Schneider Electric P3U10, P3U20, P3U30, Easergy P3 User Manual

Easergy P3

Universal Relays P3U10, P3U20 and P3U30

User Manual

P3U/en M/F005

01/2020

www.schneider-electric.com

Table of Contents

Table of Contents

1. About this manual....................................................................... 12

1.1. Purpose..........................................................................................................12

1.2. Related documents........................................................................................12

1.3. Abbreviations and terms................................................................................ 13

2. Product introduction.................................................................... 18

2.1. Warranty.........................................................................................................18

2.2. Product overview........................................................................................... 18

2.3. Product selection guide..................................................................................19

2.4. Access to device configuration...................................................................... 27

2.4.1. User accounts......................................................................................27

2.4.2. Logging on via the front panel............................................................. 28

2.4.3. HTTP and FTP logon details............................................................... 28

2.4.4. Password management....................................................................... 29

2.4.5. Changing passwords for administrator and configurator accounts via

PuTTY............................................................................................................29

2.4.6. Password restoring.............................................................................. 31

2.5. Front panel.....................................................................................................32

2.5.1. Push-buttons........................................................................................32

2.5.2. LED indicators..................................................................................... 33

2.5.3. Controlling the alarm screen................................................................34

2.5.4. Accessing operating levels.................................................................. 34

2.5.5. Adjusting the LCD contrast.................................................................. 34

2.5.6. Testing the LEDs and LCD screen.......................................................35

2.5.7. Controlling an object with selective control..........................................35

2.5.8. Controlling an object with direct control............................................... 35

2.5.9. Menus..................................................................................................35

2.6. Easergy Pro setting and configuration tool.................................................... 38

Universal Relays P3U10, P3U20 and P3U30

2.5.9.1. Moving in the menus ............................................................. 37

2.5.9.2. Local panel messages............................................................38

3. Measurement functions...............................................................40

3.1. Primary, secondary and per unit scaling........................................................ 42

3.1.1. Frequency adaptation mode................................................................ 44

3.1.2. Current transformer ratio..................................................................... 45

3.1.3. Voltage transformer ratio..................................................................... 47

3.2. Measurements for protection functions..........................................................49

3.3. RMS values....................................................................................................50

3.4. Harmonics and total harmonic distortion (THD).............................................50

3.5. Demand values..............................................................................................51

3.6. Minimum and maximum values..................................................................... 53

3.7. Maximum values of the last 31 days and 12 months..................................... 54

3.8. Power and current direction........................................................................... 56

3.9. Symmetrical components...............................................................................57

P3U/en M/F005 3

Universal Relays P3U10, P3U20 and P3U30

4. Control functions......................................................................... 59

4.1. Digital outputs................................................................................................ 59

4.2. Digital inputs.................................................................................................. 61

4.3. Virtual inputs and outputs...............................................................................63

4.4. Matrix............................................................................................................. 66

4.4.1. Output matrix....................................................................................... 66

4.4.2. Blocking matrix.................................................................................... 67

4.4.3. Object block matrix.............................................................................. 68

4.4.4. Auto-recloser matrix.............................................................................69

4.5. Releasing latches...........................................................................................69

4.5.1. Releasing latches using Easergy Pro.................................................. 69

4.5.2. Releasing latches using buttons and local panel display.....................69

4.5.3. Releasing latches using F1 or F2 buttons........................................... 70

4.6. Controllable objects....................................................................................... 70

4.6.1. Object control with digital inputs.......................................................... 72

4.6.2. Local or remote selection.....................................................................72

4.6.3. Object control with Close and Trip buttons.......................................... 73

4.6.4. Object control with F1 and F2..............................................................73

4.7. Logic functions...............................................................................................74

4.8. Local panel.....................................................................................................82

4.8.1. Mimic view........................................................................................... 83

4.8.2. Local panel configuration.....................................................................85

Table of Contents

5. Protection functions.....................................................................90

5.1. Maximum number of protection stages in one application.............................90

5.2. General features of protection stages............................................................90

5.3. Application modes..........................................................................................98

5.4. Current protection function dependencies..................................................... 98

5.5. Dependent operate time................................................................................ 98

5.5.1. Standard dependent delays using IEC, IEEE, IEEE2 and RI curves.100

5.5.2. Custom curves................................................................................... 114

5.5.3. Programmable dependent time curves.............................................. 115

5.6. Synchronism check (ANSI 25)..................................................................... 116

5.7. Undervoltage (ANSI 27)...............................................................................120

5.8. Directional power (ANSI 32) ....................................................................... 123

5.9. Phase undercurrent (ANSI 37).....................................................................125

5.10. Broken conductor (ANSI 46BC) ................................................................ 126

5.11. Negative sequence overcurrent (ANSI 46) ................................................127

5.12. Incorrect phase sequence (ANSI 46) ........................................................129

5.13. Negative sequence overvoltage protection (ANSI 47)............................... 130

5.14. Motor start-up supervision (ANSI 48) ........................................................131

5.15. Thermal overload (ANSI 49 RMS)............................................................. 136

5.16. Breaker failure 1 (ANSI 50BF)................................................................... 140

5.17. Breaker failure 2 (ANSI 50BF)................................................................... 141

5.18. Switch-on-to-fault (ANSI 50HS) ................................................................ 147

5.19. Phase overcurrent (ANSI 50/51)................................................................149

4 P3U/en M/F005

Table of Contents

Universal Relays P3U10, P3U20 and P3U30

5.20. Ground fault overcurrent (ANSI 50N/51N) ................................................ 153

5.20.1. Ground fault phase detection...........................................................157

5.21. Capacitor bank unbalance (ANSI 51C) .....................................................158

5.22. Locked rotor (ANSI 51LR)..........................................................................164

5.23. Voltage-dependent overcurrent (ANSI 51V) ............................................. 166

5.24. Overvoltage (ANSI 59)...............................................................................168

5.25. Capacitor overvoltage (ANSI 59C) ............................................................171

5.26. Neutral overvoltage (ANSI 59N)................................................................ 176

5.27. Motor restart inhibition (ANSI 66) ..............................................................178

5.28. Directional phase overcurrent (ANSI 67) .................................................. 181

5.29. Directional ground fault overcurrent (ANSI 67N)....................................... 185

5.29.1. Ground fault phase detection...........................................................191

5.30. Transient intermittent ground fault (ANSI 67NI).........................................192

5.31. Second harmonic inrush detection (ANSI 68F2)........................................197

5.32. Fifth harmonic detection (ANSI 68H5)....................................................... 198

5.33. Auto-recloser function (ANSI 79) .............................................................. 199

5.34. Overfrequency and underfrequency (ANSI 81) .........................................204

5.35. Rate of change of frequency (ANSI 81R).................................................. 206

5.36. Lockout (ANSI 86)......................................................................................211

5.37. Programmable stages (ANSI 99)............................................................... 212

6. Supporting functions................................................................. 215

6.1. Event log......................................................................................................215

6.2. Disturbance recording..................................................................................217

6.3. Cold load start and magnetizing inrush........................................................223

6.4. System clock and synchronization...............................................................224

6.5. Voltage sags and swells...............................................................................230

6.6. Voltage interruptions....................................................................................232

6.7. Current transformer supervision (ANSI 60) .................................................234

6.8. Voltage transformer supervision (ANSI 60FL)............................................. 236

6.9. Circuit breaker wear.....................................................................................237

6.10. Circuit breaker condition monitoring.......................................................... 243

6.11. Energy pulse outputs..................................................................................245

6.12. Running hour counter................................................................................ 249

6.13. Timers........................................................................................................250

6.14. Combined overcurrent status.....................................................................252

6.15. Main short-circuit fault locator.................................................................... 254

6.16. Feeder fault locator (ANSI 21FL)............................................................... 259

6.17. Trip circuit supervision (ANSI 74) ..............................................................263

6.17.1. Trip circuit supervision with one digital input....................................263

6.17.2. Trip circuit supervision with two digital inputs.................................. 269

7. Communication and protocols...................................................273

7.1. Cybersecurity...............................................................................................273

7.2. Communication ports...................................................................................273

7.2.1. Remote and extension ports..............................................................274

P3U/en M/F005 5

Universal Relays P3U10, P3U20 and P3U30

7.2.2. Ethernet port......................................................................................274

7.2.3. Disabling the Ethernet communication.............................................. 274

7.3. Communication protocols............................................................................ 275

7.3.1. Modbus RTU and Modbus TCP.........................................................276

7.3.2. Profibus DP........................................................................................276

7.3.3. SPA-bus.............................................................................................277

7.3.4. IEC 60870-5-103 (IEC-103)...............................................................277

7.3.5. DNP 3.0............................................................................................. 278

7.3.6. IEC 60870-5-101 (IEC-101)...............................................................278

7.3.7. IEC 61850..........................................................................................279

7.3.8. HTTP server – Webset...................................................................... 279

7.4. IP filter..........................................................................................................279

7.4.1. Configuring the IP filter...................................................................... 280

7.4.2. Unexpected packets.......................................................................... 282

7.4.3. Alarms................................................................................................282

8. Applications and configuration examples..................................284

Table of Contents

8.1. Substation feeder protection........................................................................284

8.2. Industrial feeder / motor protection.............................................................. 286

8.3. Using CSH120 and CSH200 with core balance CTs................................... 286

9. Installation................................................................................. 289

9.1. Safety in installation.....................................................................................289

9.2. Checking the consignment...........................................................................290

9.3. Product identification....................................................................................291

9.4. Storage........................................................................................................ 292

9.5. Mounting...................................................................................................... 293

9.6. Connections.................................................................................................296

9.6.1. Rear panel......................................................................................... 297

9.6.2. Auxiliary voltage.................................................................................309

9.6.3. Local port...........................................................................................309

9.6.4. Connection data.................................................................................310

9.6.5. External option modules.................................................................... 316

9.6.5.1. VSE-001 fiber optic interface module...................................316

9.6.5.2. VSE-002 RS-485 interface module...................................... 317

9.6.5.3. VSE-009 DeviceNet interface module..................................319

9.6.5.4. VPA-3CG Profibus interface module.................................... 320

9.6.5.5. VIO 12A RTD and analog input / output modules................ 321

9.6.6. Block diagrams.................................................................................. 322

9.6.7. Connection examples........................................................................ 329

9.7. Voltage system configuration.......................................................................339

9.8. CSH120 and CSH200 Core balance CTs.................................................... 346

10. Test and environmental conditions..........................................350

10.1. Disturbance tests....................................................................................... 350

10.2. Electrical safety tests................................................................................. 351

10.3. Mechanical tests........................................................................................ 352

10.4. Environmental tests................................................................................... 352

6 P3U/en M/F005

Table of Contents Universal Relays P3U10, P3U20 and P3U30

10.5. Environmental conditions...........................................................................353

10.6. Casing........................................................................................................353

11. Maintenance............................................................................ 354

11.1. Preventive maintenance.............................................................................354

11.2. Periodic testing...........................................................................................355

11.3. Hardware cleaning..................................................................................... 355

11.4. System status messages........................................................................... 355

11.5. Spare parts.................................................................................................355

11.6. Self-supervision..........................................................................................355

11.6.1. Diagnostics.......................................................................................356

12. Order codes and accessories................................................. 358

12.1. Order codes............................................................................................... 358

12.2. Accessories................................................................................................360

13. Firmware revision....................................................................362

P3U/en M/F005 7

Universal Relays P3U10, P3U20 and P3U30 Legal information

Legal information

The Schneider Electric brand and any registered trademarks of Schneider Electric

Industries SAS referred to in this guide are the sole property of Schneider Electric

SA and its subsidiaries. They may not be used for any purpose without the

owner's permission, given in writing. This guide and its content are protected,

within the meaning of the French intellectual property code (Code de la propriété

intellectuelle français, referred to hereafter as "the Code"), under the laws of

copyright covering texts, drawings and models, as well as by trademark law. You

agree not to reproduce, other than for your own personal, noncommercial use as

defined in the Code, all or part of this guide on any medium whatsoever without

Schneider Electric's permission, given in writing. You also agree not to establish

any hypertext links to this guide or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the guide or its

content, except for a non-exclusive license to consult it on an "as is" basis, at your

own risk. All other rights are reserved.

Electrical equipment should be installed, operated, serviced and maintained only

by qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

As standards, specifications and designs change from time to time, please ask for

confirmation of the information given in this publication.

8 P3U/en M/F005

Safety information

Safety information

Important information

Read these instructions carefully and look at the equipment to become familiar

with the device before trying to install, operate, service or maintain it.

The following special messages may appear throughout this publication or on the

equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

Universal Relays P3U10, P3U20 and P3U30

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

The addition of either symbol to a “Danger” or “Warning” safety

label indicates that an electrical hazard exists which will result in

personal injury if the instructions are not followed.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to physical injury.

Please note

Electrical equipment must only be installed, operated, serviced, and maintained

by qualified personnel. A qualified person is one who has skills and knowledge

related to the construction, installation, and operation of electrical equipment and

has received safety training to recognize and avoid the hazards involved.

No responsibility is assumed by Schneider Electric for any consequences arising

out of the use of this material.

Protective grounding

The user is responsible for compliance with all the existing international and

national electrical codes concerning protective grounding of any device.

P3U/en M/F005 9

Universal Relays P3U10, P3U20 and P3U30 North America regulatory compliance

North America regulatory compliance

Certificate number: 20190829-E215590

Issue date: 2019-August-29

UL certifies that the Easergy P3 products comply with the following standards:

• UL 508 Industrial Control Equipment

• CSA C22.2 No. 14-13 Industrial Control Equipment

• IEEE C37.90-2005 Guide for Power System Protection Testing

• IEEE C37.90.1-2012 Standard for Surge Withstand Capability (SWC) Tests

for Relays and Relay Systems Associated with Electrical Power Apparatus

• IEEE C37.90.2-2004 Standard for Withstand Capability of Relay Systems to

Radiated Electromagnetic Interference from Trancievers

10 P3U/en M/F005

EU directive compliance Universal Relays P3U10, P3U20 and P3U30

EU directive compliance

EMC compliance

2014/30/EU

Compliance with the European Commission's EMC Directive. Product Specific

Standard was used to establish conformity:

• EN 60255-26 2013

Product safety

2014/35/EU

Compliance with the European Commission's Low Voltage Directive. Product

Specific Safety Standard was used to establish conformity:

• EN 60255-27 2014

P3U/en M/F005 11

Universal Relays P3U10, P3U20 and P3U30 1. About this manual

1. About this manual

1.1. Purpose

This document contains instructions on the installation, commissioning and

operation of Easergy P3U10, P3U20 and P3U30.

This document is intended for persons who are experts on electrical power

engineering, and it covers the relay models as described by the order code.

Related topics

Order codes on page 358

1.2. Related documents

Table 1 - Related documents

Document

Easergy P3 Universal Relay P3U Quick Start P3U/EN QS/xxxx

Easergy Pro Setting and Configuration Tool User Manual P3eSetup/EN M/xxxx

RTD and mA Output/Input Modules User Manual P3VIO12A/EN M/A001

Profibus Interface Module User Manual P3VPA3CG/EN M/A001

IEC 61850 configuration instructions P3APS17001EN

Rapid Spanning Tree Protocol (RSTP) P3APS17002EN

Parallel Redundancy Protocol for Easergy P3 relays with dualport 100 Mbps Ethernet interface

Communication parameter protocol mappings P3TDS17005EN

Easergy P3 protection functions' parameters and recorded

values

DeviceNet data model P3APS17008EN

Identification

P3APS17004EN

P3TDS17006EN

1

IEC103 Interoperability List P3TDS17009EN

DNP 3.0 Device Profile Document P3TDS17010EN

P3 Standard Series facia label instruction P3TDS17011EN

Principles of numerical protection techniques P3INS17019EN

1

xxxx = revision number

12 P3U/en M/F005

1. About this manual Universal Relays P3U10, P3U20 and P3U30

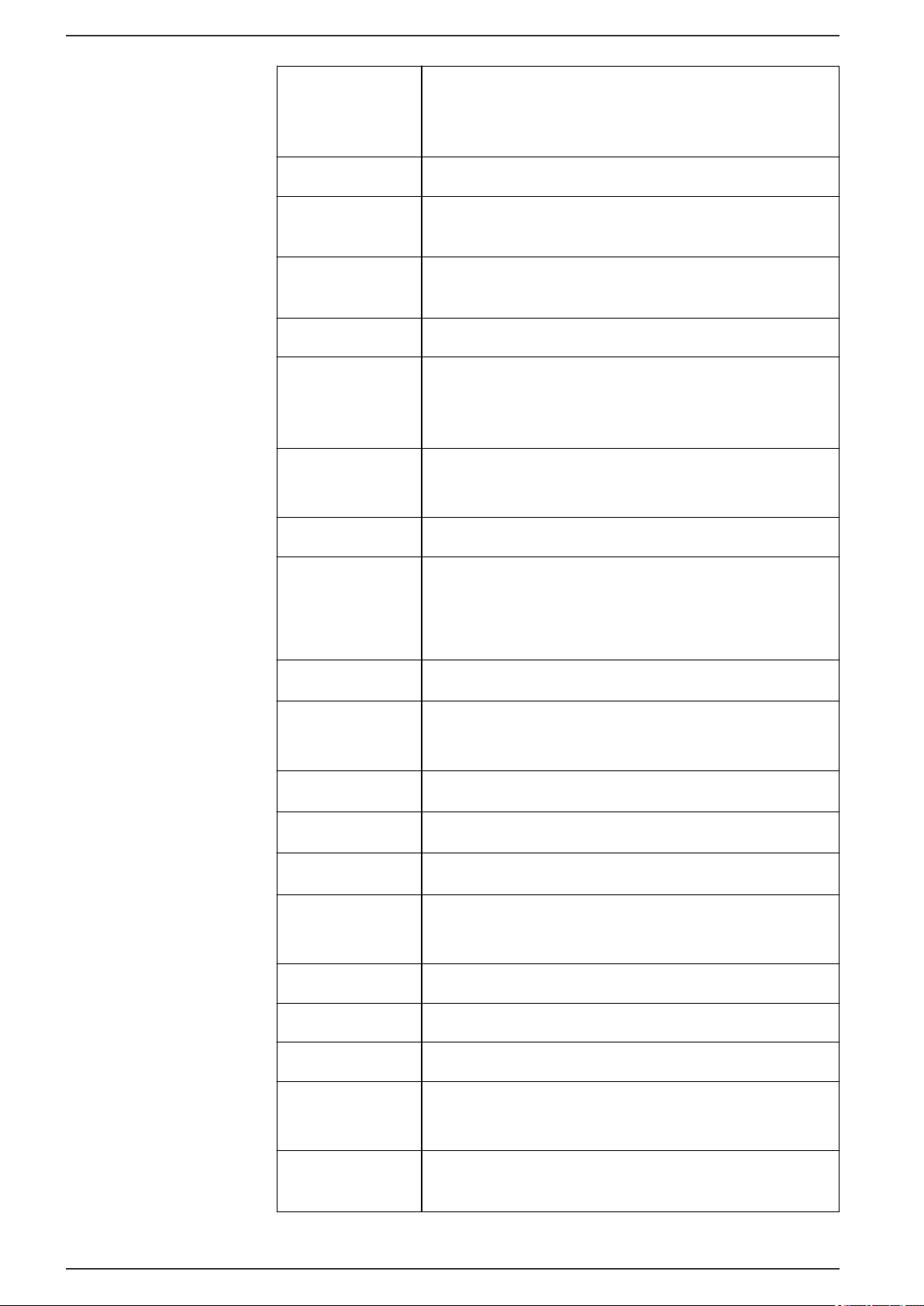

1.3. Abbreviations and terms

AFD Arc flash detection

ANSI American National Standards Institute

A standardization organisation

bps Bits per second

CB Circuit breaker

CBFP Circuit breaker failure protection

CLPU Cold load pickup

CM Common mode

Controlling output Heavy duty output rated for the circuit breaker controlling

CPU Central processing unit

cosφ Active power divided by apparent power = P/S

(See power factor PF.)

Negative sign indicates reverse power.

CT Current transformer

CT

PRI

CT

SEC

Dead band See hysteresis.

DI Digital input

Digital output Relay's output contact

DM Differential mode

DMS Distribution management system

Nominal primary value of current transformer

Nominal secondary value of current transformer

DO Digital output

Document file Stores information about the relay settings, events and fault logs

DSR Data set ready

An RS232 signal. Input in front panel port of Easergy P3 devices

to disable rear panel local port.

DST Daylight saving time

Adjusting the official local time forward by one hour for summer

time.

DT Definite time

P3U/en M/F005 13

Universal Relays P3U10, P3U20 and P3U30 1. About this manual

DTR Data terminal ready

An RS232 signal. Output and always true (+8 Vdc) in front panel

port of Easergy P3 relays.

Easergy P3 Standard P3U10, P3U20 and P3U30 relays

Easergy P3

P3F30, P3L30, P3M30/32, P3G30/32 and P3T32 relays

Advanced

eSetup Easergy Pro Setting and configuration tool for Easergy P3 protection relays,

later called Easergy Pro

F2BIO 2 x optical BIO interfaces, fibre

GOOSE Generic object-oriented substation event

A specific definition of a type of generic substation event, for

peer-peer communication.

Hysteresis I.e. dead band

Used to avoid oscillation when comparing two nearby values.

IDMT Inverse definite minimum time

I

MODE

Nominal current of the selected mode

In feeder mode, I

In motor mode, I

MODE

MODE

= CT

= I

MOT

PRIMARY

.

.

I

MOT

I

NOM

Nominal current of the protected motor

Nominal current

Rating of CT primary or secondary

I

SET

I

N(nom)

I

0 SET

Start setting value I> (50/51)

Nominal current of IN input in general

Start setting value I0>

IEC International Electrotechnical Commission

An international standardization organisation

IEC-101 Communication protocol defined in standard IEC 60870-5-101

IEC-103 Communication protocol defined in standard IEC 60870-5-103

IEEE Institute of Electrical and Electronics Engineers

IRIG-B Inter-Range Instrumentation Group time code B

Standard for time transfer

IT Instrument transformer (current or voltage transformer): electrical

device used to isolate or transform voltage or current levels

14 P3U/en M/F005

1. About this manual Universal Relays P3U10, P3U20 and P3U30

LAN Local area network

Ethernet-based network for computers and devices

Latching Digital outputs and indication LEDs can be latched, which means

that they are not released when the control signal is releasing.

Releasing of latched devices is done with a separate action.

LCD Liquid crystal display

LED Light-emitting diode

NTP Network Time Protocol for LAN and WWW

OVF Indication of the event overflow

P Active power

Unit = [W]

PF Power factor

The absolute value is equal to cosφ, but the sign is 'IND' for

inductive i.e. lagging current and 'CAP' for capacitive i.e. leading

current.

PLC Programmable logic controller

P

M

Nominal power of the prime mover

(Used by reverse/under power protection.)

POC signals

Binary signals that are transferred in the communication channel

of two P3L30 line differential relays in both directions. POC

signals are used to transfer statuses of the DI, VI, VO and logic

outputs.

pu

PU

Per unit

Depending of the context, the per unit refers to any nominal

value.

For example, for overcurrent setting 1 pu = 1 x I N .For example,

for overcurrent setting 1 pu = 1 x I

MOT

.

P3U P3U10, P3U20 and P3U30 protection relay

Q Reactive power

Unit = [var]

RELxxxxx Short order code

RH Relative humidity

RMS Root mean square

RS232 or RS485

(EIA-232 or EIA-485)

Standard defining the electrical characteristics of a serial

communication interface

P3U/en M/F005 15

Universal Relays P3U10, P3U20 and P3U30 1. About this manual

RTU Remote terminal unit

S Apparent power

Unit = [VA]

SCADA Supervisory control and data acquisition

SF Alarm duty watchdog output is energized when the auxiliary

power supply is on and the product status is operative. This

output is referenced as "service status output" in the setting tool.

Signaling output Alarm duty output rated, not suitable for direct circuit breaker

controlling

SNTP Simple Network Time Protocol for LAN and WWW

SOTF Switch on to fault

SPST Single pole single throw

SPDT Single pole double throw

TCS Trip circuit supervision

THD Total harmonic distortion

V Voltage V

V

NSEC

Voltage at input Vc at zero ohm ground fault. (Used in voltage

measurement mode “2LL+VN”)

V

A

Voltage input for VAB or VA depending on the voltage

measurement mode

V

B

Voltage input for VBC or VB depending on the voltage

measurement mode

V

C

Voltage input for VCA or VN depending on the voltage

measurement mode

V

N

Neutral voltage

Rating of VT primary or secondary

V

NOM

Nominal voltage

Rating of VT primary or secondary

UMI User-machine interface

USB Universal serial bus

UTC Coordinated Universal Time

Used to be called GMT = Greenwich Mean Time

Webset http configuration interface

16 P3U/en M/F005

1. About this manual Universal Relays P3U10, P3U20 and P3U30

VI Virtual input

VO Virtual output

VT Voltage transformer

VT

VT

PRI

SEC

Nominal primary value of voltage transformer

Nominal secondary value of voltage transformer

Parameter names in user manual and Easergy Pro

Some parameters may have a different name in this user manual compared to the

Easergy Pro setting tool.

Table 2 - Parameter names in user manual and Easergy Pro

User manual Easergy Pro

Base angle setting range Angle offset

Characteristic curve / curve type Delay type

Cooling time coefficient Rel. cooling time coefficient

Dependent time coefficient Inv. time coefficient

Operate angle Pick-up sector size

Operate time Operation delay

Self-blocking value of undervoltage Low voltage blocking

Start value Pick-up setting

Start voltage

Time multiplier Inv. time coefficient / Inverse delay

3BIO 3 x hard-wired BIO interfaces

VN setting for INDir stage > (67N)

P3U/en M/F005 17

Universal Relays P3U10, P3U20 and P3U30

2. Product introduction

2.1. Warranty

This product has a standard warranty of 10 years.

2.2. Product overview

The relay communicates with other systems using common protocols, such as the

Modbus RTU, ModbusTCP, IEC 60870-5-103, IEC 60870-5-101, IEC 61850, SPA

bus, and DNP 3.0.

User interface

The relay can be controlled in three ways:

2. Product introduction

• Locally with the push-buttons on the relay front panel

• Locally using a PC connected to the USB port on the front

• Via remote control over the optional remote control port on the relay rear

panel.

Easergy P3U10, P3U20 and P3U30 include all the essential protection functions

needed to protect feeders and motors in distribution networks of utilities, industry

and power plants for all level of voltage below 132 kV. Further, the relay includes

several programmable functions, such as trip circuit supervision and circuit

breaker protection and communication protocols for various protection and

communication situations.

Protection functions

• Universal, adaptive protection functions for user-configurable applications like

feeder, motor and voltage protection from basic non-directional to directional

overcurrent protection, thermal overload, and auto-recloser

• Neutral overvoltage, overvoltage and frequency protection including

synchronism check for two breakers

• Single-line diagram, measurements and alarms in the user-machine interface

(UMI)

• User-configurable interlocking for primary object control

• Optional arc flash detection utilizing point sensors and a fiber loop that can

provide system wide arc flash detection.

Virtual injection

• Current and voltage injection by manipulating the database of the product by

setting tool disturbance recorder file playback through the product's database

Robust hardware

• User-selectable Ethernet, RS485 or RS232 -based communication interfaces

• Designed for demanding industrial conditions with conformal-coated printed

circuit boards

• Standard USB connection (type B) for Easergy P3 setting software

18 P3U/en M/F005

1

4

3

2. Product introduction Universal Relays P3U10, P3U20 and P3U30

Common technology for cost efficiency

• Powerful CPU supporting IEC 61850

• Thanks to four setting groups, adaptation to various protection schemes is

convenient

User-machine interface (UMI)

• Clear LCD display for alarms and events

• Single-line diagram mimic with control, indication and live measurements

• Programmable function keys and LEDs

• Circuit breaker ON/OFF control

• Common firmware platform with other Easergy P3 range protection relays

NOTE: If the device has been powered off for more than about one week, the

UMI language after starting is IEC but after about two minutes, it is

automatically updated to ANSI.

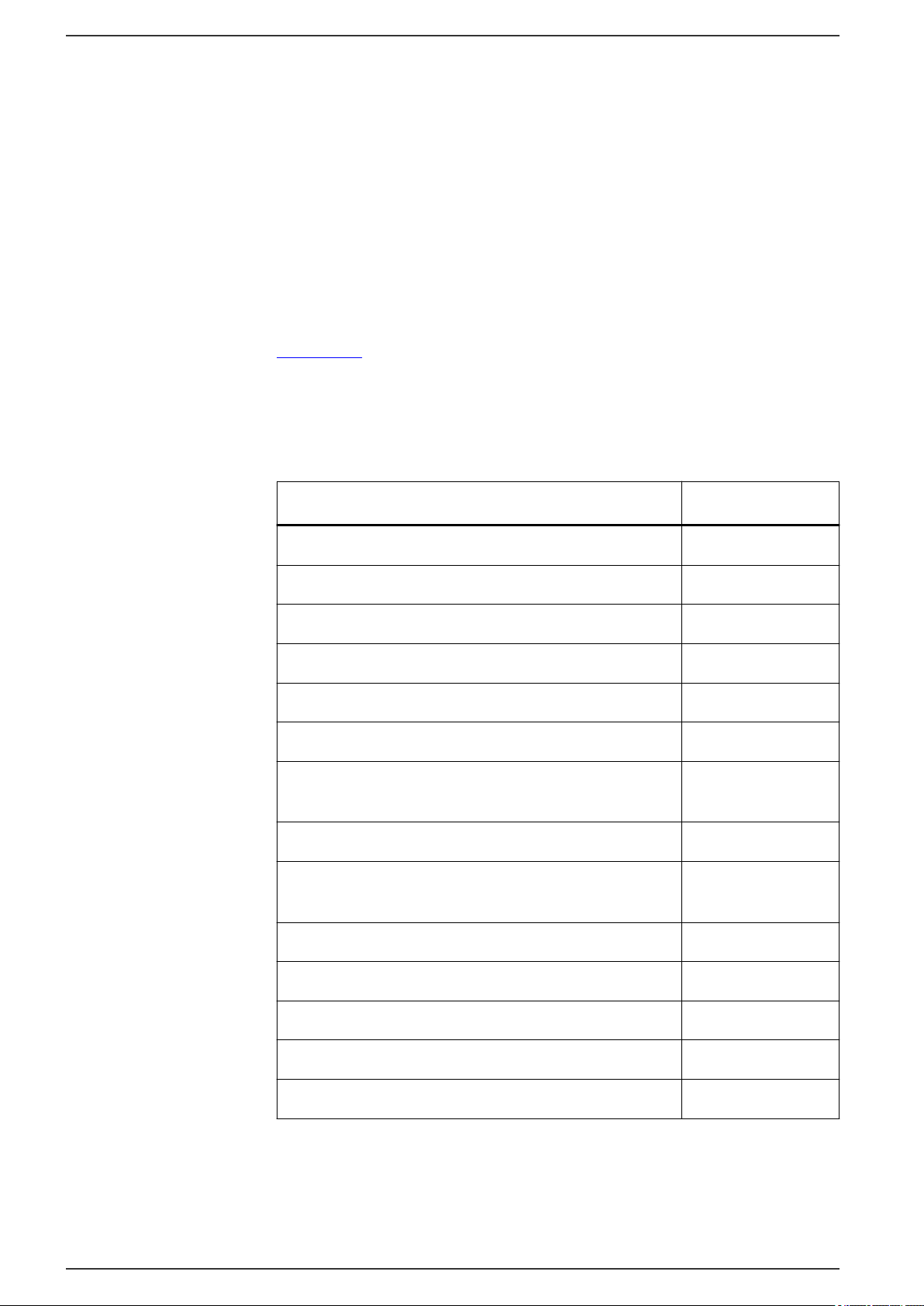

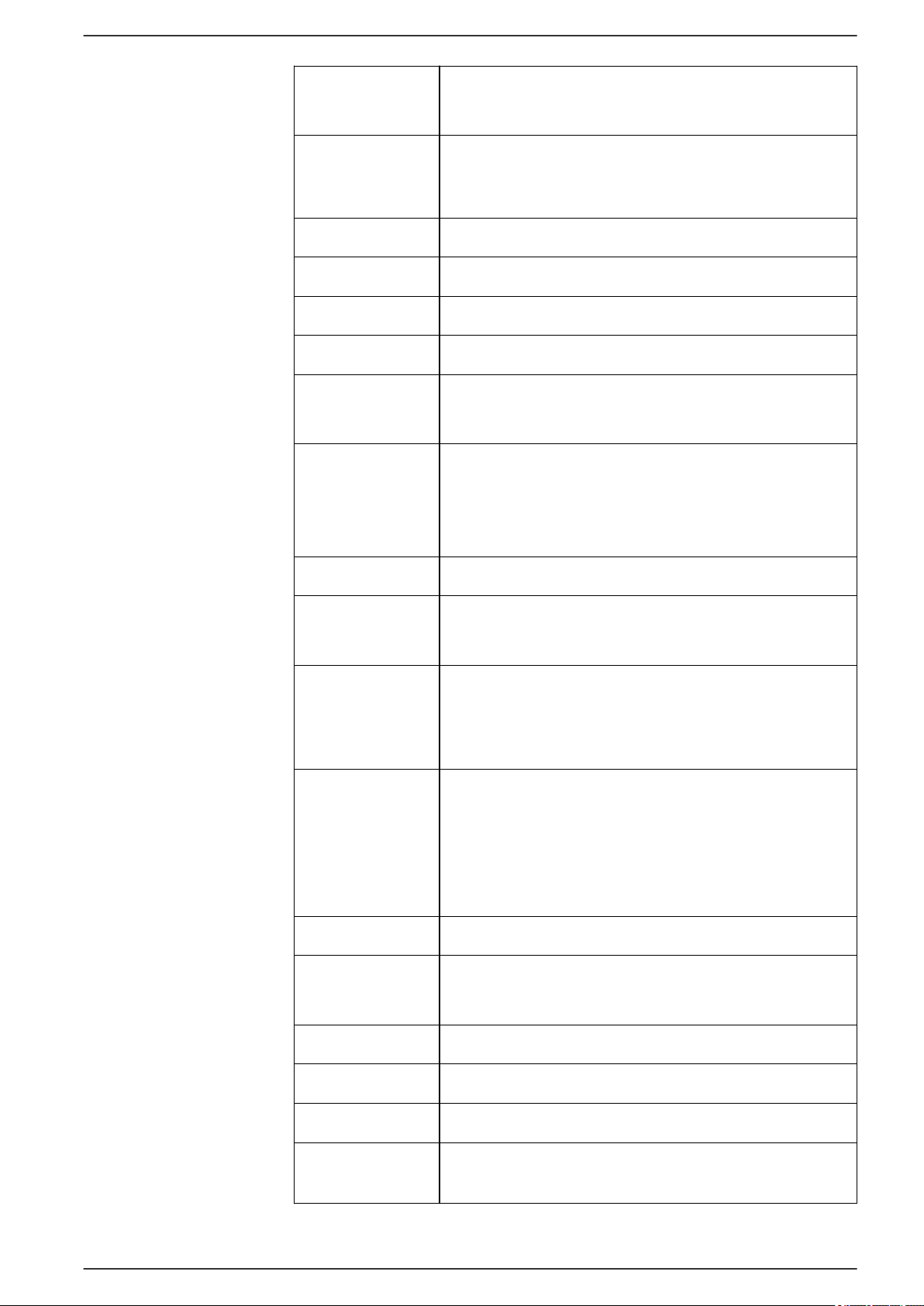

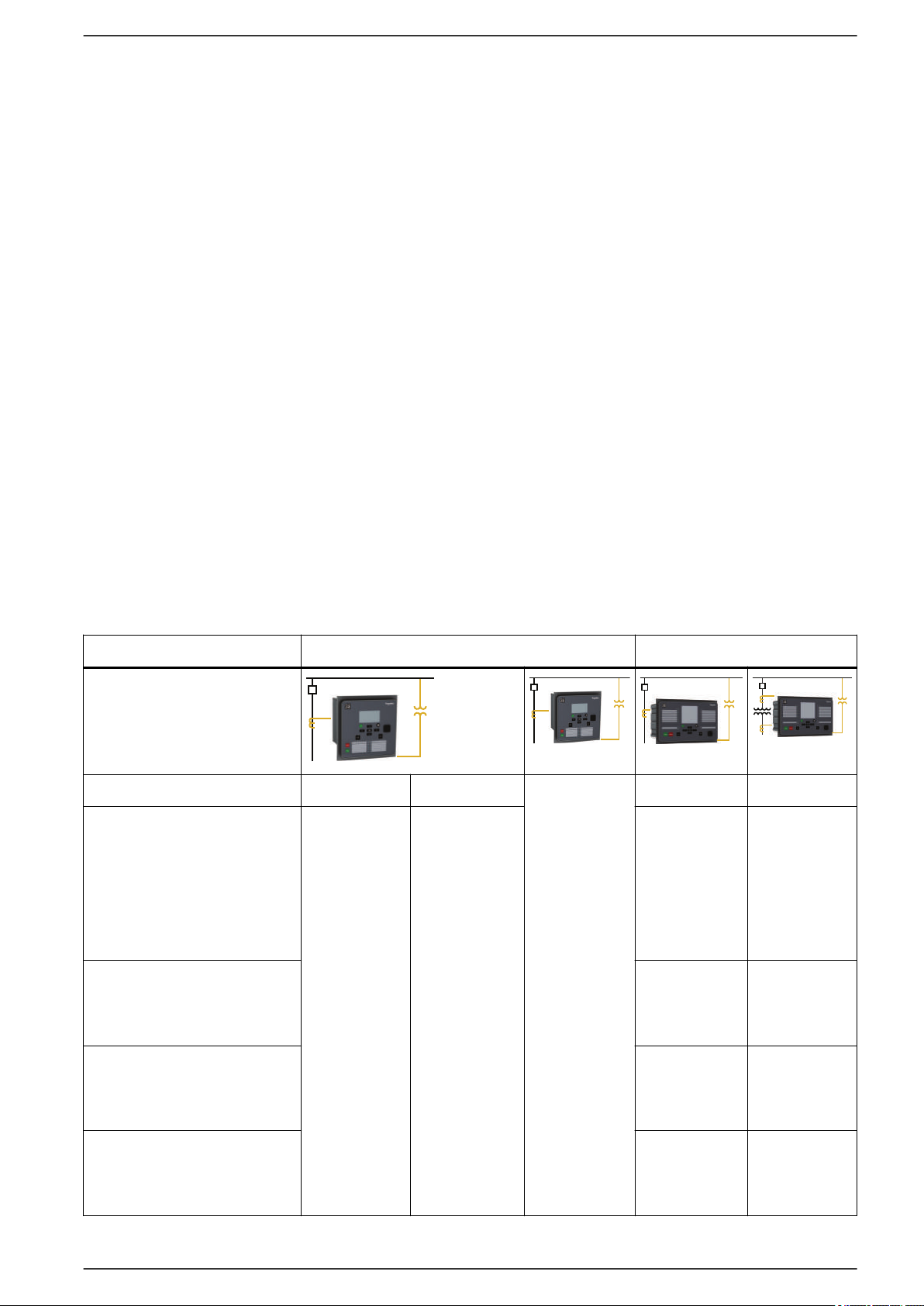

2.3. Product selection guide

The selection guide provides information on the Easergy P3 platform to aid in the

relay selection. It suggests Easergy P3 types suitable for your protection

requirements, based on your application characteristics. The most typical

applications are presented along with the associated Easergy P3 type.

Table 3 - Applications

Easergy P3 Standard Easergy P3 Advanced

Voltage – –

Feeder

Transformer

P3U10 P3U20

Motor

P3U30

with

directional

o/c

with voltage

protection

P3F30

w.

directional

P3L30

w. line diff. &

distance

–

P3M30

–

–

P3T32

with

differential

P3M32

with

differential

Generator

P3G30

P3U/en M/F005 19

P3G32

with

differential

1

4

3

Universal Relays P3U10, P3U20 and P3U30 2. Product introduction

Easergy P3 Standard Easergy P3 Advanced

Measuring

inputs

Phase current 1/5A CT (x3) 1/5A CT (x3) 1/5A CT (x6)

Residual current 1/5A CT or 0.2/1A CT 5/1A+1/0.2A 5/1A+1/0.2A +

5/1A CT

Voltage VT (x1) VT (x4) VT (x4) VT (x4)

Arc-flash sensor input – 0 to 4 point

sensor

0 to 4 point

sensor

Digital I/O Input 2 8/10 16 6 to 36 6 to 16

Output 5 + WD 5/8 + WD 8 + WD 10 to 21 + WD 10 to 13 + WD

Analog I/O Input –

Output –

Temperature sensor input –

2

0 or 4

2

0 or 4

0 or 8 or 12

2

0 or 8 or 12

0 or 4

0 or 4

2

2

2

Front port USB USB

Nominal power supply

24 V dc or 24...48 V dc or 48...230 V ac/dc

3

24...48 V dc or 110...240 V ac/dc

Ambient temperature, in service -40...60°C (-40...140°F) -40...60°C (-40...140°F)

2

Using external RTD module

3

Check the available power supply range from the device's serial number label.

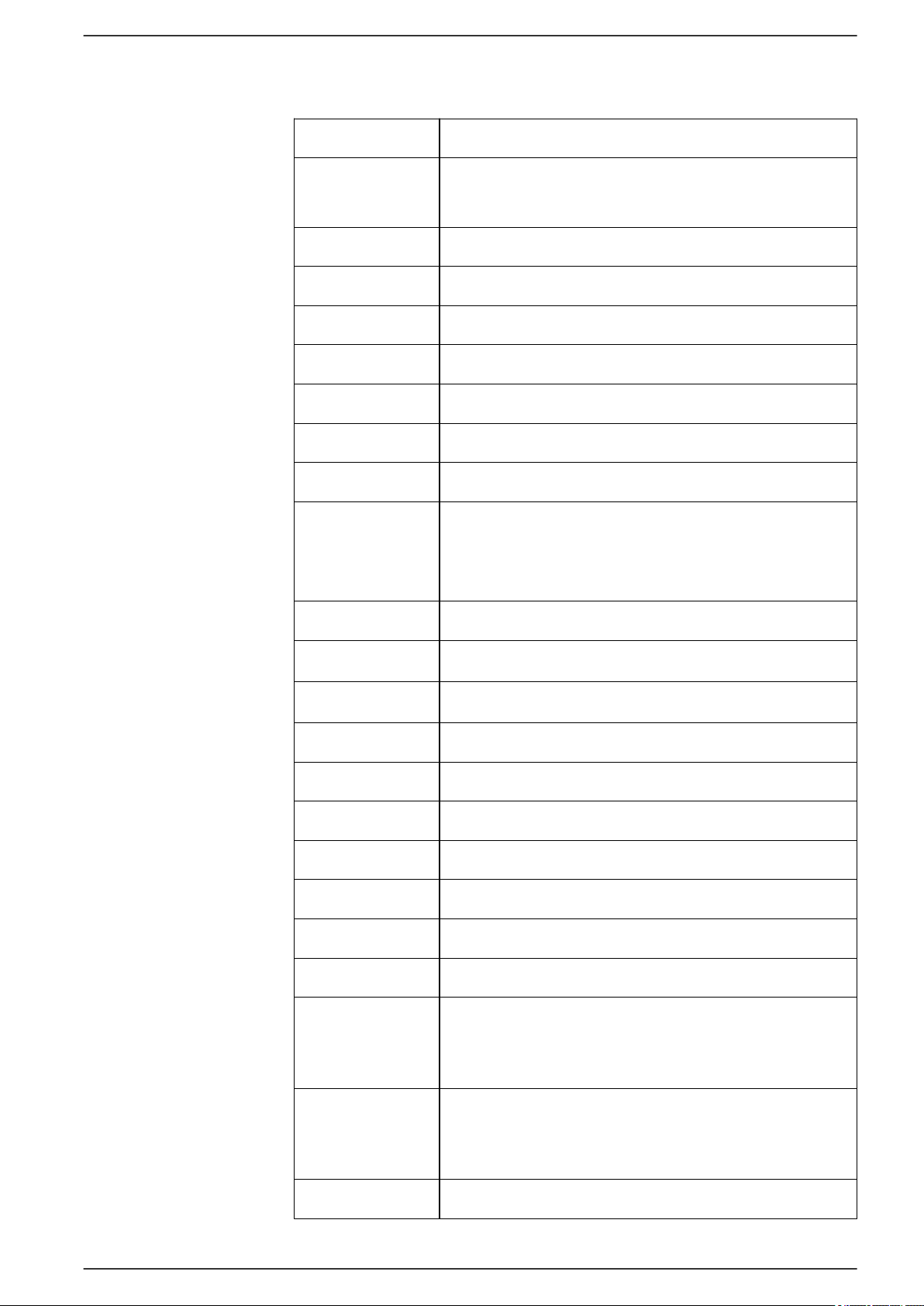

Table 4 - Communication & others

Easergy P3 Standard Easergy P3 Advanced

Communication

Rear ports RS-232 – ■ ■ ■

IRIG/B ■ ■ ■

RS-485 – ■ Using external

ETHERNET – ■ ■ ■

Protocols IEC 61850 Ed1

& Ed2

IEC 60870-5-101 – ■ ■ ■ ■

IEC 60870-5-103 – ■ ■ ■ ■

I/O module

– ■ ■ ■ ■

Using external

I/O module

DNP3 Over

– ■ ■ ■ ■

Ethernet

Modbus serial – ■ ■ ■ ■

Modbus TCP/IP – ■ ■ ■ ■

DeviceNet – ■ ■ ■ ■

Profibus DP – ■ ■ ■ ■

20 P3U/en M/F005

2. Product introduction Universal Relays P3U10, P3U20 and P3U30

Easergy P3 Standard Easergy P3 Advanced

SPAbus – ■ ■ ■ ■

Redundancy

protocols

Others

Control

Logic Matrix ■ ■

Cyber security Password Password

Withdrawability (Pluggable

connector)

Remote UMI – ■

RSTP – ■ ■ ■ ■

PRP – ■ ■ ■ ■

1 object

Mimic

Logic equations ■ ■

8 objects

Mimic

■ –

8 objects

Mimic

NOTE: The numbers in the following tables represent the amount of stages

available for each Easergy P3 type.

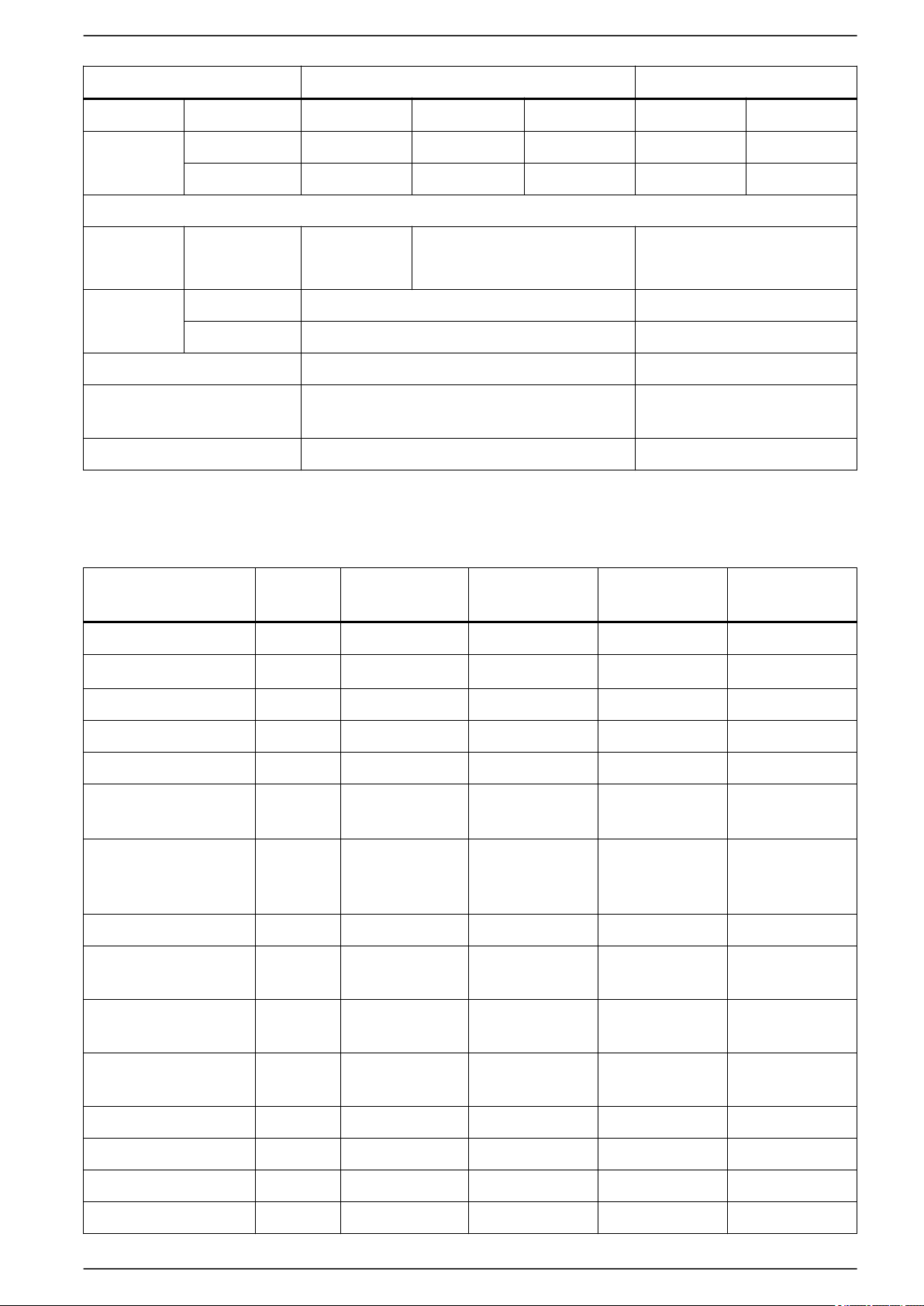

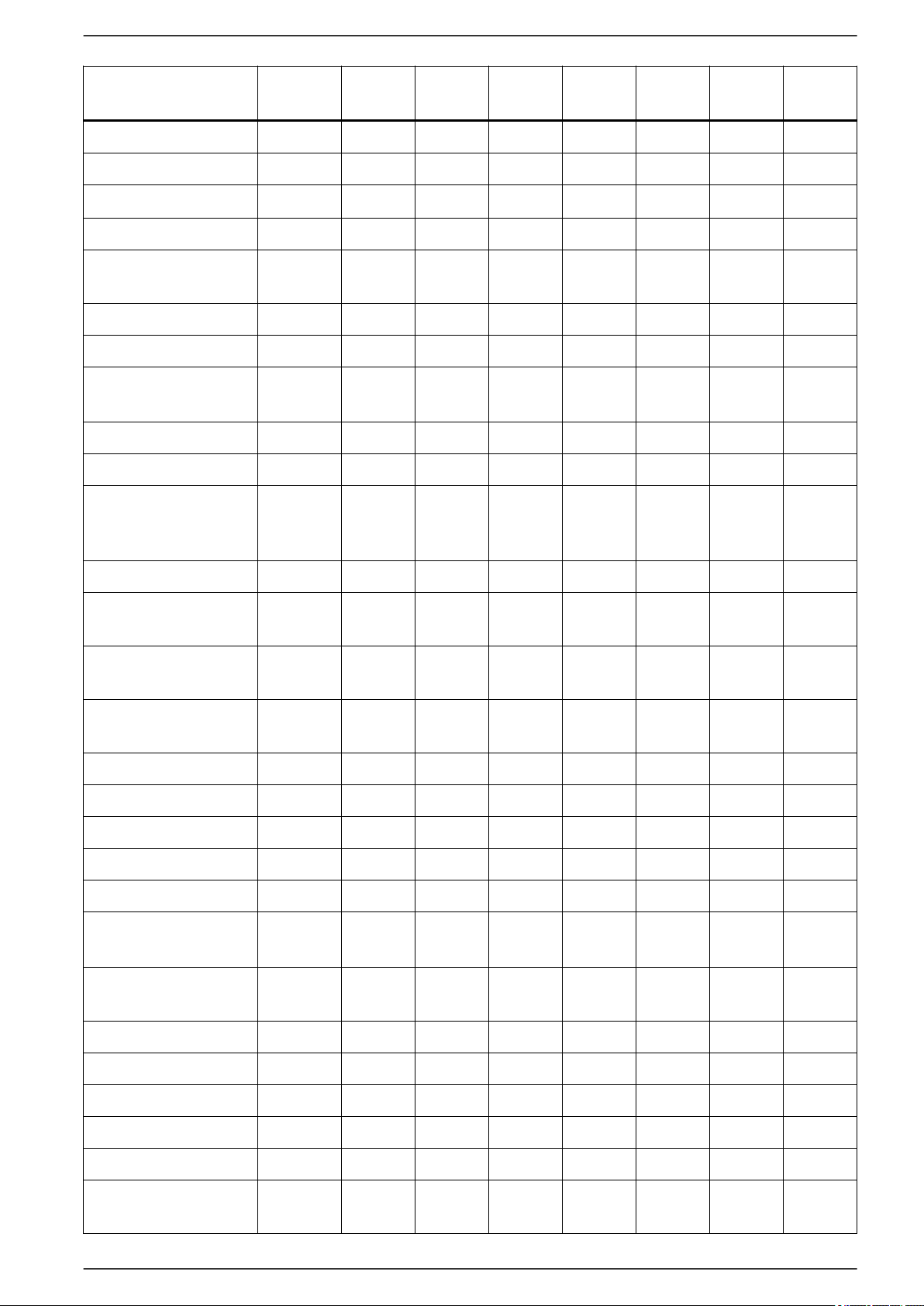

Table 5 - Protection functions for P3U

Protection functions ANSI

code

Feeder

P3U10/20

Feeder P3U30 Motor P3U10/20 Motor P3U30

Fault locator 21FL – 1 – 1

Synchronism check

Undervoltage 27 – 3 – 3

Directional power 32 – 2 – 2

Phase undercurrent 37 1 1 1 1

RTD temperature

monitoring

Negative sequence

overcurrent (motor,

generator)

Incorrect phase sequence 46 – – 1 1

Cur. unbalance, broken

conductor

Negative sequence

overvoltage protection

Excessive start time,

locked rotor

5

4

25 – 2 – 2

38/49T 12 12 12 12

46 – – 2 2

46BC 1 1 – –

47 – 3 – 3

48/51LR – – 1 1

Thermal overload 49 1 1 1 1

Phase overcurrent 50/51 3 3 3 3

Ground fault overcurrent 50N/51N 5 5 5 5

Breaker failure 50BF 1 1 1 1

P3U/en M/F005 21

Universal Relays P3U10, P3U20 and P3U30 2. Product introduction

Protection functions ANSI

code

Feeder

P3U10/20

Feeder P3U30 Motor P3U10/20 Motor P3U30

SOTF 50HS 1 1 1 1

Capacitor bank

unbalance

6

Voltage-dependent

51C 2 2 2 2

51V – 1 – 1

overcurrent

Overvoltage 59 – 3 – 3

Capacitor overvoltage 59C 1 1 – –

Neutral overvoltage 59N 3 3 3 3

CT supervision 60 1 1 1 1

VT supervision 60FL – 1 – 1

Starts per hour 66 – – 1 1

Directional phase

67 – 4 – 4

overcurrent

Directional ground fault

67N 3 3 3 3

o/c

Transient intermittent 67NI 1 1 – –

Second harmonic inrush

68F2 1 1 1 1

detection

Fifth harmonic detection 68H5 1 1 1 1

Auto-Recloser 79 5 5 – –

Over or under frequency 81 – 2/2 – 2/2

Rate of change of

81R – 1 – 1

frequency

Under frequency 81U – 2 – 2

Lockout 86 1 1 1 1

Programmable stages 99 8 8 8 8

Cold load pickup (CLPU) – 1 1 1 1

Programmable curves – 3 3 3 3

Setting groups

4

The availability depends on the selected voltage measurement mode (in the Scaling setting view in Easergy Pro)

5

Using external RTD module

6

Capacitor bank unbalance protection is connected to the ground fault overcurrent input and shares two stages with the ground fault

overcurrent protection.

7

Not all protection functions have 4 setting groups. See details in the manual.

7

– 4 4 4 4

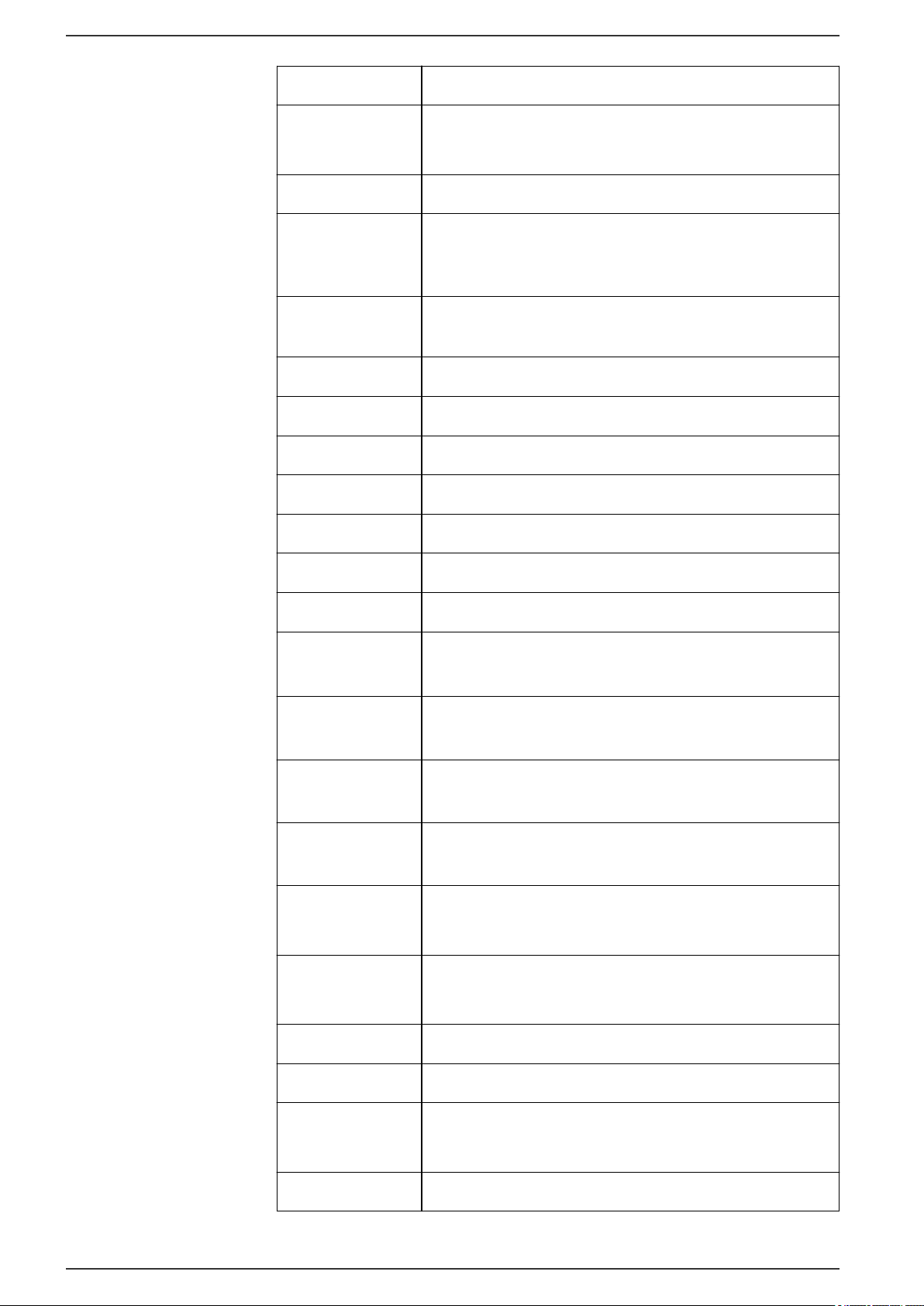

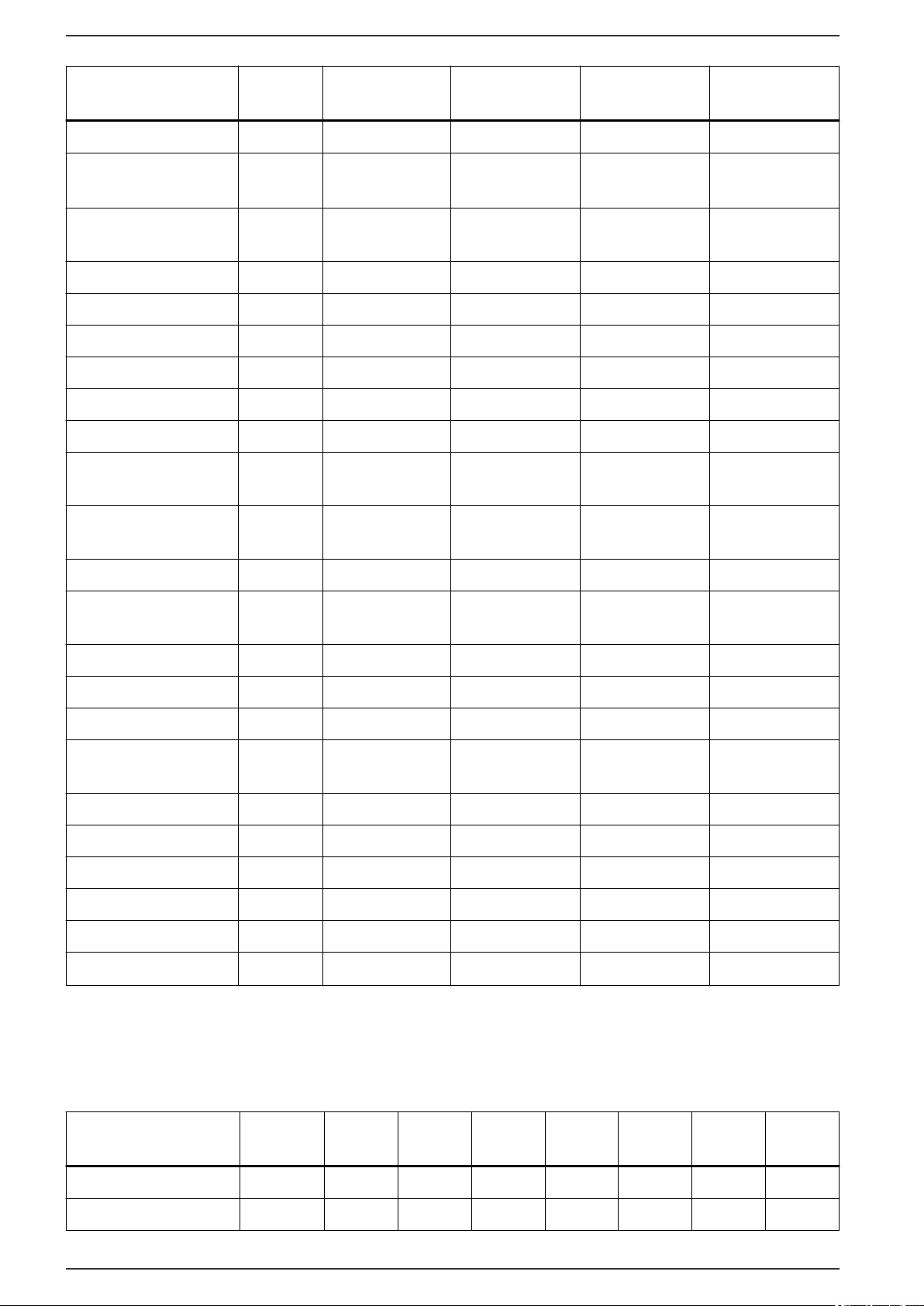

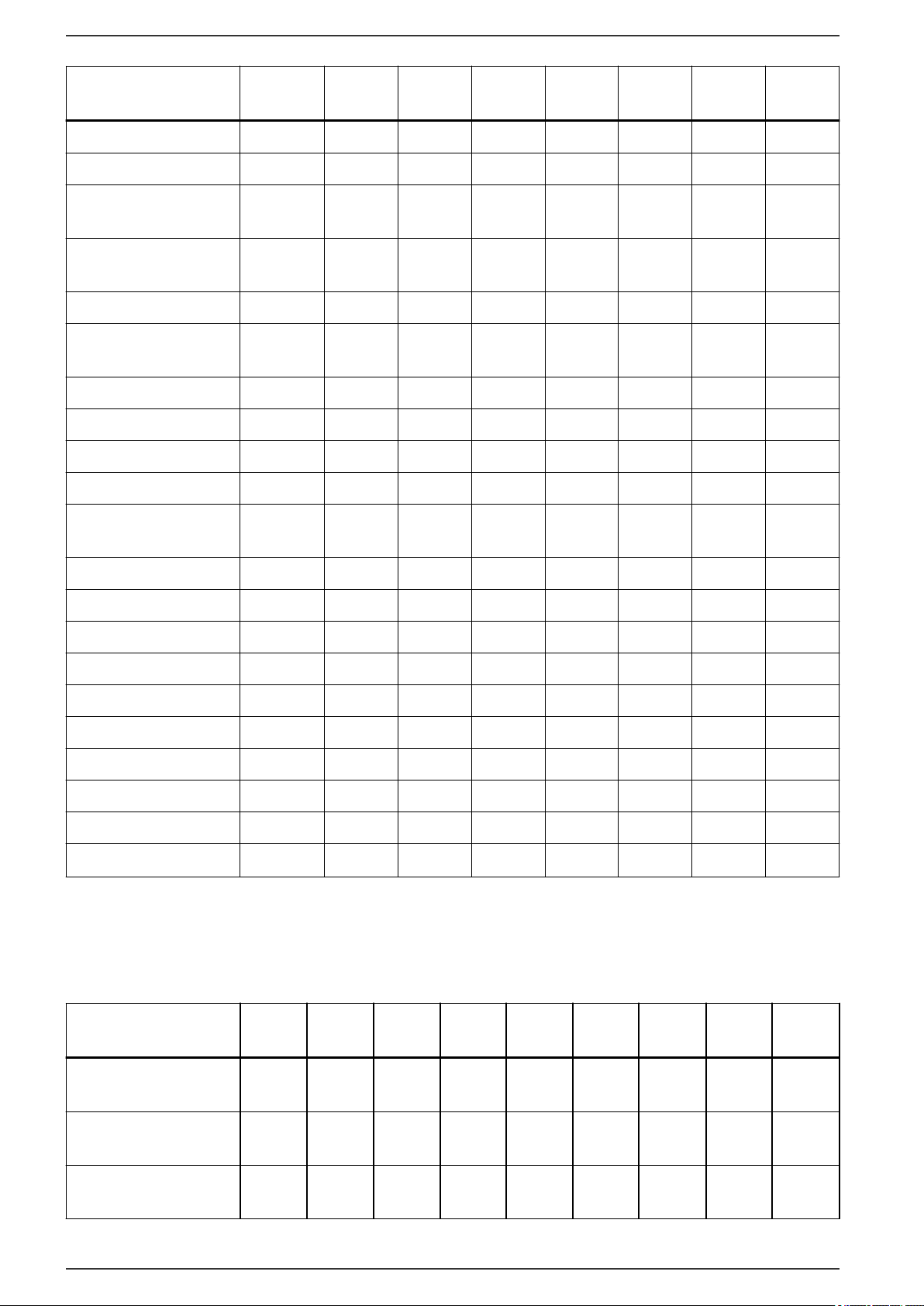

Table 6 - Protection functions for Px3x

Protection functions ANSI

P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

code

Distance 21 – 1 – – – – –

Under-impedance 21G – – – – 2 2 –

22 P3U/en M/F005

2. Product introduction Universal Relays P3U10, P3U20 and P3U30

Protection functions ANSI

P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

code

Fault locator 21FL 1 1 – – – – –

Overfluxing 24 – – – – 1 1 1

Synchronism check

8

Undervoltage 27 3 3 3 3 3 3 3

Positive sequence undervoltage

Directional power 32 2 2 2 2 2 2 2

Phase undercurrent 37 – – 1 1 – – –

RTD temperature

monitoring

9

Loss of field 40 – – – – 1 1 –

Under-reactance 21/40 – – – – 2 2 –

Negative sequence

overcurrent (motor,

generator)

25 2 2 2 2 2 2 2

27P – – – – 2 2 –

38/49T 12 12 12 12 12 12 12

46 – – 2 2 2 2 2

Incorrect phase sequence 46 – – 1 1 – – –

Cur. unbalance, broken

46BC 1 1 – – – – –

conductor

Negative sequence

47 3 3 3 3 3 3 3

overvoltage protection

Excessive start time,

48/51LR – – 1 1 – – –

locked rotor

Thermal overload 49 1 1 1 1 1 1 1

Phase overcurrent 50/51 3 3 3 3 3 3 3

Ground fault overcurrent 50N/51N 5 5 5 5 5 5 5

Breaker failure 50BF 1 1 1 1 1 1 1

SOTF 50HS 1 1 1 1 1 1 1

Capacitor bank

unbalance

10

Voltage-dependent

51C 2 2 2 2 2 2 2

51V 1 1 – – 1 1 –

overcurrent

Overvoltage 59 3 3 3 3 3 3 3

Capacitor overvoltage 59C 1 1 – – – – –

Neutral overvoltage 59N 2 2 2 2 2 2 2

CT supervision 60 1 1 1 1 1 2 2

VT supervision 60FL 1 1 1 1 1 1 1

Restricted ground fault

64REF – – – – – 1 1

(low impedance)

P3U/en M/F005 23

Universal Relays P3U10, P3U20 and P3U30 2. Product introduction

Protection functions ANSI

P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

code

Stator ground fault 64S – – – – 1 1 –

Starts per hour 66 – – 1 1 – – –

Directional phase

overcurrent

Directional ground fault

o/c

Transient intermittent 67NI 1 1 – – – – –

Second harmonic inrush

detection

Fifth harmonic detection 68H5 1 1 1 1 1 1 1

Pole slip 78PS – – – – 1 1 –

Auto-Recloser 79 5 5 – – – – –

Over or under frequency 81 2/2 2/2 2/2 2/2 2/2 2/2 2/2

Rate of change of

frequency

67 4 4 4 4 4 4 4

67N 3 3 3 3 3 3 3

68F2 1 1 1 1 1 1 1

81R 1 1 1 1 1 1 1

Under frequency 81U 2 2 2 2 2 2 2

Lockout 86 1 1 1 1 1 1 1

Line differential 87L – 2 – – – – –

Machine differential 87M – – – 2 – 2 –

Transformer differential 87T – – – – – – 2

Programmable stages 99 8 8 8 8 8 8 8

Arc flash detection (AFD) – 8 8 8 8 8 8 8

Cold load pickup (CLPU) – 1 1 1 1 1 1 1

Programmable curves – 3 3 3 3 3 3 3

Setting groups

8

The availability depends on the selected voltage measurement mode (in the Scaling setting view in Easergy Pro)

9

Using external RTD module

10

Capacitor bank unbalance protection is connected to the ground fault overcurrent input and shares two stages with the ground fault

overcurrent protection.

11

Not all protection functions have 4 setting groups. See details in the manual.

11

– 4 4 4 4 4 4 4

Table 7 - Control functions

Control functions P3U10/20P3U30 P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

Switchgear control and

1/2 4 6 6 6 6 6 6 6

monitoring

Switchgear monitoring

– – 2 2 2 2 2 2 2

only

Programmable switchgear

■ ■ ■ ■ ■ ■ ■ ■ ■

interlocking

24 P3U/en M/F005

2. Product introduction Universal Relays P3U10, P3U20 and P3U30

Control functions P3U10/20P3U30 P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

Local control on single-

■ ■ ■ ■ ■ ■ ■ ■ ■

line diagram

Local control with O/I keys ■ ■ ■ ■ ■ ■ ■ ■ ■

Local/remote function ■ ■ ■ ■ ■ ■ ■ ■ ■

Function keys 2 2 2 2 2 2 2 2 2

Custom logic (logic

■ ■ ■ ■ ■ ■ ■ ■ ■

equations)

Control with Smart App ■ ■ ■ ■ ■ ■ ■ ■ ■

Table 8 - Measurements

Measurement P3U10/20P3U30 P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

RMS current values ■ ■ ■ ■ ■

12

■

■

RMS voltage values ■ ■ ■ ■ ■ ■ ■ ■ ■

RMS active, reactive and

– ■ ■ ■ ■ ■ ■ ■ ■

apparent power

12

■

12

■

Frequency ■ ■ ■ ■ ■ ■ ■ ■ ■

Fundamental frequency

■ ■ ■ ■ ■

12

■

■

12

■

■

current values

Fundamental frequency

– ■ ■ ■ ■ ■ ■ ■ ■

voltage values

Fundamental frequency

– ■ ■ ■ ■ ■ ■ ■ ■

active, reactive and

apparent power values

Power factor – ■ ■ ■ ■ ■ ■ ■ ■

Energy values active and

– ■ ■ ■ ■ ■ ■ ■ ■

reactive

Energy transmitted with

– ■ ■ ■ ■ ■ ■ ■ ■

pulse outputs

Demand values: phase

■ ■ ■ ■ ■ ■ ■ ■ ■

currents

Demand values: active,

– ■ ■ ■ ■ ■ ■ ■ ■

reactive, apparent power

and power factor

12

Min and max demand

■ ■ ■ ■ ■ ■ ■ ■ ■

values: phase currents

Min and max demand

■ ■ ■ ■ ■ ■ ■ ■ ■

values: RMS phase

currents

P3U/en M/F005 25

Universal Relays P3U10, P3U20 and P3U30 2. Product introduction

Measurement P3U10/20P3U30 P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

Min and max demand

values: active, reactive,

apparent power and

power factor

Maximum demand values

over the last 31 days and

12 months: active,

reactive, apparent power

Minimum demand values

over the last 31 days and

12 months: active,

reactive power

Max and min values:

currents

Max and min values:

voltages

Max and min values:

frequency

– ■ ■ ■ ■ ■ ■ ■ ■

– ■ ■ ■ ■ ■ ■ ■ ■

– ■ ■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■ ■ ■

– ■ ■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■ ■ ■

Max andmin values:

– ■ ■ ■ ■ ■ ■ ■ ■

active, reactive, apparent

power and power factor

Harmonic values of phase

■ ■ ■ ■ ■

12

■

■

12

■

12

■

current and THD

Harmonic values of

– ■ ■ ■ ■ ■ ■ ■ ■

voltage and THD

Voltage sags and swells – ■ ■ ■ ■ ■ ■ ■ ■

12

Function available on both sets of CT inputs

Table 9 - Logs and records

Logs and Records P3U10/20P3U30 P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

Sequence of event record ■ ■ ■ ■ ■ ■ ■ ■ ■

Disturbance record ■ ■ ■ ■ ■ ■ ■ ■ ■

Tripping context record ■ ■ ■ ■ ■ ■ ■ ■ ■

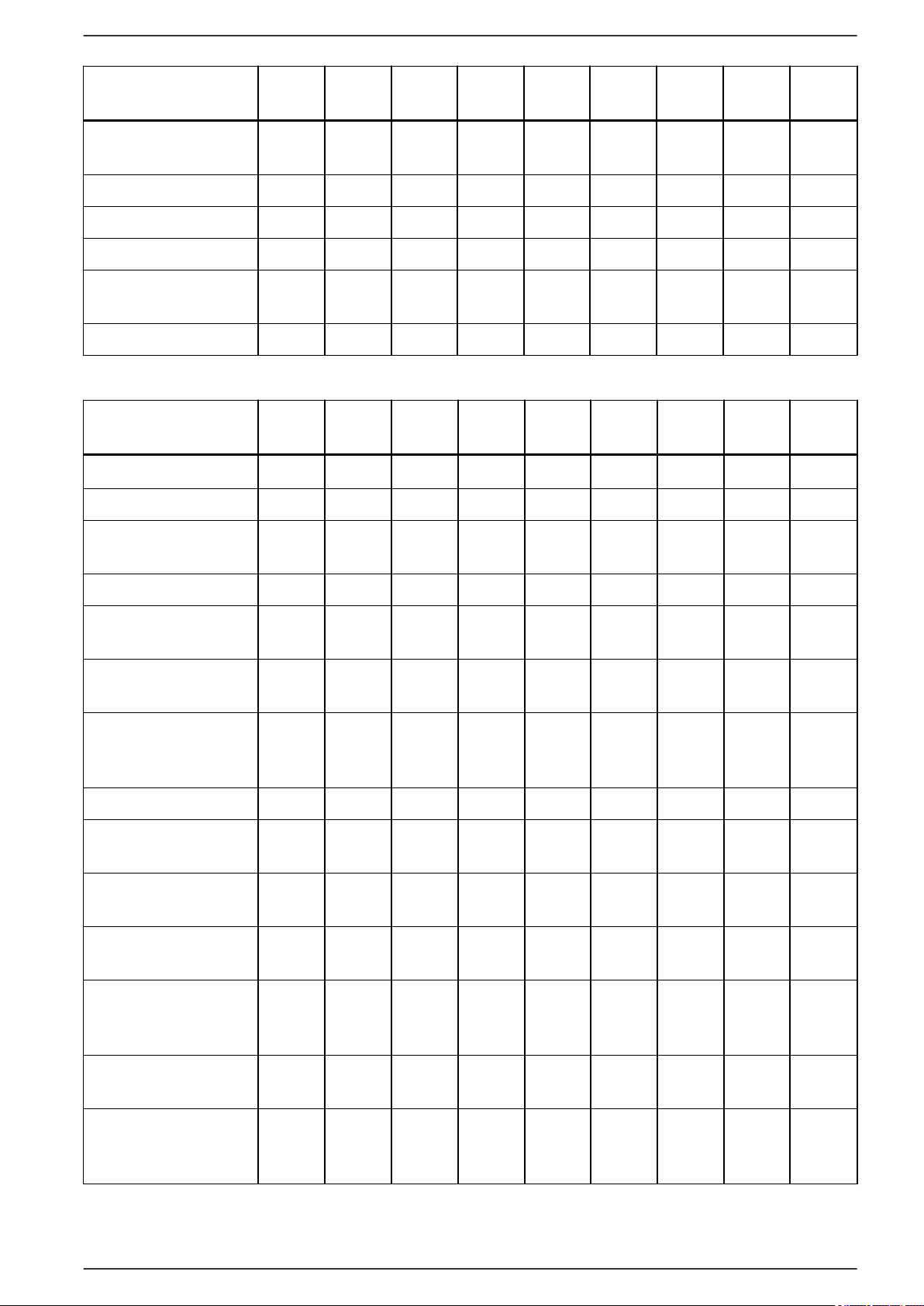

Table 10 - Monitoring functions

Monitoring functions

Trip circuit supervision

P3U10/

20

P3U30 P3F30 P3L30 P3M30 P3M32 P3G30 P3G32 P3T32

1 1 1 1 1 1 1 1 1

(ANSI 74)

Circuit breaker monitoring 1 1 1 1 1 1 1 1 1

Relay monitoring ■ ■ ■ ■ ■ ■ ■ ■ ■

26 P3U/en M/F005

2. Product introduction Universal Relays P3U10, P3U20 and P3U30

NOTE:

(1) Capacitor bank unbalance protection is connected to the ground fault overcurrent

input and shares two stages with the ground fault overcurrent protection.

(2) Not all protection functions have four setting groups. See details in the manual.

(3) Function available on both sets of CT inputs

(4) Using external RTD module

(5) The availability depends on the selected voltage measurement mode (in the Scaling

setting view in Easergy Pro).

2.4. Access to device configuration

You can access the device configuration via:

• the Easergy Pro setting tool

• the device’s front panel

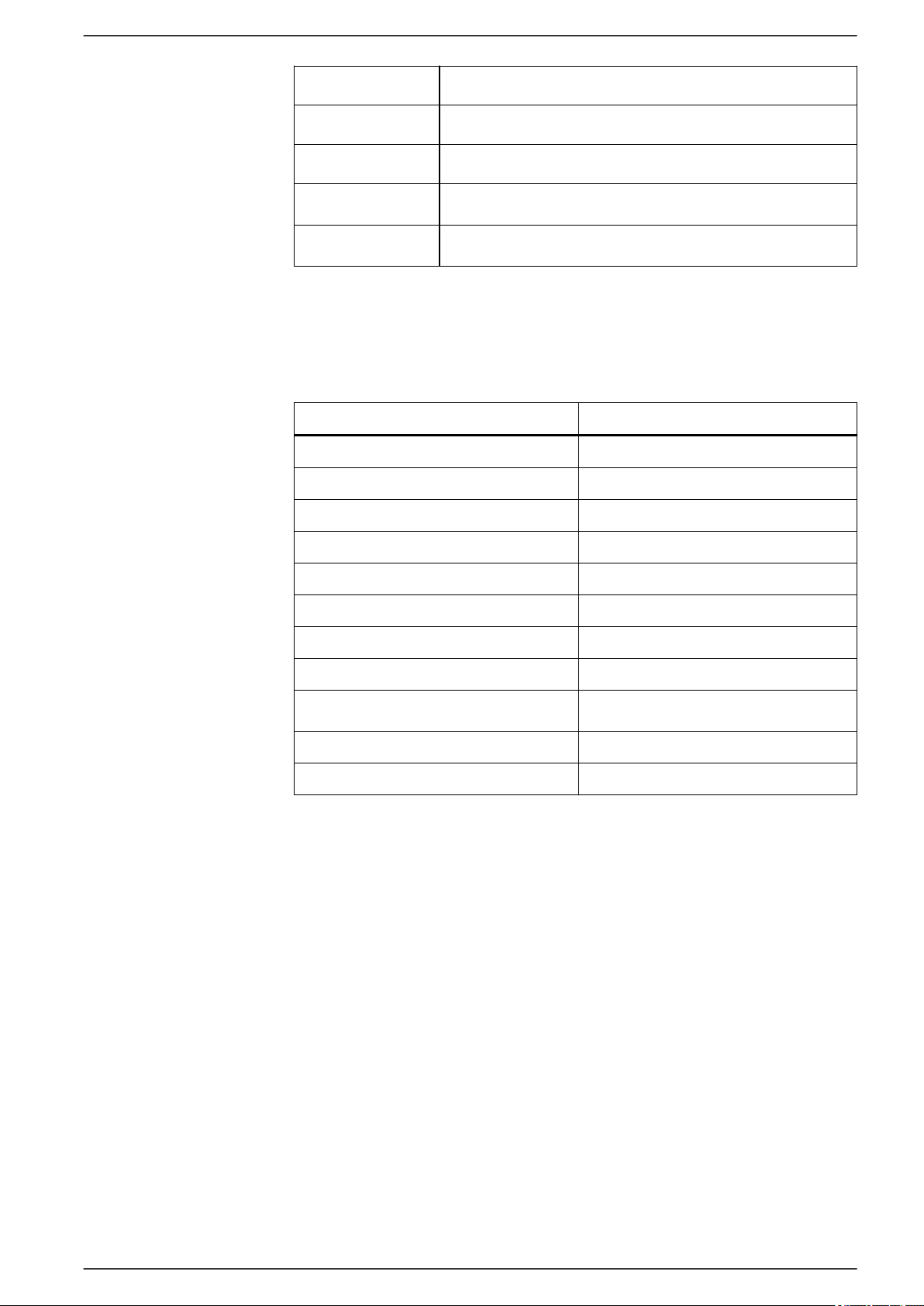

2.4.1. User accounts

By default, the Easergy P3 device has five user accounts.

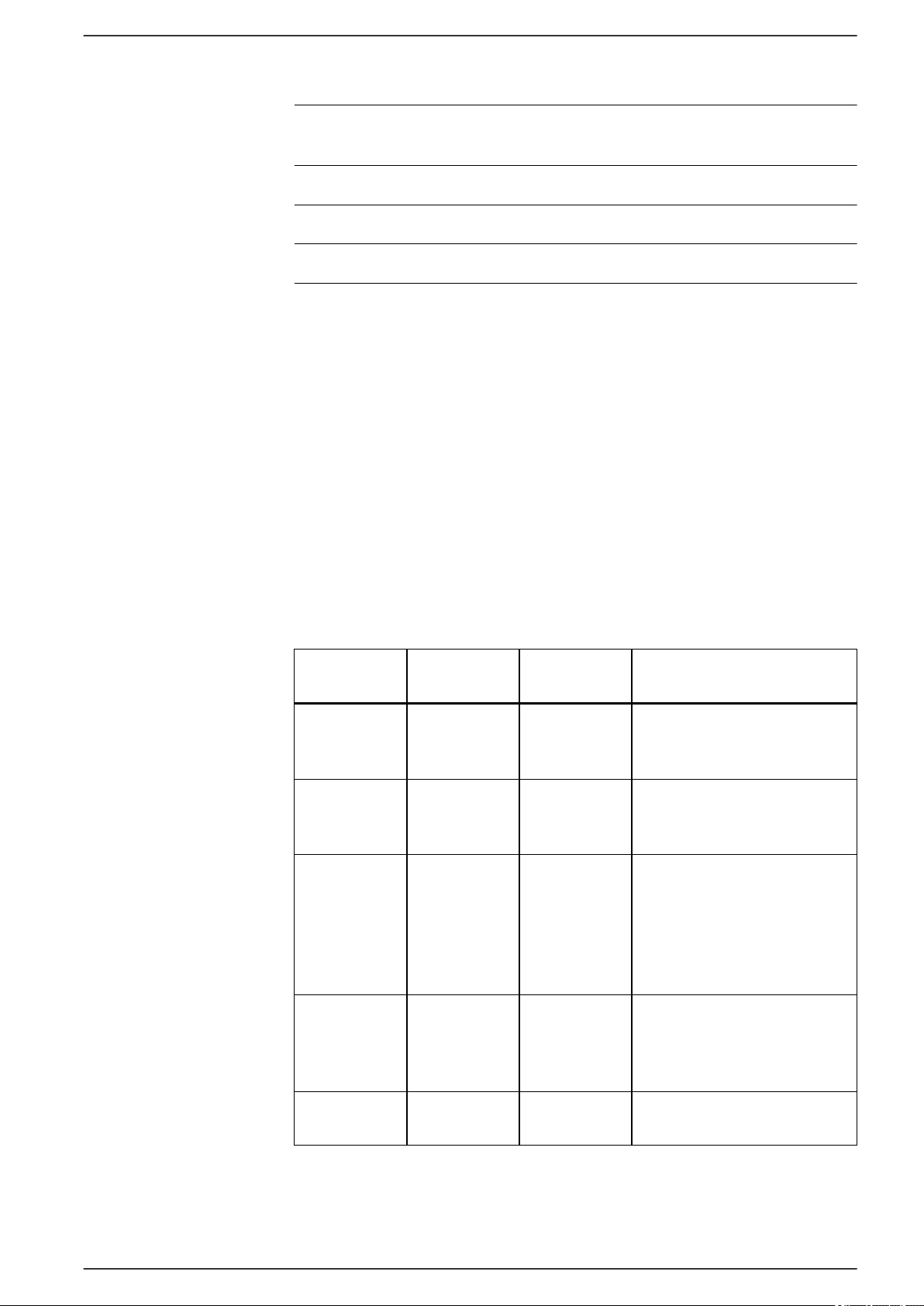

Table 11 - User accounts

User account User name Default

Use

password

User user 0 Used for reading parameter

values, measurements, and

events, for example

Operator operator 1 Used for controlling objects and

for changing the protection stages’

settings, for example

Configurator conf 2 Needed during the device

commissioning. For example, the

scaling of the voltage and current

transformers can be set only with

this user account. Also used for

logging on to the HTTP server

Administrator admin 3 Needed for changing the

passwords for other user accounts

and for creating new user

accounts

Easergy easergy 2 Used for logging on to the FTP

server

P3U/en M/F005 27

***************

0

Universal Relays P3U10, P3U20 and P3U30 2. Product introduction

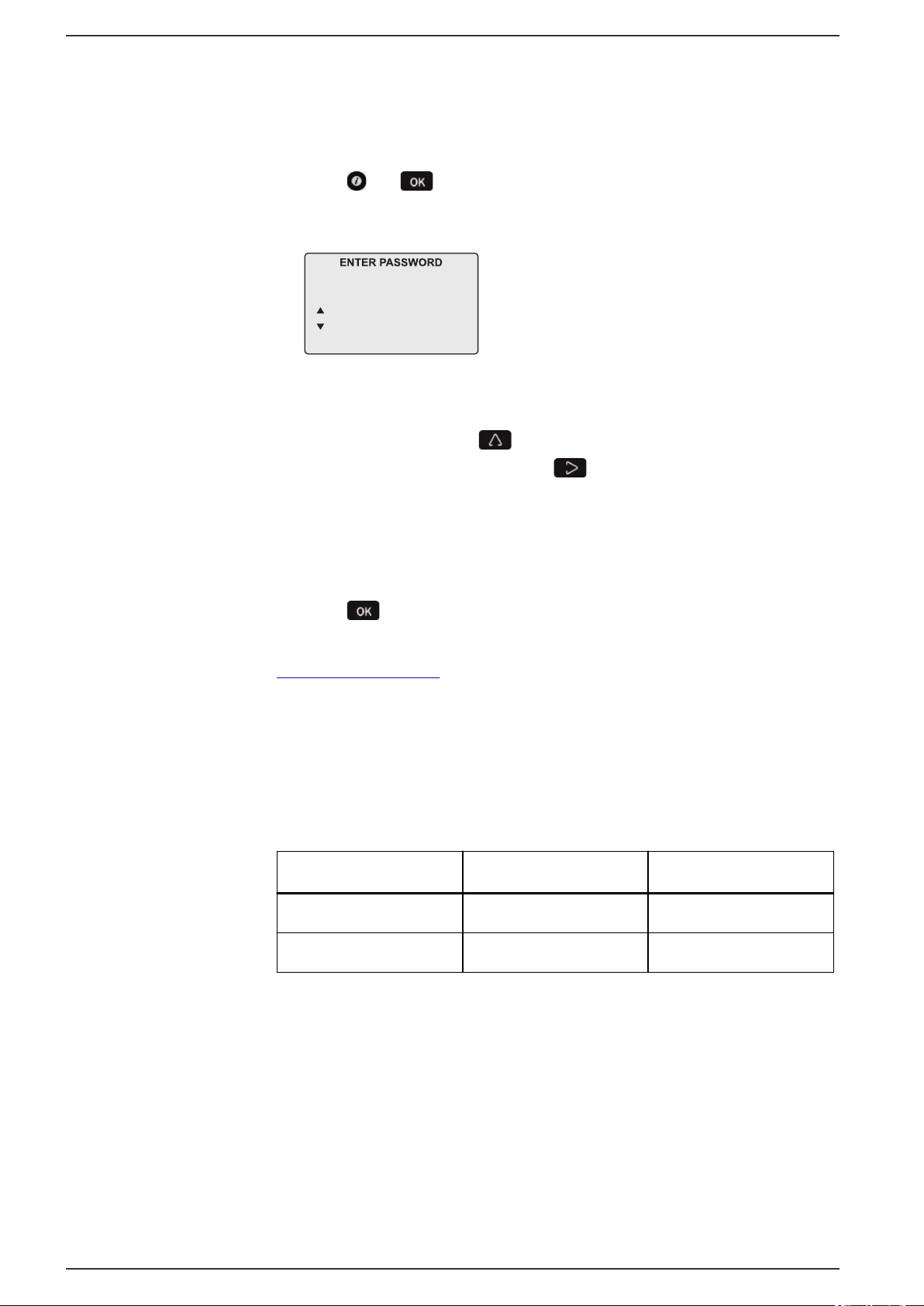

2.4.2. Logging on via the front panel

NOTE: To log on via the front panel, you need a password that consists of

digits only.

1. Press and on the front panel. The Enter password view opens.

Figure 1 - Enter password view

2. Enter the password for the desired access level.

Select a digit value using

move to the next digit position using

NOTE: There are 16 digit positions in the Enter password view. Enter the

password starting from the first digit position.

For example, if the password is 2, you can enter 2***, **2*, ***2, or 0002

to log on.

3. Press

Related topics

Password management on page 29

to confirm the password.

2.4.3. HTTP and FTP logon details

You can log on to the HTTP server and FTP using these user names and

passwords.

Table 12 - HTTP and FTP logon details

Protocol User name Password

, and if the password is longer than one digit,

.

28 P3U/en M/F005

HTTP conf 2

FTP easergy 2

2. Product introduction

2.4.4. Password management

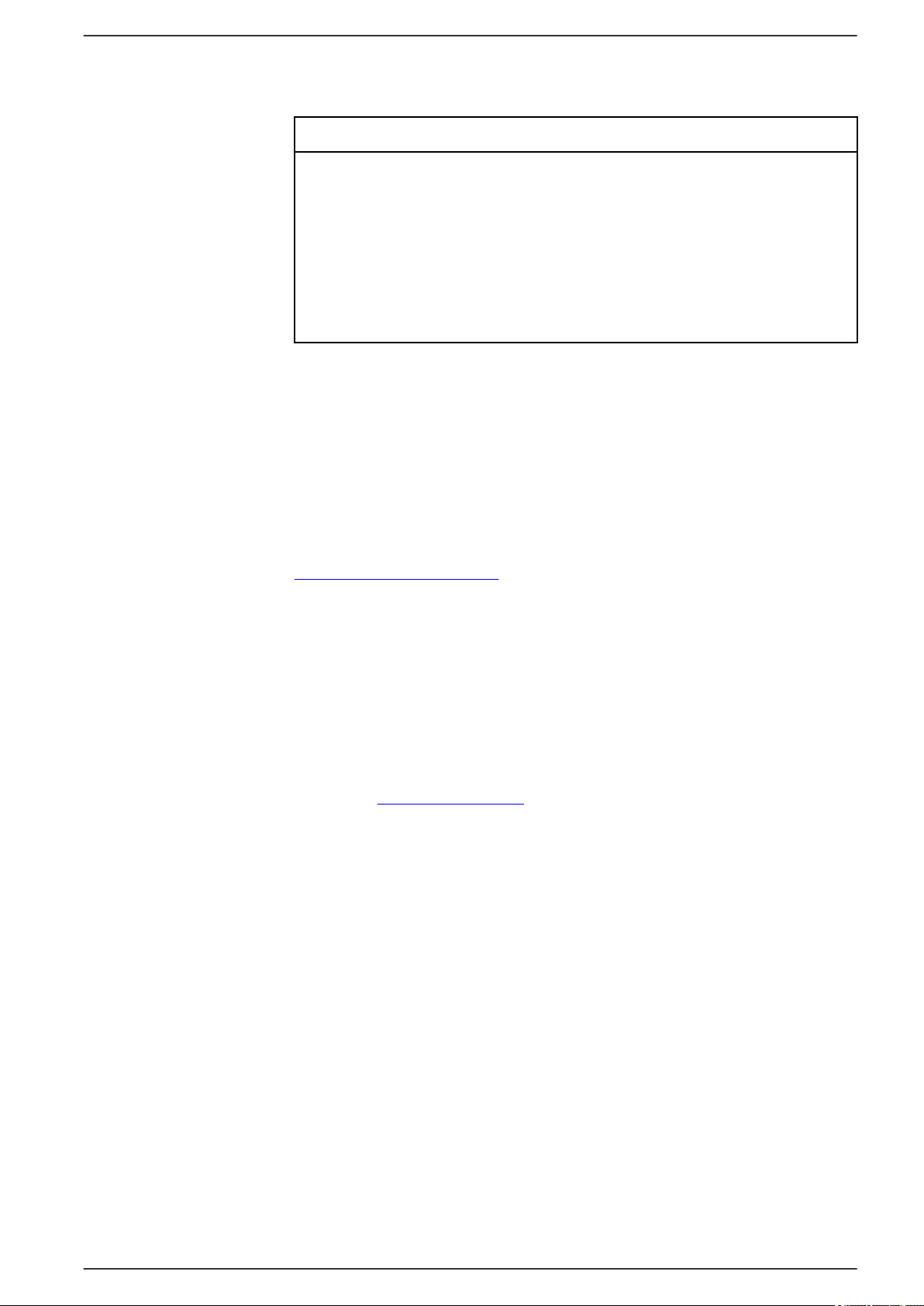

CYBERSECURITY HAZARD

To improve cybersecurity:

• Change all passwords from their default values when taking the protection

device into use.

• Change all passwords regularly.

Failure to follow these instructions can increase the risk of unauthorized

access.

You can change the password for the operator or configurator user accounts in

the General > Device info setting view in Easergy Pro.

The password can contain letters, digits or any other UTF-8 characters (total 1–32

characters). However, the new password cannot be any of the default passwords

(digits 0–4 or 9999).

Universal Relays P3U10, P3U20 and P3U30

NOTICE

NOTE: To log on via the front panel, you need a password that consists of

digits only.

Related topics

Logging on via the front panel on page 28

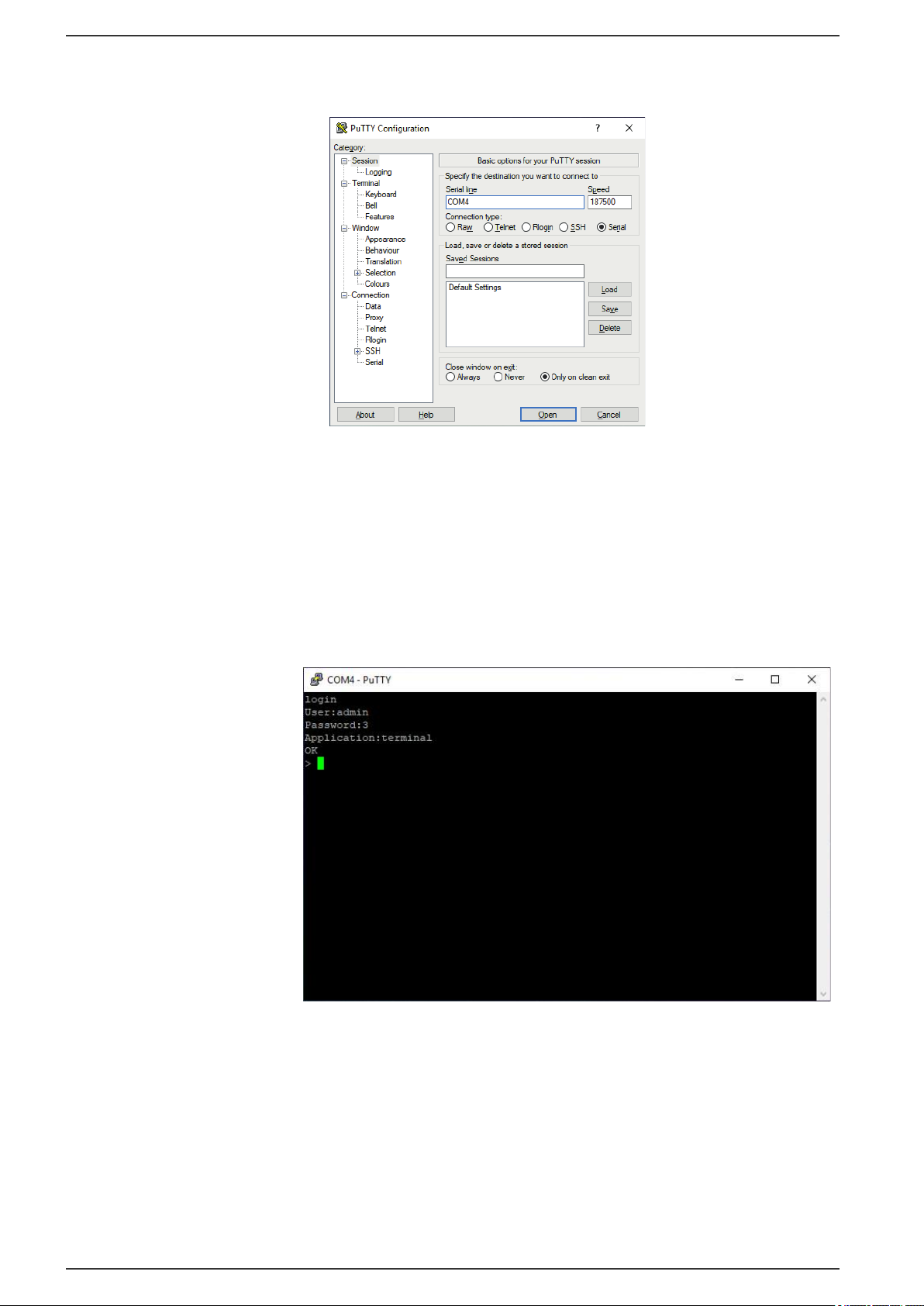

2.4.5. Changing passwords for administrator and configurator accounts via PuTTY

Change the password for the administrator and configurator user accounts to

reach an optimal cybersecurity level. To log on as the administrator user, you

need to use either a serial terminal software or a Telnet client software. This

instruction describes how to change the passwords using PuTTY which is freely

available at https://www.putty.org/.

1. Download and install PuTTY.

2. Connect the Easergy P3 device to your PC via the USB port in the device's

front panel.

3. Find the COM port number for the device (for example, with Easergy Pro).

4. Connect to the device’s COM port via PuTTY.

a. Open PuTTY.

The PuTTY Configuration dialog box opens.

P3U/en M/F005 29

Universal Relays P3U10, P3U20 and P3U30

2. Product introduction

Figure 2 - PuTTY Configuration dialog box

b. In the Serial line field, type the COM port name.

c. In the Speed field, set the communication speed to 187500 bps.

d. Click Open.

The PuTTY command window opens.

5. Log on as the administrator by giving command login.

Figure 3 - PuTTY login

6. Change the password for the administrator account by giving the command

passwd.

30 P3U/en M/F005

Loading...

Loading...