SHARP LC121M2U, LC-150M2U Service Manual

1

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

SX8Z8LC-121M2U

SERVICE MANUAL

MODELS LC-121M2U/150M2U

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original

condition and only parts identical to those specified be used.

LC-121M2U

LC-150M2U

LCD AV MONITOR

SERVICE MANUAL

LC-121M2U

LC-150M2U

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

SHARP CORPORATION

CONTENTS

Page

1. IMPORTANT SERVICE SAFETY PRECAUTION .................................................................................... 2

2. SPECIFICATIONS ................................................................................................................................... 4

3. PART NAMES.......................................................................................................................................... 5

4. DISASSEMBLY OF THE SET.................................................................................................................. 6

5. ADJUSTING PROCEDURE OF EACH SECTION ................................................................................... 8

6. INTEGRATED CIRCUIT TERMINAL ARRANGEMENTS ........................................................................ 19

7. TROUBLE SHOOTING TABLE................................................................................................................ 24

8. CHASSIS LAYOUT .................................................................................................................................. 29

9. SCHEMATIC DIAGRAM .......................................................................................................................... 32

10. BLOCK DIAGRAM ................................................................................................................................... 47

11. PRINTED WIRING BOARD ASSEMBLIES .............................................................................................. 49

12. REPLACEMENT PARTS LIST ................................................................................................................. 54

13. PACKING OF THE SET ........................................................................................................................... 65

MODELS

LCD AV MONITOR

2

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

1. IMPORTANT SERVICE SAFETY PRECAUTION

æ Service work should be perfomed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any

circuit should be attempted.

2. Disconnect AC power before servicing.

CAUTION

FOR CONTINUED PROTECTION

AGAINST A RISK OF FIRE, REPLACE

ONLY WITH SAME TYPE F701, F703 (1.6A

125V), F702 (2.5A 125V).

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user,

perform the following safety checks:

1. Inspect all lead dress to make certain that leads

are not pinched, and check that hardware is not

lodged between the chassis and other metal

parts in the receiver.

2. Inspect all protective devices such as non-me-

tallic control knobs, insulation materials, cabinet

backs, adjustment and compartment covers or

shields, isolation resistor-capacitor networks,

mechanical insulators, etc.

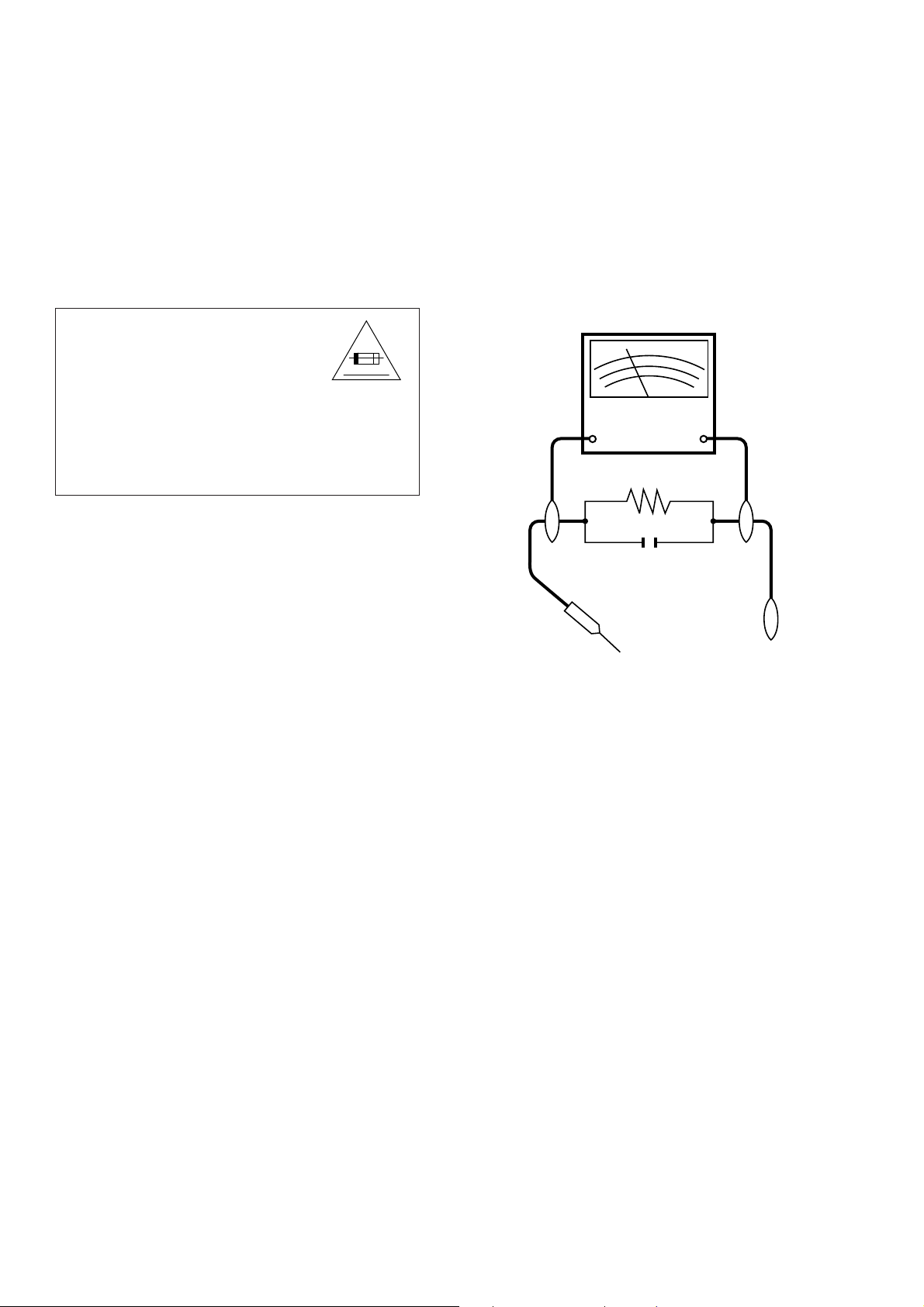

3. To be sure that no shock hazard exists, check for

current in the following manner.

• Plug the AC Adapter directly into a 120-volt AC

outlet, and connect the DC power cable into the

monitor's DC jack. (Do not use an isolation

transformer for this test).

• Using two clip leads, connect a 1.5k ohm, 10

watt resistor paralleled by a 0.15µF capacitor in

series with all exposed metal cabinet parts and

a known earth ground, such as electrical conduit

or electrical ground connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per

volt, or higher, sensitivity or measure the AC

voltage drop across the resisor.

• Connect the resistor connection to all exposed

metal parts having a return path to the chassis

(antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and meas-

ure the AC voltage drop across the resistor.

All checks must be repeated with the AC Adap-

tor plug connection reversed.(If necessary, a

nonpolarized adaptor plug must be used only for

the purpose of completing these checks.)

5A 125V

Any reading of 0.3V RMS(this corresponds

to 0.2 milliamp. AC.) or more is excessive and

indicates a potential shock hazard which must

be corrected before returning the receiver to

the owner.

SAFETY NOTICE

Many electrical and mechanical parts in LCD monitor

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be nec-

essarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by

“ å” and shaded areas in the

Replacement Parts Lists

and Schematic Diagrams

.

For continued protection, replacement parts must be

identical to those used in the original circuit.

The use of a substitute replacement parts which do not

have the same safety characteristics as the factory

recommended replacement parts shown in this service

manual, may create shock. fire. or other hazards.

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

DVM

AC SCALE

1.5k ohms.

10W

0.15 µF

TEST PROBE

3

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

1. PRECAUTIONS A PRENDRE LORS DE LA REPARATION

ÆÆ

ÆÆ

Æ Ne peut effectuer la réparation qu’ un technicien spécialisé qui s’est parfaitement

accoutumé à toute vérification de sécurité et aux conseils suivants.

AVERTISSEMENT

1. N’entreprendre aucune modification de tout cir-

cuit.

C’est dangereux.

2. Débrancher le récepteur avant toute réparation.

PRECAUTION

POUR LA PROTECTION CONTINUE

CONTRE LES RISQUES D’INCENDIE,

REMPLACER LE FUSIBLE PAR UN FUSIBLE

DE MEME TYPE F701, F703 (1.6A 125V), F702

(2.5A 125V).

VERIFICATIONS CONTRE L’INCEN-

DIE ET LE CHOC ELECTRIQUE

Avant de rendre le récepteur à l’utilisateur,

effectuer les vérifications suivantes.

1. Inspecter tous les faisceaux de câbles pour

s’assurer que les fils ne soient pas pincés ou

qu’un outil ne soit pas placé entre le châssis et

les autres pièces métalliques du récepteur.

2. Inspecter tous les dispositifs de protection comme

les boutons de commande non-métalliques, les

isolants, le dos du coffret, les couvercles ou

blindages de réglage et de compartiment, les

réseaux de résistance-capacité, les isolateurs

mécaniques, etc.

3. S’assurer qu’il n’y ait pas de danger

d’électrocution en vérifiant la fuite de courant, de

la facon suivante:

• Brancher l’adaptateur CA dans la prise CA de

120 V et le câble d’alimentation CC dans le jack

du moniteur. (Ne pas utiliser un transformateur

pour cet essai.)

• A l’aide de deux fils à pinces, brancher une

résistance de 1,5kΩ 10 watts en paralléle avec

un condensateur de 0,15µF en série avec toutes

les pièces métalliques exposées du coffret et

une terre connue comme une conduite électrique

ou une prise de terre branchée à la terre.

• Utiliser un voltmètre CA d’une sensibilité d’au

moins 5000Ω/V pour mesurer la chute de ten-

sion en travers de la résistance.

• Raccordez la résistance à toutes les pièces

exposées qui ont un chemin de retour au châssis

(antenne, coffret métallique, têtes de vis, bou-

tons, arbres de commande, emblème, etc) et

mesurez une chute de tension CA à travers la

résistance.

5A 125V

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les téléviseurs présentent des caractéristiques spéciales

relatives à la sécurité, qui ne sont souvent pas évidentes

à vue. Le degré de protection ne peut pas être

nécessairement augmentée en utilisant des pièces de

remplacement étalonnées pour haute tension, puissance,

etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel; les

pièces électriques qui présentent ces particularités sont

identifiées par la marque “ å” et hachurées dans la liste

des pièces de remplacement et les diagrammes

schématiques.

Pour assurer la protection, ces pièces doivent être

identiques à celles utilisées dans le circuit d’origine.

L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par

l’usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies, radiations X ou autres acci-

dents.

0,15 µF

SONDE D'ESSAI

DVM

Echelle CA

1.5 k ohm

10W

AUX PIECES

METALLIQUES

EXPOSEES

BRANCHER A UNE

TERRE CONNUE

Il faut répéter les vérifications en inversant la

connexion de la fiche de l'adaptateur CA (S'il

y a lieu, utilisez une fiche non polarisée pour

seulement compléter ces vérifications.)

Une valeur de 0,3 V RMS ou plus (correspond

à 0,2 mA C.A.) est excessive et implique un

danger de secousse électrique, qui devra être

supprimé avant de retourner l'appareil à

l'utilisateur.

4

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

2. SPECIFICATIONS

Type: LCD display unit (LCD color AV monitor)

Size: 12.1" type (184.3 mm × 245.8 mm) (LC-121M2U)

15" type (305.3 mm × 229.0 mm) (LC-150M2U)

Display System: Transmitting type TN liquid crystal panel.

Driving System: TFT (Thin Film Transistor) active matrix system

Number of Picture Elements: 921,600 (480 (V) × 640 (H) × 3 (RBG) )

Speaker Output: 0.7 W × 2 (Front)

2 W × 1 (Rear)

Speaker: 30 mm × 40 mm (Elliptic) × 2 (Front)

65 mm (Round) × 1 (Rear)

Light Source: Internal Light (Built-in fluorescent lamp)

Connected Terminals: Input: DC12V, VHS, S-VHS, Audio and DVD

Output: VHS, S-VHS, Audio and Headphone

Power Source: AC 100~240·50/60Hz (Connected to AC Adapter)

Power Consumption (Approx.): 38 W (Connected to AC Adapter) (LC-121M2U)

40 W (Connected to AC Adapter) (LC-150M2U)

Operating Temparature: –10°C~40°C

Dimensions: 297.4 mm (W) × 264.6 mm (H) × 87 mm (D) (Includes Set Stand)

(LC-121M2U)

357.0 mm (W) × 309.2 mm (H) × 87 mm (D) (Includes Set Stand)

(LC-150M2U)

297.4 mm (W) × 264.6 mm (H) × 62.5 mm (D) (Not Include Set Stand)

(LC-121M2U)

357.0 mm (W) × 309.2 mm (H) × 62.5 mm (D) (Not Include Set Stand)

(LC-150M2U)

Weight (Approx.): 2.9 kg (LC-121M2U)

3.6 kg (LC-150M2U)

Accessories: Operation Manual, Guarantee Card, AC Adapter, Remote Control,

Set Stand Mounting Screws, Wall mounting set angle and Batteries

(AAA size x 2)

Specifications are subject to changed without prior notice.

5

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

3. PART NAMES

6

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

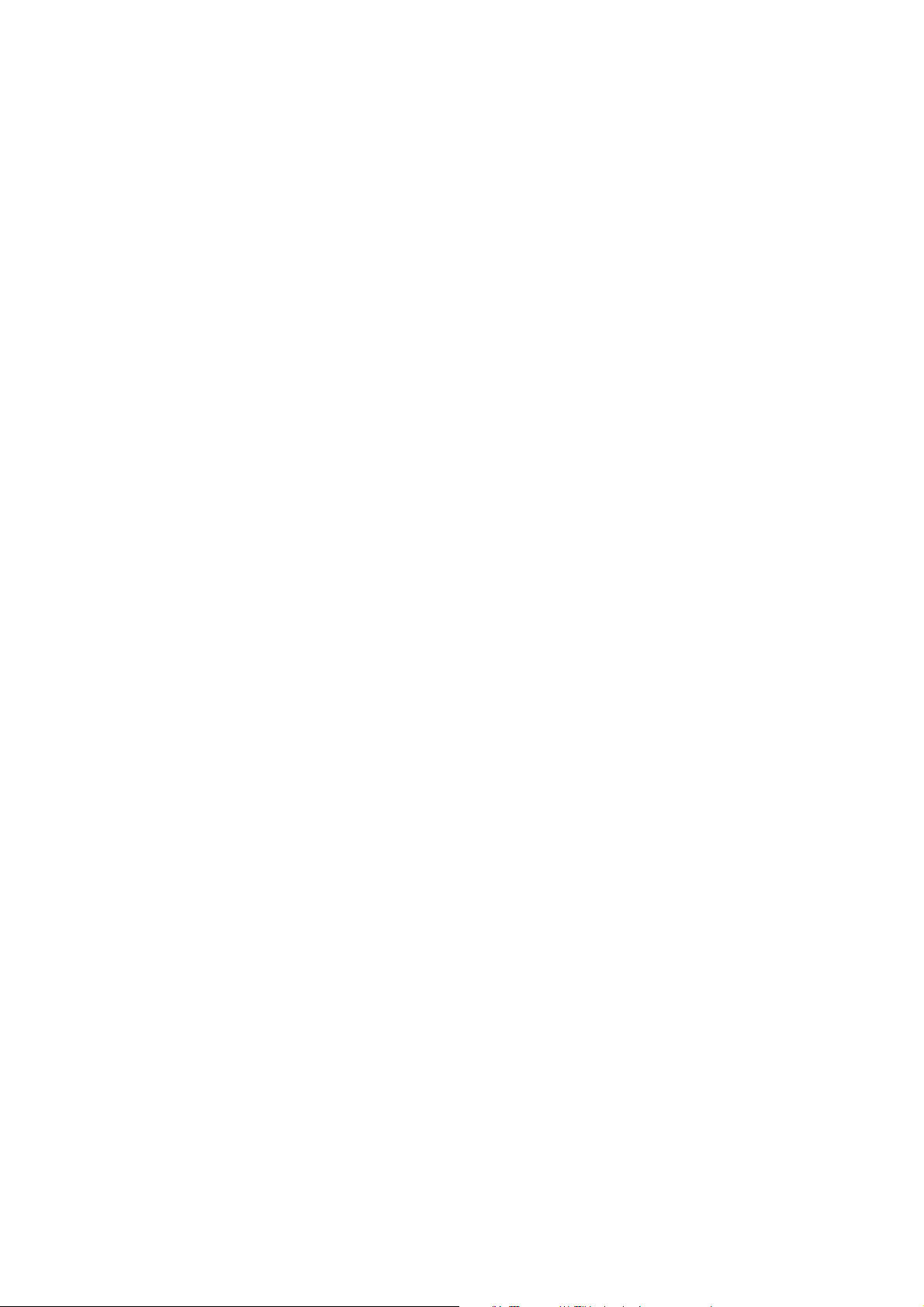

1

Push

Cabinet B

Cabinet A

b WH

Cabinet A

CCABA2338CE02 GCABA2338CEKA

(LC-121M2U)

CCABA2343CE02 GCABA2343CEKA

(LC-150M2U)

Cabinet B

CCABB2246CE02 GCABB2246CEKA (LC-121M2U)

CCABB2249CE02 GCABB2249CEKA (LC-150M2U)

Cable

a

a

a

a

a

a

a

1

4

8

5

r

7

9

e

0

q

w

7

t

u

y

u

i

2

6

3

Cabinet B

c WH

4. DISASSEMBLY OF THE SET

1. Remove four screws (1).

2. Opening six claws ( a ), release the cabinet B.

Remove the wire holder ( b ) and disconnect each

connectors (2~6).

Remove the cabinet B.

3. Remove two screws (7) which mounting the LCD

display unit.

4. Remove soldering of copper-foil tape (8) .

5. Disconnect each connectors (9~e) from the LCD

display unit.

6. Remove the cabinet A.

7. Remove four screws (r) which mounting the main

PWB unit.

8. Remove one screw (t) and remove the remote control

receptor PWB.

9. Remove five screws (y) and GND cable.

10.Remove ten screws (u) and remove the terminal

cover.

11.Remove two screws (i) and remove the switch PWB.

7

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

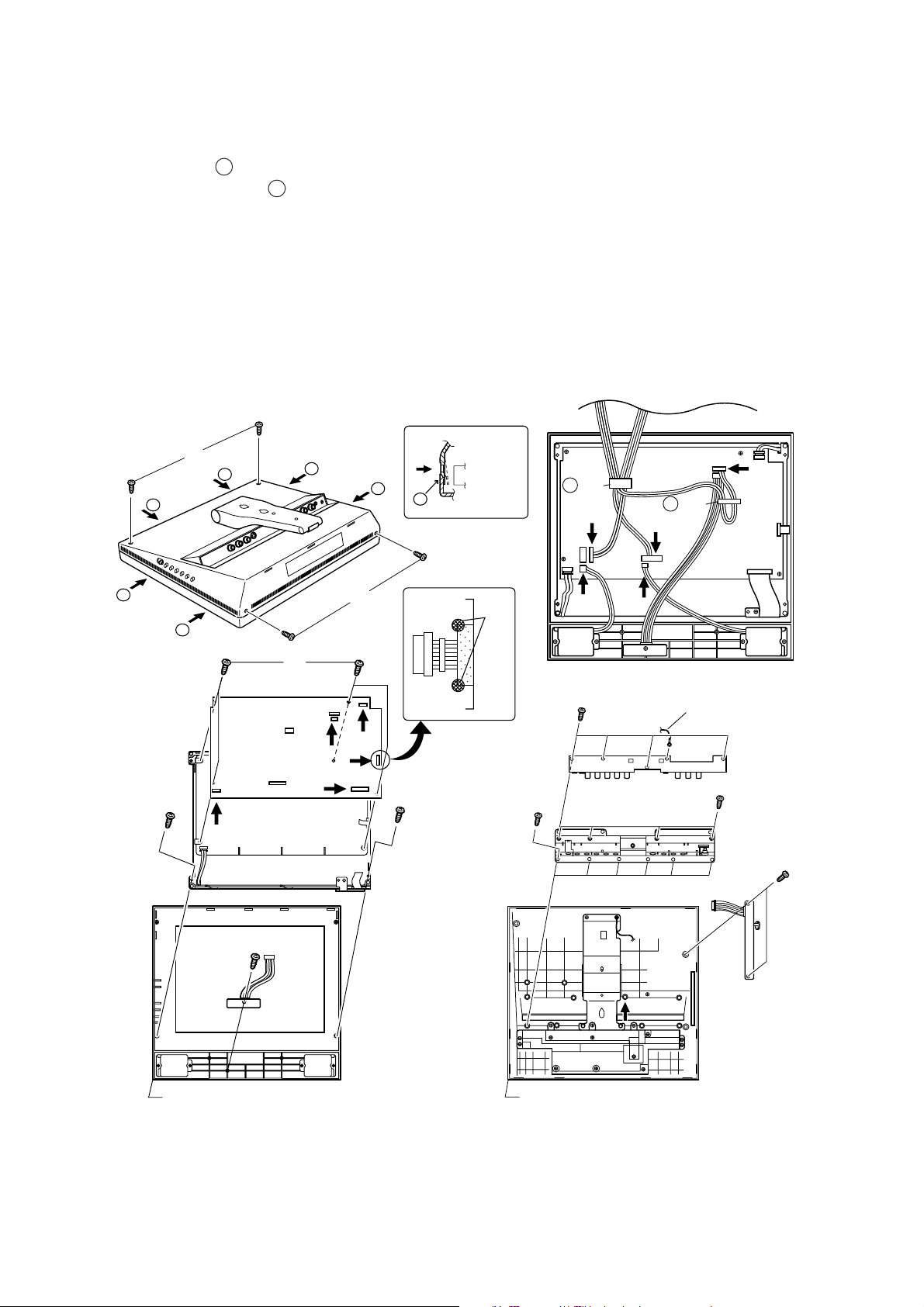

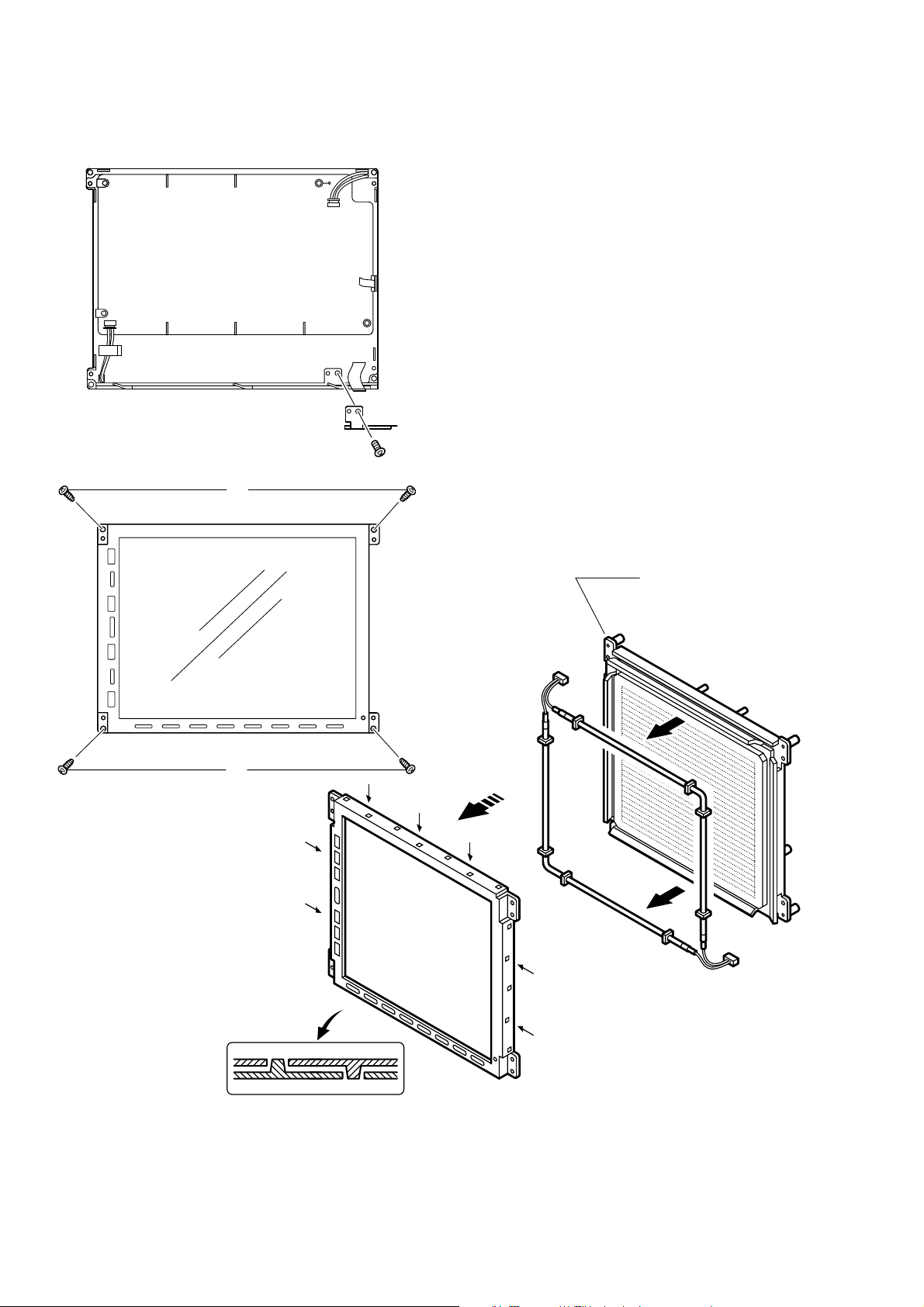

12.Remove one screw (o) and remove the SOS shield

angle.

13. Remove four screws (p) which mounting the LCD

display unit.

14.Spread bites of the LCD unit (a) out to be off from

claws.

15.Remove the Lamp unit (s).

o

Holder

LHLDZ2082CEKZ (LC-121M2U)

LHLDZ2085CEKZ (LC-150M2U)

p

p

a

s

8

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

The best adjustment is made before shipping. If any position deviation is found or after part replace is performed, adjust

as follows.

5-1. Preparation for adjustment

(1)Use the exclusive-use AC adapter or stable DC power supply.

AC adapter: UADP-0183CEZZ

DC power supply: 12 ± 0.5V

5-2. Special mode setting procedure

(1)After initialization of E

2

PROM the mode is changed to the adjustment mode.

[Procedure]

Connect TP2007 and TP2008 to GND, and turn on the power.

[Description]

• The initialization of microcomputer is as follows.

• AV position, DAC data, G/A data, and video chroma data adjustment values are taken as defaults.

(2)Change to adjustment mode

[Procedure]

Short-circuit TP2007 to GND, and turn on the power.

Or short-circuit TP2008 to GND, and turn on the power.

Or holding down the [AV INPUT] key and [MENU] key, turn on the main power, and simultaneously press the (inspection

process) [SELECT "] key and [VOL– ] key to change the mode to the adjustment mode.

[Description]

The manual adjustment or adjustment through communication with the automatic machine is performed.

(3)Inspection mode

[Procedure]

Holding down the [AV INPUT] key and [MENU] key, turn on the power.

[Description]

• In the ordinary menu select “PICTURE” with the [SELECT] key, and decide with the [VOL] key. Then select

“CONTRAST”, “TINT (only NTSC)”, “COLOR”, “BLACK LEVEL”, “SHARPNESS”, “RED” , and “BLUE” with the

[SELECT] key, and decide with the [VOL] key. After that, adjust values with the [VOL] key.

• In the ordinary menu select “SOUND” with the [SELECT] key, and decide with the [VOL] key. Then, select “TREBLE”,

“BASS”, and “BALANCE” with the [SELECT] key, and decide with the [VOL] key. After that adjust values with the [VOL]

key.

• VOLUME, CONTRAST, TINT (only NTSC), COLOR, BLACK LEVEL, SHARPNESS, RED, BLUE, TREBLE, BASS,

and BALANCE change as follows.

(4)Shipping setting mode

[Procedure]

Holding down the [AV INPUT] key and [MENU] key, turn on the main power, and simultaneously press the (inspection

process) [SELECT '] key and [VOL+] key to change the mode to the adjustment mode.

[Description]

User adjustment and other values are taken as defaults.

If AV1 is indicated as SETTING COMPLETE, setting has been completed.

ûMin.Û ûCenterÛ ûMax.Û

5. ADJUSTING PROCEDURE OF EACH SECTION

9

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

5-3. Cancel of special mode

Turn off the main unit power.

5-4. Preparation adjustment

(1)Use the exclusive-use AC adapter or stable DC power supply.

AC adapter: UADP-0183CEZZ

DC power supply: 12 ± 0.5V

5-5. OSD menu indication and items in case of manual adjustment

Adjusting range

Page Item Minimum Maximum Initial Remarks

1 + B – ADJ 0 255 128

MODEL M2H F2/M2H/M2U/M2E

TUNER OFF 1/2/OFF

AUDIO MULTIPLEX OFF OFF/ON

BOOSTER 0 0/1/2/3

SYSTEM AUTO N358/N443/PAL/PAL-M/SECAM/AUTO

COPY GUARD ON OFF/ON

CH MEMORY OFF OFF/12/16

SECAM ON OFF/ON

MULTI LANG. OFF OFF/ON

TIMER OFF OFF/ON

The Ver. No. will be displayed on the lowest part of lines.

2 TA1276 DATA ~~~~

COM 0 255 128

NTSC/PALM OSC 0 255 128

N358 BRIGHTNESS 0 255 170

R CUTOFF 0 255 80

B CUTOFF 0 255 80

N358UNICOLOR 0 127 80

R DRIVE 0 127 64

B DRIVE 0 127 64

N358SCOLOR 0 31 25

N358TINT 0 127 74

DATA COPY WAIT WAIT/SEND

3 N358 R-Y PHASE 0 3 2

N358 B-Y PHASE 0 3 1

N443 BRIGHTNESS 0 255 170

N443 UNICOLOR 0 127 80

N443 SCOLOR 0 31 25

N443TINT 0 127 74

PAL-M BRIGHTNESS 0 255 170

PAL-M UNICOLOR 0 127 80

PAL-M SCOLOR 0 31 25

PAL-M TINT 0 127 74

R-ADJ 0 255 128

One blank line.

10

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

4 PAL/SECAM OSC 0 255 128

PAL BRIGHTNESS 0 255 170

PAL UNICOLOR 0 127 80

PAL SCOLOR 0 31 25

PAL TINT 0 127 74

BELL F0 0 255 120

B-Y BLACK LEVEL 0 15 8

R-Y BLACK LEVEL 0 15 8

SECAM BRIGHTNESS 0 255 170

SECAM UNICOLOR 0 127 80

SECAM COLOR 0 127 75

SECAM TINT 0 127 74

5 DVD NT BRIGHTNESS 0 255 170

DVD NT UNICOLOR 0 127 80

DVD NT COLOR 0 127 75

DVD NT TINT 0 127 74

DVD NT R-YPHASE 0 3 2

DVD NT B-YPHASE 0 3 3

DVD PAL BRIGHTNESS

0 255 170

DVD PAL UNICOLOR 0 127 80

DVD PAL COLOR 0 127 75

DVD PAL TINT 0 127 74

I

2

C DATA 000000

I

2

C DATA WAIT WAIT/SEND

6 TEST PATTERN OFF ON/OFF

G/A DATA 0000

G/A DATA WAIT WAIT/SEND

DIGITAL SYNC SEP. 0 FF 87 Fixed

AV NTSC H 0 7F 18 Fixed

DVD NTSC H 0 7F 1C Fixed

AV PAL H 0 7F 11 Fixed

DVD PAL H 0 7F 15 Fixed

AV SECAM H 0 7F 0E Fixed

NT/PALM V 1 1F 0C Fixed

PAL V 1 1F 0B Fixed

SECAM V 1 1F 0B Fixed

7 N443 R-YPHASE 0 3 2 Fixed

N443 B-YPHASE 0 3 1 Fixed

PAL R-YPHASE 0 3 2 Fixed

PAL B-YPHASE 0 3 1 Fixed

PAL-M R-YPHASE 0 3 2 Fixed

PAL-M B-YPHASE 0 3 1 Fixed

SECAM R-YPHASE 0 3 2 Fixed

SECAM B-YPHASE 0 3 1 Fixed

DVD PAL R-YPHASE 0 3 2 Fixed

DVD PAL B-YPHASE 0 3 1 Fixed

COLOR 0 127 60 Fixed

SCONT 0 31 18 Fixed

11

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

5-6. Service Adjusting

5-6-1. Basic Adjustment

Adjustment Adjusting conditions Adjusting method

1 +B Adjustment 1. Connect the DC voltmeter to 1. Adjust +B-ADJ to 5.1V ± 0.05V.

TP1104 ( DAC 9ch )

2 Model setup 1. Select the model "M2U". When M2U is selected, the item

settings are as follows.

TUNER OFF

AUDIO MULTIPLEX OFF

BOOSTER 0

SYSTEM AUTO

COPY GUARD ON

CH MEMORY OFF

SECAM ON

MULTI LANG. OFF

TIMER OFF

3 Counter-bias adjustment 1. Set the AV1 mode to set signal 1. Adjust COM so as to minimize the

noninput state. waveform peak-peak.

2. Fit the specified adjusting instrument (DAC7ch)

to the screen center.

3. Observe the adjusting instrument

output on the oscilloscope.

4 NTSC / PAL-MOSC 1. Input the monoscope pattern of 1. Adjust NTSC/PALM OSC so as to

adjustment NTSC into AV1. get the normal screen.

(DAC8ch)

8 DAC 2 1ch 0 255 0 Fixed

DAC 2 2ch 0 255 0 Fixed

DAC 2 3ch 0 255 0 Fixed

DAC 2 4ch 0 255 0 Fixed

DAC 2 5ch 0 255 0 Fixed

DAC 2 6ch 0 255 0 Fixed

DAC 2 7ch 0 255 0 Fixed

DAC 2 8ch 0 255 0 Fixed

DAC 2 9ch 0 255 0 Fixed

DAC 2 10ch 0 255 0 Fixed

DAC 2 11ch 0 255 0 Fixed

DAC 2 12ch 0 255 0 Fixed

12

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

5-6-2. AV input Adjustment

Adjustment Adjustment conditions Adjustment method

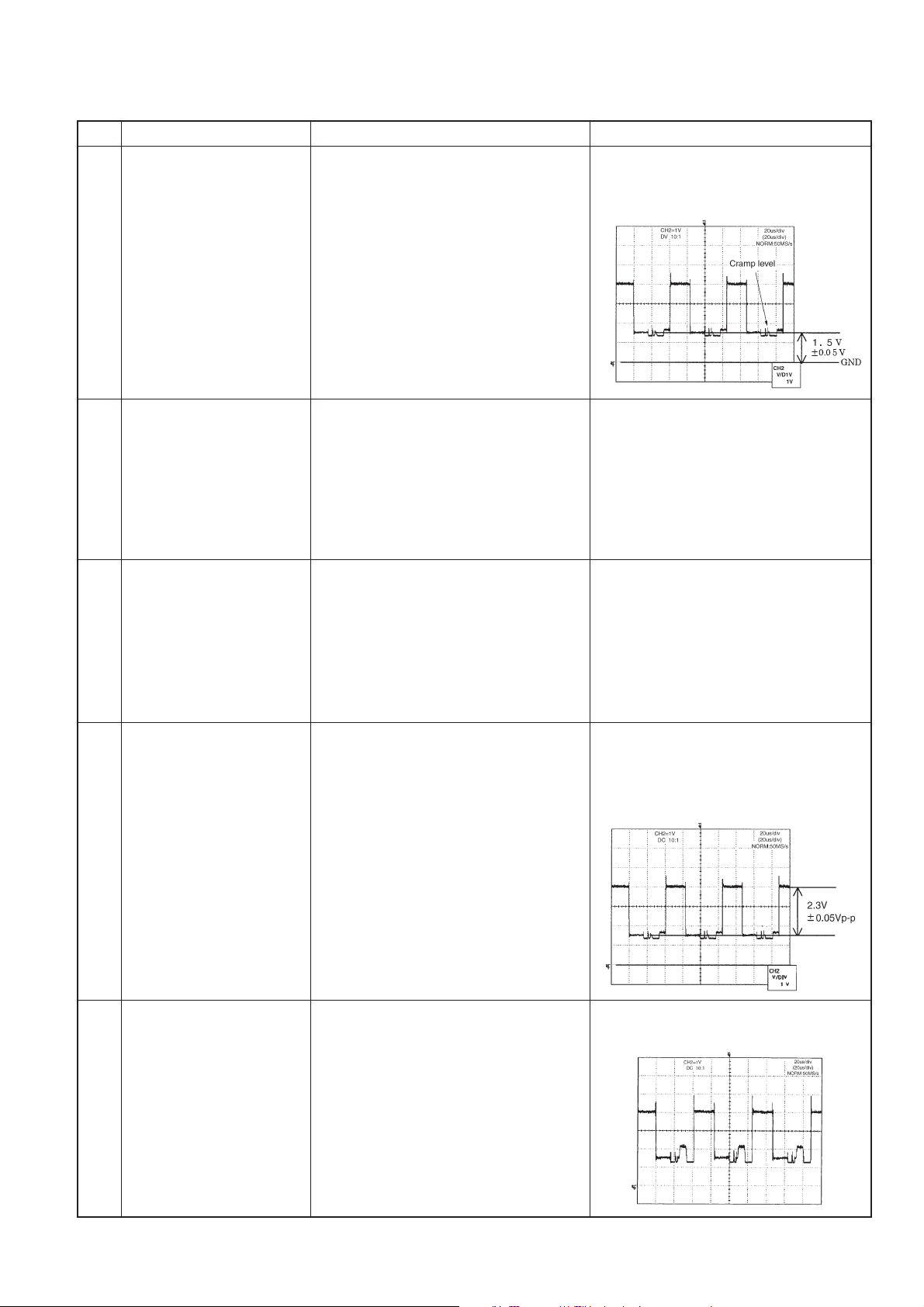

1 Brightness adjustment 1. Input the standard color bar signal 1. Adjust N358 BRIGHTNESS, and

(N358) (the same pattern as that of JPN-8CH) adjust the black level of G output so

of N358 into AV1. as to get DC 1.5±0.05V.

2. Connect the oscilloscope to TP821

(IC803, pin7, G output).

2 R-cut off adjustment 1. Input the standard color bar signal 1. Adjust R CUTOFF so as to equalize

(the same pattern as that of JPN-8CH) the black levels of green and red.

of N358 into AV1.

2. Connect the oscilloscope to TP821

(IC803, pin7, G output).

3. Connect the oscilloscope to TP819

(IC803, pin1, R output).

3 B-cut off adjustment 1. Input the standard color bar signal 1. Adjust B CUTOFF so as to equalize

(the same pattern as that of JPN-8CH) the black levels of green and blue.

of N358 into AV1.

2. Connect the oscilloscope to TP821

(IC803, pin7, G output).

3. Connect the oscilloscope to TP820

(IC803, pin8, B output).

4 Unicolor adjustment 1. Input the standard color bar signal 1. Adjust N358UNICOLOR, and

(N358) (the same pattern as that of JPN- adjust so as to get 100% white-

8CH) of N358 into AV1. black level video component equal

2. Connect the oscilloscope to TP821 to 2.3±0.05Vp-p.

(IC803, pin7, G output).

5 R DRIVE adjustment 1. Input the standard color bar signal 1. Adjust so as to get 100% white level

(the same pattern as that of JPN- identical with that of green.

8CH) of N358 into AV1.

2. Connect CH1 of oscilloscope to

TP821 (G output).

3. Connect CH2 of oscilloscope to

TP819 (R output).

13

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

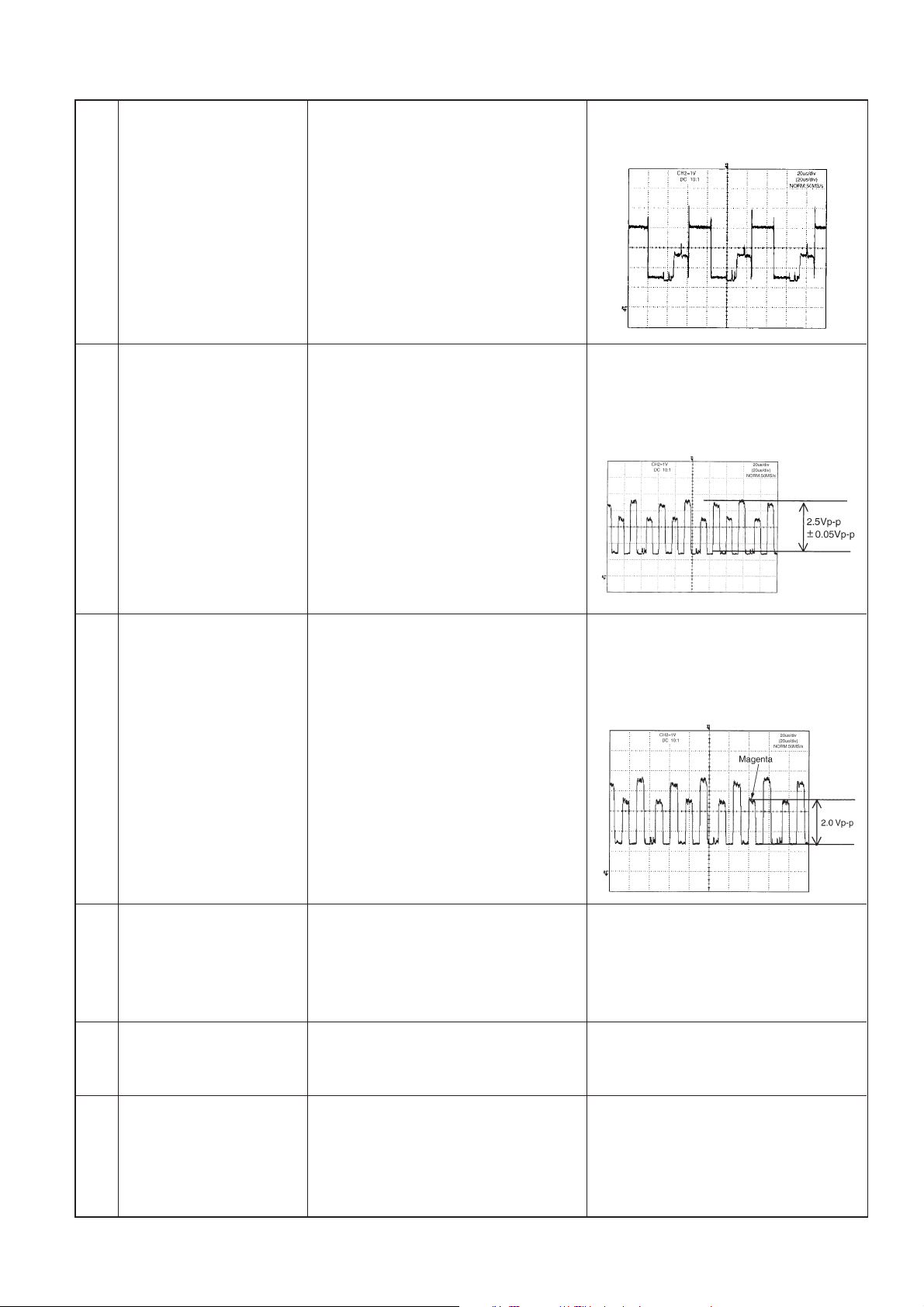

6 B DRIVE adjustment 1. Input the standard color bar signal 1. Adjust so as to get 100% white level

(the same pattern as that of JPN- identical with that of green.

8CH) of N358 into AV1.

2. Connect CH1 of oscilloscope to

TP821 (G output).

3. Connect CH2 of oscilloscope to

TP820 (B output).

7 Color level adjustment 1. Input the standard color bar signal Adjust N358 SCOLOR so as to get the

(N358) (the same pattern as that of JPN- color bar signal blue amplitude

8CH) of N358 into AV1. (black level - peak level) equal to 2.5V

2. Connect the oscilloscope to TP820 ± 0.05Vp-p.

(B output).

8 Tint adjustment 1. Input the standard color bar signal 1. Adjust N358 TINT so as to get the

(N358) (the same pattern as that of JPN- color bar signal magenta amplitude

8CH) of N358 into AV1. (black level-peak level) equal to 2.0

2. Connect the oscilloscope to TP820 ± 0.05Vp-p.

(B output).

9 N443/PAL-M adjustment 1. Position the cursor on DATA COPY 1. The indication changes from WAIT

and press VOL key. to SEND, and after the lapse of one

second WAIT is restored. Thus, N443,

PAL-M adjustment is completed.

10 4V adjustment 1. Connect the DC voltmeter to TP1110 1. Adjust R-ADJ to 4.0V ± 0.05V.

( DAC 6ch )

11 PAL/SECAM OSC 1. Input the monoscope pattern of PAL 1. Adjust PAL/SECAM OSC so as to

adjustment into AV1. get the normal screen.

(DAC8ch)

14

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

12 Brightness adjustment 1. Input the standard color bar signal 1. Adjust PAL BRIGHTNESS, and

(PAL) of PAL into AV1. adjust the black level of G output

2. Connect oscilloscope to TP821 so as to get DC 1.5 ±0.05V.

(IC803, pin7, G output).

13 Unicolor adjustment 1. Input the standard color bar signal 1. Adjust PAL UNICOLOR, and adjust

(PAL) of PAL into AV1. so as to get 100% white-black level

2. Connect oscilloscope to TP821 video component equal to 2.3±0.05

(IC803, pin7 , G output ). Vp-p.

14 Color level adjustment 1. Input the standard color bar signal Adjust PAL SCOLOR so as to get the

(PAL) (the same pattern as that of E-12CH) color bar signal blue amplitude

of PAL into AV1. (black level - peak level) equal to 2.5V

2. Connect the oscilloscope to TP820 ±0.05Vp-p.

(B output).

15 Tint adjustment 1. Input the standard color bar signal 1. Adjust PAL TINT so as to get the color

(PAL) (the same pattern as that of E-12CH) bar signal magenta amplitude (black

of PAL into AV1. level-peak level) equal to 2.0±

2. Connect the oscilloscope to TP820 0.05Vp-p.

(B output).

15

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

16 BELL f0 adjustment 1. Connect the oscilloscope to 1. Adjust BELL f0 so as to minimize the

TP2851. a-level.

17 Brightness adjustment 1. Input the standard color bar signal 1. Adjust SECAM BRIGHTNESS, and

(SECAM) (the same pattern as that of E-10CH) adjust the black level of G output to

of SECAM into AV1. DC 1.5±0.05V.

2. Connect oscilloscope to TP821

(IC803, pin7, G output).

18 Unicolor adjustment 1. Input the standard color bar signal 1. Adjust SECAM UNICOLOR, and

(SECAM) (the same pattern as that of E-10CH) adjust so as to get 100% white-black

of SECAM into AV1. level video component equal to 2.3±

2. Connect oscilloscope to TP821 0.05Vp-p.

(IC803, pin7, G output ).

19 Color level adjustment 1. Input the standard color bar signal Adjust SECAM COLOR so as to get

(SECAM) (the same pattern as that of E-10CH) the color bar signal blue amplitude

of SECAM into AV1. (black level - peak level) equal to 2.5V

2. Connect the oscilloscope to TP820 ±0.05Vp-p.

(B output).

20 Tint adjustment 1. Input the standard color bar signal 1. Adjust SECAM TINT so as to get

(SECAM) (the same pattern as that of E-10CH) the color bar signal magenta amplitude

of SECAM into AV1. (black level - peak level) equal to 2.0V

2. Connect the oscilloscope to TP820 ±0.05Vp-p.

(B output).

16

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

5-6-3. Component input Adjustment

Adjustment Adjusting conditions Adjusting method

1 Brightness adjustment 1. From SG, input the 100% white color Adjust DVD NT BRIGHTNESS, and

(NTSC) bar signal of NTSC into conponent adjust the black level of G output so

terminal. as to get DC 1.5±0.05V.

2. Connect oscilloscope to TP821

(IC803, pin7, G output).

2 Unicolor adjustment 1. From SG, input the 100% white color Adjust DVD NT UNICOLOR, and

(NTSC) bar signal of NTSC into conponent adjust so as to get 100% white-

terminal. black level video component equal

2. Connect oscilloscope to TP820 to 2.3±0.05Vp-p.

(IC803, pin8).

3 Color level adjustment 1. From SG, input the 100% white color Adjust DVD NT COLOR so as to get

(NTSC) bar signal of NTSC into conponent the color bar signal blue amplitude

terminal. (black level - peak level) equal to

2. Connect the oscilloscope to TP820 2.8V±0.05Vp-p.

(B output).

4 Tint adjustment 1. From SG, input the 100% white color Adjust DVD NT TINT so as to get the

(NTSC) bar signal of NTSC into conponent color bar signal magenta amplitude

terminal. (black level - peak level) equal to 2.3V

2. Connect the oscilloscope to TP820 ±0.05Vp-p.

(B output).

17

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

5 Brightness adjustment 1. From SG, input the 100% white color Adjust DVD PAL BRIGHTNESS, and

(PAL) bar signal of PAL into conponent adjust the black level of G output so

terminal. as to get DC 1.5±0.05V.

2. Connect oscilloscope to TP821

(IC803, pin7, G output).

6 Unicolor adjustment 1. From SG, input the 100% white color Adjust DVD PAL UNICOLOR, and

(PAL) bar signal of PAL into conponent adjust so as to get 100% white-

terminal. black level video component equal

2. Connect oscilloscope to TP820 to 2.3±0.05Vp-p.

(IC803, pin8, B output).

7 Color level adjustment 1. From SG, input the 100% white color Adjust DVD PAL COLOR so as to get

(PAL) bar signal of PAL into conponent the color bar signal blue amplitude

terminal. (black level - peak level) equal to

2. Connect the oscilloscope to TP820 2.8V±0.05Vp-p.

(B output).

8 Tint adjustment 1. From SG, input the 100% white color Adjust DVD PAL TINT so as to get

(PAL) bar signal of PAL into conponent the color bar signal magenta amplitude

terminal. (black level - peak level) equal to

2. Connect the oscilloscope to TP820 2.3V±0.05Vp-p.

(B output).

9 Tint adjustment Position the cursor on N358 TINT. Lower unconditionally the value by

10 points.

18

LC-121M2U

LC-150M2U

LC-121M2U

LC-150M2U

5-7. Shipping setting

(1)[Procedure]

Holding down the [AV INPUT] key and [MENU] key, turn on the main power, and simultaneously press the (inspection

process) [SELECT '] key and [VOL+] key to change the mode to the adjustment mode.

(2)[Indication]

AV1 is indicated as SETTING COMPLETE.

(3)[Description]

Mode is memorized as SETTING COMPLETE.

Menu setting descriptions are as follows.

VOLUME 30

CONTRAST 30 (AV1 / AV2 / COMPONENT)

TINT 0 (AV1 / AV2 / COMPONENT) (ONLY NTSC)

COLOR 0 (AV1 / AV2 / COMPONENT)

SHARPNESS 0 (AV1 / AV2 / COMPONENT)

RED 0 (AV1 / AV2 / COMPONENT)

BLUE 0 (AV1 / AV2 / COMPONENT)

COLOR SYSTEM AUTO (AV1 / AV2 / COMPONENT)

TREBLE 0

BASS 0

BALANCE 0

BRIGHTNESS BRIGHT

UPSIDE NORMAL

RIGHT / LEFT NORMAL

AV2 IN / OUT IN

AV1

SETTING COMPLETE

Loading...

Loading...