SAMSUNG SR-44 Service Manual

Model :SR-40RMB

SR-44RMB

FEB, 2000

For request : Refcs@Samsung.co.kr

1. Product Specifications

[CFC-FREE] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ITEM |

SPECIFICATION |

||

|

|

Model name |

SR 40(NMA)/NMB/RMB |

|

SR 44(NMA)/NMB/RMB |

|

|

Vailable |

|

Freezer |

92(3.3) |

|

92(3.3) |

|

|

Refrigerator |

252(8.9) |

|

284(10.0) |

|

Capacity(cu.ft) |

|

|||||

Total |

344(12.2) |

|

376(13.3) |

|||

|

|

|

|

|||

|

|

Net Dimension |

670x640x1660 |

|

670x640x1730 |

|

|

(WidthxDepthxHeight) |

(670) |

|

(670) |

||

|

|

|

|

|

||

|

Rated Voltage & frequency |

110~115V/60Hz, 127V/60Hz, 220V/5~60Hz, 230~240V/50 |

||||

|

Rated Power Defrost, Heater |

290W |

|

|||

|

Type of Refrigerator |

forced convection |

||||

|

|

Refrigerant |

HFC-134a |

|

||

|

Refrigerant Mass |

160g |

|

|||

|

Freezing Capicity |

4 STAR |

|

|||

|

Weight (Net/Gross) |

59/69(kg) |

|

63/73(kg) |

||

|

|

|

|

|

|

|

Samsung Electronics |

1 |

2. Safety warnings

Read all instructions before using this appliance in order to avoid risk of accident or possible damage.

Warning/Caution

This symbol is intended to Warning alert the user to the

possible death or injury.

This symbol is intended to Caution alert the user to the

possible injury or damage.

Description of symbols

Indicates prohibition

Do not disassemble

Do not contact

Follow Adhere the instruction strictly

Unplug from the electrical outlet

Earth the appliance to avoid the risk of an electric shock

Warning

Warning

Do not plug multiple electrical |

Do not attempt to make repairs |

Make sure the power cord is not |

appliances into the same outlet. |

yourself. |

crushed or damaged. |

• This may cause abnormal |

• This could lead to fire hazard or |

• Repair immediately all power cords |

heating or a fire hazard. |

abnormal operation causing |

or outlets that have become frayed |

|

severe personal injury. |

or otherwise damaged. |

Prohibition |

Do not disassemble |

Check the operating environment. |

Be sure the earth. |

Pull the power plug out for |

|||||

• Do not install the refrigerator in a |

• If earthing is not done, it will |

exchanging electrical equipment. |

|||||

humid (with condensation) location |

cause breakdown & electric |

• It may cause electric shock. |

|||||

or on an unstable surface. |

shock. |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Earth  Unplug

Unplug

2 |

Samsung Electronics |

Caution

Caution

Do not put bottles or kinds of |

Do not store narrow and |

Do not store pharmaceutical |

glass in the freezer. |

lengthy bottles or foods in a |

products, scientific materials, |

• Freezing of the contents |

small multi-purpose room. |

etc, in the refrigerator. |

may inflict a wound. |

• It may hurt you when refrigerator |

• The products which cotrolled by |

|

door is opened and closed |

temperature shall not be stored |

|

resulting in falling stuff down. |

in the refrigerator. |

Prohibition |

Prohibition |

Prohibition |

Do not store articles on the |

Use the rated components on |

On repair, make sure that the wires |

product. |

the replacement. |

such as harness should be bundled |

• Opening or closing the door |

• Check the correct model, rated |

tightly. |

may throw down which may |

voltage, rated correct, operating |

• Bundle tightly wires in order not to |

inflict a wound. |

temperature and so on. |

be detached by the external force |

|

|

and then not to be wet. |

Rated

component

Prohibition

On repair, remove completely dust or other things of housing parts, harness parts, and check parts.

•Cleaning may prevent the possible fire by tracking or short

After repair, check the assembled state of components.

•It must be in the same assembled state when compared with the state before disassembly.

Check if there is any trace indicating the permeation of water.

•If there is that kind of trace, change related components or do the necessary treatment such as taping using the insulating tape.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Samsung Electronics |

3 |

||||||||

3. Specifications of Electric Components

[CFC-FREE]

|

|

|

ITEM |

SPECIFICATION |

|||

|

|

Model name |

SR 40NMA/NMB/RMB |

|

SR 44NMA/NMB/RMB |

||

|

|

|

Type |

2-Door Freezer/Refrigerator |

|||

|

|

|

|

|

|

||

|

Power Source |

AC110~115V/60Hz, 127V/60Hz |

|||||

|

220V/50~60Hz, 230~240V/50Hz |

||||||

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Net Capacity |

Freezer |

92 |

|

|

92 |

|

|

Refrigerator |

252 |

|

|

284 |

||

|

(§⁄/cu.ft) |

|

|

|

|||

|

|

Total |

344/12.2 |

|

|

376/13.3 |

|

|

|

|

|

|

|||

Net Dimension |

Width |

|

|

670 |

|||

Depth(NMA) |

|

|

640(670) |

||||

|

(mm) |

|

|

|

|||

|

|

Height |

1660 |

|

|

1730 |

|

|

|

|

|

|

|||

|

Net weight (Kg) |

53 |

|

|

54 |

||

|

|

Refrigerant |

|

R134a (160g) |

|||

|

Temperature Control |

Dial (Resistance) |

|||||

|

|

Defrosting |

Automatic (Start-Finish by PCB) |

||||

|

Foam |

|

Cabinet |

Cyclo-Pentane |

|||

|

insulation |

|

Door |

Cyclo-Pentane |

|||

|

|

|

|||||

|

Liner/Door Panel |

ABS (SD-0150) |

|||||

|

|

|

|

2 Guard-Freezer |

|||

|

|

|

Door |

1 Guard-Egg,1 Guard-Bottle |

|||

|

|

|

Storage |

2 |

Guard-Variety |

||

|

|

|

|

1 Guard-Jumbo |

|||

|

|

|

|

1 Base Tray Ice |

|||

|

|

|

|

1 Case Tray Ice |

|||

|

|

|

|

1Shelf Freezer |

|||

|

Accessory |

|

Inside |

1 Case Chilled Room |

|||

|

Parts |

|

Storage |

2 Shelf Refrigerator |

|||

|

|

|

|

1 Cover Vegetable |

|||

|

|

|

|

1 Case Vegetable |

|||

|

|

|

|

1 Vegetable Partition |

|||

|

|

|

|

|

|

||

|

|

|

Interior Lamp |

Refrigerator (Freezer) |

|||

|

|

|

Movable Caster |

|

|

2 (Rear) |

|

|

|

|

Angle Adjustment |

|

2 Legs (front) |

||

|

|

|

|

|

|

|

|

4 |

Samsung Electronics |

[CFC-FREE]

|

ITEM |

|

|

|

STANDARD |

|

||||

|

Model |

|

|

|

SR40/44NMA/NMB/RMB |

|

||||

|

Power source |

110~115V/60Hz |

|

127V/60Hz |

|

220V/50~60Hz |

|

230~240V/50Hz |

||

|

|

|

|

|

|

|

|

|

|

|

Cycle |

|

|

Model |

UK162C-L1U/T3 |

UK162P-L1U/T3 |

SK170H-L1U/T3 |

|

SK170Q-L1U/T3 |

||

Compressor |

|

Starting type |

|

|

R.S.C.R |

|

||||

|

|

|

|

|

||||||

Refrigeration |

|

|

Oil charge |

|

|

FREOL ¥–15cÆ / 264cc |

|

|||

Evaporator |

|

|

Fin type |

|

||||||

|

|

|

|

|||||||

|

Condenser |

|

|

Natural convection type |

|

|||||

|

Dryer |

|

|

Molecular sieve (XH-9, 13g) |

|

|||||

|

Capillary tube |

|

|

ID 0.75 x L3400 (mm) |

|

|||||

|

R-SENSOR |

|

|

502AT |

|

|||||

|

|

|

|

|

|

502AT |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Defrost-Sensor |

|

Thermal fuse |

Rating Voltage/Ampere |

|

AC 250V / 10A |

||||

|

|

|

Open temperature |

|

72¡ 4˚C |

|||||

|

|

|

|

|

||||||

|

Starting-relay |

|

Model |

J531Q33E100M 200-2 |

|

J531Q34E220M350-2 |

J531Q35E330M385-2 |

|||

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Resistance |

|

|

|

|

|

||

|

|

|

10Ω-20PIN |

|

33Ω-2PIN |

|||||

Electrical |

protector |

|

Close temp. |

69¡ 9˚C |

|

69¡ 9˚C |

|

69¡ 9˚C |

69¡ 9˚C |

|

|

|

|

Model |

4TM419 |

|

4TM2935 |

4TM265 |

|||

|

Overload |

|

NHBYY-53 |

|

HBYY-53 |

RFBYY-53 |

||||

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Open temp. |

125¡ 5˚C |

|

120¡ 5˚C |

|

130¡ 5˚C |

125¡ 5˚C |

|

|

Capacitor |

|

Running |

250VAC/12µF |

|

250VAC/12µF |

|

350VAC/5.0µF |

350VAC/5.0µF |

|

|

|

|

|

|

|

|

|

|

|

|

|

Resistor Heater |

|

|

MORS 3W |

|

|||||

|

Heater-defrost |

290W/ 45Ω |

|

290W/ 55Ω |

|

290W/ 167Ω |

290W/ 198Ω |

|||

|

Lamp |

|

110V~130V/15w |

|

220V~240V/15W |

|||||

|

Door-Switch |

|

|

250V/0.5A, 125V/1.5A |

|

|||||

|

Earth screw |

|

|

BSBN(Brass screw) |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

Samsung Electronics |

5 |

4. Electric Circuit Diagram

[ 110~115V/ 60Hz, 127V/60Hz, 220V/50~60Hz, 230~240V/50Hz]-SR40/44

GRY – GRAY

RED – RED

BRN – BROWN

YEL – YELLOW

S/BLU – SKY BLUE

PNK – PINK

BLK – BLACK

WHT – WHITE

W/BLK – WHITE/BLACK

ORG – ORANGE

PRP – PURPLE

GRY – GRAY

RED – RED

BRN – BROWN

YEL – YELLOW

S/BLU – SKY BLUE

PNK – PINK

BLK – BLACK

WHT – WHITE

W/BLK – WHITE/BLACK

ORG – ORANGE

PRP – PURPLE

6 |

Samsung Electronics |

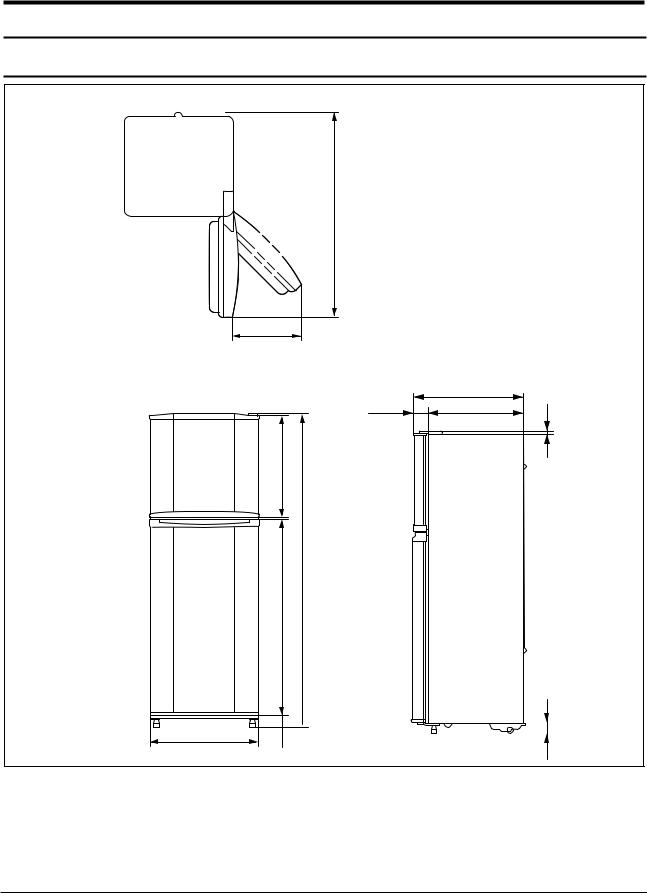

5. Extemal size and Designations

5-1) Product Dimension

1250.5

454.1

670

|

D |

80.5 |

C |

|

15 |

548.5 |

|

A 9

B

60

50

50

MODEL |

A |

B |

C |

D |

Remark |

|

SR40NMA/NMB/RMB |

1660 |

1103.5 |

549.5 |

640(670) |

SR-34 |

|

SR44NMA/NMB/RMB |

1730 |

1173.5 |

549.5 |

640(670) |

SR-30 |

|

Samsung Electronics |

7 |

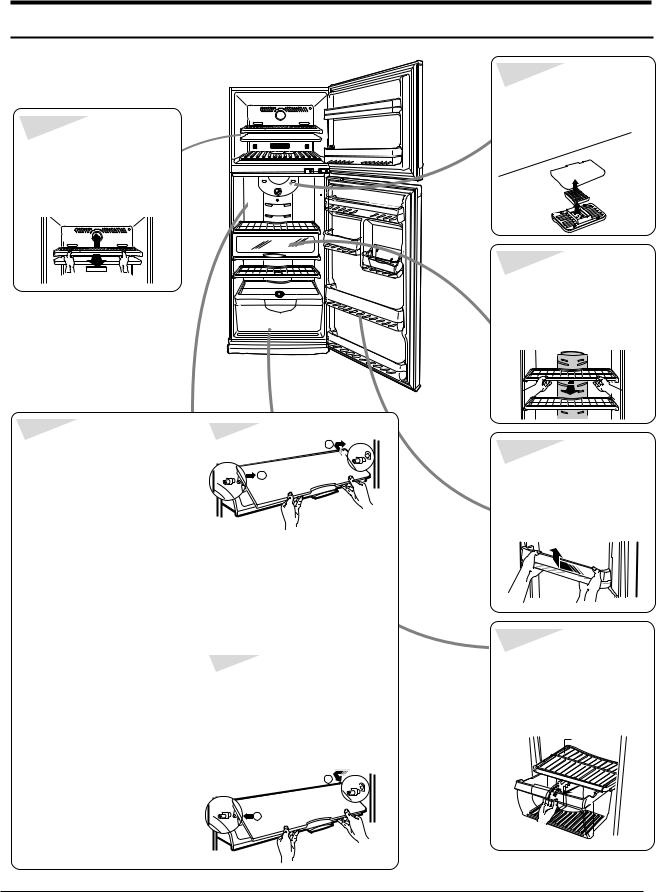

5-2) Identifying and disassembling the parts

To remove shelves in the freezing compartment

• Frist remove the icemaking molds. Tilt the shell up at front, then lift it up and pull it out of the tracks.

To remove shelves in the Disassemble |

|

chilled compartment |

1 |

• Lift up the cover, push the |

|

2 |

|

cover to the right (as shown) |

|

until the mounting hook(¤ ) |

|

disengages, then disengage |

|

the other mounting hook (¤Ł) |

|

and pull out the cover. |

|

• Pull the shelf forward until it |

|

stops. then lift it up and pull |

|

it out. |

|

•With shelf front raised slightly, engage, the roller between the rails and slide it back.

•To repace the cover, first engage the mounting hook (¤ ) as shown, then engage the other hook (¤Ł) and push in.

Reassemble

2

1 |

To remove bio deodorizer

•While pushing the front end knob of the bio deodorizer, pull it downward to disengage.

To remove shelves in the refrigerating compartment

•Hold the shelf by the front and pull it forward of the rack.

To remove door bins

•While pushing the bin to the left, lift it up to disengage.

To remove storage drawers and covers

•Lift up to remove the cover. Pull the drawer helf way out, then lifting it up, pull it out completely.

covers

8 |

Samsung Electronics |

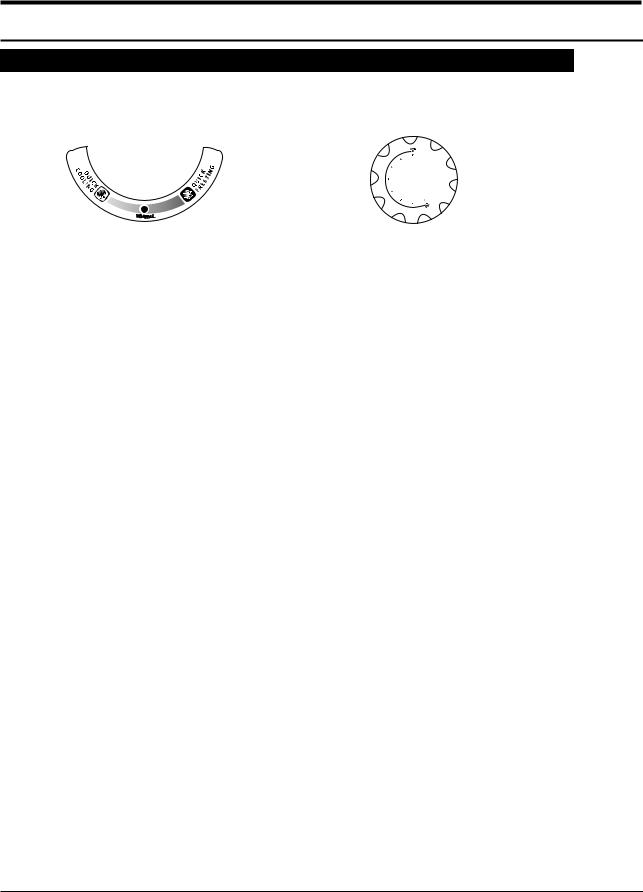

6. Schematic diagram of coolant gas circulation

6-1) Refrigeration Cycle

COMPRESSOR ¡ PIPE IMMERGE ¡ PIPE SUB CONDENSER ¡ PIPE CLUSTER ¡ PIPE HOT ¡ DRYER¡ CAPILLARY TUBE ¡ EVAPORATOR ¡ ACCUMULATOR ¡ PIPE SUCTION ¡ COMPRESSOR

Samsung Electronics |

9 |

6-2) Cool Air Circulation

•Cold air generated from the cooling system is distributed to the freezing compartment and the refrigerating compartment by the air circulation fan.

•In the freezing compartment, cold air is distributed to the compartment as well as to the shelves from the cold air exhaust port, food is frozen in the freezing compartment by cold air shower.

•Cold air that comes out of the freezing compartment is absorbed back to the lower part of the cooling system through the suction port on the median divider.

•In the refrigerating compartment, cold air is distributed to the duct cover through the median divider. Cold air supplied to the duct cover passes through the refrigerating compartment.

•After cooling the refrigerating compartment, cold air is absorbed to the lower part of the cooling system through the suction port on the median divider.

Rotating blade

10 |

Samsung Electronics |

7.Circuit operation theory

1.Temperature Control and Operational Description of Other Functions

1.Temperature Control Part Design

|

Freezer Temperature Controller |

Refrigerator Temperature Controller |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. Temperature Control Function

1)Selecting Freezer Temperature

l Selecting¡ Quick cooling~Quick freezing¡–is possible with turning temperature control knob. l Controlled temperature of each temperature control knob position is as follows:

|

Knob Position |

Quick cooling |

|

|

Normal |

|

|

Quick Freezing |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Controlled |

-16.0 |

|

-17.5 |

|

-19.0 |

-20.0 |

|

|

-21.0 |

|

-22.0 |

|||||

|

Temperature |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2)Selecting Refrigerator Temperature |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

l Selecting ¤ |

~ ¤ is possible with turning temperature control knob. |

|

|

|

|

|

|

|||||||||

|

l Controled temperature of each temperature control knob position is as follows: |

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Knob Position |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Controlled |

|

7.5 |

6.0 |

|

4.5 |

|

3.0 |

2.0 |

|

1.0 |

|

0.0 |

|

|

-1.0 |

|

|

Temperature |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution) As this controller is by the ROTARY S/W, in case it is off the position, it is set to step 4 automatically.

3. Defrosting Function

1)Defrosting is decided by the accumulated time of comp on. 2)Defrosting proceeds in order of heating ¡ recess time.

3)The first defrosting function after the initial power on starts with 4 hours of accumulated time of comp on, and then it repeats its function at every 8th hour of comp on.

4)In the process, controlling of defrosting heater ON/OFF is done by EVA-SENSOR. When the quality of EVA-SENSOR is poor (short/open) defrosting will be terminated only after recess time function without heating.

5)In the process, comp and fan maintain ON condition, after defrosting heating it operates with 10 min. recess time.

6)defrosting heating point ON and OFF operates by EVA-SENSOR and each temperature is as follows:

Heater On Point |

Heater Off Point |

Remark |

|

|

|

below -5¡ |

15¡ |

|

|

|

|

Samsung Electronics |

11 |

4. Testing Function

l This function is for PCB and test of products, work process test, and SVC.

lAfter checking the product's function by selecting TEST S/W, let the self-diagnosis function start with the POWER OFF and ON.

1)Forced Starting Function

lCOMP and FAN starts immediately after the TEST S/W on the Main PCB is pressed once. So when the forced staring function is done right at the COMP OFF point, Over Load in the COMP may be caused. Extra caution is necessary.

lWhen forced starting function is selected, COMP and FAN run for 24 hours regardless of the freezer/refrigerator temperature and knob selection. Indicating Lamp on main PCB shows that it is a forced starting function by 0.5sec interval ON/OFF.

lWhen a selected forced starting function is selected and maintains for 24 hours, defrosting function starts its operation, and when defrosting is completed normal operation is carried out according to the temperature selection knob position.

lTo release it's operation during forced starting, power should be turned off and turned on again or test release mode on 3) below should be selected.

2)Forced Defrosting Function

l If test switch is pressed once more during forced starting function, it is released immediately and forced defrosting function starts, and the Lamp on main PCB shows that it's forced defrosting by 1.0 sec. interval ON/OFF.

lWhen forced defrosting is selected COMP and FAN is turned off immediately, and defrosting heater is turned on at the same time. At this moment if the sensed temperature of EVASENSOR is higher than -5.0¡ , defrosting heater is not turned ON and operates only for recess

time and returns to normal operation.

lWhen Heating is completed it recesses for 10 mints. and after that indicating Lamp remains ON and returns to normal operation.

3)Test Function Release Mode

If TEST S/W is pressed once more when forced defrosting function is carried out, forced defrosting is released and stops for 10 mints. and after that it returns to normal operation.

12 |

Samsung Electronics |

Loading...

Loading...