Schneider Electric Limit Switches Catalog

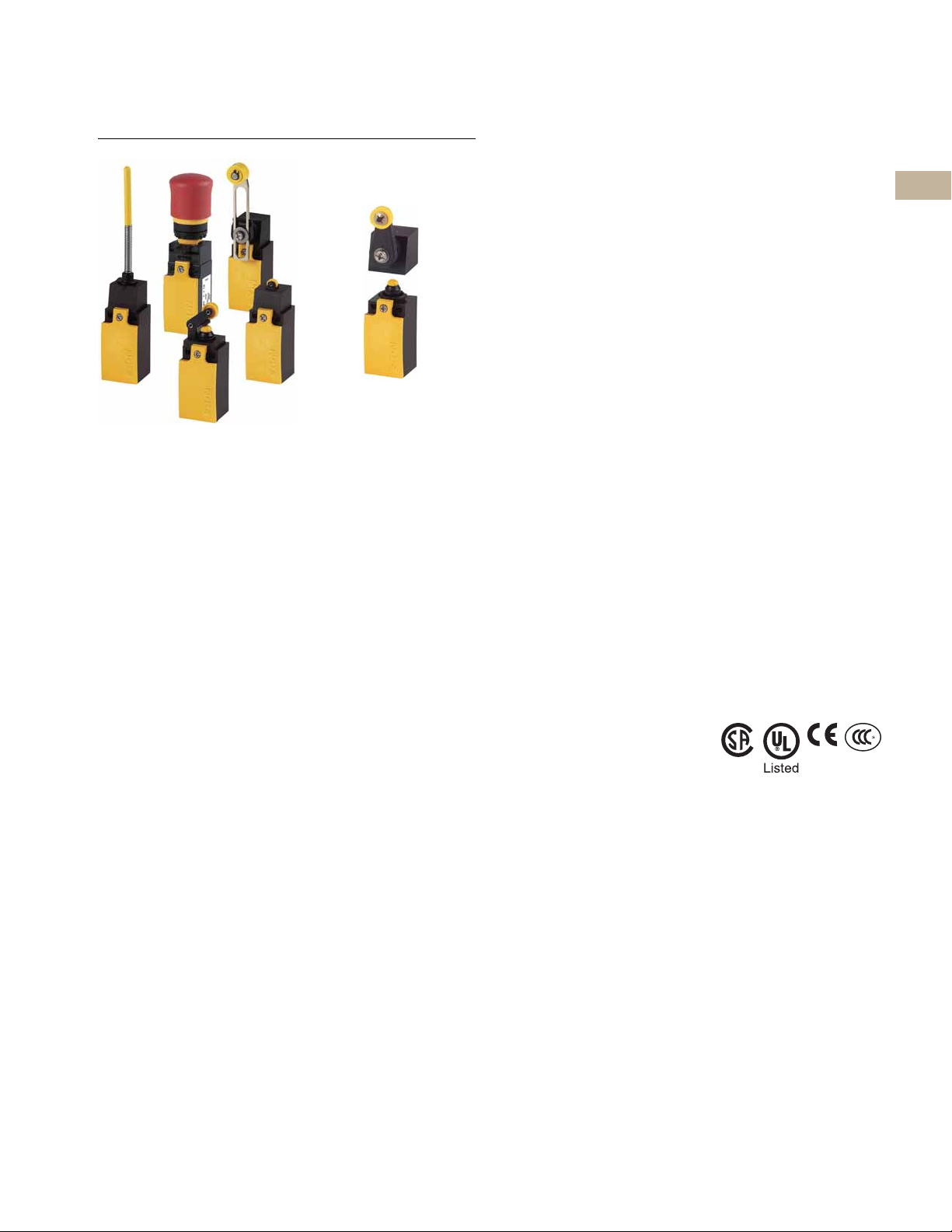

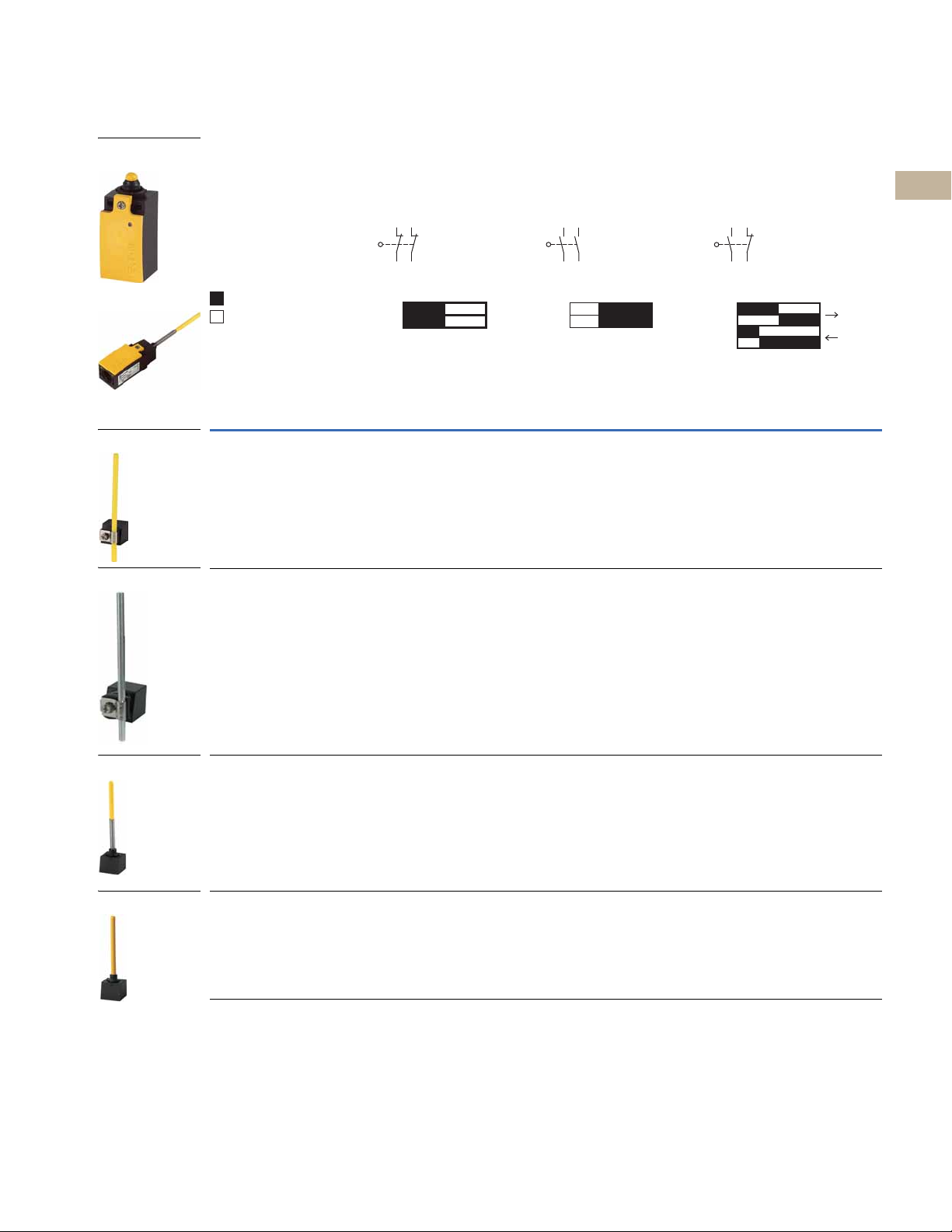

Limit Switches

E47 Precision Switch

LS-Titan Miniature DIN Switch

E49 Compact Metal Switch

Heavy-Duty Factory Sealed

6P+ Switch

Compact Prewired Switch

Learn

Online

2.0 Introduction

Technical Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-2

Product Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-3

2.1 E47 Precision Switches

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-6

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-7

2.2 Compact Prewired Switches

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-15

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-16

2.3 LS-Titan Miniature DIN Switches

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-21

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-23

2.4 E49 Mini Metal Switches

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-43

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-44

2.5 E49 Compact Metal Switches

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-49

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-50

2.6 E50 Heavy-Duty Plug-In Switches

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-54

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-55

2.7 E50 Heavy-Duty Factory Sealed 6P+ Switches

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-68

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-69

2.8 Operators

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-80

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-81

2.9 Non Plug-In Switches

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-89

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-90

2.10 Hazardous Location Limit Switches

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-92

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-93

2.11 Special Purpose Limit Switches

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-96

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-97

Unless otherwise noted, the products contained in this section should not

be used for functional safety applications. These products were not designed

or tested to IEC 60947-5-3 or recommended for functional safety.

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Volume 8—Sensing Solutions CA08100010E—May 2013

2

2

2

2

V8-T2-1

2.0

Differential

Reset Point

Initial Position

Operating

Point

Pre-travel

Over-travel

Initial Position

Over-travel

Reset Point

Operating Point

Pre-travel

Final Position

Differential

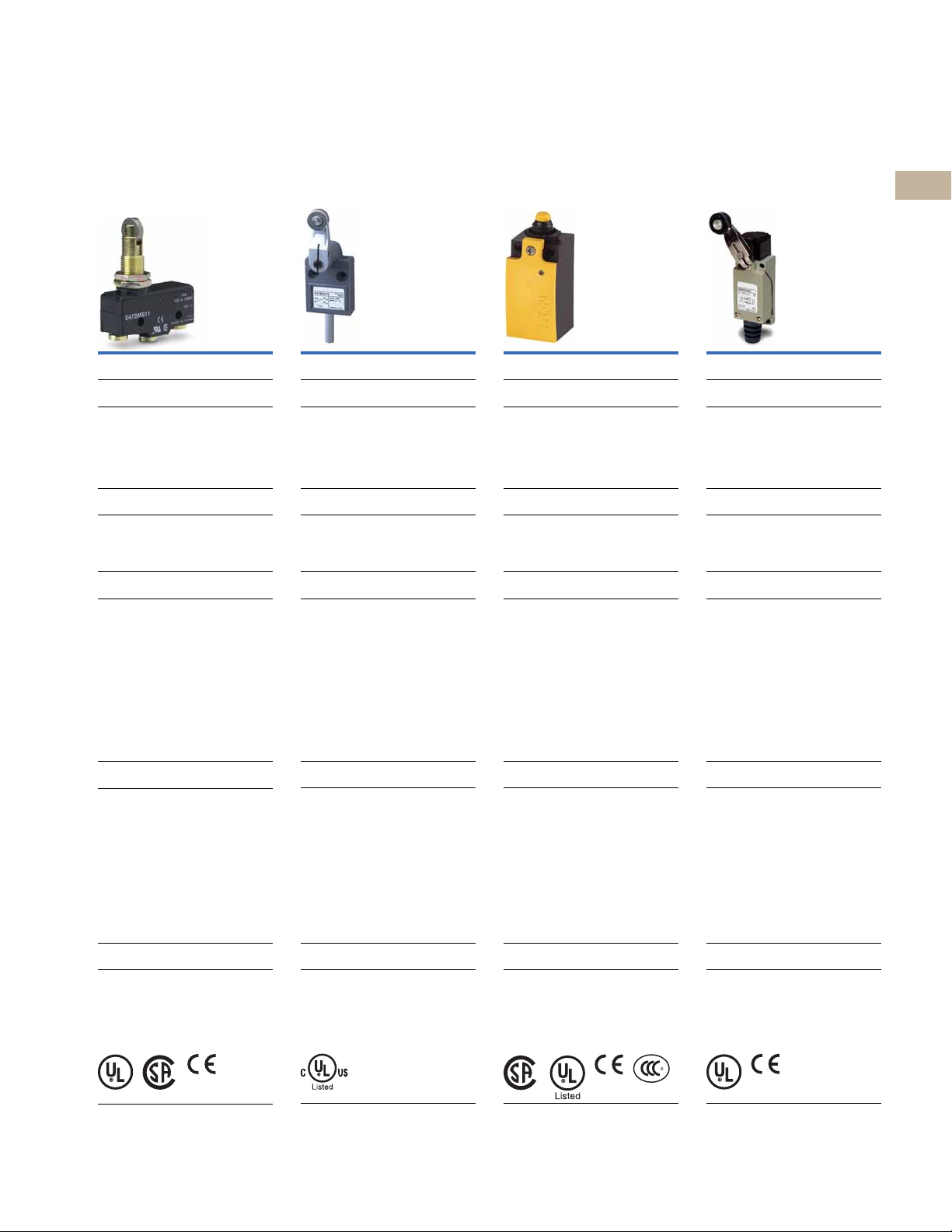

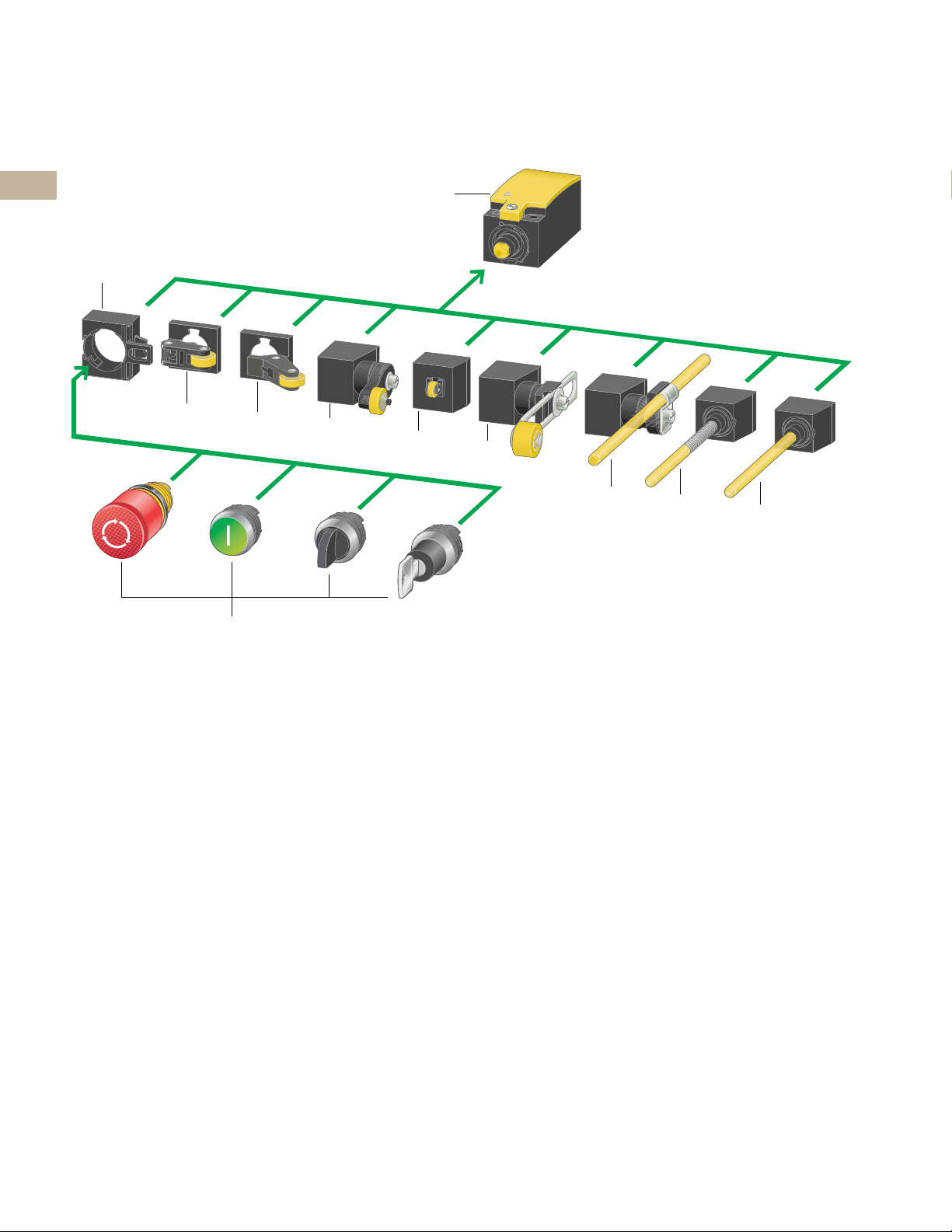

Actuator/

Operating

Head

Switch

Body

Switch

Body

Actuator/

Operating

Head

Receptacle/

Terminals

Technical Reference

2

Limit Switches

2

2

2

2

2

2

2

2

2

Mechanical Limit Switches

2

are contact sensors widely

used for detecting the

2

presence or position of

objects in industrial

applications.

2

2

2

2

Lever Type Actuator

2

Limit Switches

Introduction

Limit Switches offer high

precision in terms of accuracy

and repeatability. This is

primarily due to the fact that

they make direct contact

with the target. When an

object contacts the limit

switch lever (or plunger)

the lever moves a pre-travel

distance to the operating

point where the contacts are

tripped. Movement of the

lever beyond this point is

called the over-travel.

Limit switches contain the

following major components.

These may be modular or part

of a single-piece switch.

Limit Switch Components

2

2

2

2

2

2

2

2

2

2

2

2

2

Refer to Sensor Learning Course, Page V8-T12-4, for a

complete description of limit switch terminology.

V8-T2-2

Volume 8—Sensing Solutions CA08100010E—May 2013

Actuator

This is the part of the switch

that contacts the target.

Typical actuators are levers

and plungers. Several styles

are available, see Sensor

Learning Course, Page

V8-T12-4, for more

information.

Switch Body

This part contains the

electrical contact mechanism.

For complete information on

electrical outputs, see Sensor

Learning Course, Page

V8-T12-4.

Te rm in al s

The terminals are the point of

connection for the wiring.

These terminals may be on

the body itself, or housed in a

removable receptacle. The

limit switch may also come

equipped with a factory

installed cable or pinconnector.

Limit Switches

Introduction

2.0

Product Selection Guide

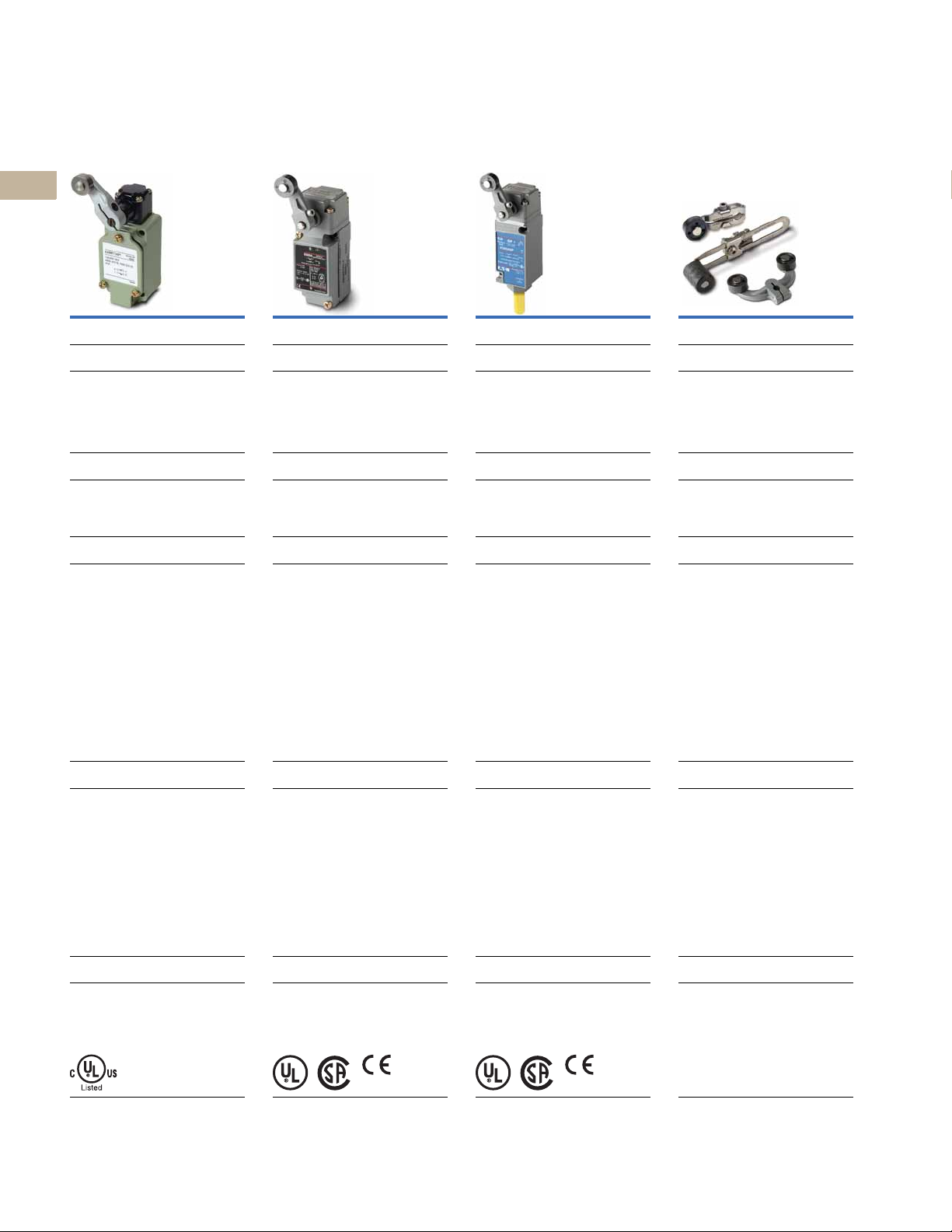

E47 Precision Switches

Page V8- T2 -6

Overview

Specified when accurate repeatability,

choice of operating forces and travel

characteristics and tightly controlled

action of cam or target in space restricted

areas are of prime importance. Cost

effective and compact.

Applications

Overhead, folding and elevator doors,

sliding gates, automated guided vehicles

and commercial instrumentation

Product Features

Self-contained switches or with an enclosed

cast housing for increased durability and

conduit connection

(1/2 in NPT)

High current capacity for power load

switching and motor handling capability

Screw and solder terminations

Booted enclosed version shields actuators

from debris

Mounting centers—1.0 in (25.4 mm),

#8 screw size

Technical Data and Specifications

Mechanical life: 3,000,000 operations min.

Electrical life: 500,000 operations min.

Contact ratings—

NEMA A600, R300, AC-15, DC-13

15A/20A, 125 or 250 Vac

Enclosure ratings—

Enclosed: NEMA 1

Construction—

Basic: Phenolic

Enclosed: Aluminum die cast

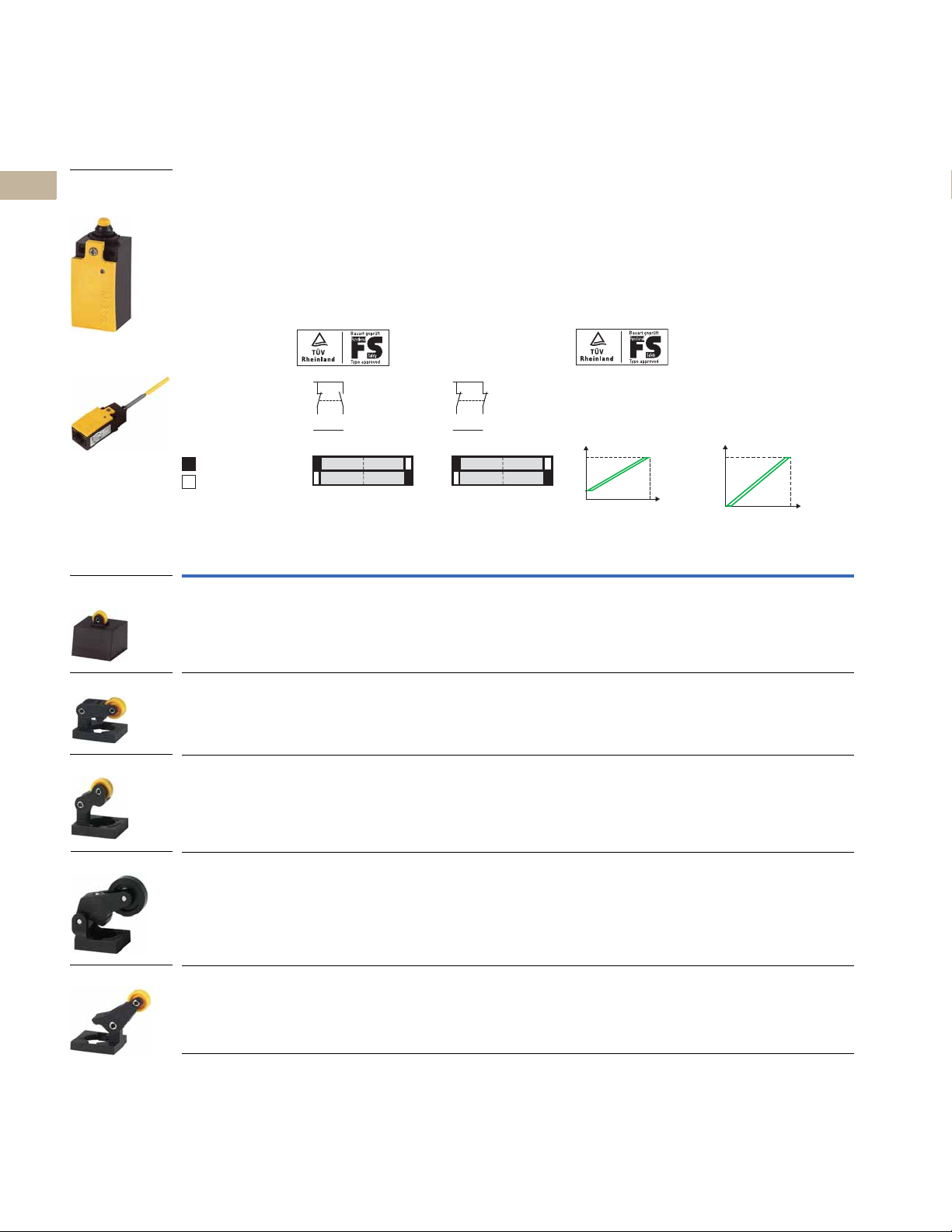

Compact Prewired

Switches

Page V8- T2 -15

Overview

Designed to be a versatile, slim device for

hard to fit applications where sealing

integrity is required.

Applications

Machine tool, food processing and

packaging

Product Features

Rugged aluminum alloy die cast housing

Sealed construction with enclosure ratings

of NEMA 4, 6 and 13

Prewired with 3m of 18 AWG, AWM 2517,

300V cable

Stackable ridge for ganged operation

Technical Data and Specifications

Mechanical life: 10,000,000 operations

min.

Electrical life: 200,000 operations

30 operations min.

Contact ratings—

NEMA B300

Enclosure ratings—

NEMA 4, 6 and 13; IP67, IP69K

Construction—

Aluminum alloy die cast

LS-Titan Miniature

DIN Switches E49 Mini Metal Switches

Page V8- T2 -21

Overview

Safety position switches with

insulated plastic or rugged metal

enclosures. Approved for worldwide

safety application.

Applications

Automatic vending machines, electronic

assembly machines, elevators and lifts,

injection molding, packaging and safety

applications

Product Features

Modular plug-in head and body components

Positive opening NC contacts for safety

applications

Operating heads can be rotated 90 degrees

to suit specific direction of operation

Technical Data and Specifications

Mechanical life: 8,000,000 operations

Contact ratings—

AC-15, 6A at 24V, 6A at 230/240V,

4A at 400/415V;

DC-13, 3A at 24V, 800 mA at 110V,

300 mA at 220V

Enclosure ratings—

IP66, IP67 (by model)

Construction—

Plastic or metal (by model)

Page V8-T2-43

Overview

Suitable for OEMs who require a small,

cost-effective solution but cannot sacrifice

durability and mechanical life as they would

if they chose a plastic IEC style switch.

Applications

Automatic vending machines, electronic

assembly machines, elevators and lifts,

injection molding, packaging

Product Features

Pre-wired units with custom cable lengths

available for high volume customers

“Fingerproof” terminals protect against

accidental shock

Double-spring mechanism for contact

reliability

Grounding terminal included

Captive screws on enclosure cover make

wiring hassle-free

SPDT double break

Technical Data and Specifications

Contact ratings—

5A at 250 Vac

5A at 30 Vdc

Enclosure ratings—

IP65

Construction—

Zinc alloy

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Approvals

®

Recognized

UL

®

Certified

CSA

CE

Approvals

cULus

Approvals

Safety function, IEC/EN 60947-5-1

TÜV-Rheinland certified (LSE models)

CSA certified

UL listed

CE

CCC

Volume 8—Sensing Solutions CA08100010E—May 2013

Approvals

UL Recognized

CE

2

2

2

2

2

2

V8-T2-3

2.0

Limit Switches

Introduction

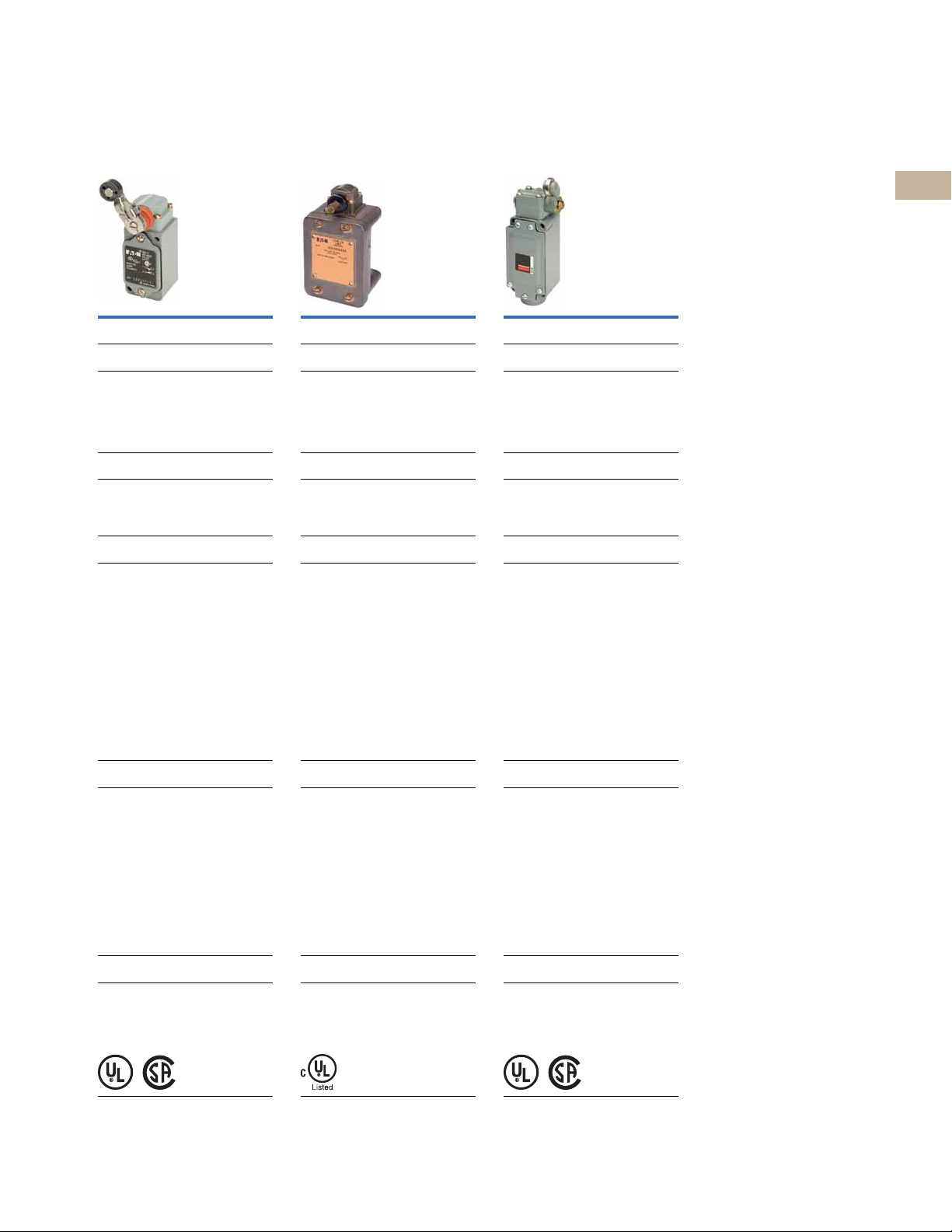

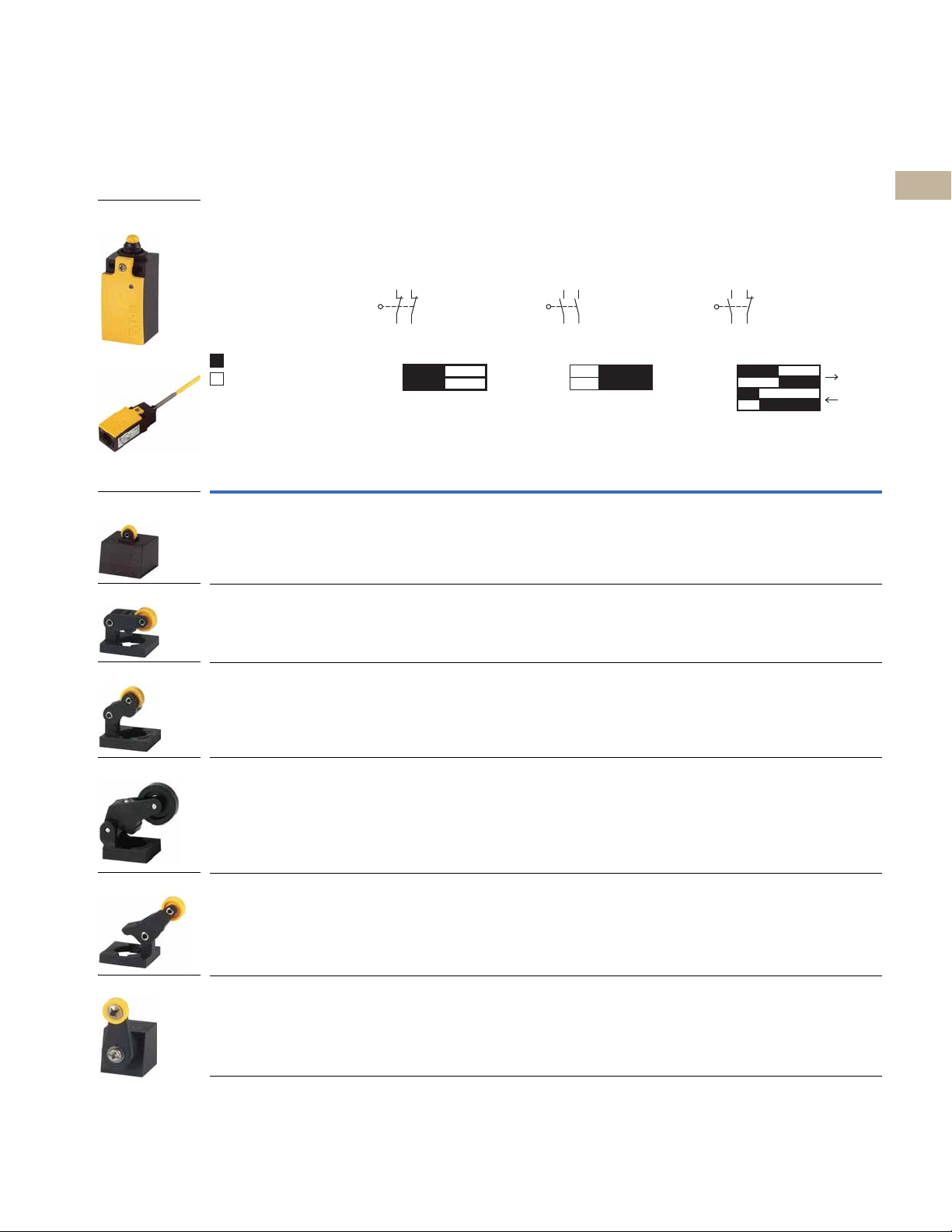

E49 Compact Metal

2

Switches

2

2

2

2

2

Page V8-T2-49

2

Overview

Designed with high mechanical strength for

2

robust environments. The rugged Aluminum

die cast construction provides reliable, oiltight, waterproof and dustproof sealing for

2

a variety of applications. Snap action 1NO1NC contacts provide flexibility in design.

2

Applications

Packaging, material handling conveyors,

2

end-of-travel and guarding operations,

baler/compactor, industrial door lifts

2

Product Features

2

Rigid die cast switch housing

Set position indicator plate for easy

2

maintenance

High mechanical strength

2

Oiltight, waterproof and dustproof

construction

2

2

2

2

Technical Data and Specifications

2

Mechanical life: 15,000,000 operations

min.

Electrical life: 500,000 operations

2

min. at full load

Contact ratings—

2

NEMA A600, R300; AC-15, DC-13

Enclosure ratings—

2

NEMA 4, 4X, 6, 6P, 12, 13; IP65, IP67

Construction—

2

Aluminum die cast

2

Approvals

cULus

2

IP67

2

2

E50 Heavy-Duty Plug-In

Switches

Page V8-T2-54

Overview

Versatile in design. High reliability. Low

maintenance costs with installation ease.

BEST CHOICE for Heavy-Duty Limit Switch

applications. Withstands physical and

chemical abuse of harsh industrial

environments.

Applications

Punch presses, waste water treatment,

machine tool, automotive, retrieval

systems, industrial truck, car wash lines

Product Features

Modular operating heads, switch bodies

and receptacles are interchangeable

without field adjustment

Order as complete assemblies or

components for stocking and

manufacturing flexibility

90 degree total travel, 5 degree pre-travel

characteristics are standard features

®

gasket, boot, and seal material

Viton

offers exceptional chemical resistance

Rotary head operating mode from CW,

CCW or CW and CCW is easily changed

without tools

Technical Data and Specifications

Mechanical life: 13,000,000 operations

min.

Electrical life: 1,000,000 operations

min. at full load (single-pole)

Contact ratings—

NEMA A600, R300

Lighted versions A150, R150

6A, 120 Vac; 10A continuous

Enclosure ratings—

NEMA 1, 3, 3S, 4, 4X, 6, 6P, 13; IP67

Construction—Zinc die cast

Approvals

UL Listed

CSA Certified

IEC 947-5-1

TUV

CE (some models)

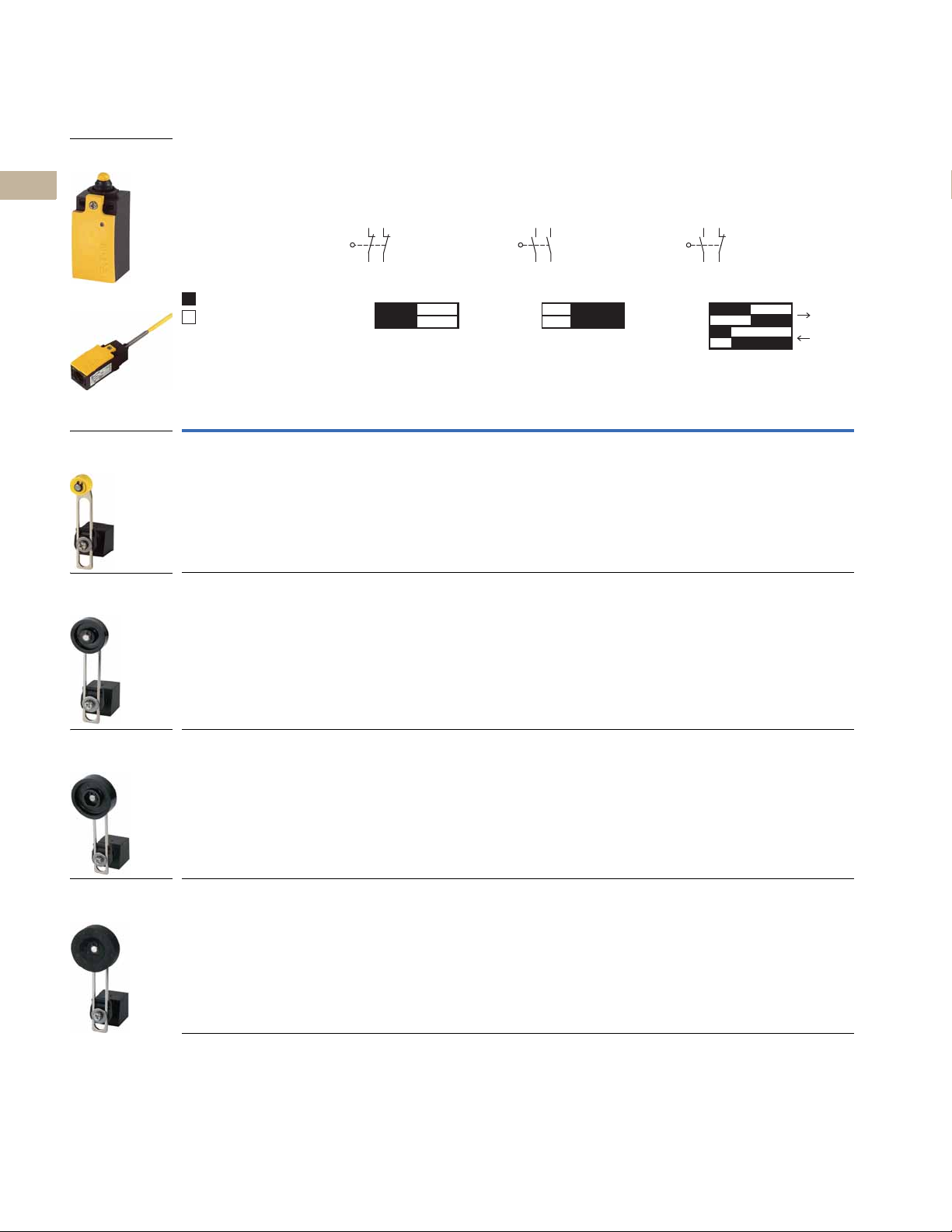

E50 Heavy-Duty Factory

Sealed 6P+ Switches Operators

Page V8- T2 -68

Overview

Designed specifically to withstand the

penetrating properties of new cutting fluids

(coolants), acid or caustic washes, salt

spray, severe vibration, shock and

temperature fluctuations, grit and debris.

Applications

Automotive, pulp and paper, food

processing, waste management, primary

metals, machine tool (cutting, forming,

bending)

Product Features

Tamperproof, one-piece switch body

assembly, epoxy filled

Factory sealed. 6P submersible. Pre-wired

with cable, pigtail or pin connector options.

All with ground connection

Utilizes E50 modular operating heads

Special V-seal on switch body/head

connection provides hermetic barrier

against fluid ingress

LED indicating light, 24V–120 Vac/dc

neon version too

Peel off see-through painting mask over

nameplate

Technical Data and Specifications

Mechanical life: 35,000,000 operations min.

Electrical life: 1,000,000 operations

min. at full load

Contact ratings—

NEMA A600, R300

Lighted versions A150, R150

6A, 120 Vac; 10A continuous

Enclosure ratings—

NEMA 1, 2, 3, 3S, 4, 4X, 6, 6P, 13; IP67,

IP69K

Construction—Zinc die cast

Approvals

UL Listed

CSA Certified

IEC 947-5-1

TUV

CE (some models)

Page V8-T2-80

Overview

Wide variety of operator types f or rotary and

wobble style limit switches.

Applications

Used with E50, E50 6P+ and 10316

limit switches

Product Features

Rollers and rods available in metal

and nonmetal contact surfaces

Technical Data and Specifications

Varies by model

Approvals

Varies by model

2

2

V8-T2-4 Volume 8—Sensing Solutions CA08100010E—May 2013

Limit Switches

Introduction

2.0

Non Plug-In Switches

Page V8-T2-89

Overview

The Industrial standard for Non Plug-In

Heavy-Duty Limit Switches. Sold as

complete assembled units only.

Applications

Serving MRO and USER replacement

requirements with broad

d market coverage

Product Features

Side and top rotary, side and top push or

wobble operation

CW, CCW or CW and CCW operating modes

are field convertible

Double break-make snap action contacts,

same polarity each pole

Captive saddle clamp terminals accept up

to #12 wire

Head can be mounted in any of four discrete

positions, intervals of 90 degrees

Technical Data and Specifications

Mechanical life: 10,000,000 operations

min.

Electrical life: 500,000 operations at

full load

Contact ratings—NEMA A600, R300

6A, 120 Vac; 10A continuous

Enclosure ratings—NEMA 1, 4, 13

Construction—

Zinc die cast

Hazardous Location

Switches Special Purpose Switches

Page V8- T2 -92

Overview

Designed for severe environmental service

in locations where there exists a danger of

an internal or external explosion of

flammable gases, vapors, metal alloy or

grain dust.

Applications

Mining, metal cutting, grain storage, forest

products, petrochemical, waste and sewage

management, pharmaceutical

Product Features

Sealed and unsealed versions available

One-way gasket on sealed version keeps

liquids out, yet allows a harmless release of

gases in the event of an internal explosion

Silicon bronze housing provides excellent

corrosion resistant properties in extreme

NEMA 4X applications

Temperature build-up on limit switch

surface is dissipated by housing design and

materials used

Utilizes the operating heads and internal

switch mechanisms of the 10316

Non Plug-In line

Technical Data and Specifications

NEMA 7, Div. 1, Class I, BCD

NEMA 9, Div. 1, Class II, EFG

Contact ratings—NEMA B600

3A, 120 Vac; 5A continuous

Enclosure ratings—LX: NEMA 7, 9

CX: NEMA 1, 4, 7, 9

CB: NEMA 1, 4, 4X, 13

CBX: NEMA 1, 4, 4X, 7, 9, 13

Construction—LX, CX: Aluminum die cast

CB, CBX: Silicon bronze

Page V8- T2 -96

Overview

Variety of special function limit switch

products.

Applications

Serving MRO and USER replacement

requirements with broad market coverage

Product Features

Special function switch lines include:

Cabinet door interlocks — when plunger

is pulled out, red band indicator visually

shows that interlock is defeated

Precision switches—1NO-1NC,

2NO-2NC, or operator only. Variety of

mounting brackets available

Pneumatic time delay—ON delay and OFF

delay. Timing range—0.05 to 60 seconds

Rotating cam shaft switches

Technical Data and Specifications

See Page V8-T2-99 for more information

Enclosure ratings—

NEMA 1 or NEMA 4 versions

Construction—

Zinc die cast

PS: Phenolic

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Approvals

UL Listed

CSA Certified

Approvals

®

Listed

cUL

Approvals

UL Listed

CSA Certified (PS and J only)

Volume 8—Sensing Solutions CA08100010E—May 2013 V8-T2-5

2

2

2

2

2

2

2.1

E47 Precision Switches

Drawings

Online

Limit Switches

E47 Precision Switches

2

2

2

2

2

2

2

2

2

2

2

E47 Precision Switches

Product Description

2

E47 Precision Switches from

Eaton’s electrical sector

2

provide high accuracy

switching at an affordable

2

price. A variety of standard

features, such as current

2

capacity, operating force,

travel characteristics and

2

actuators, lets you custom

fit the switch to your

application.

2

The switches are available

2

in their compact basic form,

or enclosed in a rugged,

metal housing.

2

2

2

2

2

2

2

2

Features

●

Compact housings are

deal for use where sp

i

i

s restricted

●

Precision, snap-action

erators provide a

op

repe

atability of electrical

and mechanical operating

haracteristics

c

●

High current capacity

to 20A) allows powe

(up

l

oad switchi

handling capability

●

Enclosed booted versions

ield actua

sh

de

bris

ng and motor

tors from

ace

ccurate

r

Contents

Description Page

E47 Precision Switches

Product Selection

Basic Switches . . . . . . . . . . . . . . . . . . . . . . V8-T2-7

Enclosed Switches. . . . . . . . . . . . . . . . . . . . V8-T2-9

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-10

Technical Data and Specifications . . . . . . . . . . V8-T2-10

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-12

Operating Characteristics

Definitions

●

OF—Operating Force

●

RF—Return Force

●

PT—Pre-Travel

●

OT—Over-Travel

●

MD—Movement

ferential

Dif

●

FP—Free Position

●

OP—Operating Position

Standards and Certifications

●

UL Recognized

●

CSA Certified

●

CE

●

RoHS

DANGER

THIS SENSOR IS NOT A

SAFETY DEVICE AND IS NOT

INTENDED TO BE USED AS A

SAFETY DEVICE. This sensor

is designed only to detect

and read certain data in an

electronic manner and

perform no use apart from

that, specifically no safetyrelated use. This sensor

product does not include

self-checking redundant

circuitry, and the failure of

this sensor product could

cause either an energized

or de-energized output

condition, which could result

in death, serious bodily

injury, or property damage.

2

2

2

2

V8-T2-6 Volume 8—Sensing Solutions CA08100010E—May 2013

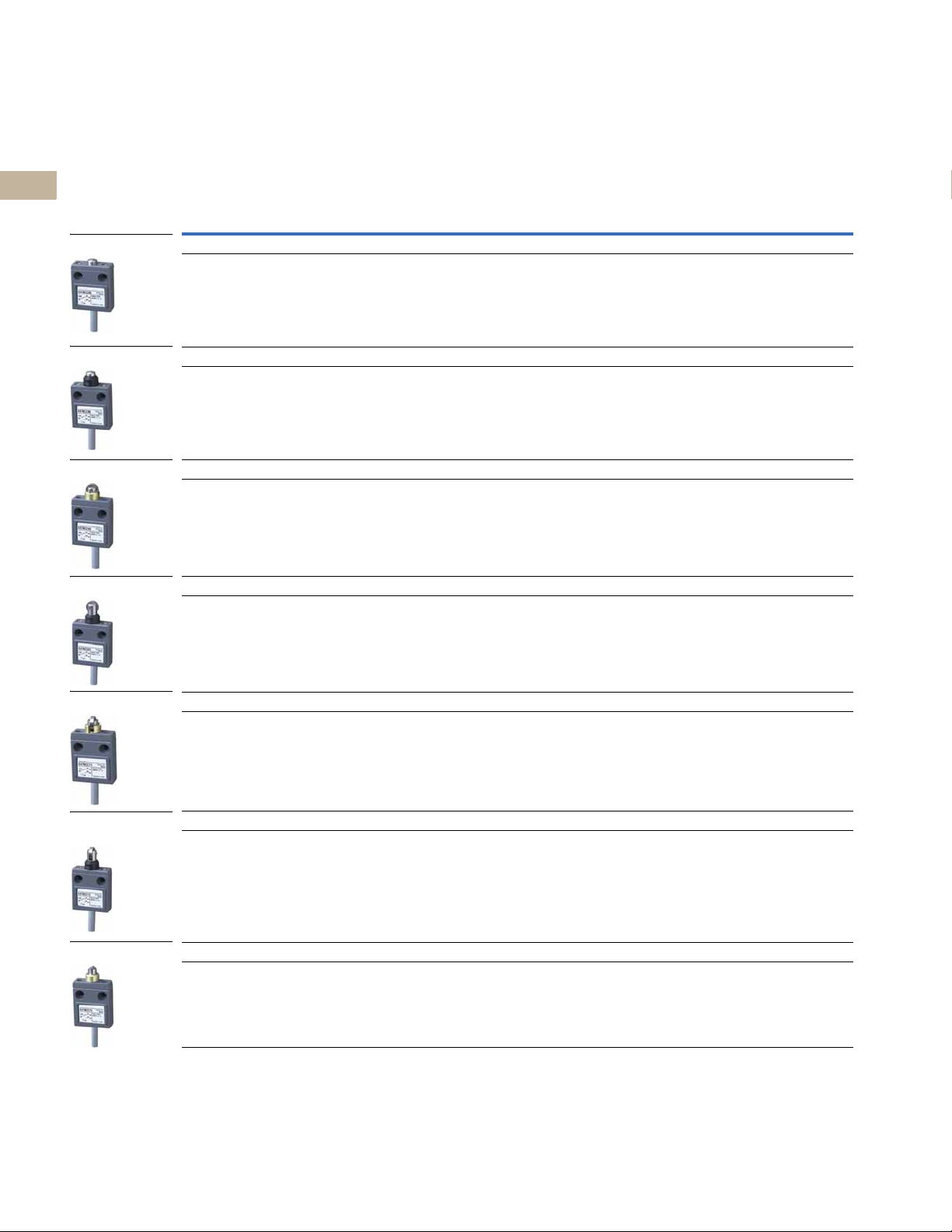

Limit Switches

Pin Plunger

Extended Plunger

Straight Plunger

Reversed Lever

Straight Lever

Standard Lever

Extended Straight

Plunger

E47 Precision Switches

2.1

Product Selection

Basic Switches

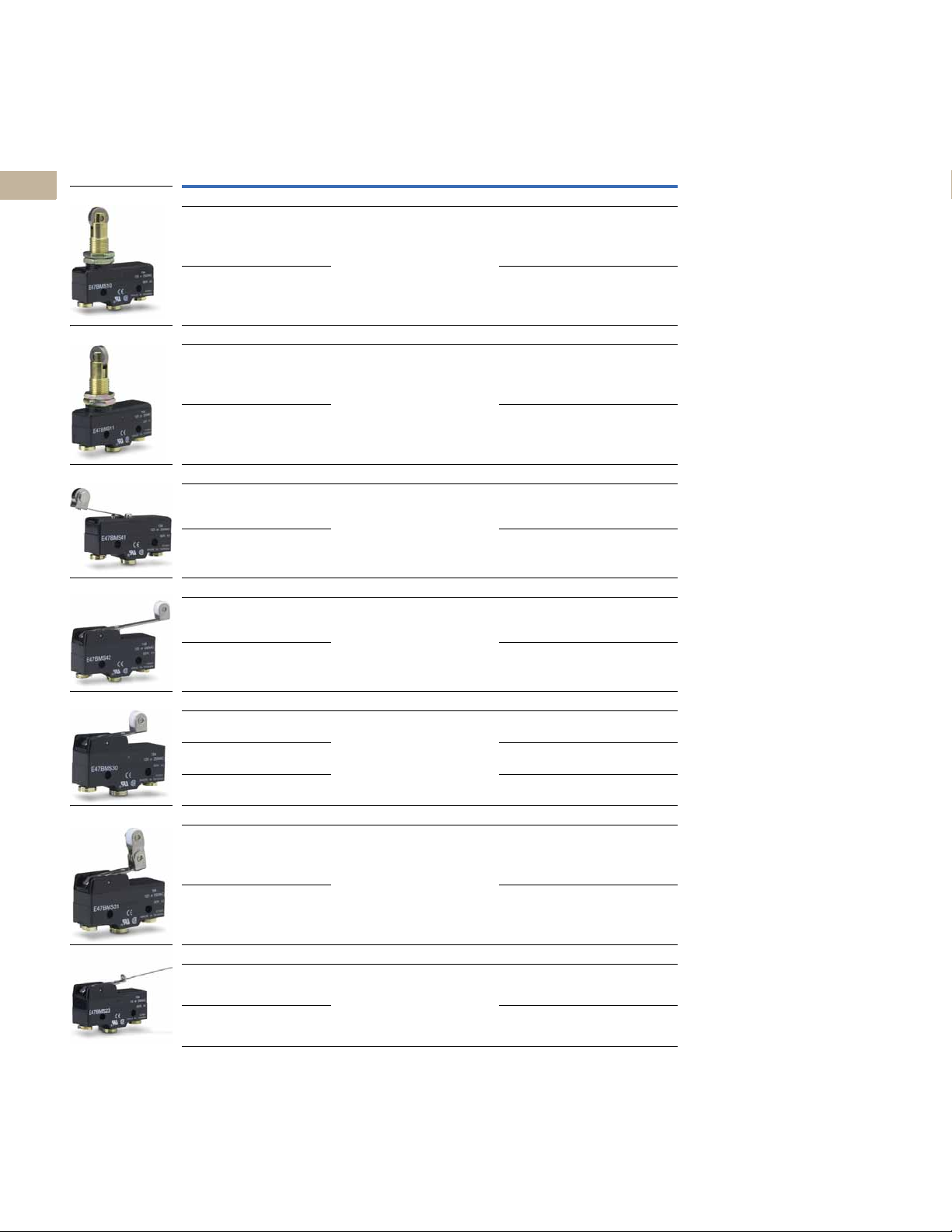

E47 Precision Switches—Basic

Type Specifications

Pin Plunger

Screw terminal OF max.—12.3 oz (350g)

Solder terminal E47BML01 E47CML01

Extended Plunger

Screw terminal OF max.—12.3 oz (350g)

Solder terminal E47BML03 —

Straight Plunger

Screw terminal OF max.—12.3 oz (350g)

Solder terminal E47BML02 E47CML02

Reversed Lever

Screw terminal OF max.—5.29 oz (150g)

Solder terminal E47BML21 —

Spade terminal E47BMT21 —

RF max.—4.02 oz (114g)

PT max.—0.016 in (0.4 mm)

OT max.—0.005 in (0.13 mm)

MD max.—0.002 in (0.05 mm)

OP—0.626 in (15.9 mm)

RF max.—4.02 oz (114g)

PT max.—0.016 in (0.4 mm)

OT max.—0.063 in (1.6 mm)

MD max.—0.002 in (0.05 mm)

OP—1.11 in (28.2 mm)

RF max.—4.02 oz (114g)

PT max.—0.016 in (0.4 mm)

OT max.—0.063 in (1.6 mm)

MD max.—0.002 in (0.05 mm)

OP—0.846 in (21.5 mm)

RF max.—0.49 oz (14g)

PT max.—0.16 in (4 mm)

OT max.—0.063 in (1.6 mm)

MD max.—0.051 in (1.3 mm)

FP max.—0.81 in (20.6 mm)

OP—0.685 in (17.4 mm)

1

15A

Catalog Number

E47BMS01 E47CMS01

E47BMS03 —

E47BMS02 E47CMS02

E47BMS21 —

20A

Catalog Number

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Straight Lever

Screw terminal OF max.—2.47 oz (70g)

Solder terminal E47BML22 —

Standard Lever

Screw terminal OF max.—3.53 oz (100g)

Solder terminal E47BML20 —

Extended Straight Plunger

Screw terminal OF max.—12.3 oz (350g)

Screw terminal (with space lugs) E47BMT04 —

Solder terminal E47BML04 E47CML04

Notes

1

OF = Operating Force; RF = Return Force; PT = Pre-Travel; OT = Over-Travel; MD = Movement Differential;

FP = Free Position; OP = Operating Position.

2

Contact Eaton’s Sensor Applications Department at 1-800-426-9184 for approval status.

RF min.—0.49 oz (14g)

PT max.—0.394 in (10 mm)

OT max.—0.220 in (5.6 mm)

MD max.—0.051 in (1.3 mm)

FP max.—1.11 in (28.2 mm)

OP—0.748 in (19 mm)

RF min.—0.99 oz (28g)

PT max.—0.197 in (5.0 mm)

OT max.—0.079 in (2.0 mm)

MD max.—0.039 in (1.0 mm)

FP max.—0.976 in (24.8 mm)

OP—0.748 in (19 mm)

RF max.—4.02 oz (114g)

PT max.—0.016 in (0.4 mm)

OT max.—0.217 in (5.5 mm)

MD max.—0.002 in (0.05 mm)

OP—0.858 in (21.8 mm)

E47BMS22 E47CMS22

E47BMS20 —

E47BMS04 E47CMS04

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Volume 8—Sensing Solutions CA08100010E—May 2013 V8-T2-7

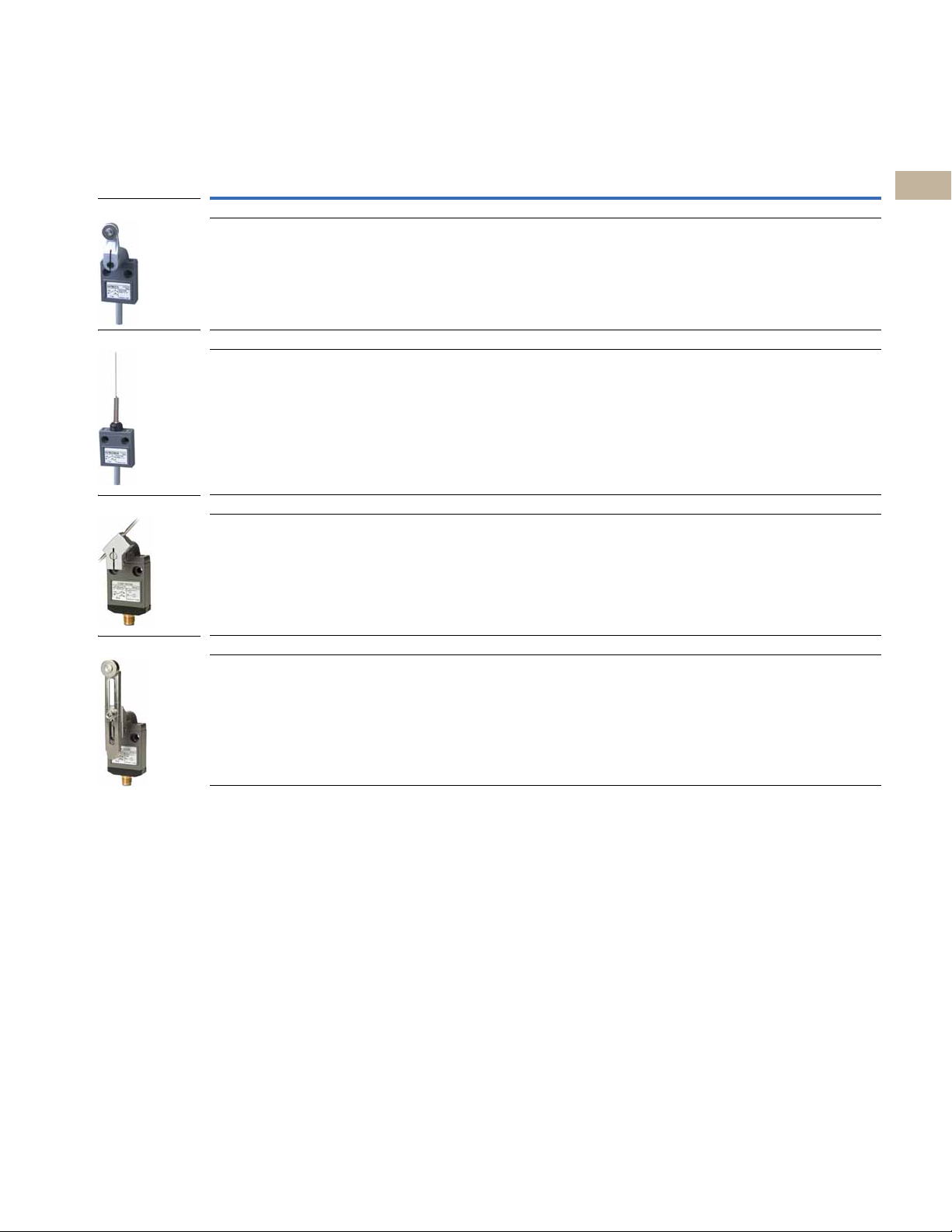

2.1

Roller Plunger

Cross Roller Plunger

Reversed Roller Lever

Extended Roller Lever

Roller Lever

One-Way Roller

Integral Leaf

Limit Switches

E47 Precision Switches

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

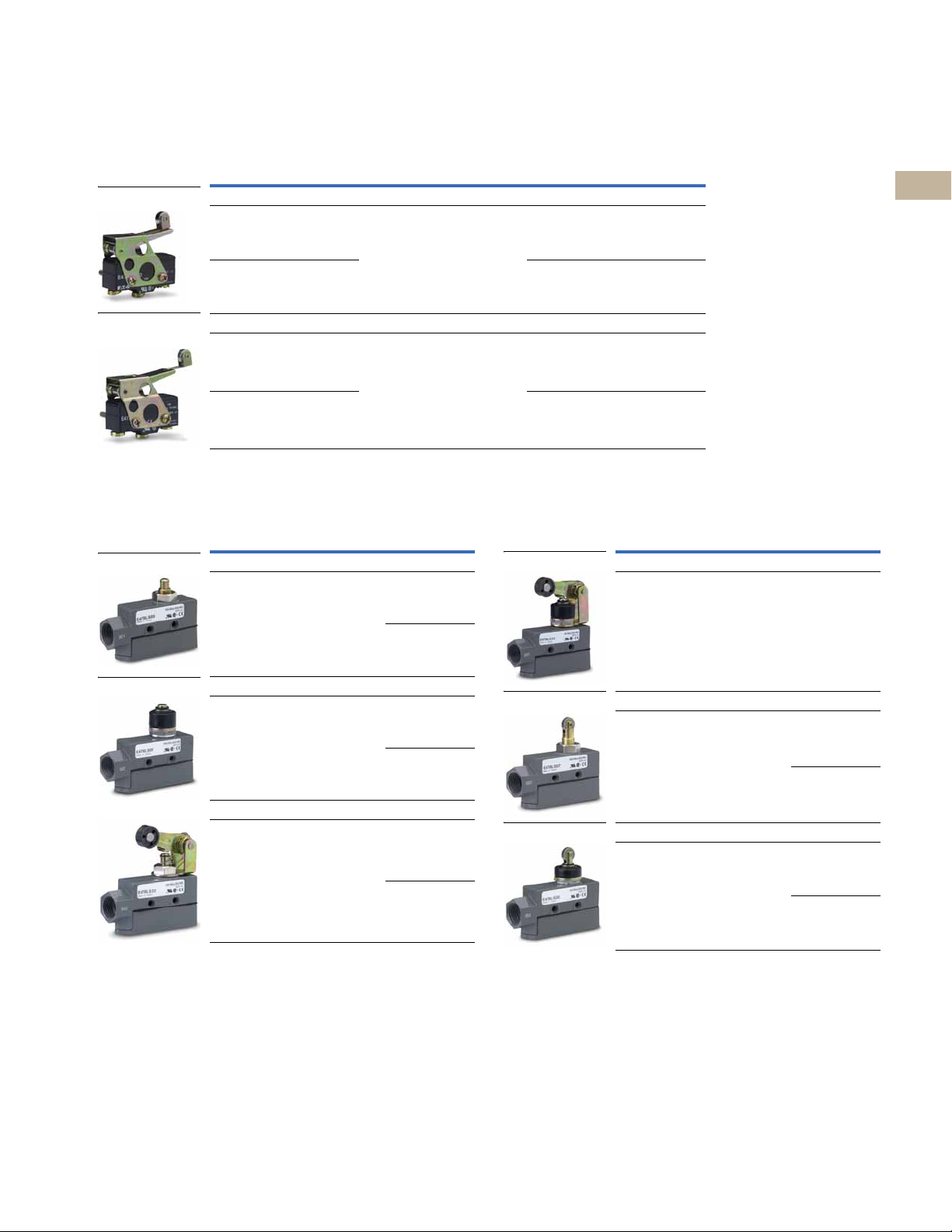

E47 Precision Switches—Basic, continued

Type Specifications

Roller Plunger

Screw terminal OF max.—12.3 oz (350g)

Solder terminal E47BML10 —

Cross Roller Plunger

Screw terminal OF max.—12.3 oz (350g)

Solder terminal E47BML11 —

Reversed Roller Lever

Screw terminal OF max.—5.29 oz (150g)

Solder terminal E47BML41 —

Extended Roller Lever

Screw terminal OF max.—5.64 oz (160g)

Solder terminal E47BML42 —

Roller Lever

Screw terminal OF max.—5.64 oz (160g)

Solder terminal E47BML30 —

Spade terminal E47BMT30 E47CMT30

One-Way Roller

Screw terminal OF max.—5.64 oz (160g)

Solder terminal E47BML31 —

Integral Leaf

Screw terminal OF max.—0.35 oz (10g)

Solder terminal E47BML23 —

Note

1

OF = Operating Force; RF = Return Force; PT = Pre-Travel; OT = Over-Travel; MD = Movement Differential;

FP = Free Position; OP = Operating Position.

RF max.—4.02 oz (114g)

PT max.—0.016 in (0.4 mm)

OT max.—0.14 in (3.6 mm)

MD max.—0.002 in (0.05 mm)

OP—1.315 in (33.4 mm)

RF max.—4.02 oz (114g)

PT max.—0.016 in (0.4 mm)

OT max.—0.14 in (3.6 mm)

MD max.—0.002 in (0.05 mm)

OP—1.315 in (33.4 mm)

RF max.—0.49 oz (14g)

PT max.—0.16 in (4 mm)

OT max.—0.063 in (1.6 mm)

MD max.—0.051 in (1.3 mm)

FP max.—1.252 in (31.8 mm)

OP—1.126 in (28.6 mm)

RF min.—0.78 oz (22g)

PT max.—0.28 in (7.1 mm)

OT max.—0.16 in (4 mm)

MD max.—0.04 in (1.02 mm)

FP max.—1.437 in (36.5 mm)

OP—1.189 in (30.2 mm)

RF min.—1.48 oz (42g)

PT max.—0.106 in (2.7 mm)

OT max.—0.094 in (2.4 mm)

MD max.—0.02 in (0.5 mm)

FP max.—1.28 in (32.5 mm)

OP—1.189 in (30.2 mm)

RF min.—1.48 oz (42g)

PT max.—0.106 in (2.7 mm)

OT max.—0.094 in (2.4 mm)

MD max.—0.02 in (0.5 mm)

FP—1.717 in (43.6 mm)

OP—1.697 in (43.1 mm)

RF min.—0.106 oz (3.0g)

PT max.—0.787 in (20.0 mm)

OT max.—0.22 in (5.6 mm)

MD max.—0.118 in (3.0 mm)

OP—0.748 in (19.0 mm)

1

15A

Catalog Number

E47BMS10 E47CMS10

E47BMS11 E47CMS11

E47BMS41 —

E47BMS42 E47CMS42

E47BMS30 E47CMS30

E47BMS31 —

E47BMS23 E47CMS23

20A

Catalog Number

V8-T2-8 Volume 8—Sensing Solutions CA08100010E—May 2013

Limit Switches

Adjustable Roller

Extended

Adjustable Roller

Plunger Actuator

Booted Plunger

Roller Lever

Booted Roller Lever

Roller Plunger

Booted Roller Plunger

E47 Precision Switches

2.1

Enclosed Switches

E47 Precision Switches—Basic, continued

Type Specifications

Adjustable Roller

Screw terminal OF max.—17.64 oz (500g)

Solder terminal E47BML40 —

Extended Adjustable Roller

Screw terminal OF max.—21.16 oz (600g)

Solder terminal E47BML43 —

E47 Precision Switches—Enclosed

Specifications

Plunger Actuator

OF max.—8.82–12.3 oz (250–350g)

RF min.—4.02 oz (114g)

PT max.—0.016 in (0.4 mm)

OT max.—0.217 in (5.5 mm)

MD max.—0.002 in (0.05 mm)

OP—1.504 in (38.2 mm)

Booted Plunger

OF max.—28.22 oz (800g)

RF min.—8.46 oz (240g)

PT max.—0.079 in (2.0 mm)

OT max.—0.197 in (5.0 mm)

MD max.—0.004 in (0.1 mm)

OP—1.803 in (45.8 mm)

Roller Lever

OF max.—20.1 oz (570g)

RF min.—6.0 oz (170g)

PT max.—0.157 in (4.0 mm)

OT max.—0.236 in (6.0 mm)

MD max.—0.016 in (0.4 mm)

1

RF min.—6.0 oz (170g)

PT max.—0.197 in (5.0 mm)

OT max.—0.5 in (12.7 mm)

MD max.—0.087 in (2.2 mm)

FP max.—1.752 in (44.5 mm)

OP—1.591 in (40.4 mm)

RF min.—10.58 oz (300g)

PT max.—0.118 in (3.0 mm)

OT max.—0.236 in (6.0 mm)

MD max.—0.079 in (2.0 mm)

FP max.—1.614 in (41 mm)

OP—1.591 in (40.4 mm)

1

Catalog Number

E47BLS05

23

E47CLS05

E47BLS06

23

E47CLS06

E47BLS32

23

E47CLS32

15A

Catalog Number

E47BMS40 —

E47BMS43 —

20A

Catalog Number

Specifications

Booted Roller Lever

OF max.—22.57 oz (640g)

RF min.—8.11 oz (230g)

PT max.—0.197 in (5.0 mm)

OT max.—0.236 in (6.0 mm)

MD max.—0.016 in (0.4 mm)

Roller Plunger

OF max.—8.82–12.3 oz (250–350g)

RF min.—4.02 oz (114g)

PT max.—0.02 in (0.5 mm)

OT max.—0.142 in (3.6 mm)

MD max.—0.002 in (0.05 mm)

OP—1.957 in (49.7 mm)

Booted Roller Plunger

OF max.—17.64 oz (500g)

RF min.—3.53 oz (100g)

PT max.—0.039 in (1.0 mm)

OT max.—0.138 in (3.5 mm)

MD max.—0.005 in (0.12 mm)

OP—1.957 in (49.7 mm)

1

Catalog Number

E47BLS33

E47BLS07

4

E47BLS11

E47BLS08

4

E47BLS12

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Notes

1

OF = Operating Force; RF = Return Force; PT = Pre-Travel; OT = Over-Travel; MD = Movement Differential;

FP = Free Position; OP = Operating Position.

2

Contact Eaton’s Sensor Applications Department at 1-800-426-9184 for approval status.

3

20 ampere version.

4

Cross roller unit.

Volume 8—Sensing Solutions CA08100010E—May 2013 V8-T2-9

2

2

2

2

2

2

2.1

One-Way Roller

Booted One-Way

Roller

Booted Wobble

45°

90°

Limit Switches

E47 Precision Switches

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Accessories

E47 Precision Switches—

Enclosed, continued

Specifications

One-Way Roller

OF max.—20.1 oz (570g)

RF min.—6.0 oz (170g)

PT max.—0.157 in (4.0 mm)

OT max.—0.236 in (6.0 mm)

MD max.—0.016 in (0.4 mm)

Booted One-Way Roller

OF max.—22.57 oz (640g)

RF min.—8.11 oz (230g)

PT max.—0.197 in (5.0 mm)

OT max.—0.236 in (6.0 mm)

MD max.—0.016 in (0.4 mm)

Terminal Wire Covers for Basic Switches

Description Catalog Number

Terminal wire cover with

45° conduit interface

1

Catalog Number

E47BLS34

E47BLS35

E47PA1

E47 Precision Switches—

Enclosed, continued

Specifications

Booted Wobble

OF max.—2.11 oz (60g)

RF min.—0.88 oz (25g)

PT max.—0.520 in (13.2 mm)

OT max.—0.315 in (8.0 mm)

MD max.—0.039 in (1.0 mm)

Description Catalog Number

Terminal wire cover with

90° conduit interface

1

Catalog Number

E47BLS14

E47PA2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Technical Data and Specifications

E47 Precision Switches

Description Specification

Operating speed 0.01m/second to 1m/second

Operating Frequency

Mechanical 120 operations/minute

Electrical 20 operations/minute

Mechanical life 3,000,000 operations minimum

Electrical life 500,000 operations minimum

Contact resistance 15M ohms maximum, initial

Insulation resistance 100M ohms minimum at 500 Vdc

Dielectric Strength

Between non-current carrying parts 1000 Vac, 50/60 Hz for 1 minute

Between current carrying parts and ground 2000 Vac, 50/60 Hz for 1 minute

Notes

1

OF = Operating Force; RF = Return Force; PT = Pre-Travel; OT = Over-Travel;

MD = Movement Differential; FP = Free Position; OP = Operating Position.

2

Cross roller unit.

2

V8-T2-10 Volume 8—Sensing Solutions CA08100010E—May 2013

Limit Switches

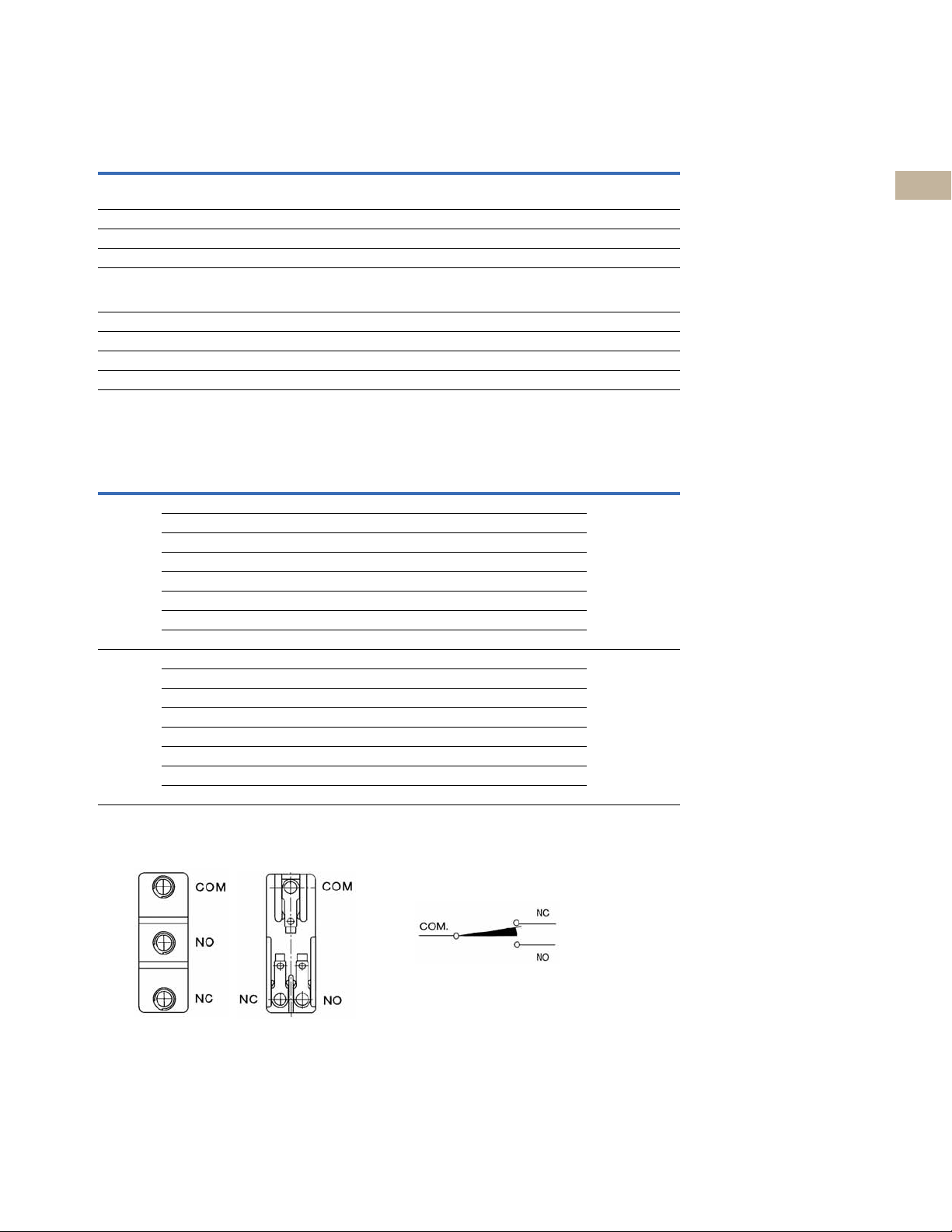

Solder TypeScrew Type

E47 Precision Switches

2.1

E47 Precision Switches, continued

Description Specification

Ambient Operating Temperature

Basic –13° to 176°F (–25° to 80°C)

Enclosed 5° to 176°F (–15° to 80°C)

Environmental rating enclosed, booted NEMA 1

Mounting centers 1.0 in (25.4 mm), #8 screw size

Terminal screws Bottom facing M4 x 0.7 (8–32)

Threaded bushing 15/32 in

Material of construction Mineral filled phenolic

Enclosure rating Aluminum die casting (ADC-3/A380); Seal boot: nitrile, butyl rubber (NBR)

Conduit fitting on enclosed type 1/2 in NPT

Maximum Ampere Ratings

Model

15A 125 Vac 15 3 1.5 15 5 2.5 30 max. 15 max.

20A 125 Vac 20 7.5 7.5 20 12.5 12.5 60 max. 30 max.

Rated

Voltage

250 Vac 15 2.5 1.25 15 3 1.5

500 Vac 3 1.5 0.75 2.5 1.5 0.75

8 Vdc 15 3 1.5 15 5 2.5

14 Vdc 15 3 1.5 10 5 2.5

30 Vdc 6 (2) 3 1.5 5 5 2.5

125 Vdc 0.4 0.4 0.4 0.05 0.05 0.05

250 Vdc 0.2 0.2 0.2 0.03 0.03 0.03

250 Vac 20 7.5 7.5 20 8.3 8.3

500 Vac6 445 22

8 Vdc 20 3 1.5 20 12.5 12.5

14 Vdc 20 3 1.5 15 12.5 12.5

30 Vdc 6 3 1.5 5 5 5

125 Vdc 0.5 0.5 0.5 0.05 0.05 0.05

250 Vdc 0.25 0.25 0.25 0.03 0.03 0.03

12

Non-Inductive Load (A) Inductive Load (A)

Resistive Load Lamp Load Inductive Load Motor Load Inrush Current (A)

NC and NO NC NO NC and NO NC NO NC NO

Screws with cup washers will accept 22–12 AWG (2.5 sq. mm maximum)

Maximum torque: 10 in-lbs.

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Terminal Configurations

Contact Configuration—

Form C Precision Snap Action

(Spade type not shown, available on some models)

Notes

1

Inductive load has a power factor of 0.04 minimum (AC) and a time constant of 7 m/second (DC).

2

Lamp load has an inrush current of six times steady-state current.

Volume 8—Sensing Solutions CA08100010E—May 2013 V8-T2-11

2

2

2

2

2

2

2

2

2

2

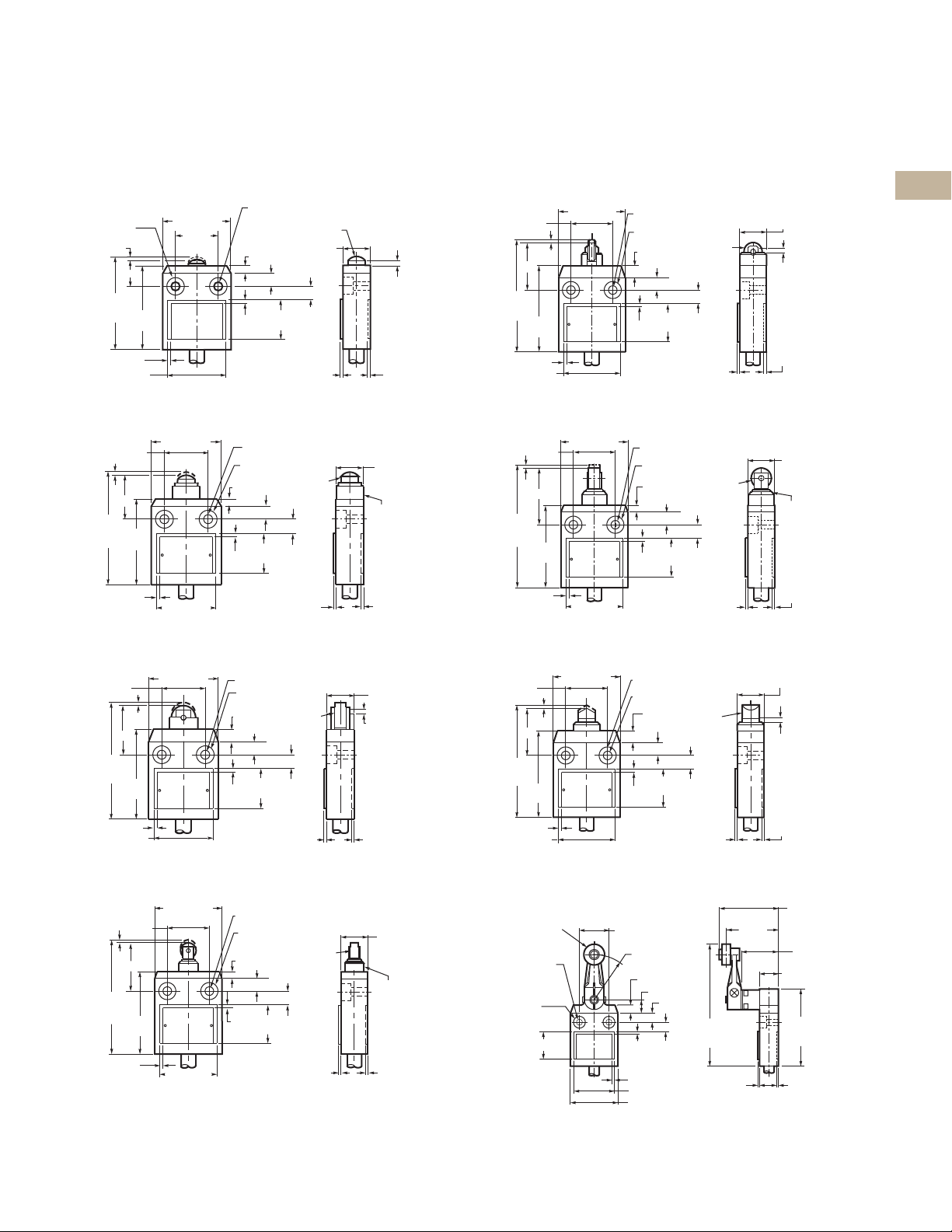

Limit Switches

2.1

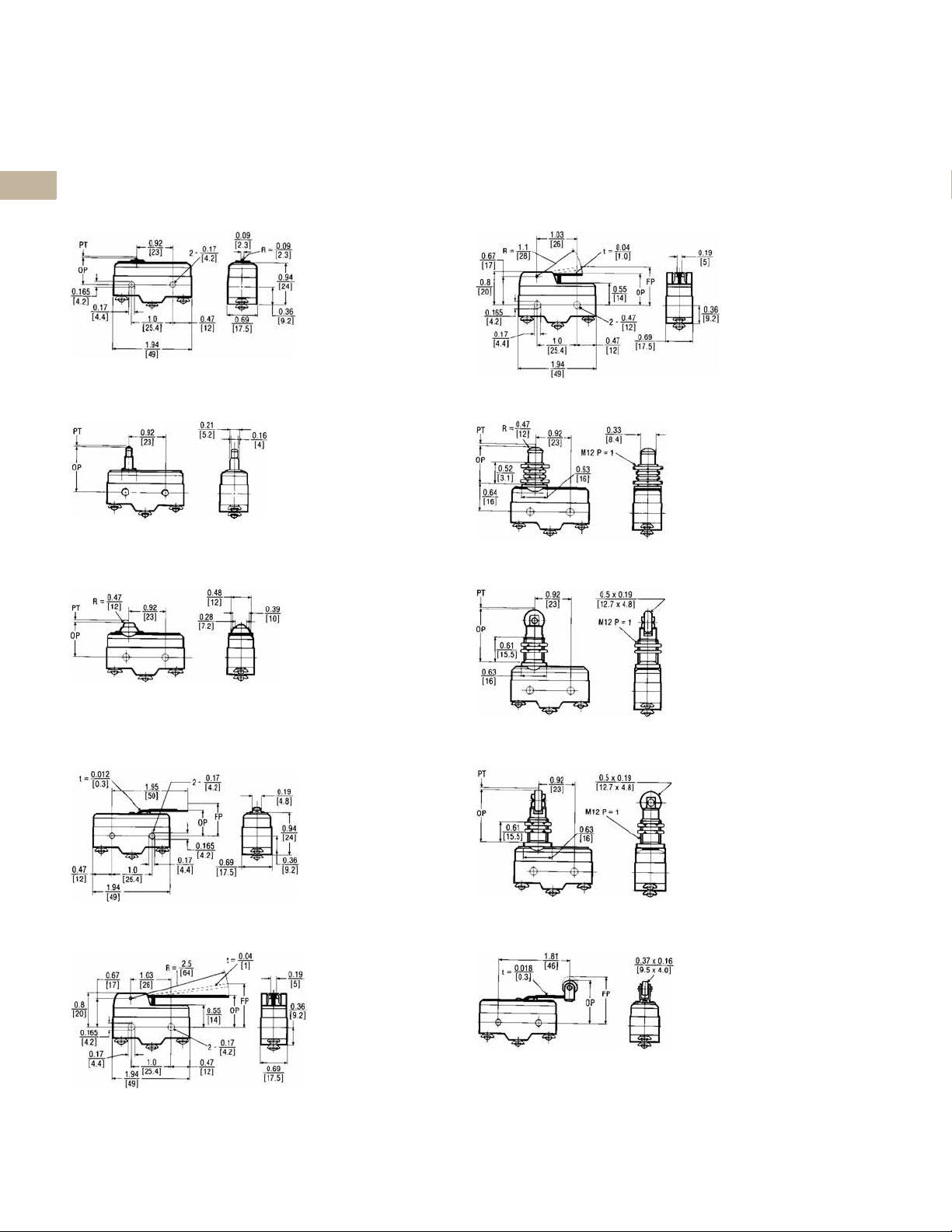

Dimensions

2

Approximate Dimensions in Inches [mm]

2

Basic Switches

Pin Plunger

2

2

2

2

2

2

Extended Plunger

2

2

2

E47 Precision Switches

Standard Lever

Extended Straight Plunger

2

2

Straight Plunger

2

2

2

2

2

Reversed Lever

2

2

2

2

2

2

Straight Lever

2

Roller Plunger

Cross Roller Plunger

Reversed Roller Lever

2

2

2

2

2

V8-T2-12 Volume 8—Sensing Solutions CA08100010E—May 2013

Limit Switches

E47 Precision Switches

2.1

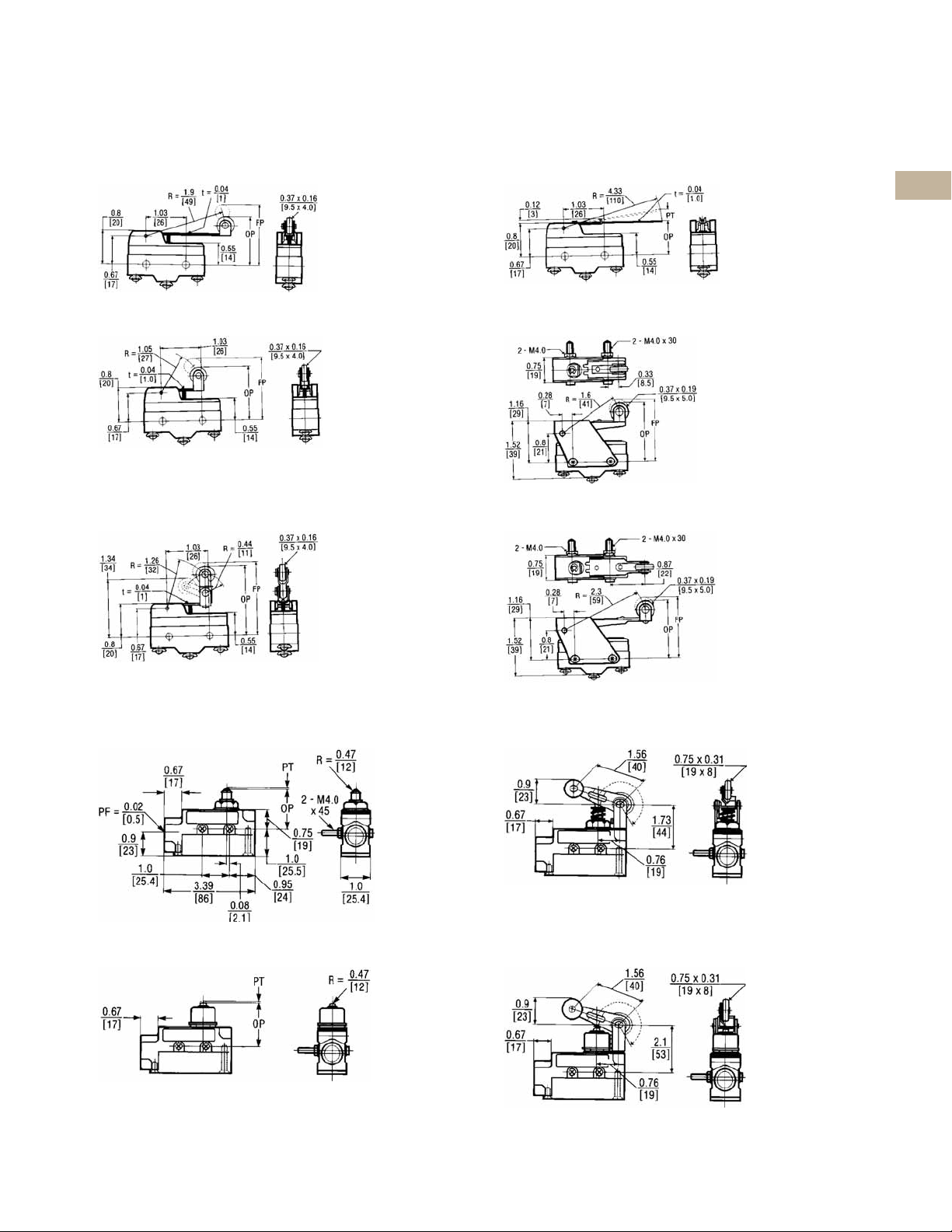

Approximate Dimensions in Inches [mm]

Extended Roller Lever

Roller Lever

One-Way Roller

Integral Leaf

Adjustable Roller

Extended Adjustable Roller

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Enclosed Switches

Plunger Actuator

Booted Plunger

Roller Lever

Booted Roller Lever

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Volume 8—Sensing Solutions CA08100010E—May 2013 V8-T2-13

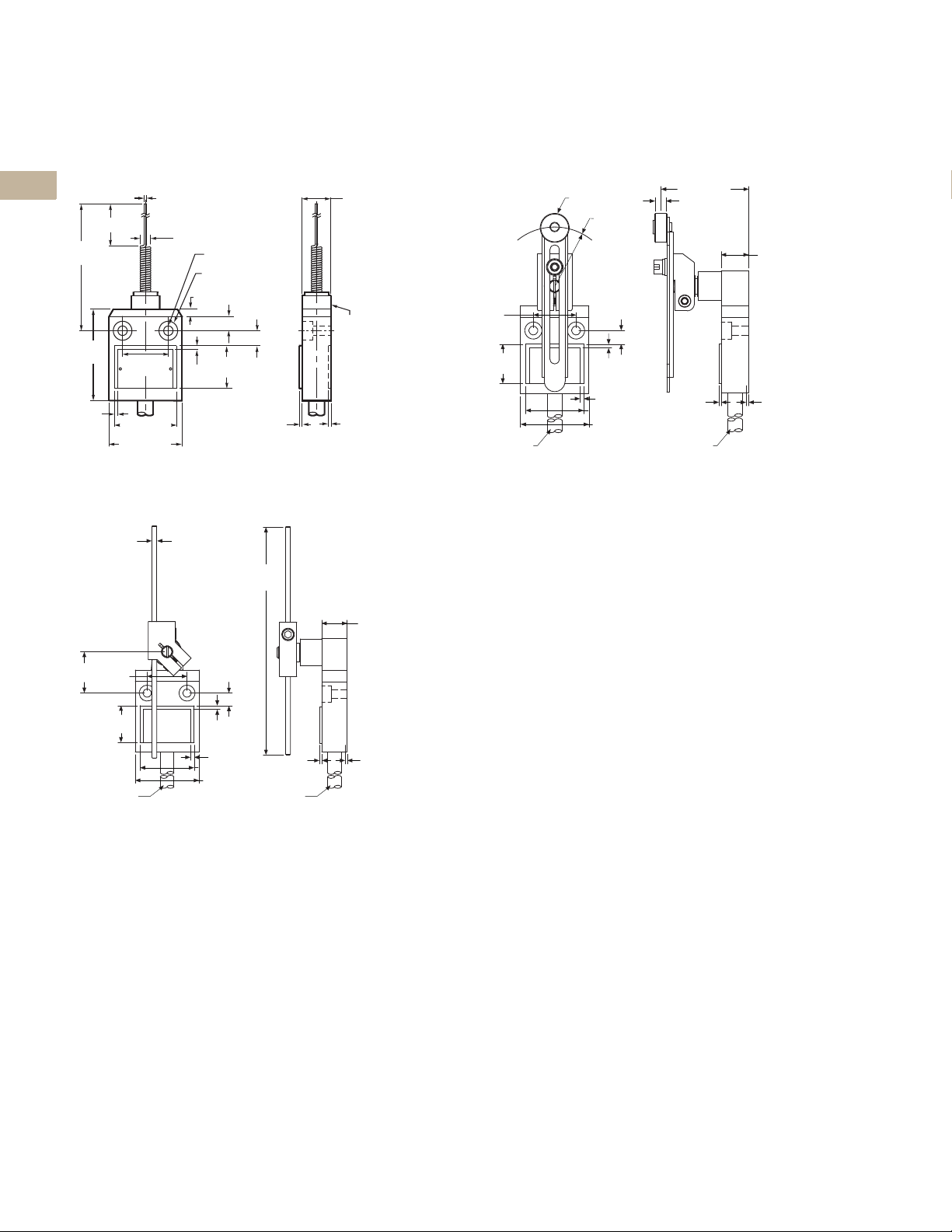

2

2

Limit Switches

0.91

[23]

0.67

[17]

0.08

[2.1]

5.91

[150]

1.00

[25.5]

1.00 [25.4] 1.00 [25.4] 0.96 [24.5]

3.37

[85.5]

0.25 [6.5]

Dia.

PT

0.37

[9.5]

2-M4.0 x 45

21

14

12

14

53

25.4

2-ø4.2

7

21

18

25

21

12

14

14

25.4

53

A

A

BB

12

39

46

21

7

2-ø4.2

2.1

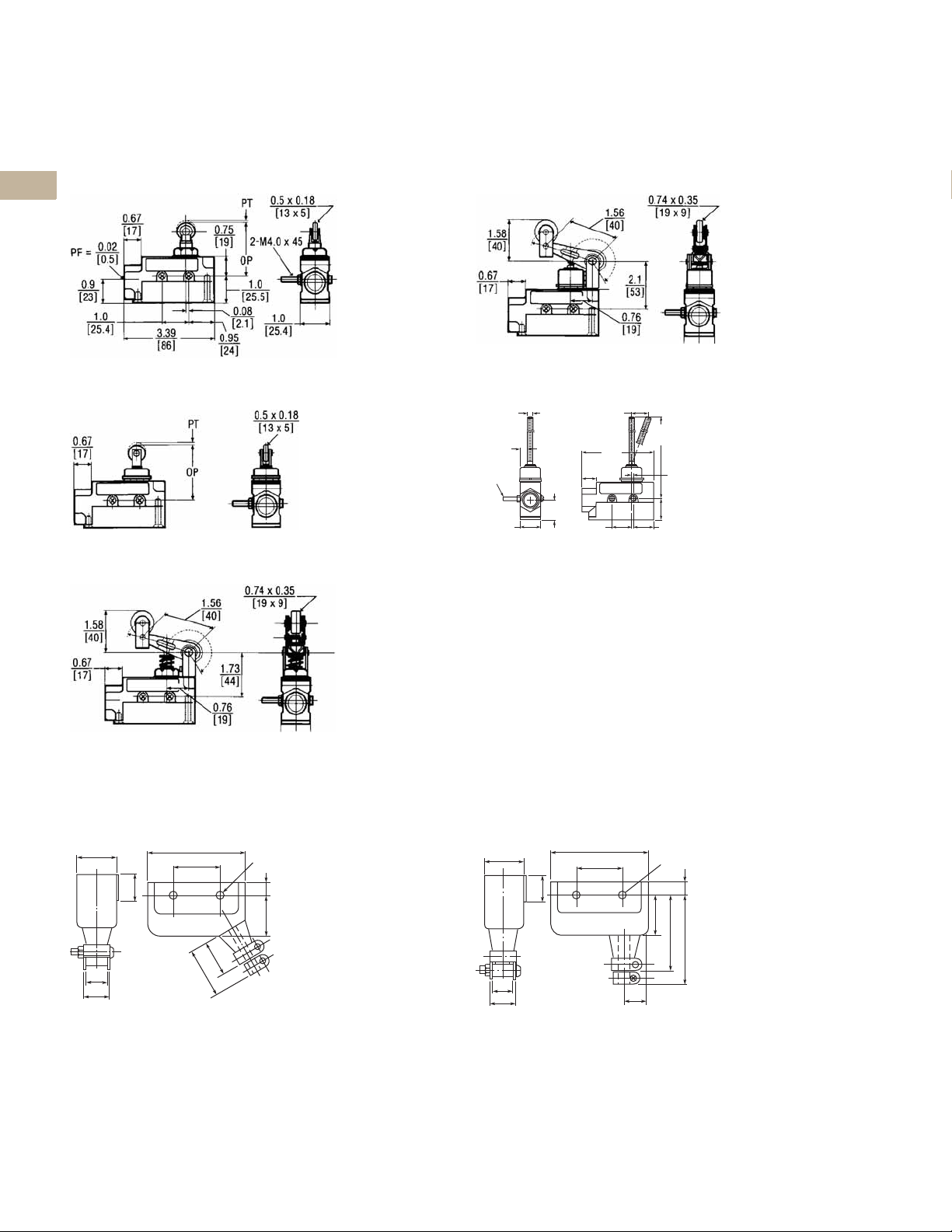

Approximate Dimensions in Inches [mm]

2

Roller Plunger

2

2

2

2

2

2

2

Booted Roller Plunger

2

2

2

E47 Precision Switches

Booted One-Way Roller

Booted Wobble

2

2

One-Way Roller

2

2

2

2

2

2

Accessories

2

Approximate Dimensions in mm

Terminal Wire Cover with 45° Conduit Interface Terminal Wire Cover with 90° Conduit Interface

2

2

2

2

2

2

2

2

2

2

V8-T2-14 Volume 8—Sensing Solutions CA08100010E—May 2013

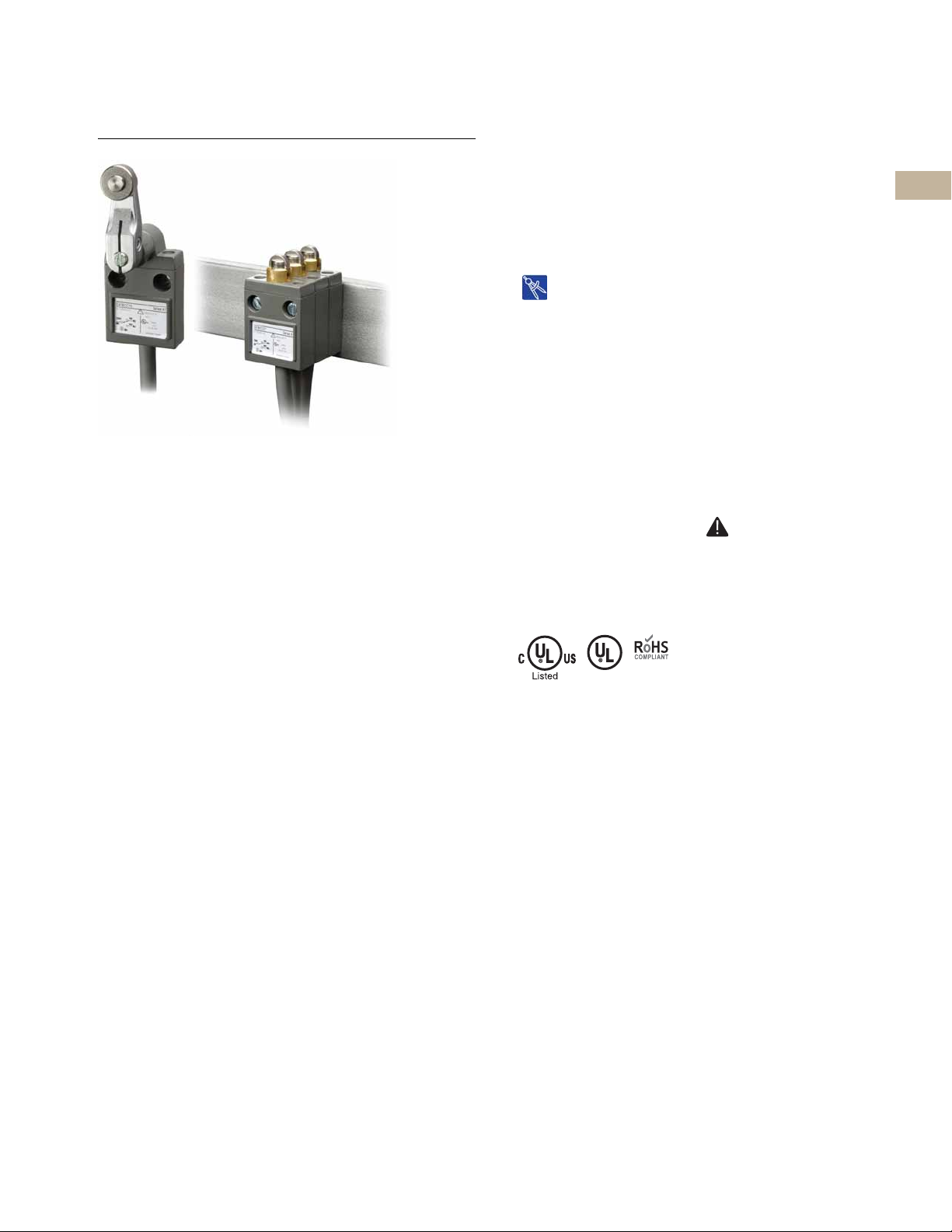

Limit Switches

Compact Prewired Switches

Drawings

Online

Compact Prewired Switches

2.2

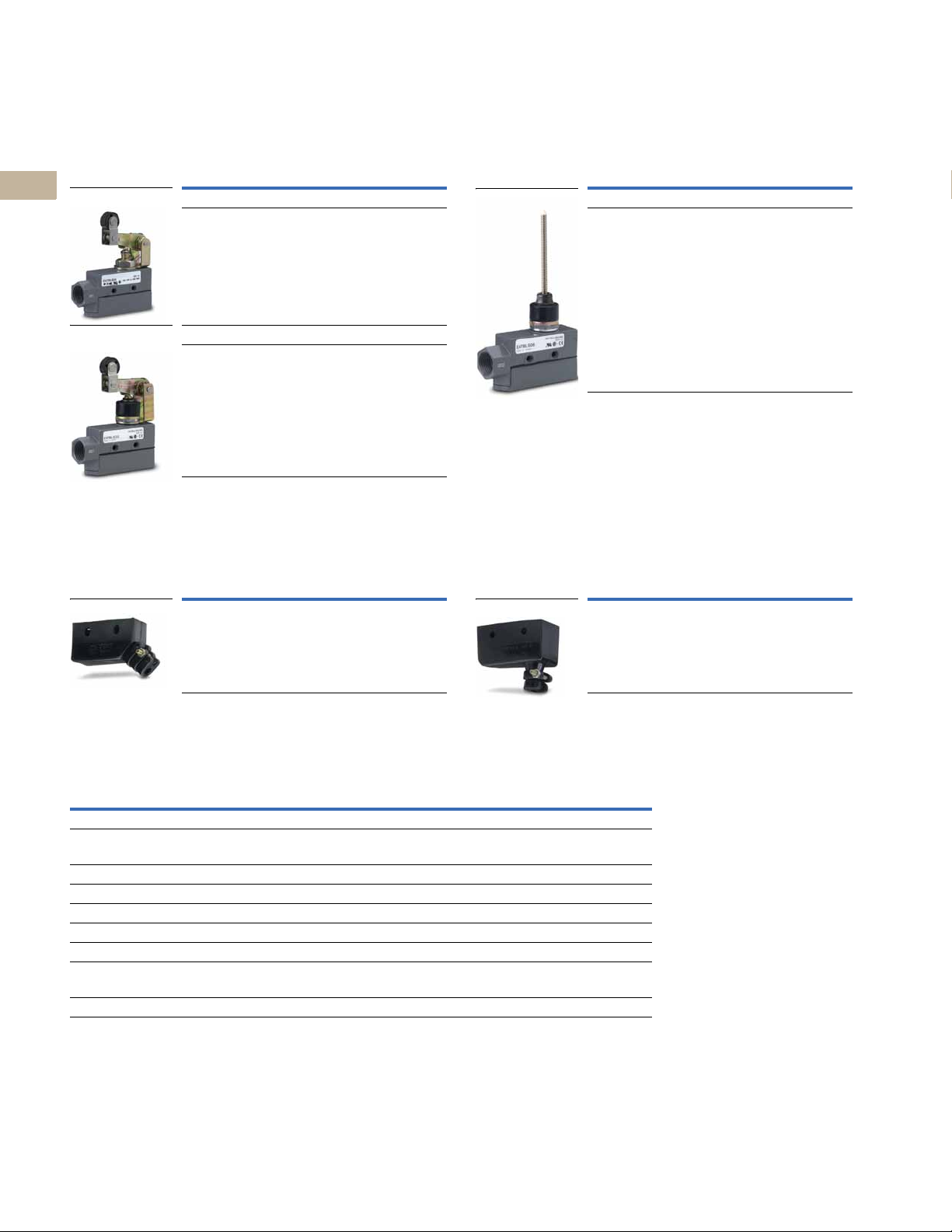

Compact Prewired Switches

Product Description

The E47 Compact Prewired

Limit Switch by Eaton’s

electrical sector is designed

to be a versatile, slim device

for hard to fit applications

where sealing integrity is

required. The rugged die

cast aluminum alloy housing,

cable connection and switch

mechanism are encapsulated

for protection against extreme

temperature (

[

14° to 158°F

moisture, shock and

vibration. This factory wired

(3m) device has NEMA

enclosure ratings of 4, 6

and 13, making it suitable

for applications such as

machine tool, food

processing and packaging.

–10° to 70°C

]), contaminants,

®

Features

●

Rugged aluminum alloy die

cast housing

●

Sealed construction with

closure ratings of

en

4,

6 and 13

●

Prewired with 3m of

AWG, AWM 2517,

18

300V cable, or microconnector version also

ilable

ava

●

Stackable ridge for ganged

eration

op

NEMA

Contents

Description Page

Compact Prewired Switches

Product Selection . . . . . . . . . . . . . . . . . . . . . . . V8-T2-16

Technical Data and Specifications . . . . . . . . . . V8-T2-18

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-18

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-19

Standards and Certifications

●

cULus (cable versions only)

●

UL (cable versions only)

●

NEMA 4, 6 and 13

●

IEC IP67, IP69K

●

RoHS

DANGER

THIS SENSOR IS NOT A

SAFETY DEVICE AND IS NOT

INTENDED TO BE USED AS A

SAFETY DEVICE. This sensor

is designed only to detect

and read certain data in an

electronic manner and

perform no use apart from

that, specifically no safetyrelated use. This sensor

product does not include

self-checking redundant

circuitry, and the failure of

this sensor product could

cause either an energized

or de-energized output

condition, which could result

in death, serious bodily

injury, or property damage.

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Volume 8—Sensing Solutions CA08100010E—May 2013 V8-T2-15

2.2

Pin Plunger

Sealed Plunger

Roller Plunger

Sealed Roller Plunger

Cross Roller Plunger

Sealed Cross Roller

Plunger

Bevel Plunger

Actuator Type

Product Selection

2

2

2

2

2

2

Limit Switches

Compact Prewired Switches

Compact Prewired Switches

Operating Force

(Maximum)

Pin Plunger

42.3 oz

(1.2 kg)

Reset Force

(Minimum)

15.9 oz

(450g)

Over-Travel

(Maximum) Pre-Travel

0.118 in

(3 mm)

0.07 in

(1.8 mm)

Movement

Differential

(Maximum)

0.008 in

(0.2 mm)

Operating

Position

0.62 ± 0.04 in

(15.7 ± 1 mm)

Standard Version

Catalog Number

E47BCC05 E47BCC05P4

Connector Version

Catalog Number

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Sealed Plunger

63.5 oz

(1.8 kg)

Roller Plunger

42.3 oz

(1.2 kg)

Sealed Roller Plunger

63.5 oz

(1.8 kg)

Cross Roller Plunger

42.3 oz

(1.2 kg)

15.9 oz

(450g)

15.9 oz

(450g)

15.9 oz

(450g)

15.9 oz

(450g)

0.118 in

(3 mm)

0.118 in

(3 mm)

0.118 in

(3 mm)

0.118 in

(3 mm)

0.07 in

(1.8 mm)

0.07 in

(1.8 mm)

0.07 in

(1.8 mm)

0.07 in

(1.8 mm)

0.008 in

(0.2 mm)

0.008 in

(0.2 mm)

0.008 in

(0.2 mm)

0.008 in

(0.2 mm)

0.99 ± 0.04 in

(24.9 ± 1 mm)

1.12 ± 0.04 in

(28.5 ± 1 mm)

1.35 ± 0.04 in

(34.3 ± 1 mm)

1.12 ± 0.04 in

(28.5 ± 1 mm)

E47BCC06 E47BCC06P4

E47BCC07 E47BCC07P4

E47BCC08 E47BCC08P4

E47BCC11 E47BCC11P4

2

2

2

2

2

2

2

2

2

2

V8-T2-16 Volume 8—Sensing Solutions CA08100010E—May 2013

Sealed Cross Roller Plunger

63.5 oz

(1.8 kg)

Bevel Plunger

42.3 oz

(1.2 kg)

15.9 oz

(450g)

15.9 oz

50g)

(4

0.118 in

(3 mm)

0.118 in

(3 mm)

0.07 in

(1.8 mm)

0.07 in

(1.8 mm)

0.008 in

(0.2 mm)

0.008 in

(0.2 mm)

1.35 ± 0.04 in

(34.3 ± 1 mm)

1.12 ± 0.04 in

(28.5 ± 1 mm)

E47BCC12 E47BCC12P4

E47BCC13 E47BCC13P4

Limit Switches

Wobble Stick

Rod Lever

Actuator Type

Roller Lever

Adjustable Level Arm

Compact Prewired Switches

2.2

Compact Prewired Switches, continued

Operating Force

(Maximum)

Roller Lever

20.5 oz

(580g)

Wobble Stick

5.3 oz

(150g)

Rod Lever

20.5 oz

(580g)

Reset Force

(Minimum)

5.3 oz

(150g)

——15° max.— — E47BCC20 E47BCC20P4

5.3 oz

(150g)

Over-Travel

(Maximum) Pre-Travel

40° 25° max. 3° — E47BCC15 E47BCC15P4

40° 25° max. 3° — — E47BCC21P4

Movement

Differential

(Maximum)

Operating

Position

Standard Version

Catalog Number

Connector Version

Catalog Number

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Adjustable Level Arm

20.5 oz

(580g)

5.3 oz

(150g)

40° 25° max. 3° — E47BCC22 E47BCC22P4

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Volume 8—Sensing Solutions CA08100010E—May 2013 V8-T2-17

Limit Switches

Common

(Black)

NC (Red)

NO (Blue)

Ground

(Green)

3 4

12

Face View of Male Connector

COM 1

2 NC

4 NO

Contacts Rated

1.0A at 124 Vac

1.0A at 30 Vdc

3

2.2

Technical Data and Specifications

2

Compact Prewired Switches

2

Description Specification

Contacts 1-SPDT (Form C)

2

Mechanical life 10,000,000 operations

Electrical life 200,000 operations, 30 operation/min. at rated load

2

Operating speed 30 operations per minute maximum

2

Operating temperature range –10° to 70°C (14° to 158°F)

Storage temperature range –10° to 70°C (14° to 158°F)

2

Humidity 95% maximum non-condensing

Vibration Malfunction durability, 10 to 55 Hz 1.5 mm double amplitude

2

Shock Malfunction durability, approximately 50G

Enclosure ratings NEMA 4, 6 and 13; IEC IP67

2

Compact Prewired Switches

2

Maximum Ampere Ratings

2

Rated

2

Voltage

125 Vac55332.51.320 max.10 max.

2

250 Vac55221.50.8

8 Vdc55541.51.5

2

14 Vdc55441.51.5

30 Vdc44331.51.5

2

125 Vdc 0.4 0.4 0.4 0.4 0.05 0.05

2

250 Vdc 0.2 0.2 0.2 0.2 0.03 0.03

Non-Inductive Load (A) Inductive Load (A)

Resistive Load Inductive Load Motor Load Inrush Current (A)

NC NO NC NO NC NO NC NO

1

2

Wiring Diagram

2

Compact Prewired Switches Micro-Connector Switches

2

2

2

2

2

Note

1

2

Inductive load ratings are tested at a power factor 0.4 min. for AC power and a time constant of 7 ms max. for DC power. Inrush current for

motor load is six times the steady state current.

2

2

2

2

2

2

2

V8-T2-18 Volume 8—Sensing Solutions CA08100010E—May 2013

Limit Switches

40.0 [1.575]

25.0

[0.984]

54.2

[2.134]

Max

49.0

[1.929]

2.0 [0.079]

1.4

[0.055]

1.5

[0.059]

2.8

[0.110]

Correct

Setting

Postion

16.0

[0.630]

Max

Ø10 [0.397]

Stainless

Steel Plunger

34.0 [1.339]

2.0

[0.079]

23.0

[0.906]

8.0 [0.315]

7.5 [0.295]

4.5 [0.177]

2 x Ø10.2

[0.402]

Depth: 6

[0.236]

2 x Ø5.1 [Ø0.201]

OP

PT

40.0 [1.575]

49.0

[1.929]

2.0

[0.079]

1.4

[0.055]

1.5

[0.059]

16.0

[0.630]

Max

Rubber

Cap

Ø10 [0.397]

Stainless

Steel Plunger

34.0 [1.339]

2.0

[0.079]

23.0

[0.906]

8.0 [0.315]

7.5 [0.295]

4.0

[0.157]

2 x Ø10.2 [0.402]

Depth: 6 [0.236]

2 x Ø5.1 [Ø0.201]

OP

PT

63.5

[2.5]

Max.

25.0

[0.984]

40.0 [1.575]

Max

2.0 [0.079]

1.4

[0.055]

1.5

[0.059]

16.0

[0.630]

Max

2.8

[0.110]

Correct

Setting

Position

Ø12.7 [0.500] x

3.8 [0.150]

Stainless Steel

Roller

34.0 [1.339]

2.0

[0.079]

23.0

[0.906]

8.0 [0.315]

7.5 [0.295]

7.0

[0.276]

67.0

[2.638]

Max

51.5

[2.028]

2 x Ø10.2 [0.402]

Depth: 6 [0.236]

2 x Ø5.1 [Ø0.201]

OP

PT

25.0

[0.984]

40.0 [1.575]

Max

2.0

[0.079]

49.0

[1.929]

1.4

[0.055]

1.5

[0.059]

16.0

[0.630]

Max

Rubber

Cap

Ø12.7 [0.500] x

3.8 [0.150]

Stainless Steel

Roller

34.0 [1.339]

2.0

[0.079]

23.0

[0.906]

8.0 [0.315]

7.5 [0.295]

4.0

[0.157]

2 x Ø10.2 [0.402]

Depth: 6 [0.236]

2 x Ø5.1 [Ø0.201]

OP

PT

25.0

[0.984]

73.0

[2.874]

Max.

1.4 [0.055]

1.5 [0.059]

34.0 [1.339]

2.0

[0.079]

2.0 [0.079]

23.0 [0.906]

11.4 [0.45]

7.5 [0.30]

8.0

[0.31]

7.0 [0.276]

R38

[1.496]

2 x

Ø10.2 [0.402]

Depth: 6 [0.236]

40.0 [1.575]

25.0

[0.984]

Ø17.0 [0.669]

x 7.0 [0.276]

Stainless

Sintered Roller

31.5

[1.240]

16.0 [0.630]

Max

65.0

[2.559]

Max

Max

50.0 [1.969]

Max.

44.0

[1.732]

2 x Ø5.1

[Ø0.201]

102.7

[4.043]

Compact Prewired Switches

2.2

Dimensions

Approximate Dimensions in mm [in]

E47BCC05

E47BCC06

E47BCC11

25.0

[0.984]

PT

OP

67.0

[2.638]

Max

51.5

[2.028]

2.0 [0.079]

34.0 [1.339]

E47BCC12

25.0

[0.984]

PT

OP

73.0

[2.874]

Max.

49.0

[1.929]

2.0

[0.079]

40.0 [1.575]

Max

40.0 [1.575]

34.0 [1.339]

2 x Ø5.1 [Ø0.201]

2 x Ø10.2 [0.402]

Depth: 6 [0.236]

7.0

[0.276]

7.5 [0.295]

8.0 [0.315]

23.0

2.0

[0.906]

[0.079]

2 x Ø5.1 [Ø0.201]

2 x Ø10.2 [0.402]

Depth: 6 [0.236]

Ø12.7 [0.500] x

4.0

[0.157]

Stainless Steel

7.5 [0.295]

8.0 [0.315]

23.0

2.0

[0.906]

[0.079]

Ø12.7 [0.500]

x 3.8 [0.150]

Stainless

Steel Roller

1.4

[0.055]

3.8 [0.150]

Roller

1.4

[0.055]

16.0

[0.630]

Max

2.8

[0.110]

Correct

Setting

Position

1.5

[0.059]

16.0

[0.630]

Max

Rubber

Cap

1.5

[0.059]

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

E47BCC07

E47BCC08

E47BCC13

25.0

[0.984]

OP

67.0

[2.638]

Max

51.5

[2.028]

2.0 [0.079]

34.0 [1.339]

PT

40.0 [1.575]

2 x Ø5.1 [Ø0.201]

2 x Ø10.2 [0.402]

Depth: 6 [0.236]

7.0

[0.276]

7.5 [0.295]

23.0

[0.906]

2.0

[0.079]

Ø10 [0.397]

Stainless

Steel PLU

8.0 [0.315]

[0.055]

1.4

16.0

[0.630]

2.8

[0.110]

Correct

Setting

Position

1.5

[0.059]

E47BCC15

Volume 8—Sensing Solutions CA08100010E—May 2013 V8-T2-19

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2.2

40.0 [1.575]

49.0

[1.929]

2.0

[0.079]

1.4

[0.055]

1.5

[0.059]

16.0

[0.630]

Max

Rubber

Cap

34.0 [1.339]

2.0

[0.079]

23.0

[0.906]

8.0 [0.315]

7.5 [0.295]

4.0

[0.157]

2 x Ø10.2 [0.402]

Depth: 6 [0.236]

2 x Ø5.1 [Ø0.201]

103.7

[2.5]

25.0

[0.984]

50.7

Ø1.2

5.7

18 AWG/4

UL, SJT (0)

Ø8.5 [0.335]

159.0

[6.257]

16.0

[0.630]

1.5

[0.059]

1.3

[0.051]

Ø3.0

[0.117]

25.9

[1.020]

8.0

[0.315]

2.0

[0.079]

2.0 [0.079]

34.0 [1.339]

40.0 [1.575]

25.0

[0.984]

23.0

[0.906]

18 AWG/4

UL, SJT (0)

Ø8.5 [0.335]

Approximate Dimensions in mm [in]

2

E47BCC20

2

2

2

2

2

Limit Switches

Compact Prewired Switches

E47BCC22

25.0

[0.984]

Ø17.5

[0.69]

R 25.0–89.0

[0.984–3.600]

8.0

[0.315]

51.2 [2.017]

7.0 [0.280]

16.0

[0.630]

2

2

2

2

2

2

2

2

2

2

2

2

2

2

E47BCC21

23.0

[0.906]

18 AWG/4

UL, SJT (0)

Ø 8.5 [0.335]

2.0

[0.079]

2.0 [0.079]

34.0 [1.339]

40.0 [1.575]

1.3

[0.051]

18 AWG/4

UL, SJT (0)

Ø 8.5 [0.335]

1.5

[0.059]

2

2

2

2

2

2

2

2

2

2

V8-T2-20 Volume 8—Sensing Solutions CA08100010E—May 2013

Limit Switches

LS-Titan Miniature DIN Switches

LS-Titan Miniature DIN Switches

2.3

LS-Titan Miniature DIN Switches

Product Description

Eaton’s LS-Titan™ limit

switch line is a complete

offering of safety position

switches designed for

worldwide application.

Economical insulated

plastic or rugged metal

enclosures and modular,

plug-in operating heads

and bodies make LS-Titan a

flexible switching solution.

A highlight of the LS-Titan

switch line is the world’s

first electronic position

switch (LSE models). These

switches feature freely

programmable operating

points that can be set

individually at any time.

Additional LSE models

provide analog outputs

proportional to the

actuator position.

LS-Titan switches are suitable

for use in safety applications

designed to protect persons

or processes.

Features

●

Modular, plug-in

stem (head a

sy

bo

dy components)

●

Positive opening NC

ntacts for safet

co

ap

plications

●

Wide variety of economical

plastic and rugged metal

versions available

●

Operating heads can

rotated 90 degrees

be

to suit specific directio

of operation

●

Unique electronic safety

sition switches (L

po

mod

els) provide anal

(0–10 Vdc or 4–20 mA)

tputs proportional

ou

act

uator position and allo

for easy configuration of

custom trip poin

a

nd

y

SE

to the

t

og

Contents

Description Page

LS-Titan Miniature DIN Switches

Product Identification . . . . . . . . . . . . . . . . . . . . V8-T2-22

Product Selection . . . . . . . . . . . . . . . . . . . . . . . V8-T2-23

LS-Titan Plastic Safety Switches . . . . . . . . . V8-T2-23

LS-Titan Plastic Electronic

Safety Position Switches . . . . . . . . . . . . . V8-T2-26

LS-Titan Metal Safety Switches . . . . . . . . . V8-T2-30

Understanding LS-Titan Electronic

Safety Position Switches . . . . . . . . . . . . . V8-T2-32

Operating Point Adjustment . . . . . . . . . . . . V8-T2-32

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-33

Technical Data and Specifications . . . . . . . . . . V8-T2-34

Contact Travel Diagrams . . . . . . . . . . . . . . . . . . V8-T2-37

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . V8-T2-40

2

2

2

2

2

2

2

2

2

2

2

Standards and Certifications

●

Can be ordered as

arate compon

sep

(

head and body) or as

completely assembled

tches

swi

●

Screw and Cage Clamp

standard on LSE mode

(

and

optionally availabl

on mechanical models)

nections provide larg

con

wi

ring areas for easi

n

installation

●

Approved for worldwide

lication

app

ents

®

ls

e

er

●

Safety function by positive

opening contacts pe

I

EC/EN 60947-5-1 up

Category 4 per EN 954-1

●

TÜV-Rheinland Certified

or Functional-Safet

f

(L

SE models)

●

CSA certified

●

er

UL listed

●

CE

●

CCC

r

to

y

2

2

2

2

2

2

2

2

Note: Cage Clamp is a

w

registered trademark of

Wago Kontakttechnik,

32423 Minden, Germany.

2

2

2

2

2

2

Volume 8—Sensing Solutions CA08100010E—May 2013 V8-T2-21

2

2

2

2

2

2.3

Product Identification

2

Limit Switches

LS-Titan Miniature DIN Switches

2

2

2

2

2

2

2

2

2

2

2

2

2

2

1

2

3

4

k

5

6

7

8

9

j

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Notes

1

Basic device

(see Pages V8-T2-23 to V8-T2-31)

According to EN 50047

With screw-on cover

Contacts: 1NO-1NC, 2NO, 2NC

Cage Clamp, screw terminal

As snap-action or standard-action switch

As electronic snap-action switch

(individually adjustable)

As 4–20 mA analog signal encoder

As 0–10 Vdc analog signal encoder

2

Fixing adapter (see Page V8-T2-33)

Allows mounting of M22 pushbuttons

3

Roller lever

(see Pages V8-T2-23 and V8-T2-26)

For one-sided operation with higher

operating speed

4

Angled roller lever

(see Pages V8-T2-23, V8-T2-26 and

V8-T2-30)

For actuation along the unit axis

5

Rotary lever (see Pages V8-T2-23,

V8-T2-27 and V8-T2-30)

For actuation from the side, for

pendulum movements

6

Roller plunger (see Pages V8-T2-23,

V8-T2-26 and V8-T2-30)

For actuation from the side with low

actuating force

7

Adjustable roller lever

(see Pages V8-T2-24, V8-T2-27,

V8-T2-28 and V8-T2-30)

For length adjustment as required

8

Actuating rod (see Pages V8-T2-25,

V8-T2-29 and V8-T2-31)

On conveyor belts for lightweight goods

9

Spring-rod (see Pages V8-T2-25,

V8-T2-29 and V8-T2-31)

For flexible actuation from all sides

j Actuating rod (see Pages V8-T2-25,

V8-T2-29 and V8-T2-31)

Withdrawable mechanism from front

k Pushbuttons from the M22 family; see

M22 catalog (CA04716001E) or

Operating heads can be rotated

by 90 degrees.

m22

2

V8-T2-22 Volume 8—Sensing Solutions CA08100010E—May 2013

Limit Switches

Plastic Safety

Switch Body

Top Push Roller

Plunger

Long Roller Lever

Short Roller Lever

Large Roller Lever

Angled Roller

Assembled Switch

Rotary Lever

13

14 24

23

NC

11–12

21–22

NC

Zw = 4.5 mm

3.0

0 3.0 6.1

13–14

13–14

21–22

21–22

Zw = 5.5 mm

1.6

0

3.0

6.1

LS-Titan Miniature DIN Switches

2.3

Product Selection

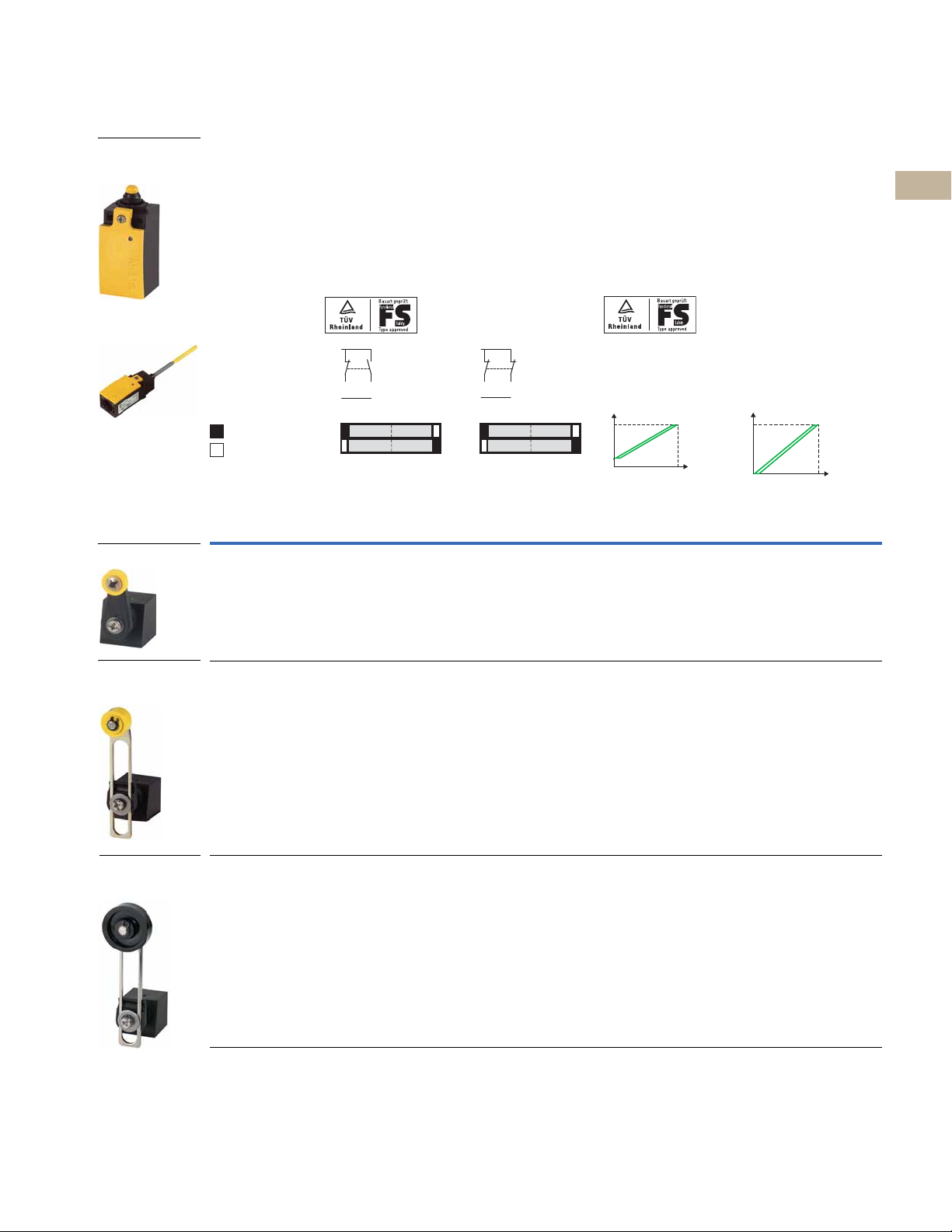

LS-Titan Plastic Safety Switches

Plastic Safety Switches

Switch Body Catalog Number LS-S02 LS-S20A LS-S11S

Output Function 2NC with positive

Terminal Connection Screw terminal

Contact Sequence

Contact Travel Snap-action contact

= contact closed

= contact open

Operating Head Type

Head Only

Catalog Number

LS-XP LS-S02-P LS-S20A-P LS-S11S-P

LS-XL LS-S02-L LS-S20A-L LS-S11S-L

2

2

2

opening contacts

11

21

12

22

2NO with slow

make/break

1

Screw terminal

13–14

23–24

1

0 2.1 6.1

2.1

ZW = 4.5 mm

NO

NO

1NO and 1NC with

positive opening contact

Screw terminal

1

21

13

14

22

2

2

2

2

2

2

2

Assembled Switch

Catalog Number

2

2

2

2

2

2

LS-XLS LS-S02-LS LS-S20A-LS LS-S11S-LS

LS-XLB LS-S02-LB LS-S20A-LB LS-S11S-LB

LS-XLA LS-S02-LA LS-S20A-LA LS-S11S-LA

LS-XRL LS-S02-RL LS-S20A-RL LS-S11S-RL

Notes

1

Cage Clamp versions available. Contact Application Engineering.

2

For operating head dimensions, see Page V8-T2-40.

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Volume 8—Sensing Solutions CA08100010E—May 2013 V8-T2-23

2.3

Adjustable

Roller Lever

(with 18 mm Roller)

Adjustable

Roller Lever

(with 30 mm Roller)

Adjustable

Roller Lever

(with 40 mm Roller)

Adjustable Roller

Lever (with 40 mm

Rubber Roller)

Plastic Safety

Switch Body

Assembled Switch

13

14 24

23

= contact closed

= contact open

NC

11–12

21–22

NC

Zw = 4.5 mm

3.0

0 3.0 6.1

13–14

13–14

21–22

21–22

Zw = 5.5 mm

1.6

0

3.0

6.1

Limit Switches

LS-Titan Miniature DIN Switches

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Plastic Safety Switches, continued

Switch Body Catalog Number LS-S02 LS-S20A LS-S11S

Output Function 2NC with positive

Terminal Connection Screw terminal

Contact Sequence

Contact Travel Snap-action contact

Operating Head Type

Head Only

Catalog Number

LS-XRLA LS-S02-RLA LS-S20A-RLA LS-S11S-RLA

LS-XRLA30 LS-S02-RLA30 LS-S20A-RLA30 LS-S11S-RLA30

2

opening contacts

1

2111

12

22

Assembled Switch

Catalog Number

2NO with slow

make/break

Screw terminal

0 2.1 6.1

13–14

23–24

2.1

ZW = 4.5 mm

1NO and 1NC with

positive opening contact

1

NO

NO

Screw terminal

1

21

13

14

22

2

2

2

2

2

2

2

2

2

2

2

2

2

2

LS-XRLA40 LS-S02-RLA40 LS-S20A-RLA40 LS-S11S-RLA40

LS-XRLA40R LS-S02-RLA40R LS-S20A-RLA40R LS-S11S-RLA40R

Notes

1

Cage Clamp versions available. Contact Application Engineering.

2

For operating head dimensions, see Page V8-T2-40.

2

V8-T2-24 Volume 8—Sensing Solutions CA08100010E—May 2013

Limit Switches

Plastic Rod Lever

Metal Rod

Spring Rod (Wobble)

3

Actuating Rod

Plastic Safety

Switch Body

Assembled Switch

13

14 24

23

NC

11–12

21–22

NC

Zw = 4.5 mm

3.0

0 3.0 6.1

13–14

13–14

21–22

21–22

Zw = 5.5 mm

1.6

0

3.0

6.1

LS-Titan Miniature DIN Switches

2.3

Plastic Safety Switches, continued

Switch Body Catalog Number LS-S02 LS-S20A LS-S11S

Output Function 2NC with positive

Terminal Connection Screw terminal

Contact Sequence

Contact Travel Snap-action contact

= contact closed

= contact open

Operating Head Type

Head Only

Catalog Number

LS-XRR LS-S02-RR LS-S20A-RR LS-S11S-RR

LS-XRRM LS-S02-RRM LS-S20A-RRM LS-S11S-RRM

2

opening contacts

1

2111

12

22

Assembled Switch

Catalog Number

2NO with slow

make/break

Screw terminal

0 2.1 6.1

13–14

23–24

2.1

ZW = 4.5 mm

1NO and 1NC with

positive opening contact

1

NO

NO

Screw terminal

1

21

13

14

22

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

LS-XS LS-S02-S LS-S20A-S LS-S11S-S

2

2

2

2

LS-XOR LS-S02-OR LS-S20A-OR LS-S11S-OR

2

2

2

2

Notes

1

Cage Clamp versions available. Contact Application Engineering.

2

For operating head dimensions, see Page V8-T2-40.

3

Not to be used as a safety position switch. Use only in conjunction with snap-action contact.

2

2

2

2

Volume 8—Sensing Solutions CA08100010E—May 2013 V8-T2-25

2.3

Plastic Electronic

Safety Position

Switch Body

Top Push Roller

Plunger

Long Roller Lever

Short Roller Lever

Large Roller Lever

Assembled Switch

Angled Roller

Q10VQ2

+U

e

electron.

= contact closed

= contact open

Q1

Q2

0.5 5.5

default=3.0

6.1

0

LS-Titan Plastic Electronic Safety Position Switches

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Limit Switches

LS-Titan Miniature DIN Switches

Plastic Electronic Safety Position Switches

Switch Body

Catalog Number LSE-11 LSE-02 LSE-AI LSE-AU

Output Function 1NO and 1 NC 2NC Analog 4–20 mA Analog 0–10V

Terminal Connections Cage Clamp

Safety Functions

and Approvals

Contact Sequence Analog 4–20 mA Analog 0–10V

Contact Travel

Operating Head Type

Head Only

Catalog Number

LS-XP LSE-11-P LSE-02-P LSE-AI-P LSE-AU-P

These models may be used in safety-oriented circuits. Visual status

LED indication is comparable to positive opening contacts. Certified

by TÜV as a “Functional-Safety” device. Suitable for protection of

people or processes.

2

Assembled Switch

Catalog Number

1

Cage Clamp

+U

Q1

Q2

1

e

electron.

Q10VQ2

0

0.5 5.5

default=3.0

4

0

I [mA]

1

S [%]

100

Cage Clamp

U [V]

10

0100

Cage Clamp

Additional diagnostic output that registers a 0V signal in the event

of a fault. Self-test function continuously tests both outputs for

overloads, short circuits to 0V and short circuits to +U

TÜV to EN 954-1, Category 3 or 4. Suitable for protection of people

or processes.

6.1

20

1

. Certified by

e

S [%]

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

LS-XL LSE-11-L LSE-02-L LSE-AI-L LSE-AU-L

LS-XLS LSE-11-LS LSE-02-LS LSE-AI-LS LSE-AU-LS

LS-XLB LSE-11-LB LSE-02-LB LSE-AI-LB LSE-AU-LB

LS-XLA LSE-11-LA LSE-02-LA LSE-AI-LA LSE-AU-LA

Notes

1

A compatible Cage Clamp tool is available as an accessory on Page V8-T2-33.

2

For operating head dimensions, see Page V8-T2-40.

2

V8-T2-26 Volume 8—Sensing Solutions CA08100010E—May 2013

Limit Switches

Rotary Lever

Adjustable

Roller Lever

(with 18 mm Roller)

Adjustable

Roller Lever

(With 30 mm Roller)

Plastic Electronic

Safety Position

Switch Body

Assembled Switch

Q10VQ2

+U

e

electron.

Q1

Q2

0.5 5.5

default=3.0

6.1

0

LS-Titan Miniature DIN Switches

2.3

Plastic Electronic Safety Position Switches, continued

Switch Body

Catalog Number LSE-11 LSE-02 LSE-AI LSE-AU

Output Function 1NO and 1NC 2NC Analog 4–20 mA Analog 0–10V

Terminal Connections Cage Clamp

Safety Functions

and Approvals

Contact Sequence Analog 4–20 mA Analog 0–10V

Contact Travel

= contact closed

= contact open

Operating Head Type

Head Only

Catalog Number

LS-XRL LSE-11-RL LSE-02-RL LSE-AI-RL LSE-AU-RL

These models may be used in safety-oriented circuits. Visual status

LED indication is comparable to positive opening contacts. Certified

by TÜV as a “Functional-Safety” device. Suitable for protection of

people or processes.

2

Assembled Switch

Catalog Number

1

Cage Clamp

+U

Q1

Q2

1

e

electron.

Q10VQ2

0

0.5 5.5

default=3.0

4

0

I [mA]

1

S [%]

100

Cage Clamp

U [V]

10

0100

Cage Clamp

Additional diagnostic output that registers a 0V signal in the event

of a fault. Self-test function continuously tests both outputs for

overloads, short circuits to 0V and short circuits to +U

TÜV to EN 954-1, Category 3 or 4. Suitable for protection of people

or processes.

6.1

20

1

. Certified by

e

S [%]

2

2

2

2

2

2

2

2

2

2

2

2

2

2

LS-XRLA LSE-11-RLA LSE-02-RLA LSE-AI-RLA LSE-AU-RLA

LS-XRLA30 LSE-11-RLA30 LSE-02-RLA30 LSE-AI-RLA30 LSE-AU-RLA30

Notes

1

A compatible Cage Clamp tool is available as an accessory on Page V8-T2-33.

2

For operating head dimensions, see Page V8-T2-40.

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Volume 8—Sensing Solutions CA08100010E—May 2013 V8-T2-27

2.3

Plastic Rod Lever

Adjustable

Roller Lever

(With 40 mm Roller)

Adjustable

Roller Lever

(With 40 mm Roller)

Plastic Electronic

Safety Position

Switch Body

Assembled Switch

Q10VQ2

+U

e

electron.

= contact closed

= contact open

Q1

Q2

0.5 5.5

default=3.0

6.1

0

Limit Switches

LS-Titan Miniature DIN Switches

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Plastic Electronic Safety Position Switches, continued

Switch Body

Catalog Number LSE-11 LSE-02 LSE-AI LSE-AU

Output Function 1NO and 1NC 2NC Analog 4–20 mA Analog 0–10V

Terminal Connections Cage Clamp

Safety Functions

and Approvals

Contact Sequence Analog 4–20 mA Analog 0–10V

Contact Travel

Operating Head Type

Head Only

Catalog Number

LS-XRLA40 LSE-11-RLA40 LSE-02-RLA40 LSE-AI-RLA40 LSE-AU-RLA40

These models may be used in safety-oriented circuits. Visual status

LED indication is comparable to positive opening contacts. Certified

by TÜV as a “Functional-Safety” device. Suitable for protection of

people or processes.

2

Assembled Switch

Catalog Number

1

Cage Clamp

+U

Q1

Q2

1

e

electron.

Q10VQ2

0

0.5 5.5

default=3.0

4

0

I [mA]

1

S [%]

100

Cage Clamp

10

Cage Clamp

Additional diagnostic output that registers a 0V signal in the event

of a fault. Self-test function continuously tests both outputs for

overloads, short circuits to 0V and short circuits to +U

TÜV to EN 954-1, Category 3 or 4. Suitable for protection of people

or processes.

6.1

20

1

U [V]

0100

. Certified by

e

S [%]

2

2

2

2

2

2

2

2

2

2

2

2

2

2

LS-XRLA40R LSE-11-RLA40R LSE-02-RLA40R LSE-AI-RLA40R LSE-AU-RLA40R

LS-XRR LSE-11-RR LSE-02-RR LSE-AI-RR LSE-AU-RR

2

2

Notes

1

A compatible Cage Clamp tool is available as an accessory on Page V8-T2-33.

2

For operating head dimensions, see Page V8-T2-40.

V8-T2-28 Volume 8—Sensing Solutions CA08100010E—May 2013

Limit Switches

Plastic Electronic

Safety Position

Switch Body

Spring Rod (Wobble)

3

Actuating Rod

Assembled Switch

Metal Rod

Q10VQ2

+U

e

electron.

Q10VQ2

+U

e

electron.

I [mA]

20

0

4

100

S [%]

10

0100

S [%]

U [V]

LS-Titan Miniature DIN Switches

2.3

Plastic Electronic Safety Position Switches, continued

Switch Body

Catalog Number LSE-11 LSE-02 LSE-AI LSE-AU

Output Function 1NO and 1NC 2NC Analog 4–20 mA Analog 0–10V

Terminal Connections Cage Clamp

Safety Functions

and Approvals

Contact Sequence Analog 4–20 mA Analog 0–10V

Contact Travel

= contact closed

= contact open

Operating Head Type

Head Only

Catalog Number

LS-XRRM LSE-11-RRM LSE-02-RRM LSE-AI-RRM LSE-AU-RRM

These models may be used in safety-oriented circuits. Visual status

LED indication is comparable to positive opening contacts. Certified

by TÜV as a “Functional-Safety” device. Suitable for protection of

people or processes.

Q1

Q2

2

Assembled Switch

Catalog Number

1

0

0.5 5.5

default=3.0

Cage Clamp

6.1

Q1

Q2

1

0

0.5 5.5

default=3.0

Cage Clamp

Additional diagnostic output that registers a 0V signal in the event

of a fault. Self-test function continuously tests both outputs for

overloads, short circuits to 0V and short circuits to +U

by TÜV to EN 954-1, Category 3 or 4. Suitable for protection of people

or processes.

6.1

1

Cage Clamp

1

. Certified

e

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

LS-XS LSE-11-S LSE-02-S LSE-AI-S LSE-AU-S

2

2

2

2

2

2

LS-XOR LSE-11-OR LSE-02-OR LSE-AI-OR LSE-AU-OR

2

2

2

2

2

Notes

1

A compatible Cage Clamp tool is available as an accessory on Page V8-T2-33.

2

For operating head dimensions, see Page V8-T2-40.

3

Not to be used as a safety position switch. Use only in conjunction with snap-action contact.

2

2

Volume 8—Sensing Solutions CA08100010E—May 2013 V8-T2-29

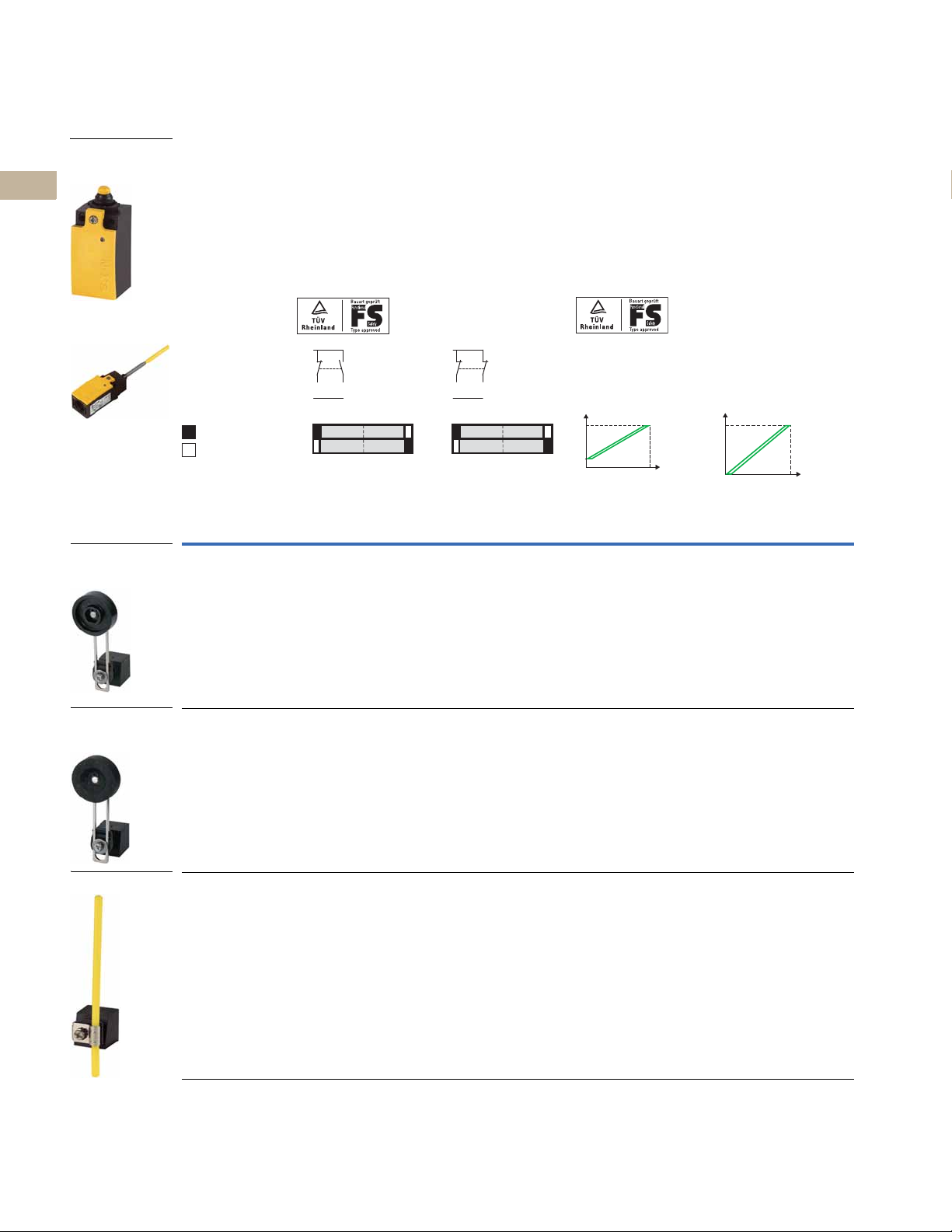

2.3

Top Push Roller

Plunger

Long Roller Lever

Angled Roller

Rotary Lever

Adjustable Roller Lever

Metal Safety

Switch Body

Assembled Switch

12

22

2111

= contact closed

= contact open

NC

11–12

21–22

NC

Zw = 4.5 mm

3.0

0 3.0 6.1

13–14

13–14

21–22

21–22

Zw = 5.5 mm

1.6

0

3.0

6.1

LS-Titan Metal Safety Switches

2

2

2

2

Limit Switches

LS-Titan Miniature DIN Switches

Metal Safety Switches

Switch Body Catalog Number LSM-02 LSM-20A LSM-11S

Output Function 2NC with positive

opening contacts

Terminal Connection Cage Clamp Cage Clamp Cage Clamp

Contact Sequence

2NO with slow

make/break

13

23

1NO and 1NC with

positive opening contact

13

21

2

2

2