Sirona C1+ Service manual

2I[ EW SJ

'

7IVZMGI 1ERYEP

)RKPMWL

IMPORTANT:

•In case of faults which you are unable to eliminate with the help of this manual, please contact our Customer Service.

•It is essential that you take this Service Manual with you for every visit to a customer.

Furthermore, you must always have the spare parts list and wiring diagrams with you as well.

You can order additional copies of this Service Manual under

•Order Number 59 06 610 from our department DZA TU in Bensheim.

See reverse side of manual for address.

D 3386.076.01.01.02 11.2001

2I[ EW SJ |

|

' |

|

7IVZMGI 1ERYEP |

|

|

)RKPMWL |

1

2

3

4

5

6

7

|

|

|

Contents |

Overview of modules and PCBs ................................................................................ |

1 – 1 |

||

Important notes ........................................................................................................... |

|

2 – 1 |

|

2.1 |

Technical data...................................................................................................... |

|

2 – 2 |

2.2 |

Warnings and safety notes................................................................................... |

2 – 2 |

|

2.3 |

Minimum configuration ......................................................................................... |

2 – 2 |

|

2.4 |

Packing position for repackaging ......................................................................... |

2 – 3 |

|

Wiring diagrams .......................................................................................................... |

|

3 – 1 |

|

3.1 |

Wiring diagram of CAN bus.................................................................................. |

3 – 2 |

|

3.2 |

EMERGENCY STOP wiring diagram ................................................................... |

3 – 3 |

|

User-defined settings.................................................................................................. |

|

4 – 1 |

|

Error catalog ................................................................................................................ |

|

5 – 1 |

|

Reading service codes................................................................................................ |

6 – 1 |

||

6.1 |

Reading the service codes on the dentist panel .................................................. |

6 – 2 |

|

6.2 |

Reading service codes with PC connection to C1+ .............................................. |

6 – 4 |

|

Service code listings................................................................................................... |

|

7 – 1 |

|

7.1 |

Abbreviations / service code listings .................................................................... |

7 – 2 |

|

7.2 |

Service code of PCB (SA) in connection box AK ................................................. |

7 – 3 |

|

|

7.2.1SW version: |

2.0 - 3.0 |

|

|

7.2.2SW version: |

1.1- 1.3 |

|

7.3 |

Service messages of PCB (AJ) in dentist element AE ......................................... |

7 – 13 |

|

|

7.3.1SW version: |

1.4 - 2.5 |

|

|

7.3.2SW version: |

1.0 - 1.3 |

|

7.4 |

Service messages of PCB (PS) in dentist panel AP ............................................ |

7 – 28 |

|

|

7.4.1SW version: 1.0 - 2.4 |

|

|

7.5 |

Service codes of PCB (TS) support arm in dentist element................................. |

7 – 37 |

|

|

7.5.1SW version: 1.4 - 1.5 |

|

|

|

7.5.2SW version: 1.0, 1.2 - 1.3 |

|

|

7.6 |

Service messages of PCB (AJ) on the assistant panel........................................ |

7 – 43 |

|

|

7.6.1SW version: 1.4 - 2.5 |

|

|

|

7.6.2SW version: 1.0 - 1.3 |

|

|

7.7 |

Service codes of PCB (PS) on the assistant panel .............................................. |

7 – 55 |

|

|

7.7.1SW version: 1.0 - 2.4 |

|

|

7.8 |

Service codes of PCB (SS) chair control ............................................................. |

7 – 64 |

|

|

7.8.1SW version: 1.1 - 2.5 |

|

|

7.9 |

Service codes of PCB (WS) in the water unit....................................................... |

7 – 76 |

|

|

7.9.1SW version: 1.0, 1.1 - 1.9, 2.0 - 2.4, 3.0 |

|

|

59 06 628 D 3386

D 3386.076.01.01.02 11.2001

1 Overview of modules and PCBs

C1+

1 Overview of modules and PCBs

1 - 2 |

59 06 610 D 3386 |

D 3386.077.01.01.02 11.2001 |

|

|

|

1 Overview of modules and PCBs

|

|

|

|

)RKPMWL |

|

|

|

|

1 |

FS |

HE |

AE |

TA WE |

ST |

Component |

|

|

|

PCB / Module |

|

|

|

|

|

Dentist element (AE) |

PS |

= |

Control panel |

|

|

|

|

|

|

|

AG |

= |

Base plate |

|

|

IR |

= |

Flexible PCB |

|

|

|

|

|

|

|

AVL |

= Supply for lamp C1+ |

|

|

|

AD2 |

= |

Camera module |

|

|

|

|

|

|

|

ACI |

= |

HF adapter, |

from C1+ |

|

HF+ |

= |

HF module, |

from C1+ |

|

AJ |

= |

Control module |

|

|

AS |

= |

SPRAYVIT module |

|

|

|

|

|

|

|

AL |

= |

Siromot module |

|

|

AV |

= |

Distributor light module |

|

|

|

|

||

|

AH |

= Solenoid valve and heater module |

||

|

AU |

= |

SIROSON module |

|

|

|

|

|

|

|

AO |

= |

HF modulation module, |

model 96 |

|

AC |

= Output stage for SIROTOM |

|

|

|

|

|

|

|

Support arm (TA) |

TS |

= |

Support arm control |

|

Assistant element (HE) |

PS |

= |

Control panel |

|

|

|

|

|

|

|

AJ |

= |

Control module |

|

|

AS |

= |

SPRAYVIT module |

|

|

|

|

|

|

|

IR |

= |

Flexible PCB |

|

|

HG |

= |

Base plate |

|

|

|

|

|

|

Water unit (WE) |

WS |

= |

Control PCB |

|

Patient chair (ST) |

SE |

= |

Chair output stage |

|

|

|

|

|

|

|

SS |

= |

Control ST |

|

|

NS |

= |

Power supply PCB |

|

|

|

|

|

|

|

SA |

= |

Connection box control |

|

|

NM |

= |

Monitor power supply |

|

|

|

|

|

|

|

SVC |

= |

Video PCB |

|

|

SL |

= |

Wiring PCB |

|

|

|

|

|

|

|

KS |

= |

4-way foot switch |

|

Foot switch (FS) |

AF |

= |

Foot switch plate |

|

59 06 610 D 3386 |

1 - 3 |

D 3386.077.01.01.02 11.2001 |

1 Overview of modules and PCBs

1 - 4 |

59 06 610 D 3386 |

D 3386.077.01.01.02 11.2001 |

|

|

|

2 Important notes

C1+

2 Important notes

|

2.1 Technical data |

Model designation |

C1+ |

Power supply |

230V 50Hz, |

|

115V 50/60Hz |

Nominal current |

4.5A at 230V, |

|

9.5A at 115V |

|

2.2 Warnings and safety notes |

Caution! |

Prior to opening the unit, connecting a measuring instrument or replacing parts: Switch the unit OFF. |

Operating safety: |

To guarantee the operating safety, the use of mobile radio telephones in the practice or hospital |

|

area must be prohibited. |

Troubleshooting: |

If you encounter difficulties search in the error catalog first and follow the procedure described |

|

in it. |

2.3 Minimum configuration

C1 serial no. < 3000

C1 component |

|

PCB |

Software version |

|

|

|

|

|

|

Dentist panel / Assistant panel |

|

PS / Control panel |

>= 1.6 |

|

|

|

|

|

|

Dentist element / Assistant element |

|

AJ / Dentist element control |

>= 1.9 |

|

|

|

|

|

|

Water unit |

|

WS / Water unit control |

>= 1.9 |

|

|

|

|

|

|

C1 serial no. > 3000 |

|

|

|

|

|

|

|

|

|

C1 component |

|

PCB |

Software version |

|

|

|

|

|

|

Water unit |

|

WS |

>= 2.1 |

|

|

|

|

|

|

C1+ serial no. > 10 000 |

|

|

||

C1+ component |

|

PCB |

Software version |

|

|

|

|

|

|

Dentist panel / Assistant panel |

|

PS / Control panel |

>= 2.3 |

|

|

|

|

|

|

Dentist element / Assistant element |

|

AJ / Dentist element control |

>= 2.5 |

|

|

|

|

|

|

Connection box |

|

SA / Connection box control |

>= 3.0 |

|

|

|

|

|

|

Patient chair |

|

SS / Chair control |

>= 2.5 |

|

|

|

|

|

|

Water unit |

|

WS / Water unit control |

>= 3.0 |

|

|

|

|

|

|

2 - 2 |

59 06 628 D 3386 |

D 3386.076.01.01.02 11.2001 |

|

|

|

2 Important notes

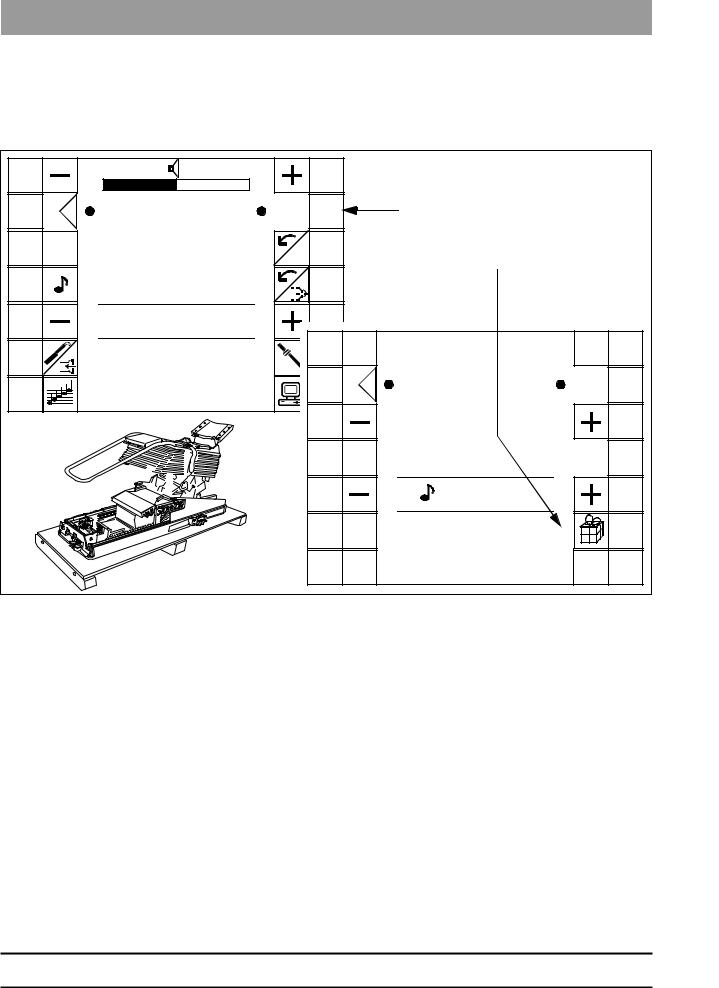

2.4 Packing position for repackaging

|

To repack the chair (e.g., for transport to a trade fair), move it to the position |

)RKPMWL |

|

|

shown. |

|

|

|

|

|

|

|

1. |

“Invisible” key |

2 |

|

|

||

Cur |

2. |

“Packing” key |

|

sor |

|

||

|

Key |

|

|

|

30 |

Vid. |

|

|

TONE |

|

|

|

|

Mod |

|

|

Auto |

|

|

|

Ret |

|

|

|

|

880 |

|

|

ROM |

SAV |

|

To do this, press the following keys:

1.“Invisible” key in basic settings dialog 2

2.“Packing position” key

The chair now moves to the packing position automatically.

59 06 628 D 3386 |

2 - 3 |

D 3386.076.01.01.02 11.2001 |

3 Wiring diagrams

C1+

3 Wiring diagrams

3.1 Wiring diagram of CAN bus

HF+

Connection area |

GA1 |

|

|

|

GA2 |

Connection area |

Dentist element |

|

|

|

Assistant element |

||

X1 |

|

|

|

X2 |

||

|

|

|

|

|

||

X1 |

|

X1 |

|

X2 |

|

X1 |

1 |

1 |

A1 |

CAN H |

CAN H HE IN A1 |

1 |

1 |

AP |

|

|

|

AE |

|

|

|

|

AK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HE |

|

HP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

2 |

2 |

B1 |

|

|

CAN L |

|

|

|

|

|

|

|

|

CAN L HE IN B1 |

2 |

2 |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Connection area |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Connection area |

|

|

|||||||||

|

|

|

|

|

|

|

|

Track |

X10 |

X3 |

X4 B1 |

A1 |

A3 |

B3 |

X3 B1 |

A1 |

A3 |

B3 |

Track |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

1 |

2 |

1 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAN L ST IN |

|

|

|

|

|

|

|

|

|

GA3 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

1 |

5 |

6 |

|

|

|

|

|

|

|

|

|||||

|

|

AT |

|

|

|

|

|

|

|

|

|

|

|

CAN H ST IN |

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAN H ST OUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAN L ST OUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAN L ST IN |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAN H ST IN |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAN H ST OUT |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAN L ST OUT |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

1 |

A |

6 |

|

|

|

5B |

1A |

2A |

4B |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

X1 |

|

|

|

|

|

X5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ST |

|

|

|

|

|

WE |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 – 2 |

59 06 628 D 3386 |

D 3386.076.01.01.02 11.2001 |

|

|

|

3 Wiring diagrams

3.2 EMERGENCY STOP wiring diagram

3 )RKPMWL

S2

X11.2

|

|

|

|

The EMERGENCY STOP can be |

|

|

PS |

X1.2 |

X3.2 |

AJ |

triggered both by the safety switch |

WS X11.3 |

|

PCB |

PCB |

and the software. |

PCB |

|||

|

|

|

|

|

X1.5B |

|

|

|

|

|

|

X5.3A |

|

|

|

|

|

X4.5B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S2 |

|

|

|

HG |

|

|

|

|

|

|

|

|

|

|

|

|

PCB |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GA3 |

|

|

|

|

X1.3 |

|

|

|

|

|

|

|

X3.3 |

|

|

|

|

GA2 |

|

|

|

|

|

|

|

|

|

|

|

|

X2.3 |

|

|

|

|

|

|

|

|

X3.2A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X2.2A |

|

S5 |

|

|

|

|

|

|

|

|

|

|

SA |

|

|

|

|

|

|

|

|

|

X3.B |

X3.A |

PCB |

|

|

|

|

|

|

|

|

X3.3A |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

X3.3B |

SL |

X4.B |

SS |

|

X4.2A |

|

|

|

|

|

S3 |

|

|

|

|

|

||

|

|

|

|

|

|

|

PCB |

|

PCB |

|

X1.2A |

|

|

|

|

|

|

|

|

X6.2A |

X4.A |

|

|||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

X6.1B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X3.3 |

|

|

|

|

|

X1.3 |

|

|

|

|

|

|

X3.2 |

|

|

|

|

|

GA1 |

|

|

|

|

|

|

X3.4 |

|

|

|

|

|

X1.3 |

|

|

|

|

|

|

|

X3.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A A |

C |

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TS |

|

|

AG |

|

|

AJ |

|

|

PS |

|

E |

V1 |

X2.5A (C1/A) |

X2.5 |

X4.5B |

X1.5B |

X3.2 |

X1.2 |

|

K |

|

||||

PCB |

PCB |

PCB |

PCB |

|

E |

|||||||

|

|

|

|

|

|

|

||||||

X3.4B (C1/A) |

|

|

|

|

|

|

K |

|||||

|

|

|

|

|

|

|

||||||

59 06 628 D 3386 |

3 – 3 |

D 3386.076.01.01.02 11.2001 |

4 User-defined settings

C1+

4 User-defined settings

Component (PCB / software)

Dentist element PCB AJ

Also in case of software upgrade from version < 1.6 to version >= 1.6

and from version < 2.0 to version >= 2.0

The following user-defined settings must be made after replacing PCBs or software on the C1.

User-defined settings

Instrument settings for all function levels

SPRAYVIT L: Instrument light, water and air temperature

SIRONA motor: Speed, instrument light, direction of rotation, cooling media, direct starter, foot switch control

Turbine: Instrument light, cooling media SIROSON L: Intensity, instrument light SIROTOM: Cutting current, coagulation current POLYLUX: Exposure time, soft start (ON / OFF)

Holder assignment for saline solution

(in case of missing Sprayvit light and water heater generate 20 pump strokes)

In case of camera integration: video mode

Dentist panel AP |

Panel-specific settings: |

|

Brightness, contrast, keyboard sensitivity, audio signal volume, |

|

key clicking tone (ON / OFF), timer settings, |

|

simplified programs (ON/OFF), cursor (ON/OFF) |

|

SIROTOM operating and alarm tone, |

|

preselection of key position for direction of rotation/cooling medium/chip |

|

blower in instrument program. |

|

Sivision / bell switch-over version 1.7 or higher |

|

In case of secondary monitor function, PC dialog (ON/OFF). |

|

Different tones for each row of keys (ON/OFF). |

|

|

Assistant element PCB AJ |

SPRAYVIT L: Instrument light, water and air temperature |

Also in case of software upgrade from |

POLYLUX: Exposure time |

version < 1.6 to version >= 1.6 |

Functionality of the 4-way foot switch for Polylux and suction function version |

and from version < 2.0 to version >= 2.0 |

2.0 or higher |

|

|

Assistant panel HP |

Panel-specific settings: |

|

Brightness, contrast, keyboard sensitivity, audio signal volume, |

|

key clicking tone (ON / OFF), timer settings, |

|

simplified programs (ON/OFF) |

|

Sivision / bell switch-over version 1.7 or higher |

|

|

Water unit PCB WS

Also in case of software upgrade

Patient chair PCB SS

Connection box PCB SA

Also in case of software upgrade

SIROLUX: Brightness, reflector stage, SIROLUX switching condition in relation to chair position,

tumbler filling quantity, tumbler filling (ON/OFF) when approaching S position, suction intensity, possibly time and date

Chair positions:

User, user size, treatment position (sitting/standing)

Track positions of dentist element

Cuspidor flushing time, cuspidor flushing (ON/OFF) when approaching S position,

4-way foot switch functionality (switch-over headrest/backrest), Type of key for bell or free key (key/switch)

4 – 2 |

59 06 628 D 3386 |

D 3386.076.01.01.02 11.2001 |

|

|

|

Component (PCB / software)

Support arm control PCB TS Also in case of software upgrade

4 User-defined settings

User-defined settings

Support arm position excluding track

Intensity of saline solution pump

4 )RKPMWL

59 06 628 D 3386 |

4 – 3 |

D 3386.076.01.01.02 11.2001 |

5 Error catalog

C1+

5 Error catalog

Compo- |

Description |

Cause |

Corrective action |

|

nent |

of problem |

|

||

|

|

|

||

Dentist |

Loss of instrument |

Software error PCB AJ of |

Replace AJ software. |

|

element |

programs. |

version <2.0 |

Part No.: 54 33 375 |

|

|

After removing the |

|

|

|

|

instruments, the |

|

|

|

|

factory settings are |

|

|

|

|

displayed for all levels |

|

|

|

|

and holders. |

|

|

|

|

Sprayvit light switched |

|

|

|

|

off. |

|

|

|

|

Service code |

|

|

|

|

message: AE 7F |

|

|

|

Dentist |

Instrument failure |

Error while reading hose |

Replace AJ software. |

|

element |

Dentist panel closes |

coding |

Part No.: 54 33 375 |

|

|

the instrument dialog. |

following, e.g., |

Check and correct (if necessary) the position |

|

|

Instrument functions |

electromagnetic |

of the SIROTOM flange (if available). |

|

|

Motor |

interference |

Do not overlap or cross the cables. |

|

|

Scaler |

or contact problems on |

|

|

|

Turbine |

hose coupling. |

|

|

|

SIROTOM |

|

|

|

|

including media spray, |

Software version PCB AJ |

|

|

|

water and instrument |

in dentist element |

|

|

|

light are shut off, if |

<1.8. |

|

|

|

active. |

|

|

|

|

After depositing and |

|

|

|

|

removing again, |

|

|

|

|

normal function. |

|

|

|

Dentist |

Instrument failure |

Software error on PCB |

Replace AJ software. |

|

element |

Instruments |

AJ in dentist element, in |

Part No.: 54 33 375 |

|

|

Motor |

case of very short |

|

|

|

Scaler |

instrument removal, e.g., |

|

|

|

SIROTOM |

due to oscillating motion |

|

|

|

do not function when |

of the thin SIROTOM |

|

|

|

activated. |

hose. |

|

|

|

Media spray, water |

|

|

|

|

and instrument light |

Software version PCB AJ |

|

|

|

are switched when |

in dentist element |

|

|

|

activated. |

<1.8. |

|

|

|

After depositing and |

|

|

|

|

removing again, same |

|

|

|

|

error. |

|

|

|

|

Can only be remedied |

|

|

|

|

by switching on/off. |

|

|

|

Dentist |

Instrument failure |

The software of PCB AL |

Replace AL software. |

|

element |

SIRONA motor |

(Siromot module) |

Part No.: 54 33 383 |

|

|

The instrument Sirona |

detects open motor load |

|

|

|

motor interrupts its |

circuits in very smooth |

|

|

|

function or does not |

motors. |

|

|

|

function when |

|

|

|

|

activated. |

Software version PCB |

|

|

|

Media spray, water |

AL in dentist element |

|

|

|

and instrument light |

<3.6. |

|

|

|

remain switched on or |

|

|

|

|

are switched when |

|

|

|

|

activated. |

|

|

|

|

After depositing and |

|

|

|

|

removing again, |

|

|

|

|

normal function. |

|

|

|

|

Service code |

|

|

|

|

message: AE 00 6B |

|

|

|

Dentist |

Sirona motor runs |

Software PCB AL in |

Replace AL software. |

|

element |

on for too long |

dentist element <3.7 |

Part No.: 54 33 383 |

|

Dentist |

Scaler switches off |

Water on the flange due |

Remedy leaks. |

|

element |

again after 1–2 |

to leaks in hose or |

|

|

|

seconds. |

heater. |

|

|

|

Scaler dialog is |

|

|

|

|

closed. |

Residual moisture due to |

Remedy moisture. |

|

|

|

thermal disinfection |

|

|

|

|

|

|

|

5 – 2 |

|

|

59 06 628 D 3386 |

|

|

|

D 3386.076.01.01.02 11.2001 |

|

|

|

|

|

|

|

5 Error catalog

Compo- |

Description |

nent |

of problem |

Dentist |

Performance of |

element |

scaler is reduced or |

|

fluctuating, or no |

|

performance. |

|

High-frequency |

|

whistling. |

Dentist |

Whistling tone from |

element |

dentist element |

|

when activating a |

|

bur instrument |

|

|

Dentist |

Motor/turbine, |

element |

immediate cooling/ |

|

driving air |

|

After removing the |

|

motor, |

|

turbine |

|

cooling/driving air is |

|

immediately on, or |

|

after releasing the foot |

|

switch cooling/ |

|

driving air and spray, |

|

if any, are not |

|

switched off. |

|

After depositing the |

|

instrument everything |

|

is switched off. |

|

Occurs on all |

|

motors/turbines, |

|

possibly only from |

|

time to time |

Dentist |

Motor/turbine, low |

element |

air outlet. |

|

After removing the |

|

motor, |

|

turbine |

|

or after releasing the |

|

foot switch, low air |

|

outlet. After |

|

depositing the |

|

instrument everything |

|

is switched off. |

|

Does not occur on |

|

exactly one motor/ |

|

turbine. |

Dentist |

No air and no water |

element |

on one bur |

|

instrument. |

Dentist |

Dripping |

element |

instruments. |

|

|

Cause

Old sealing compound of piezo is brittle.

Electrical contacts in handpiece are broken.

Pressure setting too low

MV11

Module

Solenoid valve MV11 is caught.

Defective membrane in the module of the instrument for which the error does not occur.

MV21-X on module defective (X – holder no.)

White break on “auto” valve of module due to excessive screwing torque or spring force too low.

Filter tissue of heater is dissolved.

Precipitation in the heater element.

Corrective action

Replace handpiece

Replace membrane and check input pressure, pressure = 4.3 bar +/- 0.1 (in case Sprayvit flow is active)

Replace MV11.

Replace module.

Replace solenoid valve MV11.

Replace membrane and check input pressure. Pressure = 4.3 bar +/- 0.1

(in case SPRAYVIT flow is active).

Replace MV21.X.

“Auto” valve has been reworked,

replace “auto” valve, do not tighten too hard. Check filter in heater.

Check filter in heater and replace it, if necessary, and rinse water pipes.

(Defective filter and information to Bensheim)

Replace heater and rinse water pipes.

5 English

59 06 628 D 3386 |

5 – 3 |

D 3386.076.01.01.02 11.2001 |

5 Error catalog

Compo- |

Description |

Cause |

Corrective action |

|

nent |

of problem |

|||

|

|

|||

Dentist |

No instrument dialog |

Instrument in holder 5 or |

Information for the customer. |

|

element |

when removing |

6 has not been deposited |

|

|

|

instruments. |

properly. |

|

|

|

|

Instrument tray bent |

Install a new instrument tray |

|

|

|

(holder is not aligned |

|

|

|

|

with light barrier) |

|

Dentist SPRAYVIT 4000 element occasionally without

water.

(Air is still available)

Dentist Moist air on element SPRAYVIT.

Some water is ejected when the air key is pressed.

Dentist SPRAYVIT L element handpiece becomes

hot.

Both heater cartridges heat up when only one key is pressed.

Air heater and SPRAYVIT L heat up immediately after removing the instrument.

Valve body is burnt.

Dentist Assistant element element Polylight cannot be

selected using the dentist panel.

Software PCB AJ assistant element version 2.0

Dentist Chair and AE travel element to position “0” when

an instrument is removed.

Cursor is switched off (M1 mode), panel in chair program, “FS down” activated

Support Dentist element arm does not reach control programmed

position.

Program key must be pressed several times.

Service code message in AT/HP: 40 04

(RESET AT) – frequent in C1/96).

Support Support arm does arm not swivel in joint 1, control Motor 1 is running

(Serial no.: <3000)

Transparency of ZEG |

Hose change in progress |

hose |

|

Contact problem or |

Temporary measure: |

humidity on base of air |

Clean air heater (remove also solder residue) and tighten |

heater in valve body. |

contact terminals. |

Consequence: |

|

SPRAYVIT is not |

|

detected by dentist |

|

element. |

|

Damaged o-rings on |

Replace o-rings on Sprayvit nozzle. |

Sprayvit nozzle, due to |

|

sterilization and lack of |

|

maintenance. |

|

Water in SPRAYVIT hose.

Software error in PCB AJ version 2.0

Software error dentist panel / assistant panel

PCB TS reset because watchdog tolerance is too high.

PCB TS:

Serial no. >3000:

Hardware <2.1, Software <1.5

Serial no. <3000:

Hardware <1.3

Pertinax pinion of joint 1 defective

Slipping clutch of joint 1 skids

Replace hose and replace valve body, if necessary.

Replace AJ software.

Part No.: 54 33 375

No solution as of yet.

Serial no. <3000:

Software version on PCB PS >= 1.8

Serial no. >3000:

Software version on PCB PS >= 1.7

Replacement of PCB TS.

Part No.: 46 96 931 - Serial no. >3000

Part No.: 46 85 231 - Serial no. <3000

Install new motor 1 with metal pinion

Replace slipping clutch of joint 1

5 – 4 |

59 06 628 D 3386 |

D 3386.076.01.01.02 11.2001 |

|

|

|

5 Error catalog

Compo- |

Description |

Cause |

|

nent |

of problem |

||

|

|||

Support |

Support arm does |

Gear Z70 is damaged, |

|

arm |

not swivel in joint 1, |

because motor 1 has not |

|

control |

Motor 1 is running |

been inserted deep |

|

|

Furthermore, a |

enough or grub screw is |

|

|

knocking noise can be |

missing in lower support |

|

|

heard (serial no.: |

arm bearing. |

|

|

>3000). |

|

|

Support |

Support arm motors |

Pot. target value is |

|

arm |

run on. |

outside the movement |

|

control |

Support arm motors |

range |

|

|

keep running for a few |

|

|

|

seconds after |

|

|

|

reaching the |

|

|

|

programmed position. |

|

|

Support |

Support arm motor 1 |

Slipping clutch of joint 1 |

|

arm |

does not reach |

has not been tightened |

|

control |

programmed |

enough at factory |

|

|

position. |

Only serial no.: >3000 |

|

|

Program key must be |

|

|

|

pressed twice |

Slipping clutch of joint 1 |

|

|

|

too weak only serial no.: |

|

|

|

<3000 |

Corrective action

Replace lower support arm bearing entirely. Rep. no. 5433623

Check the fastening and fitting of the potentiometers, then try to travel to the corresponding program positions again and press the save key.

Tighten slipping clutch with a screwdriver, as necessary. Factory setting: 20 +- 5N

Replace slipping clutch of joint 1.

Installation instructions currently being drafted

Support |

Unit head drops |

Spring weight |

Tighten the spring using allen screw on spring arm. |

arm |

when an additional |

compensation not |

Remarks: The slipping clutch of the height adjustment is |

control |

load is applied. |

properly set. |

exclusively required to dampen the spring force. It is preset |

|

|

|

at the factory and can be adjusted slightly in exceptional |

|

|

|

cases. Generally, the following applies: Always tighten the |

|

|

|

spring for weight - force adjustment. |

Support |

The unit head keeps |

Slipping clutch torn off. |

Dismount the slipping clutch. |

arm |

falling back to the |

|

When the driving pin is not hammered in deep enough, |

control |

lowest position. |

|

drive it in and then mount back the slipping clutch with an |

|

|

|

undamaged groove. |

|

|

Slipping clutch has burst |

Replace slipping clutch. Rep. no. 3319501 |

|

|

due to excessive |

|

|

|

tightening |

|

Support |

Unit head does not |

The grub screw used to |

Tighten the grub screw and secure with Loctite. |

arm |

swivel, motor is |

attach the pinion to the |

(The back-geared motor must be dismounted to do this) |

control |

running. |

back-geared motor 3 is |

|

|

|

loose. |

|

Assistant |

Polylight cannot be |

Software error PCB AJ |

Replace AJ software (basic retrofit kit). |

element |

started. |

software, assistant |

|

|

After removing the |

element. |

|

|

instrument the timer in |

Polylight detection in |

|

|

the assistant panel |

case of an old Polylight |

|

|

does not switch over |

(without electronics) |

|

|

to the Polylight values |

using fan current |

|

|

and the Polylight |

defective. |

|

|

cannot be started. |

Software version on PCB |

|

|

|

AJ, |

|

|

|

Assistant element <1.9. |

|

Assistant Polylight light power element is not in green range

when measured with Translux Test.

Fiber optic is not properly inserted or locked in place in the module.

Lamp has air leaks so that the quartz tube has become opaque.

Lamp has not been inserted properly.

Dirt in filter of lamp module, at light entrance or exit of fiber optic and of handpiece.

Pull out the fiber optic and insert it again, until it catches.

Replace the halogen lamp. Only use selected Osram Xenophot HLX bulbs.

Lamp must lie flat against the heat sink, place the lug on the lamp in the notch intended for this purpose.

Clean all interfaces with ethanol

59 06 628 D 3386 |

5 – 5 |

D 3386.076.01.01.02 11.2001 |

5 English

5 Error catalog

Compo- |

Description |

nent |

of problem |

Assistant |

Short total failure. |

element |

SIROLUX (unit |

|

model), film viewers, if |

|

any, are shut off and |

|

must be switched on |

|

again. |

|

The suction and |

|

separator function are |

|

interrupted for 2–4 |

|

seconds and start up |

|

by themselves again. |

|

Service code |

|

message in AP/HP: |

|

40 08 |

Water |

Amalgam separator |

unit |

full message too |

|

early. |

|

Panel display |

|

amalgam and |

|

continuous tone, |

|

rotor not filled yet |

|

(total weight of rotor |

|

<500 g) |

Water |

Amalgam separator |

unit |

goes over to fault |

|

mode, loud noises |

|

and vibration from |

|

amalgam separator. |

|

Amalgam is flashing |

|

and intermittent |

|

beeping tone. |

|

Service code |

|

message: WE 06 |

Water |

Amalgam separator |

unit |

goes over to fault |

|

mode. |

|

Amalgam is flashing |

|

and intermittent |

|

beeping tone. |

|

(loud drive noise, |

|

rustling or standstill) |

|

Service code WE: 5C |

|

Drive below target |

|

speed |

|

|

Water |

There is barely any |

unit |

water arriving to the |

|

tumbler filling. |

Water |

Tumbler filling does |

unit |

not work from time |

|

to time. |

|

|

Water |

Vibrations of the |

unit |

amalgam separator |

Cause

Software error on PCB WS, which can lead to a RESET of the module when filling the water tank and the disinfectant injection.

Serial no. <3000:

Software version on PCB WS <1.9.

Serial no. >3000:

Software version on PCB WS <2.1.

Software version on PCB WS <2.0.

Driver bolt defective.

Bearing damage on motor (audible) due to leak in pump

Motor is blocking

Bearing in lower part is defective

Rotor axle is defective

Drain is blocked up

Suction from lower part is blocked up

Media pipe is clogged due to precipitation in the heater element.

Software version on PCB WS <2.4.

Float switch in mixing tank is caught.

Amalgam separator has been mounted stressed

Defective rotor or flyweight

Suction from lower part is blocked up

Transport safety device has not been removed.

Corrective action

Replace AJ software.

Part No.: 54 33 391

Replace WS software.

Part No.: 54 33 391

Replace amalgam drive.

Replace amalgam drive.

Replace the amalgam drive.

Check the rotor’s operation (must run smoothly) replace lower part, if necessary.

Replace rotor

Check siphon and drain, clean them if necessary. Check the hose path

Clean suction channel in lower part of amalgam separator.

Replace heater,

clean media pipes, if necessary.

A solution is being worked out.

Replace float switch.

Position all connections to amalgam separator so as to leave 1mm clearance in all directions from amalgam separator,

Replace rotor

Clean suction channel

Remove the transport safety device

5 – 6 |

59 06 628 D 3386 |

D 3386.076.01.01.02 11.2001 |

|

|

|

|

|

|

5 Error catalog |

|

|

|

|

|

|

|

|

|

|

|

Compo- |

Description |

Cause |

Corrective action |

|

nent |

of problem |

|

||

|

|

|

||

Water |

Tumbler falls into |

Slope of cuspidor too |

Reduce slope of cuspidor, if possible |

|

unit |

cuspidor |

steep |

Order silicone mat free of charge |

|

|

|

|

|

|

|

|

|

Part No.: 54 46.443 |

|

|

|

Vibrations of the |

Use of tumblers with hollow bottom |

|

|

|

See: Vibrations of the amalgam separator |

|

|

|

|

amalgam separator |

|

|

Water |

Cuspidor does not |

Clogged drain, def. water |

Check drain and air pressure; |

|

unit |

drain off |

detector, air pressure too |

Clean water detector or replace, if necessary; |

|

|

intermittent beeping |

low |

|

|

|

tone |

|

If everything is in order, reduce the flow of the cuspidor |

|

|

Service code WE: 07 |

|

|

|

|

|

flushing |

|

|

|

|

|

|

|

Water |

Water escapes from |

Leaks on tumbler plug |

Replace sealing ring in plug adapter |

|

unit |

water unit |

adapter |

Part No.: 70 36 189 (red o-rings) |

|

|

|

Water escapes from |

Check slope of drain, |

|

|

|

mixing tank overflow, |

Clean the siphon |

|

|

|

Clogged or badly |

|

|

|

|

positioned drain |

|

|

Water |

Suction does not |

MV 33 is caught |

Replace MV 33 |

|

unit |

switch off or is |

|

|

|

|

delayed |

|

|

|

Water |

Water unit is |

Lack of stiffness in left- |

Retrofit reinforcing plate |

|

unit |

deformed in left- |

handed version |

Part No.: 47 08 272 |

|

|

handed version |

|

|

|

Water |

Disinfectant |

Metering valve is leaking |

Replace the metering valve |

|

unit |

consumption too |

|

Part No.: 14 35.580 |

|

|

high |

|

|

|

Water |

Flushing water |

Control nozzle not |

||||||

unit |

quantity: |

properly adjusted |

||||||

|

too low |

|

C |

|

||||

|

too high |

|

|

|||||

|

1. |

|

|

B |

|

2. |

||

|

|

|

|

|

||||

|

|

|

|

|

||||

|

|

|

|

|||||

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A

B

1.Adjusting cuspidor flushing:

For right-handed version – Remove side panel A of water unit and adjust control nozzle B until the bottom of the cuspidor is flushed evenly. Remount back side panel A of water unit.

For left-handed version – Remove cover C. Lift rubber cover and adjust control nozzle B using a coin until the bottom of the cuspidor is flushed evenly. Refit the cover.

2.Check the swivel-back motion of the cuspidor:

–Swivel the cuspidor into the movement range of the chair

–Press the manual chair button and start the chair program consecutively

The cuspidor must always swivel back into the starting position automatically

|

|

1. |

|

|

|

|

Leaks in connection |

|

|

|

|

Patient |

Counter nut on ceramic |

Tighten the nut, fix by a lock nut and secure with locking |

|

||

chair |

box |

valve is loose |

varnish |

|

|

Patient |

No chair motion after |

Output stage relay is |

Replace PCB SE - Version 1.1. |

|

|

chair |

switching on. |

caught. |

|

|

|

|

Serial no.: <3000 |

|

|

|

|

|

Chair output stage |

|

|

|

|

|

version: Hardware |

|

|

|

|

|

PCB SE 1.0 |

|

|

|

|

|

Service code |

|

|

|

|

|

message: ST 03 37 |

|

|

|

|

|

(also 01 01) |

|

|

|

|

|

|

|

|

|

|

59 06 628 D 3386 |

|

|

5 – 7 |

|

|

D 3386.076.01.01.02 11.2001 |

|

|

|

||

|

|

|

|

|

|

5 English

5 Error catalog

Compo- |

Description |

Cause |

Corrective action |

|

nent |

of problem |

|||

|

|

|||

Patient |

No chair motion after |

Temperature sensibility |

Replace the software on PCB SS |

|

chair |

switching on |

of PCB SS, |

|

|

|

only in cooled |

Software version on PCB |

|

|

|

treatment center |

SS <2.0 |

|

|

|

Service code |

|

|

|

|

message: ST 02 00 |

|

|

|

|

to 02 05 |

|

|

Patient Chair does not reach chair programmed

position.

Program key must be pressed several times, particularly when travelling to S or 0 position.

No service code message in ST. Software PCB SS <1.8.

Patient Chair does not reach chair programmed

position.

Program key must be pressed several times, or chair does not leave position. EMERGENCY STOP relay is switching.

Service code message in AP/HP: 40 04

(RESET AT)

No service code message in ST.

(more frequent for serial no.: >3000)

Patient Chair does not reach chair programmed

position. Service code message: 08 0X; X = 0...2

EMERGENCY STOP activated by EMERGENCY STOP sensory mechanism.

Defective or badly adjusted safety switch for foot part, or defective cable.

Service code ST 09 11, EMERGENCY STOP activated by safety switch for foot part.

Defective safety switch for backrest, or defective cable or backrest mechanics jammed.

Service code ST 09 13, EMERGENCY STOP activated by free lift switch of backrest.

PCB TS is RESET due to excessively high watchdog tolerance.

Replace software for diagnostics

PCB SS, version >= 2.0 to recognize source of EMERGENCY STOP.

Serial no.: <3000, Part No.: 54 33 680 Serial no.: >3000, Part No.: 54 33 409

Adjust or replace the switch or cable.

(Switch must only switch shortly before the upper end stop and must not be charged in the lower end stop).

Replace the switch or cable.

Eliminate the stiffness of the backrest.

Replace PCB TS.

PCB TS:

C1/96, Serial no. >3000: Serial no.: >3000, Part No.: 46 96 931 Hardware: <2.1,

software: <1.5

C1/A: Serial no. <3000: Serial no.: <3000, Part No.: 46 85 231 Hardware: <1.3

Broken wire in the motor |

Replace motor sensor circuit (L16). |

sensor circuit (L16) |

|

Serial no. <3000. |

|

Contacts pushed back |

Check contacts. |

on connector X15 |

|

on motor circuit (L16). |

|

Potentiometer 0–2 |

Switch the potentiometers between each other and check if |

defective. |

error is reproduced, |

|

replace the potentiometer, if necessary |

Patient |

Chair does not reach |

Potentiometer 3 no |

|

Install roller kit |

|

||

chair |

programmed |

longer moves into gear |

|

Part No.: 54 33 870 |

|

||

|

position. Service |

due to worn sword rollers |

|

|

|||

|

code message: 08 03 |

|

|

|

|

|

|

Patient |

Chair does not travel |

Unintentional call of the |

Information to customers. |

|

|||

chair |

to programmed |

factory programs, mostly |

|

|

|||

|

position. |

with foot switch. |

|

|

|

||

|

|

(Display with icon |

|

|

in |

|

|

|

|

|

|

|

|||

|

|

odontogram) |

|

|

|

|

|

|

|

|

|

|

|

|

|

5 – 8 |

|

|

|

|

|

59 06 628 D 3386 |

|

|

|

|

|

|

D 3386.076.01.01.02 11.2001 |

|

|

|

|

|

|

|

|

|

|

Loading...

Loading...