Panasonic FP0-C10RSA, FP0-C14CRSA, FP0-C10CRSA, FP0-C14RSA, FP0-C16PA Specifications

...

FP0 Series

Programmable Controller

Panasonic ... the new name for

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

FP0 – Super Compact PLC

Incredibly small, alone or even as multiple combined units

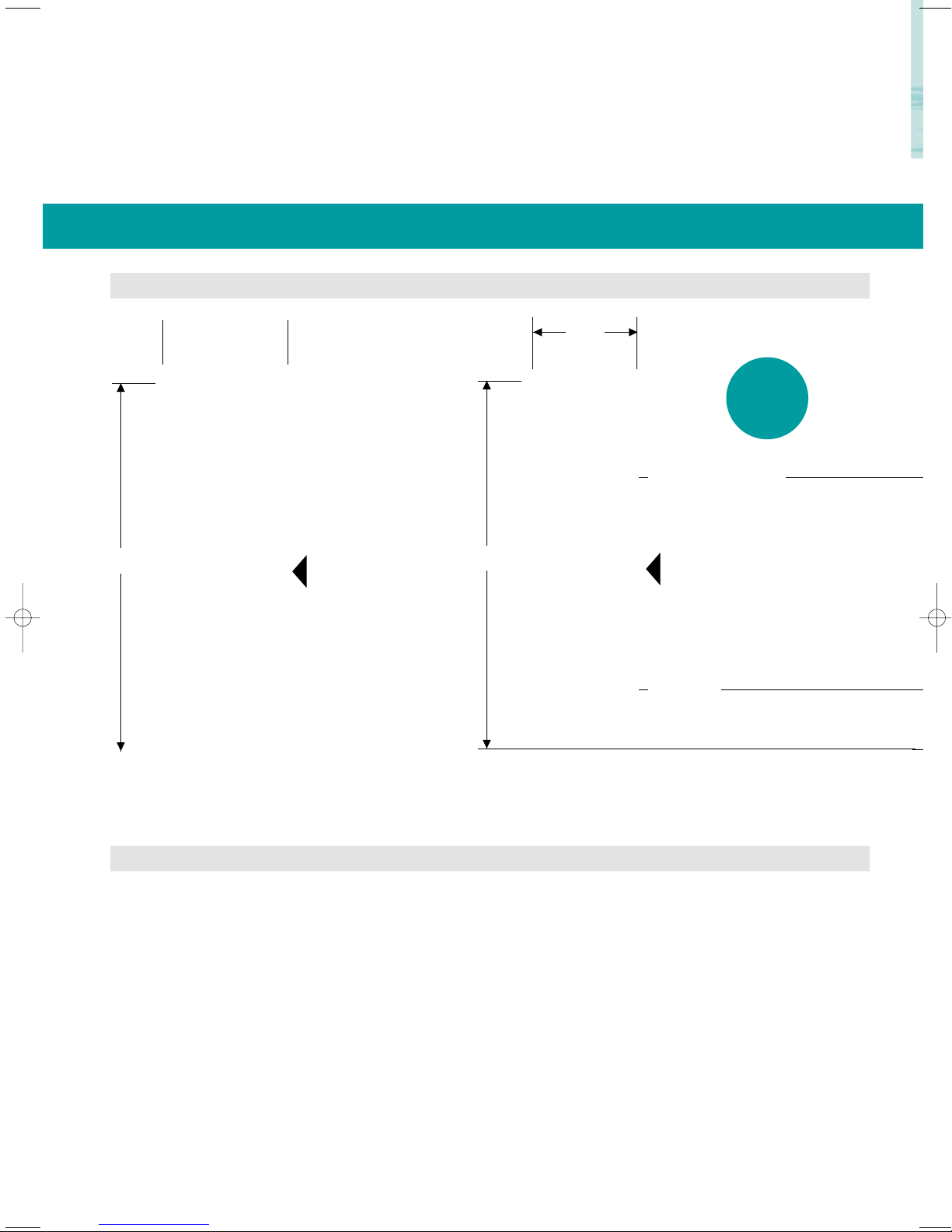

A control unit a mere 25mm in width. Even expanded to I/O 128 points, the width is still only 105mm.

The attachment area is the smallest in its class.

The control unit's dimensions are: W25* x H90 x D60mm.

Also, the I/O unit can be expanded to a maximum of

128-points. Even so, the size is still only W105 x H90 x

D60mm, a super compact design that breaks all previous

common sense rules on small-scale PLCs. With the

smallest-ever attachment area, the FP0 is perfect for

installation in machines, facilities, and control boards

where miniaturization is progressing even further.

*30mm width limited to I/O 32-points control unit.

Choose among 3 types of attachment

DIN rail

Slim attachment

plate model

Flat attachment plate

model (cannot be used

with expansions)

Input/output terminal

TOOL-Port

Hooks up by using the programming

software

or FPWIN GR and a single cable.

25mm

90mm

The photo shows an I/O

14-point control unit.

This size is uniform for

all except the I/O 32-point

control unit.

Supply voltage: 24VDC

NAiS Control FPWIN Pro

Actual

size

From I/O 10-points…

Super Compact Size

COM-Port: 2nd RS232C Interface

(optional for all CPU units for serial communication)

90mm

AC Power Supply:

• Supply voltage

85 to 265VAC

• Output 24VDC/

0.7A for FP0 PLC

(DC type)

NOTE:

A seperation between

the power supply and

the FP0 is needed to

allow for heat

dissipation.

➝

➝

30.4mm

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Either 10 Points or the Maximum of 128 Points

You save this much space!

3

The expansion unit can be attached easily

without any cables.

The expansion unit can easily be attached directly to the

control unit. Special expansion cables, backplanes, and

so forth, are unnecessary as the expansion unit employs

a stacking system that uses expansion connectors and

locking levers on the surface of the unit itself.

Because of its super compact size and high capabilities,

the units are useful in a wide variety of applications.

Relay sequence

replacement

In-house detectors

Conveyer control

Parts feeders

Food processing and

packaging machines

Parking meters

Auto-stockers

Driving range

Easy Expansion

…up to 128 I/Os

Control

unit

Expansion

unit

Expansion

unit

Expansion

unit

(Maximum possible expansion is three units)

■ Networking:

- ETHERNET

- PROFIBUS

- S-LINK

- MEWNET-F

■ Analogue modules featuring

different numbers of input and

output channels

■ Programming software:

- Control FPWIN Pro according

to IEC 61131-3

- Control FPWIN GR easy,

conventional programming

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

105mm

Control unit Expansion unit Expansion unit Expansion unit

The photo illustrates adding

three I/O 32-point expansion

units to an I/O 32-point control

unit, yielding 128 points.

Supply voltage 24VDC.

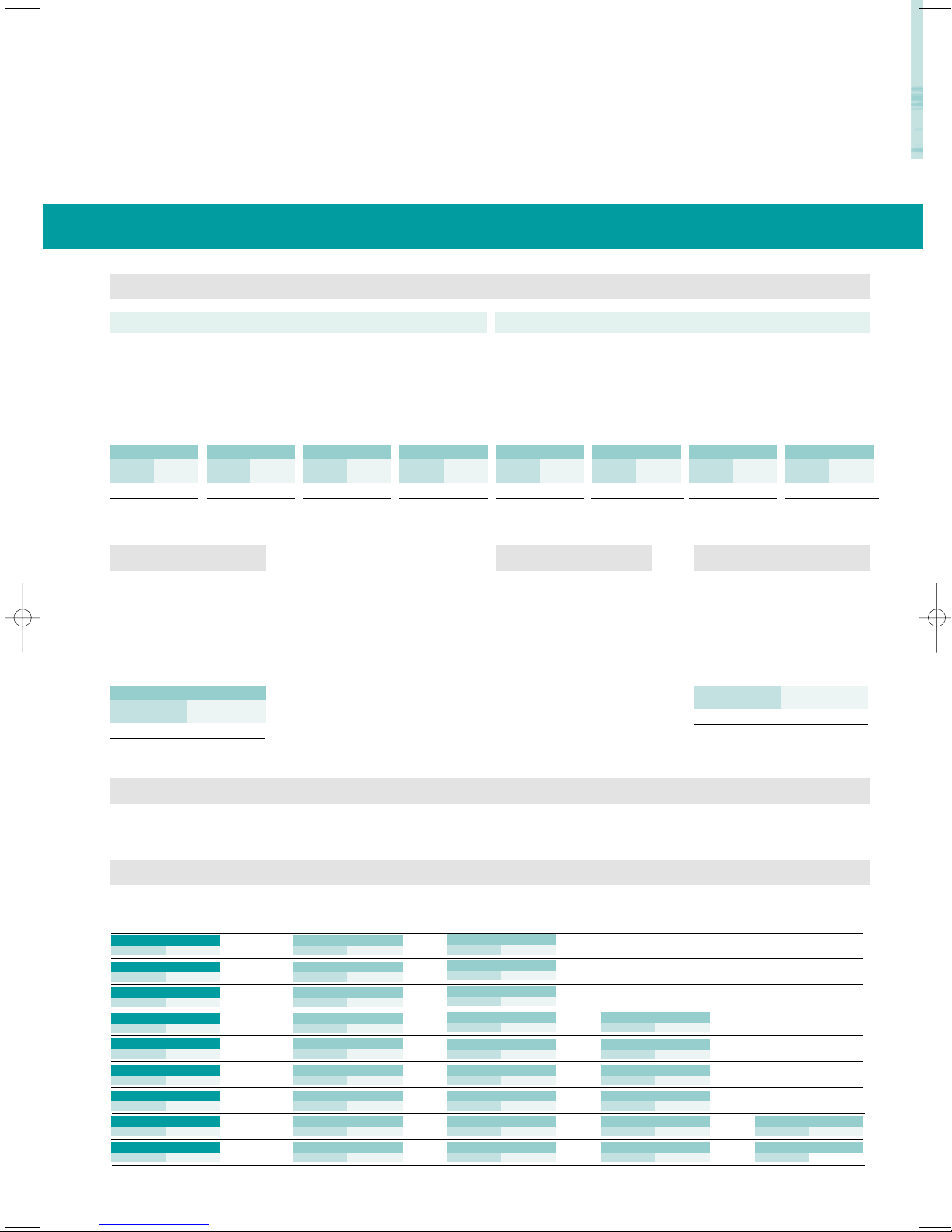

FP0 CPU Units

A rich line-up of both single and combined units

=

+

=+

=+

=+

=+

+

+

=++

=++

= +++

= +++

22

Input 12 Output 10

14

Input 8 Output 6

8

Input 4 Output 4

26

Input 14 Output 12

10

Input 6 Output 4

16

Input 8 Output 8

30

Input 16 Output 14

14

Input 8 Output 6

16

Input 8 Output 8

34

Input 18 Output 16

10

Input 6 Output 4

16

Input 8 Output 8

8

Input 4 Output 4

38

Input 20 Output 18

14

Input 8 Output 6

16

Input 8 Output 8

8

Input 4 Output 4

42

Input 22 Output 20

10

Input 6 Output 4

16

Input 8 Output 8

16

Input 8 Output 8

46

Input 24 Output 22

14

Input 8 Output 6

16

Input 8 Output 8

16

Input 8 Output 8

54

Input 28 Output 26

14

Input 8 Output 6

16

Input 8 Output 8

16

Input 8 Output 8

8

Input 4 Output 4

()

Total number

of I/O points

()

Control unit

()

Expansion unit 1

X20~/Y20~

()

Expansion unit 2

X40~/Y40~

()

Expansion unit 3

X60~/Y60~

=+++

62

Input 32 Output 30

14

Input 8 Output 6

16

Input 8 Output 8

16

Input 8 Output 8

16

Input 8 Output 8

Control Units

A maximum of 3 expansion units can be added to the control unit. (

Combining relay output types

and transistor output types

is also possible. In this event, the maximum number of I/O points when using a relay output type control panel is 110.)

10 points

Input

6 points

FP0-C10RSA FP0-C10CRSA

with 2nd RS232C

FP0-C14CRSA

with 2nd RS232C

FP0-C16PA (PNP)

FP0-C16TA (NPN)

FP0-C32PA (PNP)

FP0-C32TA (NPN)

FP0-C16CPA (PNP)

FP0-C16CTA (NPN)

with 2nd RS232C

FP0-C32CPA (PNP)

FP0-C32CTA (NPN)

with 2nd RS232C

FP0-C14RSA

Output

4 points

10 points

Input

6 points

Output

4 points

14 points

Input

8 points

Output

6 points

14 points

Input

8 points

Output

6 points

16 points

Input

8 points

Output

8 points

16 points

Input

8 points

Output

8 points

32 points

Input

16 points

Output

16 points

32 points

Input

16 points

Output

16 points

AC Power Supply

FP0-PSA2

Input

85 to 265VAC

Terminal type

Output

24VDC/0.7A

S-LINK CPU

FP0-SL1

S-LINK master

for up to 128 I/Os

Control Unit 10k

FP0-T32C

32 points

Input

16 points

FP0-T32CPA (PNP)

FP0-T32CTA (NPN)

with 2nd RS232C

Output

16 points

This advanced FP0 CPU

offers additional features:

■ 10,000 steps

program memory

■ Battery backed RAM

■ Real-time clock

■ 16383 words

data register

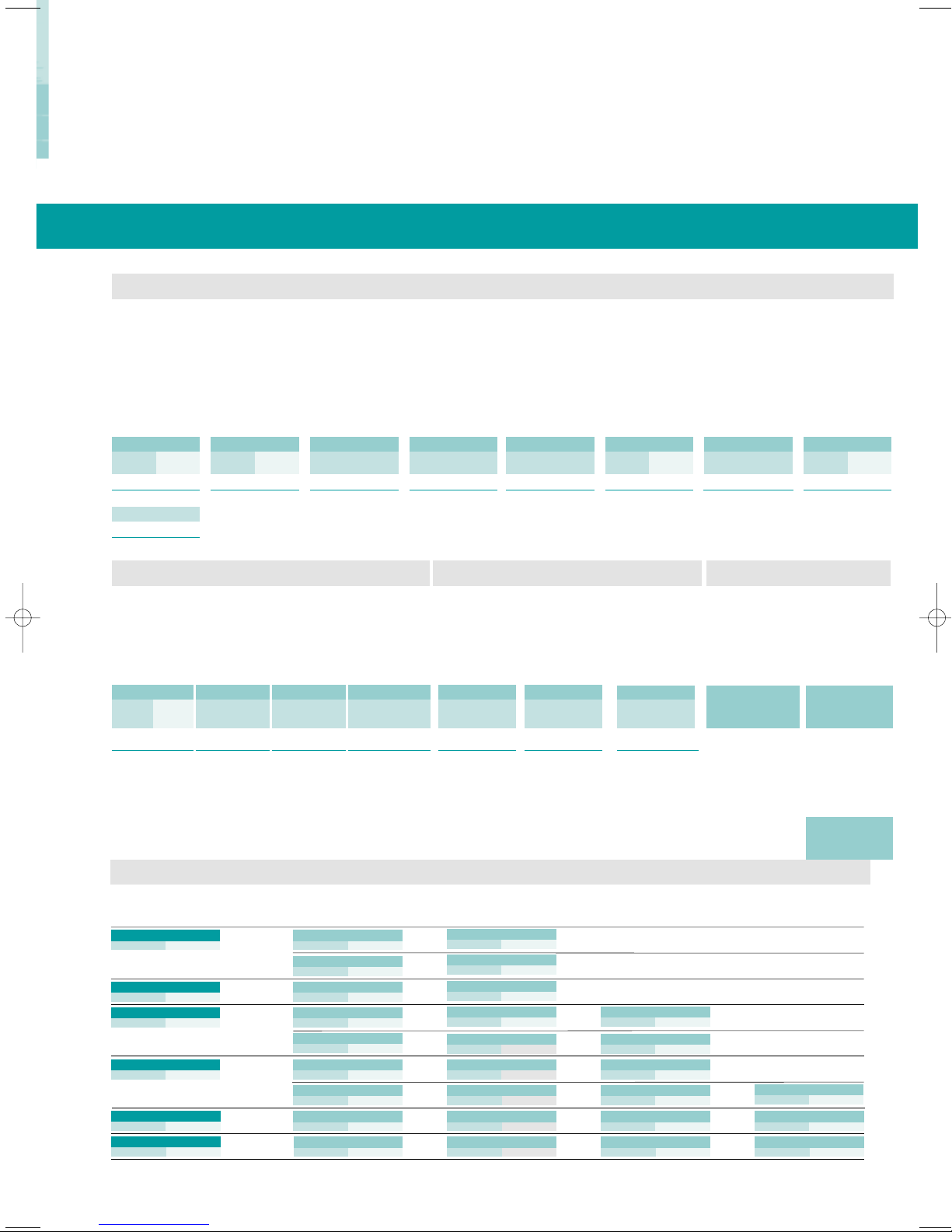

Expansion combinations

Combinations with relay output type – Examples

Relay output type Transistor output type

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

FP0 Expansion Units

Choose the number of I/O points to suit the application

5

Combinations with transistor output type – Examples

=

+

=+

=+

=+

=+

+

+

=++

=++

= +++

+

= +++

48

Input 24 Output 24

32

Input 16 Output 16

16

Input 8 Output 8

16

Input 8 Output 8

32

Input 16 Output 16

64

Input 32 Output 32

32

Input 16 Output 16

32

Input 16 Output 16

80

Input 40 Output 40

32

Input 16 Output 16

32

Input 16 Output 16

16

Input 8 Output 8

16

Input 8 Output 8

32

Input 16 Output 16

32

Input 16 Output 16

96

Input 48 Output 48

32

Input 16 Output 16

32

Input 16 Output 16

32

Input 16 Output 16

16

Input 8 Output 8

32

Input 16 Output 16

32

Input 16 Output 16

112

Input 56 Output 56

32

Input 16 Output 16

32

Input 16 Output 16

32

Input 16 Output 16

16

Input 8 Output 8

()

Total number

of I/O points

()

Control unit

()

Expansion unit 1

X20~/Y20~

()

Expansion unit 2

X40~/Y40~

()

Expansion unit 3

X60~/Y60~

=+++

16

Input 8 Output 8

128

Input 64 Output 64

32

Input 16 Output 16

32

Input 16 Output 16

32

Input 16 Output 16

32

Input 16 Output 16

Digital I/O Units

Relay output type Input only type

Transistor output type

Analogue I/O Units Thermocouple and RTD Units Networking Units

PROFIBUS

FP0-DPS2

(DP Slave)

MEWNET-F

FP0-IOL

(MEWNET-F Slave)

S-Link CPU

FP0-SL1

(S-LINK Master)

FP0-E16RSA FP0-E8XA FP0-E16XAFP0-E8RSA

FP0-E8YRSA

8 points

Input

8 points

16 points

Input

16 points

8 points

Input

4 points

Option:

Output 8 points

Output

4 points

16 points

Input

8 points

Output

8 points

FP0-E8YPA (PNP)

FP0-E8YTA (NPN)

FP0-E16YPA (PNP)

FP0-E16YTA (NPN)

FP0-E16PA (PNP)

FP0-E16TA (NPN)

FP0-E32PA (PNP)

FP0-E32TA (NPN)

8 points

Output

8 points

16 points

Input

8 points

Output

8 points

16 points

Output

16 points

32 points

Input

16 points

Output

16 points

8 points3 points 4 points 4 points

Input

8 points

FP0-A80A

• Input (12 bit):

10V, 0 – 5V,

0 – 20mA

• Output (12 bit):

10V, 0 – 20mA

–

–

4 – 20mA

–

–

10V

10V, 100mV

0 – 5V, 0 – 20mA

–

Input

2 points

Output

1 points

Output

4 points

Output

4 points

FP0-A21A FP0-A04I FP0-A04V

4 points

Input

4 points

FP0-TC4 FP0-TC8

8 points

6 points

Input

6 points

• K, J, T, R type thermocouples can

be used

• Resolution: 0,1°C

• Accuracy: 0,8°C (R type: 3°C)

• Temperature range:

-100 to 1500°C

Input

8 points

FP0-RTD6

• Pt100, Pt1000,

NI1000

• Temperature

range -200

to 500ºC

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

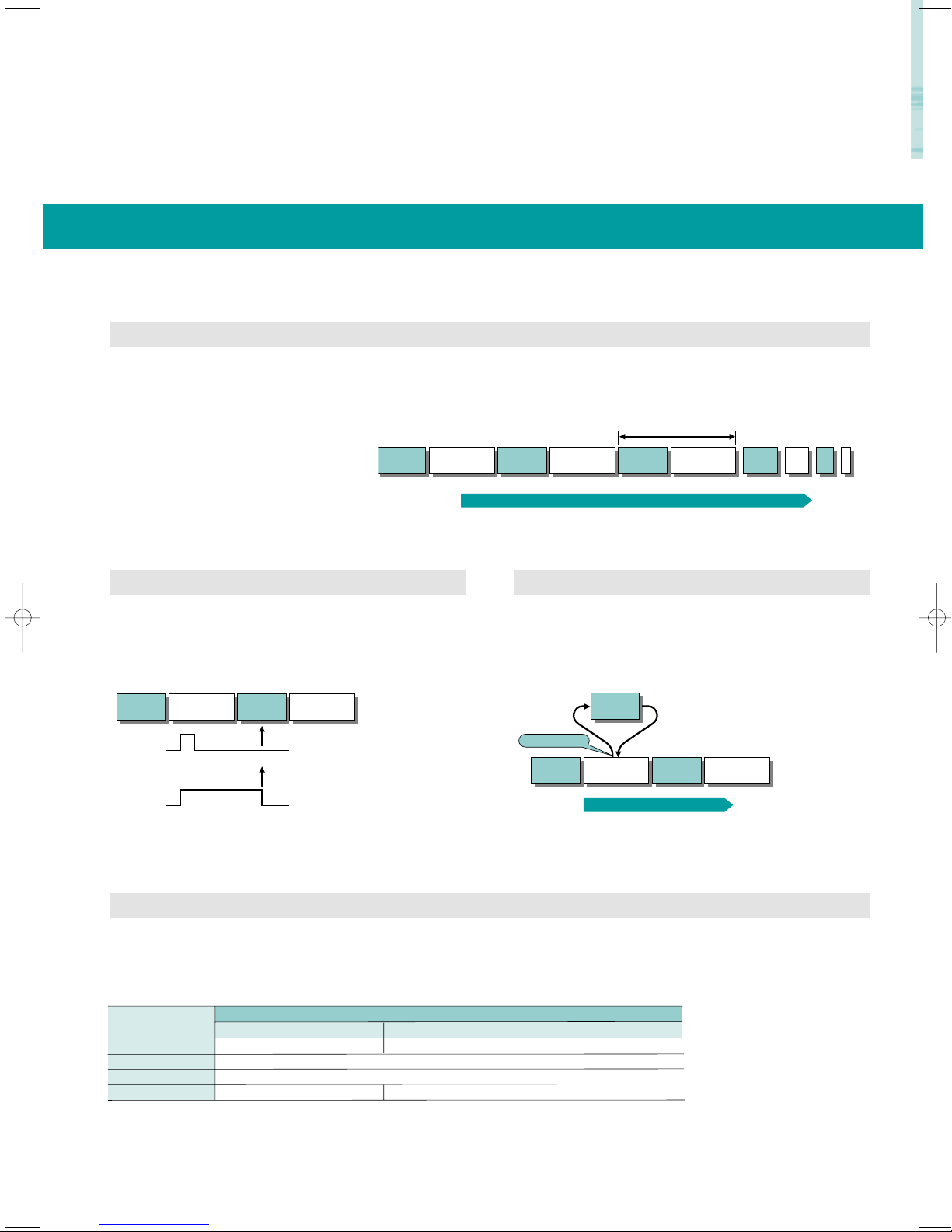

FP0 – Impressive Capabilities

High specifications for both speed and capacity

0.9µs per basic instruction. Pulse catch and interrupt input functions meet the need for high-speed response.

High-speed execution

Execution speed of 0.9µs per basic instruction. 500 steps program yields a scanning time of 1ms, which means the FP0

boosts the fastest processing time among the products of this class.

• Internal processing in the FP0

Large capacity

Pulse catch function

Can read pulses as short as 50µs, which greatly facilitates

sensor input.

• Pulse catch function

Interrupt input function

Accurate processing, unaffected by scan time

• Interrupt input function

I/O

refresh

Program

execution

I/O

refresh

Program

execution

1 scan

I/O

refresh

Program

execution

Internal processing in the FP0

I/O

refresh

Program

execution

I/O

refresh

Program

execution

Sensor input

signal

Cannot

read.

Lengthening

of sensor

input signal

Can

read!

With pulse catch function

Internal processing in the FP0

I/O

refresh

Program

execution

I/O

refresh

Program

execution

Interrupt

program

Interrupt input

Interrupt program executed when

interrupt input enters.

A top-class large 5k and 10k steps program capacity housed within a compact body. Furthermore, data capacity for internal

devices like the data register is also ample. The unit's high performance is even suited to complicated controls

and controls with multiple amounts of data.

I/O 10-point, 14-point, 16-point type

Control unit type

I/O 32-point type

2 720 steps

1 660 words

5 000 steps

6 144 words

1 008 points

144 points

FP0-T32 CP/T

10 000 steps

16 383 words

Program size

Internal relays

Timers/Counters

Data registers

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

FP0 – Impressive Capabilities

FP0 functions

7

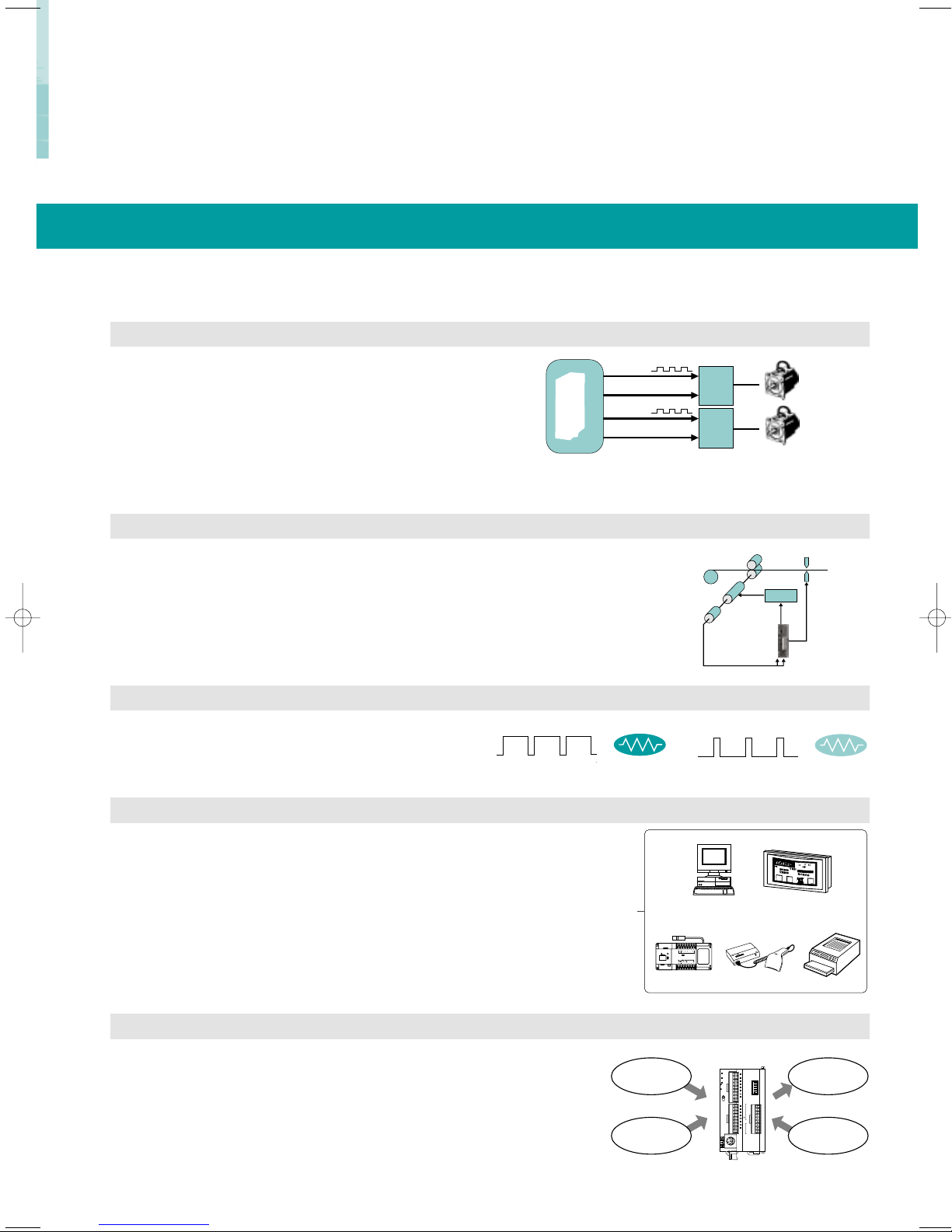

Equipped with 2-axis independent positioning and high-speed counter for support of PWM output.

Pulse output function

(For transistor output type only) The unit comes equipped with

2 channels for the output of up to 10kHz pulses (5kHz during

2-channel output). Since these two channels can be separately

controlled, the PLC is also suitable for independent 2-axis

positioning. Setting automatic trapezoid control, automatic return

to home position and JOG operation are made very easy by using

instructions specially designed for such operations.

Positioning control is a breeze with

the auto trapezoid control command!

Y0

Y2

Motor

driver 1

Pulse output

Clockwise output/

counter-clockwise output

Y1

Y3

Motor

driver 2

Pulse output

Clockwise output/

counter-clockwise output

High-speed counter function

The high-speed counter is prepared for 4 channels in single phase, and 2 channels in

2-phase. In single phase, the 4-channel total is 10kHz, and in 2-phase the 2-channel total is

2kHz total speed, making the unit suitable for conveyer control, inverter control, and so

forth using an encoder.

PWM output function

Its PWM (Pulse Width Modulation) output function makes

it possible to provide temperature control with a single

compact FP0 unit. (For transistor output type only)

Feeder roller

Lead wiring,

tape

Cutter

Encoder

Motor

START/STOP

signal

Inverter

Cutter blade

control signal

Encoder output

inputted into

high-speed counter

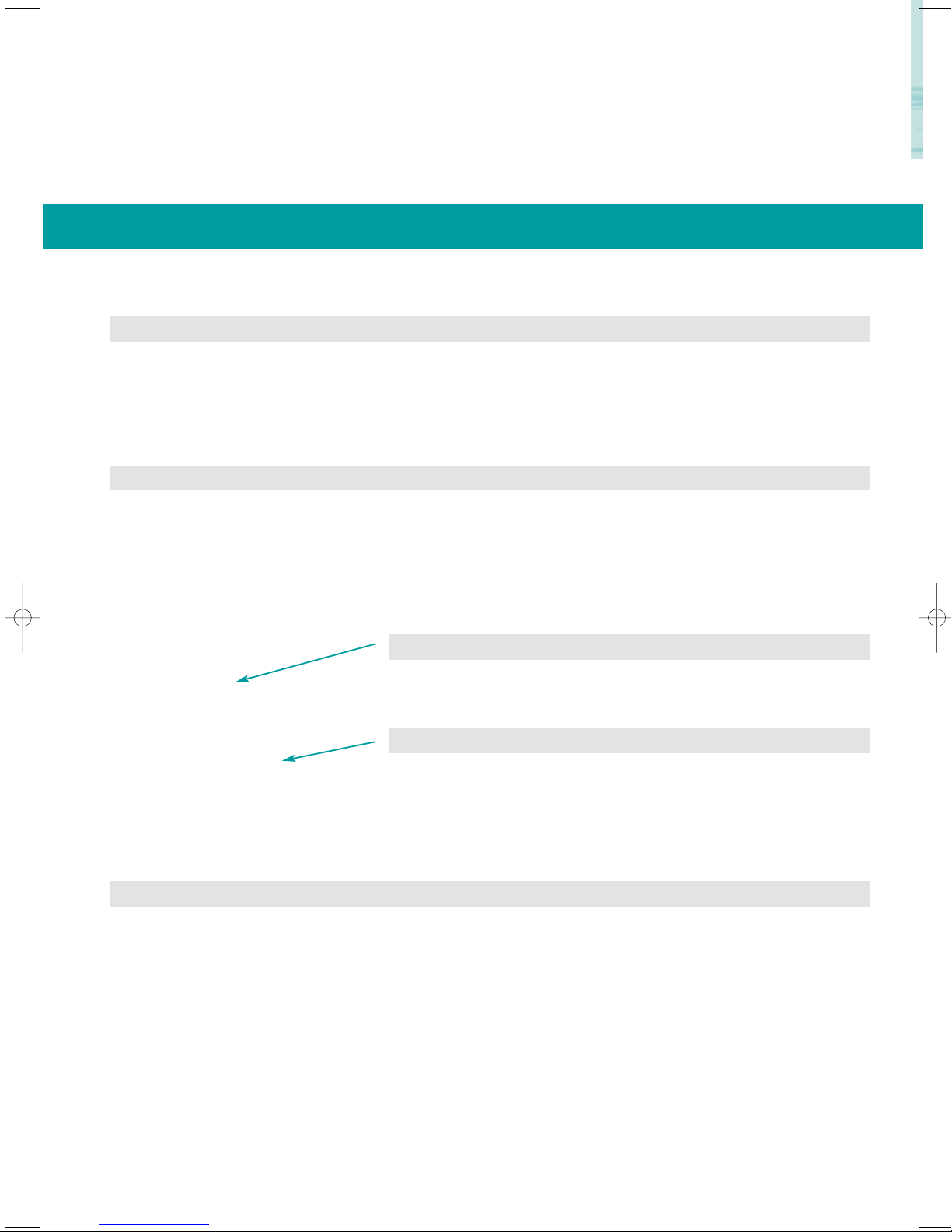

Serial communication function

• The FP0’s second RS232C port (types C10CRS, C14CRS, C16C, C32C,

and T32C) allows direct connection to computers and operation display

panels. Also, bi-directional data communication with barcode readers

and other RS232C devices is made easy.

• Both the relay type and transistor output type control units are optionally

equipped with a 2nd RS232C port.

Host computer

(Personal computer)

Operation

display panel

FP0

●

For connecting to computers and operation display panels

●

For data communication with RS232C devices

Imagechecker Bar code reader Serial printer

RS-232C

POWER READY

MODE

A

B

C

KEY PAD

CAMERA

MONITOR

COM COM D2 D4 D6 D8 D9

FLASH

D1 D3 D5 D7

READY

MICRO-IMAGECHECKER

M100

Matsuhita Electronic Works, Ltd.

24VDC

START

ACK IN1 IN3 IN5

COM COM IN2 IN4 COM

Heater

power up

● When pulse width values are increased...

● When reduced...

Analogue control function

Analogue control is made simple with four types of analoque modules

featuring different numbers of input and output channels.

Also, despite the small size, the I/O resolution is a high 1/4000 (12 bits).

Support various I/O ranges by setting the DIP switches on the analogue

I/O unit for simple operation.

PROG.

RUN

ALARM

ERROR

PROG

RUN

Pressure sensor

Laser analogue

sensor

Inverter

Potentiometer

MODE

OFF ON

V 0

IN

I 0

COM

FP0 - A21

OUT

I 1

V

I

1

2

3

4

5

Stepping

motor

Servo motor

Stepping

motor

Servo motor

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

● When reduced...

power up

power down

Heater

FP0 Communication

Serial interfaces and modem compatible

Programming interface TOOL-Port (also for communication)

In Computer Link mode, this port offers access to the entire FP0 memory area. For example during data exchange between

a host PC running SCADA software and an FP0 PLC, the Windows

®

based MEWNET-DDE Server assumes total control of

the communications protocol (MEWTOCOL.COM). Therefore the user can disregard the allocation of data ranges and

transfer parameters, because there is no additional programming required. The programmer is thus free to concentrate

exclusively on the project application requirements.

Communication Interface COM-Port

(flexible with two modes of operation, Computer Link and General Purpose)

In addition to the Computer Link communication possibilities described above, the optional integrated RS232C COM-Port

in the FP0 CPU module (types FP0-C10CRS, FP0-C14CRS, FP0-C16C, FP0-C32C and FP0-T32C) offers flexible programming

i.e. General Purpose. In this configuration it is possible to realise communication connections with different RS232C

peripheral devices, e.g. Bar Code Readers, slave devices, printers, measurement sensors or telecommunication

transmitters, etc.

Communication Interface COM-Port

Freely programmable RS232C interface for CPU modules type FP0-C10CRS,

FP0-C14CRS, FP0-C16C, FP0-C32C and FP0-T32C

Communication – Simple and efficient via two serial interfaces: TOOL-Port and COM-Port (RS232C interface).

Programming Interface TOOL-Port

For programming, and additionally Master/Slave communication, using

MEWTOCOL COM (Matsushita protocol)

Modem compatible

Even modem communication function is built into this compact body. Using a single telephone line,

programming maintenance can be carried out in remote facilities. With C-NET, multiple FPO units can be

connected.

■ 1:1 communication ■ 1:N communication ■ Multidrop communication

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

FP0 Communication

Easier maintenance than ever before

9

Maintenance saving

■ Overwrite function in RUN mode

It is possible to overwrite a program while the FP0 is running, such as during program debugging and startup

adjustments.

■ Backup battery unnecessary

The program memory uses EEPROM. The program and device contents can be stored without a backup battery, and

even programming for a machine builder is safe.

■ Password function

A password function can be set in order to change a program. Limited to people authorized to make program changes,

protection can be guaranteed better than ever.

■ Input/output verification LED

Every unit is equipped with LED I/O indicators, housed within a compact body. Input/output status can be verified

at a glance.

Terminal type can be

plugged straight in without

resorting to crimping (made

by Phoenix Contact Co.).

Can handle wires from

0.3 to 1.25mm

2

.

Compatible models

FP0-C10RS, C10CRS, C14CRS, E8RS, E16RS

Unit connectors can be used

with 16-points and 32-points

units. Due to the loose-wiring,

pressure contact type design,

wiring is easy without the

need for insulation.

(MIL-C-83503)

Compatible models

FP0-C16T/C16P/C16CT/C16CP, C32T/C32P/C32CT/C32CP,

E16T/E16P, E32T/E32P,

FP0-T32CP/T32CT

Program memory uses EEPROM. In addition, programs can be changed even in RUN mode!

Simple installation

Comes with either terminal block or connector. Either type is easy to connect to wiring by simply

removing the terminal section.

Terminal block

MIL connector

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Loading...

Loading...