Panasonic LH-512 Installation Manual

INSTRUCTION MANUAL

M3 screws

Please arrange

separately.

A

B

C

D

LED Type Optical Displacement Sensor

Sensor Head

Thank you very much for using SUNX sensors. Please read this

Instruction Manual carefully and thoroughly for the correct and optimum

use of this sensor. Kindly keep this manual in a convenient place for

quick reference.

This product is not a safety sensor. Its use is not intended or designed

to protect life and prevent body injury or property damage from

dangerous parts of machinery. It is a normal object detection sensor.

LH-50

Series

For details, please refer to the User’s Manual of the controller

LH-CL6(P) or LH-CS6(P)/LH-CD6(P).

z SPECIFICATIONS

Type

Item

Applicable

Controller (Note 2)

Center measuring distance

Measuring range

Emitting element Red LED (modulated, peak wavelength: 650nm)

Spot diameter (Note 3)

Linearity (Note 5) Within Ѱ0.2% F.S.

Ambient temperature

Ambient humidity 35 to 85% RH, Storage: 35 to 85% RH

Ambient illuminance

(Incandescent light)

Protection

(Except connector part)

Material Enclosure: PEI, Enclosure cover: Aluminum

Cable

Cable extension Extension up to total 10.2m is possible with optional cable.

Weight 70g approx. (with cable), 45g approx. (without cable)

Notes:

1) Conditions which have not been specified are to be taken as: use of an applicable

controller, 24V DC supply voltage, Ҥ 20ѵ ambient temperature, SELECT gain

setting, 300ms response time setting, center measuring distance, interference

prevention function not used and white ceramic board object.

2) For details of the applicable controller, please refer to the instruction manual of the

controller.

3) This is the value at the center measuring distance, and is based on the definition of

1/e

spreads out of the specified spot diameter and, depending on the conditions

around the measured object, may affect the measurement accuracy.

4) This is the typical value at the center measuring distance for a white ceramic board

object. The given values are for the analog output of the applicable controller.

5) This is the value for white ceramic board object. The linearity may differ depending on

the measured object. The given value is for the analog output of the applicable

controller.

Model No.

300ms 2 m4m20m

100ms 4 m8m40m

40ms 5 m14m65m

30ms 6 m16m75m

20ms 7 m28m92m

10ms 10 m40m 130m

Resolution (Note 4)

2

(13.5%) of the beam axis light intensity. Take care that some amount of light

1ms 20 m 120 m 400 m

Controller response time

0.5ms 40 m 160 m 580 m

40mm type

LH-54 LH-58 LH-512

LH-CL6(P), LH-CS6(P), LH-CD6(P)

40mm 80mm 120mm

Ѱ10mm (30 to 50mm) Ѱ20mm (60 to 100mm) Ѱ30mm (90 to 150mm)

1.6mm or less 2.0mm or less 3.0mm or less

0 to Ҥ45ѵ (No dew condensation allowed)

Storage: ҥ20 to Ҥ 60ѵ

3,000Rx or less 2,000Rx or less

0. 22mm

0.2m long, with a connector at the end

80mm type 120mm type

IP67 (IEC)

2

11-core composite cabtyre cable,

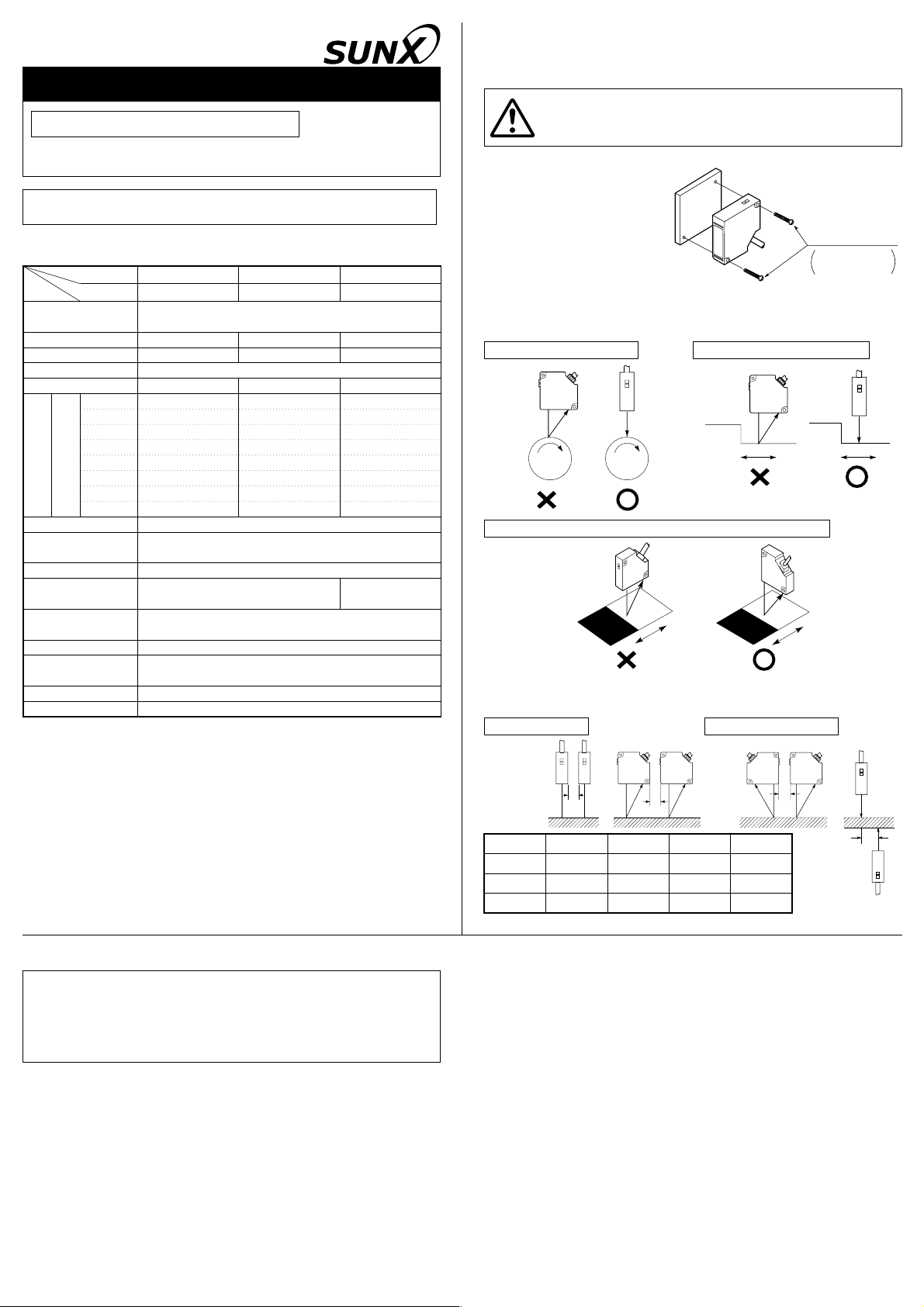

x MOUNTING

ӟ Install the sensor head

such that the sensing

surface of the sensor head

and the measured object

are parallel. The screw

tightening torque should be

0.5NОm or less.

ӟ In case the measured object is moving as shown below, take care of

the mounting direction of the sensor head, as an error may be

generated depending on the mounting direction.

Eccentricity measurement

In case of extreme change in color or material at a boundary

ӟ In case several sensor heads are arranged in a row, mount them by

keeping the minimum distance given below.

Parallel mounting Face-to-face mounting

Model No. A C D

LH-54

LH-58

LH-512

Note: The above values are for the case when the interference prevention function is used.

0mm 10mm 17mm

0mm 10mm 17mm

0mm 30mm 17mm

B

0mm

0mm

0mm

Level difference measurement

c CAUTIONS

The sensor head has been designed to meet the specifications

when used along with the optional exclusive controller. In case it is

used in a combination that does not use the optional exclusive

controller, not only the specifications may not be met, but it may also

cause an accident, etc. Hence, always use the sensor head along

with the exclusive controller.

ӟ Take care that wrong wiring will damage the sensor.

ӟ Use this product 10min. after the power is supplied. Immediately on

supply of power, the electrical circuit is yet to stabilize, which may

cause variation in measured values.

ӟ Do not allow any water, oil, fingerprints, etc., which may refract light,

or dust, dirt, etc., which may block light, to stick to the

emitting/receiving surfaces of the sensor head. In case they are

present, wipe them with a clean, soft cloth or lens paper.

ӟ Take care that in case the measured object has a highly reflective

surface or is transparent, accurate measurement may not be

possible.

ӟ Although this sensor uses a red LED as the beam source, do not

directly see the beam emitted from the sensor head, since it has

been focused and has high optical intensity.

ӟ Take care that extraneous light, such as sunlight or light having the

same wavelength, does not fall on the receiving part of the sensor

head. Especially for accurate measurements, install a shield, etc., to

block extraneous light.

Although the sensor head has IP67 protection, measurement in water

ӟ

or rain is not possible. Further, the connector part is not water-proof.

ӟ Avoid use at places subject to intense vibrations or shock.

ӟ Avoid dust, dirt, and steam.

ӟ Take care that the sensor head does not come in direct contact with

water, oil, grease, or organic solvents, such as, thinner, etc.

ӟ In case noise generating equipment (switching regulator, inverter

motor, etc.) is used in the vicinity of this product, connect the frame

ground (F.G.) terminal of the equipment to an actual ground.

ӟ Do not run the wires together with high-voltage lines or power lines

or put them in the same raceway. This can cause malfunction due to

induction.

ӟ This sensor is suitable for indoor use only.

Loading...

Loading...