Siemens 941, 942, 546-00750A, 546-00750AE, 546-00750BE Installation Instructions Manual

Installation Instructions

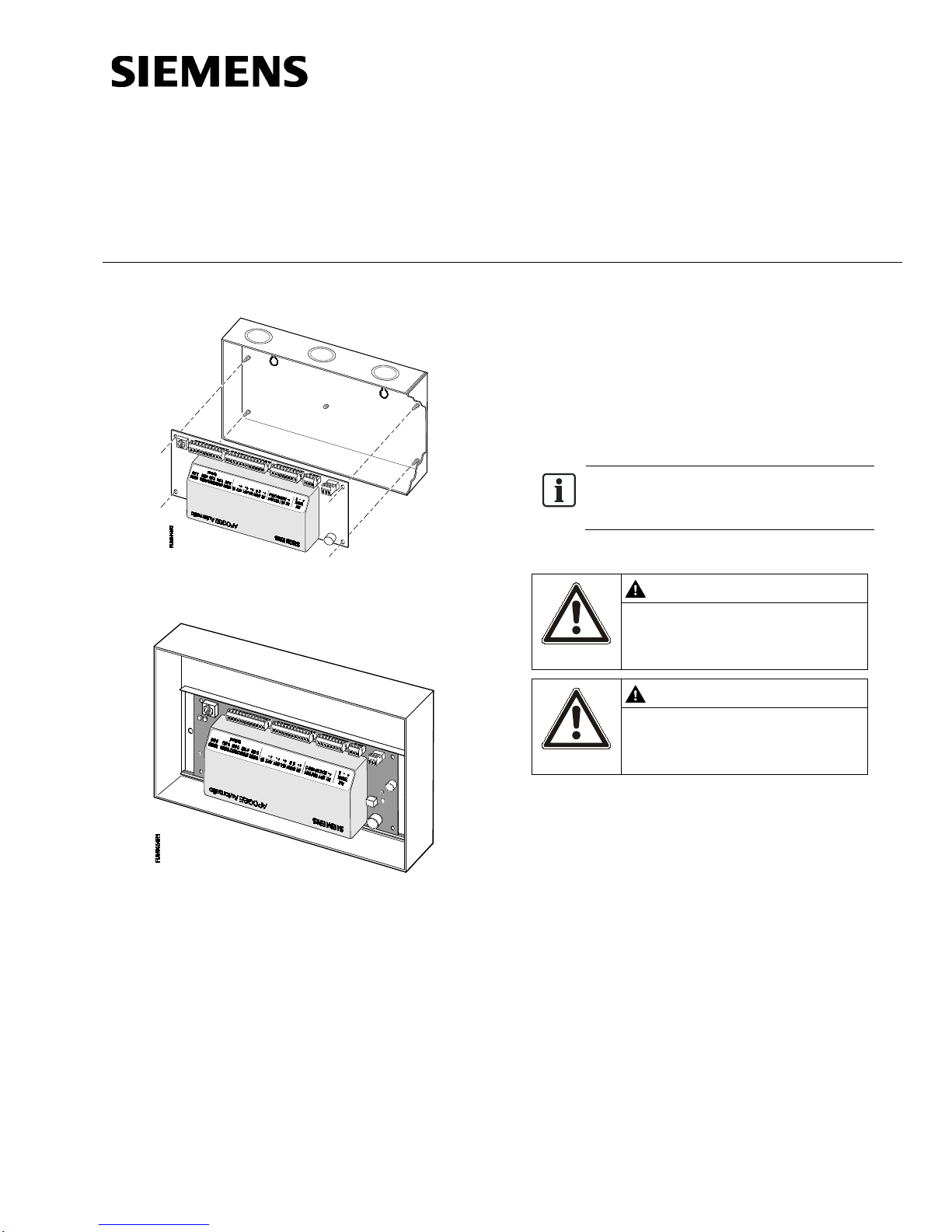

CE Compliant Fume Hood Control le r —

and mounting rail

546-00705E

CE Compliant Fume Hood Controller

enclosure

NOTE:

proof bag until you are ready to install.

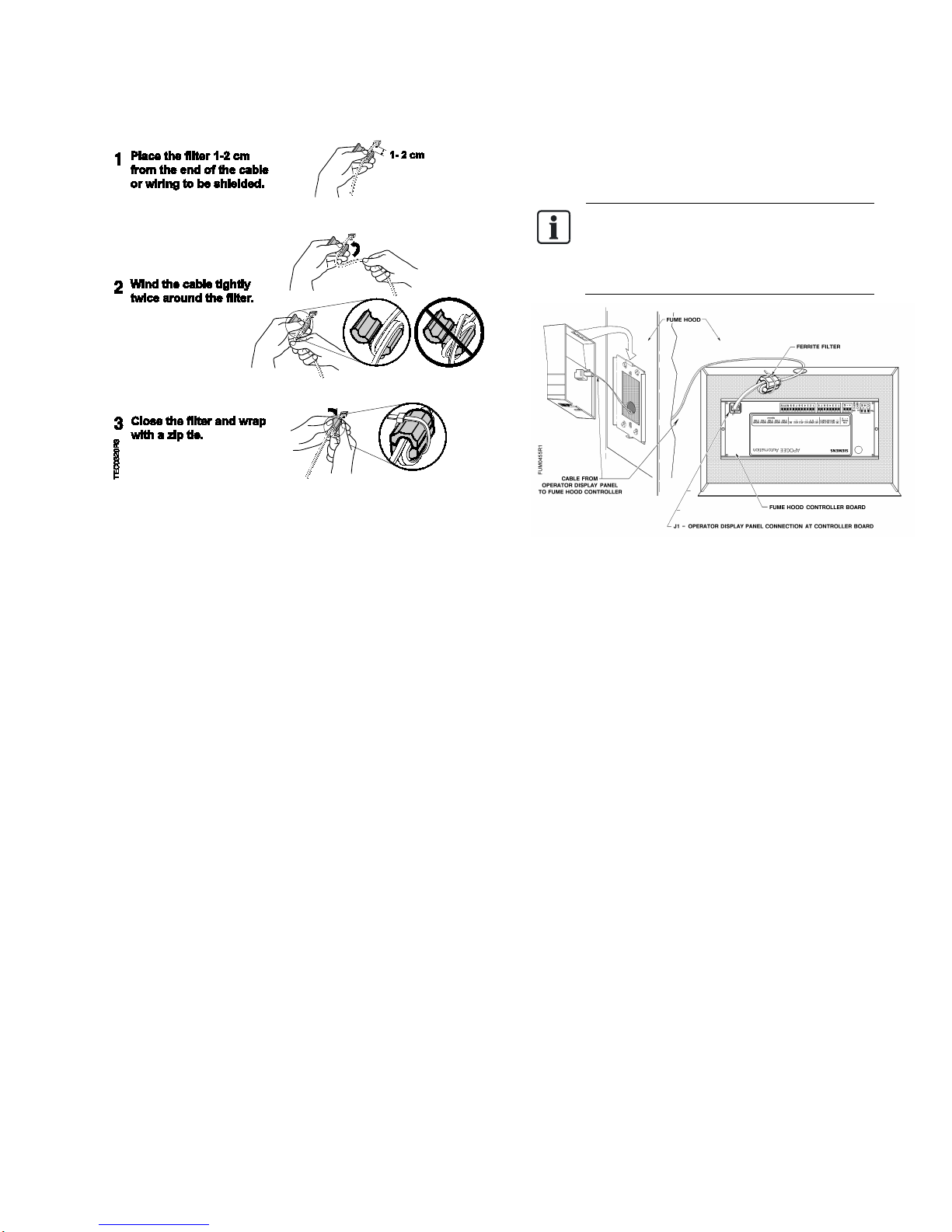

WARNING

Personal injury/loss of life may

occur if you do not follow the

procedures as specified.

CAUTION

Equipment damage or loss of data

may occur if you do not follow the

procedures as specified.

Document No. 546-00085

December 8, 2011

Application 941 and 942

Figure 1. CE Compliant Fume Hood

Controller(Standard enclosure).

Product Numbers

546-00705

Keep the controller board in its static

Warning/Caution Notation

CE Compliant Fume Hood Controller

— Application 941 and 942 with cover

— Application 941 and 942 with FHC

Figure 2. CE Compliant Fume Hood Controller

(Otherenclosure).

Control Applications

941 and 942

Product Description

The Fume Hood Controller Board (Figure 1 and

Figure 2) is the main termination board for the Fume

Hood Controller. The board comes with a ferrite filter

to suppress electrical emissions from the 8-

conductor cable. The ferrite filter must be installed to

meet FCC requirements and CE compliance

Item No. 546-00085. Rev. CA Page 1 of 7

Expected Installation Times

23 minutes.

Required Tools and Materia ls

• Smallflat-blade screwdriver

Prerequisites

• Fume Hood Controller Enclosure is mounted

and wiring has been roughed-in.

• Operator Display Panel is instal led and

cable pulled to location of controller.

Document No. 546-00085

NOTE:

enclosuremust be grounded.

CAUTION

Do not connect an earth ground

to prevent ground loop currents.

CAUTION

The Fume Hood Controller DOs

interposing relay must be used.

CAUTION

is not FCC and CE compliant.

Installation Instructions

December 8, 2011

Instructions

1. If the Fume Hood Controller will be used with a

field panel, then disconnect the Field Level

Network (FLN) trunk from the field panel.

2. Place the ESD wrist strap on your wrist and

attach it to a good earth ground.

3. Carefully remove the controller board from the

anti-static bag.

4. To mount the controller, do one of the following:

• Center the controller board over the

mounting posts in the bottom of the

controller enclosure (Figure 1). Insert the

corner holes of the board onto the mounting

posts. Press firmly on the board to snap it

securely into place. Repeat for all

controllers.

• Secure the mounting rail inside the

enclosure at the controller’s desired

location and snap it into place on the

mounting rail (Figure 2). Repeat for all

controllers.

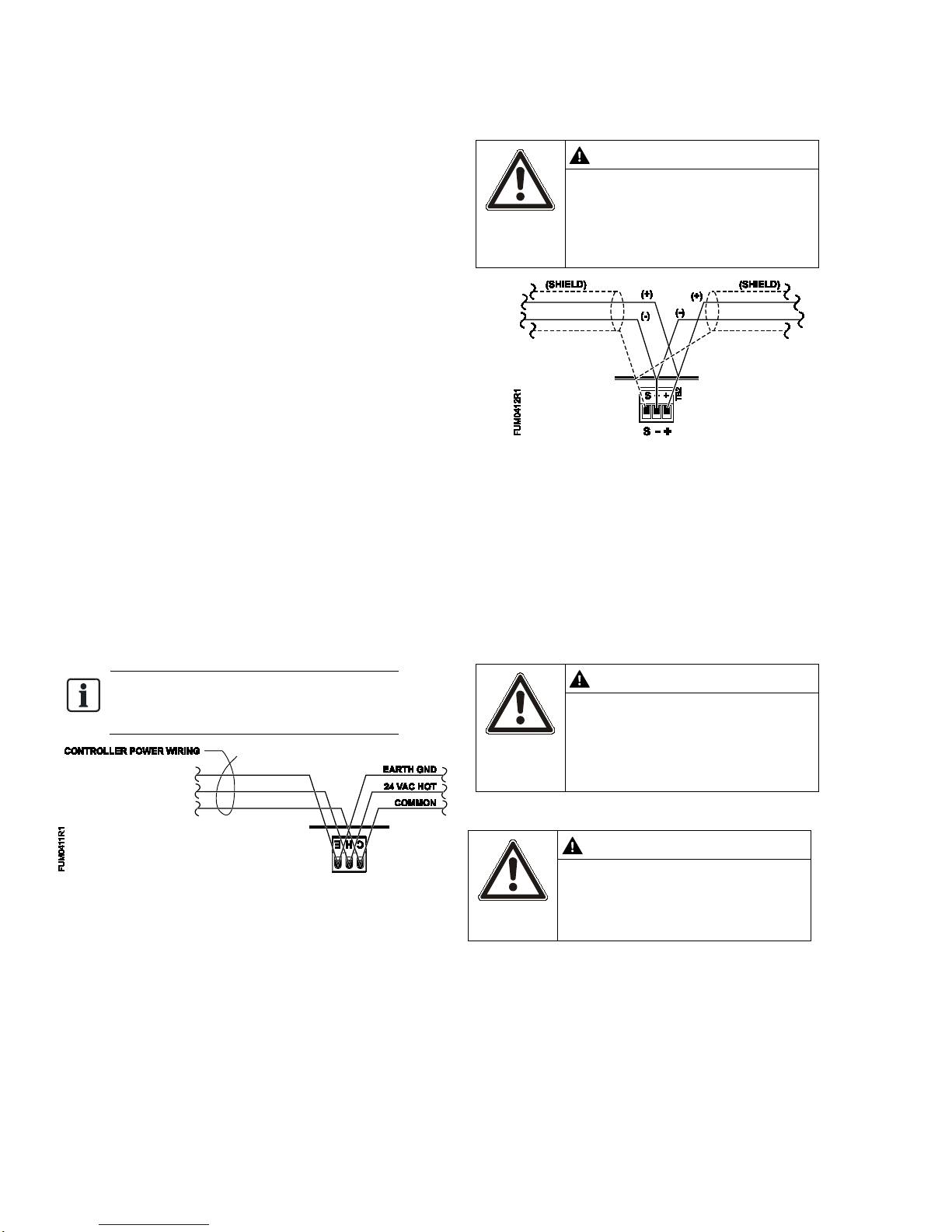

5. After installing all controller boards, verify that

power is OFF. Connect a certified 24 Vac Class

II power source to the Fume Hood Controller,

see Figure 3.

to the FLN trunk shield terminal.

The earth ground should be

connected only at the field panel

Figure 4. FLN Trunk Wiring.

8. Connect the point wiring for the appropriate

Fume Hood Controller application as shown in

Figure 7 and Figure 8. The wiring for sashes is

shown in Figure 9 through Figure 14. Red/Signal

and Black/Common polarity must be maintained

on all sash sensors. Terminate both connections

of a 24 Vac load directly to the controller board.

The 24 Vac “H” terminal is switched through a

triac to the NO terminations when the associated

DO is energized.

To meet CE requirements, the

Figure 3. Power Trunk Wiring.

6. Connect the FLN trunk wiring as shown in

Figure 4.

7. After all controllers are connected to the FLN

reconnect the FLN trunk to the field panel.

Page 2 of 7 Siemens Industry, Inc.

control 24 Vac loads only. The

maximum rating is 12 VA for

each DO. For higher ratings an

9. Follow the instructions in Figure 5.

Ferrite filter(s) must be installed

on the Operator Display Panel

(ODP) cable. If not, the controlle r

Figure 5. Installing a Ferrite Filter.

NOTE:

Document No. 546-00085

Installation Instructions

December 8, 2011

10. Plug the Operator Display Panel cable into the

Operator Display Panel Communication port on

the controller board (Figure 6 and Figure 7).

The ferrite filter must be installed on the

cable inside the enclosure to meet FCC

and CE requirements (

Figure 6).

Figure 6. Ferrite Filter Installed.

The installation is complete.

Siemens Industry, Inc. Page 3 of 7

Loading...

Loading...