Nissan Micra 2005 User Manual

BRAKE SYSTEM

F BRAKES

A

B

SECTION BR

CONTENTS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

PrecautionsforProcedureswithoutCowlTopCover..... 3

Precautions for Brake System .................................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 5

NVH Troubleshooting Chart ..................................... 5

BRAKE PEDAL .......................................................... 6

Inspection and Adjustment ....................................... 6

PLAY AND CLEARANCE BETWEEN BRAKE

PEDAL AND FLOOR PANEL WITH PEDAL

DEPRESSED. ....................................................... 6

Removal and Installation .......................................... 7

COMPONENTS .................................................... 7

REMOVAL ............................................................. 7

INSPECTION AFTER REMOVAL ......................... 8

INSTALLATION ..................................................... 8

BRAKE FLUID ............................................................ 9

Level Inspection ....................................................... 9

Checking Brake Line ................................................ 9

Drain and Refill ......................................................... 9

Bleeding Brake System .......................................... 10

BRAKE PIPING AND HOSE .....................................11

Hydraulic Circuit ......................................................11

RemovalandInstallationofFrontBrakePipingand

Brake Hose .............................................................11

REMOVAL ............................................................11

INSTALLATION ................................................... 12

Removaland Installationof RearBrakePipingand

Brake Hose ............................................................ 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 12

Inspection ............................................................... 13

BRAKE MASTER CYLINDER .................................. 14

BRAKE SYSTEM

Removal and Installation ........................................ 14

REMOVAL ...........................................................14

INSTALLATION ................................................... 14

Disassembly and Assembly .................................... 14

DISASSEMBLY ................................................... 15

INSPECTION AFTER DISASSEMBLY ............... 15

ASSEMBLY ......................................................... 15

BRAKE BOOSTER ...................................................17

On-Vehicle Service .................................................17

OPERATING CHECK ..........................................17

AIRTIGHTNESS INSPECTION ...........................17

Removal and Installation ........................................ 17

COMPONENTS ...................................................17

REMOVAL ...........................................................17

INSTALLATION ................................................... 18

VACUUM LINES ....................................................... 19

Components ...........................................................19

Removal and Installation ........................................ 19

VACUUM HOSE .................................................. 19

VACUUM PUMP .................................................. 19

Inspection ...............................................................20

VISUAL INSPECTION .........................................20

CHECK VALVE INSPECTION ............................. 20

FRONT DISC BRAKE ............................................... 21

On Board Inspection ............................................... 21

PAD WEAR INSPECTION ................................... 21

Components ...........................................................21

Removal and Installation of Brake Pad .................. 22

REMOVAL ...........................................................22

INSTALLATION ................................................... 22

RemovalandInstallationofBrakeCaliperAssembly

...23

REMOVAL ...........................................................23

INSTALLATION ................................................... 23

Disassembly and Assembly of Brake Caliper

Assembly ................................................................ 23

DISASSEMBLY ................................................... 23

BRAKE CALIPER INSPECTION ......................... 24

C

D

E

BR

G

H

I

J

K

L

M

BR-1

ASSEMBLY .........................................................24

Removal and Installation of Disc Rotor ...................25

REMOVAL ...........................................................25

INSTALLATION ....................................................25

DISC ROTOR INSPECTION ...............................25

BRAKE BURNISHING PROCEDURE .................26

REAR DRUM BRAKE ............................................... 27

Components ........................................................... 27

RemovalandInstallation ofDrum BrakeAssembly...28

REMOVAL ...........................................................28

INSPECTION AFTER REMOVAL ........................ 28

INSTALLATION ....................................................29

Removal and Installation of Wheel Cylinder ...........30

REMOVAL ............................................................30

INSTALLATION ....................................................30

Disassembly and Assembly of Wheel Cylinder .......30

DISASSEMBLY ....................................................30

ASSEMBLY ..........................................................30

Wheel Cylinder Inspection ......................................31

SERVICE DATA AND SPECIFICATIONS (SDS) ......32

General Specifications ............................................32

Brake Pedal ............................................................32

Brake Booster .........................................................32

Check Valve ............................................................32

Front Disc Brake .....................................................33

Rear Drum Brake ....................................................33

BR-2

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

EFS002FV

A

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Informationnecessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

● To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

● Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Procedures without Cowl Top Cover

EFS006DI

When performingthe procedure after removingcowl top cover,cover

the lower end of windshield with urethane, etc.

B

C

D

E

BR

G

H

I

PIIB3706J

Precautions for Brake System

● Clean dust on front brake and rear brake with a vacuum dust collector. Do not blow with compressed air.

● Recommended fluid is brake fluid “DOT 3” or “DOT 4”.

● Never reuse drained brake fluid.

● Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed

EFS002FW

on painted areas, wash it away with water immediately.

● To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use new brake fluid.

● Never use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

● Use a flare nut wrench when removing flare nuts, and use a flare

nut torque wrench when tightening flare nuts.

● Always tighten brake lines to the specified torque when install-

ing.

● Before working, turn ignition switch OFF and disconnect electri-

cal connector of ABS actuator and electric unit (control unit) or

the battery cables.

● Burnish the brake contact surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage.

Refer to BR-26, "

BRAKE BURNISHING PROCEDURE" .

SBR820BA

J

K

L

M

BR-3

PREPARATION

PREPARATION

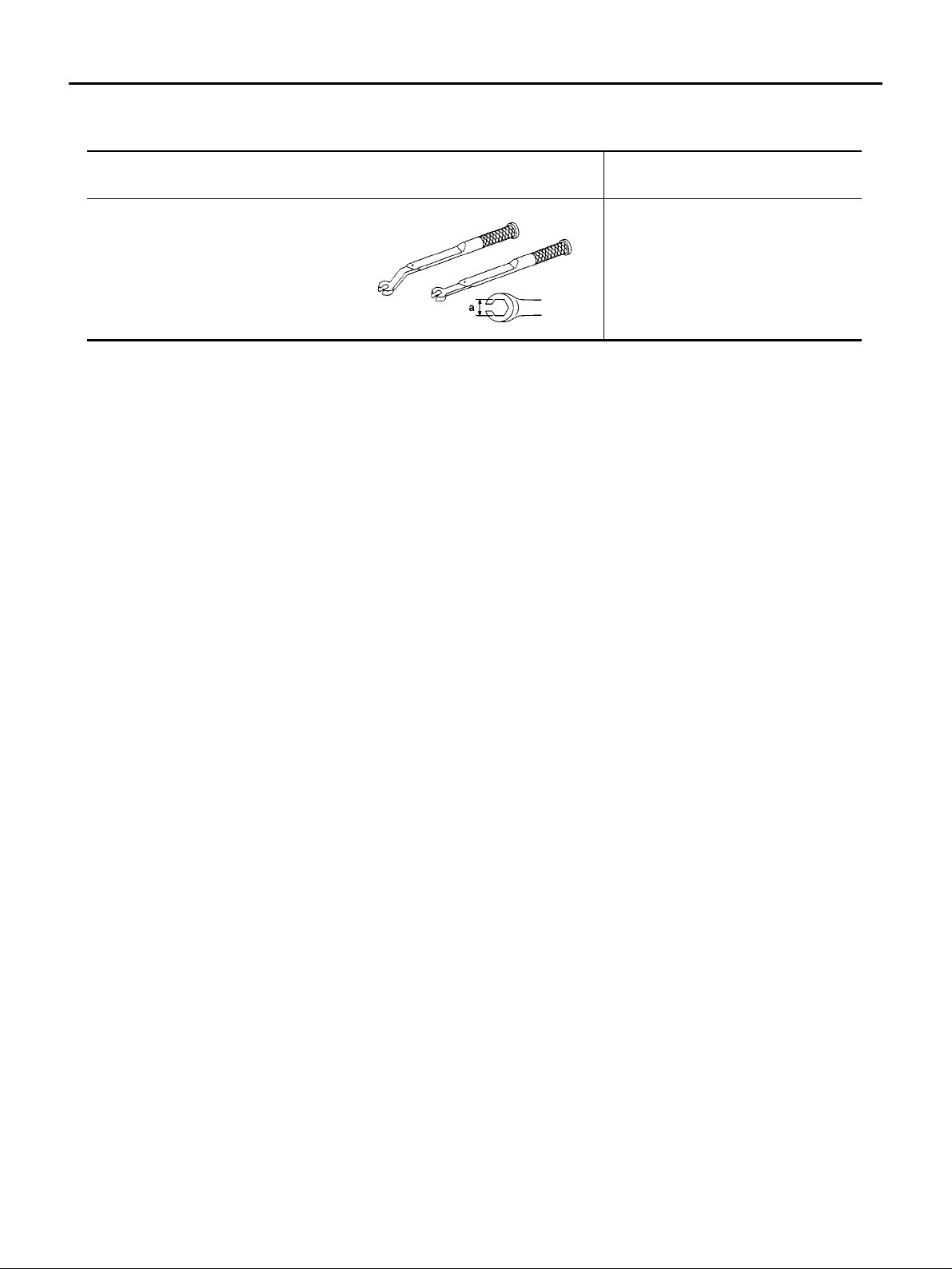

Special Service Tools

Tool number

Tool name

GG94310000

Flare nut torquewrench

a: 10 mm (0.39 in)

PFP:00002

EFS002G1

Description

Removing and installing each brake

piping

NT406

BR-4

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING PFP:00003

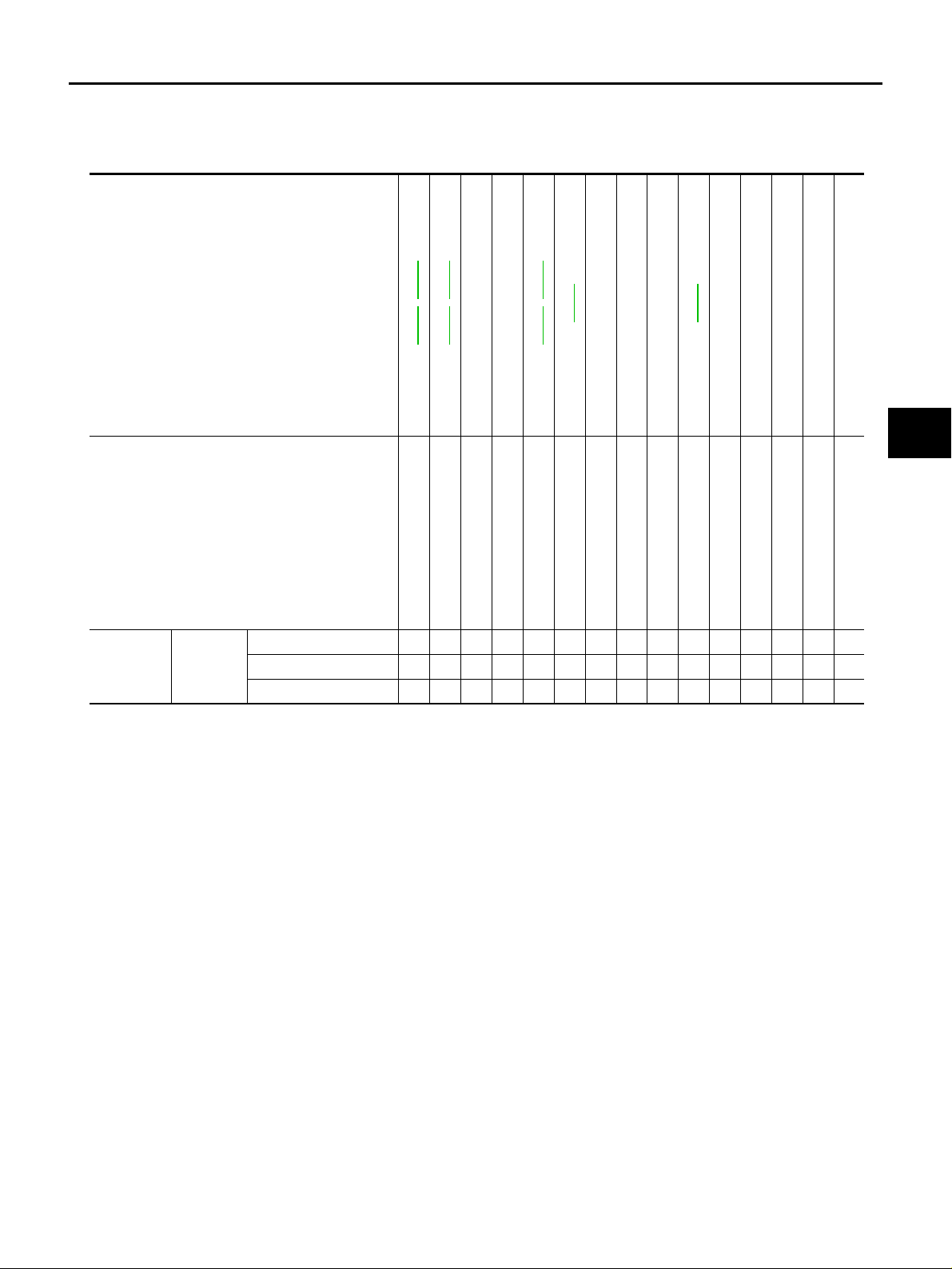

NVH Troubleshooting Chart

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

EFS002IV

A

B

C

Reference page

Possible cause and

SUSPECTED PARTS

Symptom BRAKE

X: Applicable

—

, BR-29

BR-25

—

—

BR-25

—

BR-26

D

—

BR-21, BR-28

BR-21, BR-28

E

NVH in FAX, RAX and FSU, RSU section

NVH in WT section

NVH in WT section

NVH in FAX section

NVH in PS section

BR

G

H

Pads or linings - damaged

Pads or linings - uneven wear

Return spring damaged

Rotorordrumimbalance

Rotorordrumdamage

Rotor runout

Rotorordrumdeformation

Rotorordrumdeflection

Rotorordrumrust

Rotor thickness variation

AXLE AND SUSPENSION

TYRES

ROAD WHEEL

DRIVESHAFT

STEERING

Noise ××× ×××

Shake ××××

Shimmy, Judder ЧЧЧЧЧЧЧЧЧЧ ×

×

×

×

×

I

J

K

BR-5

L

M

BRAKE PEDAL

BRAKE PEDAL

Inspection and Adjustment

PLAY AND CLEARANCE BETWEEN BRAKE PEDAL AND FLOOR PANEL WITH PEDAL DEPRESSED.

● Check the pedal play.

● Check the brake pedal free height from the dash floor panel.

● If value is outside the standard, make an adjustment to the fol-

lowing dimension.

PFP:46501

EFS002G6

SFIA1116E

LHD

H1 Brake pedal height

RHD

Depressed pedal height

H

2

[under a force of 490 N (50 kg, 110 lb) with the engine running]

C Clearance between the stopper rubber and the threaded end of stop lamp switch. 0.74 - 1.96 mm (0.029 - 0.077 in)

A Pedal play 3 - 11 mm (0.12 - 0.43 in)

M/T models 161 - 171 mm (6.34 - 6.73 in)

A/T models 171 - 181 mm (6.73 - 7.13 in)

M/T models 156 - 166 mm (6.14 - 6.54 in)

A/T models 166 - 176 mm (6.54 - 6.93 in)

M/T models 80 mm (3.15 in) or more

A/T models 85 mm (3.35 in) or more

BR-6

BRAKE PEDAL

Removal and Installation

EFS002G7

COMPONENTS

SFIA1114E

1. Snap pin 2. Stop lamp switch 3. Clip

4. Brake pedal assembly 5. Clevis pin

CAUTION:

● Be careful not to deform brake tube.

● Do not strike the brake pedal assembly against anything during removal and installation.

REMOVAL

1. Remove instrument lower driver panel. Refer to IP-4, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove accelerator pedal harness clip and connector.

3. Disconnect stop lamp switch harness connector and remove stop lamp switch from the pedal assembly.

(Remove it by rotating the switch by 45°)

4. Remove snap pin and clevis pin from the brake booster clevis.

5. Remove pedal assembly mounting nut and then remove pedal assembly from the vehicle while moving

the master cylinder and brake booster to the engine room side while being careful not to deform the brake

tube.

6. Remove accelerator pedal from the brake pedal.

A

B

C

D

E

BR

G

H

I

J

K

L

BR-7

M

SFIA1115E

BRAKE PEDAL

INSPECTION AFTER REMOVAL

● Check brake pedal for bend, damage, and cracks on the welded parts. Replace applicable part if any non-

standard condition is detected.

INSTALLATION

● For information regarding the tightening torque, refer to BR-7, "COMPONENTS" . Install in the reverse

order of removal.

● After installing brake pedal assembly to the vehicle, adjust brake pedal.

BR-8

BRAKE FLUID

BRAKE FLUID PFP:KN100

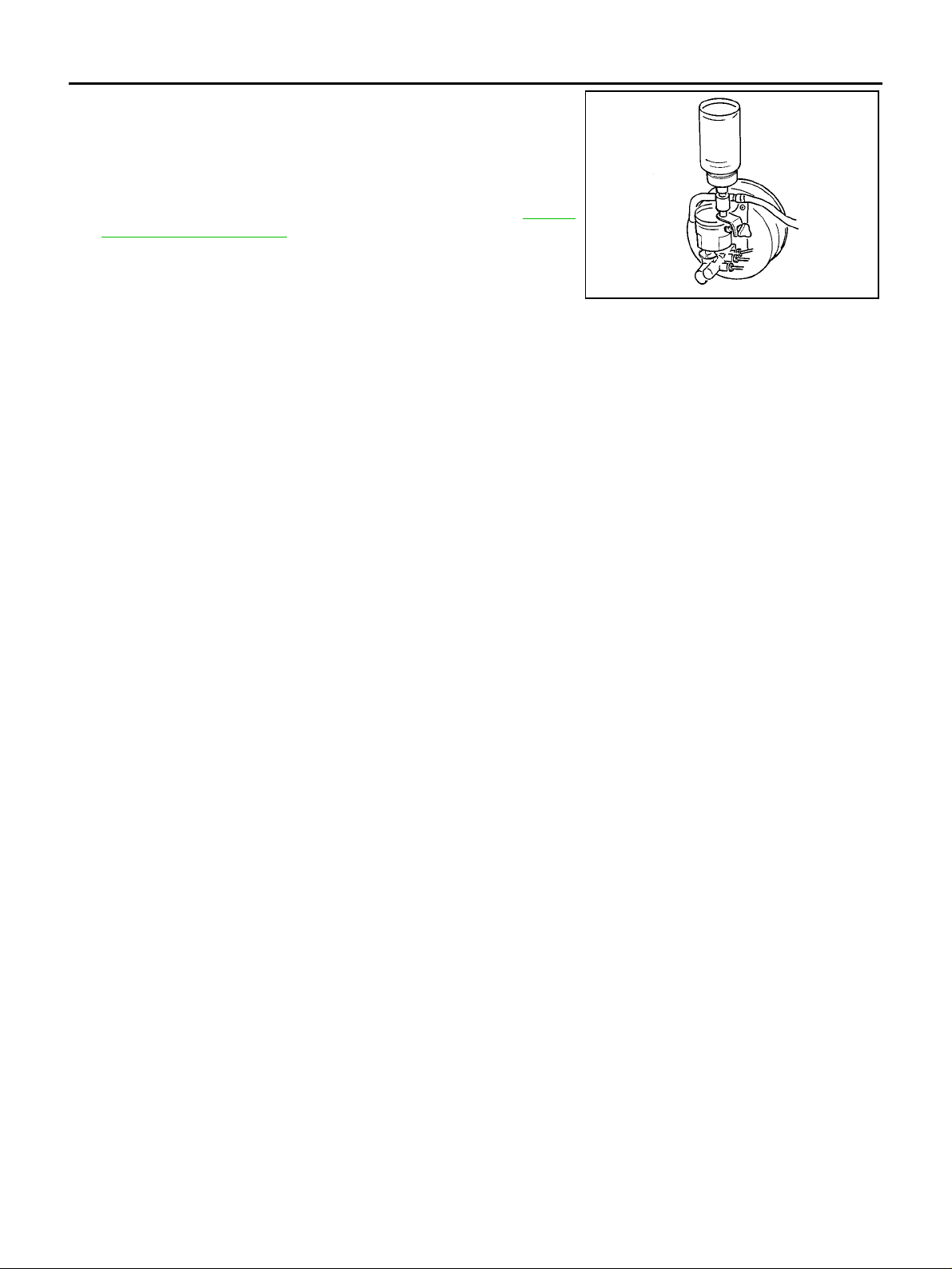

Level Inspection

● Make sure the fluid level in the reservoir tank is within the stan-

dard (between MAX and MIN lines).

● Visually check around the reservoir tank for fluid leaks.

● If fluid level is excessively low, check brake system for leaks.

● If warning lamp remains illuminated after parking lever is

released, check brake system for fluid leakage.

Checking Brake Line

CAUTION:

If leakage occurs around joints, retighten or, if necessary, replace damaged parts.

1. Check brake line (tubes and hoses) for cracks, deterioration or

other damage. Replace any damaged parts.

2. Check for oil leakage by fully depressing brake pedal while

engine is running.

EFS002G8

SFIA0527J

EFS002G9

A

B

C

D

E

BR

G

SBR389C

Drain and Refill

EFS002GA

CAUTION:

● Refill with new brake fluid “DOT 3” or “DOT 4”.

● Do not mix different types of brake fluid (DOT 3, DOT 4).

● Never reuse drained brake fluid.

● Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

1. Turn ignition switch OFF, and remove ABS actuator connector.

2. Connect a vinyl tube to the air bleeder.

3. Drain brake fluid gradually from the air bleeder of each wheel

while depressing the brake pedal.

H

I

J

K

L

M

BR-9

BRA0007D

BRAKE FLUID

4. Make sure that there is no foreign material in the reservoir tank,

and refill with new brake fluid.

5. Rest foot on brake pedal. Loosen air bleeder. Slowly depress

pedal until it stops. Tighten air bleeder. Release brake pedal.

Repeat this process a few times, then pause to add new brake

fluid to master cylinder. Continue until new brake fluid flows out.

For information regarding air bleeding work, refer to BR-10,

"Bleeding Brake System" .

BRA0006D

Bleeding Brake System

EFS002GB

CAUTION:

● While bleeding, pay attention to master cylinder fluid level.

● Fill reservoir with new brake fluid “DOT 3” or “DOT 4”

● Do not mix different types of brake fluid (DOT 3, DOT 4)

1. Turn ignition switch OFF, and remove A BS actuator connector.

2. Connect a vinyl tube to t he rear left wheel air bleeder.

3. Fully depress brake pedal 4 to 5 times.

4. With brake pedal depressed, loosen air bleeder and bleed air, and then quickly tighten the air bleeder.

5. Repeat steps 3 - 4 until all of the air is out of the brake line.

6. Tighten the air bleeder to the specified torque.

Tightening torque : 10 N·m (1.0 kg-m, 7 ft-lb)

7. Repeat steps 2 to 6. Occasionally refill master cylinder reservoir tank with brake fluid in order to keep it at

least half-full. Bleed air in the following order: front RH wheel, RH rear wheel, and front LH wheel.

BR-10

BRAKE PIPING AND HOSE

BRAKE PIPING AND HOSE PFP:46210

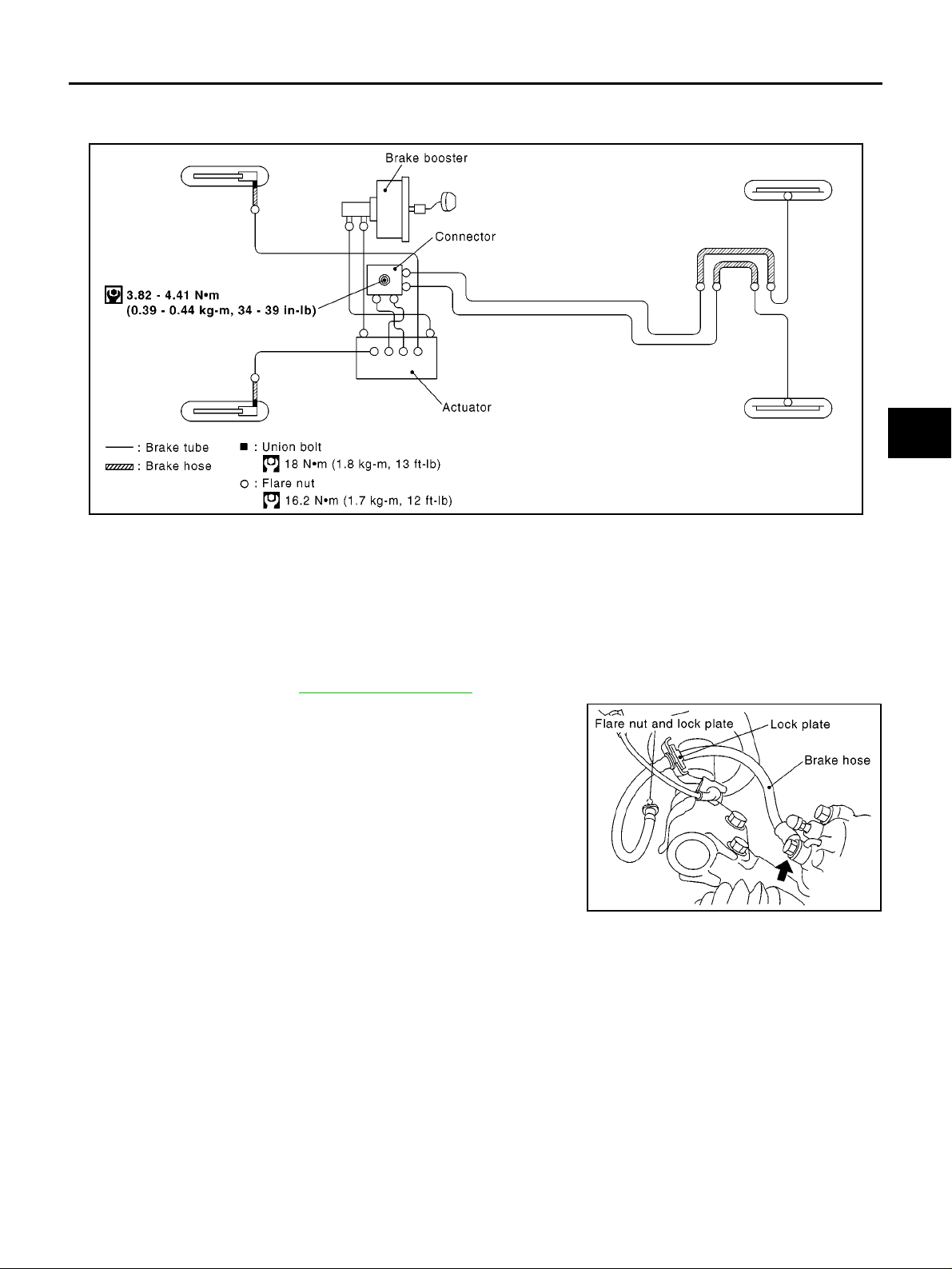

Hydraulic Circuit

EFS002GC

A

B

C

D

E

BR

MFIB9017E

Removal and Installation of Front Brake Piping and Brake Hose

EFS002GD

REMOVAL

CAUTION:

● Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

● All hose must be free from excessive bending, twisting and pulling.

● Cover brake fluid line connections to prevent dust and other foreign material from entering.

1. Drain brake fluid. Refer to BR-9, "

2. Using a flare nut wrench, remove the flare nutso f the brake tube

and disconnect the brake tube from the brake hose.

3. Remove brake caliper union bolts and disconnect caliper

assembly from brake hose.

4. First remove the lock plate from the mounting positions of brake

tubes and struts, and then brake hose.

Drain and Refill" .

SFIA1118E

G

H

I

J

K

L

M

BR-11

Loading...

Loading...