Schneider Electric PM2200R User Manual

EasyLogic™PM2200R series

User Manual

QGH9011501-02

02/2021

www.se.com

Legal Information

The Schneider Electric brand and any trademarks of Schneider Electric SE and its

subsidiaries referred to in this guide are the property of Schneider Electric SE or its

subsidiaries. All other brands may be trademarks of their respective owners.

This guide and its content are protected under applicable copyright laws and

furnished for informational use only. No part of this guide may be reproduced or

transmitted in any form or by any means (electronic, mechanical, photocopying,

recording, or otherwise), for any purpose, without the prior written permission of

Schneider Electric.

Schneider Electric does not grant any right or license for commercial use of the guide

or its content, except for a non-exclusive and personal license to consult it on an "as

is" basis. Schneider Electric products and equipment should be installed, operated,

serviced, and maintained only by qualified personnel.

As standards, specifications, and designs change from time to time, information

contained in this guide may be subject to change without notice.

To the extent permitted by applicable law, no responsibility or liability is assumed by

Schneider Electric and its subsidiaries for any errors or omissions in the informational

content of this material or consequences arising out of or resulting from the use of the

information contained herein.

Safety information

Important information

Read these instructions carefully and look at the equipment to become familiar

with the device before trying to install, operate, service, or maintain it. The

following special messages may appear throughout this manual or on the

equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety label indicates

that an electrical hazard exists which will result in personal injury if the

instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that accompany this symbol to avoid possible

injury or death.

EasyLogic™PM2200R series

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Failure to follow these instructions will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to physical injury.

Please note

Electrical equipment should be installed, operated, serviced and maintained only

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material. A qualified person is one who

has skills and knowledge related to the construction, installation, and operation of

electrical equipment and has received safety training to recognize and avoid the

hazards involved.

QGH9011501-02 3

Table of Contents

Safety precautions ......................................................................................9

Introduction ................................................................................................10

Meter overview......................................................................................... 10

Main features ........................................................................................... 10

Feature summary .....................................................................................10

Measured parameters...............................................................................12

Data display and analysis tools..................................................................14

EasyLogic™PM2200R series

Energy ...............................................................................................12

Non Reset energy............................................................................... 12

Demand .............................................................................................12

Instantaneous.....................................................................................13

Power quality...................................................................................... 13

Data recording (PM2230R) .................................................................. 13

Input/output (PM2230R) ......................................................................13

Other measurements ..........................................................................13

Power Monitoring Expert .....................................................................14

Power SCADA Operation .................................................................... 14

Meter configuration .............................................................................14

Hardware reference..................................................................................15

PM2200R meter models and accessories...................................................15

Supplemental information..........................................................................16

Meter mounting and wiring ........................................................................16

Meter wiring considerations....................................................................... 16

Direct connect voltage limits ................................................................ 16

Balanced system considerations .......................................................... 18

RS-485 wiring ..........................................................................................18

Pulse output............................................................................................. 19

Meter display .............................................................................................20

Display overview ......................................................................................20

LED indicators.......................................................................................... 20

Alarm / energy pulsing LED .................................................................20

Heartbeat / serial communications LED ................................................20

Notification icons ......................................................................................21

Meter display language .............................................................................21

Meter screen navigation............................................................................ 21

Navigation symbols............................................................................. 22

Meter screen menus overview .............................................................22

Setting up the display................................................................................23

Meter Setup ............................................................................................... 24

Configuring basic setup parameters using the display .................................24

Configuring advanced setup parameters using the display...........................26

Setting the rate......................................................................................... 26

Setting up regional settings .......................................................................27

Setting up the screen passwords ...............................................................28

Lost password .................................................................................... 28

Setting the clock ................................................................................. 29

Retrofit..................................................................................................... 29

QGH9011501-02 5

EasyLogic™PM2200R series

Retrofit setting .................................................................................... 29

SnapShot.................................................................................................30

Viewing SnapShot page ......................................................................30

SnapShot setting ................................................................................30

Configuring Favorite Page ...................................................................30

Auto reset configuration....................................................................... 31

I/O Modules................................................................................................32

Analog input applications ..........................................................................32

Analog output applications ........................................................................ 34

Status input (DI) applications .....................................................................36

Digital output applications .........................................................................37

Relay output applications .......................................................................... 38

IO LED Indicator.......................................................................................40

Alarms......................................................................................................... 41

Alarms overview ....................................................................................... 41

Alarm types.............................................................................................. 41

Unary alarms............................................................................................ 41

Available unary alarms ........................................................................41

Digital alarms ........................................................................................... 42

Available digital alarms ........................................................................42

Standard alarms....................................................................................... 42

Example of over and under setpoint (standard) alarm operation..............42

Maximum allowable setpoint................................................................44

Available standard alarms ................................................................... 44

Alarm priorities .........................................................................................46

Alarm setup overview................................................................................ 47

LED alarm indicator ..................................................................................49

Configuring the LED for alarms using the display...................................49

Configuring the LED for alarms using ION Setup ...................................49

Alarm display and notification ....................................................................49

Active alarms list and alarm history log ....................................................... 50

Alarms counters .......................................................................................51

Resetting alarms using ION Setup .............................................................51

Meter logging .............................................................................................52

Logs overview ..........................................................................................52

Setting up the data log .............................................................................. 52

Saving the data log contents using ION Setup ............................................52

Alarm log .................................................................................................53

Meter resets ...............................................................................................54

Meter resets............................................................................................. 54

Meter initialization.....................................................................................54

Performing resets using ION Setup ...................................................... 54

Measurements and calculations.............................................................56

Meter initialization.....................................................................................56

Real-time readings ...................................................................................56

Energy measurements..............................................................................56

Quadrant based VARh ..............................................................................56

Min/max values ........................................................................................57

Power demand .........................................................................................57

Power demand calculation methods ..................................................... 57

6 QGH9011501-02

EasyLogic™PM2200R series

Block interval demand .........................................................................57

Synchronized demand......................................................................... 58

Thermal demand ................................................................................58

Current demand .......................................................................................59

Predicted demand............................................................................... 59

Peak demand ..................................................................................... 60

Timer.......................................................................................................60

Multi-tariff ...................................................................................................61

Multi-tariff implementation .........................................................................61

Command mode overview......................................................................... 61

Time of day mode overview ....................................................................... 62

Time of day mode tariff validity .............................................................62

Time of day tariff creation methods .......................................................62

Example tariff configurations for a four-tariff system ...............................63

Input mode overview.................................................................................63

Digital input assignment for input control mode......................................64

Active tariff control mode ...........................................................................64

Configuring time of day mode tariffs using the display ............................65

Configuring input mode tariffs using the display .....................................66

Power quality .............................................................................................67

Harmonics overview ................................................................................. 67

Total harmonic distortion %........................................................................67

Harmonic content calculations ............................................................. 67

THD% calculations..............................................................................67

Displaying THD% data ..............................................................................67

Maintenance and upgrades..................................................................... 68

Maintenance overview ..............................................................................68

Troubleshooting LED indicators .................................................................68

Meter memory..........................................................................................68

Meter battery............................................................................................68

Viewing firmware version, model and serial number ....................................69

Firmware upgrades................................................................................... 69

Technical assistance .................................................................................69

Low voltage current transformer (LVCT) ............................................... 70

Overview ................................................................................................. 70

LVCT features ..........................................................................................70

Available LVCT options .............................................................................70

LVCT wiring.............................................................................................. 72

Verifying accuracy..................................................................................... 73

Overview of meter accuracy ...................................................................... 73

Accuracy test requirements .......................................................................73

Verifying accuracy test ..............................................................................74

Required pulses calculation for accuracy verification testing ........................ 75

Total power calculation for accuracy verification testing ...............................76

Percentage error calculation for accuracy verification testing ....................... 76

Accuracy verification test points.................................................................76

Energy pulsing considerations ...................................................................77

VT and CT considerations..........................................................................77

Example calculations ................................................................................77

Typical sources of test errors .....................................................................79

QGH9011501-02 7

EasyLogic™PM2200R series

Power and power factor ........................................................................... 80

Power and power factor ............................................................................ 80

Current phase shift from voltage ................................................................80

Real, reactive and apparent power (PQS)................................................... 80

Power factor (PF) ..................................................................................... 81

Power factor sign convention ...............................................................81

Power factor min/max convention.........................................................82

Power factor register format................................................................. 82

Command interface ..................................................................................84

Command interface .................................................................................. 84

Using protected command interface ........................................................... 84

Specifications ............................................................................................86

China Standard Compliance ................................................................... 91

8 QGH9011501-02

Safety precautions EasyLogic™PM2200R series

Safety precautions

Installation, wiring, testing and service must be performed in accordance with all

local and national electrical codes.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate Personal Protective Equipment (PPE) and follow safe

electrical work practices. See NFPA 70E, CSA Z462 or other local

standards.

• Turn off all power supplying this device and the equipment in which it is

installed before working on or in the equipment.

• Always use a properly rated voltage sensing device to confirm that all power

is off.

• Follow guidelines in the Wiring section of the related Installation Sheet.

• Assume communications and I/O wiring are hazardous live until determined

otherwise.

• Do not exceed the maximum ratings of this device.

• Do not short secondary terminals of Voltage Transformer (VT).

• Do not open secondary terminals of Current Transformer (CT).

• Ground secondary circuit of CTs.

• Do not use the data from the meter to confirm power is off.

• Replace all devices, doors and covers before turning on power to this

equipment.

Failure to follow these instructions will result in death or serious injury.

NOTE: See IEC 60950-1 for more information on communications and I/O

wiring connected to multiple devices.

WARNING

UNINTENDED OPERATION

• Do not use this device for critical control or protection of persons, animals,

property or equipment.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

WARNING

POTENTIAL COMPROMISE OF SYSTEM AVAILABILITY, INTEGRITY, AND

CONFIDENTIALITY

• Change default passwords/passcodes to help prevent unauthorized access

to device settings and information.

• Disable unused ports/services and default accounts, where possible, to

minimize pathways for malicious attacks.

• Place networked devices behind multiple layers of cyber defenses (such as

firewalls, network segmentation, and network intrusion detection and

protection).

• Use cybersecurity best practices (for example: least privilege, separation of

duties) to help prevent unauthorized exposure, loss, modification of data and

logs, interruption of services, or unintended operation.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

QGH9011501-02 9

EasyLogic™PM2200R series Introduction

Introduction

Meter overview

The PM2200R series meters are digital meters that offer comprehensive 3-phase

electrical instrumentation and load management facilities in a compact, rugged

package.

The meters offer value for the demanding needs of your energy monitoring and

cost management applications. All meters in the PM2200R series range feature

high quality, reliability and affordability in a compact and easy to install format.

Main features

The PM2200R series meters supports many features, a few of the features are

listed below:

• Self guided LCD display and navigation

• Energy accounting and balancing

• Measurement of both True PF and Displacement PF

• Active, reactive, and apparent energy readings

• Min/Max values of instantaneous parameters with timestamp.

• Cybersecurity: The meter enables disabling the RS-485 port through front

panel keys against unauthorized access. This feature can also be used for

toggling between the RTU devices in case of limited availability of nodes in

software system.

• SnapShot: The meter features include snapshot, which captures values of

average voltage, average current, total active power, and delivered energy

based on configured time in HH.MM format.

• Suppression current: This is the minimum current at which the meter starts

functioning. The meter can be configured to disregard the measurement of

induced / auxiliary load current in the circuit. The suppression current

selection can be done through the front display and through communication.

The suppression current range is from 5 mA to 99 mA. The meter shows

measurement if applied value is above the suppression value. The default

suppression current is 5 mA.

Embedded intelligence allows the CTs to be automatically detected by the meter

when plugged in and automatically configures the CT ratio parameters. You can

use the meter as a stand-alone device, but its extensive capabilities are fully

realized when used as part of an energy management system.

For applications, feature details and the most current and complete specifications

of the PM2200R meters, see the EasyLogic PM2000R series technical datasheet

at www.se.com.

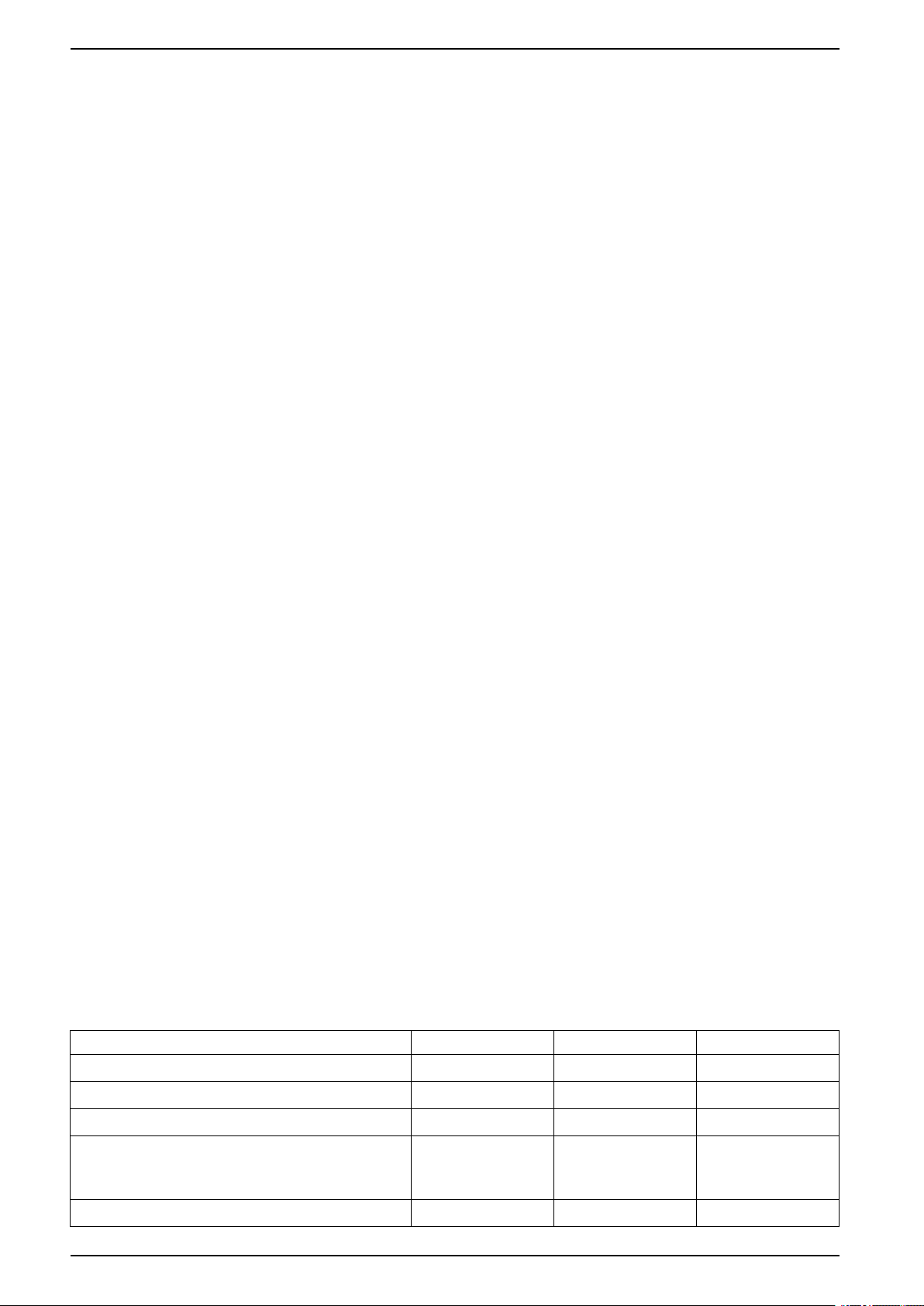

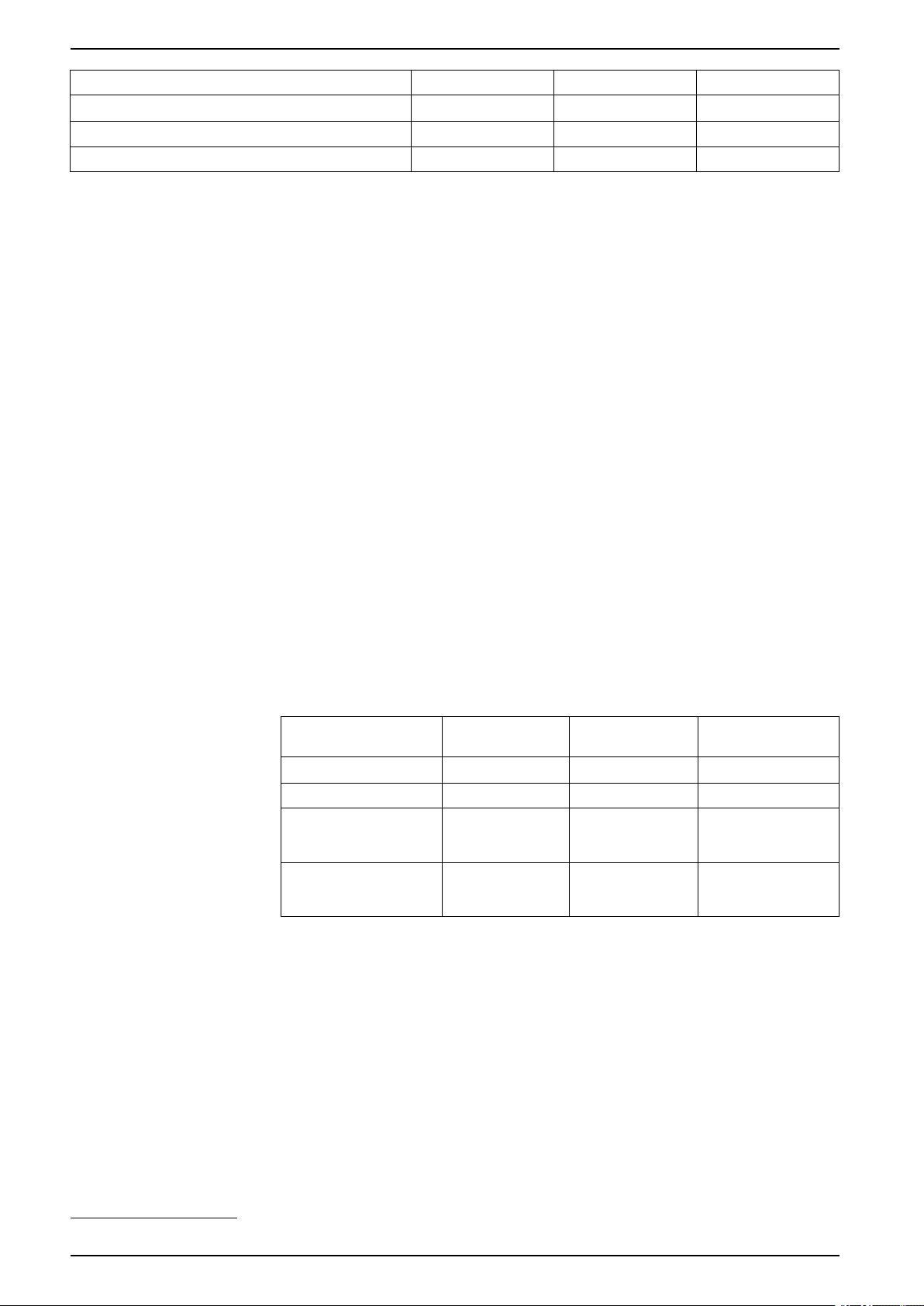

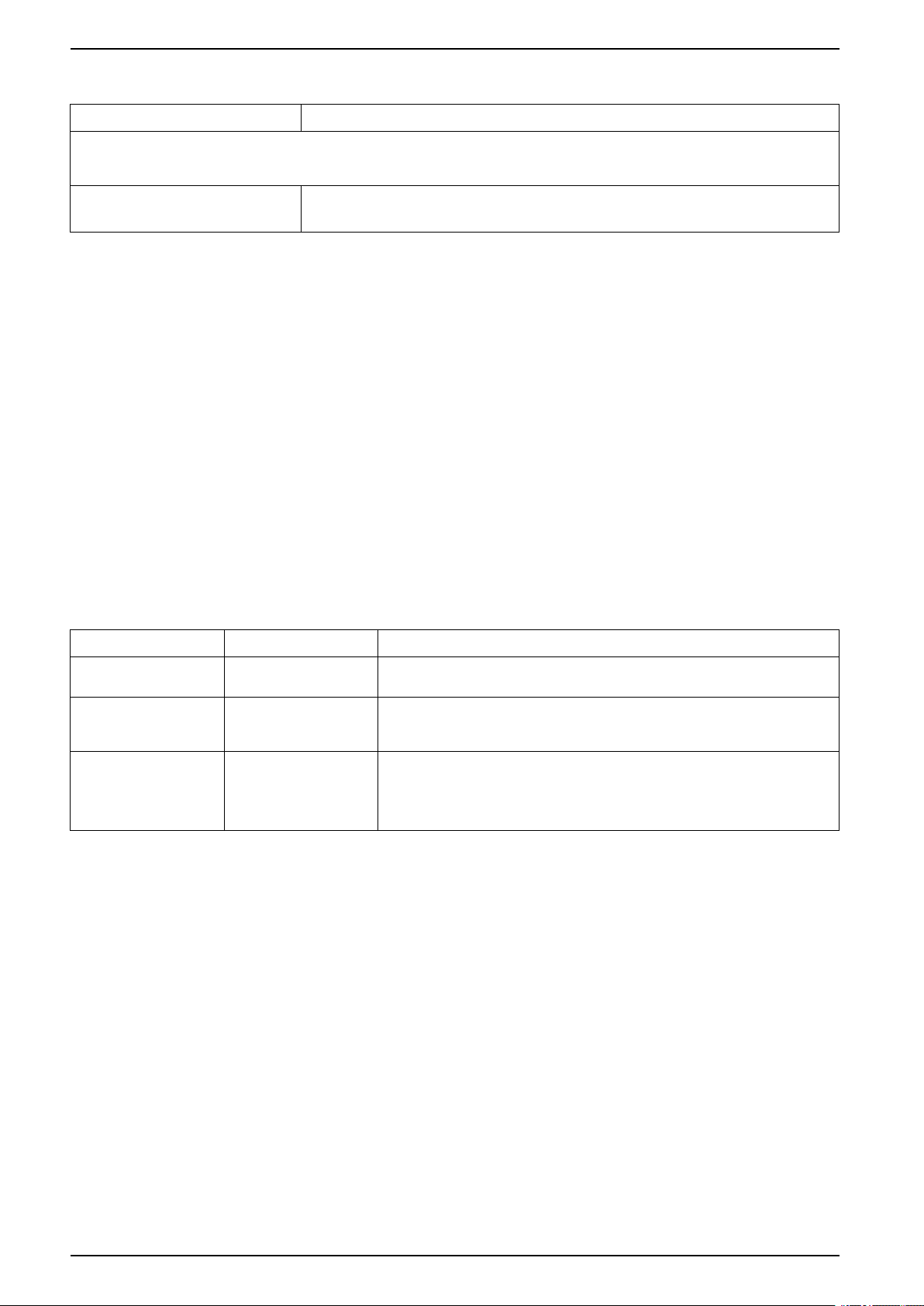

Feature summary

Parameter PM2210R PM2220R PM2230R

Accuracy Class for Wh Class 1 Class 1 Class 0.5S

Accuracy Class for VARh 1.0 1.0 1.0

Sampling rate per cycle 64 64 64

Current:

• Per-phase and 3 phase average

• Calculated neutral current

Voltage:

10 QGH9011501-02

✔ ✔ ✔

✔ ✔ ✔

Introduction EasyLogic™PM2200R series

Parameter PM2210R PM2220R PM2230R

• V L-N - per-phase and 3 phase average

• V L-L - per-phase and 3 phase average

Power Factor

• Per phase and 3 phase total

Frequency

Power:

True PF True PF

Displacement PF

✔ ✔ ✔

✔ ✔ ✔

• Active power (kW) - Phase wise and total

• Apparent power (kVA) - Phase wise and total

• Reactive power (kVAR) - Phase wise and total

3 Phase unbalance Current Current

Voltage

Demand parameters (kW, kVA, kVAR, I)

• Last demand

✔

(no timestamp)

✔ ✔

• Present demand

• Predictive demand

• Peak demand: Timestamp for peak demand

Energy: kWh, kVAh, kVARh (4 Quadrant)

• Delivered (Import / Forward)

• Received (Export / Reverse)

1

Delivered (D)

Received (R)

Total (D+R)

Net (D-R)

Delivered (D)

Received (R)

Total (D+R)

Net (D-R)

Last cleared (Old)

True PF

Displacement PF

Current

Voltage

Delivered (D)

Received (R)

Total (D+R)

Net (D-R)

1

Last cleared (Old)

1

THD %:

✔ ✔ ✔

• Voltage L-N

• Voltage L-L

• Current per phase

Individual Harmonics

Min / Max with timestamp

–

–

th

Up to 15

individual

harmonics

✔ ✔

Up to 31stindividual

harmonics

• V L-L average

• V L-N average

• Current average

• Frequency

• Active power, Total

• Apparent power, Total

• Reactive power, Total

• Power factor, Total

Communication POP RS-485 Modbus RTU RS-485 Modbus RTU

Expandable Analog IO modules (1 input and 1 output)

Expandable Analog IO modules (2 inputs and 2 outputs)

Expandable Relay Output modules (2 digital inputs and 2

— —

— —

— —

✔

✔

✔

relay outputs)

Expandable Digital IO modules (2 inputs and 2 outputs)

Data Logging

— —

— —

✔

✔

• Energy (W, VA, VAR): Delivered / Received

• Power: Active / Apparent / Reactive

• Demand (W, VA, VAR, A): Last

Retrofit

—

✔ ✔

For configuring legacy communication data models.

1. Indicated features can be read through communication only.

QGH9011501-02 11

EasyLogic™PM2200R series Introduction

Parameter PM2210R PM2220R PM2230R

SnapShot

Multi-tariff

Auto reset

2

—

— —

—

✔ ✔

✔

✔ ✔

Measured parameters

Energy

The meter stores all accumulated active, reactive, and apparent energy

parameters in nonvolatile memory:

• kWh, kVARh, kVAh (delivered)

• kWh, kVARh, kVAh (received)

• kWh, kVARh, kVAh (delivered + received)

• kWh, kVARh, kVAh (delivered - received)

All energy parameters represent the total for all three phases.

NOTE: Based on the energy scale selection, when kWh, kVARh, kVAh (delivered)

or kWh, kVARh, kVAh (received ) of the energy parameters overflow at 999.99 all

energy parameter value resets.

Non Reset energy

Demand

Non Reset energy parameters are Wh, VAh and VARh for both Del and Rec. Non

Reset energy parameters are available on display in Diag page under

Maintenance and through communication..

These parameter values cannot be reset either through display or communication.

These Non Reset energy values will overflow automatically when they reach

maximum value based on overflow limit.

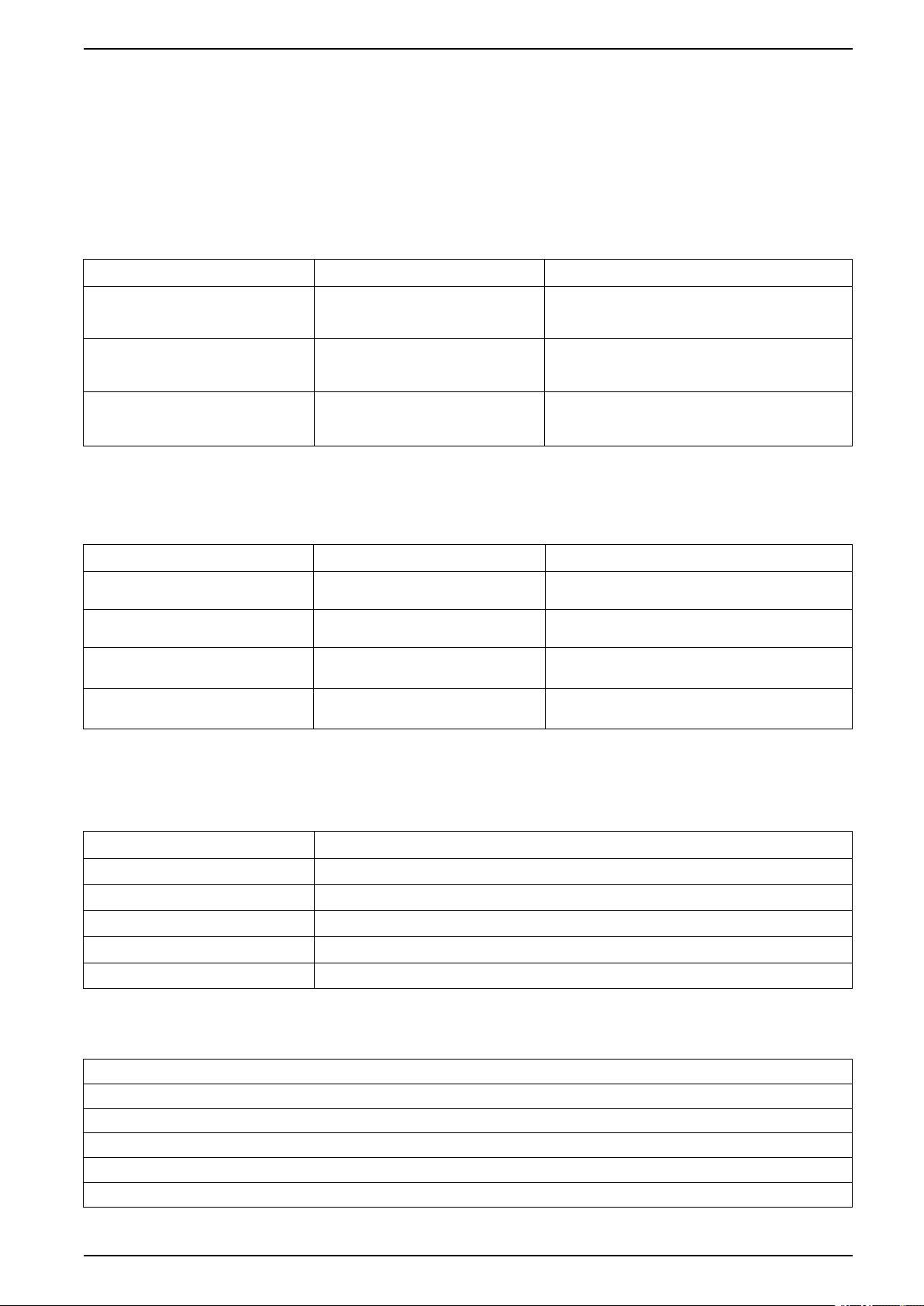

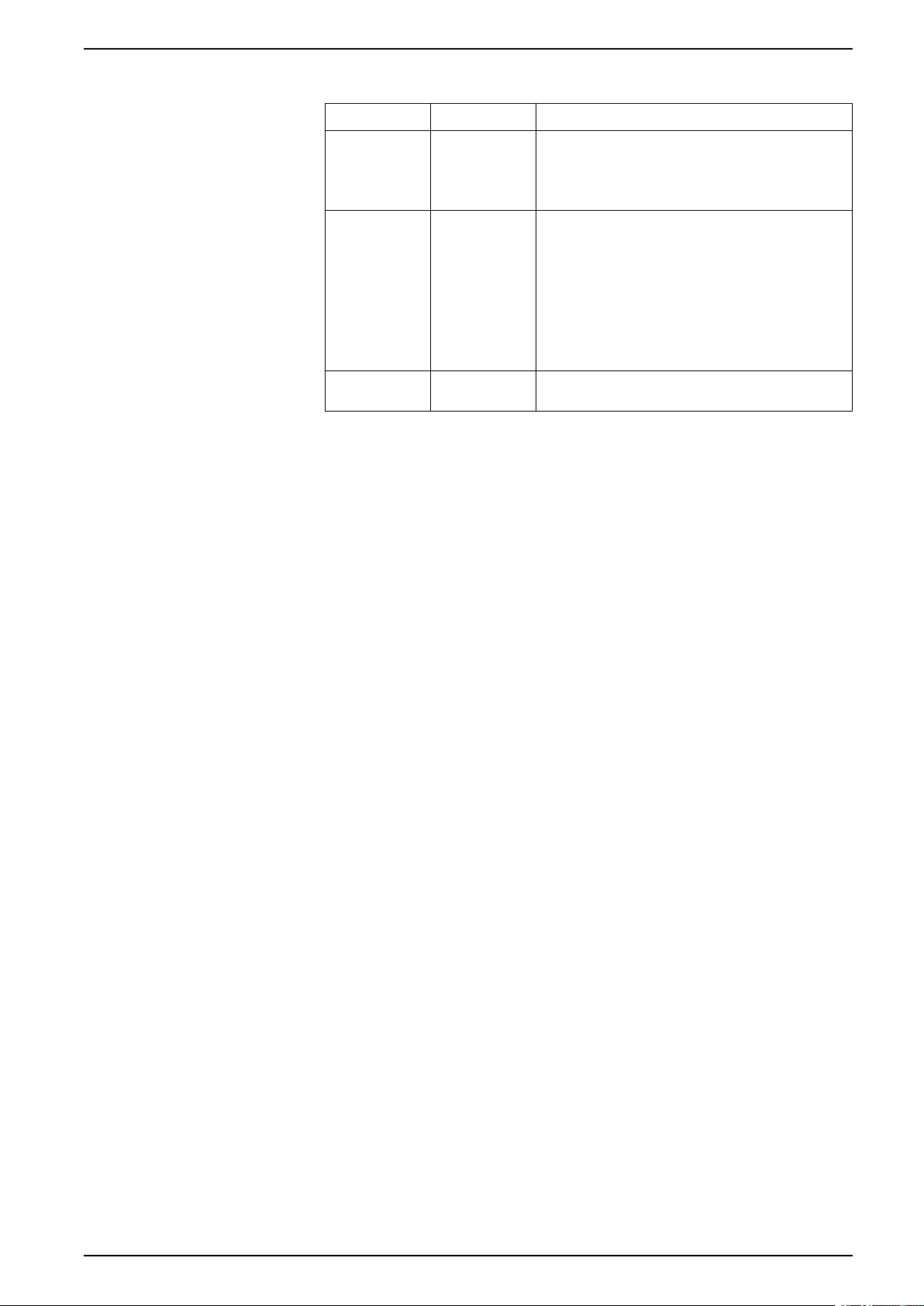

Command Accumulated

Reset sub systems Clear No Clear Clear

Initialization Clear No Clear Clear

Reset all energies Clear No clear No clear (update with

Reset all accumulated

energies

energies

Clear No clear No clear (update with

Non Reset

energies

Old energies

Accumulated

energies)

Accumulated

energies)

The meter provides last, present, predicted, and maximum (peak) demand values,

and a timestamp when the maximum (peak) demand occurred.

The meter supports standard demand calculation methods, including sliding block,

fixed block, rolling block, thermal and synchronized.

Peak demand registers can be reset manually (password protected).

Demand measurements include:

• W, VAR, VA demand total

• Amps demand average

2. Indicated features can be read through communication only.

12 QGH9011501-02

Introduction EasyLogic™PM2200R series

Instantaneous

The meter provides highly accurate 1-second measurements, average values,

including true RMS, per phase and total for:

• Per phase and average voltage (line-to-line, line-to-neutral)

• Per phase and average current, and neutral current

NOTE: Neutral current is calculated.

• Per phase and total power (VA, W, Var)

• Per phase and average for true and displacement power factor

• System frequency

• Per phase and maximum of all three for voltage unbalance and current

unbalance

Power quality

The meter provides complete harmonic distortion metering, recording, and realtime reporting, up to the 15

PM2230R for all voltage and current inputs.

The following power quality measurements are available:

Data recording (PM2230R)

The meter stores each new minimum and new maximum value with date and

timestamp for all instantaneous values (average, total, and each phase).

The meter also records the following:

Input/output (PM2230R)

th

harmonic for PM2220R and up to 31stharmonic for

• PM2220R: Individual odd harmonics up to 15

th

order (Voltage and current, per

phase)

• PM2230R: Individual odd harmonics up to 31

st

order (Voltage and current, per

phase)

• Total harmonic distortion (THD%) for current and voltage (displays line-to-line

or line-to-neutral, based on selected system configuration)

• Alarms (with 1s timestamping)

• Parameters configured for data logging

• Data, alarm history, and diagnostics logs

The meter supports optional input and output capabilities.

Other measurements

Additional measurements recorded by the meter include several timers.

These timers include:

• PM2230RI/O timer displays the powered ON duration of the input or output.

• Operating timer displays the powered ON duration of the meter.

• Active load timer displays the duration of the connected load, based on the

specified minimum current for the load timer setpoint setting.

QGH9011501-02 13

EasyLogic™PM2200R series Introduction

Data display and analysis tools

Power Monitoring Expert

EcoStruxure™Power Monitoring Expert is a complete supervisory software

package for power management applications.

The software collects and organizes data gathered from your facility’s electrical

network and presents it as meaningful, actionable information via an intuitive web

interface.

Power Monitoring Expert communicates with devices on the network to provide:

• Real-time monitoring through a multi-user web portal

• Trend graphing and aggregation

• Power quality analysis and compliance monitoring

• Preconfigured and custom reporting

See the EcoStruxure

how to add your device into its system for data collection and analysis.

Power SCADA Operation

™

Power Monitoring Expert online help for instructions on

Meter configuration

EcoStruxure™Power SCADA Operation is a complete real-time monitoring and

control solution for large facility and critical infrastructure operations.

It communicates with your device for data acquisition and real-time control. You

can use Power SCADA Operation for:

• System supervision

• Real-time and historical trending, event logging

• PC-based custom alarms

See the EcoStruxure

how to add your device into its system for data collection and analysis.

Meter configuration can be performed through the display or PowerLogic™ION

Setup.

ION Setup is a meter configuration tool that can be downloaded for free at

www.se.com.

See the ION Setup online help or in the ION Setup device configuration guide. To

download a copy, go to www.se.com and search for ION Setup device

configuration guide.

™

Power SCADA Operation online help for instructions on

14 QGH9011501-02

Hardware reference EasyLogic™PM2200R series

Hardware reference

PM2200R meter models and accessories

The PM2200R meter is available in one physical form factor and variant.

Meter models

Model Commercial reference Description

PM2210R METSEPM2210R Front panel mount, 96 x 96 mm form factor,

PM2220R METSEPM2220R Front panel mount, 96 x 96 mm form factor,

PM2230R METSEPM2230RCL05 Front panel mount, 96 x 96 mm form factor,

EasyLogic VAF power and energy meter with THD%

and POP.

EasyLogic VAF power and energy meter with RS-485

communication and odd harmonics up to 15

EasyLogic VAF power and energy meter with RS-485

communication and odd harmonics up to 31

NOTE: The I/O modules are supported byPM2230R models only.

Meter accessories

Model Commercial reference Description

2 Channel Digital Input Output Module METSEPM2KDGTLIO22 and

2 Channel Analog Input Output Module METSEPM2KANLGIO22 and

1 Channel Analog Input Output Module METSEPM2KANLGIO11 and

2 Channel Digital Input and Relay

Output Module

METSEPM2KDGTLIO22D

METSEPM2KANLGIO22D

METSEPM2KANLGIO11D

METSEPM2K2DI2RO and

METSEPM2K2DI2ROD

Digital I/O module with 2 channel input and output.

Analog I/O module with 2 channel input and output.

Analog I/O module with single channel input and

output.

Relay module with dual channel digital input and

relay output.

th

st

order.

order.

NOTE: Only use LVCT specified by Schneider Electric.

LVCT available options (Schneider Electric make)

LVCT (0.333V AC) Current ratings

METSECTV250xx series 60 A, 100 A, 125 A, 160 A

METSECTV290xx series 60 A, 100 A, 120 A, 125 A, 150 A, 160 A, 200 A

METSECTV350xx series 60 A, 100 A, 120 A, 125 A, 150 A, 160 A, 200 A, 250 A

METSECTV450xx series 250 A, 300 A, 400 A, 500 A, 600 A, 630 A

METSECTV70xxx series 800 A, 1000 A, 1250 A

RJ45 CAT 5e (Schneider Electric)

DCEPCURJ01GYM

DCEPCURJ02GYM

DCEPCURJ03GYM

DCEPCURJ05GYM

DCEPCURJ10GYM

DCEPCURJX5GYM

QGH9011501-02 15

EasyLogic™PM2200R series Hardware reference

See the PM2200R series catalog pages, available from www.se.com, or consult

your local Schneider Electric representative for information available for your

meter.

Supplemental information

This document is intended to be used in conjunction with the installation sheet that

ships in the box with your device and accessories.

See your device’s installation sheet for information related to installation.

See your product’s catalog pages at www.se.com for information about your

device, its options and accessories.

You can download updated documentation from www.se.com or contact your local

Schneider Electric representative for the latest information about your product.

Meter mounting and wiring

For mounting and wiring instructions and safety precautions, see the installation

sheet that was shipped with your device

You can also download the latest copy at www.se.com.

Meter wiring considerations

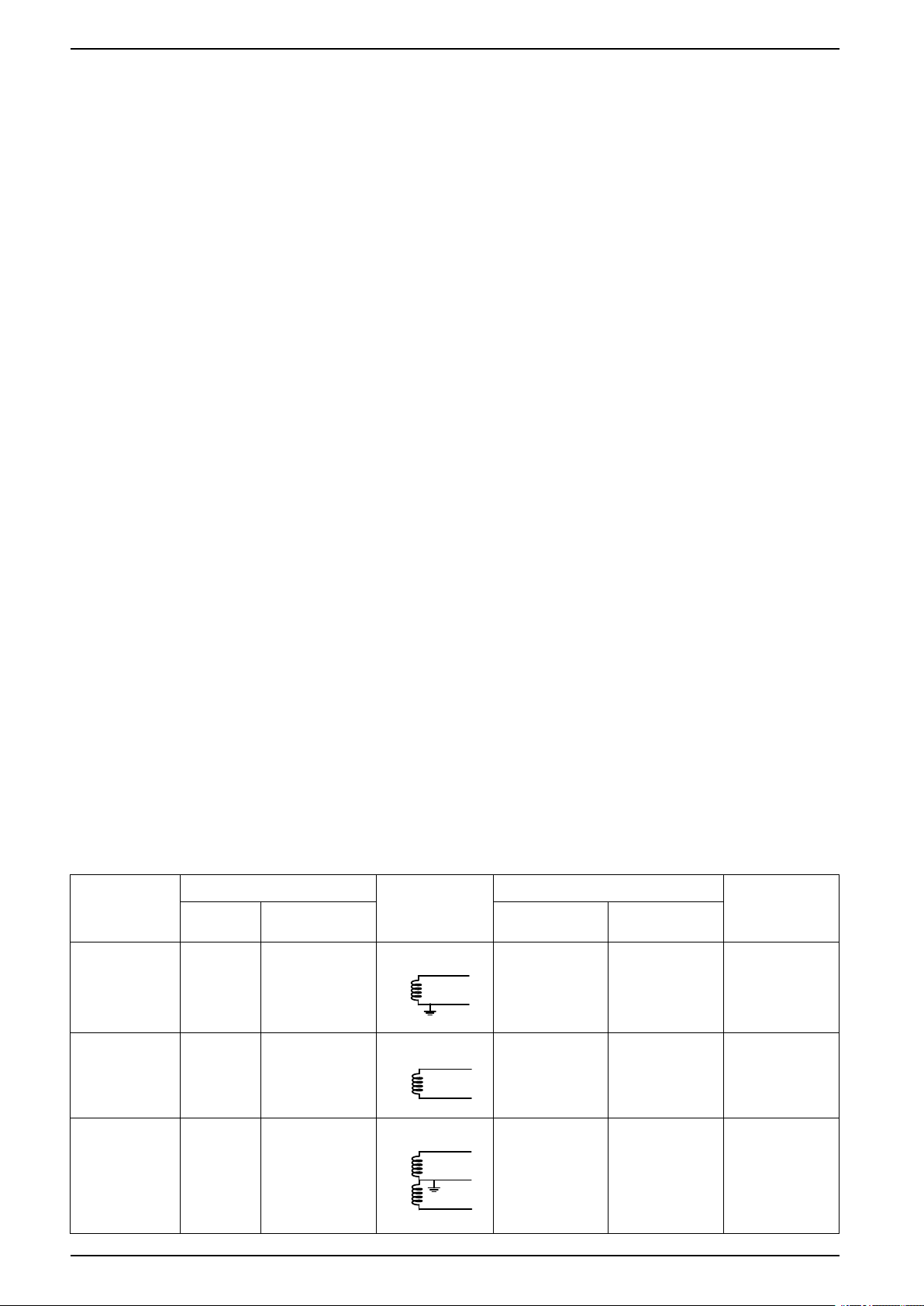

Direct connect voltage limits

You can connect the meter’s voltage inputs directly to the phase voltage lines of

the power system if the power system’s line-to-line or line-to-neutral voltages do

not exceed the meter’s direct connect maximum voltage limits.

The meter's voltage measurement inputs are rated by the manufacturer for up to

277 V L-N / 480 V L-L. However, the maximum voltage allowed for direct

connection may be lower, depending on the local electrical codes and regulations.

As per installation category II / III the maximum voltage on the meter voltage

measurement inputs should not exceed 277 V L-N / 480 V L-L for CAT III and 347

V L-N / 600 V L-L for CAT II.

If your system voltage is greater than the specified direct connect maximum

voltage, you must use VTs (voltage transformers) to step down the voltages.

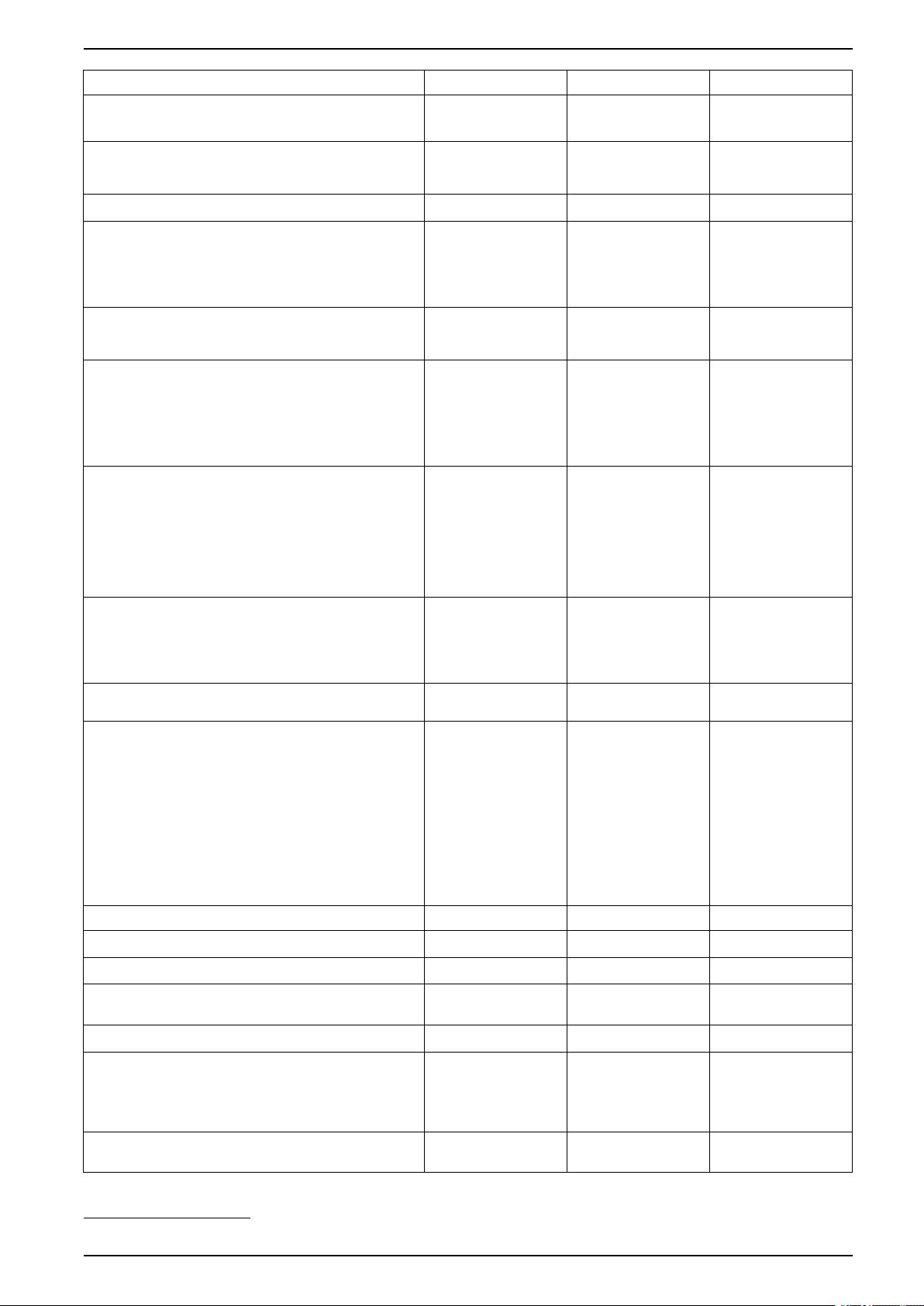

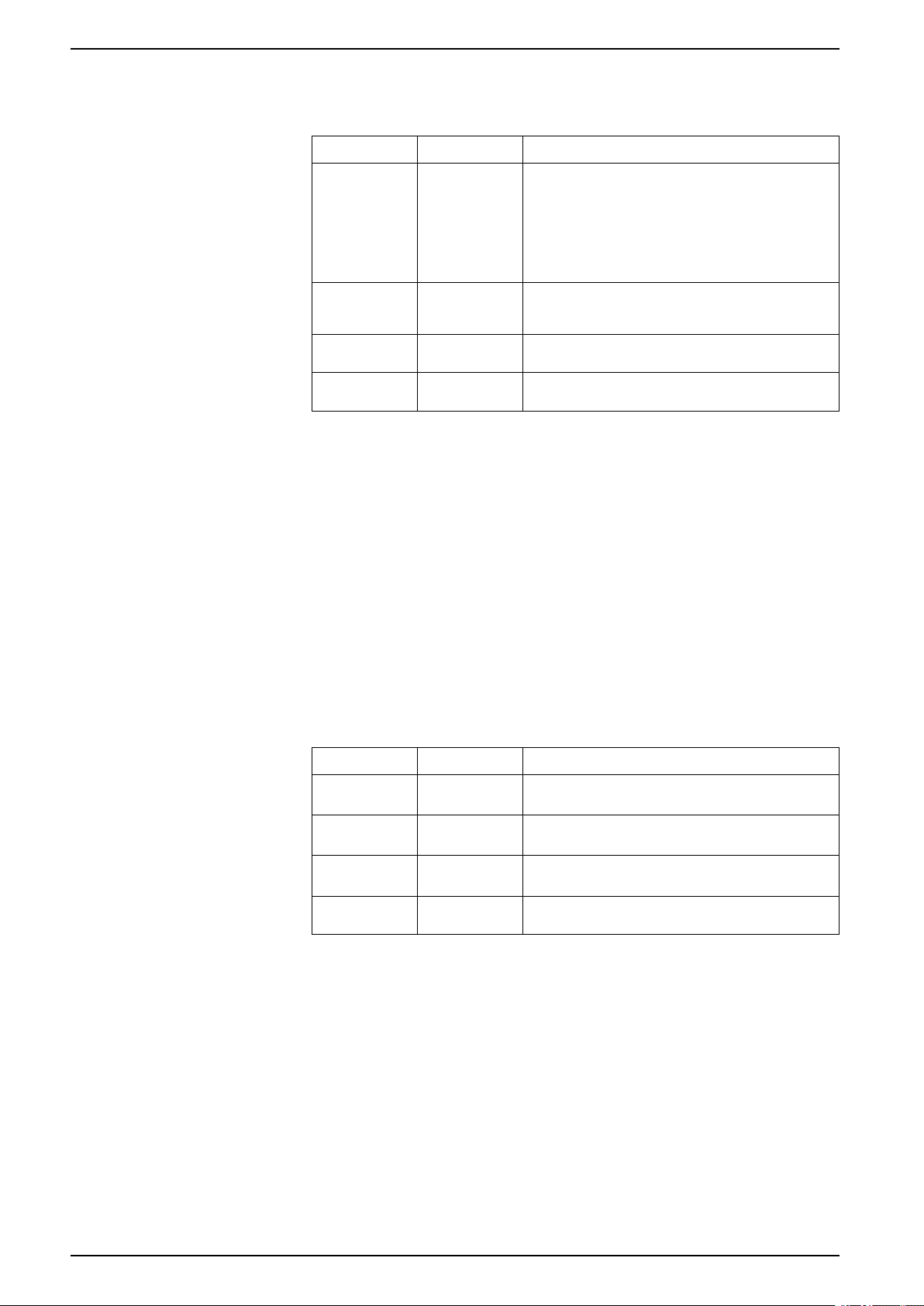

Power system

description

Single-phase 2wire line-toneutral

Meter setting Symbol Direct connect maximum (UL / IEC) # of VTs (if

Display

(meter)

1PH2W LN 1PH 2Wire L-N

Display

(communication)

Installation

category III

≤ 277 V L-N ≤ 347 V L-N 1 VT

Installation

category II

required)

Single-phase 2wire line-to-line

Single-phase 3wire line-to-line

with neutral

16 QGH9011501-02

1PH2W LL 1PH 2Wire L-L

1PH3W LL

With N

1PH 3Wire L-L

with N

480 V L-L 600 V L-L 1 VT

≤ 277 V L-N / 480

V L-L

≤ 347 V L-N / 600

V L-L

2 VT

Hardware reference EasyLogic™PM2200R series

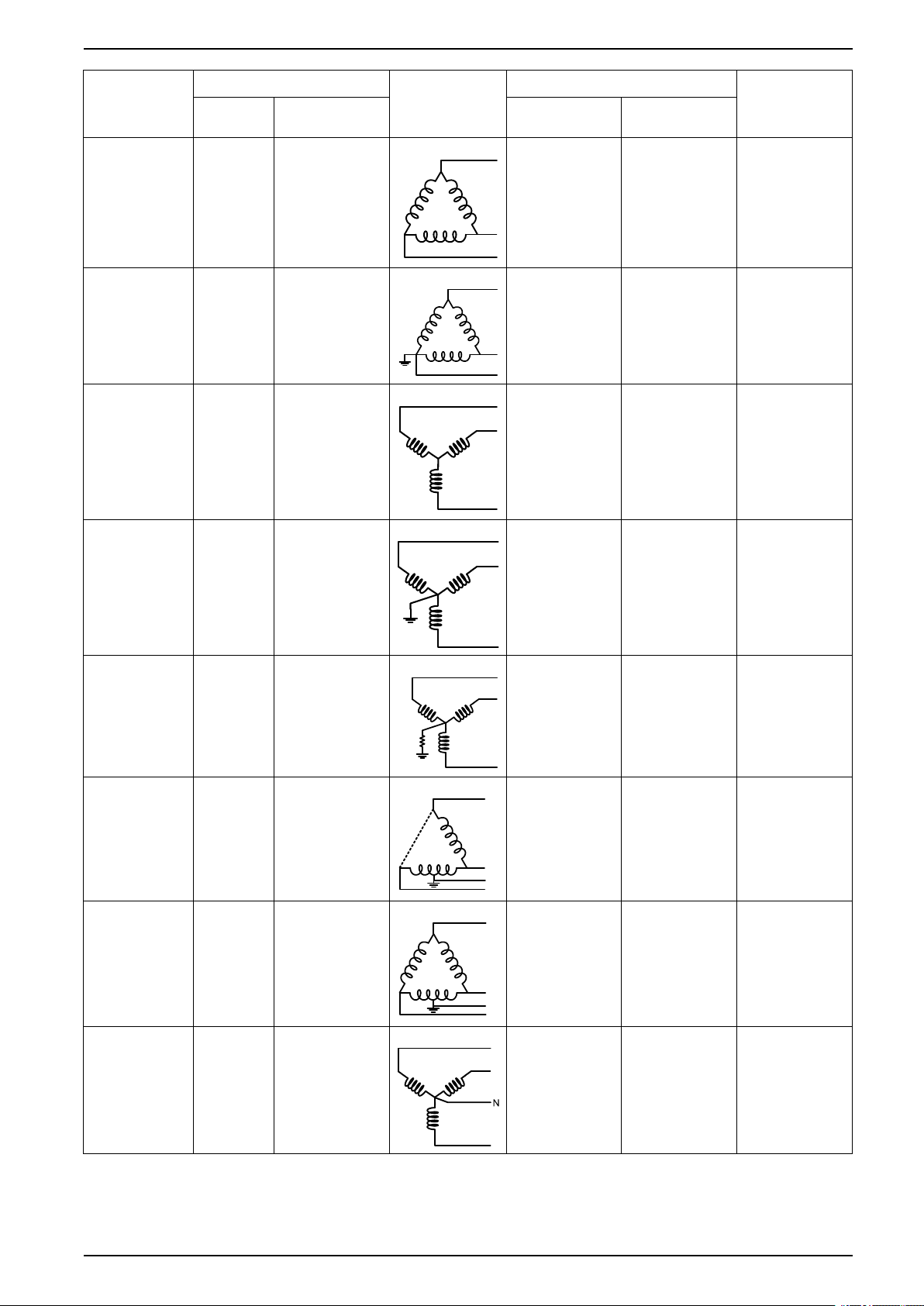

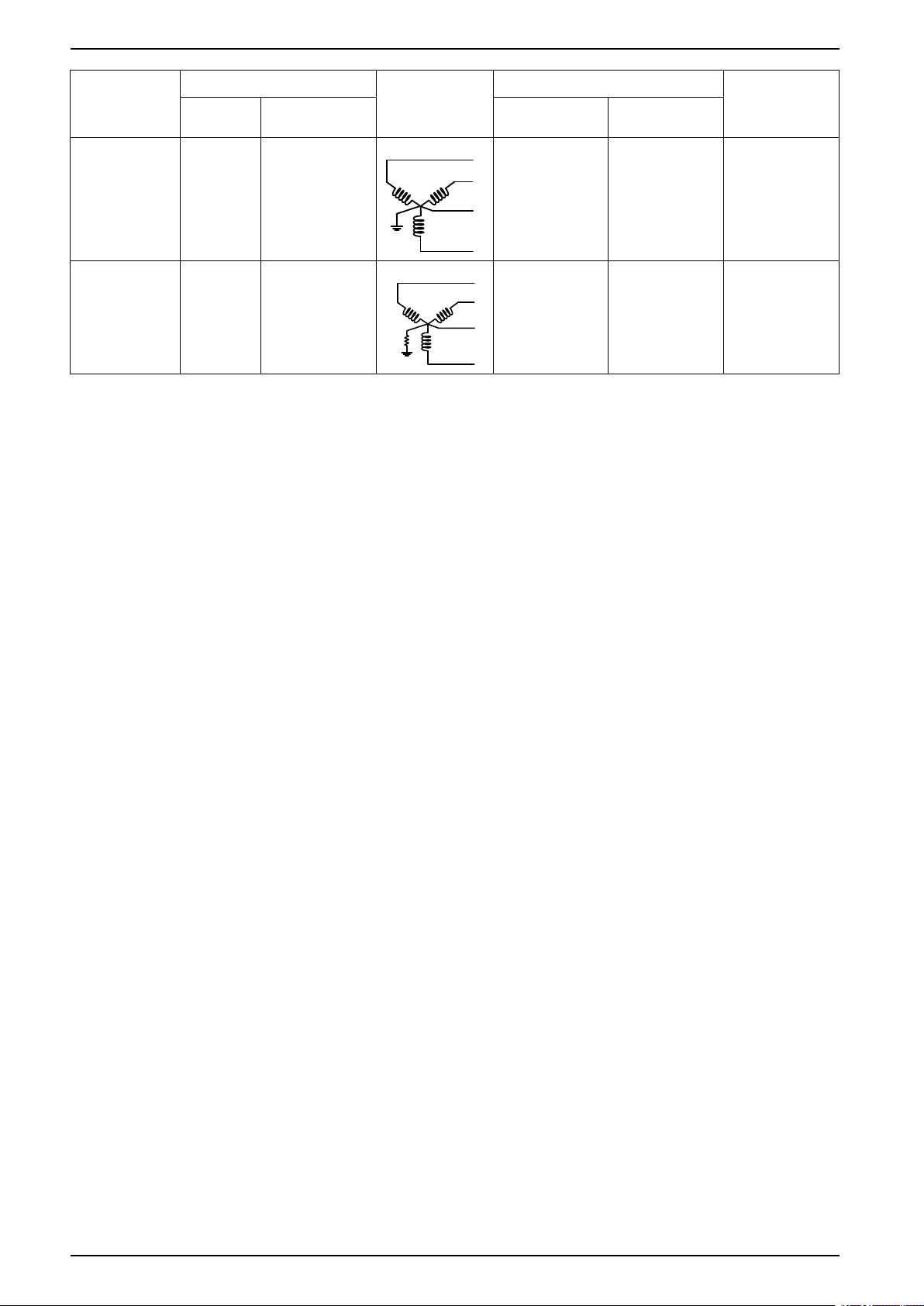

N

N

Power system

description

3-phase 3-wire

Delta

ungrounded

3-phase 3-wire

Delta corner

grounded

3-phase 3-wire

Wye ungrounded

3-phase 3-wire

Wye grounded

Meter setting Symbol Direct connect maximum (UL / IEC) # of VTs (if

required)

Display

(meter)

3PH3W Dlt

Ungnd

3PH3W Dlt

Crnr Gnd

Display

(communication)

3PH 3Wire

Ungrounded Delta

3PH 3Wire

Corner Grounded

Installation

category III

Installation

category II

480 V L-L 600 V L-L 2 VT

480 V L-L 600 V L-L 2 VT

Delta

3PH3W

Wye Ungnd

3PH3W

Wye Gnd

3PH 3Wire

Ungrounded Wye

3PH 3Wire

Grounded Wye

480 V L-L 600 V L-L 2 VT

480 V L-L 600 V L-L 2 VT

3-phase 3-wire

Wye resistancegrounded

3-phase 4-wire

open Delta

center-tapped

3-phase 4-wire

Delta centertapped

3-phase 4-wire

ungrounded Wye

3PH3W

Wye Res

Gnd

3PH4W

Opn Dlt Ctr

Tp

3PH4W Dlt

Ctr Tp

3PH4W

Wye Ungnd

3PH 3Wire

Resistance

Grounded Wye

3PH 4Wire

Center-Tapped

Open Delta

3PH 4Wire

Center-Tapped

Delta

3PH 4Wire

Ungrounded Wye

480 V L-L 600 V L-L 2 VT

240 V L-N / 480 V

L-L

240 V L-N / 480 V

L-L

≤ 277 V L-N / 480

V L-L

240 V L-N / 480 V

L-L

240 V L-N / 480 V

L-L

≤ 347 V L-N / 600

V L-L

3 VT

3 VT

3 VT or 2 VT

QGH9011501-02 17

EasyLogic™PM2200R series Hardware reference

N

N

Power system

description

3-phase 4-wire

grounded Wye

3-phase 4-wire

resistancegrounded Wye

Meter setting Symbol Direct connect maximum (UL / IEC) # of VTs (if

Display

(meter)

3PH4W

Wye Gnd

3PH4W

Wye Res

Gnd

Display

(communication)

3PH 4Wire

Grounded Wye

3PH 4Wire

Resistance

Grounded Wye

Balanced system considerations

In situations where you are monitoring a balanced 3-phase load, you may choose

to connect only one or two CTs on the phase(s) you want to measure, and then

configure the meter so it calculates the current on the unconnected current

input(s).

NOTE: For a balanced 4-wire Wye system, the meter’s calculations assume

that there is no current flowing through the neutral conductor.

Installation

category III

≤ 277 V L-N / 480

V L-L

≤ 277 V L-N / 480

V L-L

Installation

category II

≤ 347 V L-N / 600

V L-L

≤ 347 V L-N / 600

V L-L

required)

3 VT or 2 VT

3 VT or 2 VT

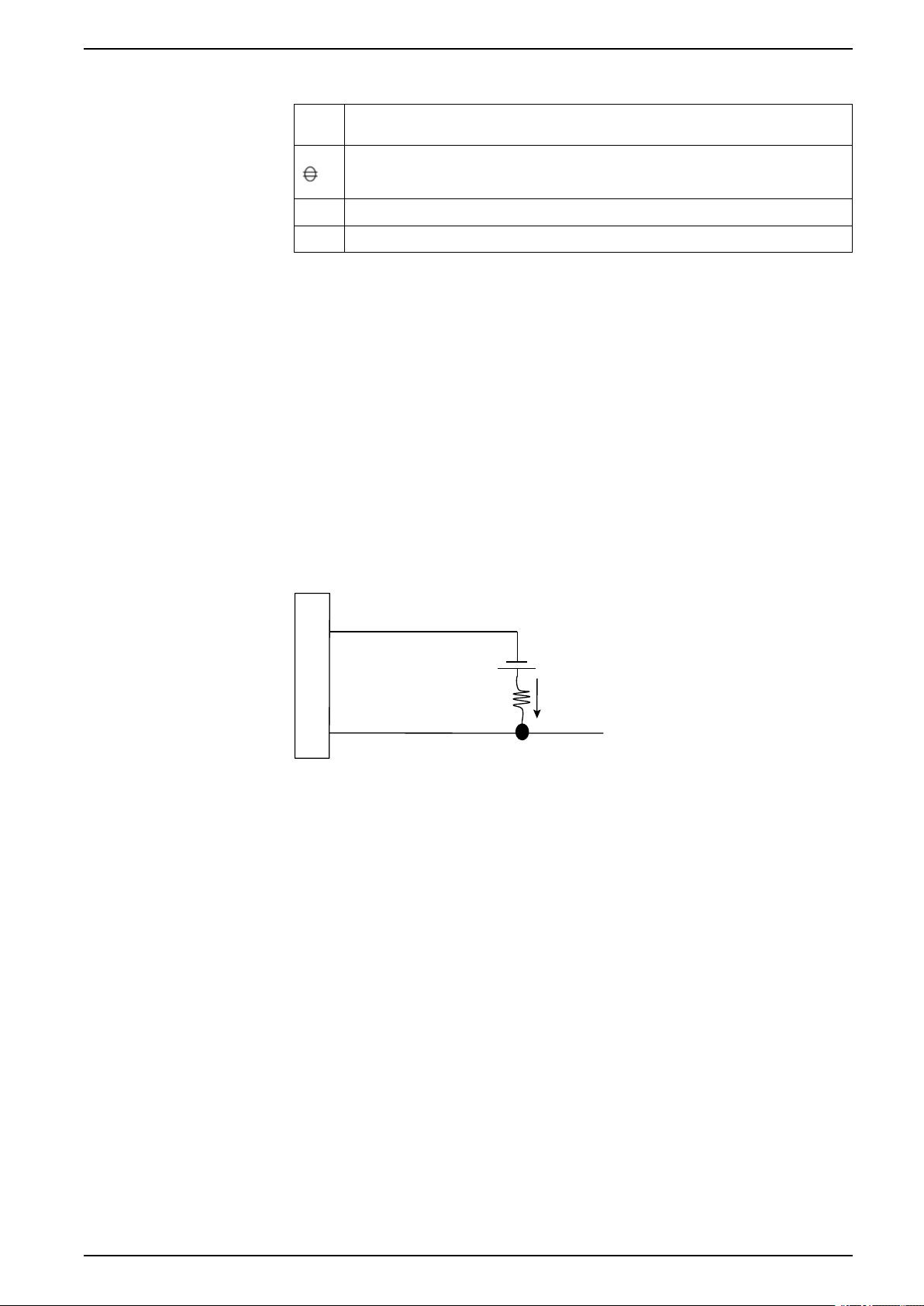

RS-485 wiring

RS-485 cable

Balanced 3-phase Wye system with 2 CTs

The current for the unconnected current input is calculated so that the vector sum

for all three phases equal zero.

Balanced 3-phase Wye or Delta system with 1CT

The currents for the unconnected current inputs are calculated so that their

magnitude and phase angle are identical and equally distributed, and the vector

sum for all three phase currents equal zero.

NOTE: You must always use 3 CTs for 3-phase 4-wire center-tapped Delta or

center-tapped open Delta systems.

Connect the devices on the RS-485 bus in a point-to-point configuration, with the

(+) and (-) terminals from one device connected to the corresponding (+) and (-)

terminals on the next device.

Use a shielded 2 twisted pair or 1.5 twisted pair RS-485 cable to wire the devices.

Use one twisted pair to connect the (+) and (-) terminals, and use the other

insulated wire to connect the C terminals

The total distance for devices connected on an RS-485 bus should not exceed

1000 m (3280 ft).

18 QGH9011501-02

Hardware reference EasyLogic™PM2200R series

D1+

≤40V

≤20mA

D1-

(60)

(61)

RS-485 terminals

C Common. This provides the voltage reference (zero volts) for the data plus and data minus

signals

Shield. Connect the bare wire to this terminal to help suppress signal noise that may be

present. Ground the shield wiring at one end only (either at the master or the last slave

device, but not both.

-

Data minus. This transmits/receives the inverting data signals.

+

Data plus. This transmits/receives the non-inverting data signals.

NOTE: If some devices in your RS-485 network do not have the C terminal,

use the bare wire in the RS-485 cable to connect the C terminal from the

meter to the shield terminal on the devices that do not have the C terminal.

Pulse output

NOTE: Applicable only for PM2210R meter model

The meter is equipped with one pulse output port (D1+, D1-).

You can configure the pulse outputs for use in the following application:

• energy pulsing applications, where a receiving device determines energy

usage by counting the k_h pulses coming from the meter’s pulse output port.

One pulse output can handle voltage less than or equal to 40 V DC (20 mA

maximum). For higher voltage applications, use an external relay in the switching

circuit.

QGH9011501-02 19

EasyLogic™PM2200R series Meter display

C

G

E

F

D

B

A

H

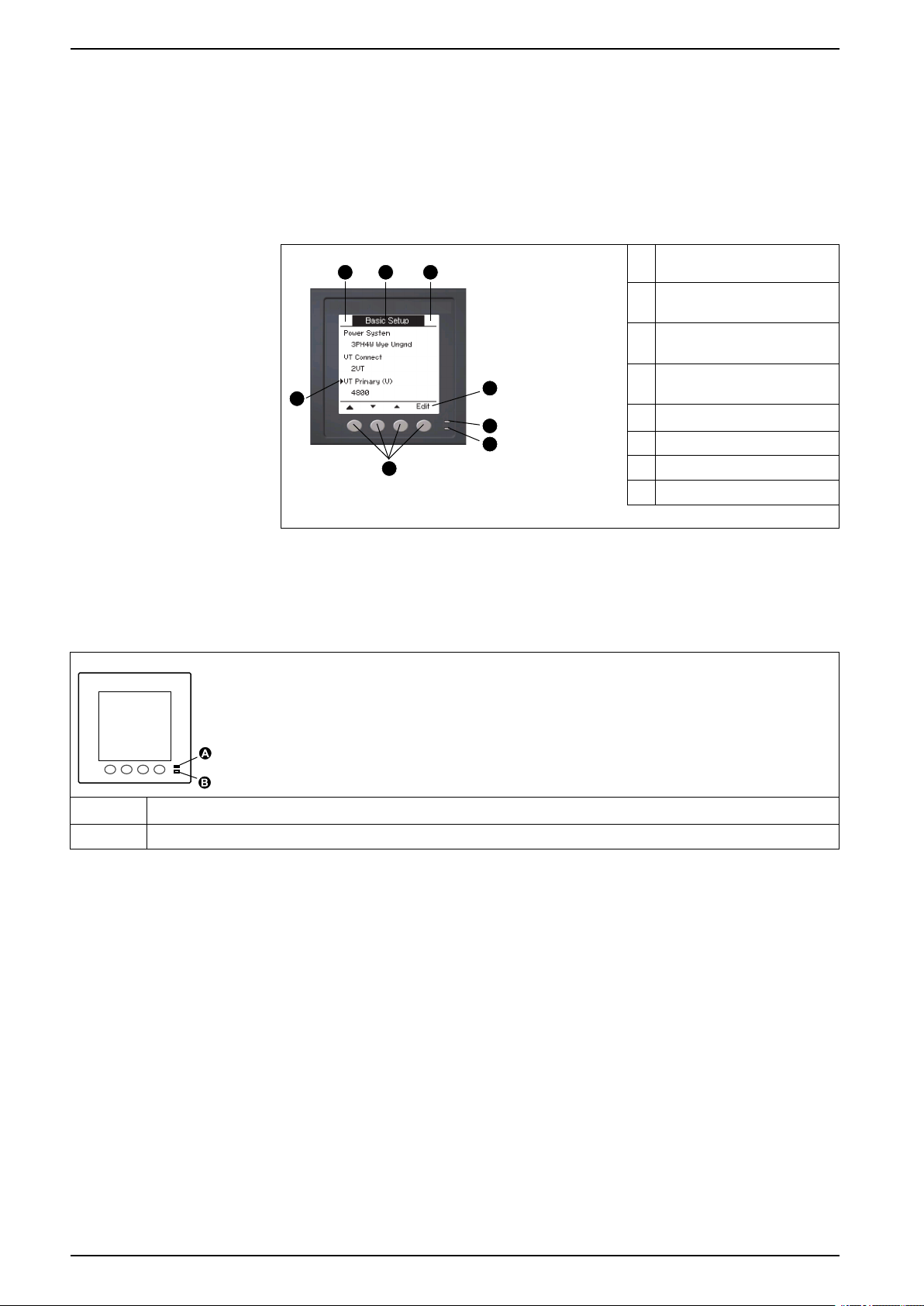

Meter display

Display overview

The display (integrated or remote) lets you use the meter to perform various tasks

such as setting up the meter, displaying data screens, acknowledging alarms, or

performing resets.

A Navigation / menu selection

buttons

B Heartbeat / communications

LED (green)

C Alarm / energy pulsing LED

(orange)

D Navigation symbols or menu

options

E Right notification area

F Screen title

G Left notification area

H Cursor

LED indicators

The LED indicators alert or inform you of meter activity.

A Alarm / energy pulsing LED

B Heartbeat / serial communications LED

Alarm / energy pulsing LED

The alarm / energy pulsing LED can be configured for alarm notification or energy

pulsing.

When configured for alarm notification, this LED blinks every one second

indicating that a high, medium or low priority alarm is tripped. The LED provides a

visual indication of an active alarm condition or an inactive but unacknowledged

high priority alarm.

When configured for energy pulsing, this LED flashes at a rate proportional to the

amount of energy consumed. This is typically used to verify the power meter’s

accuracy.

Heartbeat / serial communications LED

The heartbeat / serial communications LED blinks to indicate the meter’s

operation and serial Modbus communications status.

20 QGH9011501-02

Meter display EasyLogic™PM2200R series

The LED blinks at a slow, steady rate to indicate the meter is operational. The LED

flashes at a variable, faster rate when the meter is communicating over a Modbus

serial communications port.

You cannot configure this LED for other purposes.

NOTE: A heartbeat LED that remains lit and does not blink (or flash) can

indicate a problem. In this case, power down the meter and reapply power. If

the LED still does not blink or flash, contact Technical Support.

Notification icons

To alert you about meter state or events, notification icons appear at the top left or

top right corner of the display screen.

Icon Description

The wrench icon indicates that the power meter is in an overvoltage

condition or requires maintenance. It could also indicate that the

energy LED is in an overrun state.

The alarm icon indicates an alarm condition has occurred.

Meter display language

If your meter is equipped with a display screen, you can configure the meter to

display the measurements in one of several languages.

The following languages are available:

• English

• French

• Spanish

• German

• Portuguese

• Russian

• Chinese

• Turkish

Meter screen navigation

The meter’s buttons and display screen allow you to navigate data and setup

screens, and to configure the meter’s setup parameters.

QGH9011501-02 21

EasyLogic™PM2200R series Meter display

Amps [I] Volts [U-V] Energy [E]

PF

Hz [F]

Maint

Power [PQS]

THD

Unbal

MnMx

(+1)

Alarm

(+2)

Timer

(+1)

Clock

(+1)

Harm

(+1)

Rate

Fav

(+1)

Snap

(+1)

I/O

(+2)

(+1)

Applicable only for PM2220R/PM2230R meter models

(+2)

Applicable only for PM2230R meter model

A. Press the button below the

appropriate menu to view

that screen

B. Press the right arrow to

view more screens

C. In setup mode, a small

right arrow indicates the

selected option

D. In setup mode, a small

down arrow indicates that

there are additional

parameters to display. The

down arrow disappears

when there are no more

parameters to display.

E. In setup mode, press the

button under Edit to

change that setting. If the

item is read-only, cannot

be configured with the

meter’s existing setup, or

can only be configured

using software, Edit

disappears.

Navigation symbols

Navigation symbols indicate the functions of the associated buttons on your

meter’s display.

Symbol Description Actions

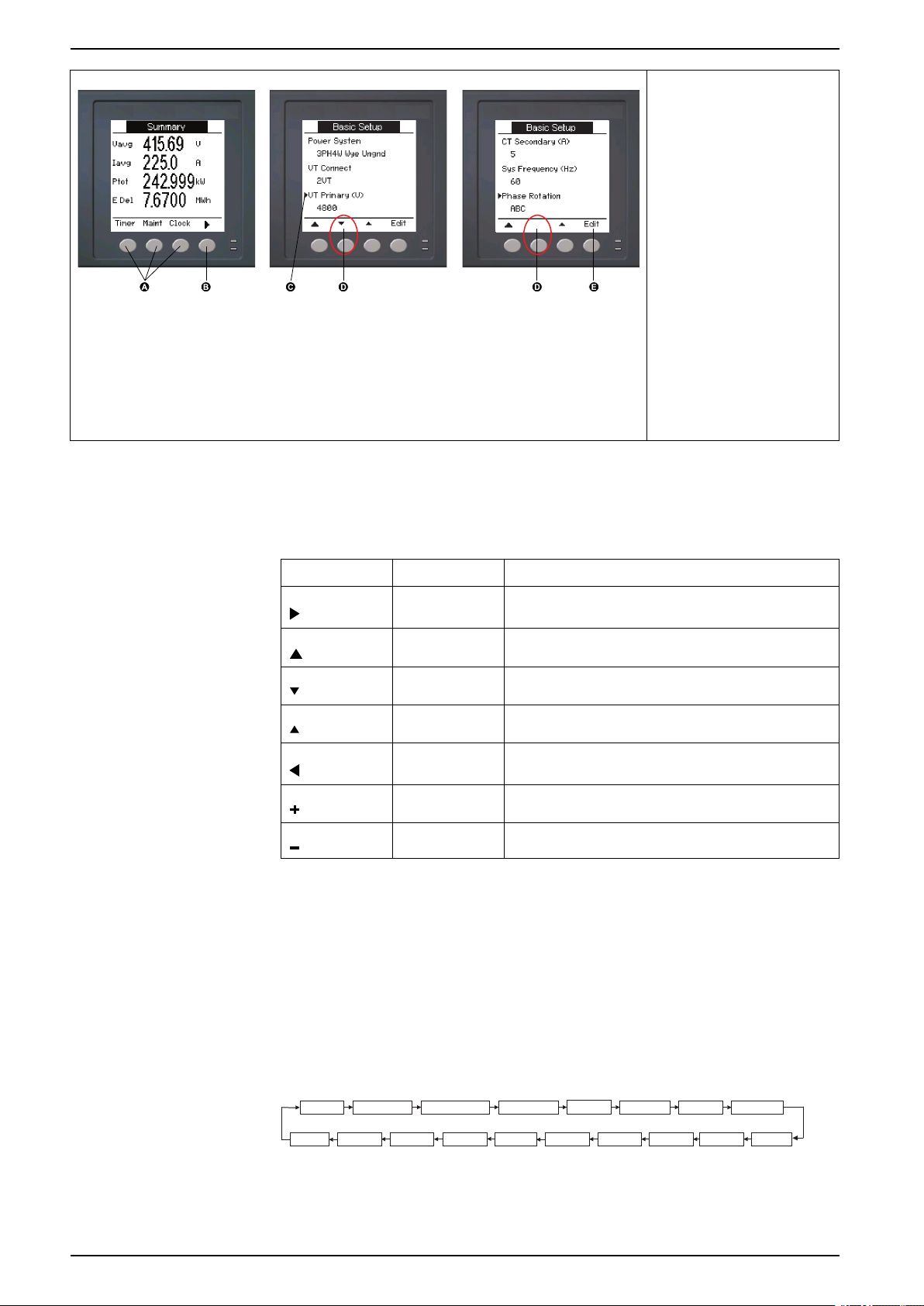

When you reach the last screen, press the right arrow again to cycle through the

screen menus.

Meter screen menus overview

Right arrow Scroll right and display more menu items or move cursor

one character to the right

Up arrow Exit screen and go up one level

Small down

arrow

Move cursor down the list of options or display more items

below

Small up arrow Move cursor up the list of items or display more items

above

Left arrow Move cursor one character to the left

Plus sign Increase the highlighted value or show the next item in the

list.

Minus sign Show the previous item in the list

22 QGH9011501-02

All meter screens are grouped logically, according to their function.

You can access any available meter screen by first selecting the Level 1 (top level)

screen that contains it.

Level 1 screen menus - IEEE title [IEC title]

Meter display EasyLogic™PM2200R series

Setting up the display

You can change the display screen’s settings, such as contrast, backlight timeout,

and screen timeout .

1. Navigate to Maint > Setup.

2. Enter the setup password (default is “0”), then press OK.

3. Navigate to HMI > Disp.

4. Move the cursor to point to the parameter you want to modify, then press

Edit.

5. Modify the parameter as required, then press OK.

6. Move the cursor to point to the next parameter you want to modify, press Edit,

make your changes, then press OK.

7. Press the up arrow to exit.

8. Press Yes to save your changes.

Display settings available using the display

Parameter Values Description

Contrast 1 - 9 Increase or decrease the value to increase or decrease

Bcklght Timeout

(min)

Screen Timeout

(min)

0 - 60 Set how long (in minutes) before the backlight turns off

0 - 60 Set how long (in minutes) before the screen turns off

the display contrast.

after a period of inactivity. Setting this to “0” disables

the backlight timeout feature (i.e., backlight is always

on).

after a period of inactivity. Setting this to “0” disables

the screen timeout feature (i.e., display is always on).

To configure the display using ION Setup, see the “PM2000” topic in the ION

Setup online help or in the ION Setup device configuration guide, available for

download at www.se.com.

QGH9011501-02 23

EasyLogic™PM2200R series Meter Setup

Meter Setup

Configuring basic setup parameters using the display

You can configure basic meter parameters using the display.

Proper configuration of the meter’s basic setup parameters is essential for

accurate measurement and calculations. Use the Basic Setup screen to define the

electrical power system that the meter is monitoring.

If standard (1-sec) alarms have been configured and you make subsequent

changes to the meter’s basic setup, all alarms are disabled to prevent undesired

alarm operation.

NOTICE

UNINTENDED EQUIPMENT OPERATION

• Verify all standard alarms settings are correct and make adjustments as

necessary.

• Re-enable all configured alarms.

Failure to follow these instructions can result in equipment damage.

After saving the changes, confirm all configured standard alarm settings are still

valid, reconfigure them as required, and re-enable the alarms.

1. Navigate to Maint > Setup.

2. Enter the setup password (default is “0”), then press OK.

3. Navigate to Meter > Basic.

4. Move the cursor to point to the parameter you want to modify, then press

Edit.

5. Modify the parameter as required, then press OK.

6. Move the cursor to point to the next parameter you want to modify, press Edit,

make your changes, then press OK.

24 QGH9011501-02

Meter Setup EasyLogic™PM2200R series

7. Press Yes to save your changes.

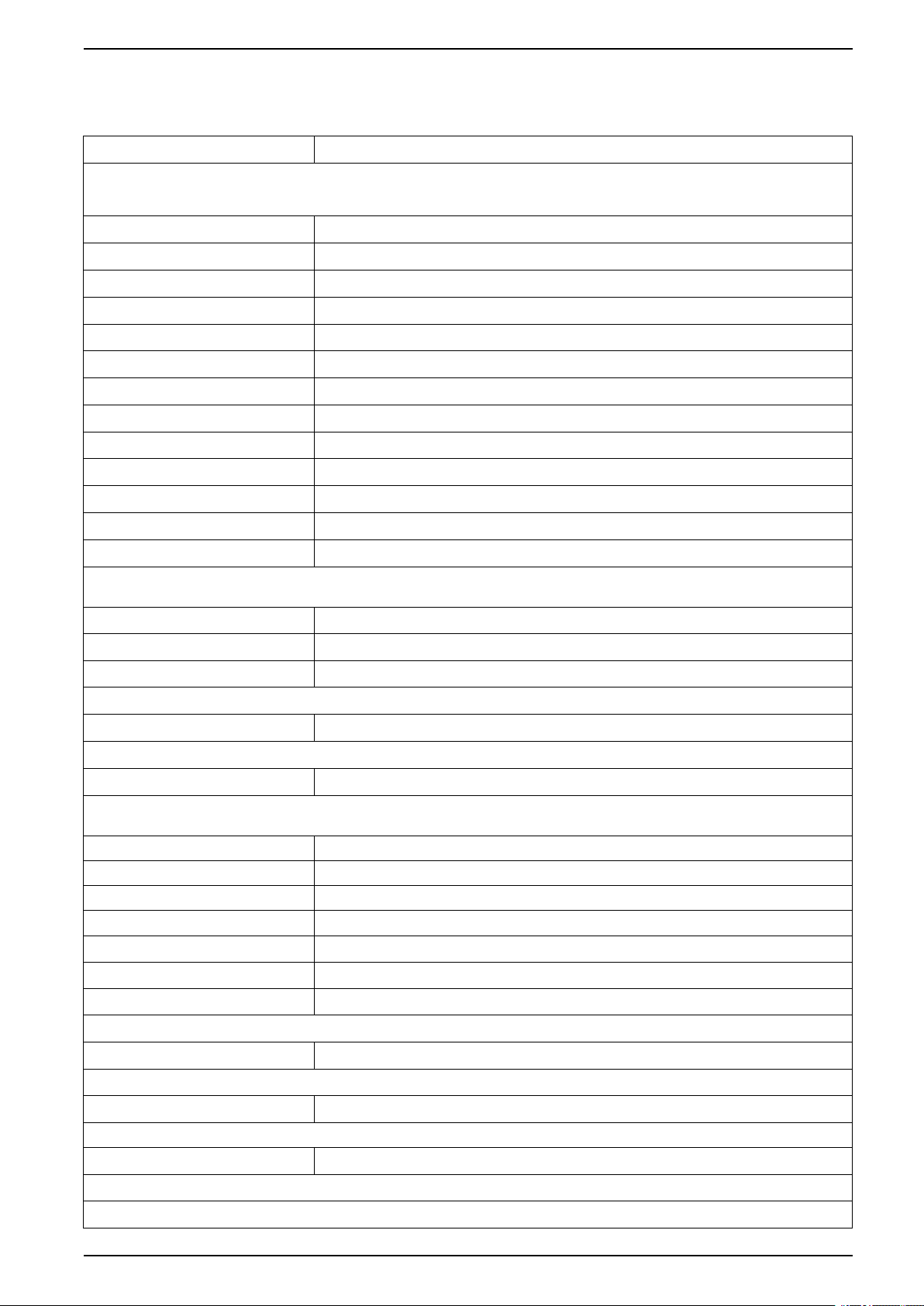

Basic setup parameters available using the display

Values Description

Power System

Select the power system type (power transformer) the meter is wired to.

1PH2W LN Single-phase 2-wire line-to-neutral

1PH2W LL Single-phase 2-wire line-to-line

1PH3W LL with N Single-phase 3-wire line-to-line with neutral

3PH3W Dlt Ungnd 3-phase 3-wire ungrounded delta

3PH3W Dlt Crnr Gnd 3-phase 3-wire corner grounded delta

3PH3W Wye Ungnd 3-phase 3-wire ungrounded wye

3PH3W Wye Gnd 3-phase 3-wire grounded wye

3PH3W Wye Res Gnd 3-phase 3-wire resistance-grounded wye

3PH4W Opn Dlt Ctr Tp 3-phase 4-wire center-tapped open delta

3PH4W Dlt Ctr Tp 3-phase 4-wire center-tapped delta

3PH4W Wye Ungnd 3-phase 4-wire ungrounded wye

3PH4W Wye Gnd 3-phase 4-wire grounded wye

3PH4W Wye Res Gnd 3-phase 4-wire resistance-grounded wye

VT Connect

Select how many voltage transformers (VT) are connected to the electrical power system.

Direct Con Direct connect; no VTs used

2VT 2 voltage transformers

3VT 3 voltage transformers

VT Primary (V)

1 to 1,000,000 Enter the size of the VT primary, in Volts.

VT Secondary (V)

100, 110, 115, 120 Select the size of the VT secondary, in Volts.

CT on Terminal

Define how many current transformers (CT) are connected to the meter, and which terminals they are connected to.

I1 1 CT connected to I1 terminal

I2 1 CT connected to I2 terminal

I3 1 CT connected to I3 terminal

I1 I2 2 CT connected to I1, I2 terminals

I2 I3 2 CT connected to I2, I3 terminals

I1 I3 2 CT connected to I1, I3 terminals

I1 I2 I3 3 CT connected to I1, I2, I3 terminals

CT Primary (A)

60 to 1250A Automatically detected and configured.

Sys Frequency (Hz)

50, 60 Select the frequency of the electrical power system, in Hz.

Phase Rotation

I1I2I3, I3I2I1 Select the phase rotation of the 3-phase system.

Phase Polarity

Refer to HMI for phase polarity information.

QGH9011501-02 25

EasyLogic™PM2200R series Meter Setup

Basic setup parameters available using the display (Continued)

Values Description

A.Suppression

This is the minimum current at which the meter starts functioning. The meter can be configured to disregard the measurement of induced /

auxiliary load current in the circuit.

5 to 99 Select the Threshold Current (Suppression Current), in mA.

NOTE: The default suppression current is 5 mA.

Configuring advanced setup parameters using the display

You can configure a subset of advanced parameters using the display.

1. Navigate to Maint > Setup.

2. Enter the setup password (default is “0”), then press OK.

3. Navigate to Meter > Advan.

4. Move the cursor to point to the parameter you want to modify, then press

Edit.

5. Modify the parameter as required, then press OK.

6. Move the cursor to point to the next parameter you want to modify, press Edit,

make your changes, then press OK.

7. Press Yes to save your changes.

Advanced setup parameters available using the display

Parameter Values Description

Label

Load Timer Setpt (A) 0 - 9 Specifies the minimum average current at the load before the timer starts. The

Pk I dmd for TDD (A) 0 - 9 Specifies the minimum peak current demand at the load for inclusion in total

—

This label identifies the device, e.g., “Power Meter”. You cannot use the display to

edit this parameter. Use ION Setup to change the device label.

meter begins counting the number of seconds the load timer is on (i.e., whenever

the readings are equal to or above this average current threshold.

demand distortion (TDD) calculations. If the load current is below the minimum

peak current demand threshold, the meter does not use the readings to calculate

TDD. Set this to “0” (zero) if you want the power meter to use the metered peak

current demand for this calculation.

Setting the rate

The Rate setup screens allow you to set the different rate parameters.

1. Navigate to Maint > Setup.

2. Enter the setup password (default is “0”), then press OK.

3. Navigate to Rate.

4. Move the cursor to point to Rate1 or Rate2 to modify, then press Edit.

5. Move the cursor to point to Channel or Factor per (k__h) to modify, then

press Edit.

6. Modify the parameter as required, then press OK.

7. Press up arrow and press Yes to save your changes.

26 QGH9011501-02

Meter Setup EasyLogic™PM2200R series

8. Press the up arrow to exit.

Parameter Values Description

Label Rate1 / Rate2

Channel None, Active

Factor per (k__

h)

To configure the Rate using ION Setup, see the “PM2000 series meter” topic

in the ION Setup online help or in the ION Setup device configuration guide,

available for download at www.se.com.

Setting up regional settings

You can change the regional settings to localize the meter screens and display

data in a different language, using local standards and conventions.

NOTE: In order to display a different language other than those listed in the

Language setup parameter, you need to download the appropriate language

file to the meter using the firmware upgrade process.

Example: CO2

Emission,

Energy Cost

Del, Active Rec,

Active Del +

Rec, Reactive

Del, Reactive

Rec, Reactive

Del + Rec,

Apparent Del,

Apparent Rec,

Apparent Del +

Rec

0.000 to

99999.999

You can edit the label using ION Setup

Select a channel from the list.

You can edit the factor value between 0.000 to

99999.999.

1. Navigate to Maint > Setup.

2. Enter the setup password (default is “0”), then press OK.

3. Navigate to HMI > Region.

4. Move the cursor to point to the parameter you want to modify, then press

Edit.

5. Modify the parameter as required, then press OK.

6. Move the cursor to point to the next parameter you want to modify, press Edit,

make your changes, then press OK.

7. Press the up arrow to exit.

QGH9011501-02 27

EasyLogic™PM2200R series Meter Setup

8. Press Yes to save your changes.

Regional settings available using the display

Parameter Values Description

Language English US,

French,

Spanish,

German,

Portuguese,

Chinese,

Russian and

Turkish

Date Format MM/DD/YY, YY/

MM/DD, DD/

MM/YY

Time Format 24Hr, AM/PM Set how you want the time to be displayed, e.g.,

HMI Mode IEC, IEEE Select the standards convention used to display menu

Setting up the screen passwords

It is recommended that you change the default password in order to prevent

unauthorized personnel from accessing password-protected screens such as the

diagnostics and reset screens.

This can only be configured through the front panel. The factory-default setting for

all passwords is “0” (zero).

1. Navigate to Maint > Setup.

Select the language you want the meter to display.

Set how you want the date to be displayed, e.g., month/

day/year.

17:00:00 or 5:00:00 PM.

names or meter data.

2. Enter the setup password (default is “0”), then press OK.

3. Navigate to HMI > Pass.

4. Move the cursor to point to the parameter you want to modify, then press

Edit.

Parameter Values Description

Setup 0000 - 9999 Sets the password for accessing the meter setup

Energy Resets 0000 - 9999 Sets the password for resetting the meter’s

Demand Resets 0000 - 9999 Sets the password for resetting the meter’s recorded

Min/Max Resets 0000 - 9999 Sets the password for resetting the meter’s recorded

screens (Maint > Setup).

accumulated energy values.

peak demand values.

minimum and maximum values.

5. Modify the parameter as required, then press OK.

6. Move the cursor to point to the next parameter you want to modify, press Edit,

make your changes, then press OK.

7. Press the up arrow to exit.

8. Press Yes to save your changes.

Lost password

Visit www.se.com for support and assistance with lost passwords or other

technical problems with the meter.

Make sure you include your meter’s model, serial number and firmware version in

your email or have it readily available if calling Technical Support.

28 QGH9011501-02

Loading...

Loading...