Panasonic LD-600 Installation Manual

INSTRUCTION MANUAL

Laser Type Edge Detection Sensor Head

LD-600

Thank you very much for using SUNX products. Please read this Instruction Manual carefully and thoroughly for the correct and optimum use of this product. Kindly keep this manual in a convenient place for quick reference.

This product is to inspect (discriminate/measure) sensing objects. Never use this product for prevention of accidents which damage a

WARNING human life or properties, or for safety maintenance.

1 OUTLINE

This product is a sensor head to detect the edge of on inserted object.

2 FOR SAFE USE OF A LASER PRODUCT

With the objective of preventing injuries to laser product users, JIS C 6802-1997, 'Safety Standard for Laser Products', based on the IEC (International Electrical Standard Committee) standards, was stipulated. In JIS C 6802-1997, laser products are divided into classes corresponding to the degree of danger of the laser component, and preventive measures to assure safety which should be taken with each class are stipulated.

This product is classified as a Class 1 laser product by JIS C 6802-1997 'Safety Standard for Laser Products'.

Classification of laser product

|

|

Class |

|

Degree of danger |

|

||||

|

|

|

|

|

|

|

|

|

|

Class 1 |

|

Intrinsically safe design |

|

|

|

|

|||

Class 2 |

|

Visible and low power (wavelength 400 to 700nm). |

|

||||||

|

Eyes react instinctively to laser beam and protect |

|

|||||||

|

|

|

|

|

|||||

|

|

|

|

Dangerous if eyes are exposed to laser beam through optical |

|||||

Class 3A |

|

means. Visible beam should be 5mW or less. Invisible beam |

|||||||

|

|

|

|

should not exceed 5 times the Class 1 power. |

|

||||

|

|

|

|

Dangerous if eyes are exposed to laser beam directly. Unfo- |

|||||

Class 3B |

|

cused, pulsed laser radiation 0.5W or less can be observed |

|||||||

|

|

|

|

by means of diffuse reflection. |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Too intense. |

|

|

|

|

|

Class 4 |

|

Even diffuse reflection is possibly dangerous. |

|

||||||

|

|

|

|

It can burn the skin or cause a fire. |

|

|

|

||

|

Summary of the safety precautions for user of a laser product |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Class |

Class 1 |

Class 2 |

Class 3A |

Class 3B |

|

Class 4 |

|

|

|

Beam paths |

Not applicable |

|

Required |

|

|||

|

|

|

|

|

|

|

Depends on lev- |

|

|

product |

|

Key control |

|

Not applicable |

|

el & wavelength |

|

Required |

|

|

|

|

|

|

|

of laser radiation |

|

|

|

|

|

|

|

|

|

|

Depends on lev- |

|

|

Laser |

|

Remote interlock |

|

Not applicable |

|

el & wavelength |

|

Required |

|

|

|

|

|

|

|

Depends on lev- |

|

|

|

|

|

|

|

|

|

|

of laser radiation |

|

|

|

|

Beam stop or |

|

Not applicable |

|

el & wavelength |

|

Required |

|

|

|

attenuator |

|

|

|

||||

|

|

|

|

|

of laser radiation |

|

|

||

|

|

Warning signs |

|

Not applicable |

|

Required |

|||

controlOperation |

|

Protection |

Protective |

|

|

|

Depends on lev- |

|

|

|

|

Not applicable |

|

el & wavelength |

|

Required |

|||

|

eyewear |

|

|

|

|||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

of laser radiation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Protective |

Not applicable |

Depends on level & wavelength of |

||||

|

|

|

clothing |

laser radiation |

|

||||

|

|

Training |

Not applicable |

|

Required |

|

|||

|

|

|

|

|

|

|

|

|

|

Note: The table shown above is to indicate the summary of the requirements. For the details, refer to the contents of JIS.

The following label is affixed on this product in accordance with the Safety Standard for Laser Product.

1

%.#55 .#5'4 241&7%6

3 SPECIFICATIONS

|

Type |

Sensor head |

|

Item |

Model No. |

LD-600 |

|

Applicable sensor |

LD-C60 (Note) |

||

controller |

|

||

|

|

||

Power supply |

12V DC 5% (supplied from controller) |

||

Current consumption |

200mA or less |

||

Scan time |

|

0.6ms approx. |

|

|

|

Red semiconductor laser Class 1 |

|

Emitting element |

Max. output: 0.45mW |

||

Peak emission wavelength: 670nm |

|||

|

|

||

|

|

(IEC/JIS standard: Class 1) |

|

Receiving element |

CCD linear image sensor |

||

Power indicator |

Red LED (Lights up when the power is ON) |

||

Sensing range |

15.004mm |

||

Number of pixel |

1,364 pixels |

||

Resolution |

|

11 m/pixel |

|

Ambient remperature |

0 to +40 (No dew condensation), Storage: -10 to +60 |

||

Ambient humidity |

35 to 85% RH, Storage: 35 to 85% RH |

||

Enclosure earthing |

Capacitor earth |

||

Connection |

Connector 10P (Connected to the controller) |

||

Weight |

|

420g approx. |

|

Note: For details of the controller (LD-C60), please refer to the instruction manual enclosed with the controller.

4 CAUTIONS

|

Although this product corresponds to a Class 1 laser |

|

product, it is dangerous to see the laser beam which has |

|

been passed through a viewing optical system such as a |

|

lens, etc. Hence, please avoid this. |

|

This product has been designed to meet the specifications |

|

when it is used along with the optional exclusive controller. |

|

If a controller other than the exclusive controller is used, not |

WARNING |

only the specifications may not be met, but it may also be a |

|

cause for malfunction or break down. Hence, please ensure |

|

to use this product along with the optional exclusive |

|

controller. |

|

Before using this product, please allow a warming up time |

|

of 3 min. after the power supply is switched on. |

Always use the sensor with the connector to be joined to the controller. This product is not a measuring instrument. Hence, we do not offer any calibration services.

Make sure that the power is off while wiring to the controller.

If power is supplied from a commercial switching regulator, ensure that the frame ground (F.G.) terminal of the power supply is connected to an actual ground.

In case noise generating equipment (switching regulator, inverter motor etc.) is used in the vicinity of this product, connect the frame ground (F.G.) terminal of the equipment to an actual ground.

Do not run the wires together with high-voltage lines or power lines or put them in the same raceway. This can cause malfunction due to induction.

Take care that the sensor head is not directly exposed to fluorescent lamp from a rapid-starter lamp or a high frequency lighting device, as it may affect the sensing performance.

In order to reduce noise, make the wiring as short as possible.

Make sure that stress is not applied directly to the sensor head cable joint.

Do not allow any water, oil fingerprints, etc., which may refract light, or dust, dirt, etc., which may block light, to stick to the emitting/receiving surfaces of the sensor head. In case they are present, wipe them with a clean, soft cloth or lens paper.

Avoid dust, dirt, and steam.

Take care that the sensor does not come in direct contact with water, oil, grease or organic solvents, such as, thinner, etc.

In this product, capacitor earth is used to enhance the noise characteristics. In case there is a high frequency noise generating equipment, such as, an ultrasonic welding machine, etc., near the sensor head and if the mounting base is electrically conducting (metallic, etc.), then insulate the sensor head from the mounting base.

Make sure to use an isolation transformer for the DC power supply. If an auto-transformer (single winding transformer) is used, this product or the power supply may get damaged.

In case a surge is generated in the used power supply, connect a surge absorber to the supply and absorb the surge.

When power is supplied, do not touch the product or the conducting portion of the connector attached cable. It may cause erroneous operation.

This sensor is suitable for indoor use only.

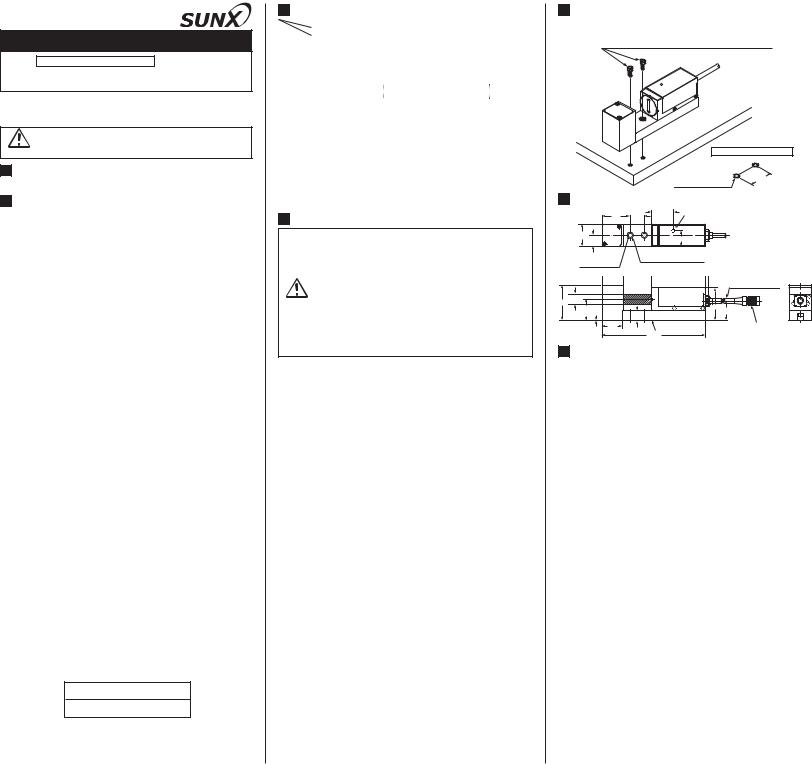

5 MOUNTING

Mount the sensor head using the accessory 2 Nos. M4 (length 12mm) hexagon-socket-head bolts, with a tightening torque of 1.2N m or less.

M4 (length 12mm) hexagon-socket-head bolts (accessory)

Mounting hole dimensions

20 0.2mm

2-M4 tapped holes

6 DIMENSIONS (Unit: mm)

|

40 |

30.2 |

Power indicator (red) |

|

|

20 |

|

||

32 |

16 |

|

22.6 |

|

(Beam axis) |

|

|

||

2- |

4.5 |

2- 8 spot facing 6 deep |

||

mounting holes |

||||

(mounting holes) |

||||

|

|

|||

30

30

40

40

75

75

5

5

5.7 cable 1m long

15

50 (Sensing width)

30 |

|

|

46 27.7 |

(Beam axis) |

|

14 |

Connector |

|

|

||

|

|

|

|

0.5 |

29 |

|

Reference mounting plane |

|

|

|

145.5

7 WARRANTY

Warranty Period

SUNX warrants this product for twelve (12) months from the date of shipment or delivery to the purchaser's appointed warehouse.

Scope of Warranty

During the above mentioned period, if a failure of the product occurs under normal use and operation, and if SUNX determines that it is responsible for the failure, it shall repair the defect or replace the product.

However, in no event shall SUNX be liable for the failure, damage or loss stipulated below:

(1)Failure caused by instructions, standards, or handling specified by the customer

(2)Failure caused by modifications done in the structure, capabilities, specifications, etc., without consulting SUNX, after the purchase or the delivery of the product

(3)Failure caused by a development which could not be foreseen based upon the technology in practice at the time of purchase or contract

(4)Failure caused by use which deviates from the conditions/environment given in the product catalog or specifications

(5)In case this product is used by being incorporated in the customer's machine, failure which could be avoided if the customer's machine had functions and structure commonly accepted in the industry

(6)Failure due to Force Majeure

Further, the warranty given here is limited only to this product which has been purchased or delivered. SUNX shall not be responsible for any consequential damage or loss arising out of the failure of this product.

Scope of Service

The cost of the delivered product does not include the cost of dispatching an engineer, etc. In case any such service is needed, it should be separately requested.

SUNX Limited |

http://www.sunx.co.jp/ |

Head Office

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-(0)568-33-7211 FAX: +81-(0)568-33-2631

Overseas Sales Dept.

Phone: +81-(0)568-33-7861 FAX: +81-(0)568-33-8591

PRINTED IN JAPAN

Loading...

Loading...