Pioneer PDP-4280XA/XD, PDP-428XD Schematic

ORDER NO.

ARP3441

PDP-4280XA

PLASMA TELEVISION

PDP-4280XA

PDP-4280XD

PDP-428XD

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model |

Type |

|

|

|

Power Requirement |

Remarks |

||||

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XA |

WYV5 |

AC 220 V to 240 V |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

WYVIXK5 |

AC 220 V to 240 V |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XD |

WYV5 |

AC 220 V to 240 V |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

WYVIXK5 |

AC 220 V to 240 V |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

PDP-428XD |

WYV5 |

AC 220 V to 240 V |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

WYVIXK5 |

AC 220 V to 240 V |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For details, refer to "Important Check Points for good servicing".

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2007

PIONEER CORPORATION 2007

T-IZS-002 JUNE 2007 Printed in Japan

|

1 |

|

2 |

|

3 |

|

4 |

|

|

|

|

|

|

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty. If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

BThis product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 - Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols

(fast operating fuse) and/or

(fast operating fuse) and/or

(slow operating fuse) on PCB indicate that replacement parts must be of identical designation.

(slow operating fuse) on PCB indicate that replacement parts must be of identical designation.

REMARQUE |

|

|

(POUR MODÈLE CANADIEN SEULEMENT) |

|

|

Les symboles de fusible |

(fusible de type rapide) et/ou |

(fusible de type lent) sur CCI indiquent que les pièces |

C |

de remplacement doivent avoir la même désignation. |

|

SAFETY PRECAUTIONS

NOTICE : Comply with all cautions and safety related notes located on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an

Disolation transformer should be inserted between the power line and the set in safety before any service is performed.

2.When replacing a chassis in the set, all the protective devices must be put back in place, such as barriers, nonmetallic knobs, adjustment and compartment covershields, isolation resistorcapacitor, etc.

3. When service is required, observe the original lead dress. Extra precaution should be taken to assure correct lead dress in the high voltage circuitry area.

4. Always use the manufacture's replacement components. Especially critical components as indicated on the circuit diagram should not be replaced by other manufacture's.

EFurthermore where a short circuit has occurred, replace those components that indicate evidence of overheating.

5.Before returning a serviced set to the customer, the service technician must thoroughly test the unit to be certain that it is completely safe to operate without danger of electrical shock, and be sure that no protective device built into the set by the manufacture has become defective, or inadvertently defeated during servicing. Therefore, the following checks should be performed for the continued protection of the customer and servicetechnician.

F

6.Perform the following precautions against unwanted radiation and rise in internal temperature.

•Always return the internal wiring to the original styling.

•Attach parts (Gascket, Ferrite Core, Ground, Rear Cover, Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

•When the front case is removed, make sure nothing hits the panel face, panel corner, and panel edge (so that the glass does not break).

•Make sure that the panel vent does not break. (Check that the cover is attached.)

•Handle the FPC connected to the panel carefully. Twisting or pulling the FPC when connecting it to the

connector will cause it to peel off from the panel. 8. Pay attention to the following.

•Pay extreme caution when the front case and rear panel are removed because this may cause a high risk of disturbance to TVs and radios in the surrounding.

2 |

|

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XA |

|

|

|

|

||||

|

1 |

|

2 |

|

|

|

3 |

|

4 |

|

|

|

|

|

|

|

|

||||

|

5 |

|

6 |

|

|

Leakage Current Cold Check

With the AC plug removed from an AC power source, place a jumper across the two plug prongs. Turn the AC power switch on. Using an insulation tester (DC 500V), connect one lead to the jumpered AC plug and touch the other lead to each exposed metal part (input/output terminals, screwheads, metal overlays, control shafts, etc.), particularly any exposed metal part having a return path to the chassis. Exposed metal parts having a return path to the chassis should have a minimum resistor reading of 4 MΩ.

The below 4 MΩ resistor value indicate an abnormality which require corrective action. Exposed metal parts not having a return path to the chassis will indicate an open circuit.

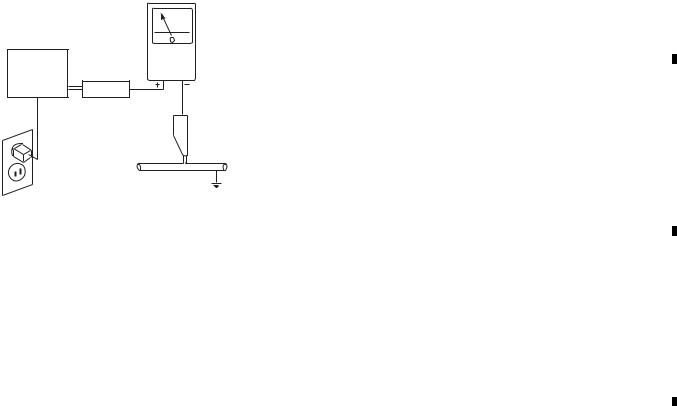

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not use an isolation transformer for this check).

Turn the AC power switch on.

U s i n g a " L e a k a g e C u r r e n t Te s t e r ( S i m p s o n M o d e l 2 2 9 equivalent)", measure for current from all exposed metal parts of the cabinet (input/output terminals, screwheads, metal overlays, control shaft, etc.), particularly any exposed metal part having a return path to the chassis, to a known earth ground (water pipe, conduit, etc.). Any current measured must not exceed 1 mA.

|

7 |

|

|

8 |

|

|

|

A |

|||

|

PRODUCT SAFETY NOTICE |

|

|||

|

|

|

|||

|

Many electrical and mechanical parts in PIONEER set have |

|

|||

|

special safety related characteristics. These are often not evident |

|

|||

|

from visual inspection nor the protection afforded by them |

|

|||

|

necessarily can be obtained by using replacement components |

|

|||

|

rated for higher voltage, wattage, etc. Replacement parts which |

|

|||

|

|

||||

|

have these special safety characteristics are identified in this |

|

|||

|

Service Manual. |

|

|

||

|

Electrical components having such features are identified by |

|

|||

|

marking with a >on the schematics and on the parts list in this |

|

|||

|

Service Manual. |

|

|

||

|

The use of a substitute replacement component which dose not |

B |

|||

|

h a v e t h e s a m e s a f e t y c h a r a c t e r i s t i c s a s t h e P I O N E E R |

|

|||

|

recommended replacement one, shown in the parts list in this |

|

|||

|

Service Manual, may create shock, fire or other hazards. |

|

|||

|

Product Safety is continuously under review and new instructions |

|

|||

|

are issued from time to time. For the latest information, always |

|

|||

|

consult the current PIONEER Service Manual. A subscription to, |

|

|||

|

|

||||

|

or additional copies of, PIONEER Service Manual may be |

|

|||

|

obtained at a nominal charge from PIONEER. |

|

|

||

C

|

|

Reading should |

|

Leakage |

not be above |

Device |

current |

1 mA |

under |

tester |

|

test |

|

|

Test all |

|

|

exposed metal |

|

|

surfaces |

|

|

|

|

D |

Also test with |

|

|

plug reversed |

|

Earth |

(Using AC adapter |

|

ground |

plug as required) |

|

|

AC Leakage Test

A N Y M E A S U R E M E N T S N OT W I T H I N T H E L I M I T S

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

E

F

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

PDP-4280XA |

|

|

||||

|

|

|

|

|

|

|

|

|||

|

5 |

|

6 |

|

|

|

7 |

|

8 |

|

|

|

|

|

|

|

|

||||

|

1 |

|

2 |

|

3 |

|

4 |

|

|

|

|

|

|

A

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol. Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

B

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

C

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7Make sure screws and soldering scraps do not remain inside the product. Please check that neither solder debris nor screws remain inside the product.

8There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

D9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries. Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification. Adjustments should be performed in accordance with the procedures/instructions described in this manual.

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification. Adjustments should be performed in accordance with the procedures/instructions described in this manual.

E

3. Lubricants, Glues, and Replacement parts |

Use grease and adhesives that are equal to the specified substance. |

Make sure the proper amount is applied. |

4. Cleaning |

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

F |

|

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be |

|

|

installed before shipment. Please be sure to follow this method especially if it is specified in this manual. |

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XA |

|

|

|

|

||||

|

1 |

|

2 |

|

|

|

3 |

|

4 |

|

|

|

|

|

|

|

|

||||

|

5 |

|

|

6 |

|

|

7 |

|

8 |

|

|

|

|

||||||

CONTENTS |

|

|

|

|

|

|

|||

|

SAFETY INFORMATION ......................................................................................................................................................... |

|

|

|

|

2 |

|||

|

1. SERVICE PRECAUTIONS.................................................................................................................................................... |

|

|

|

|

7 |

|||

|

1.1 NOTES ON SOLDERING............................................................................................................................................... |

|

|

|

|

7 |

|||

|

1.2 CHARGED SECTION AND HIGH VOLTAGE GENERATING POINT ............................................................................ |

|

8 |

||||||

|

2. SPECIFICATIONS................................................................................................................................................................. |

|

|

|

|

9 |

|||

|

2.1 ACCESSORIES.............................................................................................................................................................. |

|

|

|

|

9 |

|||

|

2.2 SPECIFICATIONS ........................................................................................................................................................ |

|

|

|

|

10 |

|||

|

2.3 PANEL FACILITIES ...................................................................................................................................................... |

|

|

|

|

13 |

|||

|

3. BASIC ITEMS FOR SERVICE ............................................................................................................................................ |

|

|

|

|

22 |

|||

|

3.1 CHECK POINTS AFTER SERVICING ......................................................................................................................... |

|

|

|

|

22 |

|||

|

3.2 QUICK REFERENCE ................................................................................................................................................... |

|

|

|

|

23 |

|||

|

3.3 PCB LOCATION ........................................................................................................................................................... |

|

|

|

|

25 |

|||

|

3.4 CLEANING ................................................................................................................................................................... |

|

|

|

|

26 |

|||

|

4. BLOCK DIAGRAM .............................................................................................................................................................. |

|

|

|

|

28 |

|||

|

4.1 OVERALL WIRING DIAGRAM (1/2)............................................................................................................................. |

|

|

|

|

28 |

|||

|

4.2 OVERALL WIRING DIAGRAM (2/2)............................................................................................................................. |

|

|

|

|

30 |

|||

|

4.3 OVERALL BLOCK DIAGRAM (1/2).............................................................................................................................. |

|

|

|

|

32 |

|||

|

4.4 OVERALL BLOCK DIAGRAM (2/2).............................................................................................................................. |

|

|

|

|

34 |

|||

|

4.5 POWER SUPPLY UNIT................................................................................................................................................ |

|

|

|

|

36 |

|||

|

4.6 42 X DRIVE ASSY........................................................................................................................................................ |

|

|

|

|

37 |

|||

|

4.7 42 Y DRIVE, 42 SCAN A and B ASSYS |

....................................................................................................................... |

|

|

|

38 |

|||

|

4.8 POWER SUPPLY BLOCK of 42 X, Y DRIVE and 42 SCAN A, B ASSYS ................................................................... |

|

39 |

||||||

|

4.9 42 ADDRESS ASSY..................................................................................................................................................... |

|

|

|

|

40 |

|||

|

4.10 42 DIGITAL and SENSOR ASSYS............................................................................................................................. |

|

|

|

|

41 |

|||

|

4.11 POWER SUPPLY BLOCK of MULTI BASE SECTION ............................................................................................... |

|

42 |

||||||

|

4.12 TANSHI ASSY ............................................................................................................................................................ |

|

|

|

|

44 |

|||

|

4.13 42/60LED and 42IR (42RLS&IR) ASSYS................................................................................................................... |

|

45 |

||||||

|

4.14 POWER SUPPLY BLOCK of 42IR (42RLS&IR) and SIDE KEY ASSYS ................................................................... |

|

46 |

||||||

|

5. DIAGNOSIS ........................................................................................................................................................................ |

|

|

|

|

47 |

|||

|

5.1 POWER SUPPLY OPERATION ................................................................................................................................... |

|

|

|

|

47 |

|||

|

5.1.1 LED DISPLAY INFORMATION .............................................................................................................................. |

|

|

|

|

47 |

|||

|

5.1.2 POWER ON SEQUENCE ...................................................................................................................................... |

|

|

|

|

48 |

|||

|

5.1.3 DETAILS OF POWER ON SEQUENCE ................................................................................................................ |

|

49 |

||||||

|

5.2 DIAGNOSIS FLOWCHART OF FAILURE ANALYSIS.................................................................................................. |

|

53 |

||||||

|

5.2.1 WHOLE UNIT......................................................................................................................................................... |

|

|

|

|

53 |

|||

|

5.2.2 POWER SUPPLY UNIT ......................................................................................................................................... |

|

|

|

|

55 |

|||

|

5.2.3 DRIVE ASSY.......................................................................................................................................................... |

|

|

|

|

56 |

|||

|

5.2.4 DIGITAL ASSY ....................................................................................................................................................... |

|

|

|

|

60 |

|||

|

5.2.5 MAIN ASSY............................................................................................................................................................ |

|

|

|

|

61 |

|||

|

5.2.6 VIDEO SYSTEM .................................................................................................................................................... |

|

|

|

|

62 |

|||

|

5.2.7 AUDIO SYSTEM .................................................................................................................................................... |

|

|

|

|

69 |

|||

|

5.3 DIAGNOSIS OF PD (POWER-DOWN) ........................................................................................................................ |

|

|

|

|

72 |

|||

|

5.3.1 BLOCK DIAGRAM OF THE POWER-DOWN SIGNAL.......................................................................................... |

|

72 |

||||||

|

5.3.2 PD (POWER-DOWN) DIAGNOSIS OF FAILURE ANALYSIS ............................................................................... |

|

73 |

||||||

|

5.4 DIAGNOSIS OF SD (SHUTDOWN) ............................................................................................................................. |

|

|

|

|

76 |

|||

|

5.4.1 BLOCK DIAGRAM OF THE SHUTDOWN SIGNAL............................................................................................... |

|

76 |

||||||

|

5.4.2 SD (SHUTDOWN) DIAGNOSIS............................................................................................................................. |

|

|

|

|

77 |

|||

|

5.5 NON-FAILURE INFORMATION.................................................................................................................................... |

|

|

|

|

78 |

|||

|

5.5.1 INFORMATION ON SYMPTOMS THAT DO NOT CONSTITUTE FAILURE ......................................................... |

78 |

|||||||

|

5.5.2 FUNCTION OF DECREASING THE BRIGHTNESS LEVEL ................................................................................. |

|

82 |

||||||

|

5.6 OUTLINE OF THE OPERATION................................................................................................................................ |

|

|

|

|

83 |

|||

|

5.6.1 PANEL DRIVE-POWER ON/OFF FUNCTION....................................................................................................... |

|

83 |

||||||

|

5.6.2 SPECIFICATION OF THE FAN CONTROL ........................................................................................................... |

|

84 |

||||||

|

5.6.3 PROCESSING IN ABNORMALITY........................................................................................................................ |

|

|

|

|

85 |

|||

A

B

C

D

E

F

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

PDP-4280XA |

|

|

||||

|

|

|

|

|

|

|

|

|||

|

5 |

|

6 |

|

|

|

7 |

|

8 |

|

|

|

|

|

|

|

|

||||

1  2

2  3

3  4

4

|

6. SERVICE FACTORY MODE ............................................................................................................................................... |

88 |

|

|

6.1 OUTLINE OF THE SERVICE FACTORY MODE.......................................................................................................... |

88 |

|

A |

6.1.1 SERVICE FACTORY MODE TRANSITION CHART .............................................................................................. |

88 |

|

|

6.1.2 HOW TO ENTER/EXIT SERVICE FACTORY MODE ............................................................................................ |

88 |

|

|

6.1.3 FUNCTIONS WHEN ENTERING THE SERVICE FACTORY MODE..................................................................... |

89 |

|

|

6.1.4 REMOTE CONTROL CODE IN SERVICE FACTORY MODE ............................................................................... |

90 |

|

|

6.1.5 PDP SERVICE REMOTE CONTROL..................................................................................................................... |

91 |

|

|

6.1.6 FACTORY HIERARCHICAL TABLE....................................................................................................................... |

92 |

|

|

6.1.7 INDICATIONS IN SERVICE FACTORY MODE |

94 |

|

|

|||

|

....................................................................................................................................6.2 DETAILS OF FACTORY MENU |

96 |

|

|

6.2.1 INFORMATION....................................................................................................................................................... |

96 |

|

|

6.2.2 PANEL FACTORY (+)........................................................................................................................................... |

104 |

|

|

6.2.3 OPTION ................................................................................................................................................................ |

114 |

|

|

6.2.4 INITIALIZE............................................................................................................................................................ |

115 |

|

B |

7. DISASSEMBLY ................................................................................................................................................................. |

116 |

|

|

7.1 CHART OF REMOVAL ORDER FOR THE MAIN PARTS AND BOARDS ................................................................. |

116 |

|

|

7.2 DISASSEMBLY ........................................................................................................................................................... |

117 |

|

|

8. EACH SETTING AND ADJUSTMENT .............................................................................................................................. |

123 |

|

|

8.1 ADJUSTMENT REQUIRED WHEN THE UNIT IS REPAIRED OR REPLACED ........................................................ |

123 |

|

|

8.2 BACKUP OF THE EEPROM (DIGITAL ASSY)........................................................................................................... |

125 |

|

|

.............................................................................................................................8.3 HOW TO CLEAR HISTORY DATA |

128 |

|

|

|||

|

8.4 ADJUSTMENT WHEN THE SERVICE PANEL ASSY IS REPLACED ....................................................................... |

129 |

|

|

8.5 ADJUSTMENT WHEN THE DRIVE ASSYS ARE REPLACED .................................................................................. |

138 |

|

|

9. RS-232C............................................................................................................................................................................ |

141 |

|

|

9.1 OUTLINE OF RS-232C COMMAND........................................................................................................................... |

141 |

|

C |

9.1.1 PREPARED TOOLS ............................................................................................................................................. |

141 |

|

9.1.2 USING RS-232C COMMANDS |

141 |

||

|

|||

|

9.2 LIST OF RS-232C COMMANDS ................................................................................................................................ |

142 |

|

|

9.3 DETAILS OF EACH COMMANDS .............................................................................................................................. |

149 |

|

|

9.3.1 QS1 (PANEL STATUS)......................................................................................................................................... |

149 |

|

|

9.3.2 QS2 (PANEL OPERATION DATA)........................................................................................................................ |

150 |

|

|

9.3.3 QS3 (OTHER DATA ON THE PANEL) ................................................................................................................. |

151 |

|

|

9.3.4 QAJ (PANEL ADJUSTMENT DATA) |

152 |

|

|

|||

|

9.3.5 QPW (VIDEO ADJUSTMENT DATA OF THE PANEL)......................................................................................... |

153 |

|

|

9.3.6 QPM (PULSE METER VALUE) ............................................................................................................................ |

153 |

|

|

9.3.7 QPD (PD LOGS) .................................................................................................................................................. |

154 |

|

|

9.3.8 QSD (SD LOGS) .................................................................................................................................................. |

155 |

|

D |

9.3.9 QSE (DESTINATION PECULIAR INFORMATION).............................................................................................. |

156 |

|

9.3.10 QMT (TEMPERATURE / FAN ROTATION / ROOM LIGHT SENSOR) |

156 |

||

|

|||

|

9.3.11 QNG (SHUTDOWN INFORMATION OF MTB)................................................................................................... |

157 |

|

|

9.3.12 QSI (INPUT SIGNAL DATA) ............................................................................................................................... |

159 |

|

|

9.3.13 DRV (PANEL DRIVE-POWER ON / OFF).......................................................................................................... |

159 |

|

|

9.3.14 FAY / FAN (ADJ. COMMANDS PERMISSION / PROHIBITION)........................................................................ |

160 |

|

|

9.3.15 FAJ / UAJ / CBU / BCP (BACKUP FUNCTION FOR ADJUSTMENT VALUE) |

160 |

|

|

|||

|

...........................................................................................................................10. EXPLODED VIEWS AND PARTS LIST |

162 |

|

|

10.1 PACKING SECTION ................................................................................................................................................. |

162 |

|

|

10.2 REAR SECTION ....................................................................................................................................................... |

164 |

|

|

10.3 FRONT SECTION..................................................................................................................................................... |

166 |

|

|

10.4 CHASSIS SECTION (1/2)......................................................................................................................................... |

168 |

|

E |

10.5 CHASSIS SECTION (2/2)......................................................................................................................................... |

170 |

|

|

10.6 PANEL CHASSIS SECTION..................................................................................................................................... |

172 |

|

|

10.7 MULTI BASE SECTION ............................................................................................................................................ |

172 |

|

|

10.8 PDP SERVICE ASSY 428 ........................................................................................................................................ |

176 |

|

|

10.9 TABLE TOP STAND (PDP-4280XA and PDP-4280XD ONLY)................................................................................. |

178 |

|

|

|

|

|

|

|

|

F

6 |

|

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XA |

|

|

|

|

||||

|

1 |

|

2 |

|

|

|

3 |

|

4 |

|

|

|

|

|

|

|

|

||||

|

5 |

|

6 |

|

7 |

|

8 |

|

|

|

|

|

|

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

•For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs accompanied by reworking of soldering.

•Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 °C. Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 °C in general, although the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of the soldering iron.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting temperatures (hard to melt/easy to harden).

B

The following lead-free solders are available as service parts:

•Parts numbers of lead-free solder: GYP1006 1.0 in dia.

GYP1007 0.6 in dia. GYP1008 0.3 in dia.

C

D

E

F

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

PDP-4280XA |

|

|

||||

|

|

|

|

|

|

|

|

|||

|

5 |

|

6 |

|

|

|

7 |

|

8 |

|

|

|

|

|

|

|

|

||||

|

|

1 |

|

2 |

|

3 |

|

4 |

|

||||

|

|

|

|

|

|||||||||

|

|

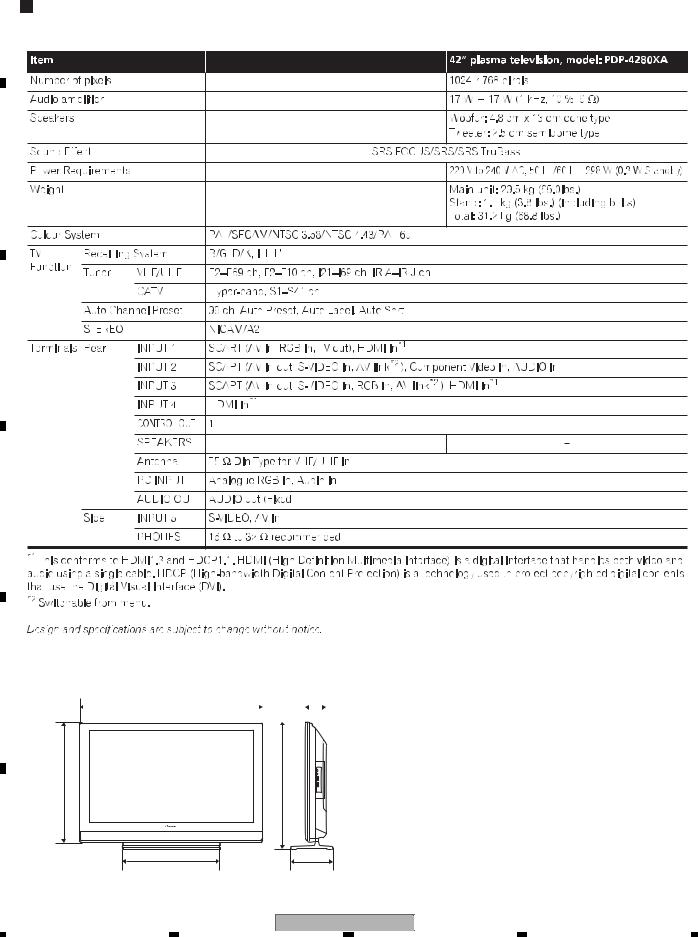

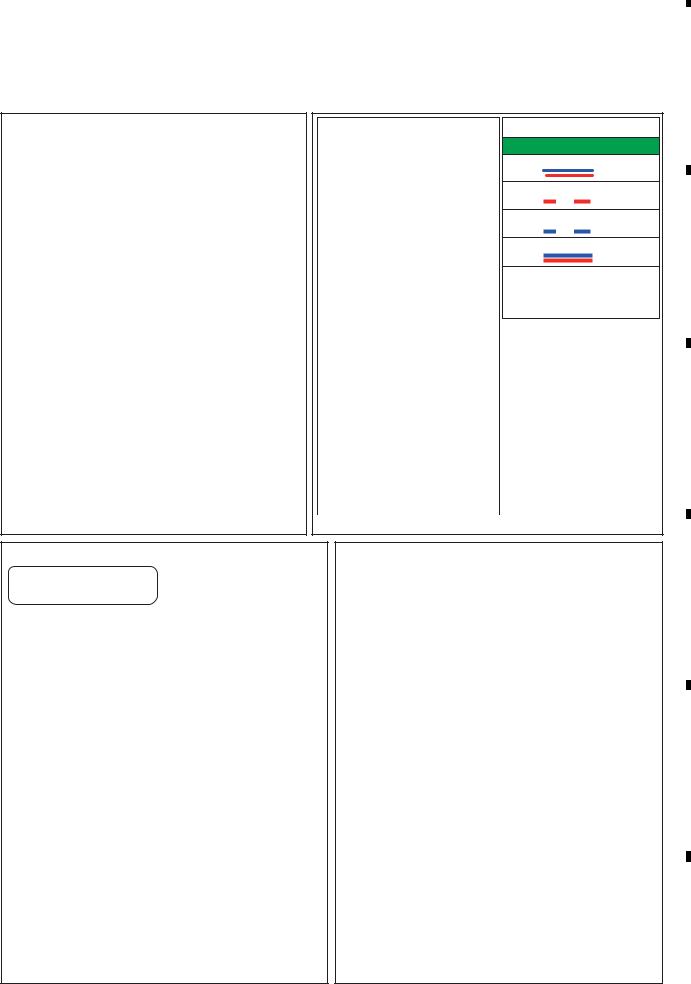

1.2 CHARGED SECTION AND HIGH VOLTAGE GENERATING POINT |

|

||||||||||

A |

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

Charged Section |

|

|

|

|

|

High Voltage Generating Point |

|

||

The places where the commercial AC power is used without passing through the power supply transformer.

If the places are touched, there is a risk of electric shock. In addition, the measuring equipment can be damaged if it is connected to the GND of the charged section and the GND of the non-charged section while connecting the set directly to the commercial AC power supply. Therefore, be sure to connect the set via an insulated transformer and supply the current.

B1. Power cord

2.AC inlet

3.Power switch

4.Fuse (In the POWER SUPPLY Unit)

5.STB transformer and Converter transformer (In the POWER SUPPLY Unit)

6. Other primary side of the POWER SUPPLY Unit

C |

|

: Part is Charged Section. |

: Part is the High Voltage Generating Points other than the Charged Section.

: Part is the High Voltage Generating Points other than the Charged Section.

The places where voltage is 100 V or more except for the charged places described above. If the places are touched, there is a risk of electric shock.

The VSUS voltage remains for several minutes after the power to the unit is turned off. These places must not be touched until about 10 minutes after the power is turned off, or it is confirmed with a tester that there is no residual VSUS voltage.

If the procedures described in “5.6.1 PANEL DRIVE-POWER ON/OFF FUNCTION ” are performed before the power is turned off, the voltage will be discharged in about 30 seconds.

POWER SUPPLY Unit |

........................................................(200 V) |

42 X DRIVE Assy................................................................ |

(200 V) |

42 Y DRIVE Assy................................................ |

( - 230 V to 500 V) |

42 SCAN A Assy................................................. |

( - 230 V to 500 V) |

42 SCAN B Assy................................................. |

( - 230 V to 500 V) |

|

42 SCAN B Assy |

42 Y DRIVE Assy |

POWER SUPPLY Unit |

42 X DRIVE Assy |

Conductive plate X |

|

|

|

|

|

|

|

|

|

|

|

|

D

E

|

|

|

|

|

|

|

|

|

|

|

|

|

42 SCAN A Assy |

AC inlet |

|

||

|

|

||||

|

|

||||

F

Power switch

Fig. High Voltage Generating Point (Rear view)

8 |

|

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XA |

|

|

|

|

||||

|

1 |

|

2 |

|

|

|

3 |

|

4 |

|

|

|

|

|

|

|

|

||||

|

5 |

|

6 |

|

7 |

|

8 |

|

|

|

|

|

|

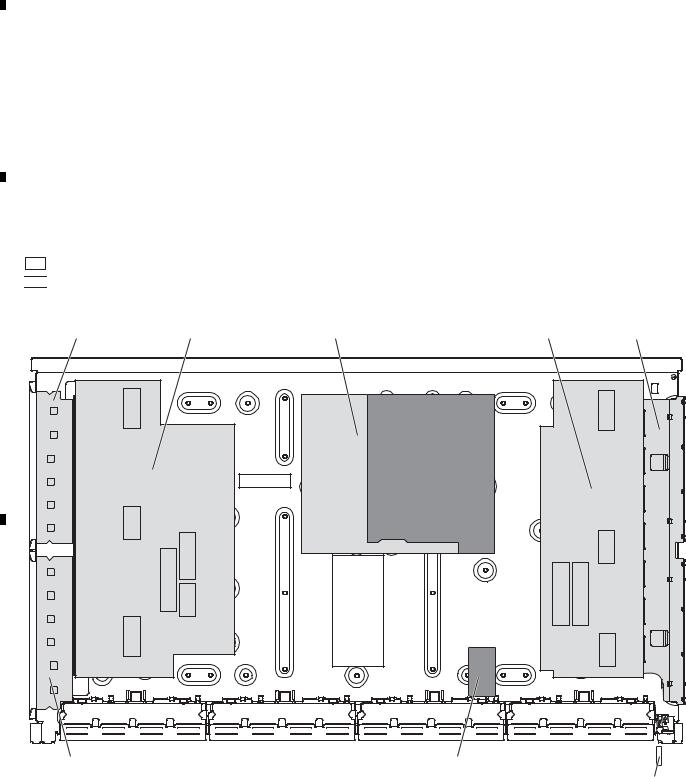

2. SPECIFICATIONS

2.1 ACCESSORIES

A

Remote control unit (PDP-4280XA) |

Remote control unit (PDP-4280XD) |

Remote control unit (PDP-428XD) |

|

(AXD1553) |

(AXD1552) |

(AXD1551) |

|

|

|

|

|

|

|

|

|

B

Dry cell battery (R06, AA)

Band assy (AXY1192)

Band assy (AXY1192)

Screw: ×2 |

Plastic band: ×2 |

Binder Assy

Binder Assy

(AEC1908)

Speed clamp: ×3 |

Bead band: ×3 |

C

PDP-4280XA, XD only

Ferrite core (L5321) (ATX1039)

Ferrite core (L5321) (ATX1039)

Ferrite core |

Cable tie |

Power cord |

|

|

|||

(ADG1214) |

|

||

|

(for ferrite core) |

|

|

|

|

|

D

Cleaning cloth (AED1285) |

Power cord |

|

|

(ADG1223) |

|

|

|

|

|

|

|

WYVIXK5 type only

Warranty card |

E |

|

|

Operating instructions (PDP-4280XD) |

Operating instructions (PDP-428XD) |

|

|

|

||

Operating instructions (PDP-4280XA) |

(ARE1485: WYV5) |

(ARE1484: WYV5) |

|

(ARC1602: WYV5) |

(ARC1601: WYV5) |

|

|

(ARE1478: WYV5) |

|

||

(ARE1476: WYVIXK5) |

(ARE1475: WYVIXK5) |

|

|

(ARE1477: WYVIXK5) |

|

||

(ARC1587: WYVIXK5) |

(ARC1586: WYVIXK5) |

|

|

|

|

F

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

PDP-4280XA |

|

|

||||

|

|

|

|

|

|

|

|

|||

|

5 |

|

6 |

|

|

|

7 |

|

8 |

|

|

|

|

|

|

|

|

||||

|

1 |

|

2 |

|

3 |

|

4 |

|

|

|

|

|

|

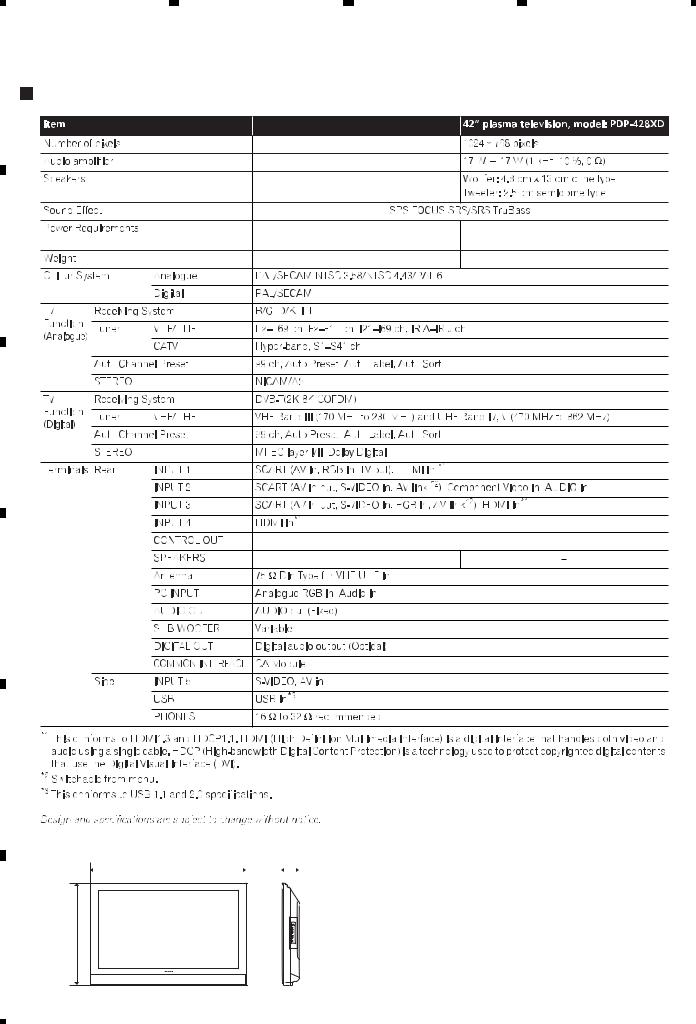

2.2 SPECIFICATIONS

A |

PDP-4280XA |

B |

C |

D |

" Dimensions

E

1040 |

|

|

|

115 |

|

||

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

679 |

719 |

F |

550 |

237 |

|

|

|

Unit: mm |

|

10 |

|

PDP-4280XA |

|

1 |

2 |

3 |

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

|

|

|

PDP-4280XD

PDP-4280XD

220 V to 240 V AC, 50 Hz/60 Hz, 299 W (0.4 W Standby)

Main unit: 29.6 kg (65.3 lbs.)

Stand: 1.7 kg (3.8 lbs.) (including bolts)

Total: 31.3 kg (69.0 lbs.)

A

B

C

D

E

" Dimensions

1040 |

|

|

|

115 |

|

|

||

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

679 |

719 |

F

550 |

|

|

|

237 |

|

Unit: mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

|

|

|

|

|

|

PDP-4280XA |

|

|

||||

|

|

|

|

|

|

|

|

|||

|

5 |

|

6 |

|

|

|

7 |

|

8 |

|

|

|

|

|

|

|

|

||||

1 |

2 |

3 |

4 |

A |

|

|

|

PDP-428XD |

|

|

|

|

|

|

220 V to 240 V AC, 50 Hz/60 Hz, 299 W (0.4 W |

|

|

|

Standby) |

B |

|

|

29.6 kg (65.3 lbs.) |

|

|

|

|

C |

|

|

|

D |

|

|

|

E |

|

|

|

F

" Dimensions

1040 |

|

|

115 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

679

Unit: mm

12 |

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XA |

|

|

|

|

|||

1 |

|

2 |

|

|

|

3 |

|

4 |

|

|

|

|

|

|

|

||||

|

5 |

|

6 |

|

7 |

|

8 |

|

|

|

|

|

|

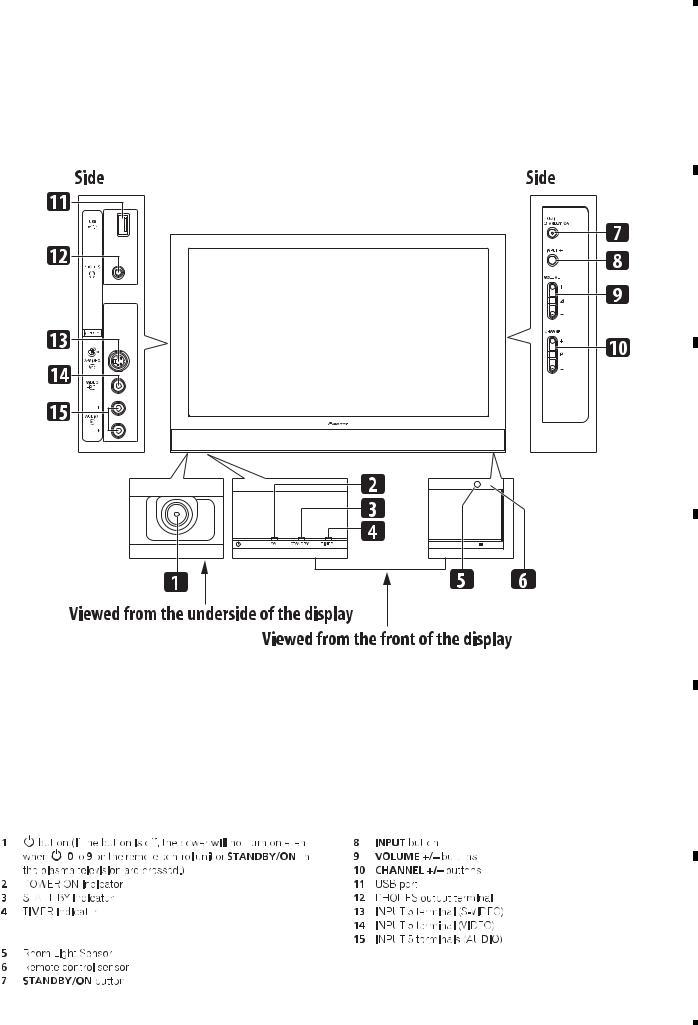

2.3 PANEL FACILITIES

A

PDP-4280XA

PDP-4280XA

Front Section

Front Section

B

C

D

E

F

|

|

|

|

|

|

|

|

13 |

|

|

|

|

|

|

PDP-4280XA |

|

|

||||

|

|

|

|

|

|

|

|

|||

|

5 |

|

6 |

|

|

|

7 |

|

8 |

|

|

|

|

|

|

|

|

||||

|

1 |

|

2 |

|

3 |

|

4 |

|

|

|

|

|

|

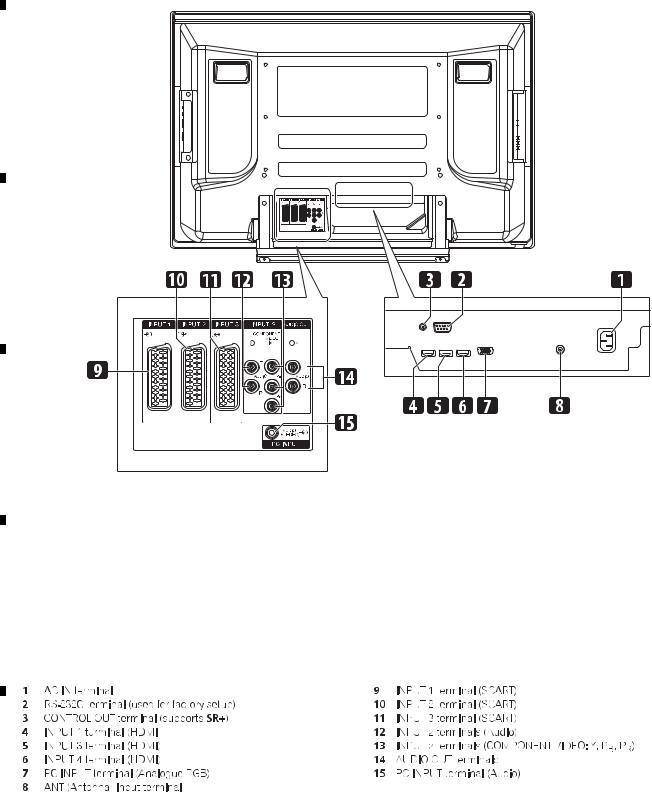

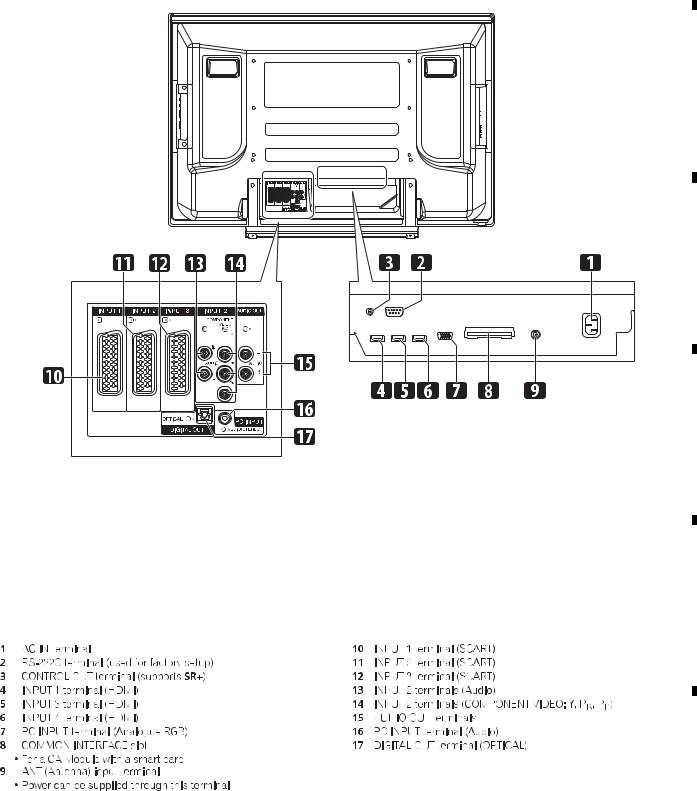

A

PDP-4280XA

PDP-4280XA

Rear Section

Rear Section

B

C

D

E

F

14 |

|

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XA |

|

|

|

|

||||

|

1 |

|

2 |

|

|

|

3 |

|

4 |

|

|

|

|

|

|

|

|

||||

|

5 |

|

6 |

|

7 |

|

8 |

|

|

|

|

|

|

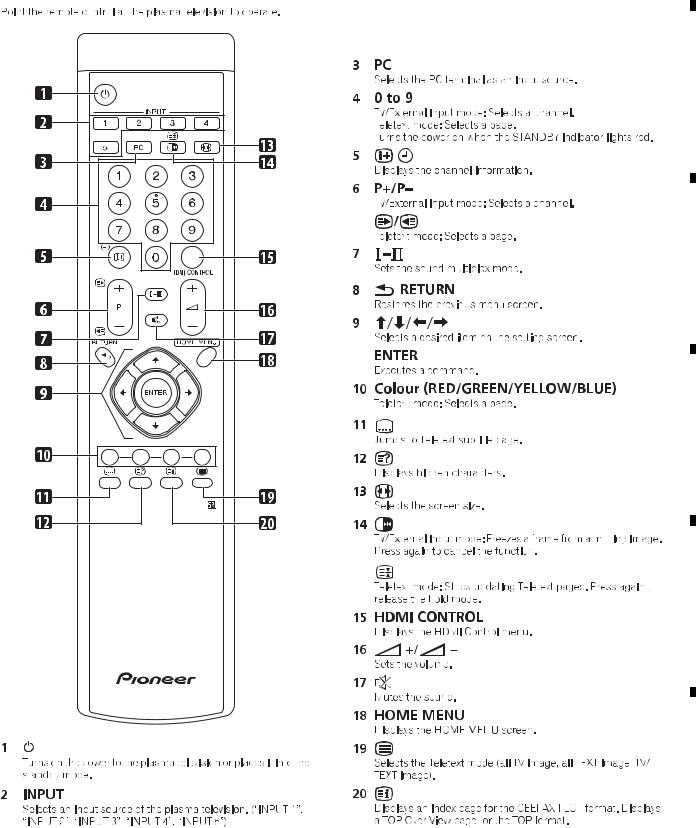

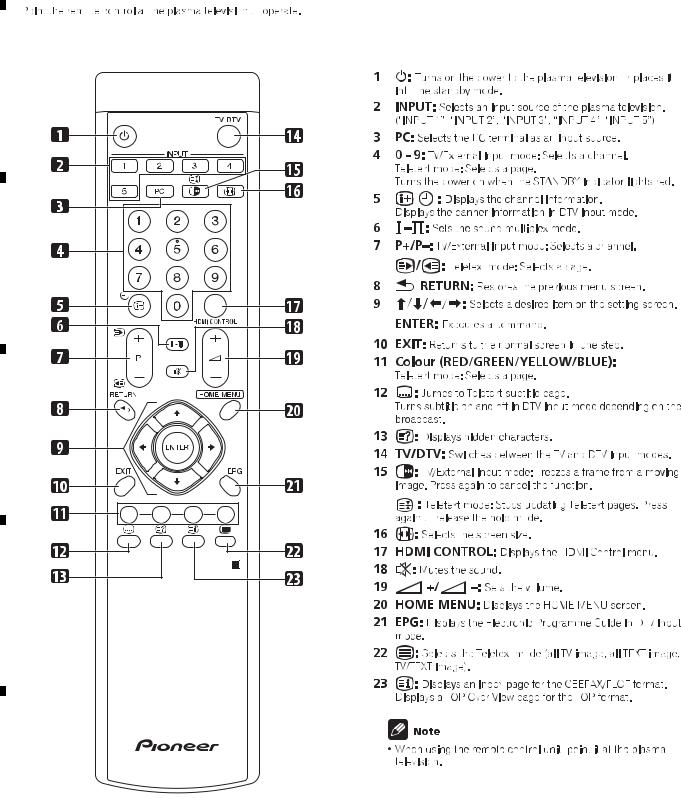

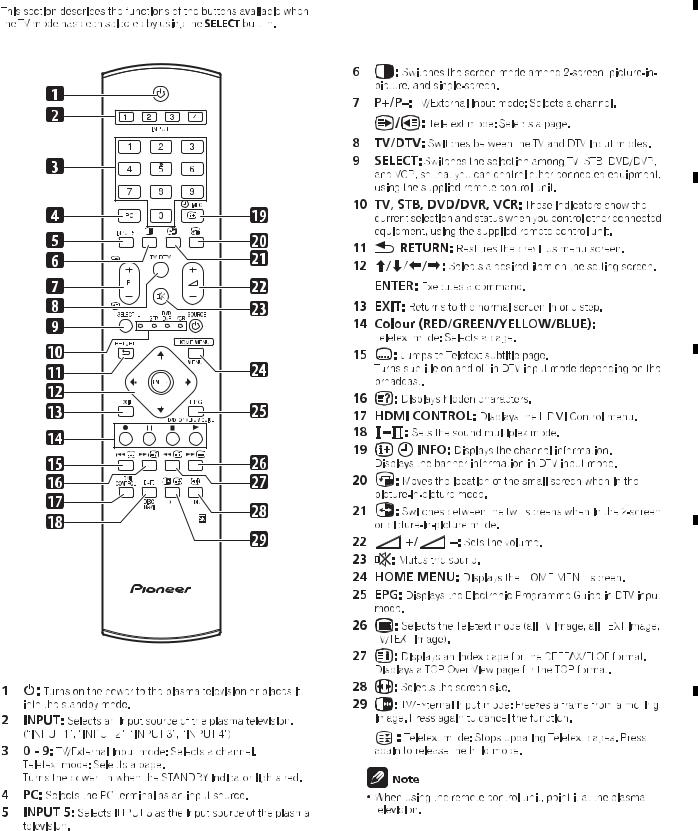

A

PDP-4280XA

PDP-4280XA

Remote Control Unit

Remote Control Unit

B

C

D

E

F

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

PDP-4280XA |

|

|

||||

|

|

|

|

|

|

|

|

|||

|

5 |

|

6 |

|

|

|

7 |

|

8 |

|

|

|

|

|

|

|

|

||||

|

1 |

|

2 |

|

3 |

|

4 |

|

|

|

|

|

|

A

PDP-4280XD

PDP-4280XD

Front Section

Front Section

B

C

D

E

|

TIMER indicator |

|

|

F |

• The TIMER indicator lights up when one or more DTV |

|

programmes are preset for watching or recording. |

16 |

|

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XA |

|

|

|

|

||||

|

1 |

|

2 |

|

|

|

3 |

|

4 |

|

|

|

|

|

|

|

|

||||

|

5 |

|

6 |

|

7 |

|

8 |

|

|

|

|

|

|

A

PDP-4280XD

PDP-4280XD

Rear Section

Rear Section

B

C

D

E

F

|

|

|

|

|

|

|

|

17 |

|

|

|

|

|

|

PDP-4280XA |

|

|

||||

|

|

|

|

|

|

|

|

|||

|

5 |

|

6 |

|

|

|

7 |

|

8 |

|

|

|

|

|

|

|

|

||||

|

1 |

|

2 |

|

3 |

|

4 |

|

|

|

|

|

|

A

PDP-4280XD

PDP-4280XD

Remote Control Unit

Remote Control Unit

B

C

D

E

F

18 |

|

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XA |

|

|

|

|

||||

|

1 |

|

2 |

|

|

|

3 |

|

4 |

|

|

|

|

|

|

|

|

||||

|

5 |

|

6 |

|

7 |

|

8 |

|

|

|

|

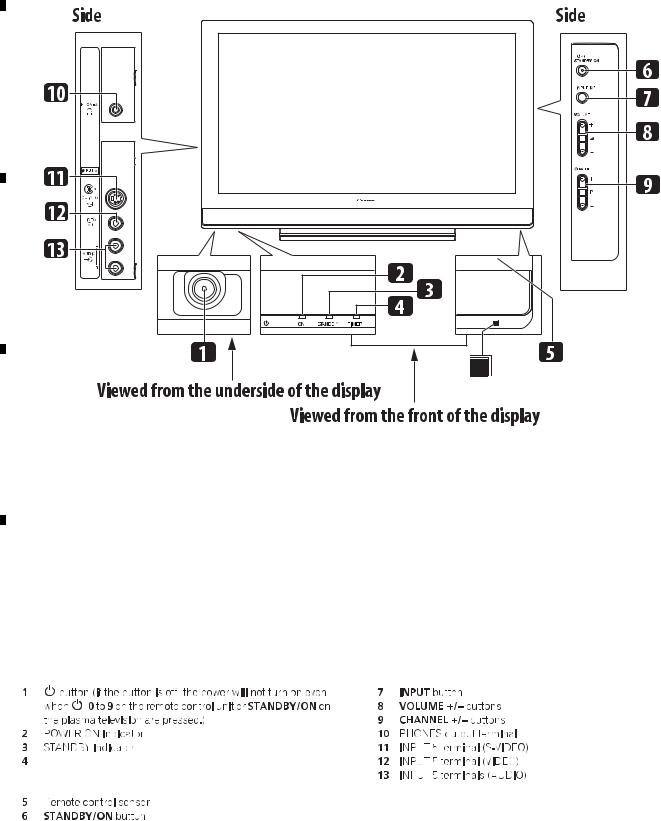

PDP-428XD

PDP-428XD

Front Section

Front Section

• The TIMER indicator lights up when one or more DTV programmes are preset for watching or recording.

|

|

|

|

|

|

|

|

19 |

|

|

|

|

|

PDP-4280XA |

|

||||

|

|

|

|

|

|

|

|||

|

5 |

|

6 |

|

|

|

7 |

|

8 |

|

|

|

|

|

|

||||

A

B

C

D

E

F

|

1 |

|

2 |

|

3 |

|

4 |

|

|

|

|

|

|

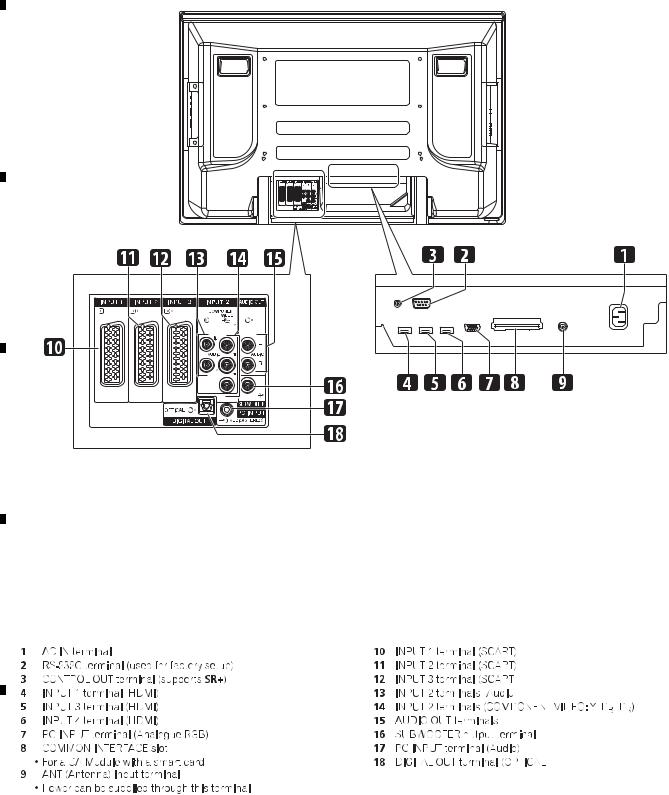

A

PDP-428XD

PDP-428XD

Rear Section

Rear Section

B

C

D

E

F

20 |

|

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XA |

|

|

|

|

||||

|

1 |

|

2 |

|

|

|

3 |

|

4 |

|

|

|

|

|

|

|

|

||||

|

5 |

|

6 |

|

7 |

|

8 |

|

|

|

|

|

|

A

PDP-428XD

PDP-428XD

Remote Control Unit

Remote Control Unit

B

C

D

E

F

|

|

|

|

|

|

|

|

21 |

|

|

|

|

|

|

PDP-4280XA |

|

|

||||

|

|

|

|

|

|

|

|

|||

|

5 |

|

6 |

|

|

|

7 |

|

8 |

|

|

|

|

|

|

|

|

||||

|

1 |

|

2 |

|

3 |

|

4 |

|

|

|

|

|

|

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

Items to be checked after repair (PDP)

To ensure the quality of the product after repair, check the recommended items shown below:

|

|

No. |

Procedures |

Item to be checked |

|

|

1 |

Check if all the symptoms pointed out by the customer have been |

The symptoms in question must not be reproduced. |

|

||||

|

|

|

addressed. |

|

|

|

|

|

|

|

|

2 |

Connect the peripheral equipment. |

Connect all external peripheral equipment as originally connected |

|

|

and check if the connections are correct. |

||

|

|

|

|

|

|

|

|

|

|

|

|

3 |

Check the video and audio. |

Tune in to the stations that the customer would normally receive |

|

|

and check if video and audio are normal. |

||

|

|

|

|

|

B |

|

4 |

Check the buttons and controls. |

Use the buttons and controls on the remote control unit and main |

|

|

unit and check if they operate properly. |

||

|

|

|

|

|

|

|

|

|

|

|

|

5 |

Check the cabinet. |

Check for any scratches or dirt that have been made or attached |

|

|

on the cabinet after receiving the product for repair. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

See the table below for the items to be checked regarding video and audio:

|

|

Item to be checked regarding video |

Item to be checked regarding audio |

|

|

Block noise |

Distortion |

|

|

|

|

|

|

Horizontal noise |

Noise |

C |

|

|

|

|

Dot noise |

Volume too low |

|

|

|

||

|

|

|

|

|

|

Disturbed image (video jumpiness) |

Volume too high |

|

|

|

|

|

|

Too dark |

Volume fluctuating |

|

|

|

|

|

|

Too bright |

Sound interrupted |

|

|

|

|

|

|

Mottled color |

|

|

|

||

|

|

|

|

D

E

F

22 |

|

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XA |

|

|

|

|

||||

|

1 |

|

2 |

|

|

|

3 |

|

4 |

|

|

|

|

|

|

|

|

||||

|

5 |

|

6 |

|

7 |

|

8 |

|

|

|

|

3.2 QUICK REFERENCE

Quick Reference upon Service Visit 1

Notes, PD/SD diagnosis, and methods for various settings

Notes when visiting for service

1.Notes when disassembling/reassembling

1Rear case

When reassembling the rear case, the screws must be tightened in a specific order. Be careful not to tighten them in the wrong order forcibly. For details, see "Rear Case" in "7. DISASSEMBLY".

2Attaching screws for the HDMI connector

When attaching the HDMI connector after replacing the Main Assy, secure the HDMI connector manually with a screwdriver, but not with an electric screwdriver. If you tighten the screws too tightly with an electric screwdriver, the screw heads may be damaged, in which case the screws cannot be untightened/tightened any more.

2.On parts replacement

1How to discharge before replacing the Assys

A charge of significant voltage remains in the Plasma Panel even after the power is turned off. Safely discharge the panel before replacement of parts, in either manner indicated below:

A:Let the panel sit at least for 3 minutes after the power is turned off.

B:Turn the Large Signal System off before the power is turned off then, after 1 minute, turn the power off.

For details, see "5.6.1 PANEL DRIVE-POWER ON/OFF FUNCTION".

2 On the settings after replacement of the Assys

Some boards need settings made after replacement of the Assys. For details, see "8. EACH SETTING AND ADJUSTMENT".

3.On various settings

1Setting in Factory mode

After a Mask indication into the panel is performed, be sure to set the Mask setting to "OFF" then exit Factory mode.

PD/SD

|

|

No. of LEDs |

|

|

Item |

flashing |

|

|

|

Red |

Blue |

section |

SQ_LSI |

|

Blue 1 |

Communication with the module IIC |

|

Blue 2 |

|

Panel |

DIGITAL-RST2 |

|

Blue 3 |

Panel high temperature |

|

Blue 4 |

|

|

Audio/ Short-circuit SP terminal |

|

Blue 5 |

|

Communication with the Module UCOM |

|

Blue 6 |

section |

Main 3-wire serial communication |

|

Blue 7 |

Main IIC communication |

|

Blue 8 |

|

Communication with the Main UCOM |

|

Blue 9 |

|

MTB |

|

||

FAN |

|

Blue 10 |

|

|

Unit high temperature |

|

Blue 11 |

|

Digital Tuner communication |

|

Blue 12 |

|

MTB-RST2/RST4 |

|

Blue 13 |

|

Main EEPROM |

|

Blue 15 |

POWER |

Red 2 |

|

|

SCAN |

Red 3 |

|

|

SCN-5V |

Red 4 |

|

|

Y-DRIVE |

Red 5 |

|

|

Y-DCDC |

Red 6 |

|

|

Y-SUS |

Red 7 |

|

|

ADRS |

Red 8 |

|

|

X-DRIVE |

Red 9 |

|

|

X-DCDC |

Red 10 |

|

|

X-SUS |

Red 11 |

|

|

DIG-DCDC |

Red 12 |

|

|

UNKNOWN |

Red 15 |

|

|

LED Display Information

Rewriting software

PD (2-15)

SD (1-15)

No backup

This indication does not display all LED patterns.

For details, please refer to 5.1.1 LED DISPLAY INFORMATION.

A

B

C

How to locate several items on the Factory menu

{} : Item on the Factory menu

[ ] : Key on the remote control unit

"" : Screen indication

1.Confirmation of accumulated power-on time and power-on count

Select {INFORMATION} then {HOUR METER}. (After entering Factory mode, press [ ] five times.)

2.Confirmation of the Power-down and Shutdown histories

1 Panel system

PD: Select {PANEL FACTORY} then {POWER DOWN}.

(After entering Factory mode, press [MUTING] once, press [ENTER/SET], then press [ ] three times.)

SD: Select {PANEL FACTORY} then {SHUT DOWN}.

(After entering Factory mode, press [MUTING] once, press [ENTER/SET], then press [ ] four times.)

2 MTB section

Select {INFORMATION} then {MAIN NG}.

(After entering Factory mode, press [ ] three times.)

3.How to display the Mask indication

1 Mask indication in the panel side

1. Select {PANEL FACTORY} then {RASTER MASK SETUP}.

(After entering Factory mode, press [MUTING] once, press [ENTER/SET], then press [ ] 8 times.)

2. Press [ENTER/SET], then select a Mask indication, using [ ] or [ ].

Adjustments and Settings after replacement of the Assys (Procedures in Factory mode)

1.Digital Video Assy: Transfer of backup data

Select {PANEL FACTORY}, {ETC}, then {BACKUP DATA}. (After entering Factory mode, press [MUTING] once, press [ENTER/SET], press [ ] seven times, then press [ENTER/SET].)

Select {TRANSFER}, using [ ], then hold [ENTER/SET] pressed for at least 5 seconds.

After transfer of backup data is completed, {ETC} is automatically selected, and the LED on the front panel returns to normal lighting.

2.MAIN Assy: Execution of FINAL SETUP.

Select {INITIALIZE} then {FINAL SETUP}, then press [ENTER/SET]. (After entering Factory mode, press [MUTING] three times, then press [ ] four times.)

Select "YES", using [ ]. Then hold [ENTER/SET] pressed for at least 5 seconds.

After "FINAL SETUP IS COMPLETE" is displayed on the screen, turn the POWER switch of the main unit off.

3.POWER SUPPLY Unit: Clearance of the accumulated power-on count and maximum temperature value

Select {PANEL FACTORY}, {ETC}, then {P COUNT INFO}. (After entering Factory mode, press [MUTING] once, press [ENTER/SET], press [ ] seven times, press [ENTER/SET], then press [ ] six times.)

Press [ ] to select "CLEAR". Hold [ENTER/SET] pressed for at least 5 seconds. After clearance is completed, "ETC" is automatically selected. Clear the maximum temperature value (MAX TEMP) in the same manner.

4.Other Assys: Clearance of the maximum temperature value

Select {PANEL FACTORY}, {ETC}, then {MAX TEMP}. (After entering Factory mode, press [MUTING] once, press [ENTER/SET], press [ ] seven times, press [ENTER/SET], then press [ ] seven times.)

Press [ ] to select "CLEAR". Hold [ENTER/SET] pressed for at least 5 seconds. After clearance is completed, "ETC" is automatically selected.

D

E

F

|

|

|

|

|

|

|

|

23 |

|

|

|

|

|

|

PDP-4280XA |

|

|

||||

|

|

|

|

|

|

|

|

|||

|

5 |

|

6 |

|

|

|

7 |

|

8 |

|

|

|

|

|

|

|

|

||||

|

1 |

|

2 |

|

3 |

|

4 |

|

|

|

|

|

|

A

Quick Reference upon Service Visit 2

Mode transition and structure of layers in Service Factory mode

Mode transition in Service Factory mode

Up

• To shift to another mode, press [MUTING].

• To shift to another item in a specific mode, press [i] or [j].

• To shift to the next nested layer below for an item with a "(+)" indication, press [ENTER/SET].

To return to the next nested layer above, also press [ENTER/SET].

|

|

Down |

B |

INFORMATION mode |

INITIALIZE mode |

|

1. VERSION (1) |

1. SIDE MASK LEVEL |

|

2. VERSION (2) |

2. FINAL SETUP |

|

3. MAIN NG |

3. Wide XGA AUTO |

4.TEMPERATURE

5.HOUR METER

6.HDMI SIGNAL INFO1

7.HDMI SIGNAL INFO2

8.VDEC SIGNAL INFO1

9. VDEC SIGNAL INFO2

|

PANEL FACTORY mode |

|

OPTION mode |

|

1. PANEL INFORMATION |

|

1. EDID WRITE MODE |

C |

2. PANEL WORKS |

|

2. CH PRESET |

3. POWER DOWN |

|

3. SYNC DET |

|

|

|

4.SHUT DOWN

5.PANEL-1 ADJ

6.PANEL-2 ADJ

7.PANEL FUNCTION

8.ETC.

9.RASTER MASK SETUP

10.PATTEN MASK SETUP

11. COMBI MASK SETUP

Structure of Layers in Service Factory Mode

INFORMATION mode |

|

1. VERSION (1) |

The software versions for each microcomputer |

2. VERSION (2) |

The Flash memory versions for each device |

3. MAIN NG |

The shutdown message ID/event times |

|

(Going Clear mode by [ENTER/SET] key) |

3-1. CLEAR |

Select Yes by [l] key, l pressing and hold [ENTER/SET] key |

4. TEMPERATURE |

The temperature/FAN rotating status/Room light sensor |

5. HOUR METER |

The HOUR METER/P-COUNT information |

6.HDMI SIGNAL INFO 1 The information of HDMI information files

7.HDMI SIGNAL INFO 2 The information of HDMI information files

8.VDEC SIGNAL INFO 1 The signal information of VDEC

9.VDEC SIGNAL INFO 2 The signal information of VDEC

PANEL FACTORY mode |

Refer to [PANEL FACTORY MODE] |

OPTION mode |

|

1. EDID WRITE MODE |

For factory use |

2. CH PRESET |

For production line use |

3. SYNC DET |

For technical analysis |

INITIALIZE mode |

|

1. SIDE MASK LEVEL |

For factory use |

1-1. SIDE MASK LEVEL |

|

2. FINAL SETUP |

Set to Factory default settings (it should perform after |

2-1. DATA RESET |

replacing a MAIN Assy) |

3. Wide XGA AUTO |

For technical analysis |

|

|

Structure of Layers in Panel Factory Mode 1 |

|

|

|

1. PANEL INFORMATION |

Version indication of the panel |

D |

|

2. PANEL WORKS |

Indications of the accumulated power-on time, pulse-meter |

|

|

count, and power-on count of the panel |

|

|

|

|

|

|

|

3. POWER DOWN |

Indication of the Power-down history |

|

|

4. SHUT DOWN |

Indication of the Shutdown history |

|

|

5. PANEL-1 ADJ (+) |

|

|

|

1. VOL SUS |

|

|

|

2. VOL OFFSET |

Settings required after replacement of the panel |

|

|

• • • • • |

|

|

|

|

|

|

|

8. VOL YNOFS4 |

|

|

|

||

|

|

9. RESET1ST_KSB |

Modification not required because these items |

|

|||

|

|

10. RESET2ND_KSB |

|

|

|

• • • • • |

are basically for factory presetting |

|

|

23. YSTL_FMR_HZ |

|

|

|

24. SUS FREQ |

For AM noise prevention (Depending on the mode, |

|

|

|

brightness of the screen changes.) |

|

|

|

For confirmation of the result of the setting change, |

E |

|

|

the unit must be turned off then back on again. |

|

6. PANEL-2 ADJ (+) |

|

|

|

|

|

|

|

|

1. R-HIGH |

|

|

|

2. G-HIGH |

|

|

|

3 .B-HIGH |

Parameters for the WB adjustment of the panel, which are |

|

|

4. R-LOW |

required during adjustment after panel replacement |

|

|

5. G-LOW |

|

|

|

6. B-LOW |

|

|

|

7. ABL |

Setting of the power consumption. A setting table is |

|

|||

|

|

|

available for each vertical signal. |

|

|

|

|

|

|

To "Structure of Layers in Panel Factory Mode 2" |

|

F |

|

|

|

Structure of Layers in Panel Factory Mode 2

7. PANEL FUNCTION (+) |

|

1. R-LEVEL |

|

2. G-LEVEL |

|

3. B-LEVEL |

|

4. ADDRESS L1 |

Items for use by engineers |

5. ADDRESS L2 |

|

• • • • • |

|

11. ADDRESS U4 |

|

12. STK MODE |

|

8. ETC (+) |

|

1. BACKUP DATA |

For transferring backup data (after replacement of |

|

the DIGITAL Assy) |

2. DIGITAL EEPROM |

To clear data of the digital video |

3. PD INFO. |

|

4. SD INFO. |

For clearance of data for the corresponding items. |

5. HR-MTR INFO. |

The clearing method is the same: Select "CLEAR", |

6. PM/B1-B5 |

using [l], then hold [ENTER/SET] pressed for at |

7. P COUNT INFO. |

least 5 seconds. After clearance is completed, {ETC} |

8. MAX TEMP. |

is automatically selected. |

9. RASTER MASK SETUP (+) |

|

1. MASK OFF |

|

2. RST MASK 01 |

For use while Raster Mask (full mask) is displayed. |

• • • • • |

Use [i] or [j] to select the type of mask. |

26.RST MASK 25

10.PATTEN MASK SETUP (+)

1.MASK OFF

2. PTN MASK 01 |

For use while Pattern Mask is displayed. Use [i] or |

• • • • • |

[j] to select the type of mask. |

50.PTN MASK 49

11.COMBI MASK SETUP (+)

1.MASK OFF

2. CMB MASK 01 |

For use while Combination Mask is displayed. |

• • • • • |

Use [i] or [j] to select the type of mask. |

18. CMB MASK 17 |

|

24 |

|

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XA |

|

|

|

|

||||

|

1 |

|

2 |

|

|

|

3 |

|

4 |

|

|

|

|

|

|

|

|

||||

|

5 |

|

6 |

|

7 |

|

8 |

|

|

|

|

|

|

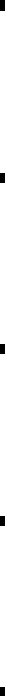

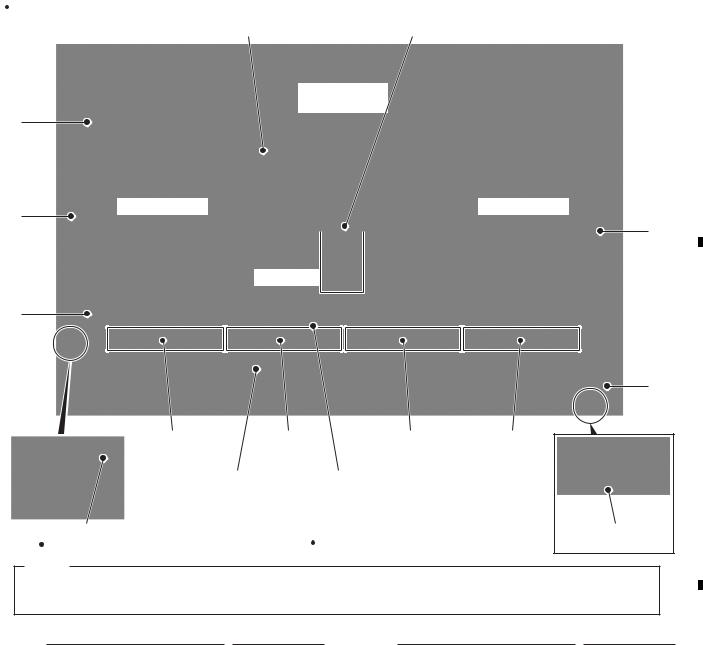

3.3 PCB LOCATION

A

This photo. is PDP-4280XD model.

SENSOR Assy |

42 DIGITAL Assy |

|

|

|

|

|

|

|

Assy |

POWER SUPPLY |

|

|

||

42 SCAN B |

Unit |

|

|

||

Assy |

42 Y DRIVE Assy |

|

SIDE KEY |

||

|

||

42 SCAN A Assy |

MAIN Assy |

|

|

|

42 ADDRESS |

42 ADDRESS |

42 ADDRESS |

|

|

Assy |

Assy |

|

Assy |

|

|

TANSHI Assy |

232C Assy |

|

42IR (42RLS&IR) Assy |

|

|

Rear view |

|

Front view |

|

|

|

|

B

42 X DRIVE Assy Assy

IOSIDE

C

POWER SW |

Assy |

|

XGA |

|

|

|

|

|

|

|

42 ADDRESS

Assy

D

42/60LED Assy

Front view

Front view

Note:

The wiring shown in the photo is different from the actual wiring, because the product in the photo is a prototype. Upon servicing, be sure to restore the original wiring of the unit after repair work.

Mark No. Description Part No. Mark No. Description Part No.

LIST OF ASSEMBLIES

NSP |

42 ADDRESS ASSY |

AWV2451 |

TANSHI ASSY (PDP-4280XA) |

AWW1251 |

E |

||

NSP |

42 SCAN A ASSY |

AWW1266 |

TANSHI ASSY (PDP-4280XD) |

AWW1249 |

|

||

|

|

|

IC2801 - IC2806 |

SN755875PZT-P |

TANSHI ASSY (PDP-428XD) |

AWW1247 |

|

|

|

|

|

||||

NSP |

42 SCAN B ASSY |

AWW1267 |

SIDE IO ASSY |

AWW1253 |

|

||

|

|

|

IC2901 - IC2906 |

SN755875PZT-P |

232C ASSY |

AWW1254 |

|

|

|

|

|

||||

|

42 X DRIVE ASSY |

AWV2452 |

|

|

|

||

|

|

|

|

||||

|

42 Y DRIVE ASSY |

AWW1262 |

42/60LED ASSY |

AWW1276 |

|

||

|

XGA POWER SW ASSY |

AWW1261 |

42IR ASSY (PDP-4280XA, XD) |

AWW1282 |

|

||

|

|

|

|

|

42RLS&IR ASSY (PDP-428XD) |

AWW1277 |

|

|

42 DIGITAL ASSY |

AWW1271 |

SIDE KEY ASSY |

AWW1286 |

|

||

|

SENSOR ASSY |

AWW1272 |

|

|

|

||

|

|

|

|

> |

POWER SUPPLY UNIT |

AXY1157 |

|

> |

MAIN ASSY (PDP-4280XA) |

AWV2463 |

|

|

F |

||

> |

MAIN ASSY (PDP-4280XD) |

AWV2462 |

PDP SERVICE ASSY 428 |

AWU1276 |

|

||

> |

MAIN ASSY (PDP-428XD) |

AWV2461 |

|

|

|

||

|

|

|

|

|

|

|

|

25 |

|

|

|

|

|

|

PDP-4280XA |

|

|

||||

|

|

|

|

|

|

|

|

|||

|

5 |

|

6 |

|

|

|

7 |

|

8 |

|

|

|

|

|

|

|

|

||||

|

1 |

|

2 |

|

3 |

|

4 |

|

|

|

|

|

|

3.4 CLEANING

A

|

|

Name |

Part No. |

Remarks |

|

|

Cleaning liquid |

GEM1004 |

Used to fan cleaning. |

|

|

|

|

|

|

|

Cleaning paper |

GED-008 |

Refer to “10.4 CHASSIS SECTION (1/2)”. |

|

|

|

B

C

D

E

F

26 |

|

|

|

|

|

|

|

|

|

|

|

|

PDP-4280XA |

|

|

|

|

||||

|

1 |

|

2 |

|

|

|

3 |

|

4 |

|

|

|

|

|

|

|

|

||||

|

5 |

|

6 |

|

7 |

|

8 |

|

|

|

|

|

|

A

B

C

D

E

F

|

|

|

|

|

|

|

|

27 |

|

|

|

|

|

|

PDP-4280XA |

|

|

||||

|

|

|

|

|

|

|

|

|||

|

5 |

|

6 |

|

|

|

7 |

|

8 |

|

|

|

|

|

|

|

|

||||

|

1 |

|

2 |

|

3 |

|

4 |

|

|

|

|

|

|

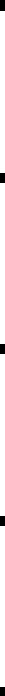

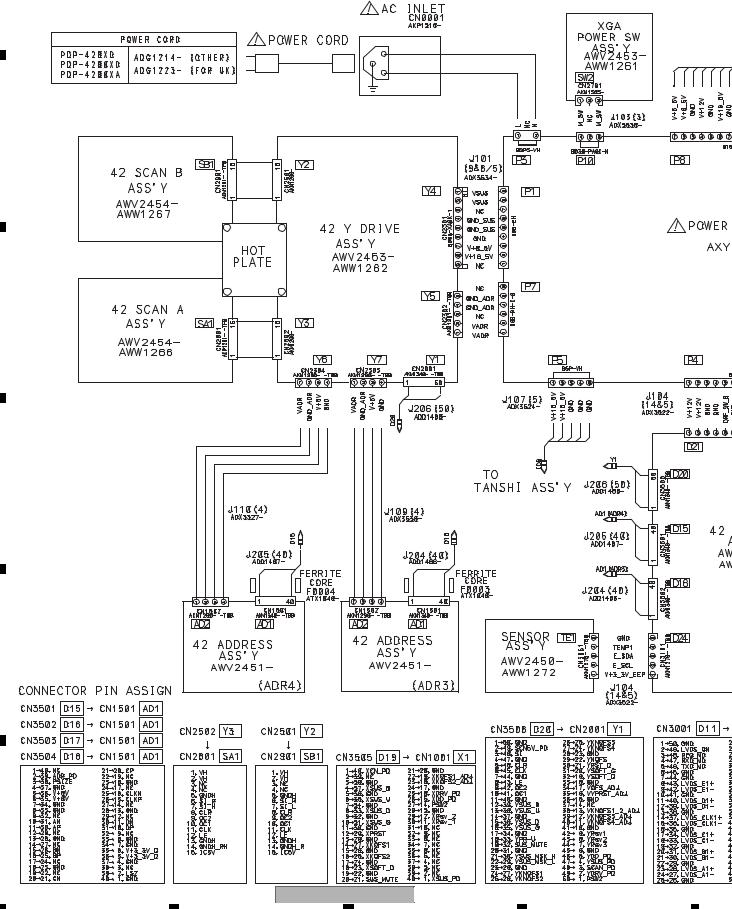

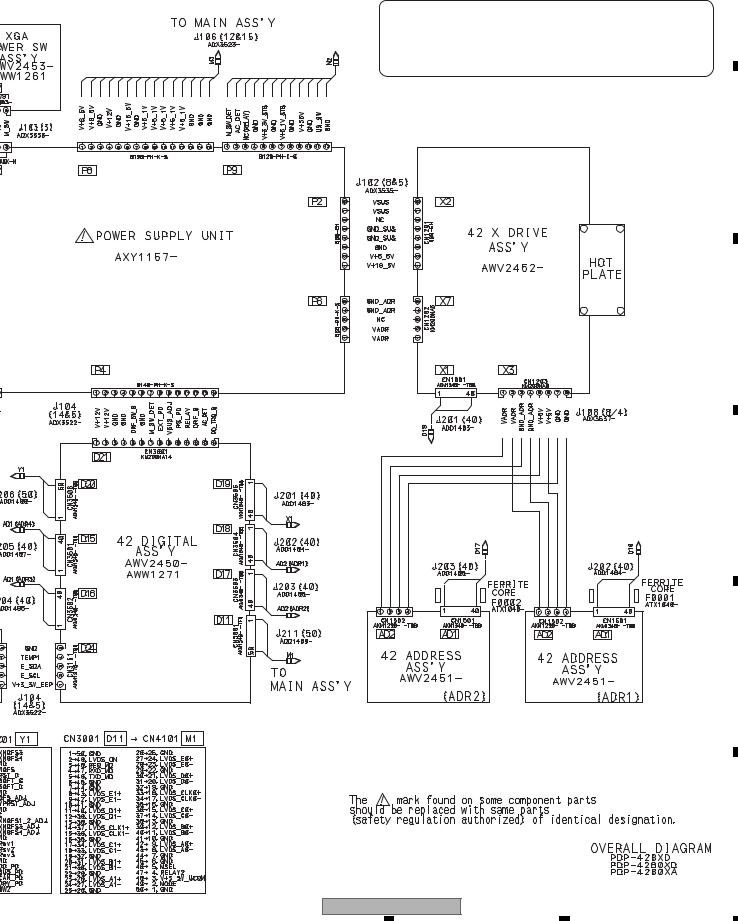

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM (1/2)

A

B

C

D

E

F

28 |

|

PDP-4280XA |

|

1 |

2 |

3 |

4 |

|

5 |

|

6 |

|

|

|

5 |

|

6 |

|

|

||

|

|

|

7 |

|

8 |

|

|

|

|

A

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

The