Sirona Orthophos 3 Service manual

loqelmelp=P=L=P=`ÉéÜ=L=P=ap

pЙкобЕЙ=j~ем~д

IMPORTANT:

•Please note that this document applies from serial number 8000 and for modification to ORTHOPHOS 3 DS.

•For units with serial number below 8000 please use the Service Manual, order number 18 73 467.

•In case of faults which you are unable to eliminate with the help of this manual, please contact our Customer Service.

•It is essential that you take this Service Manual with you for every visit to a customer.

Furthermore, you must always have the spare parts list and the wiring diagrams with you as well.

You can order additional copies of this Service Manual under the

•order number 58 35 744 from our department GZP in Bensheim.

See reverse side of manual for address.

sЙклбзе=SKM

D 3285.077.02.06.02 07.2004

loqelmelp=P=L=P=`ÉéÜ=L=P=ap

pЙкобЕЙ=j~ем~д= о~дбЗ=Скзг=лЙкб~д=езK=UMMM ~åÇ=Сзк=гзЗбСбЕ~нбзе=нз=loqelmelp=P=ap

sЙклбзе=SKM

The following are also required:

• Spare parts list

Order no. 33 33 908

• Circuit diagrams

ORTHOPHOS 3 / 3 Ceph / 3 DS Order no.59 01 629

•Tools

–Hexagonal-head screwdrivers, angled, sizes 1, 5, 2 – 10

–Allen key, size 4, length 200 mm, for socket head screws

–Set of hexagonal wrenches, sizes 4 – 14 with 1/4” ratschet, extension and 4 socket head (Allen) inserts 3 – 6 mm

–Spirit level

–Open-end wrenches, sizes 5.5, 7, 8, 10, 13, 30, and 19, 22 for Ceph

–Torx screwdrivers, sizes 10, 20, 25

–Phillips-head srewdriver, size 1

–Insulated slot-head screwdrivers, sizes 0, 1, 2, 3, 4, 6

–Pliers for retaining ring

•Auxiliary equipment

–Digital multimeter, accuracy class 1

–Soldering iron for cable repairs

–Diagonal cutter

–Cable ties

–Teflon insulating tape

Important Notes 1

List of Messages 2

Troubleshooting 3

Checks and Adjustments 4

Service Routines 5

Repairs 6

Maintenance 7

|

|

|

Contents |

|

|

|

|

1 |

Important Notes ................................................................................................................... |

1 - 1 |

|

|

1.1 |

Important Notes ......................................................................................................... |

1 - 3 |

|

1.2 |

List of software versions ........................................................................................... |

1 - 5 |

|

1.3 |

Major Assemblies and Components .......................................................................... |

1 - 6 |

|

1.4 |

Removing Panels ...................................................................................................... |

1 - 8 |

|

1.5 |

Photographs of PC Boards ...................................................................................... |

1 - 11 |

2 |

List of Messages................................................................................................................... |

2 - 1 |

|

|

2.1 |

List of Help Messages ............................................................................................... |

2 - 3 |

|

2.2 |

List of Error Messages .............................................................................................. |

2 - 4 |

|

2.3 |

List of Service Routines ............................................................................................. |

2 - 8 |

|

2.4 |

List of Error Messages for SIDEXIS .......................................................................... |

2 - 9 |

3 |

Troubleshooting.................................................................................................................... |

3 - 1 |

|

|

3.1 |

Unit cannot be switched on, nothing displayed on the Multitimer .............................. |

3 - 7 |

|

3.1 A Exposure too dark .................................................................................................. |

3 - 7.4 |

|

|

3.2 |

Demonstration mode cannot be turned ON/OFF ...................................................... |

3 - 9 |

|

3.3 |

The Teleradiography exposure is not released ....................................................... |

3 - 11 |

|

3.4 |

Correcting errors of help messages H3 04. ............................................................. |

3 - 13 |

|

3.5 |

Correcting errors of help messages H3 06. ............................................................. |

3 - 15 |

|

3.6 |

Correcting errors of help messages H3 11. ............................................................. |

3 - 17 |

3.7Correcting error of messages E1 01, E1 02, E2 03: Signal paths to

control board DX1 are interrupted. .......................................................................... |

3 - 19 |

3.8Correcting error of message E2 01: X-ray tube assembly overheated. .................. 3 - 21

3.9 |

Correcting error of message E2 |

04: Zero power range has been re-initialized. ...... |

3 |

- 23 |

3.10 |

Correcting error of message E2 |

11: Anode voltage too high. ................................. 3 |

- 25 |

|

3.11 |

Correcting error of message E2 |

12: Anode current too high. .................................. |

3 |

- 27 |

3.12 |

Correcting error of message E2 |

13: Filament voltage too high. .............................. |

3 |

- 29 |

3.13Correcting error of message E2 14: Short-circuit in bridge. ................................... 3 - 31

3.14Correcting error of message E2 16: kVACTUAL – Cable is interrupted. ................... 3 - 33

3.15Correcting error of message E2 20: Interrupted exposure lead in Multitimer cable. 3 - 35

3.16 |

Correcting error of message E2 |

40: VH setpoint out of tolerance. .......................... |

3 - 39 |

3.17 |

Correcting error of message E2 |

43: VH setpoint out of tolerance. .......................... |

3 - 41 |

3.18 |

Correcting error of message E2 |

44: kV setpoint out of tolerance. ........................... |

3 - 43 |

3.19Correcting error of message E2 45: mA setpoint out of tolerance. ......................... 3 - 45

3.20Correcting error of messages E3 01, E3 02: Actuator M2 has

not left/reached the tripping position. ...................................................................... 3 - 47

3.21Correcting error of messages E3 05, E3 06: Cassette carriage has

not left/reached the reference point. ........................................................................ |

3 - 49 |

3.22 Correcting error of message E3 12: Key for height adjustment pressed |

|

during unit self-adjustment. ..................................................................................... |

3 - 51 |

58 35 744 D 3285

D 3285.077.02.06.02 07.2004

VII

Contents

3.23 |

Correcting error of messages E3 32, E3 33: Start position for rotation was |

|

|

|

not exited/reached. .................................................................................................. |

|

3 - 53 |

3.24 |

Correcting error of message E3 |

36: Cassette holder was swivelled from |

|

|

the Pan position during Pan exposure. .................................................................... |

3 - 57 |

|

3.25 |

Correcting error of message E3 |

39 / E3 42: Light barrier for Ceph position |

|

|

rotation indicates invalid status ............................................................................... |

|

3 - 61 |

3.26Correcting error of message E3 46: Position of cassette holder cannot be

determined. ............................................................................................................. 3 - 63

3.27Correcting error of message E4 01: Exposure aborted by SIDEXIS (with XOP). ... 3 - 65

3.28 |

Correcting error of message E4 01: Exposure aborted by SIDEXIS (with XAB) ..... |

3 - 67 |

3.29 |

Correcting error of message E4 06: Fault at one of the supply voltages |

|

|

(with XOP). .............................................................................................................. |

3 - 69 |

3.30 |

Correcting error of message E4 06: Fault at one of the supply voltages |

|

|

(with XAB) ............................................................................................................... |

3 - 71 |

3.31 |

Correcting error of message E4 08: Aborted by SIDEXIS during radiation |

|

|

(with XOP) ............................................................................................................... |

3 - 73 |

3.32 |

Correcting error of message E4 08: Aborted by SIDEXIS during radiation |

|

|

(with XAB) ............................................................................................................... |

3 - 77 |

3.33 |

Correcting error of message E4 11: Image receptor not ready for exposure |

|

|

(with XOP). .............................................................................................................. |

3 - 81 |

3.34 |

Correcting error for message E4 11: Image receptor not ready for exposure |

|

|

(with XAB) ............................................................................................................... |

3 - 85 |

3.35 |

Correcting error of message E4 16: Active signal present when switching ON |

|

|

(with XOP). .............................................................................................................. |

3 - 89 |

3.36 |

Correcting error of message E4 16: Active signal present when switching ON |

|

|

(with XAB) ............................................................................................................... |

3 - 91 |

4 Checks and Adjustments...................................................................................................... |

4 - 1 |

|

4.1 |

Phantom radiograph — Adjusting actuator M2 ......................................................... |

4 - 5 |

4.2 |

Checking and adjusting the X-ray beam for Panorama radiography ...................... |

4 - 13 |

4.3 |

Checking and adjusting the X-ray beam for Cephalometry ..................................... |

4 - 17 |

4.4 |

Checking the symmetry on the Cephalometer ........................................................ |

4 - 19 |

4.5 |

Checking and adjusting the ear olives .................................................................... |

4 - 21 |

4.6 |

X-ray tube assembly: action to be taken during/after replacement? ....................... |

4 - 23 |

4.7 |

Radiographic density of spinal column not correct .................................................. |

4 - 25 |

4.8 |

Checking exposure times ........................................................................................ |

4 - 27 |

4.9 |

Checking the tube current ....................................................................................... |

4 - 29 |

4.10 |

Adjusting board DX1 ............................................................................................... |

4 - 31 |

4.11 |

Checking and adjusting the light localizers ............................................................. |

4 - 33 |

VIII

58 35 744 D 3285 D 3285.077.02.06.02 07.2004

|

|

|

|

Contents |

|

|

|

|

|

5 |

Service Routines .................................................................................................................. |

5 - 1 |

||

|

|

5.1 |

Selecting Service routines ......................................................................................... |

5 - 7 |

|

|

5.2 |

Setting exposure readiness on the PC ...................................................................... |

5 - 9 |

|

|

5.3 |

Service routine S.01 Radiation without rotation ...................................................... |

5 - 11 |

|

|

5.4 |

Service routine S.02 Radiation without rotation for Ceph ........................................ |

5 - 13 |

|

|

5.5 |

Service routine S.03 Setpoints: kV, mA, preheating ................................................ |

5 - 15 |

|

|

5.6 |

Service routine S.04 Actual values: kV, mA, preheating ......................................... |

5 - 19 |

|

|

5.7 |

Service routine S.05 Heating adjustment ................................................................ |

5 - 23 |

|

|

5.8 |

Service routine S.06 Radiation counter (decimal display) ....................................... |

5 - 27 |

|

|

5.9 |

Service routine S.07 Erasing the error memory ...................................................... |

5 - 29 |

|

|

5.10 |

Service routine S.09 Erasing EEPROM DX1 .......................................................... |

5 - 31 |

|

|

5.11 |

Service routine S.11 Setting the kV increase correction value for |

|

|

|

|

Panorama radiography ............................................................................................ |

5 - 33 |

|

|

5.12 |

Service routine S.13 Hardware service ................................................................... |

5 - 35 |

|

|

5.13 |

Service routine S.14 Rotation functions .................................................................. |

5 - 37 |

|

|

5.14 |

Service routine S.15 Checking the actuator M2 ...................................................... |

5 - 41 |

|

|

5.15 |

Service routine S.16 Film holder service ................................................................. |

5 - 45 |

|

|

5.16 |

Service routine S.17 Unit identification ................................................................... |

5 - 49 |

|

|

5.17 |

Service routine S.18 Checking the height adjustment ............................................. |

5 - 51 |

|

|

5.18 |

Service routine S.25 Adjusting the film/screen combination or the |

|

|

|

|

kVmA step series .................................................................................................... |

5 - 53 |

|

|

5.19 |

Service routine S.27 Setting country code .............................................................. |

5 - 55 |

|

|

5.20 |

Service routine S.32 Image receptor service: Panorama ........................................ |

5 - 57 |

|

|

5.21 |

Service routine S.35 PC service ............................................................................. |

5 - 59 |

|

|

5.22 |

Service routine S.37 XAB OP service ..................................................................... |

5 - 61 |

6 |

Repairs ................................................................................................................................. |

6 - 1 |

||

|

|

6.1 |

Replacing the rotation motor M1 ............................................................................... |

6 - 5 |

|

|

6.2 |

Replacing the actuator M2 ........................................................................................ |

6 - 9 |

|

|

6.3 |

Replacing the spindle with motor M4 for height adjustment .................................... |

6 - 11 |

|

|

6.4 |

Replacing the cassette holder for Panorama radiography ...................................... |

6 - 15 |

|

|

6.5 |

Replacing the rope and/or the cassette drive motor M3 ......................................... |

6 - 17 |

|

|

6.6 |

Replacing socket contact for image receptor .......................................................... |

6 - 21 |

|

|

6.7 |

Replacing Column Stand ........................................................................................ |

6 - 23 |

|

|

6.8 |

Replacing rotary knob and sensor ejector ............................................................... |

6 - 27 |

|

|

6.9 |

Replacing ring cable L4 ........................................................................................... |

6 - 29 |

58 35 744 D 3285

D 3285.077.02.06.02 07.2004

IX

Contents

7 |

Maintenance ......................................................................................................................... |

7 - 1 |

|

|

7.1 |

Checking the height adjustment ................................................................................ |

7 - 5 |

|

7.2 |

Checking the forehead support ................................................................................. |

7 - 7 |

|

7.3 |

Checking the diaphragm wheel ................................................................................. |

7 - 9 |

|

7.4 |

Checking the cassette holder .................................................................................. |

7 - 11 |

|

7.5 |

Checking the image receptor .................................................................................. |

7 - 13 |

|

7.6 |

Checking the light localizer ..................................................................................... |

7 - 15 |

|

7.7 |

Checking the conventional cephalometer ............................................................... |

7 - 17 |

|

7.8 |

Checking X-ray exposures ...................................................................................... |

7 - 19 |

|

7.9 |

Checking the actual kV/mA values and the preheating ........................................... |

7 - 21 |

|

7.10 |

Phantom/needle phantom exposure with ORTHOPHOS 3/3 Ceph ........................ |

7 - 23 |

|

7.11 |

Phantom/needle phantom exposure with ORTHOPHOS 3 DS/3 Ceph |

|

|

|

with Upgrade Kit ...................................................................................................... |

7 - 27 |

|

7.12 |

Checking cables for damage ................................................................................... |

7 - 29 |

|

7.13 |

Checking the grounding straps ............................................................................... |

7 - 31 |

|

7.14 |

Checking the shielding of the cables ....................................................................... |

7 - 33 |

|

7.15 |

Checking light barrier housings V1 to V7/ring cable ............................................... |

7 - 35 |

|

7.16 |

Checking the flat belt on rotation motor M1 ............................................................ |

7 - 37 |

|

7.17 |

Checking the protective ground wire and the unit’s leakage current ....................... |

7 - 39 |

X

58 35 744 D 3285 D 3285.077.02.06.02 07.2004

1 Important Notes

Contents

Important Notes

Contents

1.1 |

Important Notes ................................................................................................................. |

1 - 3 |

1.2 |

List of software versions ................................................................................................... |

1 - 5 |

1.3 |

Major Assemblies and Components .................................................................................. |

1 - 6 |

1.4 |

Removing Panels .............................................................................................................. |

1 - 8 |

1.5 |

Photographs of PC Boards .............................................................................................. |

1 - 11 |

1 - 2 |

58 35 744 D 3285 |

D 3285.077.02.06.02 07.2004 |

|

|

|

1.1 Important Notes |

|

|

1.1 Important Notes |

1.1 |

|

• The ORTHOPHOS® 3 / 3 Ceph / 3 DS |

||

|

||

operates with the following nominal line voltages: 208V, 230-240V, 50/60 Hz. |

|

|

The permissible line voltage fluctuations are 230-240V + 6%, –10%, and 208 V ± 10%. |

|

|

The internal line resistance must not exceed 0.8Ω. |

|

•Remote control

The unit can be equipped with a remote control inside the treatment room or outside an X-ray room.

For the tests the Multitimer can/must be removed from the remote control module and is to be connected directly to the unit (for remote control with the Multitimer without coiled cable, the coiled cable has to be connected for the tests according to the installation instructions).

Remember that the fault can then be in the deactivated cable.

•Warm-up time, self-adjustment, cool-down time, turn-off time

After power-up the unit always requires a warm-up time of one minute.

During this time, the self-adjustment routine for the mechanical elements and electronics of the unit is executed. Pressing a key during the self-adjustment causes an error indication at the Multitimer. The cool-down time between two consecutive exposures is ensured by the automatic exposure blockage determined by the pulse/pause ratio. The count down of the waiting time required is indicated on the Multitimer. The turn-off time of board XAB-OP must be at least 60s; otherwise the unit will not function correctly (no exposure readiness).

•For demonstration units set the test switch S1/S88 on board DX31 to position 2. LED V2 on board DX31 must light up.

Now, no X-ray radiation is generated.

In the interest of improved safety we recommend removing fuse F5 on board DX3.

•The overall software version of the unit is determined by the software versions of the EPROMs on board DX1 and of the Multitimer D4 as well as the version number of the memory card. Refer to the list of software versions. When switching the unit ON the versions are indicated on the Multitimer for about three seconds after the segment test.

•Interference of radio telephones with electromedical equipment

The use of mobile telephones in the area of the medical practice or clinic is prohibited in order to ensure the operational reliability and safety of electromedical equipment.

•Disposal

The X-ray tube assembly contains a tube which can implode, a small amount of beryllium, a lead lining and mineral oil.

•Error messages

Error messages are indicated on the Multitimer.

•Help messages H if radiographic readiness is not reached Help messages are displayed on the Multitimer.

58 35 744 D 3285 |

1 - 3 |

D 3285.077.02.06.02 07.2004 |

1.1 Important Notes

•If you have to remove panels from the unit.

Refer to section "Removing panels".

With the panels removed, remember that the direct incidence of sunshine or bright room light can cause unit malfunctions by activating the light barriers.

Therefore: Avoid direct sunshine and bright lighting above the unit!

Remember when reattaching the panels:

Secure sheet metal covers with screws.

IMPORTANT: For reasons of EMC it is essential to insert all screws.

Reinstall all panels.

•Measurements

Before connecting a measuring instrument, always switch the unit OFF.

Select the required current/voltage type and set the measuring range according to the expected value.

Carry out continuity tests only with the unit switched off.

If the release of several exposures with radiation is required for checking the measuring results, you must observe the specified cool-down intervals. This is ensured by the automatic exposure blockage (see Operating Instructions).

The pulse/interval ratio is 1:10, which means a 10 second pause has to follow after 1 second of radiation. This pulse/interval ratio is automatically guaranteed by the automatic exposure blockage.

However, preferable for the X-ray tube is a pulse/pause ratio of 1:20.

Adhere to the radiation protection guidelines before generating radiation.

Test runs initiated by pressing the T key on the Multitimer followed by actuation of the exposure release button are executed without radiation, i.e. the kV/mA displays remain blank. l

•Replacing parts

Always turn the unit OFF before replacing any parts.

When parts located close to the line transformer are to be replaced, switch off the power at the distributor box for the onsite electrical system for safety reasons.

WARNING! The discharge time for the capacitors is 4 minutes.

To protect electrostatic sensitive devices (ESD) on boards, always wear the wrist band.

The unit must be checked and newly adjusted following the replacement of the DX1 electronics, |

the X-ray tube assembly or a diaphragm. |

The article numbers for ordering spare parts can be found in the spare parts list, order no. 33 33 908. The figures in the spare parts list offer valuable assistance when replacing parts.

1 - 4 |

58 35 744 D 3285 |

D 3285.077.02.06.02 07.2004 |

|

|

|

1.2 List of software versions

1.2 List of software versions

From serial no. 8000

for ORTHOPHOS 3 / 3 Ceph / 3 DS From serial no. 6000

for systems modified to ORTHOPHOS 3 DS

IMPORTANT: No other combinations of software are allowed since these could result in undefined faults.

Multitimer

Version no. memory card

Software Multitimer D4

Software board DX1

X-RAY |

1.2 |

|

|

0 I 0 |

|

kV 0 6

mA |

2 0 |

T R

ORTHOPHOS 3 / 3 Ceph

Unit identification 30

Overall software |

|

DX1 |

D4 |

|

Memory |

|

Remarks |

|

|

|||

|

|

|

|

J115 |

EEPROM J4 |

|

Card |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Version 7.30 |

04.99 |

|

|

020 |

006 |

|

010 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Version 8.30 |

03.01 |

|

|

020 |

006 |

|

011 |

kv/mA levels for Asia and USA; |

|

|||

|

|

|

|

|

|

|

|

|

Anomaly level -1 for P1 and P11 for Asia |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Version 9.30 |

05.02 |

|

|

021 |

006 |

|

011 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ORTHOPHOS 3 DS |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Unit identification |

31 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||

Overall software |

|

|

DX1 |

D4 |

|

Memory |

SIDEXIS |

Service |

Remarks |

|||

|

|

|

EEPROM |

|

Card |

|

disk |

|

|

|||

|

|

|

EEPROM J4 |

|

|

|

|

|||||

|

|

|

|

J115 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Version 01.31 04.99 |

|

|

020 |

006 |

|

|

010 |

≥ 4.2 |

1.12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Version 02.31 11.00 |

|

|

020 |

006 |

|

|

011 |

≥ 4.2 |

1.12 |

XAB OP capable; |

||

|

|

|

|

|

|

|

|

|

|

|

conventional Ceph possible |

|

Version 03.31 03.01 |

|

|

020 |

006 |

|

|

012 |

≥ 4.2 |

1.12 |

kv/mA levels for Asia and USA; |

||

|

|

|

|

|

|

|

|

|

|

|

Anomaly level -1 for P1 and P11 |

|

|

|

|

|

|

|

|

|

|

|

|

for Asia |

|

|

|

|

|

|

|

|

|

|

|

|||

Version 04.31 05.02 |

|

|

021 |

006 |

|

|

012 |

≥ 4.2 |

1.12 |

Correcting error of message |

||

|

|

|

|

|

|

|

|

|

|

|

E4 04, E3 48 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

58 35 744 D 3285 |

1 - 5 |

D 3285.077.02.06.02 07.2004 |

1.3 Major Assemblies and Components

1.3 Major Assemblies and Components

ORTHOPHOS 3 DS

|

DX33 |

|

|

M4 |

|

RHB |

|||||

XAB OP/XAB D / DEB |

|

|

S2, S3, |

|

|

M1 |

|||||

|

|

|

|

||||||||

|

|

S4 |

|

|

|||||||

|

Rear |

|

|

Rear |

|

|

V1 |

||||

DEB discontinued as of serial no. |

|

|

|

|

|

|

|

|

|

M2 |

|

31 000 ORTHOPHOS 3 DS |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

||||||||

and replaced by XAB OP, XAB D |

|

|

|

|

|

|

|

|

V2 |

||

|

DX31 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

K3

|

DX3 |

|

I |

DX1 |

H1 |

|

|

|

O |

S1 with |

|

|

|

|

|

automatic |

S9 |

|

|

|

|

cutout |

|

Remote control . . . |

|

K2 |

K2 |

||

|

|

|

|

||

|

|

|

|

|

EDC/BE |

|

|

|

D4 |

S7 |

|

|

|

K10 |

K10 |

||

|

|

S8 |

|||

|

|

|

|

|

|

|

|

L11 |

L12 |

|

|

. . . without |

|

K11 |

|

|

L30/L31/LAN |

|

. . . with |

|

|

|

|

coiled cable |

coiled cable |

|

L8 |

|

|

|

|

L8 |

|

|

|

|

L9 |

K2 |

L9 |

Control cable of |

|

|

remote control |

|

|||

|

|

|

|

||

BE |

= |

Image receptor |

X |

= |

Connectors on boards |

DEB, EDC, |

|

|

V1 - V2 |

= |

Light barriers: |

RHB, D, DX, |

|

|

V1 |

= Start position for rotation |

|

XAB |

= |

PC boards |

V2 |

= Start position for actuator M2 |

|

T |

= |

Transformer |

|

|

|

M |

= |

Memory card |

|

|

|

H1 |

= |

X-ray tube assembly |

|

|

|

M1 |

= |

Motor for rotation |

|

|

|

M2 |

= |

Actuator |

|

|

|

M4 |

= Motor for height adjustment |

|

|

|

|

K= Connector/terminal strips on/in the unit

L= Leads/cables

S |

= Switch |

|

|

1 - 6 |

58 35 744 D 3285 |

D 3285.077.02.06.02 07.2004 |

|

|

|

|

1.3 Major Assemblies and Components |

ORTHOPHOS 3 / 3 Ceph |

1.3 |

|

|

|

M4 |

S2, S3, |

M1 |

S4 |

|

rear |

V1, V7 |

M2

V2

DX31 |

V4, V5 |

T |

|

K3

|

|

DX3 |

|

|

|

I |

DX1 |

S10 |

H1 |

|

|

|

|

|

|

O |

S1, F1, F2 |

|

S9 |

|

|

or S1 with |

|

|

|

|

automatic |

M3 |

|

|

|

cutout |

|

|

Remote control . . . |

|

|

V3 |

|

|

|

|

K2 |

|

|

D4 |

|

FH S1 |

|

|

|

|

|

|

K10 |

K10 |

S7 |

|

|

|

|

|

S8 |

|

L11 |

L12 |

|

|

|

. . . without |

|

. . . with |

|

|

K11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

coiled cable |

coiled cable |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

L8 |

|

|

|

|

|

|

|

|

L8 |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Control cable of |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

L9 |

|

K2 |

|

|

|

|

|

|

|

|

|

L9 |

|||||||||||||||

|

|

|

|

|

remote control |

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

FH |

= |

Membrane keyboard |

V1 - V7 = |

Light barriers: |

|

D, DX |

= |

PC boards |

V1 |

= |

Start position for rotation |

T |

= |

Transformer |

V2 |

= |

Start position for actuator M2 |

M |

= |

Memory card |

V3 |

= |

Start position for film cassette |

H1 |

= |

X-ray tube assembly |

V4 |

= |

Exposure position cassette holder |

F1, F2 |

= |

Main fuses |

V5 |

= |

Cassette holder in Ceph position |

M1 |

= |

Motor for rotation |

V7 |

= |

Rotation ring in Ceph position |

M2 |

= |

Actuator |

|

|

|

M3 |

= Motor for cassette movement |

|

|

|

|

M4 |

= Motor for height adjustment |

|

|

|

|

K= Connector/terminal strip on/in the unit

L= Leads/cables

S = Switch

X = Connectors on boards

58 35 744 D 3285 |

1 - 7 |

D 3285.077.02.06.02 07.2004 |

1.4 Removing Panels

1.4 Removing Panels

X-ray tube assembly, rotation ring

Push this cuff aside before lifting off the panel!

Always tighten the four mounting screws!

Don’t forget cover plate!

1 - 8 |

58 35 744 D 3285 |

D 3285.077.02.06.02 07.2004 |

|

|

|

|

1.4 Removing Panels |

Unit carriage |

1.4 |

|

Left |

Side |

|

cover plate |

||

side |

||

(loosen 2 screws |

||

cover |

||

only to remove) |

||

|

Lowers cover plate

Front cover

Bracket

Right side cover

58 35 744 D 3285 |

1 - 9 |

D 3285.077.02.06.02 07.2004 |

1.4 Removing Panels

Extension box ORTHOPHOS 3 DS

till Serial-No. 30 999

from Serial-No. 31 000

1 - 10 |

58 35 744 D 3285 |

D 3285.077.02.06.02 07.2004 |

|

|

|

|

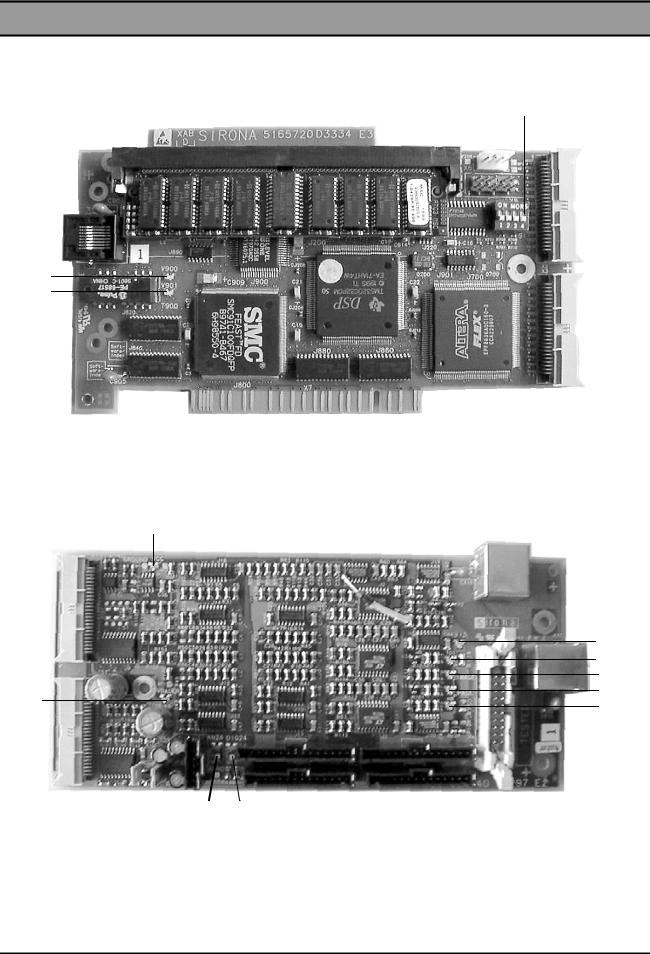

1.5 Photographs of PC Boards |

|

1.5 Photographs of PC Boards |

1.5 |

|

DX1 board |

||

|

||

51 68 658 |

|

Switch S101

Switch S101

Position 1 (left) |

V101 V103 V102 |

otherwise system start-up not possible with Boot software

LED1 |

LED2 |

LED3 |

Description |

Required action |

|

V101 |

V103 |

V102 |

|||

|

|

||||

|

|

|

|

|

|

on |

on |

on |

Controller not o.k. |

Replace and adjust DX1 |

|

|

|

|

|

|

|

on |

off |

off |

Internal XRAM not o.k. |

Replace and adjust DX1 |

|

|

|

|

|

|

|

off |

on |

off |

Internal RAM not o.k. |

Replace and adjust DX1 |

|

|

|

|

|

|

|

off |

off |

on |

Program memory for Boot software not o.k. |

Replace and adjust DX1 |

|

|

|

|

|

|

|

flashing |

flashing |

off |

Input clock of 82c54 not o.k. |

Replace and adjust DX1 |

|

|

|

|

|

|

|

flashing |

off |

flashing |

Vref2 voltage not o.k. |

Replace and adjust DX1 |

|

|

|

|

|

|

|

off |

off |

flashing |

Malfunction of Watchdog timer |

Replace and adjust DX1 |

|

|

|

|

|

|

|

off |

on |

on |

Unable to switch to memory card |

Replace and adjust DX1 |

|

|

|

|

|

|

|

flashing |

off |

off |

Program memory of memory card not o.k. |

Memory card incorrect, not or only partially |

|

|

|

|

|

programmed |

|

|

|

|

|

|

|

off |

flashing |

off |

not assigned |

|

|

|

|

|

|

|

|

flashing |

off |

on |

not assigned |

|

|

|

|

|

|

|

|

off |

flashing |

on |

not assigned |

|

|

|

|

|

|

|

|

off |

off |

off |

All tests run without errors |

Everything o.k. |

|

|

|

|

|

|

|

on |

on |

off |

No memory card detected |

Insert memory card correctly |

|

|

|

|

|

|

|

on |

off |

on |

Memory card not correct |

Insert memory card for ORTHOPHOS |

|

|

|

|

|

|

58 35 744 D 3285 |

1 - 11 |

D 3285.077.02.06.02 07.2004 |

1.5 Photographs of PC Boards

DX3 and DX31 boards

DX3

14 49 011

DX31

51 66 272

Radiation

S.88 Demonstration mode

V2

S.88  Position 2 Demonstration

Position 2 Demonstration

mode

1 - 12 |

58 35 744 D 3285 |

D 3285.077.02.06.02 07.2004 |

|

|

|

1.5 Photographs of PC Boards

DX33 board 1.5

DX33 |

F1 |

F2 |

|

51 68 526 |

|||

|

|

230V

208V

115V

F3

+30V |

+30V |

+24V |

+24V |

+9,5V |

+5V |

V18 |

V10 |

V15 |

V11 |

V16 |

V17 |

58 35 744 D 3285 |

1 - 13 |

D 3285.077.02.06.02 07.2004 |

1.5 Photographs of PC Boards

RHB board

RHB

|

|

V232 |

V212 |

V200 |

V100 |

V122 |

V112 |

V222 |

|||||||

D+5V |

-18V |

+18V |

D+24V |

A+24V |

A-5V |

A+5V |

|

1 - 14 |

58 35 744 D 3285 |

D 3285.077.02.06.02 07.2004 |

|

|

|

1.5 Photographs of PC Boards

DEB board 1.5

DEB

V905 V900 V910 V221 V216 V670 V350 V231 V232 |

V950 |

V216 LED, Out clock pulses TDI

V221 LED, radiographic mode

V231 LED, Ceph radiography mode only with ORTHOPHOS Plus DS Ceph

V232 LED, Panoramic radiography mode

V350 LED, EDC Reset (not inserted)

V670 LED, PC exposure readiness ACTIVE signal

V900 LED, digital supply voltage RHB +24V

V905 LED, analog supply voltage RHB +24V

V910 LED, supply voltage DEB +5V ORTHOPHOS

V950 LED, supply voltage DEB +5V PC

V905 |

V900 |

V910 |

V221 |

V216 |

V670 |

V350 |

V231 |

V232 |

V950 |

Status |

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

|

|

X |

X |

Standby Pan |

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

|

X |

|

X |

Standby Ceph without function |

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

|

|

|

|

|

X |

X |

Panoramic radiography mode |

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

|

|

|

|

X |

|

X |

Ceph radiography mode |

|

|

|

|

|

without function |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

X |

|

X |

|

|

X |

X |

Panoramic radiography mode |

|

|

|

Image generation test image |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ceph radiography mode |

X |

X |

X |

X |

|

X |

|

X |

|

X |

Image generation test image |

|

|

|

|

|

|

|

|

|

|

without function |

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

X |

glows |

X |

|

|

X |

X |

Panoramic radiography mode |

|

|

X-ray |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

X |

X |

X |

glows |

X |

|

X |

|

X |

Ceph radiography mode X-ray |

|

|

without function |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

58 35 744 D 3285 |

1 - 15 |

D 3285.077.02.06.02 07.2004 |

1.5 Photographs of PC Boards

XAB OP and XAB D boards

XAB D

Coding switch

V900

V901

V900 = RD Transmit, GN Receive

V901 = RD Link (adress recognition), GN 100Mbps (Megabits per sec)

XAB OP

V10

V13

V5

V6

V7

V9

V8

V12 V11

V5 LED, TDI distance pulses

V6 LED, IMAGE radiographic mode

V7 LED, radiographic mode Ceph only with ORTHOPHOS Plus DS Ceph

V8 LED, radiographic mode Pan

V9 LED, V continuous

V10 LED, VCC +5V

V11 LED, Digital supply voltage +24V

V12 LED, Analog supply voltage +24V

V13 LED, PC exposure readinesst ACTIVE signal

1 - 16 |

58 35 744 D 3285 |

D 3285.077.02.06.02 07.2004 |

|

|

|

2 List of Messages

Contents

List of Messages

Contents

2.1 |

List of Help Messages ....................................................................................................... |

2 - 3 |

2.2 |

List of Error Messages ....................................................................................................... |

2 - 4 |

2.3 |

List of Service Routines ..................................................................................................... |

2 - 8 |

2.4 |

List of Error Messages for SIDEXIS .................................................................................. |

2 - 9 |

2 - 2 |

58 35 744 D 3285 |

D 3285.077.02.06.02 07.2004 |

|

|

|

2.1List of Help Messages

After the cool-down interval has elapsed you want to release an exposure, but the Ready LED is flashing:

•Press the X-ray key on the Multitimer.

CAUTION: Take radiation protection measures.

The H3 or H4 message then appears on the kV/mA display.

•Find in the following list the actions required to return the unit to readiness for exposure.

•Before carrying out the required action clear the help message by pressing the R key on the Multitimer.

|

Help |

Description |

|

Required action |

2.1 |

|

|

message |

|

|

|||

|

|

|

|

|

||

|

H3 01 |

Rotation unit not in the start position. |

Press the Return key R. |

|

||

Ceph |

H3 04 |

Cassette holder not in Panorama position. |

Swivel cassette holder to stop position. For error |

|||

|

correction follow service routine S.16, |

see page |

||||

|

|

|||||

|

|

|

5 - 45. |

|

|

|

or |

H3 06 |

Locking button on diaphragm wheel not engaged |

Correctly engage locking button on diaphragm |

|||

(Panorama diaphragm). |

wheel, |

see page 3 - 15. |

|

|||

Panorama |

H3 12 |

|

||||

Cassette holder not in Ceph position. |

Swivel cassette holder to stop position. For error |

|||||

|

H3 11 |

|||||

|

|

correction follow service routine S.16, |

|

|||

|

|

|

see page 5 - 45. |

|

||

|

|

Rotation unit not in start position for Cephalome- |

Press R key. |

|

||

|

|

try. |

|

|

|

|

|

H3 20 |

Radiographic data not acknowledged. |

Acknowledge radiographic data with Return key R. |

|||

|

H4 01 |

Image receptor not inserted correct. |

Insert image receptor up to end stop. |

|

||

|

|

For error correction follow service routine S.32, |

||||

|

|

|

see page 5 - 57. |

|

||

SIDEXIS |

H4 03 |

SIDEXIS not ready for exposure. |

Make SIDEXIS ready for exposure. |

|

||

|

See SIDEXIS Service Manual. |

|

||||

|

|

|

||||

|

|

|

|

|||

|

H4 10 |

Image receptor not suitable for exposure set. |

Replace the image receptor in the plug-in location |

|||

|

|

according to the programmed acquisition. |

||||

|

|

|

||||

|

|

Image could not be transferred to SIDEXIS. |

Transfer exposure by SiRescue service program |

|||

|

H4 20 |

|

to the PC, see SIDEXIS User Manual. |

|

||

|

|

CAUTION Do not switch off the unit until the help |

||||

|

|

|

||||

|

|

|

message goes out. |

|

||

The above mentioned actions will eliminate help messages caused by operating errors.

If the help message cannot be eliminated by the above actions, the fault is of another nature. Proceed with troubleshooting as described on the following pages.

58 35 744 D 3285 |

2 - 3 |

D 3285.077.02.06.02 07.2004 |

2.2 List of Error Messages

|

Error |

Description |

|

Required action |

||

|

message |

|

||||

|

|

|

|

|

||

|

|

|

|

|||

Multitimer |

E1 01 |

A key on the Multitimer was pressed during self- |

Proceed according to section "Correcting error E1 |

|||

adjustment or is defective. |

01", |

see page 3 - 19. |

|

|||

|

|

|||||

|

|

|

||||

|

|

|

|

|||

|

E1 02 |

Signal paths to control board D1 are interrupted. |

Proceed according to section "Correcting error E1 |

|||

|

E2 03 |

|

02, |

see page 3 - 19. |

|

|

|

|

|

|

|

||

|

|

|

|

|||

|

E1 03 |

Faulty communication with the unit. |

Acknowledge the fault by pressing the R key on |

|||

|

|

the Multitimer. |

|

|||

|

|

|

|

|||

|

|

|

|

|||

|

|

Appears upon pressing the exposure button. |

Acknowledge the fault by pressing the R key on |

|||

|

E2 01 |

Overheated X-ray tube assembly, pulse/pause |

the Multitimer. Allow the X-ray tube assembly to |

|||

|

ratio not observed. |

cool down. If the error message reoccurs, proceed |

||||

|

|

|

according to section "Correcting error E2 01", |

|||

|

|

|

see page 3 - 21. |

|

||

|

|

|

|

|

||

|

E2 03 |

See E1 02 |

see page 3 - 19 |

|

||

|

|

|

|

|||

|

|

Zero power range has been re-initialized. |

Acknowledge the fault by pressing the R key on |

|||

|

E2 04 |

|

the Multitimer. Unfortunately, the freely |

|||

|

|

programmed values will be lost and must be |

||||

|

|

|

reprogrammed. If not possible: correct the error |

|||

|

|

|

with E2 04, see page 3 - 23. |

|||

|

|

|

|

|||

|

|

Max. radiation time of the program exceeded. |

Only possible in service mode; acknowledge the |

|||

|

E2 10 |

|

fault by pressing the R key on the Multitimer. |

|||

|

|

Does this error occur often? Board DX1 defective |

||||

. |

|

|

→ replace and perform "Adjusing board DX1", |

|||

. . |

|

|

see page 4 - 31. |

|

||

E2 |

|

|

|

|||

|

|

|

||||

E2 11 |

kVmax. (tube voltage) exceeded. |

Proceed according to section "Correcting error E2 |

||||

assembly |

|

11", |

see page 3 - 25. |

|

||

|

|

|

||||

|

|

|

|

|

||

E2 13 |

mAmax. (tube current) exceeded. |

13", |

see page 3 - 29. |

|

||

|

E2 12 |

|

12", |

see page 3 - 27. |

|

|

|

|

|

|

|||

|

|

VHmax. (filament voltage) exceeded. |

Proceed according to section "Correcting error E2 |

|||

tube |

|

|

|

|

|

|

E2 14 |

Short-circuit of an output stage on DX1 deacti- |

Proceed according to section "Correcting error E2 |

||||

|

||||||

|

vated. |

14", |

see page 3 - 31. |

|

||

|

|

|

||||

ray-X |

|

|

|

|

||

|

VHmax. continuously present. |

page 4 - 31. |

|

|||

|

E2 15 |

|

replace and perform "Adjusing board DX1", see |

|||

|

|

|

|

|||

|

E2 16 |

kVactual cable is interrupted. |

Proceed according to section "Correcting error E2 |

|||

|

|

16", |

see page 3 - 33. |

|

||

|

|

|

|

|||

|

|

|

|

|||

|

|

Non-localizable fault in obtaining the DC/AC sig- |

Acknowledge the fault by pressing the R key on |

|||

|

E2 18 |

nals. |

the Multitimer. If fault reoccurs, DX1 board is |

|||

|

|

defective → replace. Perform "Adjusting board |

||||

|

|

|

||||

|

|

|

DX1”, |

see page 4 - 31. |

|

|

|

|

|

|

|||

|

|

Occurs upon pressing the exposure button e.g. |

Close X-ray room door. Acknowledge the fault by |

|||

|

E2 20 |

with the X-ray room door contact open - exposure |

pressing the R key on the Multitimer. If the fault |

|||

|

release lead in the Multitimer cable is broken. |

reoccurs, proceed according to section "Correct- |

||||

|

|

|||||

|

|

|

ing error E2 20", see page 3 - 35. |

|||

|

|

|

|

|||

|

|

Invalid data in the data memory. |

Erase data in the EEPROM with 'Service Routine |

|||

|

E2 35 |

|

09'. Then press the R key. If the message reoc- |

|||

|

|

curs, DX1 board is defective |

→ replace and per- |

|||

|

|

|

||||

|

|

|

form "Adjusting board DX1”, |

see page 4 - 31. |

||

|

|

|

|

|

|

|

2 - 4 |

58 35 744 D 3285 |

D 3285.077.02.06.02 07.2004 |

|

|

|

Loading...

Loading...