Sirona C4+, C5+, C2+, C3+, M1+ Service manual

kÉï=~ë=çÑW=

NMKOMMR

bеЦдблЬ

IMPORTANT:

• In case of faults which you are unable to eliminate with the help

of this manual, please contact our Customer Service Center.

• It is essential that you take this Service Manual along with you

on every customer call.

Furthermore, you must always have the spare parts list and wiring dia-

grams with you as well.

You can order additional copies of this Service Manual under the

• order number 58 77 977 from our department DZL 1 in Bensheim.

See reverse side of manual for address.

`O

H

I=`P

H

I=`Q

H

I=`R

H

I=jN

H

pЙкобЕЙ=j~ем~д===== =

kÉï=~ë=çÑW=

NMKOMMR

bеЦдблЬ

`O

H

I=`P

H

I=`Q

H

I=`R

H

I=jN

H

pЙкобЕЙ=j~ем~д===== =

`Q

H

`P

H

`O

H

`R

H

jN

H

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

I

Contents

bеЦдблЬ

1 Important information..................................................................................................... 1 – 1

1.1 Technical data ...................................................................................................... 1 – 2

1.2 Warning and safety information............................................................................ 1 – 2

1.3 Symbols................................................................................................................ 1 – 2

1.4 Abbreviations........................................................................................................ 1 – 3

1.5 Minimum configuration ......................................................................................... 1 – 4

1.6 Where to save user-specific data in the C2

+

, C3

+

, C4

+

, C5

+

, M1

+

...................... 1 – 4

2 Overview of modules and PCBs.................................................................................... 2 – 1

3 Points to observe during assembly................................................................................ 3 – 1

3.1 Patient chair ......................................................................................................... 3 – 2

3.2 Protective ground / electronic ground................................................................... 3 – 2

3.3 MV1 / AD3 ............................................................................................................ 3 – 2

3.4 Connecting the water Unit/assistant element: ...................................................... 3 – 2

3.5 Assistant element: ................................................................................................ 3 – 3

4 What happens after switch-on? ..................................................................................... 4 – 1

4.1 Sequence of events.............................................................................................. 4 – 2

4.2 Checking the CAN BUS ....................................................................................... 4 – 5

4.3 CAN BUS wiring diagram ..................................................................................... 4 – 8

5 Description of the functions of ... ................................................................................... 5 – 1

5.1 Control panel / PCB AP........................................................................................ 5 – 2

5.2 Chair control/PCB CJ ........................................................................................... 5 – 3

6 How it works ... .............................................................................................................. 6 – 1

6.1 ... Water supply .................................................................................................... 6 – 2

6.2 ... Tumbler filling ................................................................................................... 6 – 2

6.3 ... Cuspidor flushing.............................................................................................. 6 – 2

6.4 ... Motor SL / EL1 ................................................................................................ 6 – 4

6.5 ... highspeed handpiece ....................................................................................... 6 – 6

6.6 ... ultrasound......................................................................................................... 6 – 8

6.7 ... Sprayvit ............................................................................................................ 6 – 9

6.8 ... Polylight in the assistant element ..................................................................... 6 – 9

6.9 ... Polylight Mini LED in the assistant/dentist element.......................................... 6 – 9

6.10 ... X-ray image viewer........................................................................................... 6 – 10

7 Points to observe when changing the ........................................................................... 7 – 1

7.1 …ADX/CJ board Serial No.

≥ 70,000 .................................................................. 7 – 3

7.2 ... ADX PCB in the dentist element ...................................................................... 7 – 3

7.3 ... Water heating voltage for Sprayvit ................................................................... 7 – 3

7.4 ... PCB HP in the assistant element ..................................................................... 7 – 3

58 77 977 D 3370

II D 3370.076.01.06.02 10.2005

Contents

8 Service LEDs................................................................................................................. 8 – 1

9 Option list....................................................................................................................... 9 – 1

10 Reading out service codes ... ........................................................................................ 10 – 1

10.1 on the display of the dentist element.................................................................... 10 – 2

10.2 ... using a notebook link to the C2

+

, C3

+

, C4

+

, C5

+

, M1

+

..................................... 10 – 3

11 Service code listings...................................................................................................... 11 – 1

11.1 Service messages of the connection box (AK) ................................................... 11 – 2

11.1.1 Software version: 1.6 - 5.8, revision date 08.2004

11.2 Service messages of the dentist element (AE) ................................................... 11 – 6

11.2.1 Software version: 1.5 - 2.37/3.37, revision date 01.2005

11.3 Service messages of the dentist panel (AP) ....................................................... 11 – 14

11.3.1 C2

+

– C5

+

: Software version: 1.7 - 5.8, revision date 08.2004

M1

+

: Software version 10.3 , revision date 08.2004

11.4 Service messages of the assistant element (HE) ................................................ 11 – 15

11.4.1 Software version: 1.4 - 2.3, revision date 10.2004

11.5 Service messages of the water unit (WE) ............................................................ 11 – 19

11.5.1 Software version: 1. - 3.2, revision date 08.2005

C2

+

, C3

+

, C4

+

, C5

+

, M1

+

1 Important information

58 77 977 D 3370

1 – 2 D 3370.076.01.06.02 10.2005

1 Important information

1.1 Technical data

Model designation C2

+

, C3

+

, C4

+

, C5

+

, M1

+

, M1

+

Power supply 230V AC 50Hz,

115V AC 50/60Hz

Nominal current 4.5A at 230V

9.5A at 115V

Main unit fuse for 230V AC: T 6.3A H , 250V AC, Order No. 10 77 452

for 100/115 V AC: T 10A H, 250V AC, Order No. 10 77 460

1.2 Warning and safety information

Caution! Prior to opening the unit, connecting a measuring instrument or replacing

parts: Switch the unit OFF.

Protective ground connection The building water supply is at protective ground potential and must not touch

the fuse box of the chair.

Warning! If there is a protective ground contact, the patient or user may be exposed to

tension in the event of a fault - risk of electric shock!

Operational reliability To ensure operational reliability, the use of mobile telephones in the practice

or hospital area must be prohibited.

Troubleshooting: If you encounter difficulties, search in the error catalog first and proceed

according to the instructions given there.

1.3 Symbols

C2

+

dentist element

C3

+

dentist element

C4

+

dentist element

C5

+

dentist element

M1

+

dentist element

C2

C2

+

+

C3

C3

+

+

C4

C4

+

+

C5

+

M1

+

bеЦдблЬ

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

1 – 3

1 Important information

Assistant element

Patient chair

Water unit

1.4 Abbreviations

Dent. el. Dentist element

AK Connection box

COM Serial interface

EMC Electromagnetic compatibility

PCB Printed circuit board

FS Foot switch

FT Foot button

GND Ground

Ass. el. Assistant element

HW Hardware

KL Holder

L Cable

LCD Liquid Crystal Display

LED Light Emitting Diode

PC Personal Computer

S Switch

SDI Sirona Dental Interface (electrical, pneumatic, hydraulic plug connection)

ST Patient chair

SW Software

T Transformer

TR Support arm

VAC AC voltage

VDC DC voltage

WE Water unit

X Connector

+V

iso

Galvanically isolated voltage

58 77 977 D 3370

1 – 4 D 3370.076.01.06.02 10.2005

1 Important information

1.5 Minimum configuration

1.6 Where to save user-specific data in the

C2

+

, C3

+

, C4

+

, C5

+

, M1

+

Component PCB Hardware

version

Software version

C2

+

Software version

C3

+

/C4

+

Software version

C5

+

Software version

M1

+

Dentist element ADX - 2.19 2.23 2.29 2.30

Dentist element AL - 4.0 4.0 4.0 4.0

Assistant element HC - 2.1 2.2 2.2 2.2

Water unit WE - 3.0 3.1 3.1 3.1

For PC networking PCB Hardware

version

Software version

C2

+

Software version

C3

+

/C4

+

Software version

C5

+

Software version

M1

+

Connection box CJ - 5.3 5.5 5.7 5.7

Dentist element AP - 5.2 5.4 5.7 10.2

Board

(Part no., designation)

Stored settings Default value

Dentist element

(42 00 221, ADX)

Mode dialog:

Language (Engl., D, I, F, E)

Pressure indication (bar/PSI)

Cursor control (On/Off)

Foot switch mode (On/Off - adjustable)

Purge time (60 sec. to 120 sec.)

Service mode / Start - Stop)

Max. light voltage per instrument

Cooling air for electric motor

Saline pump (holders 2, 3, 4, 5, 6, Off) C2

+

/M1

+

Saline pump (holders 2, 3, 4, 5, Off) C3

+

/C4

+

/C5

+

SIVISION (On/Off)

-

English

PSI

ON

adjustable

120 sec.

STOP

3.6V

100% of input pressure

OFF

OFF

OFF

Instrument parameters:

Instrument light (On/Off)

Spray (On/Off)

Direction of rotation (CW/CCW)

(storable, but is set to the default value the next time the

treatment center is turned on for safety reasons)

US intensity

Highspeed handpiece intensity

Intensity of electric motor 1

Intensity of electric motor 2

HF intensity

OFF

High-speed handpiece: ON

Electric motor: OFF

US: ON

(not programmable)

CW

20

3.5 ±0.1 bar

40,000 rpm

20,000 rpm

20

Miscellaneous:

Sprayvit ventilation (Yes/No) NO

bеЦдблЬ

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

1 – 5

1 Important information

Assistant element

(42 00 650, ass. el.)

Mode dialog:

--------------------

miscellaneous:

SPRAYVIT ventilation (Yes/No) NO

Water unit

(

42 00 627,

WE Air Water Sep.)

(42 00 619, WE)

Mode dialog:

Tumbler filling with

S program (On/Off)

Cuspidor flushing with

S program (On/Off)

SIROLUX U-POS

(Sirolux switched on if dentist element is in place)

OFF

ON

OFF

Miscellaneous:

Tumbler filling time

(2, 4, 6, 8, 10 sec.)

Flushing time

(20, 40, 60, 90, 150, 300, 360, 420 sec.)

SIROLUX intensity

(20, 40, 80, 90, 100%)

Suction intensity (4 levels)

SIROLUX status with chair programs:

Program S (On/Off)

Program 0 (On/Off)

Program 1 (On/Off)

Program 2 (On/Off)

6 sec.

60 sec.

80%

100%

OFF

OFF

ON

ON

Chair

connection box

(58 63 480, CJ)

Mode dialog:

# key (switch/button)

Miscellaneous:

Chair programs 0, S, 1, 2, for users A and B;

(Position of: lift, backrest, travel track, tilting part)

User (A/B)

Switch

Factory program

A

Dentist panel

(33 17 091, AP)

The dentist panel is not used for saving any data!

Board

(Part no., designation)

Stored settings Default value

C2

+

, C3

+

, C4

+

, C5

+

, M1

+

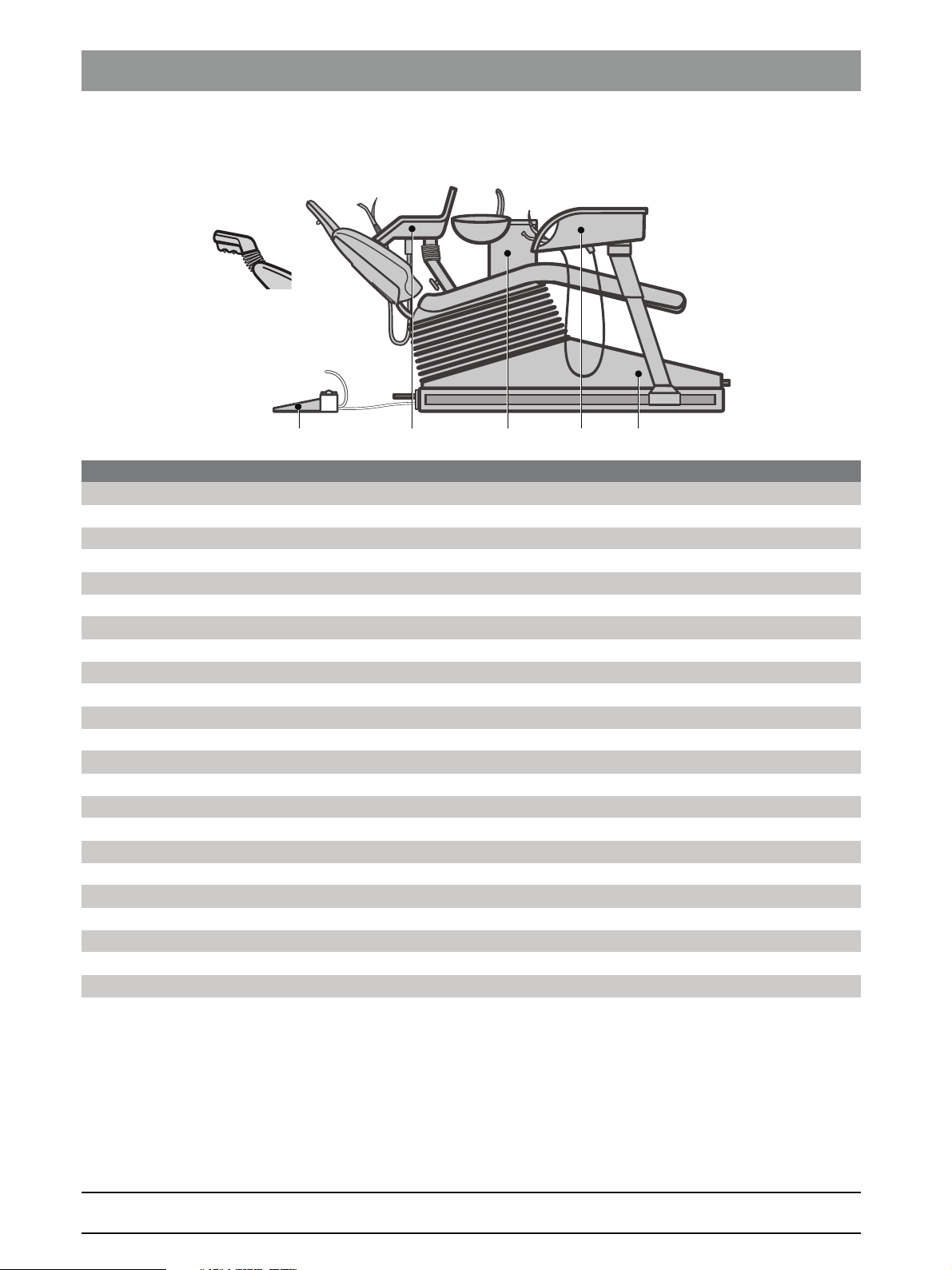

2 Overview of modules

and PCBs

58 77 977 D 3370

2 – 2 D 3370.076.01.06.02 10.2005

2 Overview of modules and PCBs

STAEHEFS WE

`O

H

Component PCB / module

Dentist element (AE) AP = Control panel

ADX = Control PCB

AL = SIRONA motor SL module

AU = SIROSON module

HF = HF module

PL = Polylux

MI = Mini LED

CC = IR PCB

Assistant element (HE) HEP = Control panel

HC = Control PCB

HP = Power supply PCB

HI = Flexible PCB

PL = POLYLUX

MI = Mini LED

Water unit (WE) WE = Control PCB

Patient chair (ST) DI = SIROLUX

CJ = Control ST

CF = Fuse PCB

SR = Relay PCB

CK = Hand switch PCB

SL = Wiring PCB

KS = 4-way foot control

Foot switch (FS) CFS = Foot switch PCB

bеЦдблЬ

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

2 – 3

2 Overview of modules and PCBs

STAEAss. FS WE

`P

H

Component PCB / module

Dentist element (AE) AP = Control panel

ADX = Control PCB

AL = SIRONA motor SL module

AU = SIROSON module

CC = IR PCB

Assistant element (HE)

HEP = Control panel

HC = Control PCB

HP = Power supply PCB

RK = IR PCB

PL = Polylux

MI = Mini LED

Water unit (WE) WE = Control PCB

Patient chair (ST) DI = SIROLUX

CJ = Control ST

CF = Fuse PCB

SR = Relay PCB

SL = Wiring PCB

CK = Hand switch PCB

KS = 4-way foot control

Foot switch (FS) CFS = Foot switch PCB

58 77 977 D 3370

2 – 4 D 3370.076.01.06.02 10.2005

2 Overview of modules and PCBs

STAEAss. FS WE

`Q

H

Component PCB / module

Dentist element (AE) AP = Control panel

ADX = Control PCB

AL = SIRONA motor SL module

AU = SIROSON module

CC = IR PCB

Assistant element (HE) HEP = Control panel

HC = Control PCB

HP = Power supply PCB

RK = IR PCB

PL = POLYLUX

MI = Mini LED

Water unit (WE) WE = Control PCB

Patient chair (ST) DI = SIROLUX

CJ = Control ST

CF = Fuse PCB

SR = Relay PCB

SL = Wiring PCB

CK = Hand switch PCB

KS = 4-way foot control

Foot switch (FS) CFS = Foot switch PCB

bеЦдблЬ

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

2 – 5

2 Overview of modules and PCBs

STAEAss.

FS

WE

`R

H

Component PCB / module

Dentist element (AE) AP = Control panel

ADX = Control PCB

AL = SIRONA motor SL module

AU = SIROSON module

CC = IR PCB

Assistant element (HE) HEP = Control panel

HC = Control PCB

HP = Power supply PCB

RK = IR PCB

PL = POLYLUX

MI = Mini LED

Water unit (WE) WE = Control PCB

WV = WE and video interface

DI = SIROLUX

Patient chair (ST) CJ = Control ST

CF = Fuse PCB

SR = Relay PCB

SL = Wiring PCB

CK = Hand switch PCB

KS = 4-way foot control

Foot switch (FS) CFS = Foot switch PCB

58 77 977 D 3370

2 – 6 D 3370.076.01.06.02 10.2005

2 Overview of modules and PCBs

jN

H

ST

AE

FS

WEAss.

Component PCB / module

Dentist element (AE) AP = Control panel

ADX = Control PCB

AL = SIRONA motor SL module

AU = SIROSON module

HF = HF module

PL = Polylux

MI = Mini LED

CC = IR PCB

Assistant element (HE) HEP = Control panel

HC = Control PCB

HP = Power supply PCB

HI = Flexible PCB

PL = POLYLUX

MI = Mini LED

Water unit (WE) WE = Control PCB

Patient chair (ST) DI = SIROLUX

CJ = Control ST

CF = Fuse PCB

SR = Relay PCB

CK = Hand switch PCB

SL = Wiring PCB

KS = 4-way foot control

Foot switch (FS) CFS = Foot switch PCB

C2

+

, C3

+

, C4

+

, C5

+

, M1

+

3 Points to observe during assembly

58 77 977D 3370

3 – 2 D 3370.076.01.06.02 10.2005

3 Points to observe during assembly

3.1 Patient chair

The patient chair can be moved without dentist element only if the

4-way foot control is installed.

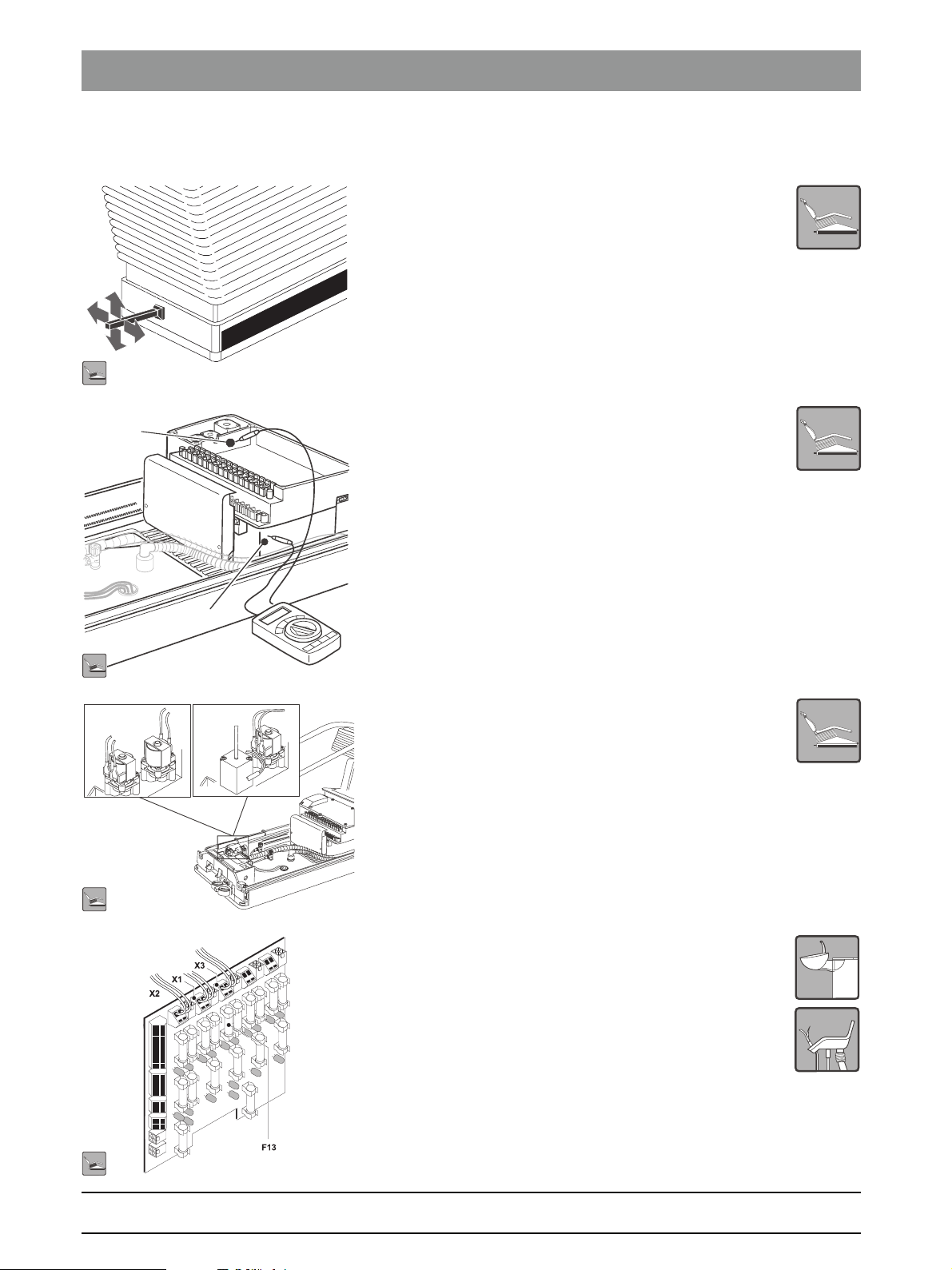

3.2 Protective ground / electronic

ground

An equipotential bonding conductor must not be connected. If

present, isolate it!!

Measure the protective ground against electronic ground.

Measure continuity from A to B:

The continuity tester must not beep.

A meter must show a reading of ∞ Ω.

3.3 MV1 / AD3

During assembly, decide whether the MV1 (version with disinfec-

tion system) or pressure reducer AD3 (version without disinfec-

tion system) is to be installed (see installation instructions).

3.4 Connecting the water Unit/assis-

tant element:

The 16V supply cables must be connected according to the color

coding to terminals X1, X2 and X3 on PCB CF in the connection

box.

A

B

AD3

MV1

Water unit

X1.1 = gray

X1.2 = pink

Dentist element

X2.1 = gray

X2.2 = pink

Assistant element

X3.1 = gray

X3.2 = pink

3

58 77 977D 3370

D 3370.076.01.06.02 10.2005

3 – 3

3 Points to observe during assembly

bеЦдблЬ

3.5 Assistant element:

The 16VAC and 24VAC cables are interconnected at the neu-

tral conductors. If the conductors are switched, there will be

a short-circuit and fuse F 13 on PCB CF will blow. If no

medium time-lag fuse is fitted, PCB HP in the assistant ele-

ment may be destroyed.

General Ensure proper installation of hoses and cables, do not allow them to be

crushed.

If hoses are interchanged, water will penetrate into the air supply system. This

may result in a failure of solenoid valves.

Crushed hoses and cables may cause failures on the entire treatment center.

Check the position of cables and media hoses before tightening any nuts.

EMC installation work EMC work that has not been performed correctly may result in faults which

are difficult to detect later on.

When all the installation work has been completed, measure the contact

resistance between protective ground and electronic ground (see 3.2 or

installation instructions).

C2

+

, C3

+

, C4

+

, C5

+

, M1

+

4 What happens after switch-on?

58 77 977 D 3370

4 – 2 D 3370.076.01.06.02 10.2005

4 What happens after switch-on?

4.1 Sequence of events

The unit transformer T1 is supplied with power via the unit main

switch S1.

The transformer supplies a voltage of 25VAC which is then rectified.

This results in a DC voltage (approx. + 35VDC).

Components AE, HE, WE and the chair (AK) are now supplied with + 35VDC

via fuse PCB CF, i.e., the required voltages (e.g., + 5V for logic, + 24V for

solenoid valves) are generated on the PCBs in the different components.

The 16VAC and 24VAC voltages in the unit are used primarily to power the

SPRAYVIT, water heater, camera supply and the halogen Polylight.

When the supply voltages are applied to the different components, the soft-

ware on the PCBs powers up (boot procedure).

A self-test is performed on the treatment center in this phase, and is audible

(for example, solenoid valves respond and relays trip).

Current is measured to detect whether any of the components (solenoid

valve, relay, or motor) has 1. a short-circuit, 2. an open circuit.

These evaluations are written into the service info memory of the individual

components AE, HE, WE and chair (AK).

CAUTION

A message relating to an open circuit does not necessarily indicate a fault. If

an open circuit is detected and the component is nevertheless functioning

completely, the current measurement is only out of tolerance.

When the self-test has been completed, the LCD indicates READY.

The clock is also displayed

NOTE

i

The clock chip is located on PCB CJ in the connection box (chair).

If the clock is functioning properly, CAN communication between the compo-

nents is generally in order.

The software recognizes ...: :

1. ... whether the treatment center is in a sanitation mode.

This signal comes from the water unit, PCB WE, via CAN communication.

If this is the case, it must be terminated or properly interrupted.

Interrupt sanitizing by simultaneously pressing the SPRAY ON/OFF and

CHIP BLOWER keys, AP SW version 5.4 and higher press intensity

key for 3 sec. (assistant element:press the SAN key for 3 sec.).

S1

T1

1

SAN

BA

R

BAR

BA

R

BAR

5

0

50

5

0

50

P

S

I

PSI

P

S

I

PSI

BA

R

BAR

BA

R

BAR

5

0

50

5

0

50

P

S

I

PSI

P

S

I

PSI

BA

R

BAR

BA

R

BAR

5

0

50

5

0

50

P

S

I

PSI

P

S

I

PSI

BA

R

BAR

BA

R

BAR

5

0

50

5

0

50

P

S

I

PSI

P

S

I

PSI

"READY" indicates that the treatment center is ready to

operate. This does not mean, however, that the treatment

center self-tests have been completed without errors.

READY

CJ

Intensity key 1

SW version 5.4 and higher

in the AP

4

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

4 – 3

4 What happens after switch-on?

bеЦдблЬ

. 2. ... whether the instrument configuration at the instrument

flanges has changed since the last power ON.

This is detected by the different instrument hoses and their

coding.

If it is determined during power-up that the instrument config-

uration differs from the stored configuration (on the ADX PCB),

the instrument values will be set as follows:

– Highspeed handpiece to full power

– 1. Motor to 40,000 rpm

– 2. Motor to 20,000 rpm

– Ultrasound to 20

CAUTION

The heater and the light in the SPRAYVIT remain turned off during

initial start-up.

The water pump must execute at least 20 strokes before the heat-

ing and light are enabled. This applies to the SPRAYVIT both in

the dentist element and in the assistant element.

If the ADX PCBs in the dentist element and HC are replaced, the

pump must execute an additional 20 strokes.

When the self-test has been completed, the individual components can com-

municate with each other via a data bus system.

This system is called: "CAN BUS"

CAN BUS, data communication between PCBs C2

+

,C3

+

, C4

+

,

M1

+

,

R297

X30

P21

ADX

HC

HP

PCB

CJ

PCB

WE

PCB

CJ

PCB

CJ

PCB

CJ

PCB

CJ

PCB

HC

PCB

HF

PCB

ADX

PCB

ADX

PCB

AP

PCB

HF

Option

C2

+

M1

+

Option

C2

+

l

M1

+

Jumper

plugs

must

be

present

Jumper

plugs

must

be

present

58 77 977 D 3370

4 – 4 D 3370.076.01.06.02 10.2005

4 What happens after switch-on?

CAN BUS, data communication between PCBs C5

+

The four components chair, dentist element, assistant element and water

unit are interconnected via a CAN serial interface.

The individual CAN drivers (transmitters and receivers for data communica-

tion) are arranged in the following order:

The individual signals - for example, cuspidor flushing, tumbler filling, instru-

ment motor ON and clock time - are transferred and relayed from component

to component via this system.

Chair = board CJ

Water unit = board WE

Assistant element = board HF

Dentist element = board ADX

Dentist element = board AP

Assistant element = board HC

4

58 77 977 D 3370

D 3370.076.01.06.02 10.2005

4 – 5

4 What happens after switch-on?

bеЦдблЬ

4.2 Checking the CAN BUS

Is the clock running ?

If not, check whether the CAN connections are crushed, and

check for short-circuits and loose pins on the connectors.

NOTE

i

Tip: The clock chip is situated on PCB CJ in the chair (connection

box).

Turn on SIROLUX FANTASTIC from the dentist side and from the

assistant side.

NOTE

i

Tip: In this way you check the CAN cabling and the functioning of

many PCBs.

The "Turn on SIROLUX" key information is passed from the den-

tist element panel (AP) to the connection box (CJ) and from there

on to the water unit (WE).

Here PCB WE drives the SIROLUX dimmer PCB.

It then turns the SIROLUX light on.

In addition, the relevant LEDs on the panels are activated by a

CAN message from the water unit.

Check the CAN BUS using the foot switch.

Move the chair with the cursor.

In this way you can test the section between foot switch, chair (connection

box) and panel.

NOTE

i

Information: You can move the chair with the 4-way foot control.

Tip:The 4-way foot control is not connected to the CAN; the chair also moves

when communication is no longer possible.

L

BAR

BAR

BAR

BAR

5050

P

S

I

PSI

P

S

I

PSI

BARBAR

50

50

50

50

P

S

I

PSI

P

S

I

PSI

CJ

Loading...

Loading...