Suzuki RM250 Owner's Service Manual

RM250

OWNER’S SERVICE MANUAL

Part No. 99011-37F56-01A

May, 2006 EN

TK

This manual should be considered a permanent part of

the motorcycle and should remain with the motorcycle

when resold or otherwise transferred to a new owner or

operator.

The manual contains important safety information and

instructions which should be read carefully before

operating the motorcycle.

FOREWORD

This manual is presented as a means whereby you

can maintain your RM250 in top working condition

at all times. Your riding skill and the maintenance

steps outlined in this manual will assure you of top

performance from your machine under any type of

competition.

We sincerely wish you and your Suzuki motorcycle

a successful partnership for many years of happy

riding.

All information, illustrations, photographs and specifications contained in the manual are based on the

latest product information available at the time of

publication. Due to improvements or other changes,

there may be some discrepancies in this manual.

Suzuki reserves the right to make production

changes at any time, without notice and without

incurring any obligation to make the same or similar

changes to vehicles previous built or sold.

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions

carefully. To emphasize special information, the

symbol and the words WARNING, CAUTION

and NOTE have special meanings. Pay special

attention to the messages highlighted by these signal words:

WARNING

Indicates a potential hazard that could

result in death or injury.

CAUTION

Indicates a potential hazard that could

result in motorcycle damage.

NOTE:

Indicates special information to make maintenance

easier or instructions clearer.

Suzuki Motor Corporation believes in conservation

and protection of Earth’s natural resources. To that

end, we encourage every vehicle owner to recycle,

trade in, or properly dispose of, as appropriate,

used motor oil, engine coolant, and other fluid, and

tires.

c COPYRIGHT SUZUKI MOTOR CORPORATION 2006

GENERAL CONSIDERATIONS

• Wear a helmet and goggles

A helmet is the most important piece of gear to

wear. Helmets do not reduce essential vision or

hearing. Generally, helmets do not cause or

intensify injury if you crash. Helmets simply help

your skull protect your intelligence, your memory,

your personality, and your life.

Your eyesight is equally valuable. Wearing suitable eye protection can help keep your vision

unblurred by the wind and help shield your eyes

from branches and airborne matter like bugs, dirt,

or pebbles kicked up by tires. Wear a helmet and

eye protection every time you ride.

• Practice on level ground

Before you begin riding, you should find a good

place to practice the skills you need to ride

safely. Find a flat, open area with enough space

to maneuver. Check with your Suzuki dealer or

call police department if you do not know where

you can ride.

Review the controls on your motorcycle before

riding.

• Know your limits

Always ride within the boundaries of your own

skills. Knowing these limits and staying within

them will help you avoid accidents. Ride only in

events appropriate for your experience.

• Wear protective gear

Wear proper clothing when you ride. Avoid loose

clothes or scarves, which could get caught in

moving parts. Abrasion injuries can be minimized

by wearing protective clothing including gloves,

strong boots that fit over the ankle, long pants,

and a long sleeve shirt or jackets. Experienced

riders often wear a kidney belt and chest or back

protector for additional comfort and protection.

• Inspect your machine before riding

Before each use, perform an inspection per “Periodic Inspection” section starting on page 2-3.

• No Passengers

Suzuki RMs are designed for the rider only.

Safely competing on a motorcycle requires that

your mental and physical skills are fully part of

the experience. You should not attempt to operate a motor vehicle, especially one with two

wheels, if you are tired or under the influence of

alcohol or other drugs. Alcohol, illegal drugs, and

even some prescription and over-the-counter

drugs and cause drowsiness, loss of coordination, loss of balance, and loss of good judgement. If you are tired or under the influence of

alcohol or other drugs, PLEASE DO NOT RIDE

your motorcycle.

• Conclusion

The actions of other riders are unpredictable.

Your motorcyclee’s condition can change. These

factors can best be dealt with by giving every ride

your full attention.

Circumstances beyond your control could lead to

an accident. You need to prepare for the unexpected by wearing a helmet and other protective

gear, and practicing safe riding techniques to

minimize the damage to you and your machine.

May all of your rides on your new Suzuki be winning

rides!

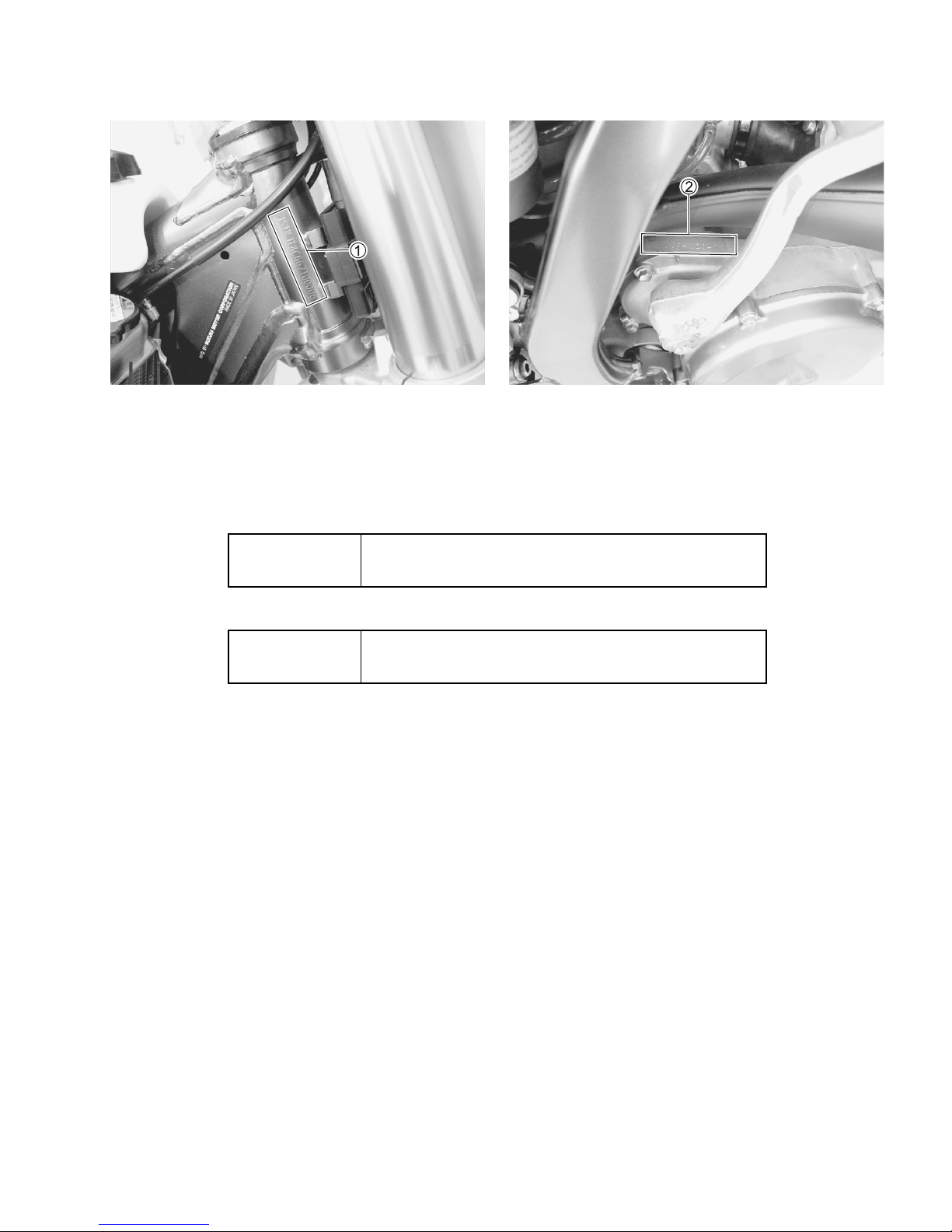

SERIAL NUMBER LOCATION

The frame number 1 is stamped on the steering head as shown in the photograph. The engine serial number 2 is stamped on the right side of the crankcase assembly.

Write down the serial numbers here for your future reference.

Frame No.

Engine No.

WARNINGS FOR SERVICING

WARNING

Never run the engine indoors or in a

garage. Exhaust gas contains carbon monoxide, a gas that is colorless and odorless

and can cause death or severe injury.

Only run the engine outdoors where there

is fresh air.

WARNING

Fuel can catch on fire if you do not handle

it properly. Gasoline vapors can catch fire

easily.

Do not smoke when servicing the machine.

Do not service the machine in an area

where there are open flames or sparks.

WARNING

Hot engine and muffler can burn you.

Wait until the engine and muffler cools

before servicing.

WARNING

Brake fluids and engine coolant can be

hazardous to humans and pets. Brake fluid

and engine coolant are harmful or fatal if

swallowed, and harmful if it comes in contact with your skin or eyes.

Keep brake fluid and engine coolant away

from children. Call your doctor immediately if swallowed, and induce vomiting.

Flush eyes or skin with water if either

brake fluid or engine coolant gets in eyes

or comes in contact with skin.

WARNING

WARNING

Servicing the machine with engine running

can be hazardous. You can be caught in

the moving parts such as the drive chain,

sprockets etc.

Be sure to stop the engine when servicing

the machine.

Servicing the machine without proper

clothes and protective gear can be hazardous. You can be injured if you do not wear

proper clothes and protective gear.

Be sure to wear proper clothes and shoes

for servicing and wear protective glasses,

mask or gloves as necessary.

PRECAUTIONS FOR SERVICING

• Replace gaskets, snap rings, circlips, O-rings

and cotter pins with new ones.

• Take care not to expand the end gap larger than

required to slip the circlip over the shaft when

installing a circlip.

• Use special tools where specified.

• Use genuine SUZUKI parts and recommended

oil.

• When two or more persons work together, pay

attention to the safety of each other.

• After reassembly, inspect parts for tightness and

operation.

REPLACEMENT PARTS

Use only genuine SUZUKI replacement parts or

their equivalent. Genuine SUZUKI parts are high

quality parts which are designed and built specially

for SUZUKI vehicles.

NOTE:

Use of replacement parts which are not equivalent

in quality to genuine SUZUKI parts can lead to performance problems and damage.

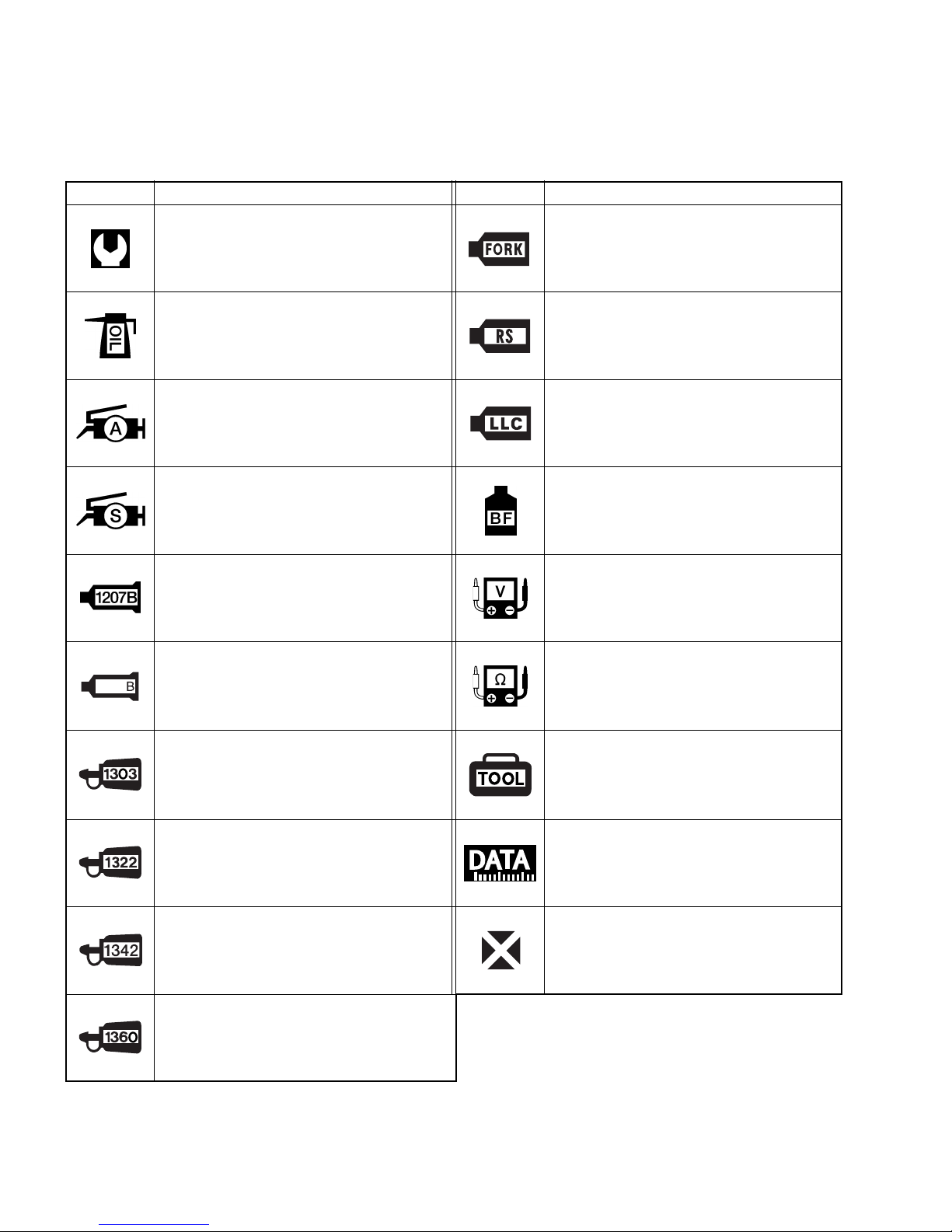

SYMBOL MARKS AND MATERIALS

Listed in the table below are the symbols indicating instructions and other information. The meaning of each

symbol is also included in the table.

SYMBOL DEFINITION SYMBOL DEFINITION

1216

Torque control required.

Data beside it indicates specified

torque.

Apply oil. Use engine oil or transmission

oil unless otherwise specified.

Apply SUZUKI SUPER GREASE “A”

or equivalent grease.

99000-25010

Apply SUZUKI SILICONE GREASE.

99000-25100

Apply SUZUKI BOND “1207B”.

99000-31140

Apply SUZUKI BOND “1216B”.

99000-31230

Use SUZUKI FORK OIL SS-05 or

equivalent fork oil.

99000-99001-SS5

Use SUZUKI REAR SUSPENSION OIL

SS-25 or equivalent rear suspension oil.

99000-99001-S25

Use engine coolant.

Apply or use brake fluid. (DOT 4)

Measure in voltage range.

Measure in resistance range.

Apply THREAD LOCK SUPER “1303”.

99000-32030

Apply THREAD LOCK SUPER “1322”

or equivalent thread lock.

99000-32110

Apply THREAD LOCK “1342”.

99000-32050

Apply THREAD LOCK SUPER “1360”.

99000-32130

Use special tool.

Indication of service data.

Replace a part with a new one when

reassembling.

GROUP INDEX

GENERAL INFORMATION

PERIODIC MAINTENANCE

TROUBLESHOOTING

MACHINE TUNING

ENGINE REMOVAL AND INSTALLATION

CYLINDER, PISTON AND EXHAUST VALVE

CLUTCH

KICK STARTER

GEARSHIFTING

TRANSMISSION AND CRANKSHAFT

1

2

3

4

5

6

7

8

9

10

FUEL SYSTEM

COOLING SYSTEM

ELECTRICAL SYSTEM

FRONT AND REAR WHEELS

FRONT AND REAR BRAKES

FRONT FORK AND STEERING

REAR SUSPENSION

SERVICING INFORMATION

11

12

13

14

15

16

17

18

GENERAL INFORMATION 1-1

GENERAL INFORMATION

CONTENTS

LOCATION OF PARTS ............................................................................... 1- 2

FUEL AND OIL RECOMMENDATION ........................................................ 1- 3

OPERATING INSTRUCTIONS .................................................................... 1- 4

STARTING THE ENGINE ...................................................................... 1- 4

STOPPING THE ENGINE ..................................................................... 1- 5

TRANSMISSION ................................................................................... 1- 5

BREAK-IN (RUNNING-IN) ........................................................................... 1- 5

WHEN THE MOTORCYCLE IS NEW ................................................... 1- 5

WHEN ENGINE PARTS ARE REPLACED ........................................... 1- 5

1

COUNTRY AND AREA CODES

The following codes stand for the applicable country(-ies) and area(-s).

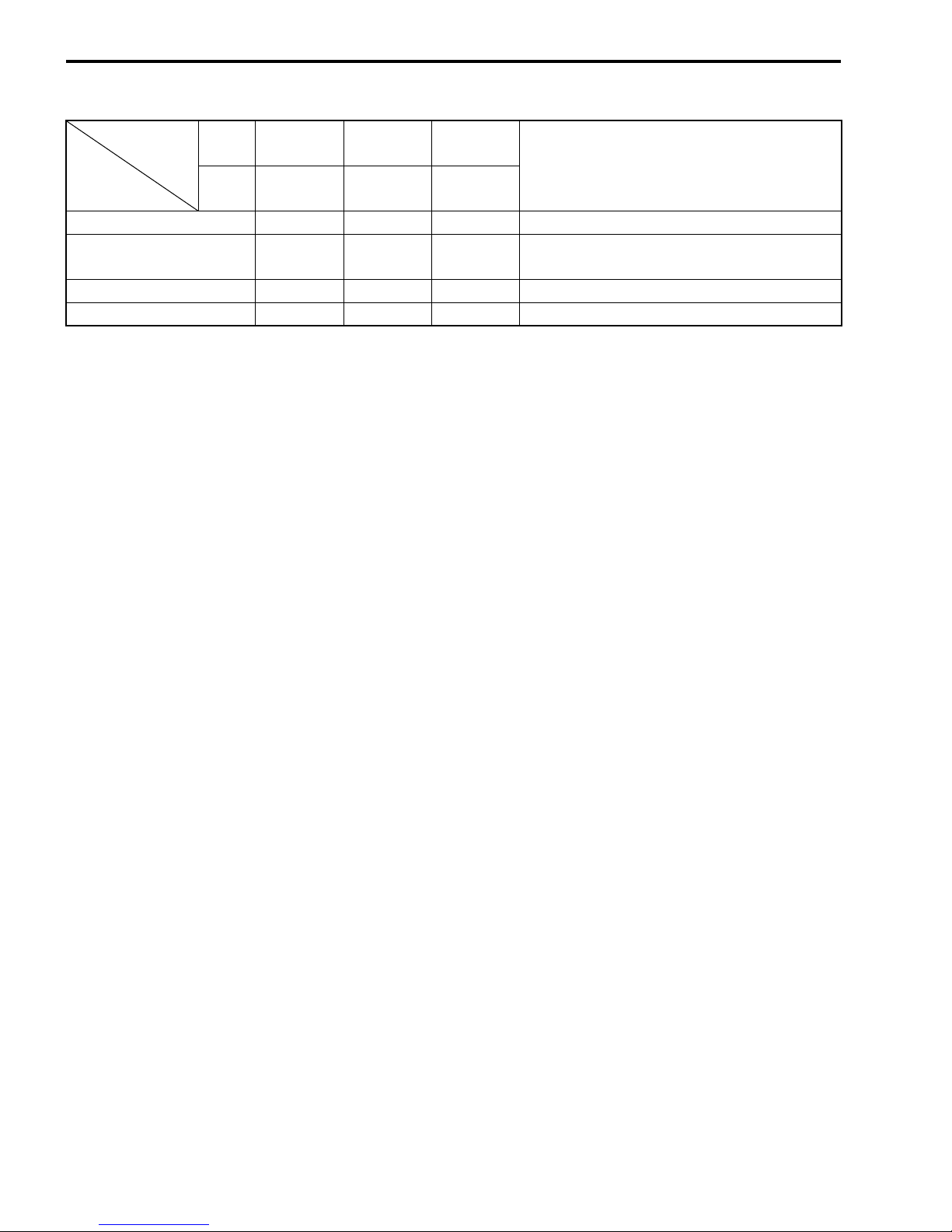

CODE COUNTRY or AREA EFFECTIVE FRAME NO.

000

E-03

E-19

E-28

Japan

U. S. A.

E.U.

Canada

JS1RJ18A000 500001 –

JS1RJ18C 72 100001 –

JS1RJ18A000 500001 –

JS1RJ18C 72 100001 –

1-2 GENERAL INFORMATION

LOCATION OF PARTS

1 Clutch lever

2 Engine stop switch

3 Clutch cable adjuster

4 Throttle grip

5 Front brake lever

6 Fuel tank cap

7 Starter knob

8 Gearshift lever

9 Fuel valve

0 Kick starter lever

A Rear brake pedal

FUEL AND OIL RECOMMENDATION

This motorcycle is of the two-stroke design, which requires a

premixture of gasoline and oil.

Gasoline: Use only unleaded gasoline of at least 90

pump octane (R/2 + M/2 method). .... For

Canada

Use only unleaded gasoline of at least 95

octane (Research Method). .... For other

countries

Engine oil: MOTUL 800 2T FACTORY LINE OFF

ROAD or equivalent Two Cycle Racing

Lubricant.

Mixing ratio: 30 : 1

Fuel tank capacity: 8.0 L (2.1/1.8 US/lmp gal)

CAUTION

A mixture containing too little oil will cause piston seizure. Too much oil will cause excessive carbon formation resulting in preignition, fouled spark plug and

loss of engine power.

GENERAL INFORMATION 1-3

Mix fuel and the engine oil at the ratio of 30:1.

NOTE:

* Mix gasoline and the engine oil thoroughly when the tempera-

ture is below 0 °C (32 °F). Vegetable-based oils can separate

easier than mineral oils.

* Use premixture oil as soon as possible after mixing, or lubrica-

tion performance of the engine oil can decrease.

* Do not mix vegetable-based oil and mineral oil.

Gasoline

(L)

5.0 167 1 4.3 1 5.4

10.0 333 2 8.6 2 10.7

15.0 500 3 12.8 3 16.0

20.0 667 4 17.1 4 21.4

Oil

(ml)

Gasoline

(US gal.)

Oil

(US oz)

Gasoline

(Imp gal.)

Oil

(Imp oz)

1-4 GENERAL INFORMATION

OPERATING INSTRUCTIONS

STARTING THE ENGINE

Inspect the transmission oil level, coolant level and air cleaner

condition before starting the engine.

When the engine is cold:

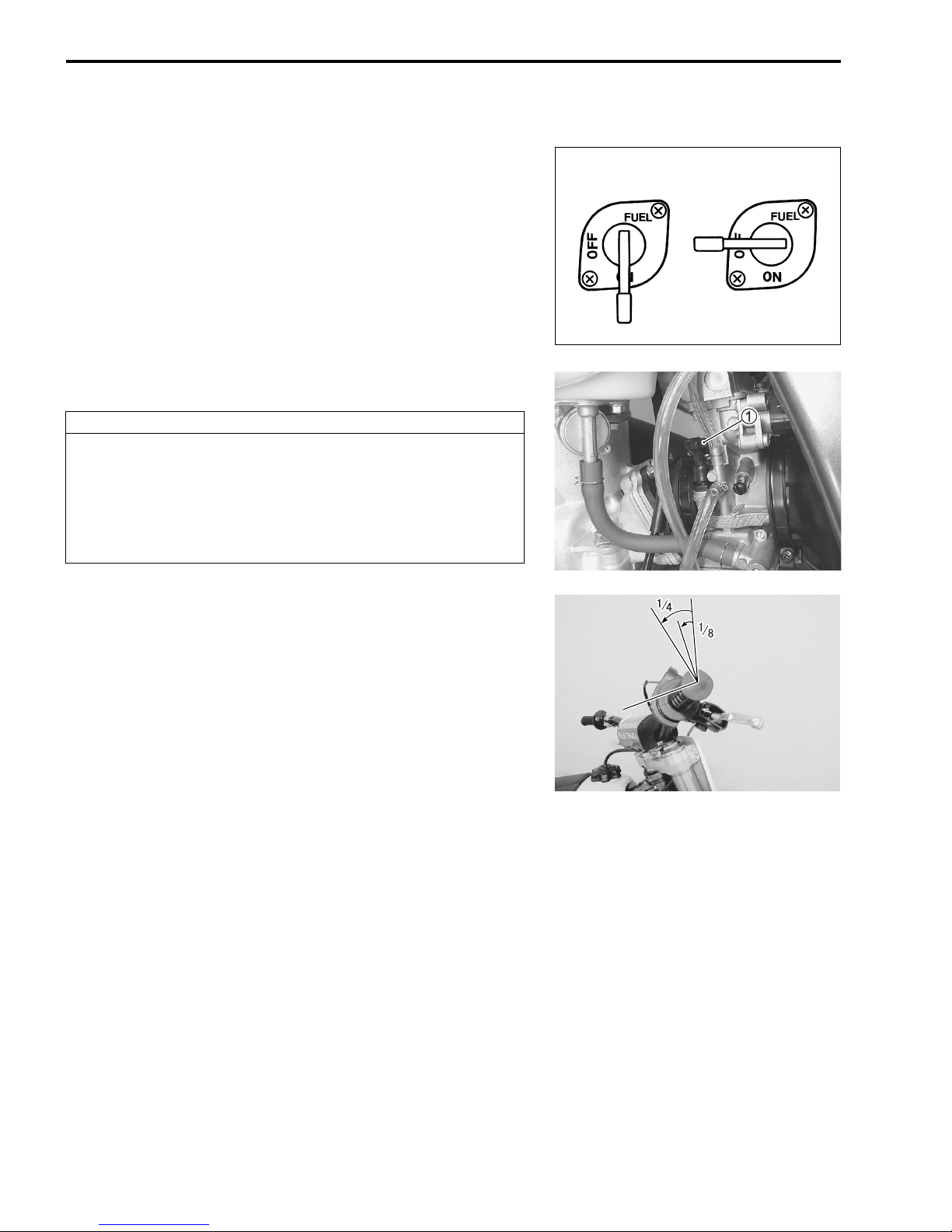

1) Turn the fuel valve lever to the “ON” position.

2) Shift the transmission into neutral.

3) Pull the bypass (starter) knob 1.

4) Close the throttle grip completely and depress the kick

starter lever forcefully.

5) Return the bypass (starter) knob when the engine revs at

steady speed.

CAUTION

Racing the engine in neutral will exceed the engine

speed limit. Exceeding the engine speed limit can

damage the engine moving parts.

Do not race the engine at high speed to avoid the

engine damage.

When the engine is warm:

1) Turn the fuel valve lever to the “ON” position.

2) Shift the transmission into neutral.

3) Open the throttle 1/8 – 1/4 turn and depress the kick starter

lever forcefully.

ON OFF

To restart after the motorcycle has fallen:

1) Shift the transmission into neutral.

2) Open the throttle completely and depress the kick starter

lever forcefully.

3) Close the throttle gradually as engine speed increases.

4) Wait until engine revs smoothly.

STOPPING THE ENGINE

1) Shift the transmission into neutral.

2) Turn the fuel valve lever to the “OFF” position.

3) Push the engine stop switch 1 to stop the engine.

WARNING

Leaving the fuel valve in the “ON” position may cause

carburetor overflow. This can cause a fire or severe

engine damage when you start the engine.

Always leave the fuel valve in the “OFF” position

when the engine is not running.

TRANSMISSION

This motorcycle has a 5-speed transmission. Neutral is located

between low and 2nd. Engage first gear by pressing the lever

down from the neutral position. You can shift into higher gears

by lifting on the shift lever once for each gear. When neutral is

desired, press or lift the lever to the position halfway between

low and 2nd gear.

GENERAL INFORMATION 1-5

N

BREAK-IN (RUNNING-IN)

WHEN THE MOTORCYCLE IS NEW

1) Warm up the engine before starting off.

2) Ride for 1 hour using less than 1/2 throttle opening with various throttle opening.

3) Ride for 1 hour using less than 3/4 throttle opening with various throttle opening.

NOTE:

* The break-in (running-in) period is the period of greatest wear.

* The bolts and nuts of the new machine can loosen quickly. Be

sure to retighten the bolts and nuts during the break-in (running-in) period.

WHEN ENGINE PARTS ARE REPLACED

Follow the same procedure when any of the following parts are

replaced:

Piston

Piston ring

Cylinder

Crankshaft

Crankshaft bearing

– MEMO –

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE 2-1

CONTENTS

PERIODIC MAINTENANCE ........................................................................ 2- 3

PERIODIC MAINTENANCE CHART .................................................... 2- 3

INSPECTION BEFORE PRACTICE ...................................................... 2- 5

INSPECTION BEFORE RACE

(All items of inspection before practice above plus) ........................ 2- 5

SPARK PLUG .............................................................................................. 2- 6

AIR CLEANER ............................................................................................. 2- 7

AIR CLEANER ELEMENT REMOVAL ................................................. 2- 7

WASHING .............................................................................................. 2- 7

INSTALLATION ..................................................................................... 2- 7

TRANSMISSION OIL ................................................................................... 2- 9

TRANSMISSION OIL LEVEL INSPECTION

AND REPLENISHMENT ....................................................................... 2- 9

TRANSMISSION OIL CHANGE ............................................................ 2-10

ENGINE COOLANT ..................................................................................... 2-11

ENGINE COOLANT LEVEL CHECK .................................................... 2-11

ENGINE COOLANT REPLENISHMENT ............................................... 2-12

ENGINE COOLING SYSTEM INSPECTION ......................................... 2-12

2

CLUTCH ....................................................................................................... 2-13

MAJOR ADJUSTMENT ........................................................................ 2-13

MINOR ADJUSTMENT ......................................................................... 2-13

THROTTLE CABLE ..................................................................................... 2-13

FUEL HOSE ................................................................................................. 2-14

FUEL VALVE ............................................................................................... 2-14

CYLINDER HEAD, CYLINDER AND PISTON ............................................ 2-15

CYLINDER HEAD ................................................................................. 2-15

CYLINDER ............................................................................................. 2-15

PISTON .................................................................................................. 2-15

EXHAUST VALVE ....................................................................................... 2-15

EXHAUST SILENCER ................................................................................. 2-16

DRIVE CHAIN AND SPROCKETS .............................................................. 2-16

DRIVE CHAIN SLACK .......................................................................... 2-16

DRIVE CHAIN ADJUSTMENT .............................................................. 2-16

20TH PITCH LENGTH ........................................................................... 2-17

2-2 PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

DRIVE CHAIN LUBRICATION ............................................................. 2-17

SPROCKET INSPECTION ................................................................... 2-17

DRIVE CHAIN GUIDE, BUFFER, CONTROL ROLLER ............................. 2-18

DRIVE CHAIN GUIDE ........................................................................... 2-18

DRIVE CHAIN GUIDE BUFFER ........................................................... 2-18

DRIVE CHAIN CONTROL ROLLER .................................................... 2-18

BRAKES ...................................................................................................... 2-18

BRAKE FLUID LEVEL ......................................................................... 2-18

BRAKE PAD ......................................................................................... 2-19

FRONT BRAKE LEVER ADJUSTMENT .............................................. 2-19

BRAKE PEDAL HEIGHT ADJUSTMENT ............................................ 2-20

CONTENTS

FRONT FORK ............................................................................................. 2-20

AIR PRESSURE ADJUSTMENT .......................................................... 2-20

STEERING .................................................................................................. 2-20

REAR SUSPENSION .................................................................................. 2-21

WHEELS AND TIRES ................................................................................. 2-21

TIRE PRESSURE ................................................................................. 2-21

WHEEL RIM .......................................................................................... 2-21

SPOKE NIPPLE .................................................................................... 2-21

LUBRICATION ............................................................................................ 2-23

PERIODIC MAINTENANCE 2-3

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE CHART

It is very important to inspect and maintain the machine regularly. Follow the guideline in the chart. The life

of parts varies depending on the riding conditions. Perform more often than shown in the chart if you use the

motorcycle under severe conditions.

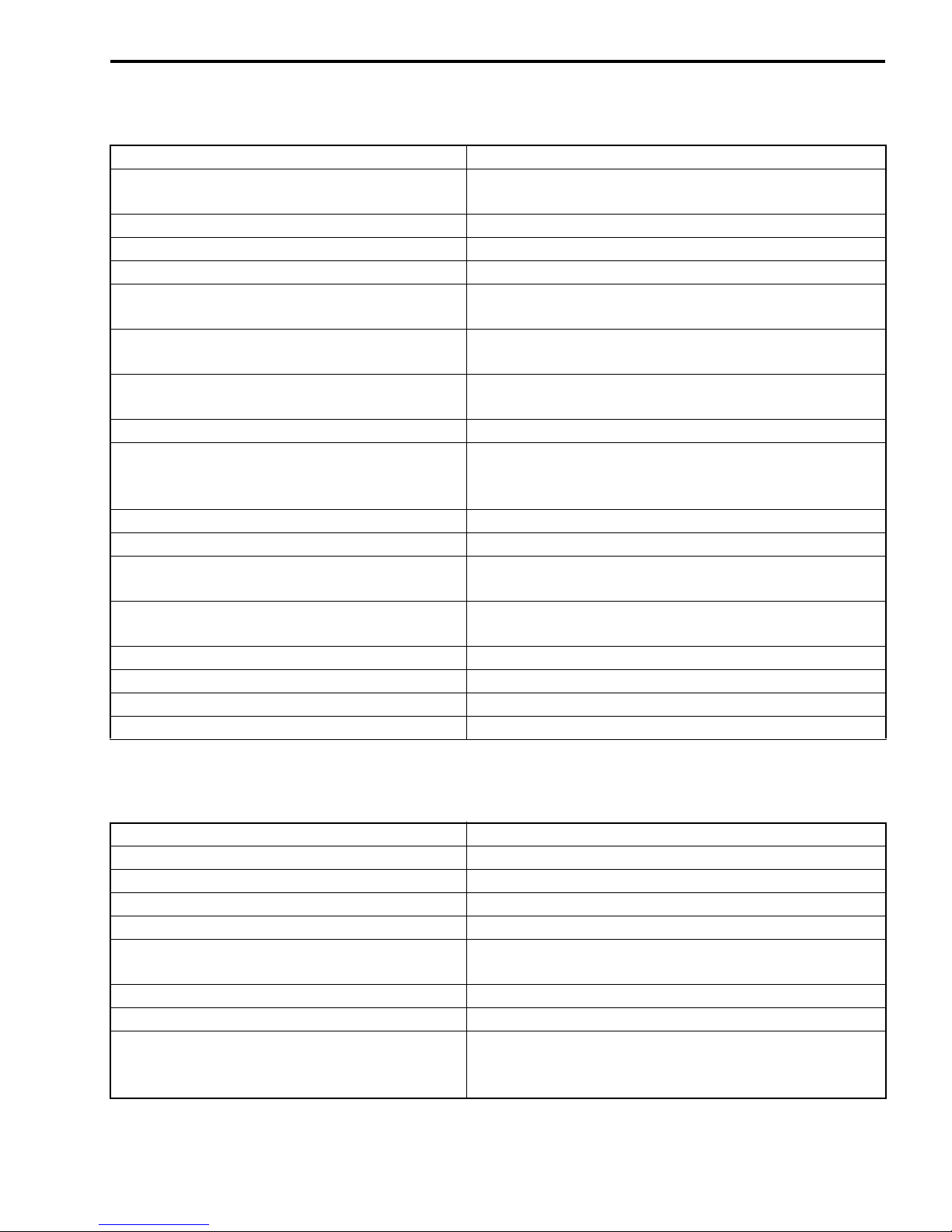

Interval

Service

Item

Spark plug I R —

Air cleaner C — — Replace air cleaner element as necessary.

Transmission oil — R — Change after 1st initial break-in.

Cooling-system I — —

Clutch I — — Replace clutch plates as necessary.

Throttle and clutch cable I & L — —

Carburetor I — —

Fuel hose I — — Replace every 4 years.

Piston — — R

Piston ring — R —

Cylinder head, cylinder — C —

Exhaust valve — C —

Crankshaft and

transmission bearing

Exhaust silencer I — —

Drive chain I & L R — Adjust slack every 30 minutes.

Engine sprocket I — —

Rear sprocket I — —

Drive chain buffer — R —

Drive chain guide — R —

Kick starter lever I & L — —

Brake I — — Replace brake hose and fluid every year.

Front fork oil — R — Change after 1st initial break-in.

Front fork I — —

Rear suspension

system pivoting portion

races

hours

Every

race

Every

2 hours

Inspect as required

I——

Every

3 races

Every

6 hours

Every

5 races

Every

10 hours

Remarks

Replace radiator hose and engine coolant

every year.

Flushing for overhaul or storage.

Check and retighten sprocket bolts at initial

and subsequent 10 minutes of riding and

each race thereafter.

Check front fork inner tube frequently for

abnormality. Check the air pressure.

Check rear suspension system frequently

and apply the grease to the pivoting portion

as necessary.

2-4 PERIODIC MAINTENANCE

Service

Item

Interval

races

hours

Every

race

Every

2 hours

Every

3 races

Every

6 hours

Every

5 races

Every

10 hours

Remarks

Tire I — —

Spoke nipple I — —

Inspect every 20 min. up to initial 2 hours

then check before each ride.

Steering I — —

Bolts and nuts T — — Retighten every 1 hour.

NOTE: R = Replace, C = Clean, T = Tighten, I = Inspect and clean, adjust lubricate or replace if necessary,

L = Lubricate.

PERIODIC MAINTENANCE 2-5

INSPECTION BEFORE PRACTICE

WHAT TO CHECK CHECK FOR

Spark plug • Heat range, fouled electrode, tightness

• Loose high-tension cord

Air cleaner element Lubrication

Transmission oil Oil level

Coolant Coolant level

Cooling system • Radiator hose damage

• Engine coolant leak

Clutch • Play

• Smooth operation

Throttle • Play

• Smooth operation

Brake fluid Fluid level

Brakes • Brake lever position

• Brake pedal height

• Operation

Drive chain Slack, lubrication, chain joint clip condition

Drive chain guide/buffer Wear, damage

Suspension • Smooth operation

• Front fork air pressure

Wheels • Spoke tension

• Rim lock tightness or damage

Tires Tire pressure

Steering Smoothness, play

Exhaust pipe Firm fixation

Bolts and nuts Tightening torque (18-8)

INSPECTION BEFORE RACE

(All items of inspection before practice above plus)

WHAT TO CHECK CHECK FOR

Air cleaner Cleanliness

Clutch Clutch disc plates wear and distortion

Brake pads Wear

Sprockets Wear

Fuel tank • Leakage

Fuel hose Damage

Exhaust pipe Damage

Piston and Cylinder • Combustion Chamber carbon deposit

• Fuel filter clogging

• Piston head carbon deposit

• Piston and cylinder wear

2-6 PERIODIC MAINTENANCE

SPARK PLUG

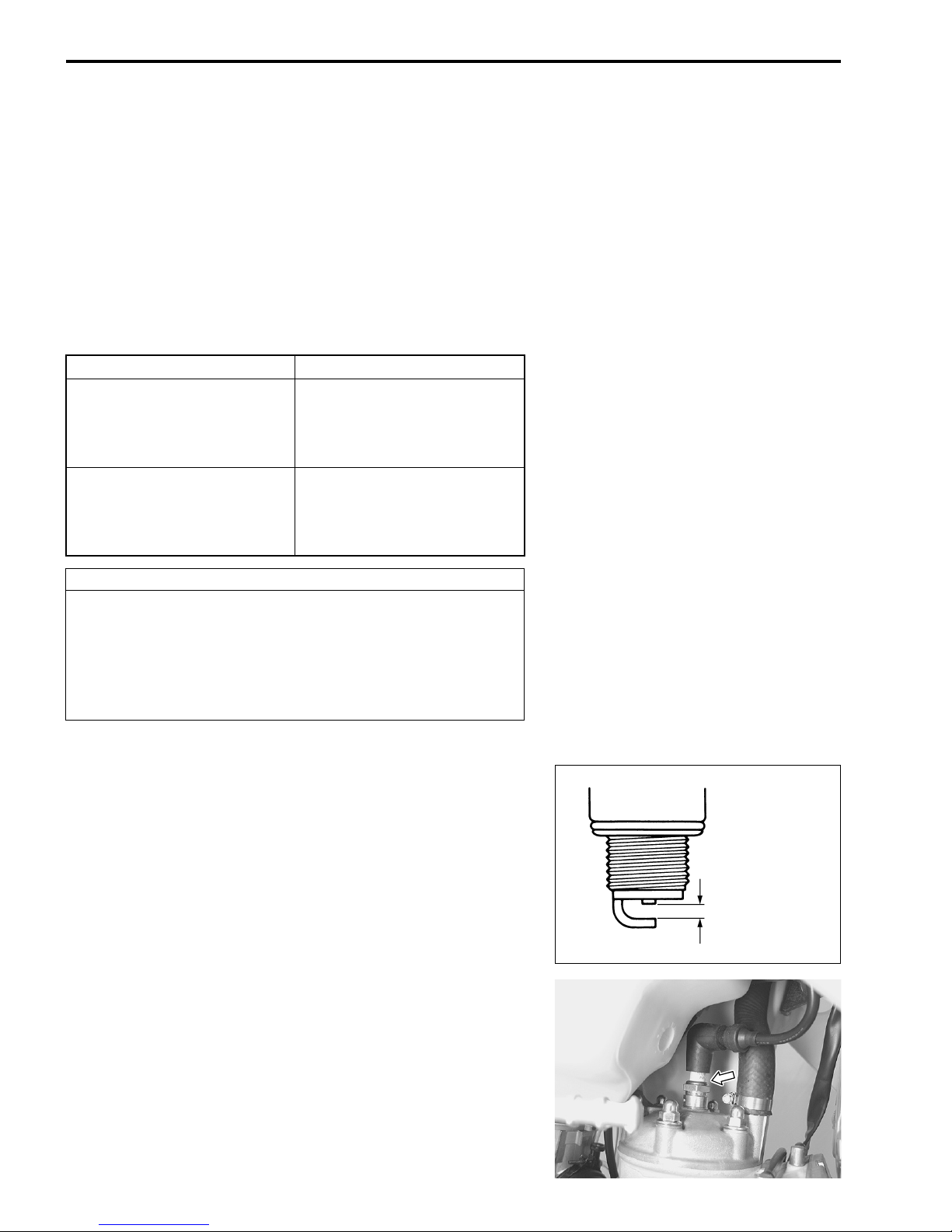

Inspect the spark plug condition, electrode color, carbon deposits, spark plug gap, and washer damage, after removing the

spark plug.

NOTE:

Remove the dirt around the spark plug before removing the

spark plug to prevent dirt from entering the combustion chamber.

Inspect the porcelain tip color.

Porcelain tip color Cause

• Hot type spark plug

White (overheated)

Black (fouled)

• Advanced ignition timing

• Lean air/fuel mixture

• Deteriorated fuel

• Cold type spark plug

• Retarded ignition timing

• Rich air/fuel mixture

• Rich oil/gasoline mixture

CAUTION

Changing the spark plug heat range improperly can

damage the engine.

Select the spark plug heat range only after adjusting

the ignition timing, carburetor setting and oil/gasoline

mixture.

Clean the spark plug and check the spark plug gap with the

thickness gauge.

Standard Spark plug: NGK BR8EG

Spark plug gap: 0.5 – 0.6 mm (0.020 – 0.024 in)

09900-20803: Thickness gauge

Tighten the spark plug to the specified torque after tightening the

spark plug temporarily by hand.

0.5 – 0.6 mm

(0.020 – 0.024 in)

Spark plug: 20 N·m (2.0 kgf-m, 14.5 lb-ft)

AIR CLEANER

AIR CLEANER ELEMENT REMOVAL

• Remove the seat. (5-4)

• Remove the air cleaner box lid.

• Remove screw 1.

• Remove the element 2 from the element holder.

WASHING

• Fill a washing pan that is large enough to hold the element

with non-flammable cleaning solvent A. Immerse the element

in the solvent and wash it.

A: MOTUL AIR FILTER CLEAN or equivalent cleaning solvent

• Squeeze the element by grasping it to remove excess sol-

vent. Do not twist or wring the element, or it will develop

cracks.

• Dry the element in a plastic bag, pour in some foam filter oil B

and work the oil into the element.

B: MOTUL AIR FILTER OIL or equivalent filter oil

• Squeeze the element to remove excess oil.

PERIODIC MAINTENANCE 2-7

INSTALLATION

• Apply grease to the element base where contacts the air

cleaner box.

• Fit the element onto the element holder.

NOTE:

Fit the projection of the element holder in the hole of the element

base.

• Install them in the air cleaner box by engaging the projection

A of the element holder with the hole B of the cleaner body.

CAUTION

Improper element installation allows dust and dirt to

enter the combustion chamber. It can result in piston

and cylinder wear.

Be sure to check the element seals properly after

installing the elements.

2-8 PERIODIC MAINTENANCE

• Install the air cleaner box lid properly as shown.

NOTE:

Running the engine without the air cleaner box lid can vary the

carburetion. Do not run the engine without the air cleaner box

lid.

Lid

Cap to the front.

Air cleaner

box front wall

NOTE:

Follow the instructions below to keep the air cleaner element dry

when cleaning the motorcycle.

* Cover the element with a plastic bag.

* Install the seat.

* Cover the inlet holes on the frame covers to prevent water

from coming into the air cleaner box.

* Do not spray high pressure water to the air cleaner box.

TRANSMISSION OIL

TRANSMISSION OIL LEVEL INSPECTION

AND REPLENISHMENT

WARNING

Transmission oil and exhaust pipe can be hot enough

to burn you.

Wait until the oil drain plug and exhaust pipe become

cool enough to touch with bare hands before draining

oil.

WARNING

New and used oil and solvent can be hazardous. Children and pets may be harmed by swallowing new or

used oil or solvent. Repeated, prolonqed contact with

used engine oil may cause skin cancer, Brief contact

with used oil or solvent may irritate skin.

PERIODIC MAINTENANCE 2-9

* Keep new and used oil and solvent away from chil-

dren and pets.

* Wear a long-sleeve shirt and waterproof gloves.

* Wash with soap if oil or solvent contacts your skin.

NOTE:

Recycle or properly dispose of used oil and solvent.

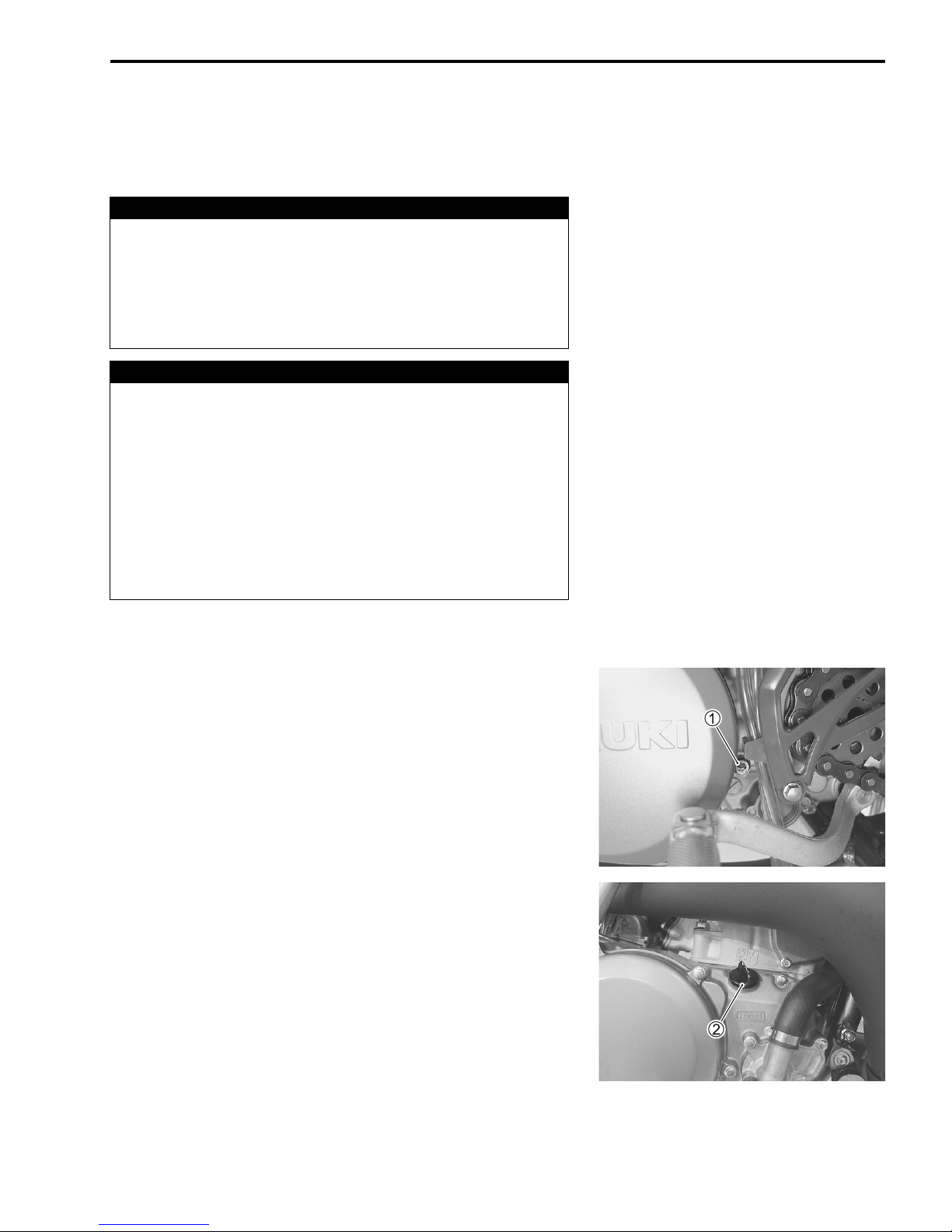

• Place the motorcycle on level ground and hold the motorcycle

vertically.

• Run the engine for a few minutes and stop it. Wait for 5 minutes.

• Remove the oil check bolt 1. Check that oil comes out of the

hole.

• If oil does not come out of the hole, open oil filler cap 2 and

add the specified oil. Tighten the filler cap and oil check bolt

and inspect again as above procedure.

Transmission oil type: SAE 10W-40, API SF/SG or

SH/SJ with JASO MA

• Tighten the filler cap firmly and tighten the oil level check bolt

to the specified torque.

Oil level check bolt: 5.5 N·m (0.55 kgf-m, 4.0 lb-ft)

2-10 PERIODIC MAINTENANCE

TRANSMISSION OIL CHANGE

• Warm up the engine.

• Place the motorcycle on the level ground and hold the motorcycle vertically.

• Remove filler cap and drain plug 1. Drain oil thoroughly.

• Tighten the drain plug firmly.

Oil drain plug: 21 N·m (2.1 kgf-m, 15.0 lb-ft)

• Pour specified amount of oil.

Oil change......... 750 ml (0.8/0.7 US/Imp qt)

Overhaul............ 850 ml (0.9/0.7 US/Imp qt)

• Tighten the filler cap.

• Run the engine for a few minutes and stop it. Wait for 5 minutes.

• Inspect the oil level. (2-9)

ENGINE COOLANT

ENGINE COOLANT LEVEL CHECK

WARNING

You can be injured by scalding fluid or steam if you

open the radiator cap when the engine is hot.

Do not open the radiator cap when the engine is hot.

Wait until engine cools.

• Remove the radiator cap.

• Check that the engine coolant level is at the bottom of the inlet

hole. If not, replenish the radiator with specified engine coolant.

• Tighten the radiator cap securely.

CAUTION

Improperly tightening the radiator cap will prevent the

cooling system from reaching the specified operating

pressure and will cause coolant overflow.

PERIODIC MAINTENANCE 2-11

Tighten the radiator cap until it locks firmly.

NOTE:

* This motorcycle does not have an overflow tank at the end of

breather hose. Therefore, engine coolant level may decrease

while riding. Check the engine coolant level every time before

riding.

* When replenishing engine coolant, be sure to use engine cool-

ant mixed with distilled water at the ratio of 50:50. Adding only

water will dilute engine coolant and it may decrease cooling

performance.

* If the motorcycle is to be exposed to temperatures below –31

°C (–24 °F), the percentage of antifreeze should be increased

to 55% or 60%, according to figure 1.

Antifreeze density Freezing point

50% –31 °C (–24 °F)

55% –40 °C (–40 °F)

60% –55 °C (–67 °F)

Freezing point

Density (%)

Fig. 1 Engine coolant density-freezing

point curve

2-12 PERIODIC MAINTENANCE

ENGINE COOLANT REPLENISHMENT

WARNING

Engine coolant is harmful if swallowed or if it comes in

contact with your skin or eyes.

Keep engine coolant away from children and pets. Call

your doctor immediately if engine coolant is swallowed and induce vomiting. Flush eyes or skin with

water if engine coolant gets in eyes or comes in contact with skin.

• Remove the radiator cap 1.

• Remove the drain plug 2 and drain engine coolant.

• Tighten the drain plug 2 and pour specified engine coolant.

Radiator drain plug: 5.5 N·m (0.55 kgf-m, 4.0 lb-ft)

Engine coolant capacity: 1 100 ml (1.2/1.0 US/lmp qt)

Use an anti-freeze and Summer coolant which is compatible

with aluminum radiator, mixed with distilled water at the ratio of

50 : 50.

NOTE:

The radiator, cylinder and cylinder head are made of aluminum

alloy. Using non-recommended coolant may corrode aluminum

alloy and may clog the coolant passageways.

• Bleed air from the cooling circuit.

ENGINE COOLING SYSTEM INSPECTION

Inspect the following items before practice and races.

• Engine coolant leakage

• Radiator hose cracks and deterioration

• Radiator mounting condition

• Radiator breather hose condition

• Radiator fin condition

CLUTCH

Adjust the clutch cable play as follows:

MAJOR ADJUSTMENT

• Loosen the lock-nut 1.

• Turn the adjuster 2 so that the clutch lever obtains 10 – 15

mm (0.4 – 0.6 in) play at the clutch lever end.

• Tighten the lock-nut 1.

MINOR ADJUSTMENT

• Turn the quick adjuster 3 so that the clutch lever obtains 10 –

15 mm (0.4 – 0.6 in) play at the clutch lever end before pressure is felt.

Clutch lever play: 10 – 15 mm (0.4 – 0.6 in)

PERIODIC MAINTENANCE 2-13

10 – 15 mm

(0.4 – 0.6 in)

THROTTLE CABLE

WARNING

Inadequate throttle cable play can cause engine speed

to rise suddenly when you turn the handlebars. This

can lead to loss of rider control.

Adjust the throttle cable play so that engine speed

does not rise due to handlebar movement.

Adjust the throttle cable play as follows:

• Loosen the lock-nut 1.

• Turn the adjuster 2 so that the throttle grip obtains 2.0 – 4.0

mm (0.08 – 0.16 in) play.

Throttle cable play: 2.0 – 4.0 mm (0.08 – 0.16 in)

• Tighten the lock-nut 1.

2.0 – 4.0 mm

(0.08 – 0.16 in)

2-14 PERIODIC MAINTENANCE

• Remove the throttle housing cover.

• Apply oil to the throttle cable 3. (2-23)

• Apply oil to the throttle cable spool 4. (2-23)

FUEL HOSE

Inspect the fuel hose for damage and fuel leakage. If any

defects are found, the fuel hose must be replaced. Replace fuel

hose every four years.

FUEL VALVE

• Drain fuel from the fuel tank.

• Remove the fuel valve.

• If the fuel filter is dirty with sediment or rust, clean it with compressed air.

WARNING

* Gasoline is very explosive. Extreme care must be

taken.

* The O-ring 1 must be replaced with a new one to

prevent fuel leakage.

CYLINDER HEAD, CYLINDER AND

PISTON

CYLINDER HEAD

• Remove the cylinder head. (6-5)

• Remove carbon deposits from combustion chamber surface.

• Inspect for pinholes, cracks and other damage.

CYLINDER

• Remove the cylinder. (6-6)

• Remove carbon deposits from the exhaust port and exhaust

valve chamber.

• Check for scratches and wear on the cylinder sleeve.

PERIODIC MAINTENANCE 2-15

PISTON

• Remove the piston. (6-6)

• Remove carbon deposits from the top surface of the piston.

• Check for scratches, cracks, and wear around the piston

bosses.

• Remove minor scuffs with #1 000 – #1 200 sand paper.

• Check piston ring wear. Remove carbon deposits from the

piston ring grooves.

EXHAUST VALVE

• Remove the exhaust valve. (6-13)

• Remove carbon deposits from the exhaust valve 1, exhaust

side valves 2 and exhaust valve cams 3.

• Check for wear and damage.

NOTE:

If tar drops from the exhaust valve breather hose when the

motorcycle is parked, change engine oil brand because some

engine oil can accumulate tar in the exhaust valve chamber.

Loading...

Loading...