SHARP LC3237D62U, LC-32D62U, LC-37D62U. Service Manual

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRE-

CAUTION ............................................................i

PRECAUTIONS A PRENDRE LORS DE

LA REPARATION...............................................ii

PRECAUTIONS FOR USING LEAD-FREE

SOLDER ........................................................... iii

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS ......................................... 1-1

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL .................................. 2-1

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS ................................................ 3-1

CHAPTER 4. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS ................... 4-1

CHAPTER 5. ADJUSTMENT

[1] ADJUSTMENT PROCEDURE ....................... 5-1

CHAPTER 6. TROUBLE SHOOTING TABLE

[1] TROUBLE SHOOTING TABLE...................... 6-1

CHAPTER 7. MAJOR IC INFORMATIONS

[1] MAJOR IC INFORMATIONS.......................... 7-1

CHAPTER 8. OVERALL WIRING/BLOCK DIAGRAM

[1] OVERALL WIRING DIAGRAM (LC-

32D62U) ........................................................8-1

[2] OVERALL WIRING DIAGRAM (LC-

37D62U) ........................................................8-3

[3] SYSTEM BLOCK DIAGRAM.........................8-5

[4] MAIN BLOCK DIAGRAM...............................8-7

CHAPTER 9. PRINTED WIRING BOARD ASSEM-

BLIES

[1] MAIN Unit ...................................................... 9-1

[2] TERMINAL Unit ............................................. 9-9

[3] R/C, LED Unit ..............................................9-15

[4] KEY Unit ......................................................9-16

CHAPTER 10. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIA-

GRAM.......................................................... 10-1

[2] R/C, LED Unit ..............................................10-2

[3] MAIN Unit ....................................................10-3

[4] TERMINAL Unit .........................................10-49

[5] KEY Unit ....................................................10-53

Parts Guide

SERVICE MANUAL

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

TopPage

CONTENTS

In the interests of user-safety (Required by safety regulations in some countries) the set should

be restored to its original condition and only parts identical to those specified should be used.

LCD COLOR TELEVISION

No. S17A9LC32D62U

LC-32D62U

LC-37D62U

DRAFT

LC-32D62U/LC-37D62U 1st

LC-32D62U/LC-37D62U 1st

i

LC-32D62U/LC-37D62U 1st

Service Manual

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRECAUTION

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE RECEIVER (Fire &

Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

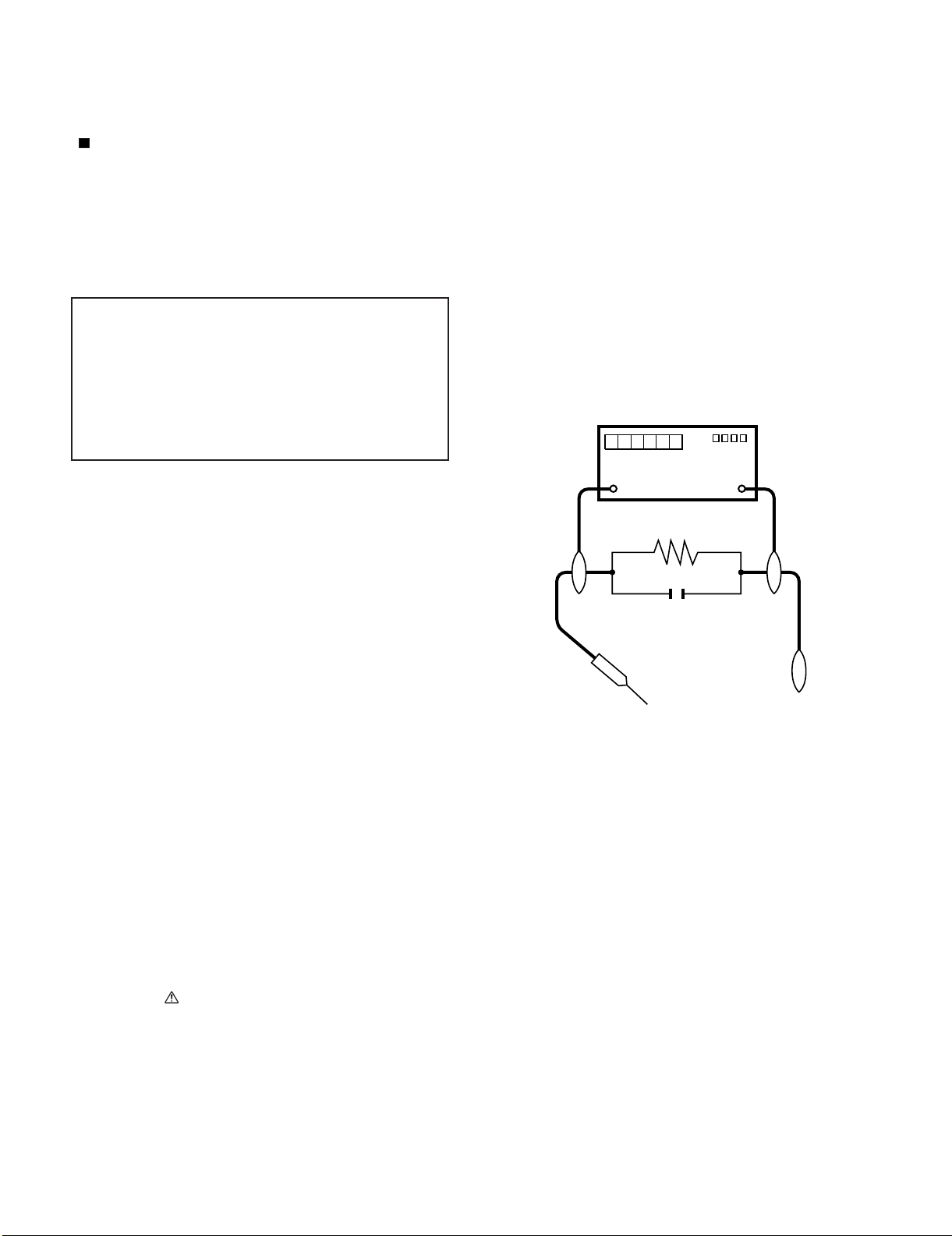

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 120 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paral-

leled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or elec-

trical ground connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sen-

sitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts List

and Schematic Diagrams.

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

CAUTION: FO R C O N T I N U E D PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSE.

F701 (250V 8A)

F4702 (250V 4A)

DVM

AC SCALE

1.5k ohm

10W

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

0.15

µ

F

TEST PROBE

LC-32D62U/LC-37D62U 1st

ii

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

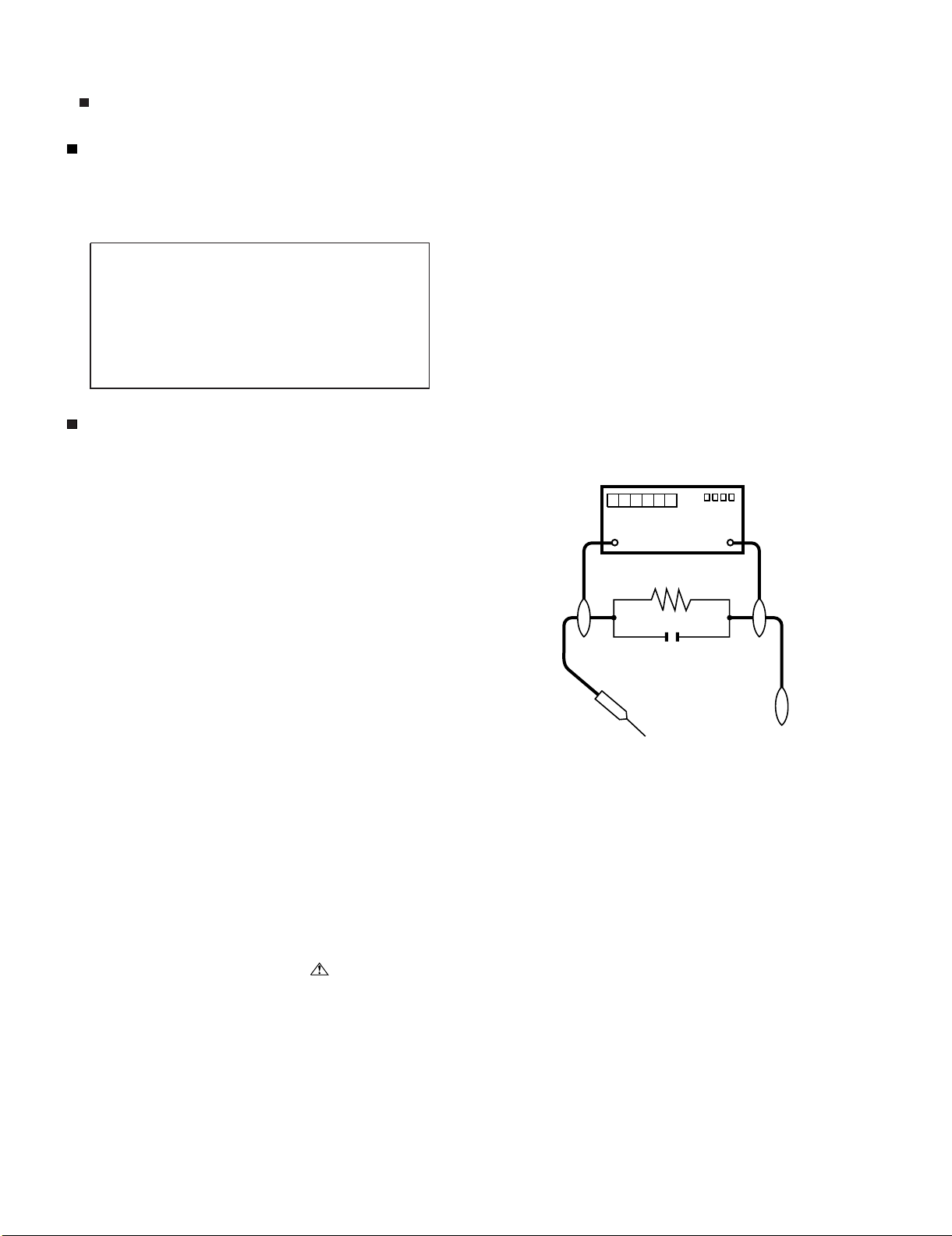

De nombreuses pièces, électriques et mécaniques, dans les télévi-

seur ACL présentent des caractéristiques spéciales relatives à la sé-

curité, qui ne sont souvent pas évidentes à vue. Le degré de protec-

tion ne peut pas être nécessairement augmentée en utilisant des

pièces de remplacement étalonnées pour haute tension, puissance,

etc.

Les pièces de remplacement qui présentent ces caractéristiques sont

identifiées dans ce manuel; les pièces électriques qui présentent ces

particularités sont identifiées par la marque " " et hachurées dans la

liste des pièces de remplacement et les diagrammes schématiques.

Pour assurer la protection, ces pièces doivent être identiques à celles

utilisées dans le circuit d'origine. L'utilisation de pièces qui n'ont pas

les mêmes caractéristiques que les pièces recommandées par l'usine,

indiquées dans ce manuel, peut provoquer des électrocutions, incen-

dies, radiations X ou autres accidents.

AVERTISSEMENT

1.

2.

3.

4.

5.

•

•

•

•

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement accoutumé à toute vérification de sécurité et aux

conseils suivants.

N'entreprendre aucune modification de tout circuit. C'est danger-

eux.

Débrancher le récepteur avant toute réparation.

Inspecter tous les faisceaux de câbles pour s'assurer que les fils

ne soient pas pincés ou qu'un outil ne soit pas placé entre le châs-

sis et les autres pièces métalliques du récepteur.

Inspecter tous les dispositifs de protection comme les boutons de

commande non-métalliques, les isolants, le dos du coffret, les cou-

vercles ou blindages de réglage et de compartiment, les réseaux

de résistancecapacité, les isolateurs mécaniques, etc.

S'assurer qu'il n'y ait pas de danger d'électrocution en vérifiant la

fuite de courant, de la facon suivante:

Brancher le cordon d'alimentation directem-ent à une prise de cou-

rant de 120V. (Ne pas utiliser de transformateur d'isolation pour

cet essai).

A l'aide de deux fils à pinces, brancher une résistance de 1.5 kΩ

10 watts en parallèle avec un condensateur de 0.15µF en série

avec toutes les pièces métalliques exposées du coffret et une terre

connue comme une conduite électrique ou une prise de terre

branchée à la terre.

Utiliser un voltmètre CA d'une sensibilité d'au moins 5000Ω/V pour

mesurer la chute de tension en travers de la résistance.

Toucher avec la sonde d'essai les pièces métalliques exposées qui

présentent une voie de retour au châssis (antenne, coffret métalli-

que, tête des vis, arbres de commande et des boutons, écusson,

etc.) et mesurer la chute de tension CA en-travers de la résistance.

Toutes les vérifications doivent être refaites après avoir inversé la

fiche du cordon d'alimentation. (Si nécessaire, une prise

d'adpatation non polarisée peut être utilisée dans le but de termin-

er ces vérifications.)

La tension de pointe mesurèe ne doit pas dépasser 0.75V (corre-

spondante au courant CA de pointe de 0.5mA).

Dans le cas contraire, il y a une possibilité de choc électrique qui

doit être supprimée avant de rendre le récepteur au client.

PRECAUTION: POUR LA PROTECTION CON-

TINUE CONTRE LES RISQUES D'INCENDIE,

REMPLACER LE FUSIBLE

F701 (250V 8A)

F4702 (250V 4A)

VERIFICATIONS CONTRE L'INCEN-DIE ET LE

CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer les vérifica-

tions suivantes.

DVM

ECHELLE CA

1.5k ohm

10W

0.15

µ

F

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

BRANCHER A UNE

TERRE CONNUE

AVIS POUR LA SECURITE

LC-32D62U/LC-37D62U 1st

iii

PRECAUTIONS FOR USING LEAD-FREE SOLDER

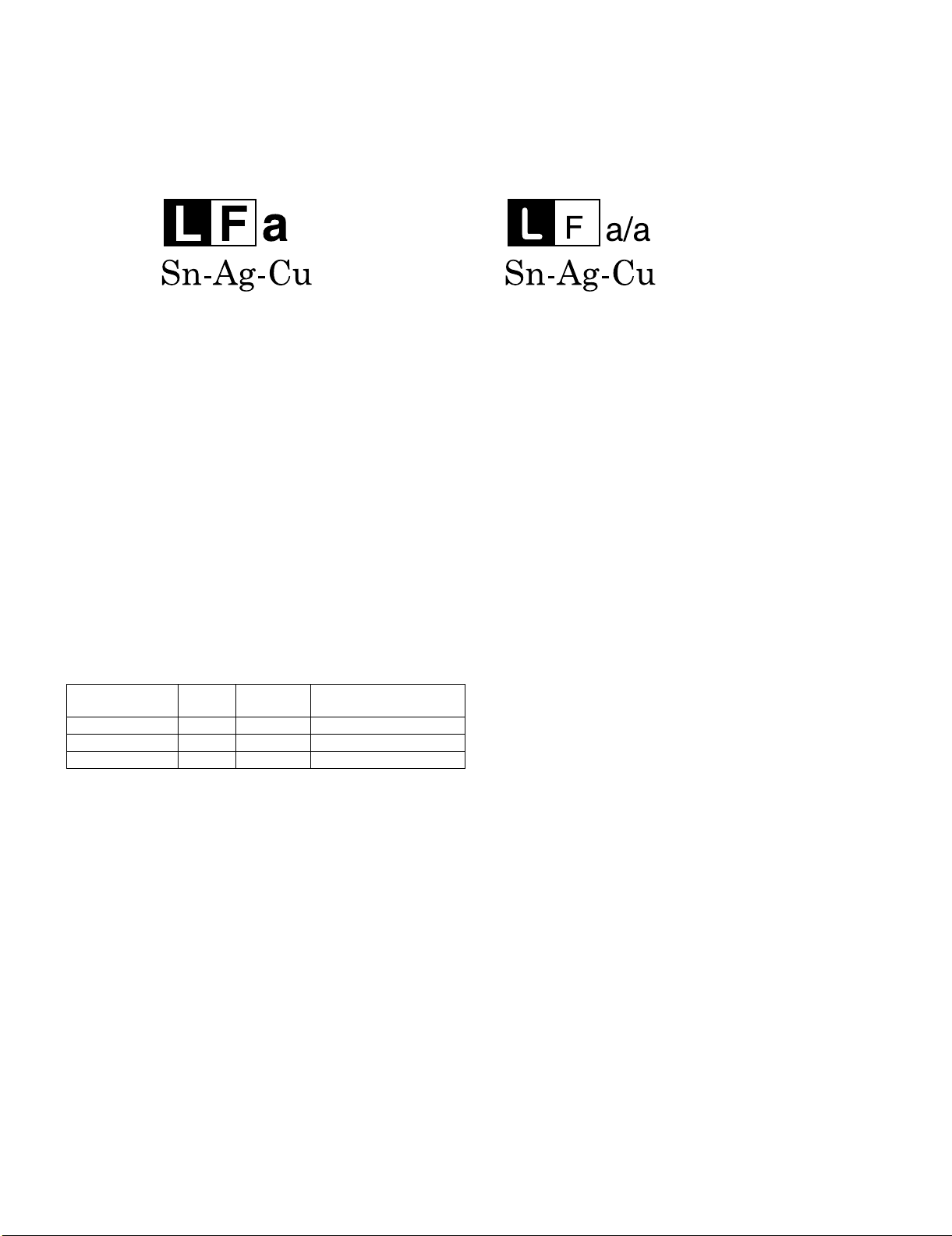

Employing lead-free solder

• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause dam-

age or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Indicates lead-free solder of tin, silver and copper. Indicates lead-free solder of tin, silver and copper.

PARTS CODE

PRICE

RANK

PART

DELIVERY

DESCRIPTION

ZHNDAi123250E BL J φ0.3mm 250g (1roll)

ZHNDAi126500E BK J φ0.6mm 500g (1roll)

ZHNDAi12801KE BM J φ1.0mm 1kg (1roll)

LC-32D62U/LC-37D62U 1st

1 – 1

LC-32D62U/LC-37D62U 1st

Service Manual

CHAPTER 1. SPECIFICATIONS

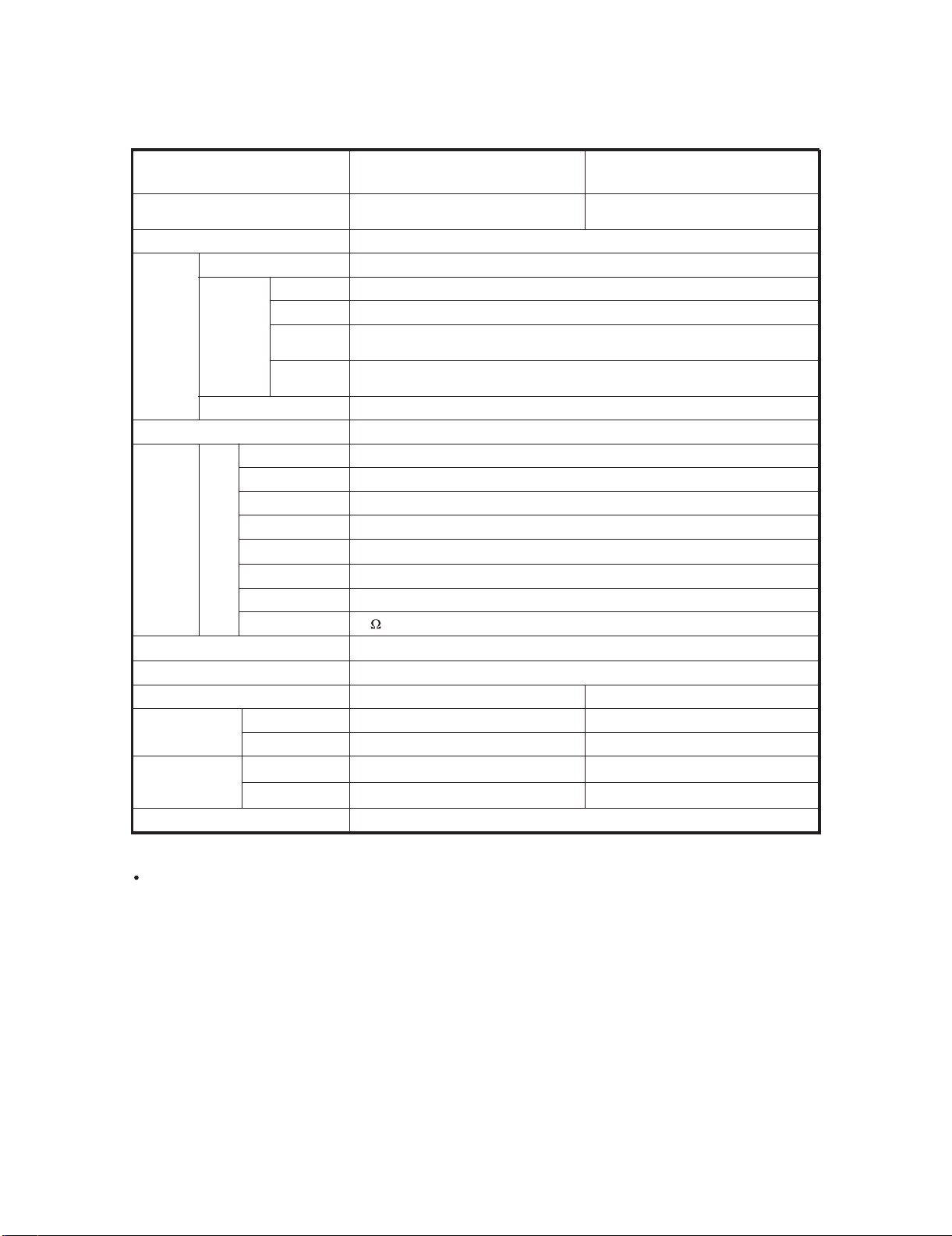

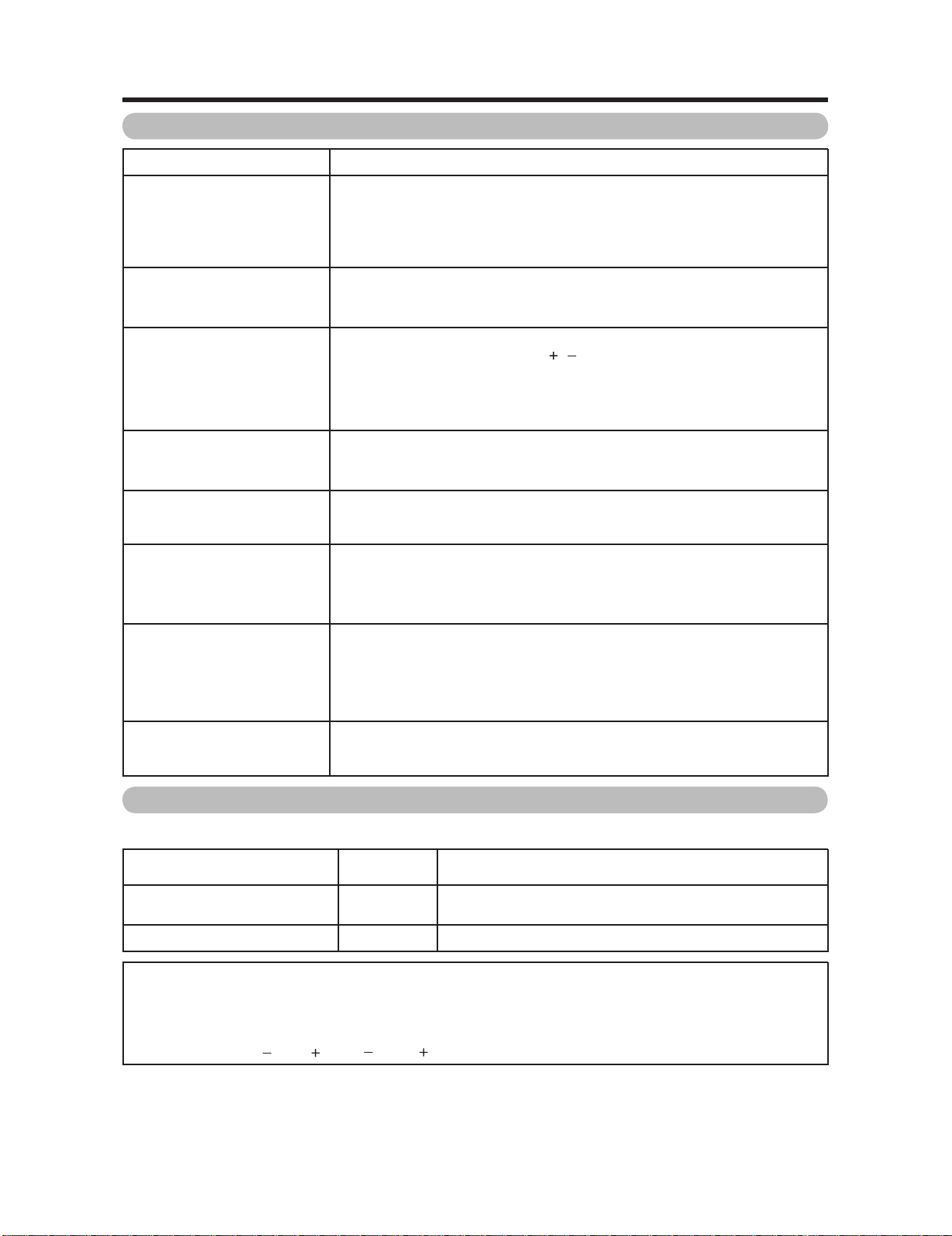

[1] SPECIFICATIONS

*1

Emergency alert messages via Cable are unreceivable.

*2

The dimensional drawings are shown on the inside back cover.

As part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for product

improvement without prior notice. The performance specification figures indicated are nominal values of production units.

There may be some deviations from these values in individual units.

LCD panel

Number of dots

TV

Function

TV-standard (CCIR)

Receiving

Channel

VHF/UHF

CATV

Digital Terrestrial

Broadcast (8VSB)

Audio multiplex

Audio out

Terminals Rear INPUT 1

INPUT 2

INPUT 3

INPUT 4

INPUT 5

DIGITAL AUDIO OUTPUT

OUTPUT

ANTENNA

OSD language

Power Requirement

Power Consumption

Weight

Dimension

*2

(W H D)

Operating temperature

6,220,800 dots (1920 1080 3 dots)

American TV Standard ATSC/NTSC System

VHF 2-13ch, UHF 14-69ch

1-135ch (non-scrambled channel only)

2-69ch

BTSC System

10W 2

AV in, COMPONENT in (Recommend to connect game console)

S-VIDEO in, AV in

Audio in, COMPONENT in

HDMI in with HDCP

Audio in, HDMI in with HDCP

Optical Digital audio output 1 (PCM/Dolby Digital)

Audio out

75 Unbalance, F Type 1 for Analog (VHF/UHF/CATV) and Digital (AIR/CABLE)

English/French/Spanish

AC120V,60Hz

32°F to 104°F (0°C to 40°C)

Item

Model: LC-32D62U

32"

Advanced Super View & BLACK TFT

LCD

TV only

TV + stand

TV + stand

TV only

160 W (0.9 W Standby with AC 120V)

44.1 lbs./20.0 kg

36.4 lbs./16.5 kg

31

25

/

64

23

9

/

32

10

3

/

4

inch

31

25

/

64

20

59

/

64

3

53

/

64

inch

Digital cable

*1

(64/256 QAM)

1-135ch (non-scrambled channel only)

Model: LC-37D62U

37"

Advanced Super View & BLACK TFT

LCD

198 W (0.9 W Standby with AC 120V)

52.9 lbs./24.0 kg

44.1 lbs./20.0 kg

36

3

/

16

25

3

/

4

11

1

/

2

inch

36

3

/

16

23

5

/

8

3

53

/

64

inch

++ +

LC-32D62U/LC-37D62U 1st

2 – 1

LC-32D62U/LC-37D62U 1st

Service Manual

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL

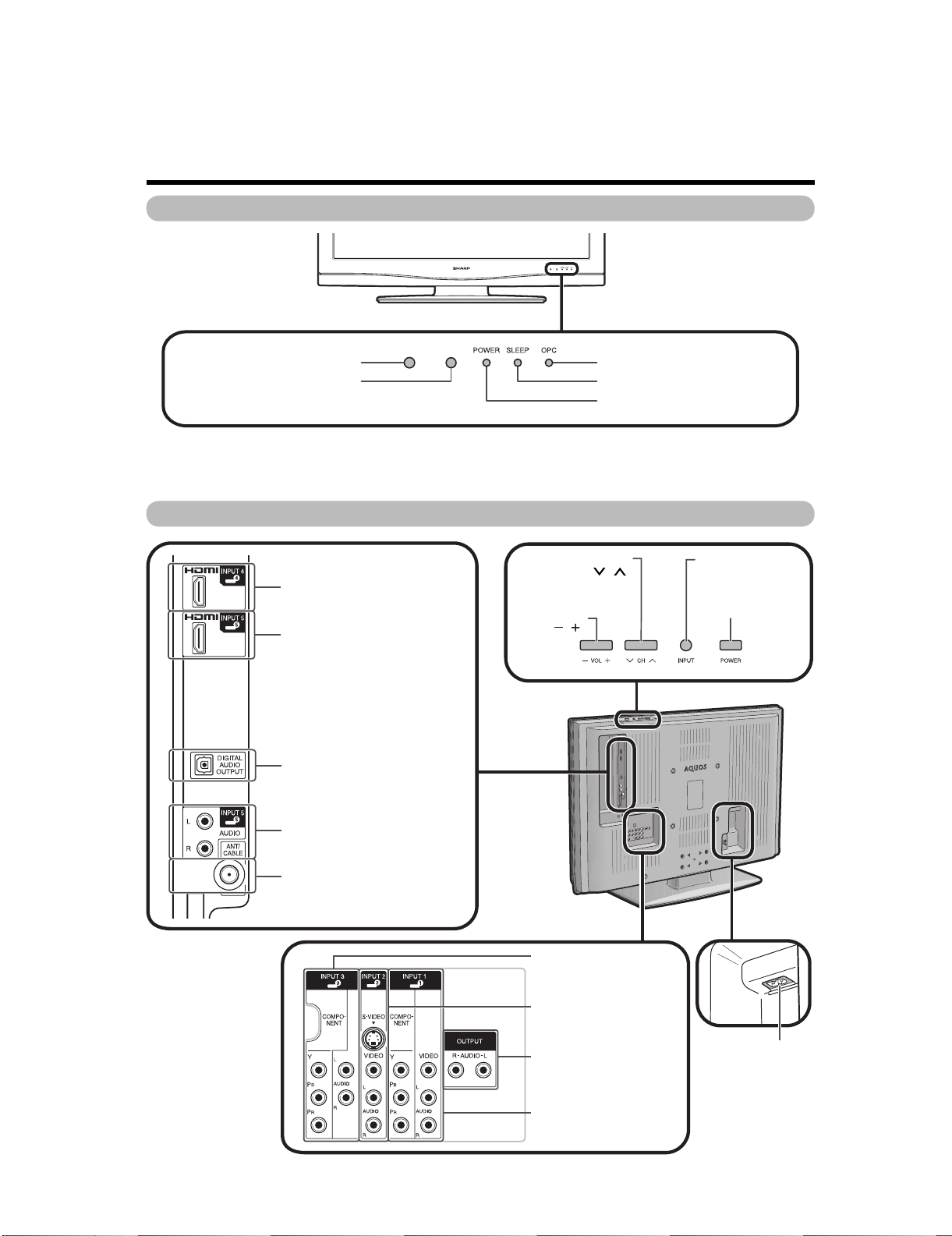

Part names

TV (Front)

OPC indicator*

POWER indicator**

OPC sensor*

Remote control sensor

SLEEP indicator**

TV (Rear)

AUDIO terminals (INPUT 5)

POWER button

Channel buttons

(CH /)

Volume

buttons

(VOL /)

INPUT button

INPUT 3 terminals

AUDIO OUTPUT terminals

HDMI terminal (INPUT 4)

Antenna/Cable in

AC INPUT terminal

INPUT 2 terminals

DIGITAL AUDIO OUTPUT terminal

HDMI terminal (INPUT 5)

INPUT 1 terminals

LC-32D62U/LC-37D62U 1st

2 – 2

3

2

114

5

6

4

8

7

17

15

16

18

19

20

10

9

21

11 23

24

25

12

13 27

22

26

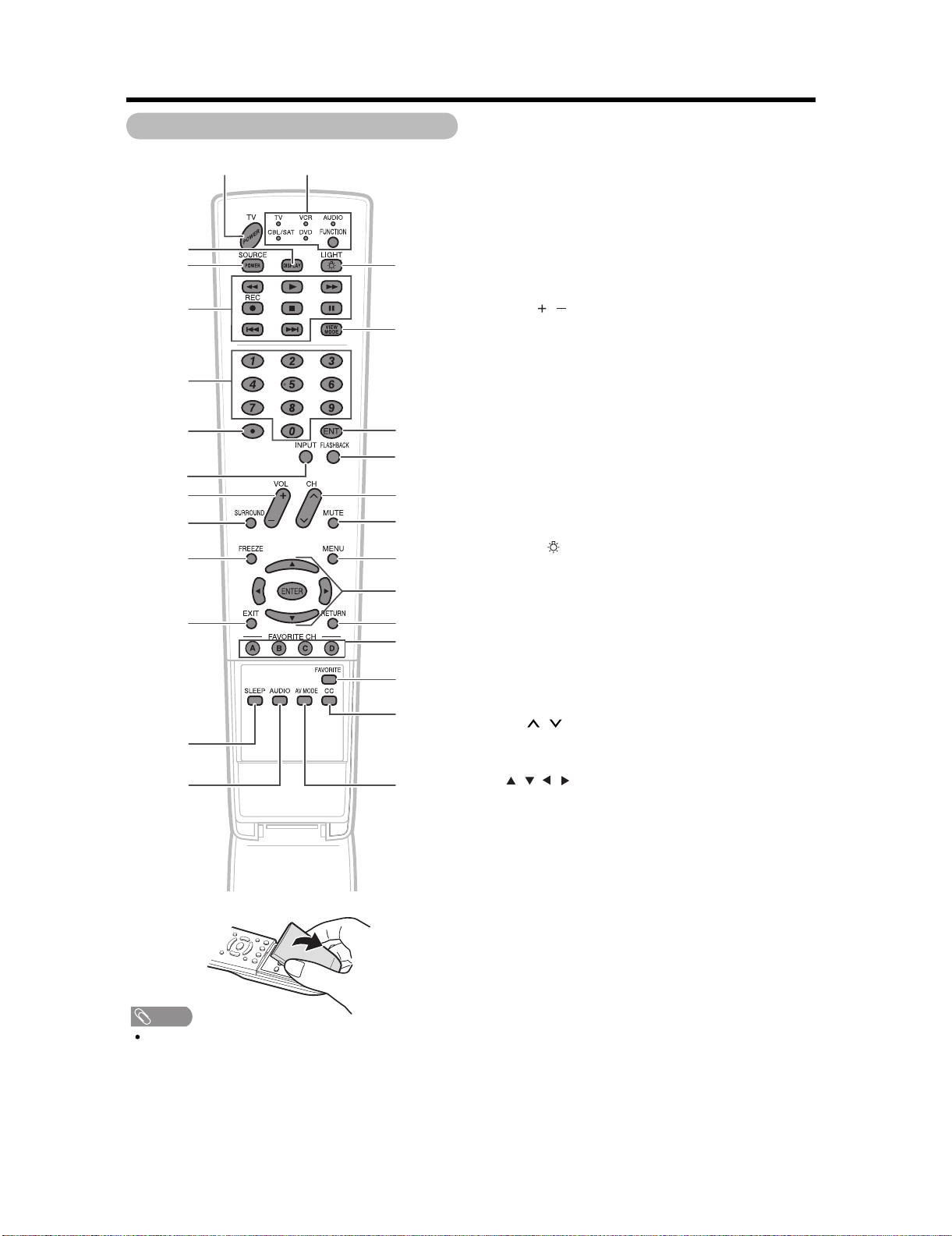

Part names

1 TV POWER: Switch the TV power on or enters

standby.

2DISPLAY:Display the channel information.

3 SOURCE POWER: Turns the power of the external

equipment on and off.

4 External equipment operational buttons: Operate

the external equipment.

50

_

9: Set the channel.

6 (DOT):

7INPUT:Select a TV input source. (TV, INPUT 1,

INPUT2,INPUT3,INPUT4,INPUT5)

8 VOL / : Set the volume.

9 SURROUND: Select Surround settings.

10 FREEZE: Set the still image. Press again to return to

normal screen.

11 EXIT: Turn off the menu screen.

12 SLEEP: Set the sleep timer.

13 AUDIO: Selects the MTS/SAP or the audio mode

during multi-channel audio broadcasts.

14 FUNCTION: Switches the remote control for TV,

CBL/SAT, VCR, DVD and AUDIO operation. Indicator

lights up for the current mode.

* To enter the code registration mode, you need to

press FUNCTION and DISPLAY at the same time.

15 LIGHT : When pressed all buttons on the remote

control unit will light. The lighting will turn off if no

operations are performed within about 5 seconds.

This button is used for performing operations in low-

light situations.

16 VIEW MODE: Select the screen size.

17 ENT: Jumps to a channel after selecting with the 0

_

9

buttons.

18 FLASHBACK: Return to the previous channel or

external input mode.

19 CH / : Select the channel.

20 MUTE: Mute the sound.

21 MENU: Display the menu screen.

22 ////ENTER: Select a desired item on the

screen.

23 RETURN: Return to the previous menu screen.

24 FAVORITE CH

A, B, C, D: Select 4 preset favorite channels in 4

different categories.

While watching, you can toggle the selected channels

by pressing A, B, C and D.

25 FAVORITE: Set the favorite channels.

26 CC: Display captions from a closed-caption source.

27 AV MODE: Select an audio or video setting.

(When the input source is TV, INPUT 1, 2 or 3:

STANDARD, MOVIE, GAME, USER, DYNAMIC (Fixed),

DYNAMIC. When the input source is INPUT 4 or 5:

STANDARD, MOVIE, GAME, PC, USER, DYNAMIC

(Fixed), DYNAMIC.)

Remote control unit

•

NOTE

When using the remote control unit, point it at the TV.

LC-32D62U/LC-37D62U 1st

2 – 3

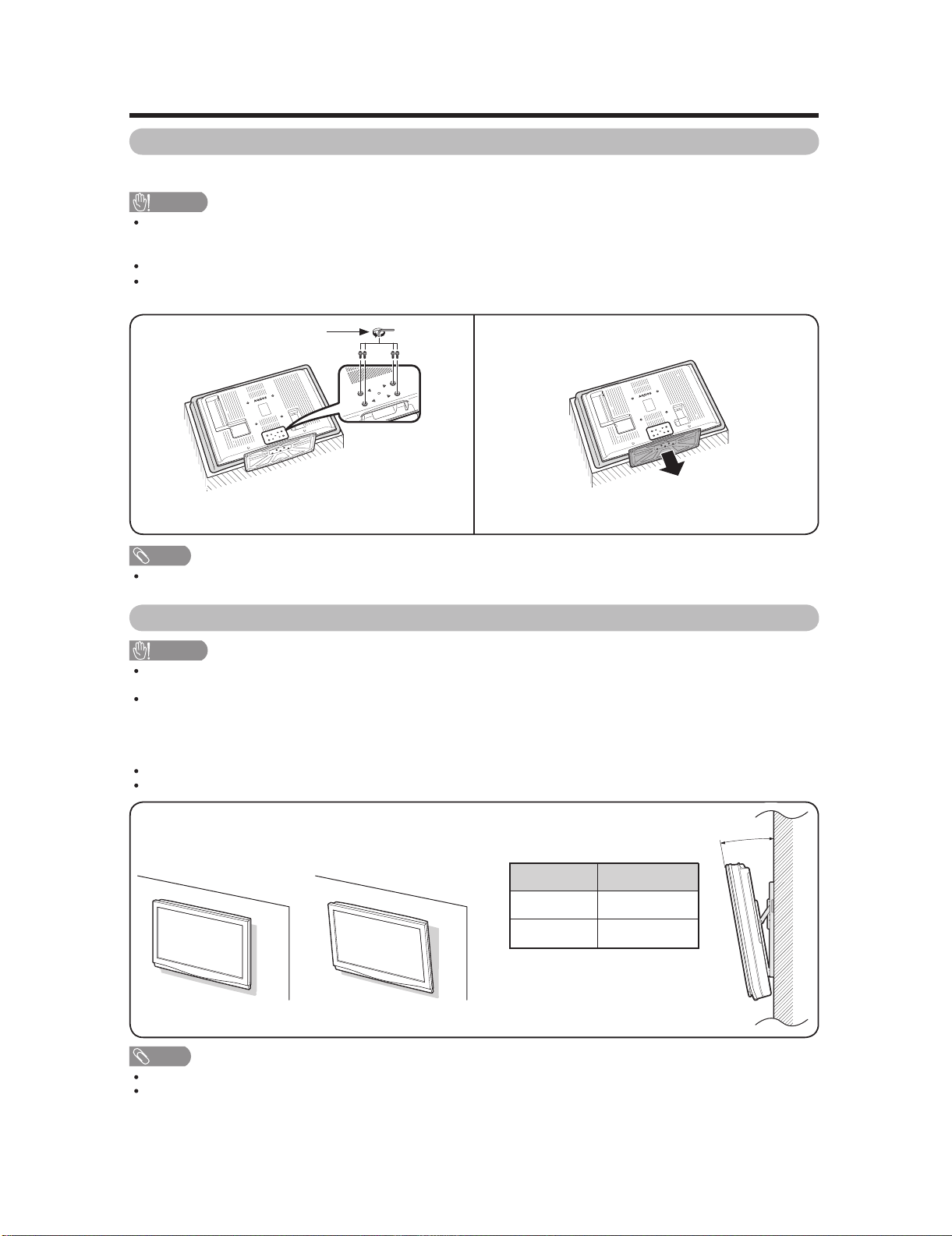

Removing the stand

Before detaching (or attaching) stand, unplug the AC cord from the AC INPUT terminal.

CAUTION

Do not remove the stand from the TV unless using an optional wall mount bracket to mount it.

Before attaching/detaching stand

Before performing work make sure to turn off the TV.

Before performing work spread cushioning over the base area to lay the TV on. This will prevent it from being

damaged.

Setting the TV on the wall

CAUTION

This TV should be mounted on the wall only with the AN-37AG2 (SHARP) wall mount bracket. The use of other wall

mount brackets may result in an unstable installation and may cause serious injuries.

Installing the TV requires special skill that should only be performed by qualified service personnel. Customers

should not attempt to do the work themselves. SHARP bears no responsibility for improper mounting or mounting

that results in accident or injury.

Using an optional bracket to mount the TV

You can ask a qualified service professional about using an optional AN-37AG2 bracket to mount the TV to the wall.

Carefully read the instructions that come with the bracket before beginning work.

Hanging on the wall

AN-37AG2 wall mount bracket.

Vertical mounting

Unfasten the four screws used to secure the stand in

place.

Detach the stand from the TV. (Hold the stand so it

will not drop from the edge of the base area.)

Appendix

NOTE

To attach the stand, perform the above steps in reverse order.

Angular mounting

1 2

Hex key

NOTE

Detach the cable clamps on the rear of the TV when using the optional mount bracket.

Due to the terminal configuration on this TV, when you wall-mount this model, make sure there is enough space between the

wall and the TV for the cables.

About setting the TV angle

Angle of TV

0/5/10°

0/5/10°

Model

LC-32D62U

LC-37D62U

LC-32D62U/LC-37D62U 1st

2 – 4

Troubleshooting

Possible Solution

Is the volume too low?

Is "Variable" selected in "Output Select"?

Have you pressed MUTE on the remote control unit?

Cautions regarding use in high and low temperature environments

Appendix

Problem

No power

Unit cannot be operated.

Remote control unit does not

operate.

Picture is cut off/with sidebar

screen.

Strange color, light color, or color

misalignment

Power is suddenly turned off.

No picture

No sound

Check if you pressed TV POWER on the remote control unit. If the

indicator on the TV does not light up, press POWER on the TV.

Is the AC cord disconnected?

Has the power been turned on?

External influences such as lightning, static electricity, may cause improper operation.

In this case, operate the unit after first turning on the power of the TV or unplugging

the AC cord and replugging it in after 1 or 2 minutes.

Is the FUNCTION set correctly? Set it to the TV setting position.

Are batteries inserted with polarity ( , ) aligned?

Are batteries worn out? (Replace with new batteries.)

Are you using it under strong or -fluorescent lighting?

Isa-fluorescent light illuminated near the remote control sensor?

Is the image position correct?

Are screen mode adjustments such as picture size made correctly?

Adjust the picture tone.

Is the room too bright? The picture may look dark in a room that is too bright.

Check the input signal setting.

Is the sleep timer set?

Check the power control settings.

The unit's internal temperature has increased. Remove any objects blocking vent or

clean.

Is connection to other components correct?

Is correct input signal source selected after connection?

Is the correct input selected?

Is picture adjustment correct?

Is "On" selected in "Audio Only"?

Is a non-compatible signal being input?

When the unit is used in a low temperature space (e.g. room, office), the picture may leave trails or appear slightly delayed.

This is not a malfunction, and the unit will recover when the temperature returns to normal.

Do not leave the unit in a hot or cold location. Also, do not leave the unit in a location exposed to direct sunlight or near a

heater, as this may cause the cabinet to deform and the Liquid Crystal panel to malfunction.

Storage temperature: 4°F to 140°F ( 20°C to 60°C)

Troubleshooting-Digital broadcasting

The error message about reception of broadcast

Failed to receive broadcast.

E203 Check the broadcast time in the program guide.

The example of an error message

displayed on a screen

No broadcast now.

Error code

E202

Possible Solution

Check the antenna cable. Check that the antenna is correctly

setup.

••

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

LC-32D62U/LC-37D62U 1st

2 – 5

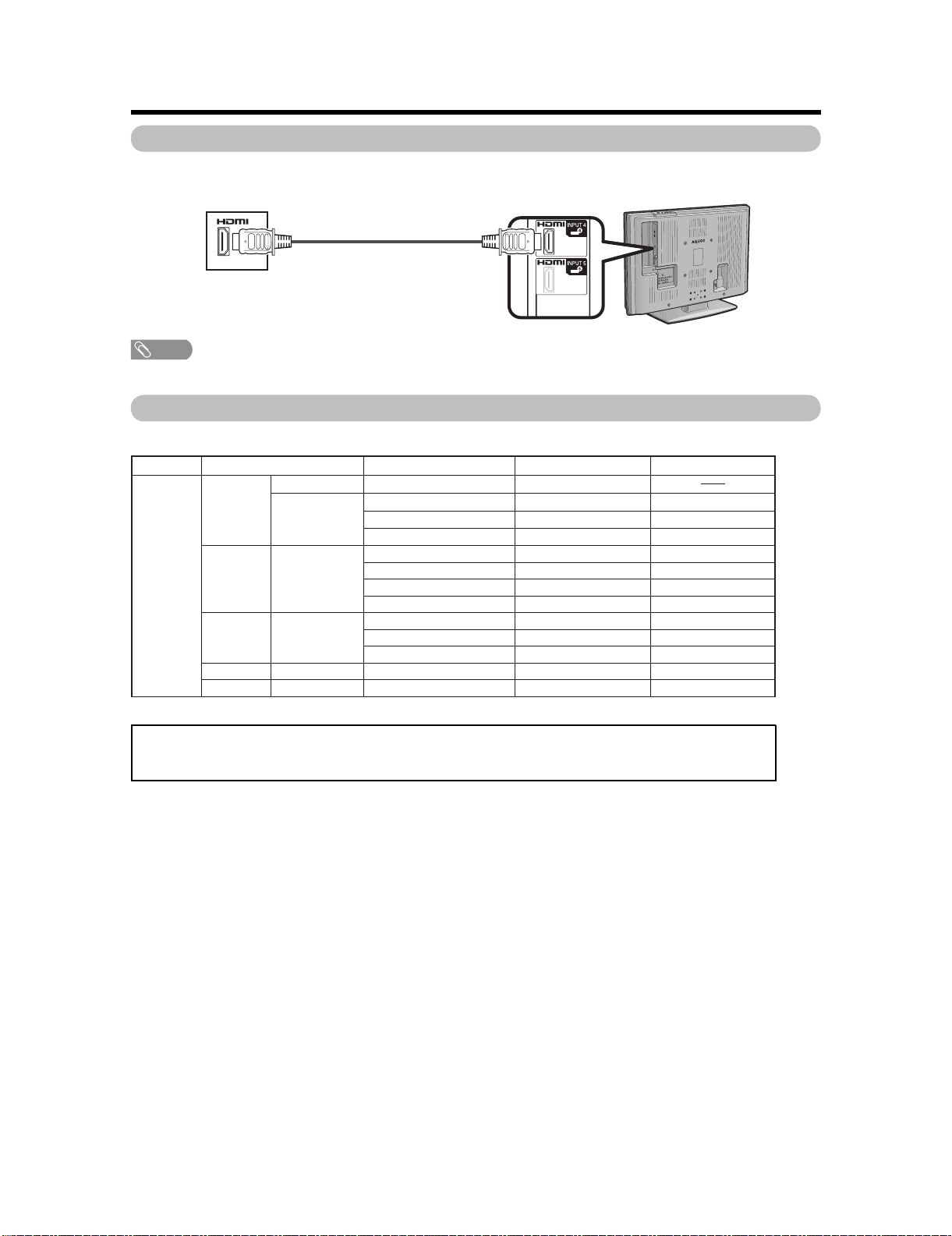

Preparation

Connecting a PC

When connecting to a PC with an HDMI terminal. (INPUT 4 or 5)

HDMI cable

(commercially available)

PC

Example

NOTE

The HDMI terminals only support digital signal.

PC compatibility chart

It is necessary to set the PC correctly to display XGA and WXGA signal.

PC

31.5 kHz

31.5 kHz

37.9 kHz

37.5 kHz

35.1 kHz

37.9 kHz

48.1 kHz

46.9 kHz

48.4 kHz

56.5 kHz

60.0 kHz

47.7 kHz

640 x 480

720 x 400

VGA

800 x 600SVGA

XGA 1024 x 768

WXGA 1360 x 768

SXGA

1280 x 1024

70 Hz

60 Hz

72 Hz

75 Hz

56 Hz

60 Hz

72 Hz

75 Hz

60 Hz

70 Hz

75 Hz

60 Hz

O

O

O

O

O

O

O

O

O

O

O

64.0 kHz 60 Hz

O

PC Resolution Horizontal Frequency Vertical Frequency VESA Standard

DDC is a registered trademark of Video Electronics Standards Association.

Power Management is a registered trademark of Sun Microsystems, Inc.

VGA and XGA are registered trademarks of International Business Machines Co., Inc.

•

LC-32D62U/LC-37D62U 1st

2 – 6

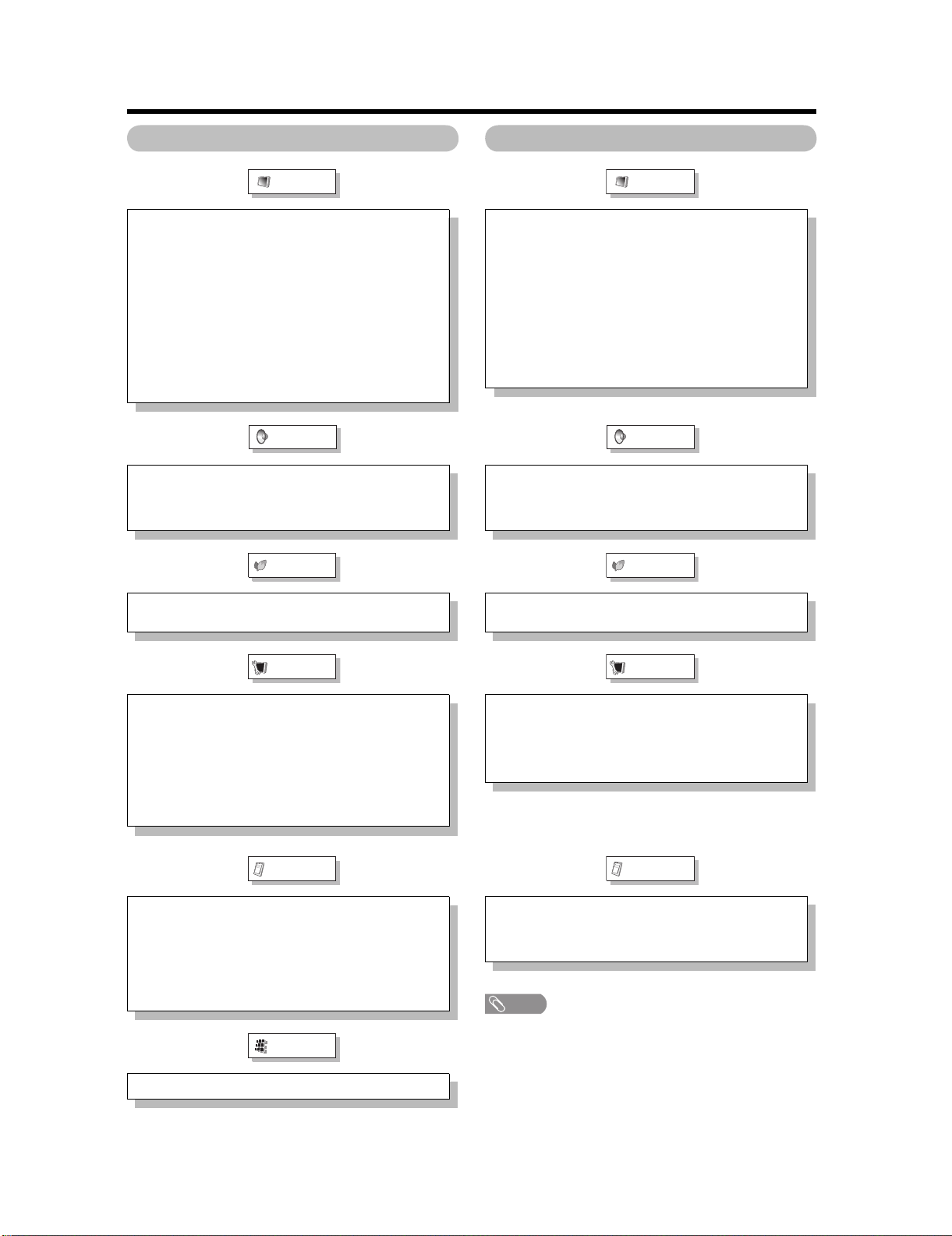

Picture

Setup

Audio

Option

Power Control

Digital Setup

Picture

Setup

Audio

Option

Power Control

Basic adjustment settings

Menu items for TV/INPUT 1/2/3 Menu items for HDMI

Treble

Bass

Balance

Surround

Reset

NOTE

Some menu items may not be displayed depending on the

selected input source.

OPC

Backlight

Contrast

Brightness

Color

Tint

Sharpness

Advanced

Color Temp.

Black

3D-Y/C

Monochrome

Film Mode

Range of OPC

Reset

Treble

Bass

Balance

Surround

Reset

OPC

Backlight

Contrast

Brightness

Color

Tint

Sharpness

Advanced

Color Temp.

Black

Monochrome

Film Mode

Range of OPC

Reset

No Signal Off

No Operation Off

No Signal Off

No Operation Off

EZ Setup

CH Setup

Antenna Setup-DIGITAL

Input Skip

Input Label

Parental CTRL

Position

Language

Reset

Input Skip

Input Signal

Input Label

Position

Language

Reset

Audio Only

Digital Noise Reduction

HDMI Setup

Output Select

Audio Only

Digital Noise Reduction

Input Select

Output Select

Color System

Caption Setup

Program Title Display

Favorite CH

Audio Setup

•

LC-32D62U/LC-37D62U 1st

3 – 1

LC-32D62U/LC-37D62U 1st

Service Manual

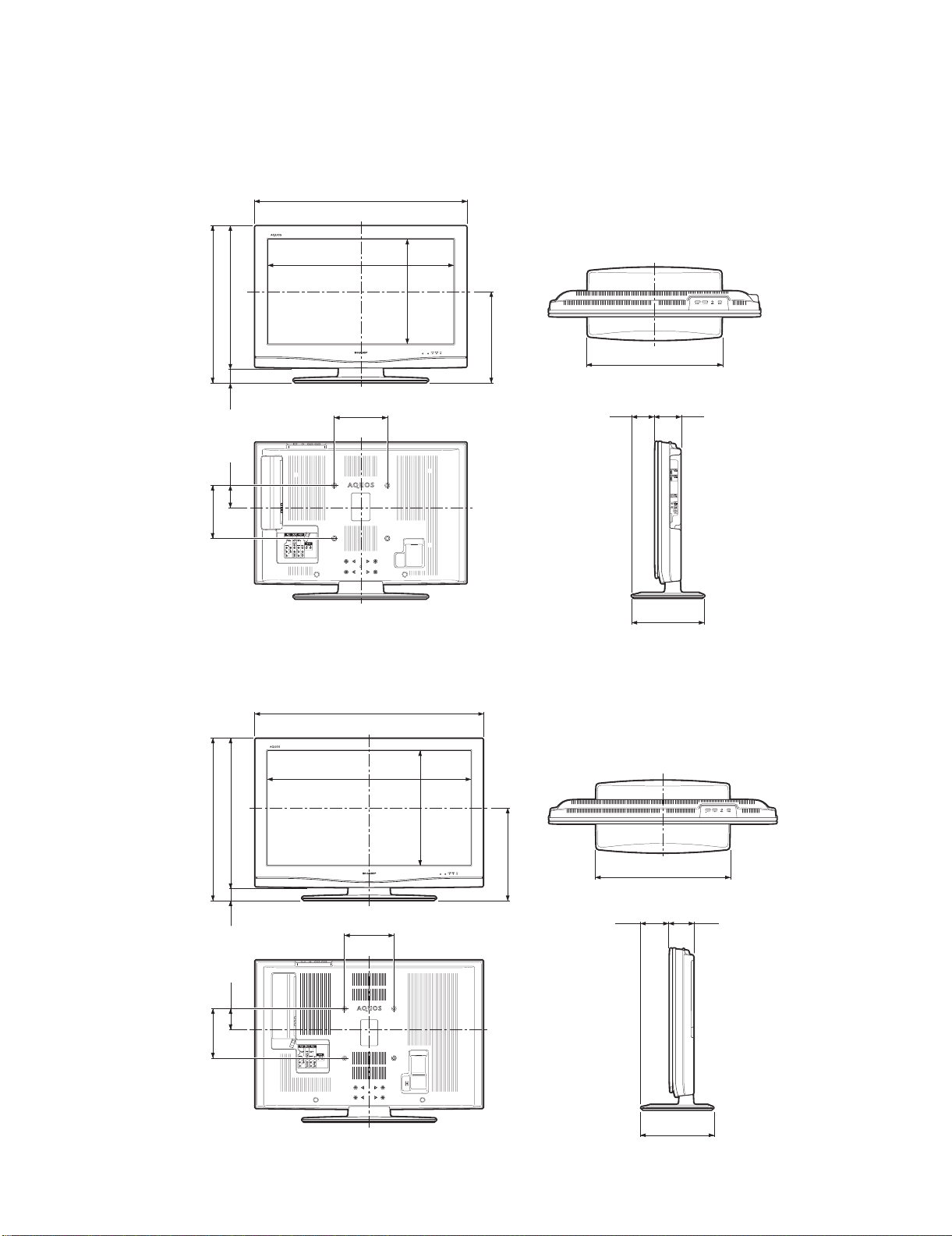

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS

LC-32D62U

LC-37D62U

Unit: Inch/(mm)

15

19

/

32

(396.1)

20

59

/

64

(531)

23

9

/

32

(591)

27

5

/

8

(701.4)

31

25

/

64

(

797)

10

3

/

4

(273)

3

15

/

32

(88)

3

53

/

64

(97)

19

31

/

32

(507)

7

7

/

8

(200)

7

7

/

8

(200)

3

23

/

64

(85)

13

35

/

64

(344)

2

3

/

8

(60)

32

25

/

64

(822.6)

36

3

/

16

(919)

3

53

/

64

(97)

4

37

/

64

(116)

11

1

/

2

(292)

21

17

/

64

(540)

18

17

/

64

(463.8)

2

9

/

64

(54)

23

5

/

8

(600)

25

3

/

4

(654)

14

47

/

64

(374)

7

7

/

8

(200)

7

7

/

8

(200)

3

23

/

64

(85)

LC-32D62U/LC-37D62U 1st

4 – 1

LC-32D62U/LC-37D62U 1st

Service Manual

CHAPTER 4. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS

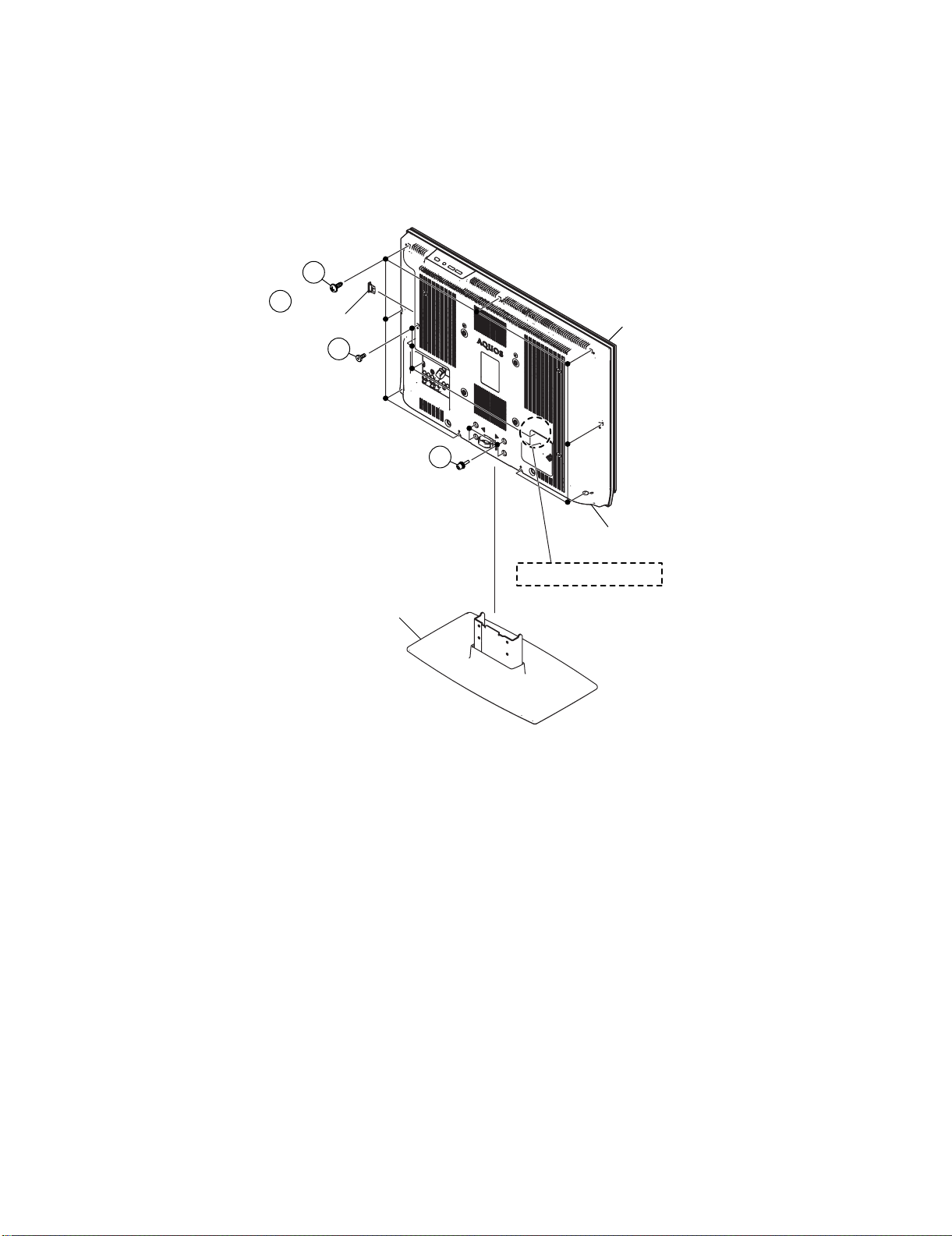

1. Remove the SD Card Cover.

2. Remove the 4 lock screws and detach the Stand Base Ass'y.

3. Remove the 9 lock screws, 3 lock screws and detach the Rear Cabinet. (LC-32D62U)

Remove the 9 lock screws, 4 lock screws and detach the Rear Cabinet. (LC-37D62U)

Front Cabinet

Rear Cabinet

SD Card Cover

Stand Base Ass'y

1

2

3

3

LC-37D62U Only

LC-32D62U/LC-37D62U 1st

4 – 2

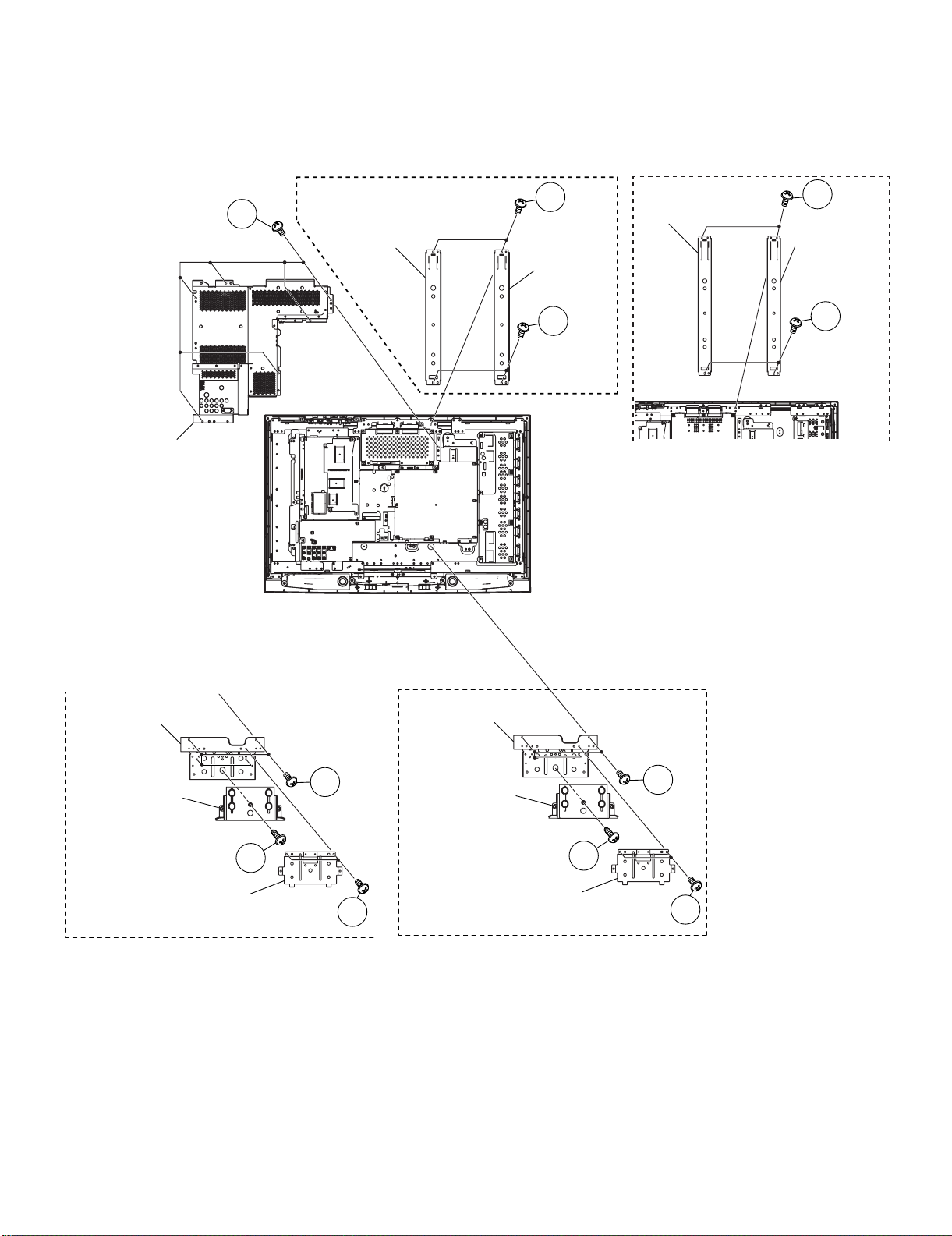

4. Remove the 2 lock screws and detach the Stand Assist Angle.

5. Remove the 4 lock screws and detach the Center Angle-L and R.

6. Remove the 1 lock screw and detach the Stand Area Cover.

7. Remove the 4 lock screws and detach the Stand Fix Angle.

8. Remove the 6 lock screws and detach the MAIN Shield.

LC-37D62U

Stand Fix Angle

Stand Area Cover

Stand Assist Angle

6

7

4

8

Center Angle-R

Center Angle-L

MAIN Shield

LC-32D62U

LC-32D62U

5

5

Stand Fix Angle

Stand Area Cover

Stand Assist Angle

6

7

4

Center Angle-R

Center Angle-L

LC-37D62U

5

5

LC-32D62U/LC-37D62U 1st

4 – 3

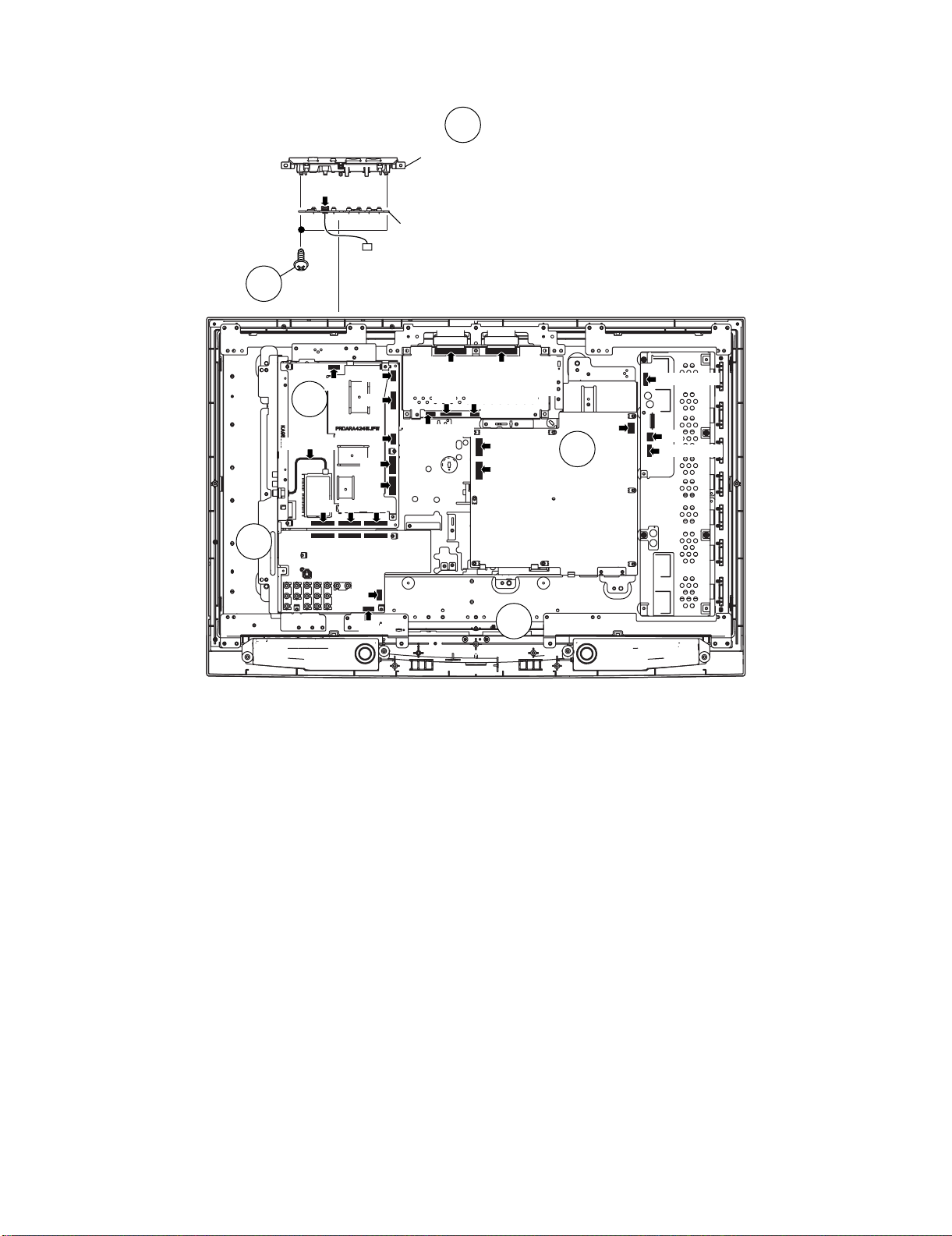

9. Disconnect all the connectors from all the PWBs.

10.Remove the Top Cover Ass'y. Remove the 2 lock screws from the Top Cover Ass'y and detach the KEY Unit.

10

9

9

9

9

10

KEY Unit

Top Cover

[PH]

[LA]

[CN2] (37D62U)

[LA]

[LB] (32D62U)

[LP]

[LB]

[LV]

[SP]

[RA]

[KM]

[KM]

[SA][FC][MA]

[PD]

[PH]

[PD]

[LB] (37D62U)

[CN5] (32D62U)

[CN4] (37D62U)

[CN4] (32D62U)

[CN3] (37D62U)

[CN1]

[CN2] (32D62U)

[F-RCA wire]

LC-32D62U/LC-37D62U 1st

4 – 4

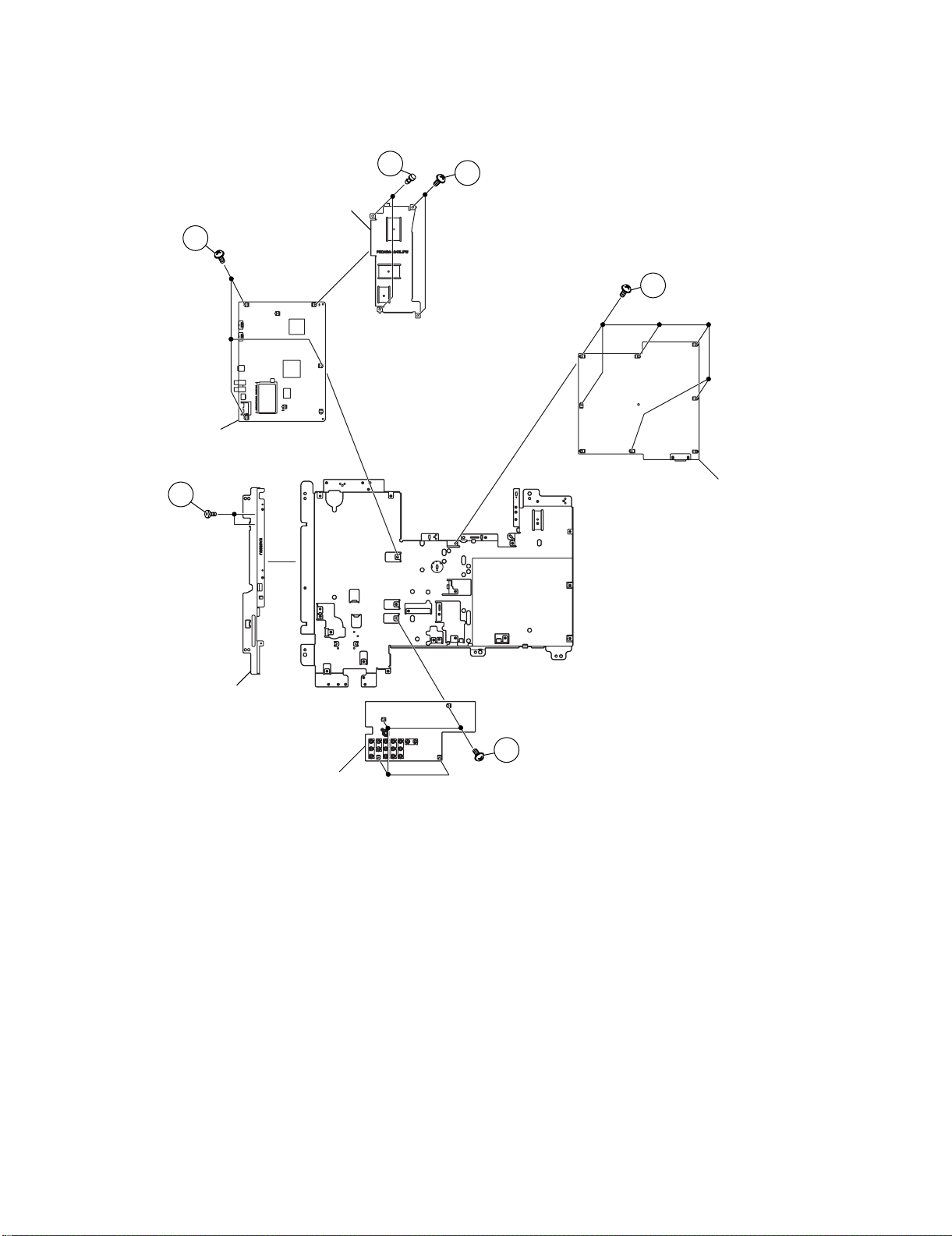

11.Remove the 4 lock screws and detach the Speaker-L and R.

12.Remove the 2 lock screws and detach the R/C, LED Unit.

13.Remove the 5 lock screws and detach the Tray Chassis.

12

11

13

11

Tray Chassis

Speaker-L

Speaker-R

R/C, LED Unit

LC-32D62U/LC-37D62U 1st

4 – 5

14.Remove the 2 lock screws and detach the Jack Angle.

15.Remove the 6 lock screws and detach the POWER Unit.

16.Remove the 4 lock screws and detach the TERMINAL Unit.

17.Remove the 5 lock screws, 2 lock rivets and detach the MAIN PWB Radiator and MAIN Unit.

MAIN Unit

POWER Unit

TERMINAL Unit

MAIN PWB Radiator

Jack Angle

15

17

17

17

16

14

LC-32D62U/LC-37D62U 1st

4 – 6

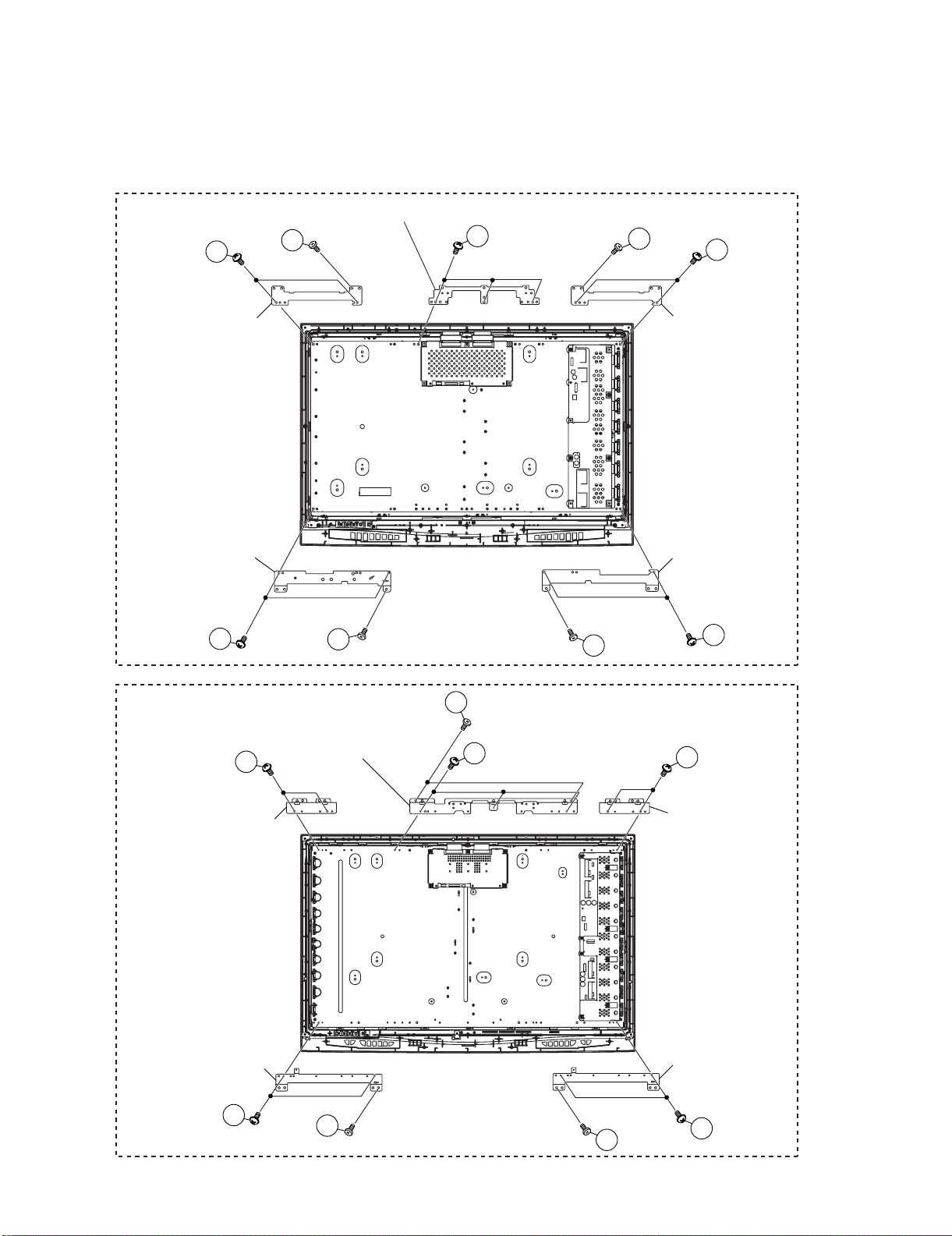

18.Remove the 6 lock screws and detach the Rug Angle Top-L and R. (LC-32D62U)

Remove the 4 lock screws and detach the Rug Angle Top-L and R. (LC-37D62U)

19.Remove the 6 lock screws and detach the Rug Angle Bottom-L and R.

20.Remove the 3 lock screws and detach the Chassis Fix Angle Top. (LC-32D62U)

Remove the 5 lock screws and detach the Chassis Fix Angle Top. (LC-37D62U)

21.Remove the LCD Panel Module.

18

19

19

19

18

20

19

18

18

Rug Angle Top-R

Chassis Fix Angle Top

Rug Angle Bottom-R

Rug Angle Bottom-L

Rug Angle Top-L

LC-32D62U

LC-37D62U

18

18

19

19

19

19

20

Rug Angle Top-R

Chassis Fix Angle Top

Rug Angle Bottom-R

Rug Angle Bottom-L

Rug Angle Top-L

20

LC-32D62U/LC-37D62U 1st

5 – 1

LC-32D62U/LC-37D62U 1st

Service Manual

CHAPTER 5. ADJUSTMENT

[1] ADJUSTMENT PROCEDURE

The adjustment values are set to the optimum conditions at the factory before shipping. If a value should become improper or an adjustment is

required due to part replacement, make an adjustment according to the following procedure.

1. After replacement of any PWB unit and/or IC for repair, please note the following.

When replacing the following units, make sure to prepare the new units loaded with updated software.

MAIN Unit: DUNTKE028WE06

2. Upgrading of each microprocessor software

CAUTION: Never “POWER OFF” the unit when software upgrade is ongoing.

Otherwise the system may be damaged beyond recovery.

2.1. Software version upgrade

The model employs the following software.

•Main software

• Monitor microprocessor software

The main software and the monitor microprocessor software can be upgraded by using a general-purpose SD memory card.

The followings are the procedures for upgrading, explained separately for each of the main software, the monitor microprocessor software.

2.2. Main software version upgrade

2.2.1 Get ready before you start

• SD memory card of 32MB or higher capacity

• PC running on Windows 98/98SE/ME/2000/XP operating system

• SD memory card reader/writer with USB connectivity

• SD memory card formatting software

(Downloadable at http://panasonic.jp/support/audio/sd/download/sd_formatter_e.html)

2.2.2 Preparations

To upgrade the main software, it is necessary to get ready the SD card for version upgrade before you start. Follow the steps below and create the SD

card for version upgrade.

1. Insert the SD card into the SD card reader/writer. Start the SD card formatting software. Click [Format]. (When you have the drive options, select

the drive where the SD card is inserted before you proceed.)

LC-32D62U/LC-37D62U 1st

5 – 2

2. When the formatting is over, the following window appears. Click [OK].

3. Click [Exit] to finish the formatting.

NOTE: When you are done, take out the SD card once to make sure it is finished, and then insert it again.

4. Copy the binary image file D62UAxxx.SDC (named temporarily) for version upgrade to the root directory (folder) of the SD card drive.

NOTE: In the SD card drive, do not store other folders or unrelated files, or more than one binary image files for version upgrade.

Now the SD card for version upgrade is ready.

2.2.3 Upgrading the software

1. Turn off the AC power (Unplug the AC power cord).

2. Insert the upgrading SD card (prepared as instructed above) into the service slot.

NOTE: Be careful not to insert the SD card in the wrong way. Otherwise the card may come into the set and fail to come out.

3. Turn on the AC power (Plug in the AC power cord).

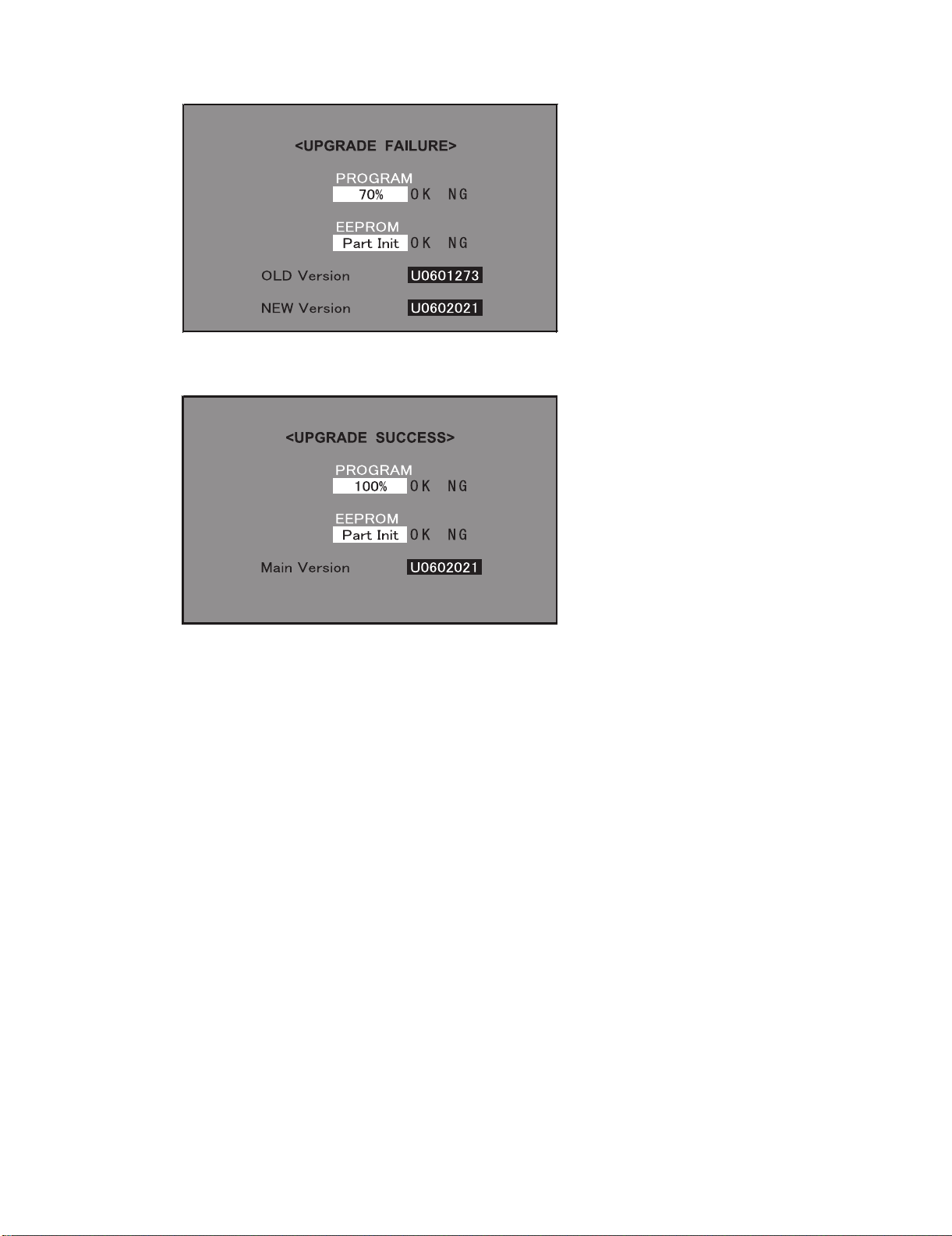

4. A couple to dozen seconds after the set starts, the upgrade screen below shows up.

LC-32D62U/LC-37D62U 1st

5 – 3

5. If any of the procedures fails, the following upgrade failure screen shows up. For the failing procedure, the “NG” marking turns red.

NOTE: In such case, try to upgrade the software again. If it still fails, the hardware may be in trouble.

6. When all the procedures are complete, the following upgrade success screen shows up. The new software version can be confirmed on screen.

The version number appears when each item has been successfully upgraded. Finally the main version number appears on screen.

7. Turn off the AC power (Unplug the AC power cord). Take out the upgrading SD card.

8. Now the software has been upgraded.

NOTE: Then get the set started and call the process adjustment screen 1/28 to check the main software version.

CAUTION: 1) Do not take out and put in the SD memory card during formatting.

2) With the SD formatted, all the data stored on the medium will be deleted.

3) Do not start the SD formatting with the memory card's WRITE PROTECT switch still on.

4) If the SD memory card format software does not recognize the SD memory card, take out and put in the SD memory card again, and

click the “UPDATE” button.

5) After checking the performance, use the set under its interface environment.

6) The SD formatting is impossible on drives that are not recognized “REMOVABLE”.

2.3. Upgrading the monitor microprocessor software

2.3.1 Kit

Have the above “Upgrading the main software” kit or equivalent at hand.

2.3.2 Preparations

As discussed in “Upgrading the main software” earlier, create the SD card for upgrading the monitor microprocessor software. For this SD card, use

the monitor microprocessor upgrading binary image file.

2.3.3 Upgrading procedure

To follow the monitor microprocessor software upgrading, the monitor screen upgrade progress indicator and the flashing power LED indicator can be

used.

1. Turn off the AC power (Unplug the AC power cord).

2. Insert the upgrading SD card (prepared as instructed above) into the service slot at the back of the set. Insert the SD card with its logo-printed face

upward (visible). Be careful not to insert the SD card in the wrong way. Otherwise the card may come into the set and fail to come out.

3. Turn on the AC power (Plug in the AC power cord).

CAUTION: Now the monitor microprocessor software starts getting upgraded. Be very careful not to turn off the power while the software is being

upgraded. Otherwise the software will fail to upgrade itself and the set will fail to get started.

LC-32D62U/LC-37D62U 1st

5 – 4

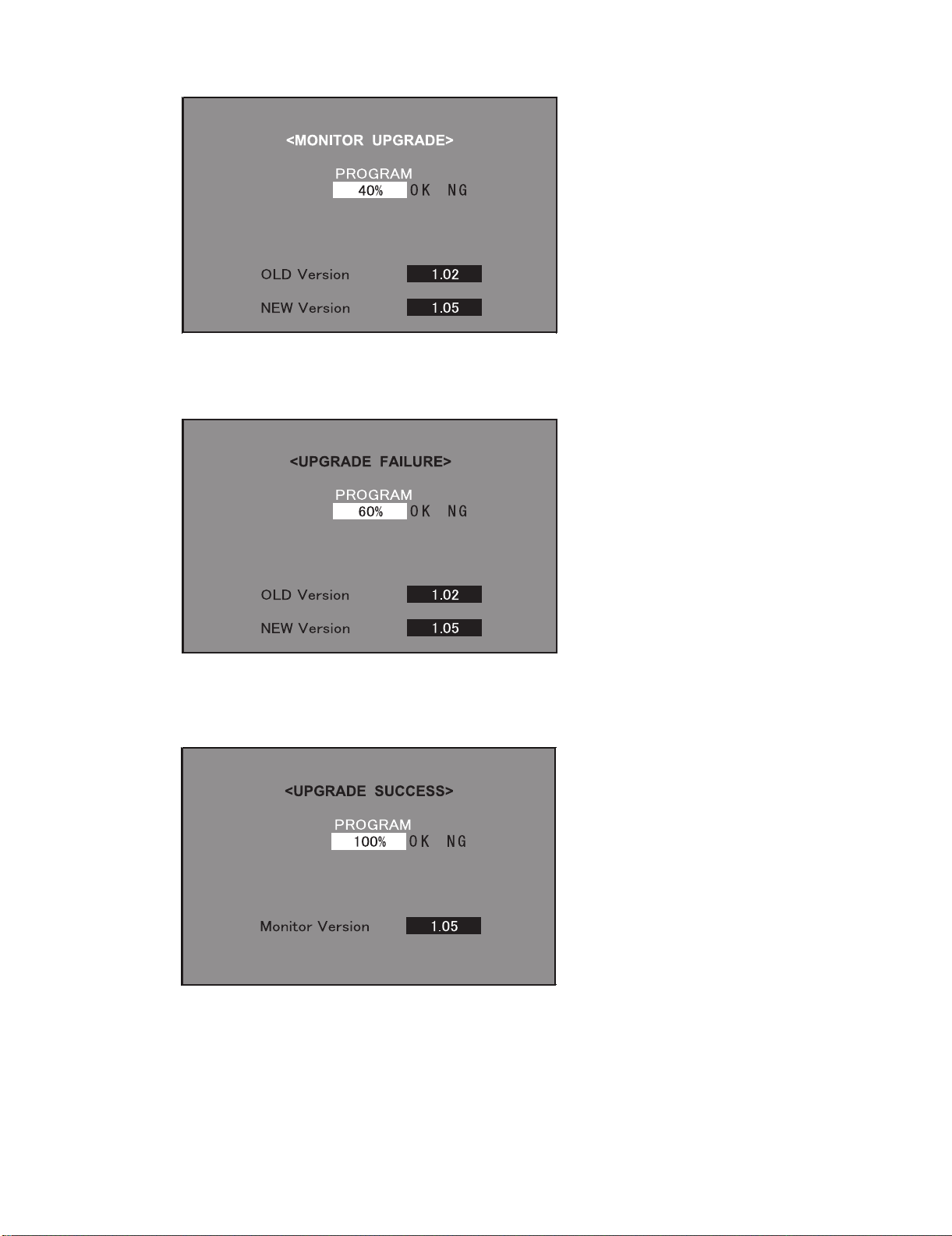

4. A couple to dozen seconds after the set starts, the upgrade screen below shows up. The upgrade progress is indicated on screen. The power LED

indicator goes out once and then starts flashing in green. (It takes 2-3 minutes to get the monitor microprocessor software upgraded.)

5. If the procedure fails, the following upgrade failure screen shows up and the “NG” marking turns red. The power LED indicator fails to start flashing

in green. Even if the usual screen reappears in several seconds, do the procedure from Step “1” again.

NOTE: In case of failure, try to upgrade the software again. If it still fails, the hardware may be in trouble.

6. When the procedure is complete, the following upgrade success screen shows up. The new software version can be confirmed on screen. The

upgrade success can also be confirmed when the power LED indicator and the OPC LED indicator start flashing alternately in green, respectively.

Double-check the upgrading and turn off the AC power (Unplug the AC power cord). Take out the upgrading SD card. Now the software has been

upgraded.

Finally get the set started and call the process adjustment screen 1/28 to check the monitor microprocessor software version.

LC-32D62U/LC-37D62U 1st

5 – 5

3. Entering and exiting the adjustment process mode

1) Before entering the adjustment process mode, the AV position RESET in the video adjustment menu.

2) While holding down the “VOL (–)” and “INPUT” keys at a time, plug in the AC cord of the main unit to turn on the power.

The letter “<K>” appears on the screen.

3) Next, hold down the “VOL (–)” and “CH ( )” keys at a time.

(The “VOL (–)” and “CH ( )” keys should be pressed and held until the display appears.)

Multiple lines of blue characters appearing on the display indicate that the unit is now in the adjustment process mode.

When you fail to enter the adjustment process mode (the display is the same as normal startup), retry the procedure.

4) To exit the adjustment process mode after the adjustment is done, unplug the AC cord from the outlet to make a forced shutdown. (When the

power was turned off with the remote controller, once unplug the AC cord and plug it again. In this case, wait 10 seconds or so before plugging.)

CAUTION: Use due care in handling the information described here lest your users should know how to enter the adjustment process mode. If the

settings are tampered in this mode, unrecoverable system damage may result.

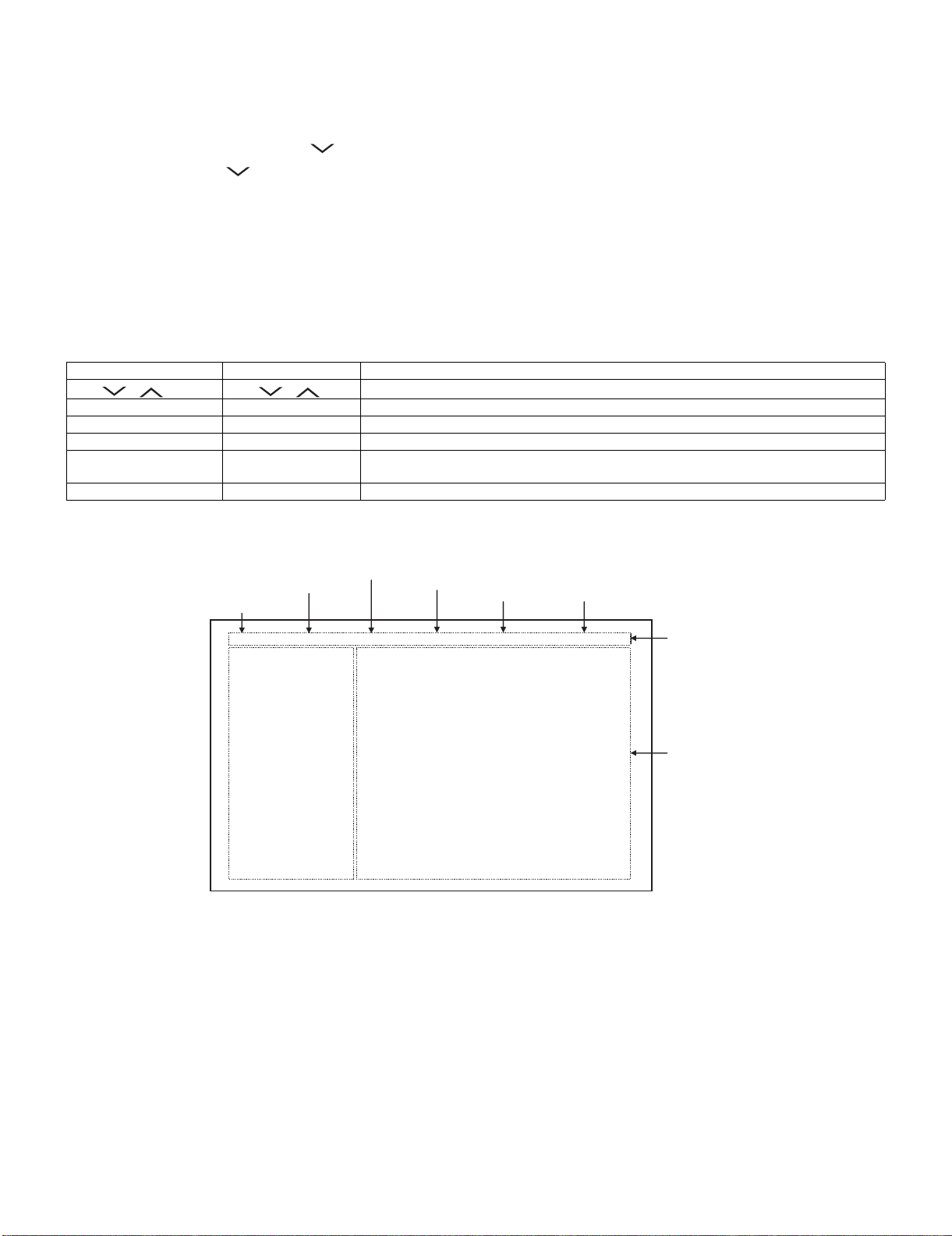

4. Remote controller key operation and description of display in adjustment process mode

1) Key operation

*Input mode is switched automatically when relevant adjustment is started so far as the necessary input signal is available.

2) Description of display

Remote controller key Main unit key Function

CH ( / ) CH ( / )

Moving an item (line) by one (UP/DOWN)

VOL (+/–) VOL (+/–) Changing a selected item setting (+1/ –1)

Cursor (UP/DOWN) ————— Turing a page (PREVIOUS/NEXT)

Cursor (LEFT/RIGHT) ————— Changing a selected line setting (+10/ –10)

INPUT ————— Input switching (toggle switching)

(TUNER→INPUT1→INPUT2→INPUT3→INPUT4→INPUT5→)

ENTER ————— Executing a function

(3) Current selected input

(2) Current page title

(4) Current color system

(1) Current page/ (5) Destination

(6) LCD Panel size/Speaker type

Total pages

1/28 [INFO] INPUT5 AUTO USA 46_UNDER

MAIN Version 0.90 ( U 2006/11/21 1A)

BOOT Version D62UB 1.01

Monitor Version 0.9

EQ DATACHECKSUM ROM (8) Parameters

TEMPAERATURE 7B

LAMP ERROR 0

NORMAL STANDBY CAUSE

0

ERROR STANDBY CAUSE 1) 0 2) 0 3) 0

0H 0M 0H 0M 0H 0M

4) 0 5) 0

0H 0M 0H 0M

(7) Adjustment

process menu

header

(LC-32D62U: 32_UNDER)

(LC-37D62U: 37_UNDER)

LC-32D62U/LC-37D62U 1st

5 – 6

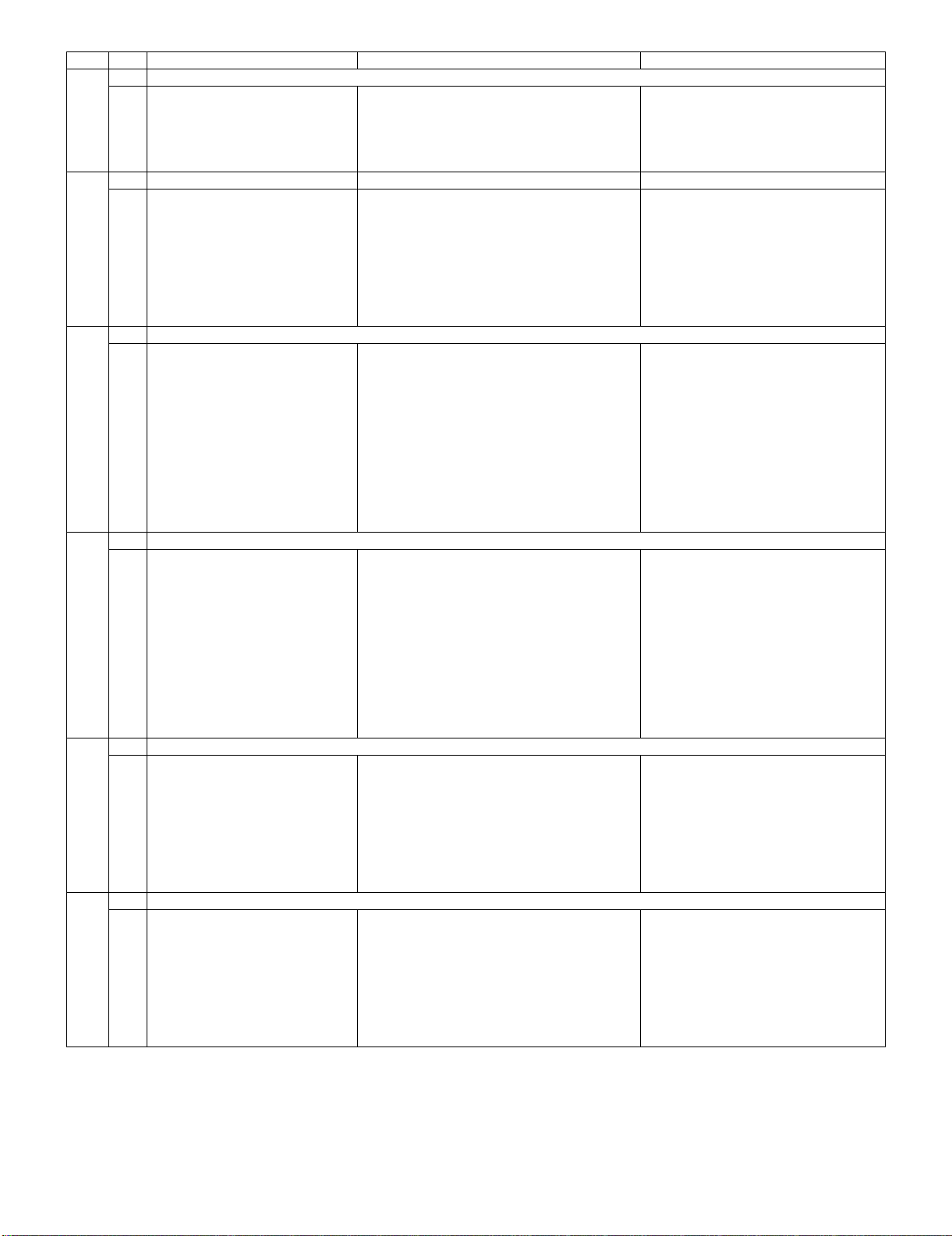

5. List of adjustment process mode menu

The character string in brackets [ ] will appear as a page title in the adjustment process menu header.

Page Line Item Description Remarks (adjustment detail, etc.)

1 [INFO]

1 MAIN Version Main software version

2BOOT Version

3 Monitor Version Monitor software version

4 EQ DATA CHECKSUM Audio data checksum

5 TEMPERATURE CPU temperature

6 LAMP ERROR Number of termination due to lamp error

7 NORMAL STANDBY CAUSE Refer to *1 under the list for details

8 ERROR STANDBY CAUSE Refer to *2 under the list for details

2 [INIT]

1 INDUSTRY INIT (Cause)

2 INDUSTRY INIT Initialization to factory settings .

3 HOTELMODE Hotel mode

4 Center Acutime Accumulated main operation time

5 RESET Reset

6 BacklightAcutime Accumulated monitor operation time

7 RESET Reset

8 LAMP ERROR RESET Reset LAMP ERROR

9 VIC XPOS X-coordinate setting for VIC READ

10 VIC YPOS Y-coordinate setting for VIC READ

11 VIC COLOR Collected color data setting for VIC READ

12 VIC SIGNAL TYPE Signal type setting for VIC READ

13 VIC READ Picture level acquisition function Level appears in green on the upper right.

3 [N358MAIN]

1 N358 ALL ADJ CVBS and TUNER signal level adjustment

2 N358 MAIN ADJ CVBS signal level adjustment

3 TUNER DAC ADJ TUNER signal level adjustment

4 N358 MAIN CONTRAST CVBS and TUNER contrast adjustment values

5 TUNER A DAC TUNER adjustment value

6 VCOM ADJ VCOM adjustment value

4 [TUNER TEST]

1 TUNER VCHIP TEST(69ch) Tuning test and VCHIP test (69 ch)

2 TUNER VCHIP TEST(7ch) Tuning test and VCHIP test (7 ch)

3 TUNER VCHIP TEST(10ch) Tuning test and VCHIP test (10 ch)

4 TUNER VCHIP TEST(15ch) Tuning test and VCHIP test (15 ch)

5 [COMP15KMAIN]

1 COMP15K MAIN ADJ Component 15K picture level adjustment (main)

2 COMP15K CONTRAST Contrast adjustment value

3 COMP15K MAIN Cb GAIN Cb GAIN adjustment value

4 COMP15K MAIN Cr GAIN Cr GAIN adjustment value

5 COMP15K Y OFFSET Y OFFSET adjustment value

6 COMP15K Cb OFFSET Cb OFFSET adjustment value

7 COMP15K Cr OFFSET Cr OFFSET adjustment value

6 [HDTV]

1 HDTV ADJ Component Hi-Vision picture level adjustment

2 CONTRAST Contrast adjustment value

3 Cb GAIN Cb GAIN adjustment value

4 Cr GAIN Cr GAIN adjustment value

5 HDTV Y OFFSET Y OFFSET adjustment value

6 HDTV Cb OFFSET Cb OFFSET adjustment value

7 HDTV Cr OFFSET Cr OFFSET adjustment value

7 [COMP67K]

1 COMP67K ADJ (33K)

2 COMP67K ADJ (67K)

3 COMP67K CONTRAST

4 COMP67K Cb GAIN

5 COMP67K Cr GAIN

6 COMP67K Y OFFSET

7 COMP67K Cb OFFSET

8 COMP67K Cr OFFSET

LC-32D62U/LC-37D62U 1st

5 – 7

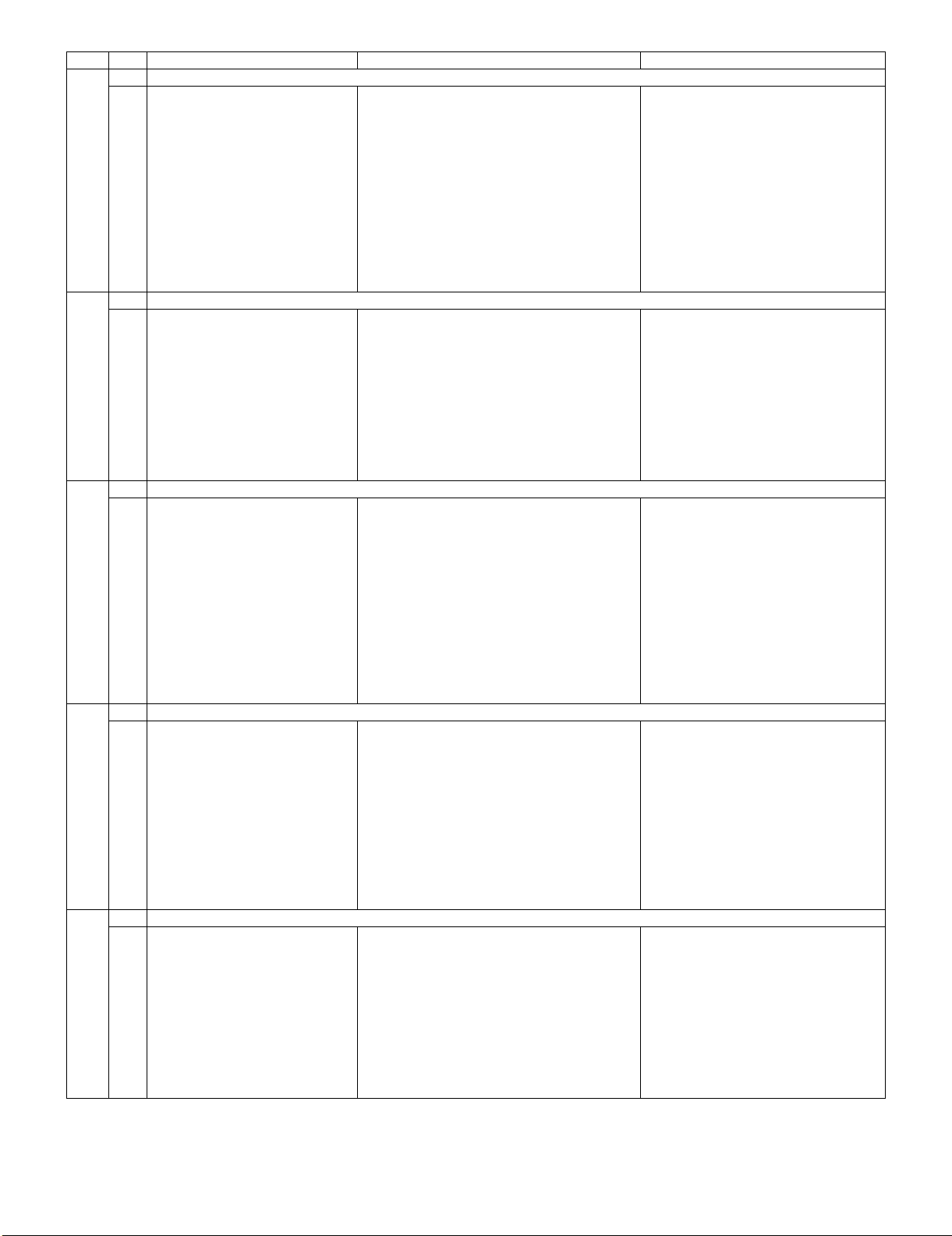

8 [FR DDRTEST]

1 DDRA TEST1

2 DDRA TEST2

3 DDRB TEST1

4 DDRB TEST2

5 DDRB TEST3

9 [M GAMMA IN]

1 MONITOR GAMMA IN 1 Standard value 1(WBI10184) Adjustment gradation setting.

2 MONITOR GAMMA IN 2 Standard value 2(WBI20352)

3 MONITOR GAMMA IN 3 Standard value 3(WBI30528)

4 MONITOR GAMMA IN 4 Standard value 4(WBI40656)

5 MONITOR GAMMA IN 5 Standard value 5(WBI50800)

6 MONITOR GAMMA IN 6 Standard value 6(WBI60928)

7 GAMMA WRITE WB adjustment data writing

8 GAMMA RESET WB adjustment data reading

10 [M GAMMA R1]

1 MONITOR GAMMA R 1 WB adjustment Point 1, R adjustment value Parameter for six-point adjustment

2 MONITOR GAMMA G 1 WB adjustment Point 1, G adjustment value

3 MONITOR GAMMA B 1 WB adjustment Point 1, B adjustment value

4 MONITOR GAMMA R 2 WB adjustment Point 2, R adjustment value

5 MONITOR GAMMA G 2 WB adjustment Point 2, G adjustment value

6 MONITOR GAMMA B 2 WB adjustment Point 2, B adjustment value

7 MONITOR GAMMA R 3 WB adjustment Point 3, R adjustment value

8 MONITOR GAMMA G 3 WB adjustment Point 3, G adjustment value

9 MONITOR GAMMA B 3 WB adjustment Point 3, B adjustment value

10 GAMMA WRITE WB adjustment data writing

11 GAMMA RESET WB adjustment data reading

11 [M GAMMA R4]

1 MONITOR GAMMA R 4 WB adjustment Point 4, R adjustment value Parameter for six-point adjustment

2 MONITOR GAMMA G 4 WB adjustment Point 4, G adjustment value

3 MONITOR GAMMA B 4 WB adjustment Point 4, B adjustment value

4 MONITOR GAMMA R 5 WB adjustment Point 5, R adjustment value

5 MONITOR GAMMA G 5 WB adjustment Point 5, G adjustment value

6 MONITOR GAMMA B 5 WB adjustment Point 5, B adjustment value

7 MONITOR GAMMA R 6 WB adjustment Point 6, R adjustment value

8 MONITOR GAMMA G 6 WB adjustment Point 6, G adjustment value

9 MONITOR GAMMA B 6 WB adjustment Point 6, B adjustment value

10 GAMMA WRITE WB adjustment data writing

11 GAMMA RESET WB adjustment data reading

12 [SOUND 1]

1 AUDIO SWITCH

2 FORCED FLAT MODE

3 AIN1_ADC_VOLUME

4 AIN2_ADC_VOLUME

5 AIN3_ADC_VOLUME

6 AIN4_ADC_VOLUME

7 AIN5_ADC_VOLUME

8 AIN6_ADC_VOLUME

13 [SOUND 2]

1 INPUT_MIXER_GAIN_SP

2 INPUT_MIXER_GAIN_HP

3 INPUT_MIXER_GAIN_EXT

4 INPUT_MIXER_GAIN_EXT_HP

5 OUTPUT_MIXER_GAIN

6SUB_VOLUME_FLAT

7 SUB_VOLUME_EQ

8 SUB_VOLUME_AUDYSSEY

Page Line Item Description Remarks (adjustment detail, etc.)

LC-32D62U/LC-37D62U 1st

5 – 8

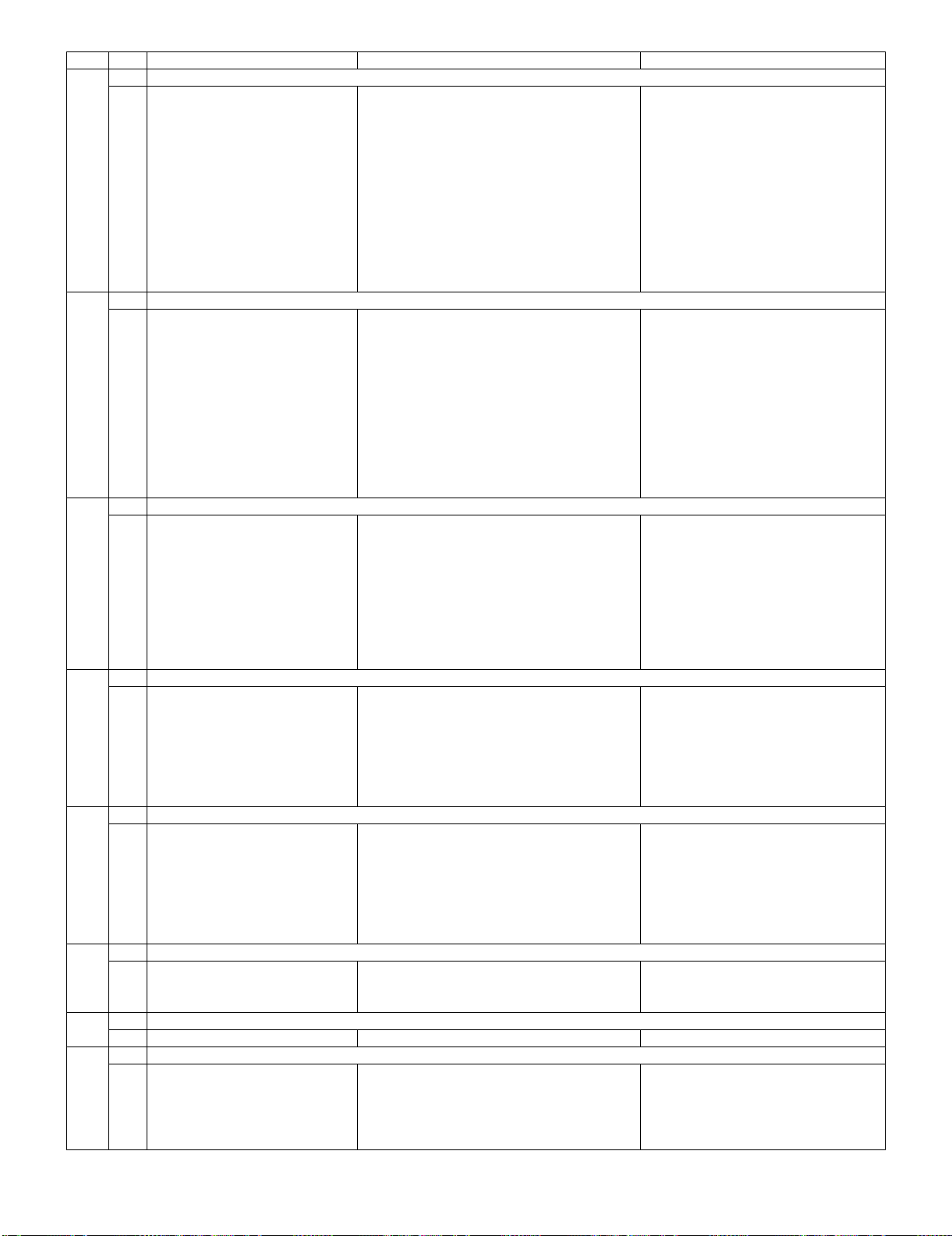

14 [SOUND 3]

1 PEQ1_F0

2 PEQ1_Q

3 PEQ1_GAIN

4 PEQ2_F0

5 PEQ2_Q

6 PEQ2_GAIN

7 PEQ3_F0

8 PEQ3_Q

9 PEQ3_GAIN

10 PEQ4_F0

11 PEQ4_Q

12 PEQ4_GAIN

15 [SOUND 4]

1 PEQ5_F0

2 PEQ5_Q

3 PEQ5_GAIN

4 VIRTUALIZER_LEVEL

5 BASS_BOOST_LEVEL

6 SLICER_LEVEL

7HPF_SW

8 HPF_LR

9LPF_SW

10 SW_MIXING_LEVEL

16 [M OPC1]

1 BRIGHTNESS DA0

2 BRIGHTNESS DA1

3 BRIGHTNESS DA2

4 BRIGHTNESS DA3

5 BRIGHTNESS DA4

6 BRIGHTNESS DA5

7 BRIGHTNESS DA6

8 BRIGHTNESS DA7

9 BRIGHTNESS DA8

10 BRIGHTNESS DA9

11 BRIGHTNESS DA10

12 BRIGHTNESS DA11

17 [M OPC2]

1 BRIGHTNESS DA12

2 BRIGHTNESS DA13

3 BRIGHTNESS DA14

4 BRIGHTNESS DA15

5 BRIGHTNESS DA16

6 BRIGHTNESS DA17

7 BRIGHTNESS DA18

8 BRIGHTNESS DA19

9 BRIGHTNESS DA20

10 BRIGHTNESS DA21

11 BRIGHTNESS DA22

18 [M OPC3]

1 BRIGHTNESS DA23

2 BRIGHTNESS DA24

3 BRIGHTNESS DA25

4 BRIGHTNESS DA26

5 BRIGHTNESS DA27

6 BRIGHTNESS DA28

7 BRIGHTNESS DA29

8 BRIGHTNESS DA30

9 BRIGHTNESS DA31

10 BRIGHTNESS DA32

Page Line Item Description Remarks (adjustment detail, etc.)

LC-32D62U/LC-37D62U 1st

5 – 9

19 [M ADL1]

1 OPC33 ADLEVEL 0

2 OPC33 ADLEVEL 1

3 OPC33 ADLEVEL 2

4 OPC33 ADLEVEL 3

5 OPC33 ADLEVEL 4

6 OPC33 ADLEVEL 5

7 OPC33 ADLEVEL 6

8 OPC33 ADLEVEL 7

9 OPC33 ADLEVEL 8

10 OPC33 ADLEVEL 9

11 OPC33 ADLEVEL 10

12 OPC33 ADLEVEL 11

20 [M ADL2]

1 OPC33 ADLEVEL 12

2 OPC33 ADLEVEL 13

3 OPC33 ADLEVEL 14

4 OPC33 ADLEVEL 15

5 OPC33 ADLEVEL 16

6 OPC33 ADLEVEL 17

7 OPC33 ADLEVEL 18

8 OPC33 ADLEVEL 19

9 OPC33 ADLEVEL 20

10 OPC33 ADLEVEL 21

11 OPC33 ADLEVEL 22

21 [M ADL3]

1 OPC33 ADLEVEL 23

2 OPC33 ADLEVEL 24

3 OPC33 ADLEVEL 25

4 OPC33 ADLEVEL 26

5 OPC33 ADLEVEL 27

6 OPC33 ADLEVEL 28

7 OPC33 ADLEVEL 29

8 OPC33 ADLEVEL 30

9 OPC33 ADLEVEL 31

22 [M V6THE]

1V6 OS THERMO 1

2V6 OS THERMO 2

3V6 OS THERMO 3

4V6 OS THERMO 4

5V6 OS THERMO 5

6V6 OS THERMO 6

7V6 OS THERMO 7

23 [M V5THE]

1V5 OS THERMO 1

2V5 OS THERMO 2

3V5 OS THERMO 3

4V5 OS THERMO 4

5V5 OS THERMO 5

6V5 OS THERMO 6

7V5 OS THERMO 7

24 [M EEP SET]

1 MONITOR TIME OUT

2 MONITOR MAX TEMP

3 MONITOR STANDBY CAUSE

25 [M TESTPTRN]

1 LCD TEST PATTERN

26 [FR REGI]

1 READ/WRITE

2 SLAVE ADDRESS

3 REGISTOR ADDRESS

4WRITE DATA

5 READ DATA

Page Line Item Description Remarks (adjustment detail, etc.)

LC-32D62U/LC-37D62U 1st

5 – 10

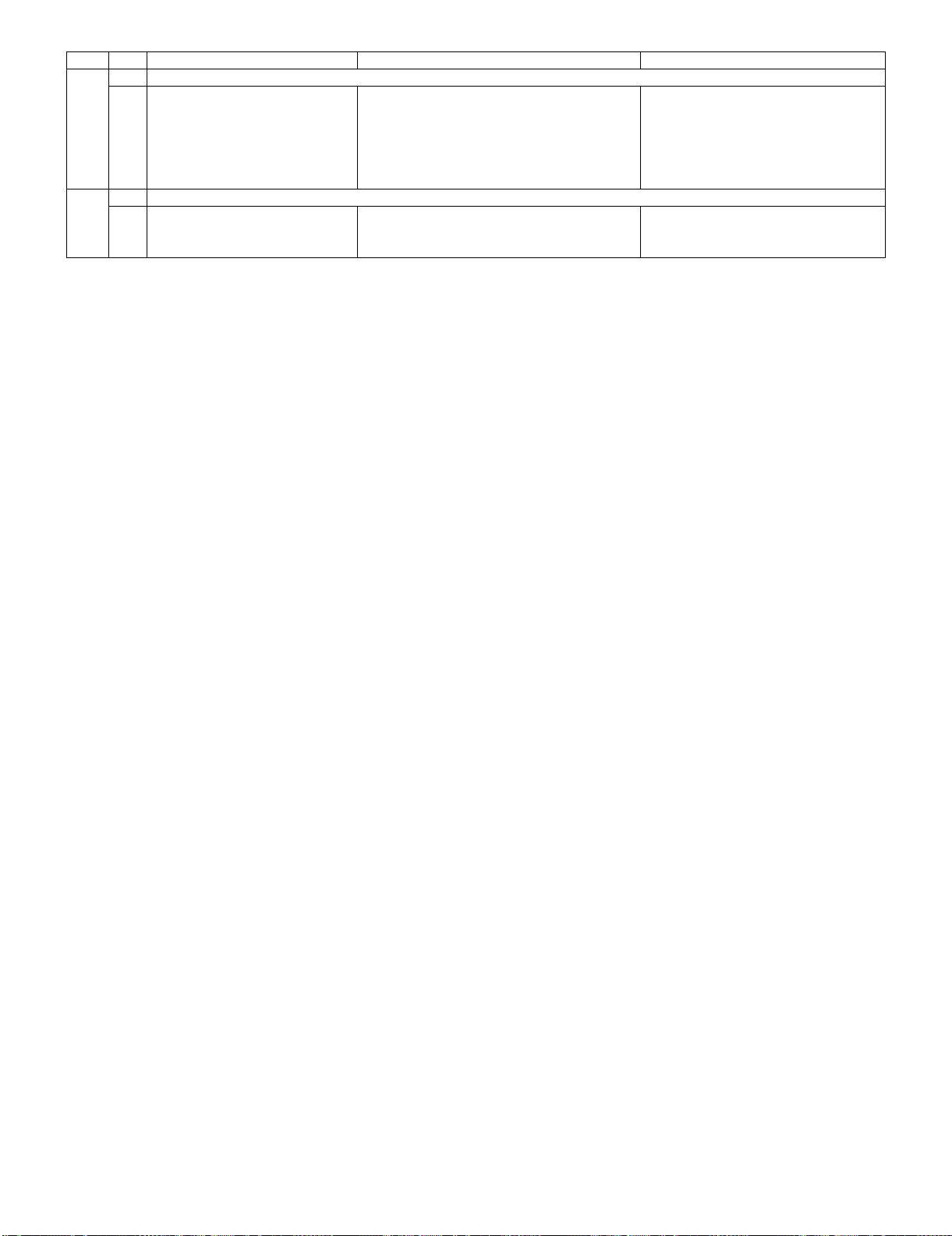

6. Special features

* STANDBY CAUSE (Page 1/28)

Display of a cause (code) of the last standby

The cause of the last standby is recorded in EEPROM whenever possible.

Checking this code will be useful in finding a problem when you repair the troubled set.

* EEP SAVE (Page 28/28)

Storage of EEP adjustment value

* EEP RECOVER (Page 28/28)

Retrieval of EEP adjustment value from storage area

27 [MEMORY CLR]

1 KEY LOCK(1217)

2 KOUTEI AREA ALL CLEAR

3 A MODE AREA CLEAR

4 BACKUP AREA CLEAR

5 B MODE AREA CLEAR

6EXECUTION

28 [ETC]

1 EEP SAVE Writing setting values to EEPROM.

2 EEP RECOVER Reading setting values from EEPROM.

3 STANDBY CAUSE RESET Reset stand by cause.

*1 Details of P1.7(NORMAL STANDBY CAUSE)

6 No operation off in the cause of “no operation off”

7 No signal off in the cause of “no signal off”

8 PC power management mode 1 in the cause of “Standby mode MODE1”

9 PC power management mode 2 in the cause of “Standby mode MODE2”

A Off timer in the cause of “SLEEP timer”

C Command from RS232C in the cause of command by RS-232C

*2 Details of P1.8(ERROR STANDBY CAUSE)

5 Prolonged unspecified-signal input in PC mode in the cause of continuous “out of range”, PC input mode

13 Temperature error in the cause of abnormal temperature

16 Monitor trouble detected in the cause of abnormal monitor mode

17 Fan lock in the cause of fan lock

Page Line Item Description Remarks (adjustment detail, etc.)

LC-32D62U/LC-37D62U 1st

5 – 11

7. Video signal adjustment procedure

7.1. Signal adjustment

1. Checking the Device

Before starting the adjustment, make sure the adjustment tool and signal generator are set for Sharp LCD US.

Checking the signal generator level adjustment (Set to the standard level.)

2. Process mode

3. Composite N358 signal/tuner adjustment

4. Component 15K signal adjustment

• Composite signal : 0.714 Vp-p ± 0.02 Vp-p (from pedestal to white)

• 15K component signal : Y level : 0.714 Vp-p ± 0.02 Vp-p (from pedestal to white)

PB, PR level : 0.7 Vp-p ± 0.02 Vp-p

• 33K component signal : Y level : 0.7 Vp-p ± 0.02 Vp-p (from pedestal to white)

PB, PR level : 0.7 Vp-p ± 0.02 Vp-p

• 1080P component signal : Y level : 0.7 Vp-p ± 0.02 Vp-p (from pedestal to white)

PB, PR level : 0.7 Vp-p ± 0.02 Vp-p

Adjustment item Adjustment conditions Adjustment procedure

1 Process mode Enter the process adjustment mode using the process adjustment remote controller.

Adjustment item Adjustment conditions Adjustment procedure

1 Setting N358 signal

US-10ch

Feed the N358 color bar signal (75% color saturation) to VIDEO 1 input.

Feed the RF signal (by use of US-10ch) to TUNER.

2 Automatic adjust-

ment execution

Move the cursor to [ N358 ALL ADJ] and press the [ENTER] key.

When [ N358 ALL ADJ FINISH] appears, the adjustment is complete.

Adjustment item Adjustment conditions Adjustment procedure

1 Setting 480i signal Feed the 100% color bar signal to VIDEO 1 COMPONENT input.

2 Automatic adjust-

ment execution

Move the cursor to [ COMP 15K ALL ADJ] and press the [ENTER] key.

When [ COMP 15K ALL ADJ FINISH] appears, the adjustment is complete.

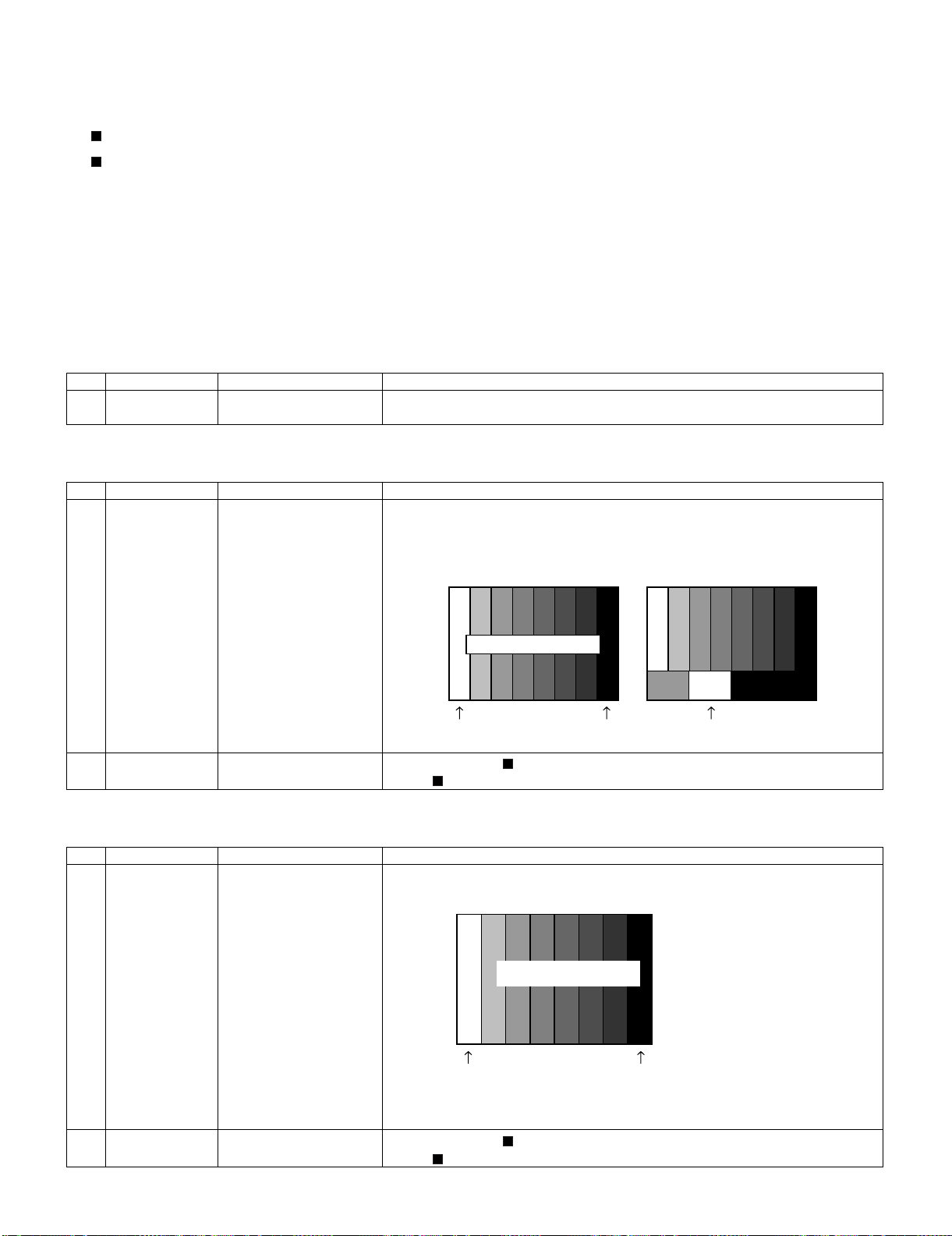

[Video input signal] [US-10ch]

100% white 0% black 100% white

75% Color saturation

0% black

480i

100% color bar

100% white

100% Color saturation

LC-32D62U/LC-37D62U 1st

5 – 12

5. Component 33K signal adjustment

6. Component 1080P signal adjustment

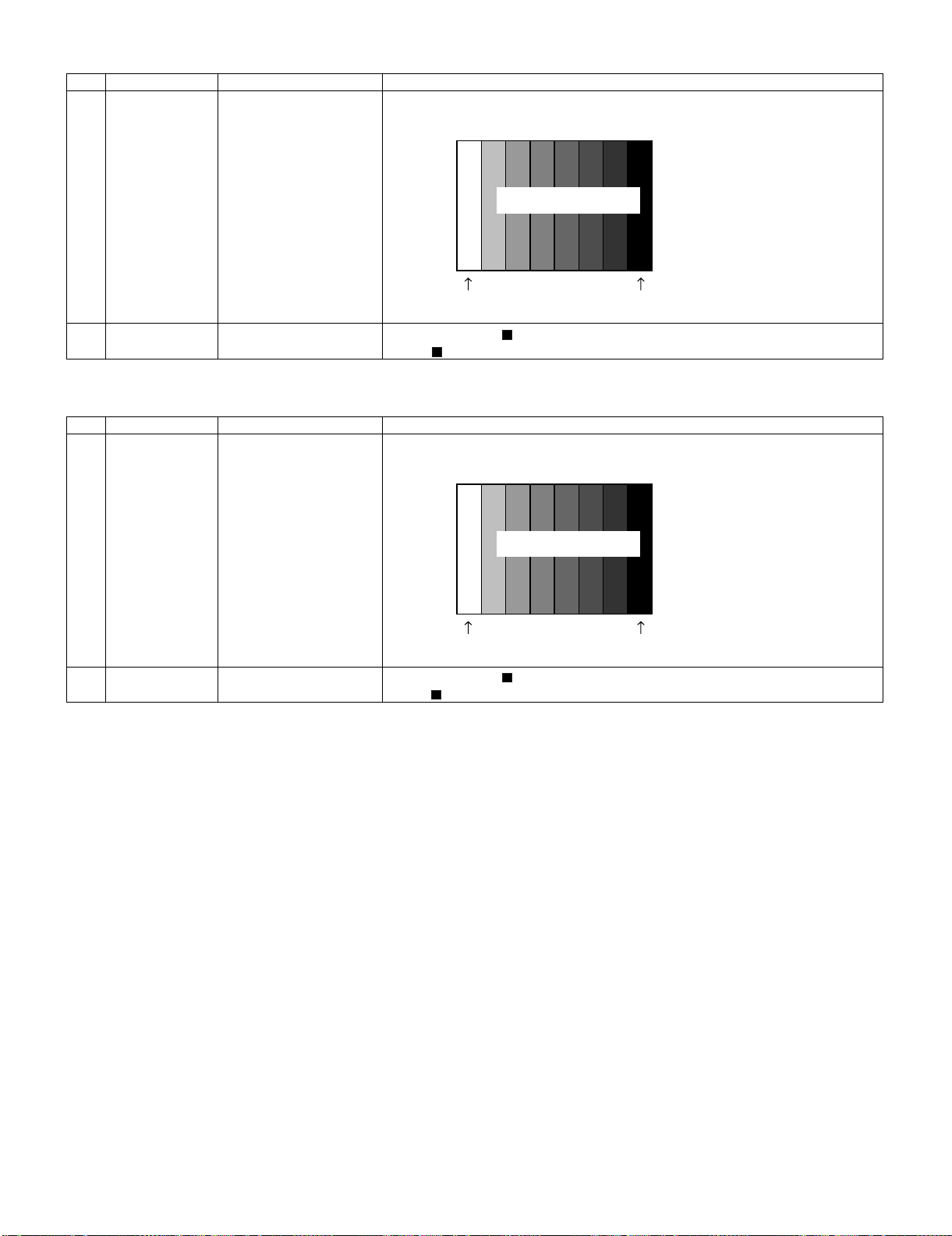

Adjustment item Adjustment conditions Adjustment procedure

1 Setting 1080i signal Feed the 100% color bar signal to VIDEO 1 COMPONENT input.

2 Automatic adjust-

ment execution

Move the cursor to [ HDTV ADJ] and press the [ENTER] key.

When [ HDTV ADJ FINISH] appears, the adjustment is complete.

Adjustment item Adjustment conditions Adjustment procedure

1 Setting 1080p signal Feed the 100% color bar signal to VIDEO 1 COMPONENT input.

2 Automatic adjust-

ment execution

Move the cursor to [ COMP67K ADJ] and press the [ENTER] key.

When [ COMP67K ADJ FINISH] appears, the adjustment is complete.

0% black

1080i

100% color bar

100% white

100% Color saturation

0% black

1080p

100% color bar

100% white

100% Color saturation

Loading...

Loading...