|

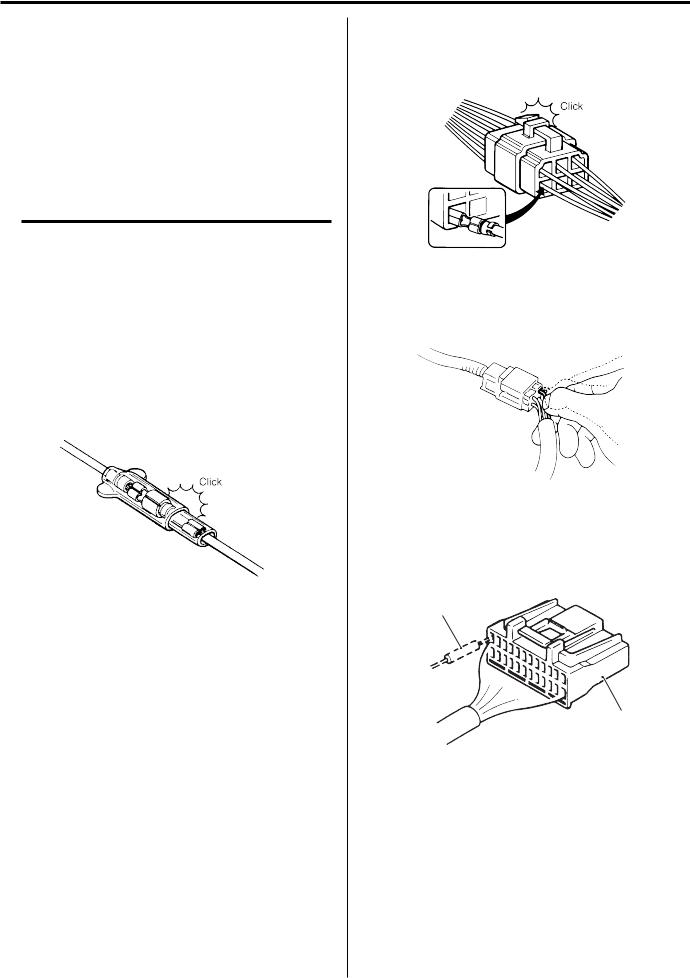

•When connecting meter probe from the terminal side of the coupler (connection from harness side not being possible), use extra care not to force and cause the male terminal to bend or the female terminal to open. Connect the probe as shown to avoid opening of female terminal. Never push in the probe where male terminal is supposed to fit.

Downloaded from www.Manualsbooks.com manuals search

00-3 Precautions:

• Check the male connector for bend and female |

• Be careful not to touch the electrical terminals of the |

connector for excessive opening. Also check the |

Ignitor unit and ABS control unit/HU. The static |

coupler for locking (looseness), corrosion, dust,etc. |

electricity from your body may damage this part. |

|

|

4 |

|

|

|

|

|

|

“A” |

|

|

||

|

|

|

|

3 |

|

|

|

|

|

|

4 |

|

|

|

|

|

|

I649G1000030-01 |

I310G1000008-01 |

|

|

|

|

|

|

||

|

3. Coupler |

|

4. Probe |

“A”: Where male terminal fits |

• When disconnecting and connecting the Ignitor unit |

|

|

|

|

|

|

||

Fuse |

|

|

|

and ABS control unit/HU couplers, make sure toturn |

||

|

|

|

OFF the ignition switch, or electronic parts mayget |

|||

• When a fuse blows, always investigate thecause, |

||||||

damaged. |

||||||

|

correct it and then replace the fuse. |

|

||||

• Do not use a fuse of a different capacity. |

1 |

|||||

• Do not use wire or any other substitute for thefuse. |

||||||

|

||||||

|

|

|

I649G1000031-01 |

|

|

|

|

|

|

|

|

1. Ignition S/W |

|

|

I649G1000001-01 |

|

|

|

|

• Never allow dust or water to contact the ABScontrol |

||||

|

||||

Ignitor unit / Various sensors / ABS control unit / HU |

unit/HU. |

|||

• Since each component is a high-precision part,great |

|

|

|

|

care should be taken not to apply any sharp impacts |

|

|

|

|

during removal and installation. |

|

|

|

|

I649G1000004-01

I649G1000003-01

Downloaded from www.Manualsbooks.com manuals search

Precautions: 00-4

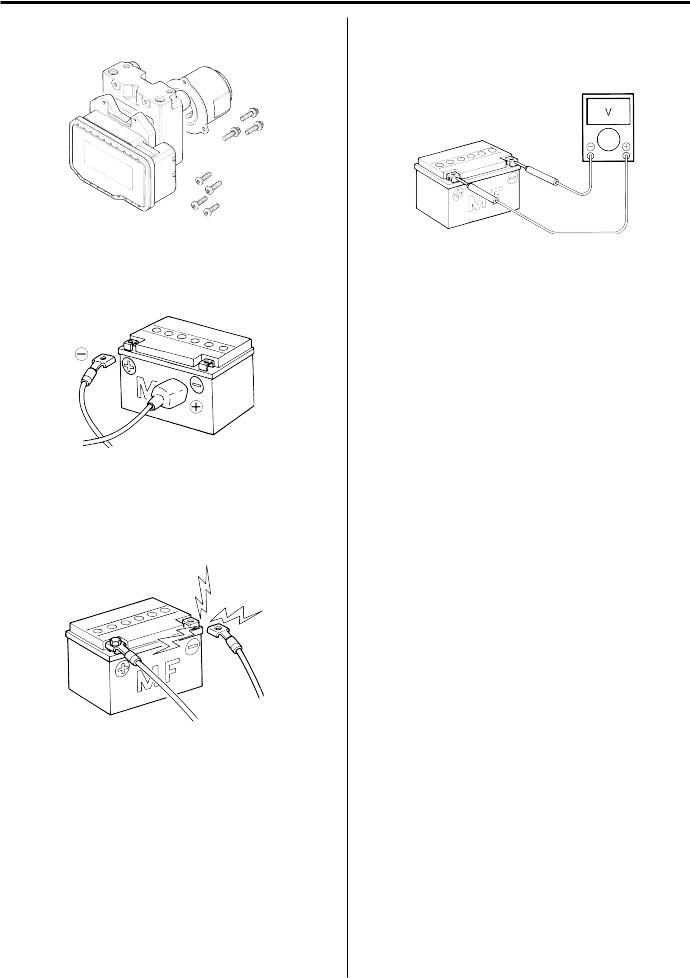

•The ABS control unit/HU cannot bedisassembled. Replace the whole unit with a new one.

I649G1000005-01

•Battery connection in reverse polarity is strictly prohibited. Such a wrong connection will damage the components of the ABS control unit/HU instantly when reverse power is applied.

I649G1000006-01

•Removing any battery terminal of a running engine is strictly prohibited. The moment such removal is made, damaging counter electromotive force will be applied to the Ignition unit and ABS control unit/HU which may result in serious damage.

I310G1000011-01

•Before measuring voltage at each terminal, check to make sure that battery voltage is 11 V or higher. Terminal voltage check at low battery voltage will lead to erroneous diagnosis.

I310G1000012-01

•Never connect any tester (voltmeter, ohmmeter, or whatever) to the Ignition and ABS control unit/HU when its coupler is disconnected. Otherwise, damage to Ignitor and ABS control unit/HU may result.

•Never connect an ohmmeter to the Ignitor and ABS control unit/HU with its coupler connected. If attempted, damage to Ignitor and ABS control unit/HU or sensors may result.

•Be sure to use a specifiedvoltmeter/ohmmeter. Otherwise, accurate measurements may notbe obtained and personal injury may result.

Electrical Circuit Inspection Procedure

While there are various methods for electrical circuit inspection, described here is a general method to check for open and short circuit using an ohmmeter and a voltmeter.

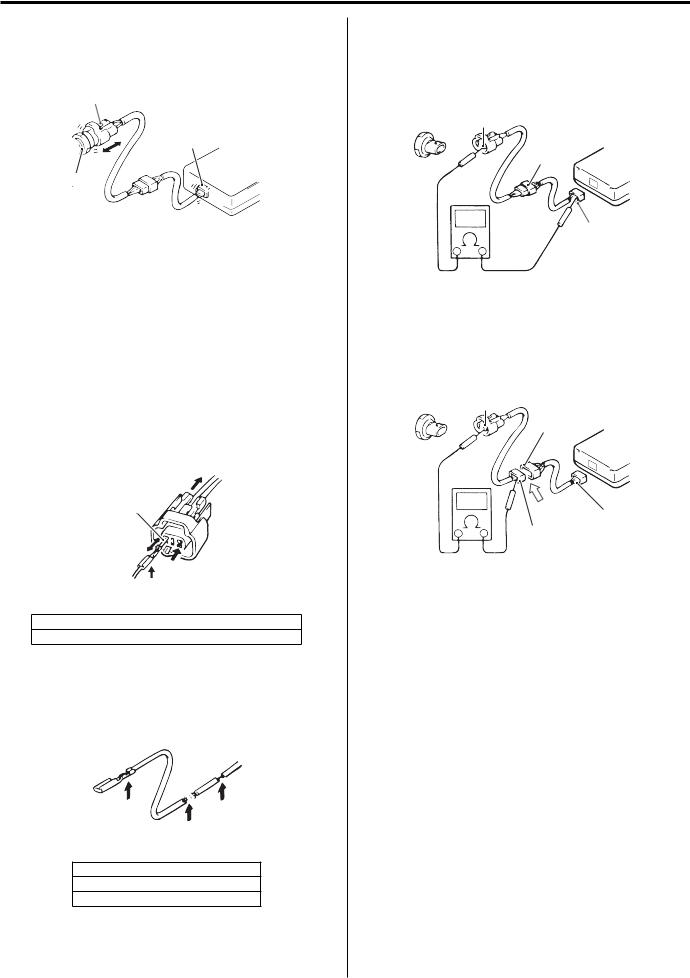

Open circuit check

Possible causes for the open circuit are as follows. As the cause can exist in the connector/coupler or terminal, they need to be checked carefully.

•Loose connection of connector/coupler

•Poor contact of terminal (due to dirt, corrosion or rust, poor contact tension, entry of foreign object etc.)

•Wire harness being open.

•Poor terminal-to-wire connection.

When checking system circuits including an electronic control unit such as ignitor, ABS control unit/HU, etc., it is important to perform careful check, starting with items which are easier to check.

Downloaded from www.Manualsbooks.com manuals search

00-5 Precautions:

1)Disconnect the negative (–) cable from the battery.

2)Check each connector/coupler at both ends of the circuit being checked for loose connection. Also check for condition of the coupler lock ifequipped.

“A”

“A”

Ignitor

1

I649G1000026-01

1. Sensor |

“A”: Check for loose connection |

|

|

3)Using a test male terminal, check the female terminals of the circuit being checked for contact tension.

Check each terminal visually for poor contact (possibly caused by dirt, corrosion, rust, entry of foreign object, etc.). At the same time, check to make sure that each terminal is fully inserted in the coupler and locked.

If contact tension is not enough, rectify the contact to increase tension or replace. The terminals must be clean and free of any foreign material which could impede proper terminal contact.

“B”

“C”

I649G1000027-01

“B”: Check contact tension by inserting and removing.

“C”: Check each terminal for bend and proper alignment.

4)Using continuity inspect or voltage check procedure as described below, inspect the wire harness terminals for open circuit and poor connection. Locate abnormality, if any.

“D” “F”

“E”

I649G1000028-01

”D”: Looseness of crimping

“E”: Open

“F”: Thin wire (A few strands left)

Continuity check

1)Measure resistance across coupler “B” (between “A” and “C” in figure).

If no continuity is indicated (infinity or over limit), the circuit is open between terminals “A” and “C”.

“A”

“B” Ignitor

“C”

I649G1000019-03

2)Disconnect the coupler “B” and measureresistance between couplers “A” and “B-1”.

If no continuity is indicated, the circuit is open between couplers “A” and “B-1”. If continuity is indicated, there is an open circuit between couplers “B-2” and “C” or an abnormality in coupler “B-2” or coupler “C”.

“A”

“B-2”

Ignitor

“B” “C”

“B-1”

I649G1000029-02

Voltage check

If voltage is supplied to the circuit being checked, voltage check can be used as circuit check.

1)With all connectors/couplers connected andvoltage applied to the circuit being checked, measure voltage between each terminal and bodyground.

2)If measurements were taken as shown in figureat the right and results are as listed below, it means that the circuit is open between terminals “A” and “B”.

Voltage between

“A” and body ground: Approx. 5V “B” and body ground: Approx. 5V “C” and body ground: 0 V

Downloaded from www.Manualsbooks.com manuals search

Precautions: 00-6

3)Also, if measured values are as listed below, a resistance (abnormality) exists which causes the voltage drop in the circuit between terminals “A” and “B”.

Voltage between

“A” and body ground: Approx. 5 V

“B” and body ground: Approx. 5 V – 2 V voltage drop

“C” and body ground: 3 V – 2 V voltage drop

“A”

Ignitor

“B”

“C”

5V

|

|

5V |

|

0V |

5V |

|

|

|

“A” |

|

“B” “C” |

I649G1000021-02

Short circuit check (Wire harness to ground)

1)Disconnect the negative (–) cable from thebattery.

2)Disconnect the connectors/couplers at both endsof the circuit to be checked.

NOTE

If the circuit to be checked branches to other parts as shown, disconnect all connectors/ couplers of those parts. Otherwise, diagnosis will be misled.

3)Measure resistance between terminal at one endof circuit (“A” terminal in figure) and body ground. If continuity is indicated, there is a short circuit to ground between terminals “A” and “C”.

“A”

“D”

“B” Ignitor

“C”

“E”

5V

“A” “C”

I649G1000022-02

“D”: To other parts |

“E”: Other parts |

|

|

4)Disconnect the connector/coupler included incircuit (coupler “B”) and measure resistance between terminal “A” and body ground. If continuity is indicated, the circuit is shorted to the ground between terminals “A” and “B”.

“A”

“D”

Ignitor

“B” “C”

I649G1000023-02

“D”: To other parts

Downloaded from www.Manualsbooks.com manuals search

00-7 Precautions:

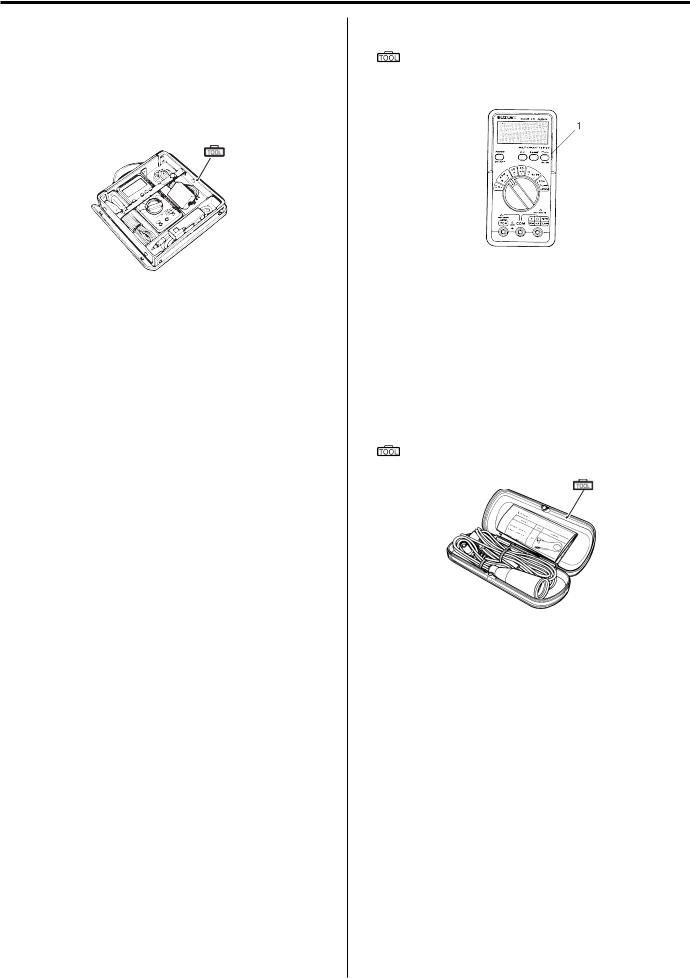

Using The Multi-Circuit Testers |

• After using the tester, turn the power off. |

|

• |

Use the Suzuki multi-circuit tester set. |

Special tool |

|

|

|

• |

Use well-charged batteries in the tester. |

: 09900–25008 (Multi-circuit tester set) |

•Be sure to set the tester to the correct testingrange.

Special tool

(A): 09900–25008 (Multi-circuit tester set)

(A): 09900–25008 (Multi-circuit tester set)

(A)

|

|

I649G1000002-01 |

|

I649G1000024-02 |

|

NOTE |

|

|

|

||

Using the testers |

|

|

|

|

• When connecting the multi-circuit tester, |

||

• Incorrectly connecting the (+) and (–) probesmay |

|

use the needle pointed probe to the back |

|

cause the inside of the tester to burnout. |

|

side of the lead wire coupler andconnect |

|

• If the voltage and current are not known,make |

|

the probes of tester to them. |

|

|

• Use the needle pointed probe to prevent |

||

measurements using the highest range. |

|

||

• When measuring the resistance with themulti-circuit |

|

the rubber of the water proof couplerfrom |

|

|

damage. |

||

tester (1), will be shown as 10.00 M and “1” |

|

||

|

|

||

flashes in the display. |

|

|

|

Special tool |

|||

• Check that no voltage is applied before making the |

|||

|

(A): 09900–25009 (Needle pointed probe set) |

||

measurement. If voltage is applied the tester maybe |

|

||

|

|

||

damaged. |

|

(A) |

|

|

|

||

I649G1000025-02

Downloaded from www.Manualsbooks.com manuals search

Table of Contents 0- i

Section 0

General Information

0

CONTENTS

General Information..................................... |

0A-1 |

General Description............................................. |

0A-1 |

Symbols .............................................................. |

0A-1 |

Abbreviations ...................................................... |

0A-2 |

Vehicle Side View ............................................... |

0A-3 |

Vehicle Identification Number ............................. |

0A-4 |

Fuel and Oil Recommendation ........................... |

0A-4 |

BREAK-IN Procedures........................................ |

0A-4 |

CylinderIdentification.......................................... |

0A-5 |

Country and Area Codes .................................... |

0A-5 |

Wire Color Symbols ............................................ |

0A-5 |

Warning, Caution and Information |

|

Labels Location................................................. |

0A-6 |

ComponentLocation........................................... |

0A-7 |

Electrical Components Location ......................... |

0A-7 |

Specifications....................................................... |

0A-9 |

Specifications ...................................................... |

0A-9 |

Special Tools and Equipment........................... |

0A-11 |

Special Tools .................................................... |

0A-11 |

Maintenance and Lubrication................. |

0B-1 |

Precautions........................................................... |

0B-1 |

Precautions for Maintenance .............................. |

0B-1 |

General Description............................................. |

0B-1 |

Recommended Fluids and Lubricants................. |

0B-1 |

Scheduled Maintenance...................................... |

0B-2 |

Periodic Maintenance Schedule Chart................ |

0B-2 |

Lubrication Points ............................................... |

0B-3 |

Repair Instructions.............................................. |

0B-4 |

Air Cleaner Element Removal and Installation.... |

0B-4 |

Air Cleaner Element Inspection and Cleaning .... |

0B-4 |

Spark Plug Removal and Installation.................. |

0B-5 |

Spark Plug Inspection and Cleaning................... |

0B-6 |

Exhaust Pipe Bolt and Muffler Mounting Bolt |

|

Inspection.......................................................... |

0B-6 |

Valve Clearance Inspection and Adjustment ...... |

0B-7 |

Fuel Line Inspection............................................ |

0B-8 |

Engine Oil and Filter Replacement........................ |

0B-9 |

Throttle Cable Play Inspection |

|

and Adjustment ............................................... |

0B-10 |

Engine Idle Speed Inspection |

|

and Adjustment............................................... |

0B-11 |

Throttle Valve Synchronization......................... |

0B-11 |

PAIR System Inspection ................................... |

0B-11 |

Clutch System Inspection.................................. |

0B-11 |

Clutch Hose Replacement ................................ |

0B-12 |

Air Bleeding from Clutch Fluid Circuit ............... |

0B-12 |

Clutch Fluid Replacement ................................. |

0B-12 |

Drive Chain Inspection and Adjustment............ |

0B-12 |

Drive Chain Cleaning and Lubricating............... |

0B-13 |

Brake System Inspection .................................. |

0B-13 |

Rear Brake Light Switch Adjustment................. |

0B-15 |

Brake Hose Replacement................................. |

0B-15 |

Air Bleeding from Brake Fluid Circuit ................ |

0B-15 |

Brake Fluid Replacement.................................. |

0B-15 |

Tire Inspection................................................... |

0B-15 |

Steering System Inspection.............................. |

0B-16 |

Front Fork Inspection ........................................ |

0B-16 |

Rear Suspension Inspection............................. |

0B-16 |

Chassis Bolt and Nut Inspection ....................... |

0B-17 |

Compression Pressure Check .......................... |

0B-18 |

Oil Pressure Check........................................... |

0B-18 |

Specifications..................................................... |

0B-19 |

Tightening Torque Specifications...................... |

0B-19 |

Special Tools and Equipment........................... |

0B-19 |

Recommended Service Material....................... |

0B-19 |

SpecialTool...................................................... |

0B-19 |

Service Data............................................. |

0C-1 |

Specifications....................................................... |

0C-1 |

Service Data........................................................ |

0C-1 |

Tightening Torque Specifications........................ |

0C-7 |

Downloaded from www.Manualsbooks.com manuals search

0A-1 General Information:

General Information

General Description

Symbols

B649G10101001

Listed in the table below are the symbols indicating instructions and other information necessary for servicing. The meaning of each symbol is also included in the table.

Symbol |

Definition |

Torque control required.

Data beside it indicates specified torque. Apply oil.

Use engine oil unless otherwise specified. Apply molybdenum oil solution

(Mixture of engine oil and SUZUKl MOLY PASTE in a ratio of 1:1). Apply SUZUKI SUPER GREASE “A” or equivalent.

99000-25010

Apply SUZUKI MOLY PASTE or equivalent. 99000-25140

Apply SUZUKI SILICONE GREASE or equivalent. 99000-25100

Apply THERMO-GREASE or equivalent. 99000-59029

Apply SUZUKI BOND “1207B” or equivalent. 99000-31140

Apply SUZUKI BOND “1215” or equivalent. 99000-31110

Apply THREAD LOCK SUPER “1303” or equivalent. 99000-32030

Apply THREAD LOCK SUPER “1322” or equivalent. 99000-32110

Apply THREAD LOCK “1342” or equivalent. 99000-32050

Apply THREAD LOCK SUPER “1360” or equivalent. 99000-32130

Use fork oil or equivalent. 99000-99001-SS8

Apply or use brake fluid.

Measure in voltage range.

Measure in resistance range.

Measure in current range.

Measure in diode test range.

Measure in continuity test range.

Use special tool.

Indication of service data.

Do not reuse.

Note on reassembly.

Downloaded from www.Manualsbooks.com manuals search

General Information: 0A-2

Abbreviations |

|

H: |

|

||

B649G10101002 |

|

HC: Hydrocarbons |

A: |

|

I: |

ABDC: After Bottom Dead Center |

|

|

|

IG: Ignition |

|

ABS: Anti-lock Brake System AC |

|

|

|

J: |

|

Alternating Current |

|

|

|

|

|

ACL: Air Cleaner, Air Cleaner Box |

|

L: |

API: American Petroleum Institute |

|

|

|

LCD: Liquid Crystal Display |

|

ATDC: After Top Dead Center A/F: |

|

|

|

LED: Light Emitting Diode (Malfunction Indicator Lamp) |

|

Air Fuel Mixture |

|

|

|

LH: Left Hand |

|

B: |

|

|

|

M: |

|

BBDC: Before Bottom Dead Center |

|

|

|

Max: Maximum |

|

BTDC: Before Top Dead Center B+: |

|

|

|

MIL: Malfunction Indicator Lamp (LED) |

|

Battery Positive Voltage |

|

|

|

Min: Minimum |

|

C: |

|

|

|

N: |

|

CKP Sensor: Crankshaft Position Sensor (CKPS) |

|

|

|

NOx: Nitrogen Oxides |

|

CKT: Circuit |

|

|

|

O: |

|

CLP Switch: Clutch Lever Position Switch (Clutch |

|

|

|

OHC: Over Head Camshaft |

|

Switch) |

|

|

|

OPS: Oil Pressure Switch P: |

|

CO: Carbon Monoxide |

|

|

|

PCV: Positive Crankcase Ventilation (Crankcase |

|

CPU: Central Processing Unit |

|

|

|

Breather) |

|

D: |

|

|

|

R: |

|

DC: Direct Current |

|

|

|

RH: Right Hand |

|

DMC: Dealer Mode Coupler |

|

|

|

ROM: Read Only Memory |

|

DOHC: Double Over Head Camshaft |

|

|

|

S: |

|

DRL: Daytime Running Light |

|

|

|

SAE: Society of Automotive Engineers |

|

F: |

|

|

|

T: |

|

FTPC Valve: Fuel Tank Pressure Control Valve |

|

|

|

TP Sensor: Throttle Position Sensor (TPS) |

|

G: |

|

|

|

|

|

GEN: Generator |

|

|

GND: Ground |

|

|

GP Switch: Gear Position Switch |

|

|

|

|

|

Downloaded from www.Manualsbooks.com manuals search

0A-3 General Information:

Vehicle Side View

B649G10101003

NOTE

Difference between photographs and actual motorcycles may exist depending on the markets.

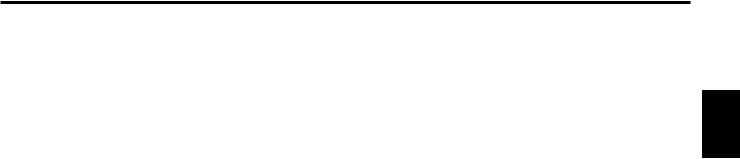

SUZUKI GSF1200 (2006-model)

Right Side

I649G1010008-01

Left Side

I649G1010009-01

SUZUKI GSF1200S (2006-model)

Right Side

I649G1010005-06

Left Side

I649G1010006-05

Downloaded from www.Manualsbooks.com manuals search

General Information: 0A-4

Vehicle Identification Number

B649G10101004

The frame serial number or V.I.N. (Vehicle Identification Number) “A” is stamped on the right side of the steering head pipe. The engine serial number “B” is located on the right side of the crankcase. These numbers are required especially for registering the machine and ordering spare parts.

“A”

I649G1010001-02

“B”

I649G1010002-03

Fuel and OilRecommendation

B649G10101005

Fuel (For USA)

Use only unleaded gasoline of at least 87 pump octane (R/2 + M/2) or 91 octane or higher rated by the research method.

Gasoline containing MTBE (Methyl Tertiary Butyl Ether), less than 10% ethanol, or less than 5% methanol with appropriate cosolvents and corrosion inhibitor is permissible.

Fuel (For Other Countries)

Gasoline used should be graded 91 octane (Research Method) or higher. Unleaded gasoline is recommended.

Engine Oil

Oil quality is a major contributor to your engine’s performance and life. Always select good quality engine oil. Use of SF/SG or SH/SJ in API with MA in JASO. Suzuki recommends the use of SAE 10W-40 engine oil. If SAE 10W-40 engine oil is not available, select an alternative according to the chart.

I310G1010005-01

Brake Fluid

Specification and classification: DOT4

! WARNING

Since the brake system of this motorcycle is filled with a glycol-based brake fluid by the manufacturer, do not use or mix different types of fluid such as silicone-based and petroleum-based fluid for refilling the system, otherwise serious damage will result.

Do not use any brake fluid taken from old or used or unsealed containers.

Never reuse brake fluid left over from a previous servicing, which has been stored for a long period.

Front Fork Oil

Use fork oil SS8 or an equivalent fork oil.

BREAK-IN Procedures

B649G10101007

During manufacture only the best possible materials are used and all machined parts are finished to a very high standard but it is still necessary to allow the moving parts to “BREAK-IN” before subjecting the engine to maximum stresses. The future performance and reliability of the engine depends on the care and restraint exercised during its early life. The general rules are asfollows.

1)Keep to these break-in engine speed limits:

Speed limits

Initial 800 km: Below 5 500 r/min Up to 1 600 km: Below 8 000 r/min Over 1 600 km: Below 11 000 r/min

2)Upon reaching an odometer reading of 1 600 km (1 000 miles) you can subject the motorcycle to full throttle operation. However, do not exceed 11 000r/ min at any time.

Downloaded from www.Manualsbooks.com manuals search

0A-5 General Information:

Cylinder Identification

B649G10101008

The four cylinders of this engine are identified as No.1, 2, 3 and No.4 cylinder, as counted from left to right (as viewed by the rider on the seat).

#1 |

#2 |

#3 |

#4 |

I649G1010010-01

Country and Area Codes

B649G10101009

The following codes stand for the applicable country(- ies) and area(-s).

Code |

Country |

Effective Frame No. |

|

or Area |

|||

|

|

||

GSF1200 K6 |

U.K. |

JS1CB112200100001 – |

|

(E-02) |

|||

|

|

||

|

|

|

|

GSF1200 K6 |

E.U. |

JS1CB112100100001 – |

|

(E-19) |

|||

|

|

||

|

|

|

|

GSF1200S K6 |

U.K. |

JS1CB111200100001 – |

|

(E-02) |

|||

|

|

||

|

|

|

|

GSF1200S K6 |

E.U. |

JS1CB111100100001 – |

|

(E-19) |

|||

|

|

||

|

|

|

|

GSF1200S K6 |

Australia |

JS1CB121300100001 – |

|

(E-24) |

|

|

|

GSF1200S K6 |

Canada |

JS1GV79A 62100001 – |

|

(E-28) |

|

|

Wire Color Symbols

|

|

|

B649G10101010 |

|

|

|

|

Symbol |

Wire Color |

Symbol |

Wire Color |

B |

Black |

Bl/B |

Blue with Black tracer |

Bl |

Blue |

Br/B |

Brown with Black tracer |

Br |

Brown |

G/B |

Green with Black tracer |

Dbr |

Dark brown |

G/Bl |

Green with Blue tracer |

Dg |

Dark green |

G/Y |

Green with Yellow tracer |

G |

Green |

O/G |

Orange with Green tracer |

Lg |

Light green |

O/R |

Orange with Red tracer |

W |

White |

O/W |

Orange with White tracer |

Y |

Yellow |

O/Y |

Orange with Yellow tracer |

B/Bl |

Black with Blue tracer |

P/B |

Pink with Black tracer |

B/Br |

Black with Brown tracer |

R/B |

Red with Black tracer |

B/G |

Black with Green tracer |

R/W |

Red with White tracer |

B/O |

Black with Orange tracer |

W/B |

White with Black tracer |

B/R |

Black with Red tracer |

Y/B |

Yellow with Black tracer |

B/W |

Black with White tracer |

Y/W |

Yellow with White tracer |

B/Y |

Black with Yellow tracer |

|

|

Downloaded from www.Manualsbooks.com manuals search

General Information: 0A-6

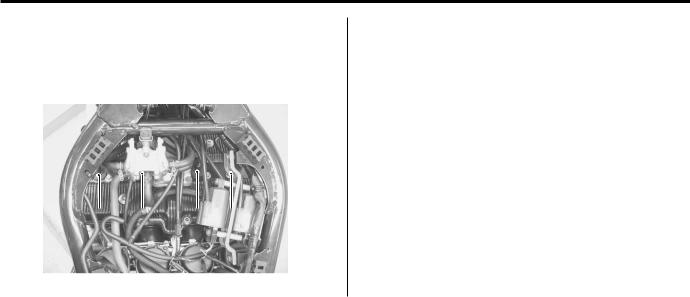

Warning, Caution and Information Labels Location

|

|

B649G10101011 |

[A] |

1 |

[C] |

|

2 |

6

8

7

|

3 |

|

|

|

5 |

|

|

|

4 |

|

|

[B] |

[D] |

10 |

|

|

|

9 |

4

I649G1010011-04

|

|

GSF1200 |

GSF1200S |

|

|

|

|

1. |

Noise label |

— |

For E-24 |

|

|

|

|

2. |

Information label |

— |

For E-28 |

|

|

|

|

3. |

Fuel caution label |

For E-02 |

For E-02, 24 |

|

|

|

|

4. |

Screen label |

— |

For E-02, 19, 24, 28 |

|

|

|

|

5. |

Warning steering label |

— |

For E-02, 19, 24, 28 |

|

|

|

|

6. |

Tire information label |

For E-02, 19 |

For E-02, 19, 24, 28 |

|

|

|

|

7. |

General warning label |

For E-02, 19 |

For E-02, 19, 24, 28 |

|

|

|

|

8. |

ICES Canada label |

— |

For E-28 |

|

|

|

|

9. |

I.D. plate |

For E-02, 19 |

For E-02, 19, 24 |

|

|

|

|

10. |

Safety plate |

— |

For E-28 |

|

|

|

|

[A]: |

Frame head (Left side) |

|

|

|

|

|

|

[B]: |

Cowling body |

|

|

|

|

|

|

[C]: |

Chain cover |

|

|

|

|

|

|

[D]: |

Frame side tube (Right side) |

|

|

|

|

|

|

Downloaded from www.Manualsbooks.com manuals search

0A-7 General Information:

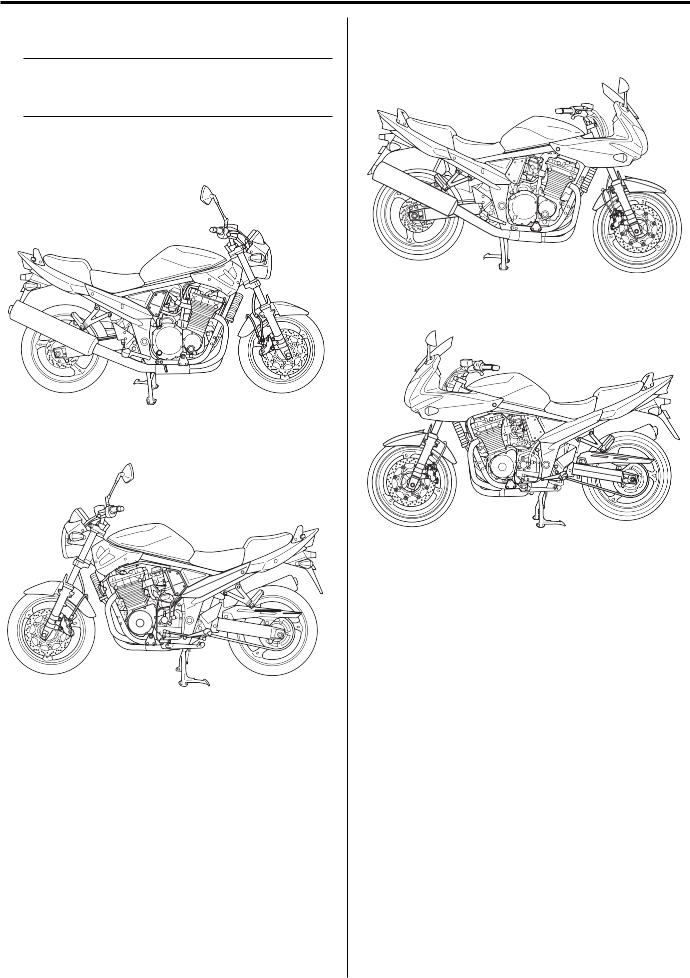

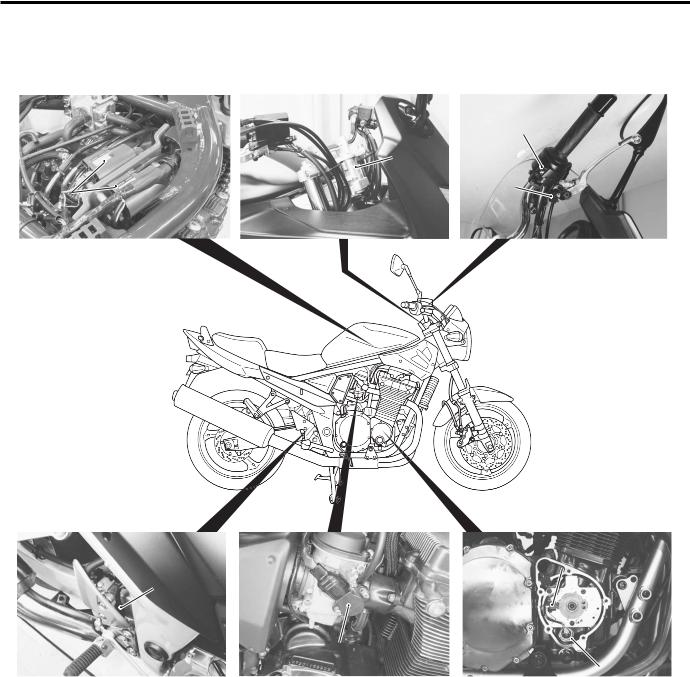

Component Location

Electrical ComponentsLocation

B649G10103001

3

|

2 |

1 |

4 |

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

I649G1010003-05 |

|

|

|

|

|

|

|

|

|

|

|

|

1. |

Ignition coil |

|

3. |

Handlebar switch (RH) |

|

5. |

Rear brake light switch |

7. |

CKP sensor |

|

|

|

|

|

|

|

|

|

|

|

|

2. |

Ignition switch |

|

4. |

Front brake light switch |

|

6. |

Throttle position sensor |

8. |

Oil pressure switch |

|

|

|

|

|

|

|

|

|

|

|

|

Downloaded from www.Manualsbooks.com manuals search

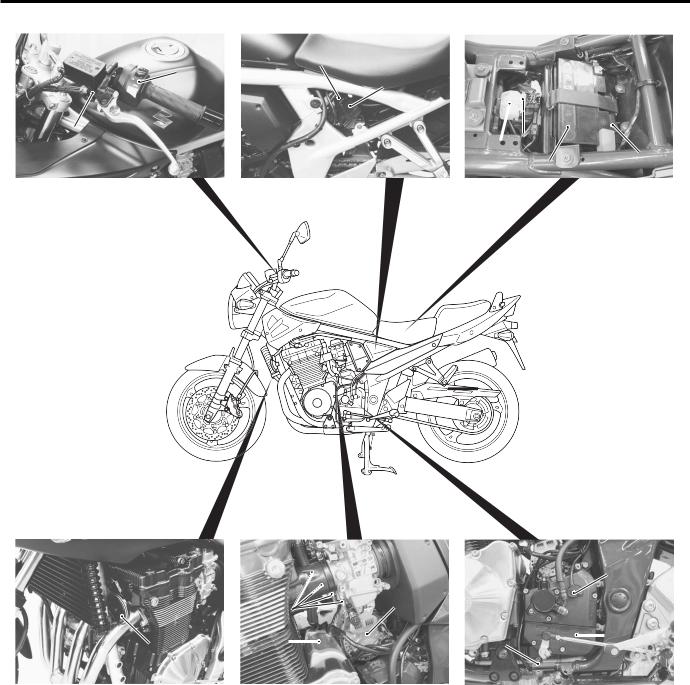

General Information: 0A-8

10 |

11 |

|

12

9

13 14

16

15

|

|

|

|

|

|

|

21 |

|||||

|

|

20 |

|

19 |

|

|

|

|

|

|

|

|

|

17 |

18 |

|

|

|

|

23 |

|

|

|

22 |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

I649G1010004-04 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

9. |

Clutch lever position switch |

14. |

Main fuse |

|

19. |

Generator |

|

|||||

|

|

|

|

|

|

|

|

|||||

10. |

Handlebar switch (LH) |

15. |

Battery |

|

20. |

Carburetor heater (For E-02, 19) |

|

|||||

|

|

|

|

|

||||||||

11. Fuse box |

16. Ignitor |

|

21. Speed sensor |

|

||||||||

|

|

|

|

|

|

|

|

|||||

12. |

Turn signal/Side-stand relay |

17. |

Horn |

|

22. |

Gear position switch |

|

|||||

|

|

|

|

|

|

|

|

|||||

13. |

Starter relay |

18. |

Starter motor |

|

23. |

Side-stand switch |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Downloaded from www.Manualsbooks.com manuals search

0A-9 General Information:

Specifications

Specifications

|

NOTE |

|

|

B649G10107001 |

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

These specifications are subject to change without notice. |

|

|

|

|||

|

|

|

|

|

|

|

|

Dimensions and dry mass |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Item |

|

Specification |

Remark |

|||

Overall length |

|

2 130 mm (83.9 in) |

|

|

|

||

Overall width |

|

790 mm (31.1 in) |

|

|

|

||

Overall height |

|

1 095 mm (43.1 in) |

GSF1200 |

||||

|

1 235 mm (48.6 in) |

GSF1200S |

|||||

|

|

|

|

||||

Wheelbase |

|

1480 mm (58.3 in) |

|

|

|

||

Ground clearance |

|

135 mm (5.3 in) |

|

|

|

||

Seat height |

|

785/805 mm (30.9/31.7 in) |

Low/High |

||||

Dry mass |

|

212 kg (467 lbs) |

GSF1200 |

||||

|

215 kg (474 lbs) |

GSF1200S |

|||||

|

|

|

|

||||

Engine |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Item |

|

Specification |

Remark |

|||

Type |

|

4-stroke, air-cooled, DOHC |

|

|

|

||

Number of cylinders |

|

4 |

|

|

|

||

Bore |

|

79.0 mm (3.110 in) |

|

|

|

||

Stroke |

|

59.0 mm (2.323 in) |

|

|

|

||

Displacement |

|

1 157 cm3 (70.6 cu. in) |

|

|

|

||

Compression ratio |

|

9.5 : 1 |

|

|

|

||

Carburetor |

|

MIKUNI BSR36 |

|

|

|

||

Air cleaner |

|

Non-woven fabric element |

|

|

|

||

Starter system |

|

Electric |

|

|

|

||

Lubrication system |

|

Wet sump |

|

|

|

||

Idle speed |

|

1 300 100 r/min |

E-28 |

||||

|

1 200 100 r/min |

Others |

|||||

|

|

|

|

||||

Drive train |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Item |

|

Specification |

Remark |

|||

Clutch |

|

Wet multi-plate type |

|

|

|

||

Transmission |

|

5-speed constant mesh |

|

|

|

||

Gearshift pattern |

|

1-down, 4-up |

|

|

|

||

Primary reduction ratio |

|

1.565 (72/46) |

|

|

|

||

|

|

|

Low |

2.384 (31/13) |

|

|

|

|

|

|

2nd |

1.631 (31/19) |

|

|

|

Gear ratios |

|

3rd |

1.250 (25/20) |

|

|

|

|

|

|

|

4th |

1.045 (23/22) |

|

|

|

|

|

|

Top |

0.913 (21/23) |

|

|

|

Final reduction ratio |

|

3.000 (45/15) |

|

|

|

||

Drive chain |

|

RK GB50GSVZ3, 116 links |

|

|

|

||

Downloaded from www.Manualsbooks.com manuals search

|

|

|

|

|

General Information: 0A-10 |

|

|

|

|

|

|

|

|

Chassis |

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

|

|

Specification |

Remark |

|

Front suspension |

|

|

Telescopic, coil spring, oil damped |

|

||

Rear suspension |

|

|

Link type, coil spring, oil damped |

|

||

Front suspension stroke |

|

|

|

130 mm (5.1 in) |

|

|

Rear wheel travel |

|

|

|

136 mm (5.4 in) |

|

|

Caster |

|

|

|

35 (right & left) |

|

|

Trail |

|

|

|

25 20’ |

|

|

Steering angle |

|

|

|

104 mm (4.10 in) |

|

|

Turning radius |

|

|

|

2.8 m (9.2 ft) |

|

|

Front brake |

|

|

|

Disc brake, twin |

|

|

Rear brake |

|

|

|

Disc brake |

|

|

Front tire size |

|

|

|

120/70ZR17M/C (58W), tubeless |

|

|

Rear tire size |

|

|

|

180/55ZR17M/C (73W), tubeless |

|

|

Electrical |

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

|

|

Specification |

Remark |

|

lgnition type |

|

|

Electronic ignition (Transistorized) |

|

||

lgnition timing |

|

|

|

7 B.T.D.C. at 1 300 r/min |

E-28 |

|

|

|

|

7 B.T.D.C. at 1 200 r/min |

Others |

||

|

|

|

|

|

||

Spark plug |

|

|

|

NGK JR9B |

|

|

Battery |

|

|

|

12 V 36 kC (10 Ah)/10 HR |

|

|

Generator |

|

|

|

Three-phase A.C. generator |

|

|

Main fuse |

|

|

|

30 A |

|

|

Fuse |

|

|

|

10/10/15/15/10 A |

|

|

Headlight |

|

|

|

12 V 60/55 W (H4) |

GSF1200 |

|

|

|

|

12 V 55 W (H7) + 12 V 55 W (H7) |

GSF1200S |

||

|

|

|

|

|

||

Position light |

|

|

|

12 V 5 W |

GSF1200 |

|

|

|

|

12 V 5W x 2 |

GSF1200S |

||

|

|

|

|

|

||

Turn signal light |

|

|

|

12 V 21 W x 4 |

|

|

Brake light/Taillight |

|

|

|

12 V 21/5 W |

|

|

License plate light |

|

|

|

12 V 5 W |

|

|

Speedometer light |

|

|

|

LED |

|

|

Tachometer light |

|

|

|

LED |

|

|

Neutral indicator light |

|

|

|

LED |

|

|

High beam indicator light |

|

|

|

LED |

|

|

Turn signal indicator light |

|

|

|

LED |

|

|

Oil pressure indicator light |

|

|

LED |

|

||

Capacities |

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

|

|

Specification |

Remark |

|

Fuel tank |

|

Including reserve |

|

20.0 L (5.3/4.4 US/lmp gal) |

|

|

|

|

Reserve |

|

4.4 L (1.2/1.0 US/lmp gal) |

|

|

Engine oil |

|

Oil change |

|

3 300 ml (3.4/2.9 US/lmp qt) |

|

|

|

With filter change |

|

3 500 ml (3.6/3.0 US/lmp qt) |

|

||

|

|

|

|

|||

|

|

Overhaul |

|

4 600 ml (4.9/4.0 US/lmp qt) |

|

|

Downloaded from www.Manualsbooks.com manuals search

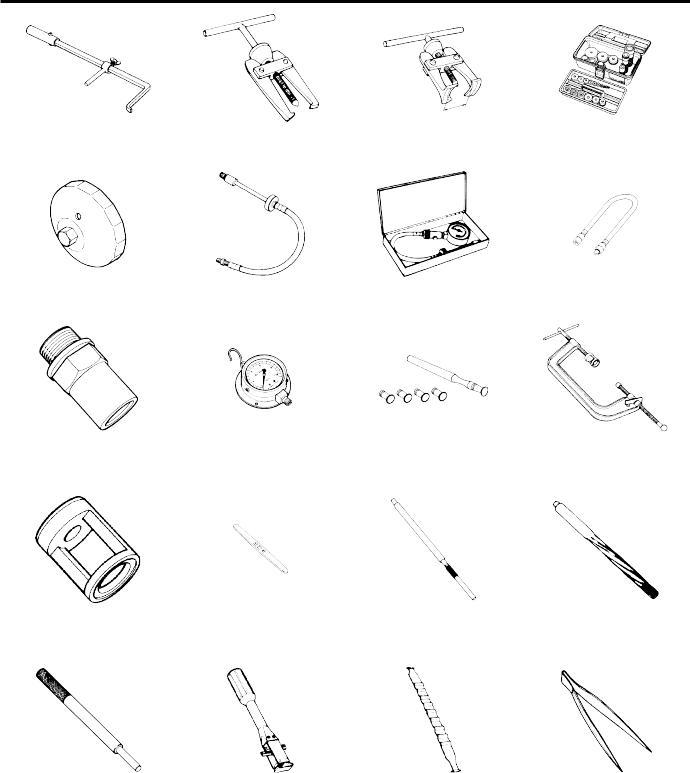

0A-11 General Information:

Special Tools and Equipment

Special Tools

|

|

|

B649G10108001 |

|

|

|

|

TT09900-06106-01 |

TT09900-06107-02 |

TT09900-06108-02 |

TT09900-20102-01 |

09900-06106 |

09900-06107 |

09900-06108 |

09900-20102 |

Snap ring pliers |

Snap ring pliers |

Snap ring pliers |

Vernier calipers |

|

|

|

(1/20 mm, 200 mm) |

|

|

|

|

TT09900-20202-01 |

TT09900-20204-01 |

TT09900-20205-01 |

TT09900-20508-01 |

09900-20202 |

09900-20204 |

09900-20205 |

09900-20508 |

Micrometer |

Micrometer |

Micrometer |

Cylinder gauge set |

(1/100 mm, 25 – 50 mm) |

(1/100 mm, 75 – 100 mm) |

(1/1 000 mm, 0 – 25 mm) |

(1/100 mm, 40 – 80 mm) |

|

|

|

|

TT09900-20602-01 |

TT09900-20605-01 |

TT09900-20607-01 |

TT09900-20701-01 |

09900-20602 |

09900-20605 |

09900-20607 |

09900-20701 |

Dial gauge |

Dial calipers |

Dial gauge |

Magnetic stand |

(1/1 000 mm) |

(1/100 mm, 10 – 34 mm) |

(1/100 mm) |

|

|

|

|

|

TT09900-20803-01 |

TT09900-20805-01 |

TT09900-21304-01 |

TT09900-22301-01 |

09900-20803 |

09900-20805 |

09900-21304 |

09900-22301 |

|

|

|

09900-22302 |

Thickness gauge |

Tire depth gauge |

V-block set |

Plastigauge |

|

|

(100 mm) |

|

|

|

|

|

TT09900-22403-01 |

TT09900-25008-01 |

TT09900-25009-01 |

TT09910-60611-01 |

09900-22403 |

09900-25008 |

09900-25009 |

09910-60611 |

Small bore gauge |

Multi circuit tester set |

Needle pointed probe set |

Universal clamp wrench |

(18 – 35 mm) |

|

|

|

Downloaded from www.Manualsbooks.com manuals search

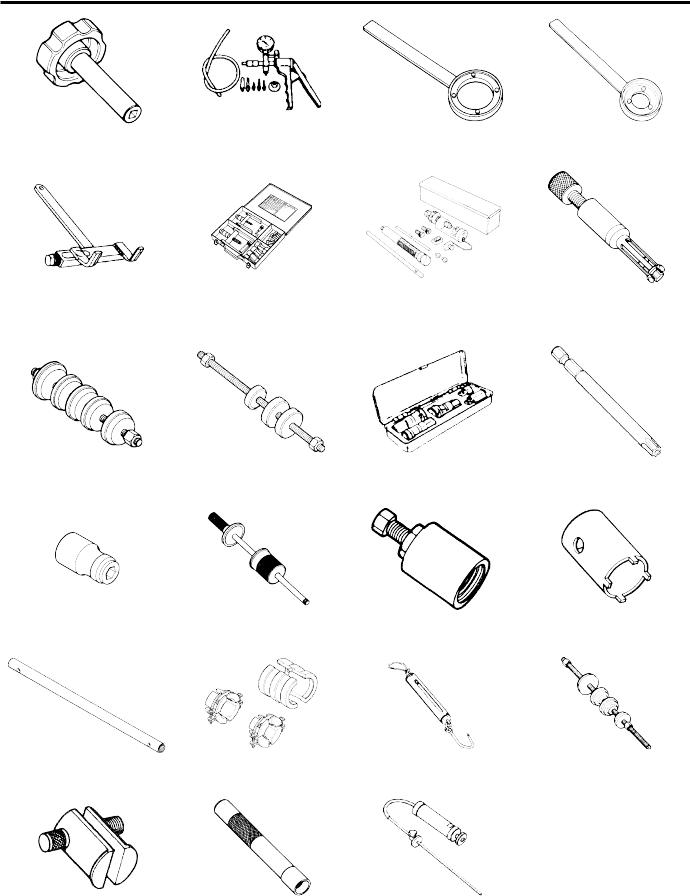

General Information: 0A-12

TT09913-50121-01 |

TT09913-60910-01 |

TT09913-61510-01 |

TT09913-70210-01 |

09913-50121 |

09913-60910 |

09913-61510 |

09913-70210 |

Oil seal remover |

Bearing remover |

Bearing remover |

Bearing installer set |

|

|

|

|

TT09915-40610-01 |

TT09915-63210-01 |

TT09915-64510-01 |

TT09915-74521-01 |

09915-40610 |

09915-63210 |

09915-64510 |

09915-74521 |

Oil filter wrench |

Compression gauge adaptor |

Compression gauge set |

Oil pressure gauge hose |

|

|

|

|

TT09915-74540-01 |

TT09915-77331-01 |

TT09916-10911-01 |

TT09916-14510-02 |

09915-74540 |

09915-77331 |

09916-10911 |

09916-14510 |

Oil pressure gauge |

Meter (for high pressure) |

Valve lapper set |

Valve spring compressor |

attachment |

|

|

|

|

|

|

|

TT09916-14910-01 |

TT09916-34542-01 |

TT09916-34570-01 |

TT09916-34580-01 |

09916-14910 |

09916-34542 |

09916-34570 |

09916-34580 |

Valve lifter attachment |

Reamer handle |

Valve guide reamer |

Valve guide reamer |

|

|

(4.95 mm) |

(10.8 mm) |

|

|

|

|

TT09916-44310-01 |

TT09916-74521-01 |

TT09916-74550-01 |

TT09916-84511-01 |

09916-44310 |

09916-74521 |

09916-74550 |

09916-84511 |

Valve guide remover/ |

Holder body |

Band (73 – 85 mm) |

Tweezers |

installer |

|

|

|

Downloaded from www.Manualsbooks.com manuals search

0A-13 General Information:

TT09917-14920-01 |

TT09917-47010-01 |

TT09920-34820-01 |

TT09920-34840-01 |

09917-14920 |

09917-47010 |

09920-34820 |

09920-34840 |

Valve adjuster driver |

Vacuum pump gauge |

Clutch pressure plate holder |

Starter clutch holder |

|

|

|

|

TT09920-53740-02 |

TT09921-20240-01 |

TT09922-22711-01 |

TT09923-73210-01 |

09920-53740 |

09921-20240 |

09922-22711 |

09923-73210 |

Clutch sleeve hub holder |

Bearing remover set |

Drive chain cutting and |

Bearing remover |

|

|

joining tool |

|

TT09924-84510-01 |

TT09924-84521-01 |

TT09930-10121-01 |

TT09930-11920-01 |

09924-84510 |

09924-84521 |

09930-10121 |

09930-11920 |

Bearing installer set |

Bearing installer set |

Spark plug wrench set |

Torx bit (JT 40H) |

|

|

|

|

TT09930-11940-01 |

TT09930-30102-01 |

TT09930-30721-01 |

TT09940-14911-01 |

09930-11940 |

09930-30102 |

09930-30721 |

09940-14911 |

Bit holder |

Sliding shaft |

Rotor remover |

Steering stem nut wrench |

|

|

|

|

TT09940-52841-01 |

TT09940-52861-01 |

TT09940-92720-01 |

TT09941-34513-01 |

09940-52841 |

09940-52861 |

09940-92720 |

09941-34513 |

Inner rod holder |

Front fork oil seal installer |

Spring scale |

Steering race installer |

|

|

|

|

TT09941-54911-01 |

TT09941-74911-01 |

TT09943-74111-01 |

|

09941-54911 |

09941-74911 |

09943-74111 |

|

Bearing outer race remover |

Steering bearing installer |

Fork oil level gauge |

|

|

|

|

|

Downloaded from www.Manualsbooks.com manuals search

Maintenance and Lubrication: 0B-1

Maintenance and Lubrication

Precautions

Precautions for Maintenance

B649G10200001

The “Periodic Maintenance Schedule Chart” lists the recommended intervals for all the required periodic service work necessary to keep the motorcycle operating at peak performance and economy. Maintenance intervals are expressed in terms of kilometers, miles and months for your convenience.

NOTE

More frequent servicing may be required on motorcycles that are used under severe conditions.

General Description

Recommended Fluids and Lubricants

B649G10201001

Refer to “Fuel and Oil Recommendation: in Section 0A”.

Downloaded from www.Manualsbooks.com manuals search

0B-2 Maintenance and Lubrication:

Scheduled Maintenance

Periodic Maintenance Schedule Chart

B649G10205001

NOTE

I = Inspect and clean, adjust, replace or lubricate as necessary.

R = Replace

T = Tighten

|

|

|

Interval |

|

|

||

Item |

km |

1 000 |

6 000 |

12 000 |

18 000 |

24 000 |

|

mile |

600 |

4 000 |

7 500 |

11 000 |

14 500 |

||

|

|||||||

|

months |

2 |

12 |

24 |

36 |

48 |

|

Air cleaner element |

|

— |

I |

I |

R |

I |

|

Exhaust pipe bolts and muffler bolts |

|

T |

— |

T |

— |

T |

|

Valve clearance |

|

I |

— |

I |

— |

I |

|

Spark plugs |

|

— |

I |

R |

I |

R |

|

Fuel line |

|

— |

I |

I |

I |

I |

|

Engine oil |

|

R |

R |

R |

R |

R |

|

Engine oil filter |

|

R |

— |

— |

R |

— |

|

Throttle cable play |

|

I |

I |

I |

I |

I |

|

Engine idle speed |

|

I |

I |

I |

I |

I |

|

Throttle valve synchronization |

|

— |

— |

I |

— |

I |

|

PAIR (air supply) system |

|

— |

— |

I |

— |

I |

|

Clutch hose |

|

— |

I |

I |

I |

I |

|

|

|

Replace every 4 years. |

|

||||

|

|

|

|

||||

Clutch fluid |

|

— |

I |

I |

I |

I |

|

|

|

Replace every 2 years. |

|

||||

|

|

|

|

||||

Drive chain |

|

I |

I |

I |

I |

I |

|

|

Clean and lubricate every 1 000 km (600 mile). |

||||||

|

|

||||||

Brakes |

|

I |

I |

I |

I |

I |

|

Brake hose |

|

— |

I |

I |

I |

I |

|

|

|

Replace every 4 years. |

|

||||

|

|

|

|

||||

Brake fluid |

|

— |

I |

I |

I |

I |

|

|

|

Replace every 2 years. |

|

||||

|

|

|

|

||||

Tires |

|

— |

I |

I |

I |

I |

|

Steering |

|

I |

— |

I |

— |

I |

|

Front forks |

|

— |

— |

I |

— |

I |

|

Rear suspension |

|

— |

— |

I |

— |

I |

|

Chassis bolts and nuts |

|

T |

T |

T |

T |

T |

|

Downloaded from www.Manualsbooks.com manuals search

Maintenance and Lubrication: 0B-3

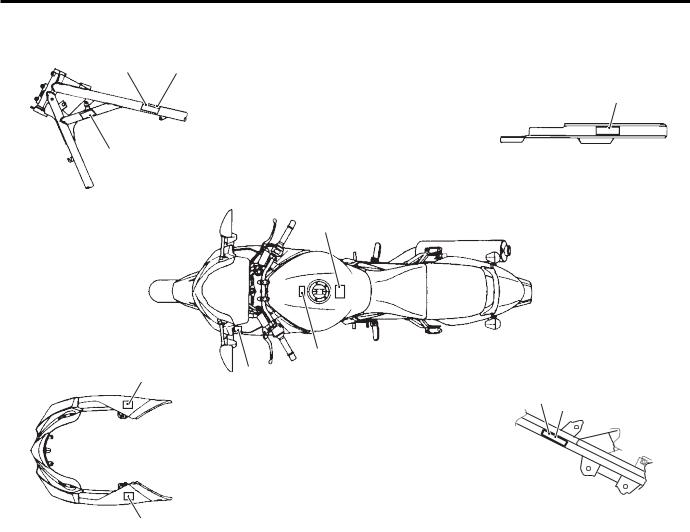

Lubrication Points

B649G10205002

Proper lubrication is important for smooth operation and long life of each working part of the motorcycle. Major lubrication points are indicated as follows.

NOTE

•Before lubricating each part, clean off any rusty spots and wipe off any grease, oil, dirt orgrime.

•Lubricate exposed parts which are subject to rust, with a rust preventative spray whenever the motorcycle has been operated under wet or rainy conditions.

1

2

3

|

|

|

7 |

|

|

4 |

|

5 |

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

I649G1020001-03 |

|

|

|

|

|

1. |

Brake lever holder and throttle cables |

5. |

Gearshift pivot and left footrest pivot |

|

|

|

|

|

|

2. |

Brake pedal pivot and right footrest pivot |

6. |

Center stand pivot and spring hook |

|

|

|

|

|

|

3. |

Clutch lever holder |

7. |

Drive chain |

|

|

|

|

|

|

4. |

Side-stand pivot and spring hook |

|

|

|

|

|

|

|

|

Downloaded from www.Manualsbooks.com manuals search

0B-4 Maintenance and Lubrication:

Repair Instructions

Air Cleaner Element Removal and Installation

B649G10206001

Inspect air cleaner element

Every 6 000 km (4 000 miles, 12 months)

Replace air cleaner element

Every 18 000 km (11 000 miles, 36 months) Removal

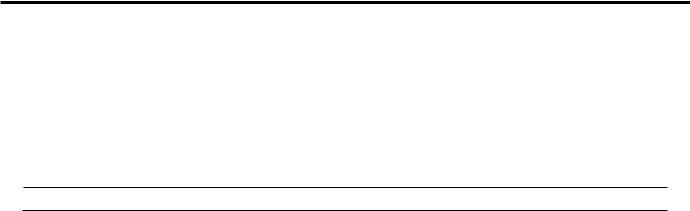

1)Remove the fuel tank. Refer to “Carburetor Assembly Removal and Installation: in Section1G”.

2)Remove the two screws and slide the aircleaner cover backward.

I649G1020002-02

3) Remove the air cleaner element(1).

1

I649G1020003-02

Installation

Reinstall the cleaned or new air cleaner element in the reverse order of removal. Pay attention to thefollowing points:

•When installing the air cleaner element into the air cleaner box, make sure that the mark points “A”up.

•After cleaning or installing the air cleaner element, drain water from the air cleaner by removing the drain plug.

I649G1020005-01

Air Cleaner Element Inspection and Cleaning

B649G10206002

Refer to “Air Cleaner Element Removal and Installation: ”.

Inspect air cleaner element

Every 6 000 km (4 000 miles, 12 months)

Replace air cleaner element

Every 18 000 km (11 000 miles, 36 months)

Inspection

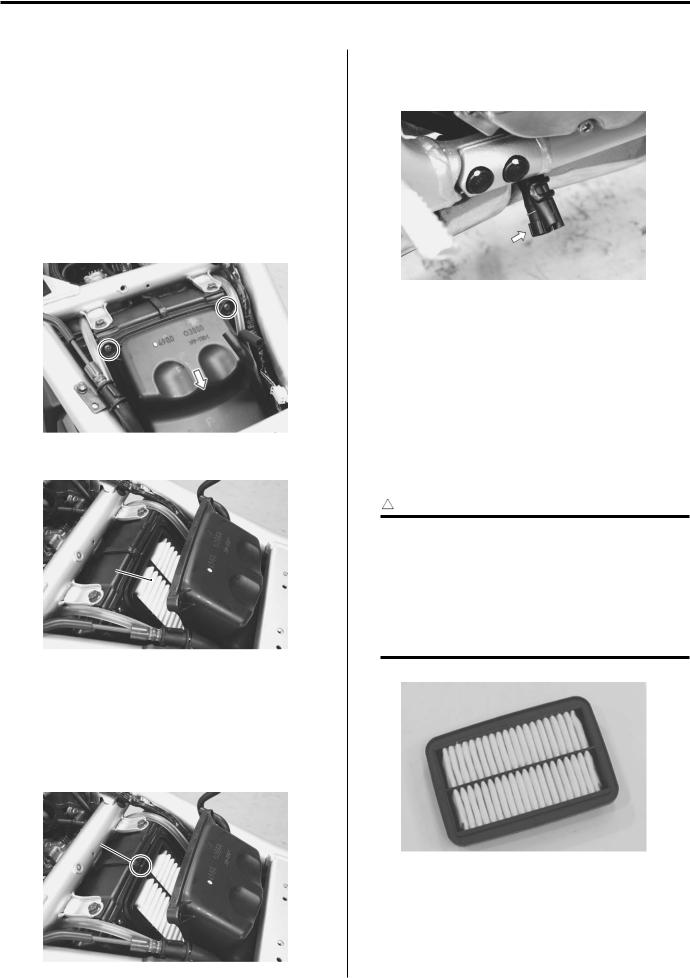

Inspect the air cleaner element for clogging.

! CAUTION

If driving under dusty conditions, clean the air cleaner element more frequently. The surest way to accelerate engine wear is to operate the engine without the element or to use a torn element. Make sure that the air cleaner is in good condition at all times. Life of the engine depends largely on this component.

“A”

I649G1020006-01

I649G1020004-02

Downloaded from www.Manualsbooks.com manuals search

Loading...

Loading...