Page 1

Manual Title

Additional Information

be certain.

AHX800 High Elongation Extensometer

Product Manual

100-231-450 A

Page 2

Copyright information © 2011 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademarks and MTS Criterion and MTS Insight are

trademarks of MTS Systems Corporation within the United States. These

trademarks may be protected in other countries.

Proprietary information Teflon is a registered trademark of E. I. du Pont de Nemours and Company.

Software use and license is governed by MTS’ End User License Agreement

which defines all rights retained by MTS and granted to the End User. All

Software is proprietary, confidential, and owned by MTS Systems Corporation

and cannot be copied, reproduced, disassembled, decompiled, reverse

engineered, or distributed without express written consent of MTS.

Software validation and

verification

Publication information

MTS software is developed using established quality practices in accordance

with the requirements detailed in the ISO 9001 standards. Because MTSauthored software is delivered in binary format, it is not user accessible. This

software will not change over time. Many releases are written to be backwards

compatible, creating another form of verification.

The status and validity of MTS’ operating software is also checked during

system verification and routine calibration of MTS hardware. These controlled

calibration processes compare the final test results after statistical analysis

against the predicted response of the calibration standards. With these established

methods, MTS assures its customers that MTS products meet MTS’ exacting

quality standards when initially installed and will continue to perform as intended

over time.

MANUAL PART NUMBER PUBLICATION DATE

100-231-450 A January 2011

100-231-450 A

* Change to Gage Length.

*

May 3013

2

AHX800 High Elongation Extensometer Product Manual

Page 3

Contents

Introduction 5

Functional Description 6

Specifications 7

Installation 9

Unpacking the Extensometer 10

Installing the AHX800 onto an MTS Criterion Frame 11

Operation 15

Setting up a Test 16

Running a Test 18

Maintenance 19

Replacing Spare Parts 20

AHX800 High Elongation Extensometer Product Manual Contents

3

Page 4

Page 5

Introduction

Contents Functional Description 6

The AHX800 High Elongation Extensometer is designed for testing high

elongation applications of elastomer materials such as latex, silicone, rubber,

polyurethane, and other similar materials. It is ideally suited for testing dog-bone

elastomer specimens per ASTM D412 and ISO 37 specifications.

Specifications 7

AHX800 High Elongation Extensometer

AHX800 High Elongation Extensometer Product Manual Introduction

5

Page 6

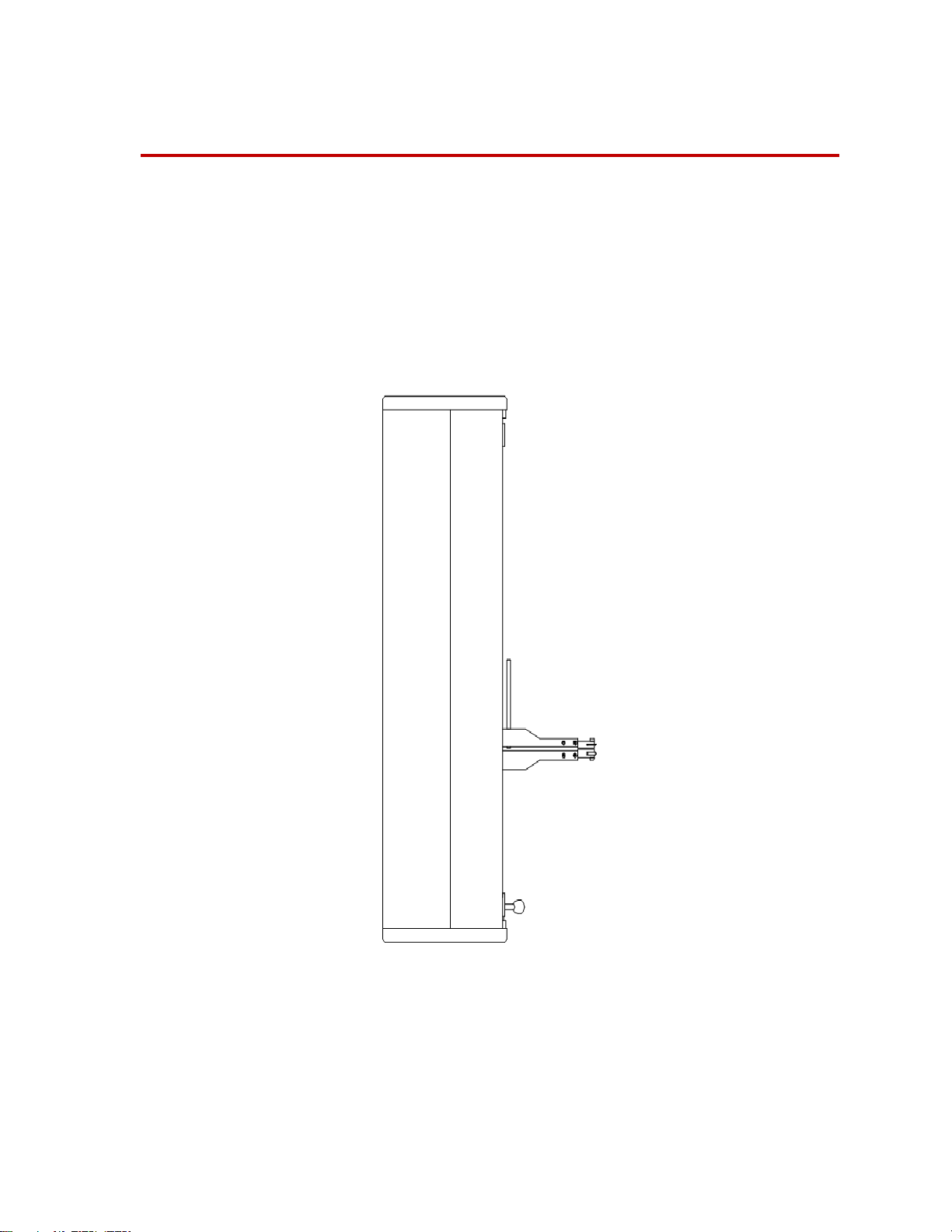

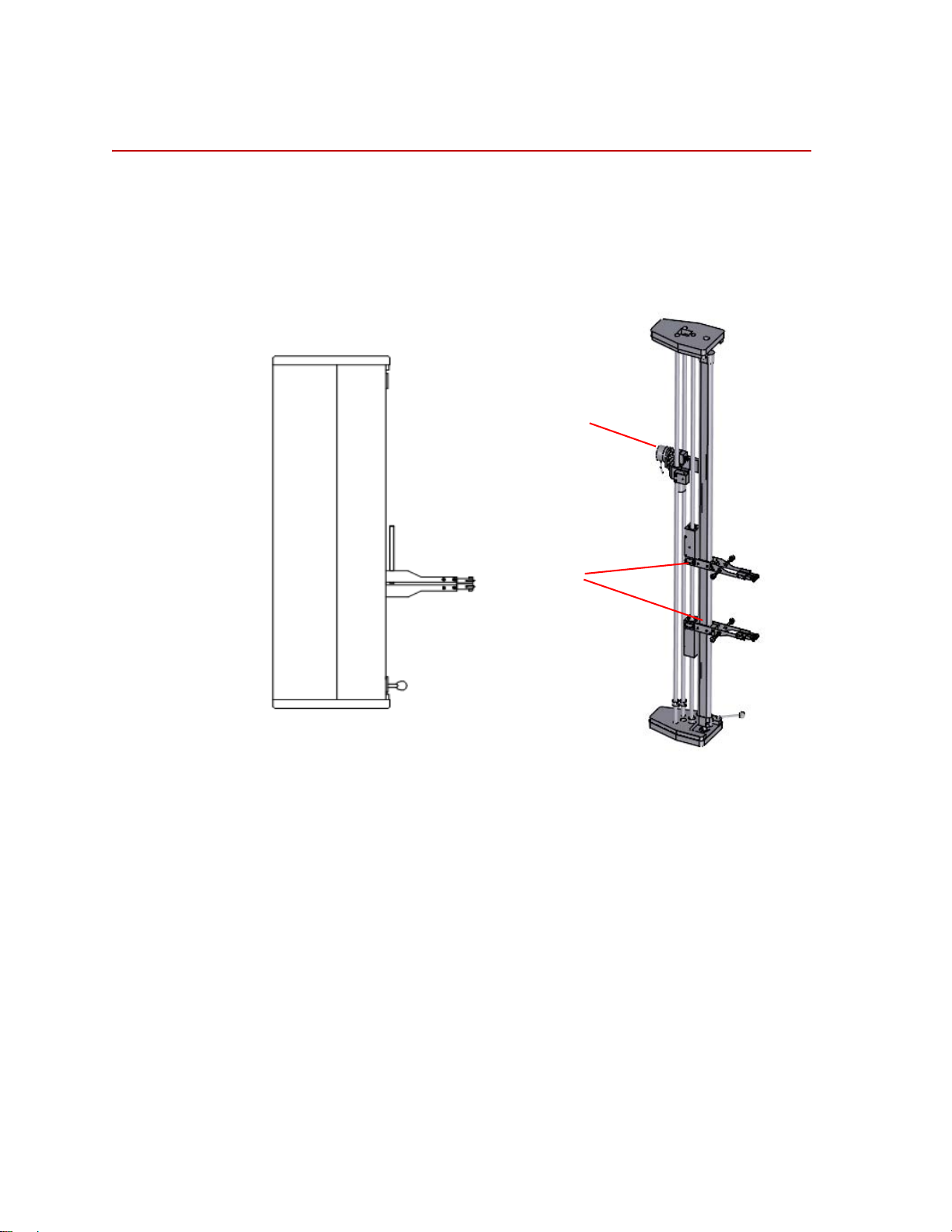

Functional Description

Arms

Optical Encoder

Functional Description

The AHX800 High Elongation Extensometer is designed to operate at

temperatures from 5 to 40°C. The key part of the extensometer is an optical

encoder. The movement of the extensometer arms makes the optical encoder

rotate. The encoder send pulses to a circuit where the pulses are converted for use

by the controller.

6

Introduction

Frame Assembly (all other component s)

The two arms of the extensometer are attached to the specimen. A cable/pulley

mechanism allows the arms to track the elongation of the specimen. The cable

movement is detected by an encoder. The encoder sends pulses to a circuit board

that converts the pulses to determine the exact displacement of the extensometer

arms.

The high elongation extensometer can rotate 90° to minimize the required

working space.

AHX800 High Elongation Extensometer Product Manual

Page 7

Specifications

PARAMETER SPECIFICATION

Usable travel 800 mm (31.5 in)

Specifications

Gage lengths

Measurement resolution 0.004 mm (0.00016 in)

Maximum arm opening 40 mm (1.57 in)

Knife edges Flat

Knife attachment method Adjustable mechanical spring

Weight Approximately 9.5 kg (20.9 lb)

Environmental For indoor use only

Temperature

Relative humidity 10 to 85%, noncondensing

Altitude For use at altitudes up to 2000 m (6500 ft)

Supply voltage + 5 V DC, 100 mA

10 - 125 mm (0.375 - 5 in)

Round

Rubber

Sharpened

5 to 40

°C

Conforms to European CE Directives

AHX800 High Elongation Extensometer Product Manual Introduction

7

Page 8

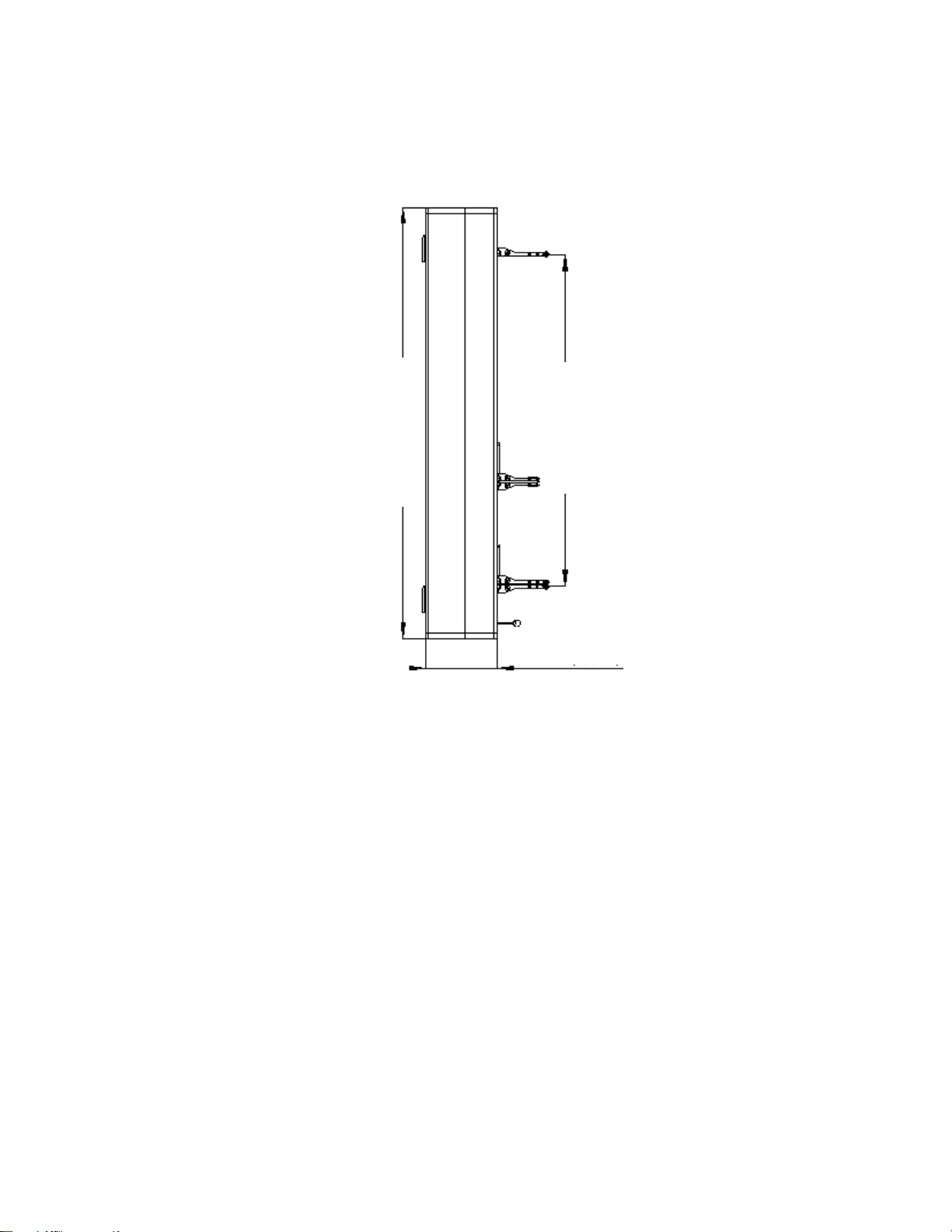

Specifications

1070 mm (42.1 in)

815 mm (32.1 in)

174 mm (6.9 in)

Dimensions

8

Introduction

AHX800 High Elongation Extensometer Product Manual

Page 9

Installation

WARNING

WARNING

Contents Unpacking the Extensometer 10

This section describes how to install the AHX800 High Elongation

Extensometer.

Installing the AHX800 onto an MTS Criterion Frame 11

The following hazards apply to all the installation procedures.

The extensometer electronics are sensitive to making electrical connections

with electrical power turned on.

Making electrical connections with power applied can cause damage to the

extensometer and/or other electronics.

Be sure electrical power is removed until instructed to turn it on.

Transporting the high

elongation

extensometer

Installation will require you to work with the extensometer.

The high elongation extensometer's arm and guide rod are easily damaged.

Handle the high elongation extensometer by its chassis.

Before transporting the high elongation extensometer, do the following:

• Use the two clamp screws to lock the arms in the bottom position.

• Set the L0 gage length stop in its lowermost position.

• Lock the carriage in its uppermost position with the screw in the red ring.

Do not forget to loosen the locking screws before attempting to use the high

elongation extensometer. See “Unpacking the Extensometer” on page 10.

AHX800 High Elongation Extensometer Product Manual Installation

9

Page 10

Unpacking the Extensometer

Collar Clamp

Collar Clamp

Unpacking the Extensometer

1. Unpack the high elongation extensometer and place it upright on a flat

surface.

2. Loosen the two locknuts on the right-side cover of the high elongation

extensometer, and then remove the right-side cover.

3. Unscrew the collar clamp on the bottom of the optical encoder assembly and

slide it to the bottom of the shaft.

4. Loosen the collar clamp on the top of the upper arm assembly , and slide it to

the top of the shaft and tighten in place. Loosen the collar clamp on the

bottom of the lower arm assembly and let it slide down to the bottom of the

shaft. The arms should freely slide from bottom to top.

10

Installation

AHX800 High Elongation Extensometer Product Manual

Page 11

Installing the AHX800 onto an MTS Criterion Frame

Lower Test Area Assembly Diagram

Round Axis

Inner Hexagon

Screw

Pin

Compression Spring

Cantilever

Hang Pin

Extensometer

Installing the AHX800 onto an MTS Criterion Frame

1. Lower Test Area Installation

A. The cantilever varies from different models; the basic shape is shown

as above.

B. Align the round axis and hang pin in the cantilever with the center hole

and the middle hole in the bottom plate of the extensometer.

C. Mount the extensometer to the cantilever and make them fit with each

other.

D. Rotate the extensometer; adjust the mounting angle of extensometer

and the frame.

E. Insert the pin, compression spring, and inner hexagon screw to lock the

cantilever and extensometer.

AHX800 High Elongation Extensometer Product Manual Installation

11

Page 12

Installing the AHX800 onto an MTS Criterion Frame

Upper Test Area Assembly Diagram

Round Axis

Cantilever

Extensometer

Hang Pin

Inner Hexagon

Screw

Pin

Compression

Spring

Top Plate

2. Upper Test Area Installation

A. The cantilever varies from different models; the basic shape is shown

as above.

B. Align the round axis and hang pin in the cantilever with the center hole

and the middle hole in the top plate of the extensometer.

C. Mount the extensometer to the cantilever; rotate the angle to make the

hang pin hitch the extensometer.

D. Adjust the mounting angle of the extensometer and frame.

E. Insert the pin, compression spring, and inner hexagon screw to lock the

extensometer and the cantilever.

12

Installation

AHX800 High Elongation Extensometer Product Manual

Page 13

Installing the AHX800 onto an MTS Criterion Frame

3. Connect the cable between the AHX800 board and the MTS Criterion

controller; one end of the cable is an RJ45 and the other end is a 15 pin D

connector.

AHX800 High Elongation Extensometer Product Manual Installation

13

Page 14

Page 15

Operation

Knife Edges

Upper Arm

Lower Arm

Adjustment

Rod Screw

Adjustment Rod

Knurled Knob

Contents Setting up a Test 16

This section describes how to use the AHX800 High Elongation Extensometer.

Running a Test 18

Component

identification

The following figure identifies the components referenced in the following

procedures.

AHX800 High Elongation Extensometer Product Manual Operation

15

Page 16

Setting up a Test

Knife Edges

Setting up a Test

To set up a test for a specimen:

1. Select a knife edge.

2. Adjust the gage length.

Choose a knife edge based on the type of specimen which will be tested.

The nature of the specimen material (surface quality, thickness, and so on.)

determines the type of knife edge to use.

The knife edges are secured with screws to the upper and lower arms.

A. Loosen the adjustment rod screw.

B. Place the appropriate wedge (desired gage length) between the knife

edges.

C. Gently press the knife edges together.

D. Tighten the adjustment rod screw.

16

Operation

3. Set the automatic return.

A. Set the arms in the desired position.

B. Loosen the locking screw on the finger holder (which is mounted to the

crosshead).

C. Adjust the crosshead so that the specimen grips are in the proper

position to hold a specimen.

D. Adjust the finger until it touches the upper arm.

E. Tighten the locking screw.

AHX800 High Elongation Extensometer Product Manual

Page 17

Setting up a Test

WARNING

4. Adjust the contact to the specimen.

The amount of clamping force on the specimen can be adjusted with the

knurled knobs of the upper and lower arm. This step must be done after the

specimen is installed. The clamping force should be adjusted when the

specimen type is changed.

Displacement limits on your test system can restrict the actuator movement

to a specified range.

Failure to establish upper and lower limits can damage the extensometer.

After adjusting the extensometer's contact with the specimen, you must adjust the

lower safety switch. The upper and lower switches control the crosshead

displacement at the end of a test according to the finger position.

AHX800 High Elongation Extensometer Product Manual Operation

17

Page 18

Running a Test

Arms Closed Arms Open

Running a Test

Before you start running a test, be sure to complete the procedures in “Setting Up

for a Test”.

1. Ensure the extensometer arms are open.

2. Insert a specimen into the grips.

3. Close the extensometer arms.

4. Perform the test.

5. When the test is complete, open the extensometer arms.

18

Operation

Note The crosshead return can be done with the arm open (the Teflon slide

reduces friction between the arms and the cam). In the case of intensive

testing, it is normal to see a thin layer (white) of Teflon on the cam.

AHX800 High Elongation Extensometer Product Manual

Page 19

Maintenance

This section describes how to maintain the AHX800 High Elongation

Extensometer. The serial number of the extensometer can be viewed at the base

of the right side of the high elongation extensometer chassis.

Routine maintenance Routine maintenance consists of visually inspecting the following:

• Check the surface quality of the knife edges.

• Remove dust and dirt from the assembly.

Cleaning the guide

column

T ake of f the left side of the assembly. Clean the guide column with a soft duster.

It is possible to use a soft tissue moistened with silicone oil to lubricate the guide

column (the silicone oil film should be very thin). Other solvent, cleaners, or

lubricants are not recommended (for example, grease or oil).

The guide column can be damaged when cleaned with cleaners or solvents

others than those recommended.

The use of cleaners, solvents, and other lubricants other than those

recommended can damage the components surface and increase the

friction of the mobile parts.

Use only silicone oil to lubricate the guide column.

AHX800 High Elongation Extensometer Product Manual Maintenance

19

Page 20

Replacing Spare Parts

Teflon Slide

Clamping

Force Spring

Leaf Arm

High Energy

Spring

Component Identification

Replacing Spare Parts

The topics on the following pages describe how to replace the spare parts. See the

following figure for component identification.

Knife

Knife edges 1. Remove the screw securing a knife edge.

2. Replace the old knife edge with a new one.

3. Secure the knife edge with the screw.

4. Repeat this procedure for all the knife edges.

Leaf arm 1. Remove the knurled knob.

2. Remove the screws securing the rear of the leaf arm.

3. Transfer the components from the old arm to the new one.

4. Loosely attach the leaf arm to the block, and screw the knurled knob back on.

5. Adjust the arm so that it is parallel with the other arms and tighten the screws.

Teflon slide 1. Remove the two screws securing the Teflon slide and replace it.

20

Maintenance

AHX800 High Elongation Extensometer Product Manual

Page 21

2. Tighten the two screws to secure the Teflon slide in place.

Clamping force spring 1. Unscrew the knurled knob until it is off the shaft.

2. Replace the old spring with the new one.

3. Screw the knurled knob back on the shaft.

High energy spring 1. Remove the screws holding the knife edge assembly.

2. Replace the spring (do not lose the small piston).

3. Install the new spring behind the small piston.

4. Install the knife edge assembly.

Replacing Spare Parts

AHX800 High Elongation Extensometer Product Manual Maintenance

21

Page 22

Page 23

Page 24

m

MTS Systems Corporation

http://www.mts.com/en/Global/index.asp

ISO 9001 Certified QMS

Loading...

Loading...