Page 1

m

be certain.

Advantage™ Wedge Action Grips

Product Information

10 kN

30 kN

50 kN

100 kN

150 kN

300 kN

015-200-202 F

Page 2

Copyright information © 1997–2002, 2008 MTS Systems Corporation. All rights reserved.

Trademark information MTS and Advantage are registered trademarks of MTS Systems Corporation

within the United States. These trademarks may be protected in other countries.

Nikal is a registered trademark of DuPont Company.

Publication information

Manual Part Number Publication Date

152002-01A July 1997

152002-02A July 1998

015-200-202 B April 1999

015-200-202 C December 2000

015-200-202 D August 2001

015-200-202 E October 2002

015-200-202 F March 2008

2

Manual Template 4.3

Page 3

Contents

Technical Support 5

How to Get Technical Support 5

Before You Contact MTS 5

If You Contact MTS by Phone 7

Problem Submittal Form in MTS Manuals 8

Preface 9

Before You Begin 9

Conventions 10

Documentation Conventions 10

Introduction 13

MTS Advantage Wedge Action Grip Functional Description 15

Grip Environment 16

MTS Advantage Wedge Action Grips Specifications 17

MTS Advantage Wedge Action Grips Dimensions 18

MTS Advantage Wedge Action Grips—Flat Specimen Wedges 19

MTS Advantage Wedge Action Grips—Round Specimen Wedges 20

Safety Information 21

Hazard Placard Placement 21

MTS Advantage™ Wedge Action Grips

3

Page 4

Installation 23

About Grip Installation 23

Install the Grips 24

Operation 25

Changing Wedges 25

Installing a Specimen 27

Maintenance 31

4

MTS Advantage™ Wedge Action Grips

Page 5

Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

MTS web site

www.mts.com

E-mail techsupport@mts.com

Telephone MTS Call Center 800-328-2255

Fax 952-937-4515

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes MTS software, look

for online help and README files that contain additional product information.

If you cannot find answers to your technical questions from these sources, you

can use the internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact MTS in one of the

following ways.

The MTS web site gives you access to our technical support staff by means of a

Technical Support link:

www.mts.com > Contact Us > Service & Technical Support

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Please include “Technical Support” in the subject line.

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

Manual Name Technical Support

The site number contains your company number and identifies your equipmen t

type (material testing, simulation, and so forth). The number is usually written on

a label on your MTS equipment before the system leaves MTS. If you do not

have or do not know your MTS site number, contact your MTS sales engineer.

Example site number: 571167

5

Page 6

When you have more than one MTS system, the system job number identifies

which system you are calling about. You can find your job number in the papers

sent to you when you ordered your system.

Example system number: US1.42460

Know information from

prior technical

If you have contacted MTS about this problem before, we can recall your file.

You will need to tell us the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem you are experiencing and know the answers to the

following questions:

• How long and how often has the problem been occurring?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the model numbers of the suspect equipment?

• What model controller are you using (if applicable)?

• What test configuration are you using?

Know relevant

computer information

If you are experiencing a computer problem, have the following information

available:

• Manufacturer’s name and model number

Technical Supp ort

6

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive in which the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

Manual Name

Page 7

Know relevant

For software application problems, have the following information available:

software information

• The software application’s name, version number, build number, and if

available, software patch number. This information is displayed briefly

when you launch the application, and can typically be found in the “About”

selection in the “Help” menu.

• It is also helpful if the names of other non-MTS applications that are

running on your computer, such as anti-virus software, screen savers,

keyboard enhancers, print spoolers, and so forth are known and available.

If You Contact MTS by Phone

Your call will be registered by a Call Center agent if you are calling within the

United States or Canada. Before connecting you with a technical support

specialist, the agent will ask you for your site number, name, company , company

address, and the phone number where you can normally be reached.

If you are calling about an issue that has already been assigned a notification

number, please provide that number. You will be assigned a unique notification

number about any new issue.

Identify system type To assist the Call Center agent with connecting you to the most qualified

technical support specialist available, identify your system as one of the

following types:

• Electromechanical materials test system

• Hydromechanical materials test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

Prepare yourself for troubleshooting while on the phone:

troubleshoot

• Call from a telephone when you are close to the system so that you can try

implementing suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

Manual Name Technical Support

7

Page 8

Write down relevant

Prepare yourself in case we need to call you back:

information

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording

or performance monitoring.

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action

is taken regarding your problem or request. If you have questions about the status

of your problem or have additional information to report, please contact MTS

again and provide your original notification number.

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems you are experiencing

with your MTS software, hardware, manuals, or service which have not been

resolved to your satisfaction through the technical support process. This form

includes check boxes that allow you to indicate the urgency of your problem and

your expectation of an acceptable response time. We guarantee a timely

response—your feedback is important to us.

The Problem Submittal Form can be accessed:

Technical Supp ort

8

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form (electronic form to

be e-mailed to MTS)

Manual Name

Page 9

Preface

Before You Begin

Safety first! Before you attempt to use your MTS product or system, read and understand the

Safety manual and any other safety information provided with your system.

Improper installation, operation, or maintenance of MTS equipment in your test

facility can result in hazardous conditions that can cause severe personal injury or

death and damage to your equipment and specimen. Again, read and understand

the safety information provided with your system before you continue. It is very

important that you remain aware of hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional MTS manuals in paper or

electronic form.

If you have purchased a test system, it may include an MTS System

Documentation CD. This CD contains an electronic copy of the MTS manuals

that pertain to your test system, including hydraulic and mechanical component

manuals, assembly drawings and parts lists, and op eration and preventive

maintenance manuals. Controller and application software manuals are typically

included on the software CD distribution disc(s).

Manual Name Preface

9

Page 10

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions As necessary, hazard notices may be embedded in this manual. These notices

contain safety information that is specific to the task to be performed. Hazard

notices immediately precede the step or procedure that may lead to an associated

hazard. Read all hazard notices carefully and follow the directions that are given.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

10

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury, equipment damage, or

endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Preface

Manual Name

Page 11

Conventions

Illustrations Illustrations appear in this manual to clarify text. It is important for you to be

aware that these illustrations are examples only and do not necessarily represent

your actual system configuration, test application, or software.

Electronic manual

conventions

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

Manual Name Preface

11

Page 12

Conventions

12

Preface

Manual Name

Page 13

Introduction

Contents MTS Advantage Wedge Action Grip Functional Description 15

The MTS Advantage W edge Action Grips hold a test specimen in a load unit for

static tension testing. The grips can accommodate flat or round specimens.

Grip Environment 16

MTS Advantage Wedge Action Grips Specifications 17

MTS Advantage Wedge Action Grips Dimensions 18

MTS Advantage Wedge Action Grips—Flat Specimen Wedges 19

Manual Name Introduction

13

Page 14

MTS Advantage Wedge Action Grips—Round Specimen Wed ges 20

What you need to

Introduction

14

know

Mts Advantage Wedge Grips

MTS Systems Corporation assumes that you know how to use your controller.

See the appropriate manual for information about performing any controllerrelated step in this manual’s procedures. You are expected to know how to:

• Turn on power (electrical or hydraulic) to the load frame

(electromechanical) or load unit (servohydraulic).

• Adjust the crosshead and/or actuator position.

Manual Name

Page 15

MTS Advantage Wedge Action Grip Functional Description

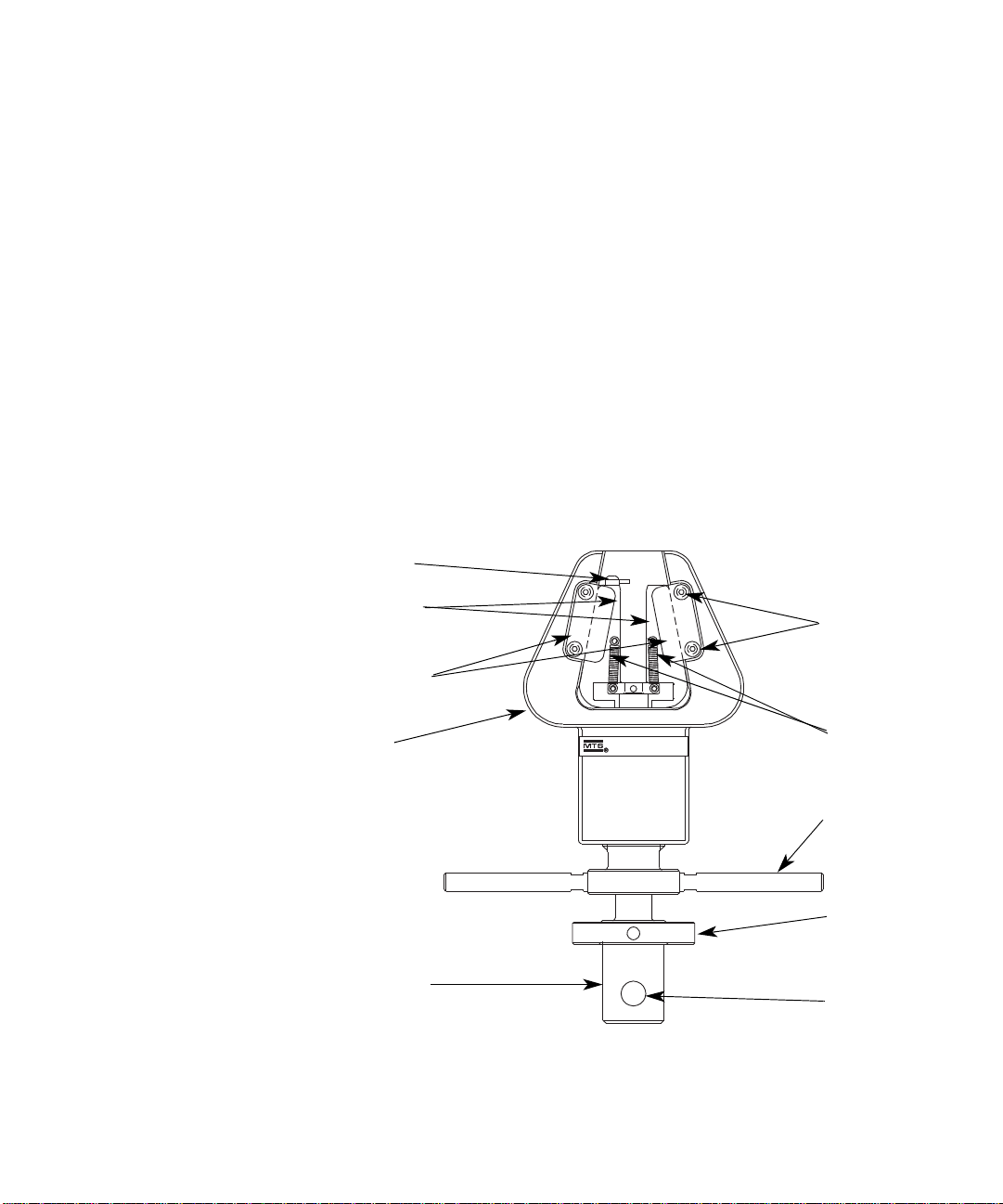

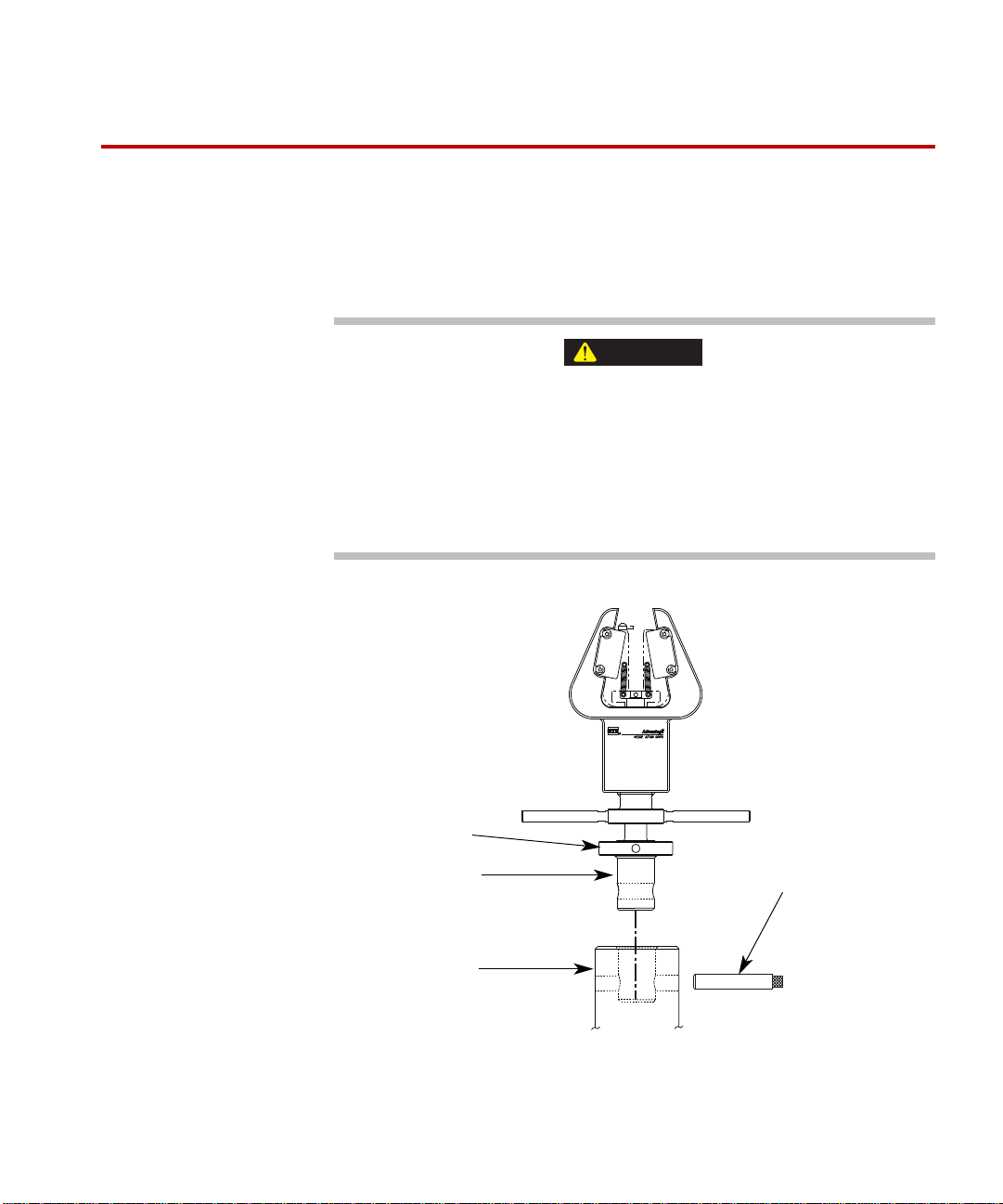

Retaining

Guides

Specimen

Guide

Grip

Body

Wedges

Retaining

Guide

Screws

Wedge

Springs

Grip

Handle

Locking

Collar

Mounting

Pin

Hole for

Mounting

Dowel

The MTS Advantage Wedge Action Grips are designed for static tension testing.

The grips are mounted in a load frame (also called a load unit) by attaching the

male mounting pin to a female mounting adapter and securing them with a

mounting dowel. A specimen can be installed either from the side of the grip or

from the top of the grip.

The grip handles are turned to apply an initial gripping force. The design of the

grips holds the wedges stationary while the specimen is being clamped. Once the

specimen is secured into both grips, a tensile load is applied to the specimen by

the test system. The tensile load pulls the specimen and wedges tighter into the

angled grip body, which increases the gripping force to prevent specimen

slippage during testing.

Two types of wedges are available for use with these grips: flat wedges for use

with flat specimens and vee-notched wedges for use with round specimens. Both

flat and vee-notched wedges are finished with a serrated texture to increase

gripping force.

Manual Name Introduction

15

Page 16

Grip Environment

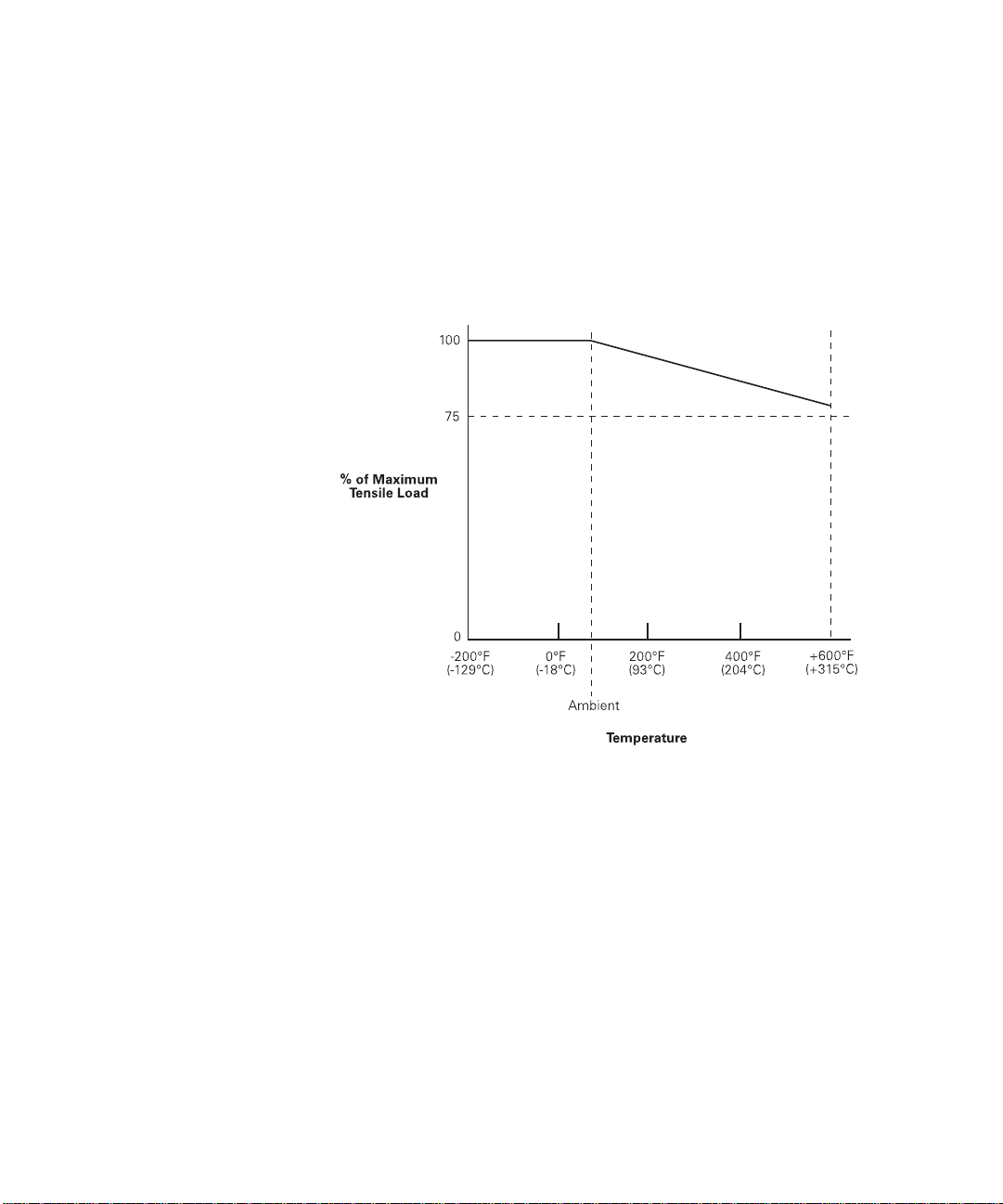

The grips can be used at temperatures from -129 °C to +315 °C

(-200 °F to +600 °F). For testing at temperatures other than ambient conditions,

the grips can be mounted inside an environmental chamber. When using the grips

above ambient temperatures, the maximum tensile load must be reduced

according to the figure below. Also, if the grips are being used above +260 °C

(+500 °F), the stainless steel springs should be removed or they might have to be

replaced periodically.

16

Introduction

Manual Name

Page 17

MTS Advantage Wedge Action Grips Specifications

Grip Ratings

ODEL MONOTONIC TENSION CAPACITY WEIGHT (PER GRIP)MAXIMUM PRELOAD TORQUE

M

10 kN 10 kN (2 kip) 4.5 kg (10 lb) 11.3 N·m (100 in·lb)

30 kN 30 kN (6.7 kip) 5.5 kg (12 lb) 11.3 N·m (100 in·lb)

50 kN 50 kN (11 kip) 7 kg (15 lb) 15 N·m (130 in·lb)

100 kN 100 kN (22 kip) 15 kg (33 lb) 45 N·m (450 in·lb)

150 kN 150 kN (33 kip) 19.6 kg (43 lb) 68 N·m (600 in·lb)

300 kN 300 kN (67 kip) 53.5 kg (118 lb) 90 N·m (800 in·lb)

Specimen installation Some of the grips have a closed back which requires specimens to be installed

from the front of the grips. Some grips have an open back which allows

specimens to be installed from the front or the back of the grip.

Specimen Installation Access Locations

ODEL INSTALLATION

M

10 kN

30 kN

50 kN

100 kN

150 kN

300 kN

Manual Name Introduction

Front and Back

Front Only

Front Only

Front Only

Front Only

Front and Back

17

Page 18

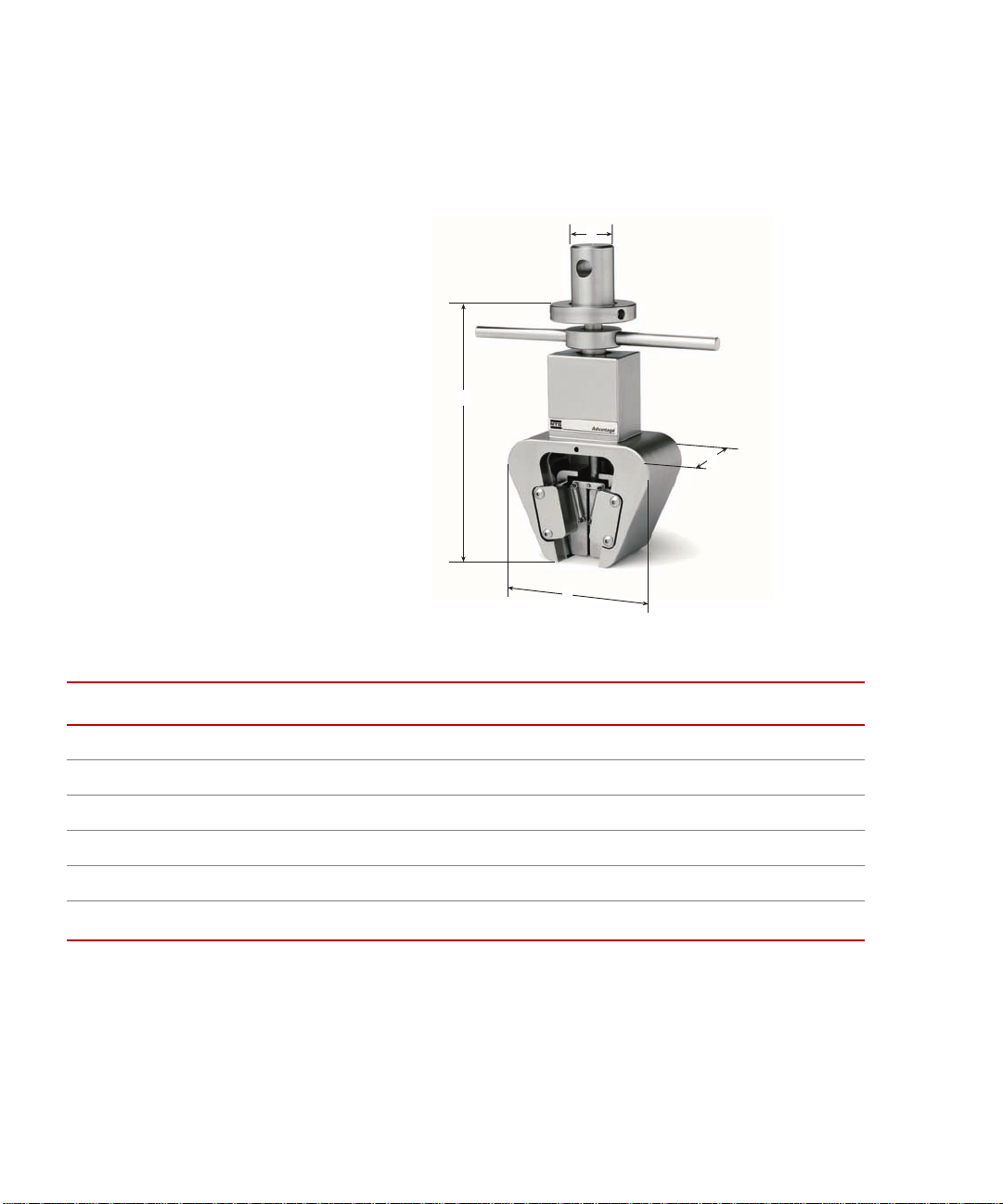

MTS Advantage Wedge Action Grips Dimensions

AA

BB

CC

DD

The dimensions shown in the figure correspond with the grip dimensions in the

following table.

Grip Dimensions

ODEL A B C

M

10 kN 172 mm (6.8 in) 132 mm (5.2 in) 62 mm (2.4 in) 1-1/4 in

30 kN 206 mm (8.1 in) 114 mm (4.4 in) 64 mm (2.5 in) 1-1/4 in

50 kN 210 mm (8.3 in) 147 mm (5.8 in) 63 mm (2.4 in) 1-1/4 in

100 kN 215 mm (8.5 in) 192 mm (7.5 in) 93 mm (3.7 in) 1-1/4 in

150 kN 259 mm (10.2 in) 193 mm (7.6 in) 102 mm (4.0 in) 1-1/4 in

300 kN 326 mm (12.8 in) 407 mm (16 in) 102 mm (4.0 in)

* 30 mm and 45 mm pin sizes are available upon request.

† Threaded stud M36 X 2 mm (1-1/2 in 12 UNC).

18

Introduction

*

D

†

Manual Name

Page 19

MTS Advantage Wedge Action Grips—Flat Specimen Wedges

T

Flat Specimen

The flat wedges are available for two force ranges.

10 kN to 50 kN (6 kip to 11 kip) Flat Specimen Wedges

PECIMEN THICKNESS (T) WEDGE WIDTH WEDGE SET

S

MM IN MM IN

0.0 to 7.9 0.00 to 0.31 25.4 1.00 053 140 801

4.06 to 10.92 0.23 to 0.52 25.4 1.00 053 140 802

* The wedge set assembly consists of a matched set of four wedges.

PART NUMBER

*

100 kN to 300 kN (22 kip to 67 kip) Flat Specimen Wedges

PECIMEN THICKNESS (T) WEDGE WIDTH WEDGE SET

S

MM IN MM IN

0.0 to 9.0 0.00 to 0.35 50.8 2.00 053 537 401

6.4 to 16 0.25 to 0.63 50.8 2.00 053 537 402

* The wedge set assembly consists of a matched set of four wedges.

Manual Name Introduction

PART NUMBER

*

19

Page 20

MTS Advantage Wedge Action Grips—Round Specimen Wedges

Round Specimen

D

The vee-notched wedges for round specimens are available for two force ranges.

10 kN to 50 kN (6 kip to 11 kip) Vee-Notched Wedges

PECIMEN DIAMETER (D) WEDGE SET

S

MM IN

PART NUMBER

*

3.0 to 7.9 Side Installation

3.0 to 7.9 Top Installation

7.0 to 9.5 Side Installation

7.0 to 12.7 Top Installation

11.5 to 12.7 Side Installation

11.5 to 16.0 Top Installation

* The wedge set assembly consists of a matched set of four wedges.

0.12 to 0.31 Side Installation

0.12 to 0.31 Top Installation

0.27 to 0.37 Side Installation

0.27 to 0.50 Top Installation

0.45 to 0.50 Side Installation

0.45 to 0.63 Top Installation

053-140-803

053-140-804

053-537-805

100 kN to 300 kN (22 kip to 67 kip) Vee-Notched Wedges

PECIMEN DIAMETER (D) WEDGE SET

S

MM IN

3.2 to 5.8 Side Installation

3.2to 7.6 Top Installation

5 to 10.4 Side Installation

5 to 12.5 Top Installation

12.2 to 15.5 Side Installation

12.2 to 19.5 Top Installation

* The wedge set assembly consists of a matched set of four wedges.

0.12 to 0.23 Side Installation

0.12 to 0.30 Top Installation

0.19 to 0.41 Side Installation

0.19 to 0.49 Top Installation

0.48 to 0.61 Side Installation

0.48 to 0.76 Top Installation

PART NUMBER

053-537-405

053-537-403

053-537-404

*

Introduction

20

Manual Name

Page 21

Safety Information

Hazard Placard Placement

Hazard placards contain specific safety information and are affixed directly to the

system so they are plainly visible.

Each placard describes a system-related hazard. When possible, international

symbols (icons) are used to graphically indicate the type of hazard and the

placard label indicates its severity. In some instances, the placard may contain

text that describes the hazard, the potential result if the hazard is ignored, and

general instructions about how to avoid the hazard.

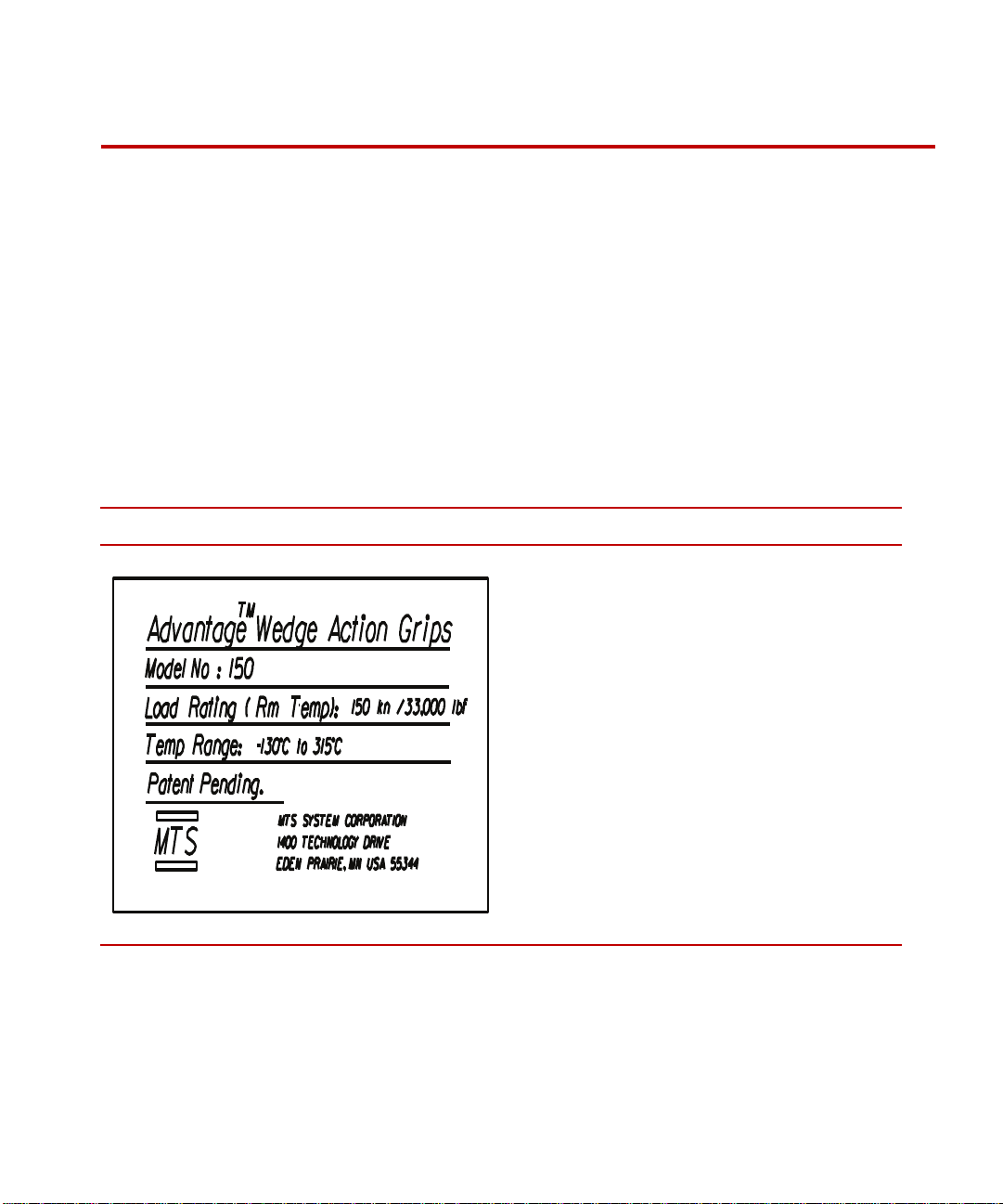

The following label is typically located on the grip.

ABEL DESCRIPTION

L

Grip ID Plate.

Contains the following information:

• Model number

• Load rating

• Temperature range

Manual Name Safety Information

21

Page 22

Safety Information

22

Manual Name

Page 23

Installation

WARNING

Locking

Collar

Mounting

Pin

Mounting

Dowel

Load Frame

Mounting

Adapter

About Grip Installation

This section describes how to install the MTS Advantage Wedge Grips in a load

frame.

Grip Installation is inherently dangerous because it occurs within the crush

zone of the force train. During installation (electrical or servohydraulic)

power is applied to the system because crosshead or actuator movement is

required.

Serious injury and damage to the equipment can occur.

Take every precaution to avoid unexpected crosshead or actuator movement.

Manual Name Installation

Installation Components

23

Page 24

Servohydraulic

adapter

Install the Grips

If you are installing the grips on a servohydraulic load unit, you must install a

load unit mounting adapter on the actuator and on the force transducer.

Servohydraulic installations require the attachment kit (MTS part number 051880-3xx) for the appropriate parts.

1. Turn on the power to the load frame.

2. Adjust the crosshead position as necessary to allow adequate room to install

the grips.

3. Turn the load frame power off.

24

Installation

4. Clean all of the surfaces that will contact each other (such as the mounting

pin and the load frame mounting adapter) and lubricate them with Nikal.

5. Install the grips.

Install the mounting pin into the load frame mounting adapter. Align the

holes of the mounting pin with the load frame mounting adapter and install

the mounting dowel to attach the grip assembly to the load frame. Repeat

this step for the other grip.

Note The 300 kN grip does not use a mounting pin or load frame mounting

adapter. It is threaded into the load frame.

6. When both grips are mounted to the load frame, align the upper and lower

grips to each other and tighten the locking collars to preload the connection.

7. Install the wedges.

Manual Name

Page 25

Operation

Retaining

Guides

Specimen

Guide

Wedges

Retaining

Guide

Screws

Wedge

Springs

Spring Anchor Post

(view rotated 90

°)

Spring

Retaining

Clip (2)

Contents Changing Wedges 25

Changing Wedges

This section describes how to operate the MTSAdv antage Wedge Action Grips.

Installing a Specimen 27

T wo standard types of wedges are available for the grips: flat wedges for flat

specimens and vee-notched wedges for round specimens. Perform the following

procedure to replace one type of wedge with the other.

Note Each wedge is labeled with the wedge part number and manufacturing

date code. Be sure that replacement wedges are a matched set before

attempting to install the wedges into the grip.

1. Remove any specimen installed in the grips. Position the actuator or

crosshead as necessary for convenient access to the grip wedges. If

applicable, remove system hydraulic pressure.

Manual Name Operation

25

Page 26

The wedge springs can become dislodged and fly out of the grip assembly.

WARNING

The wedge spring can attain a force that can hurt you.

Ensure that the retaining clip is installed on the spring anchor post.

2. The lower end of the wedge spring is secured to the spring post with a

retaining clip (star washer). If the retaining clip is not present, install one

before disconnecting the spring from the wedge. Disconnect the springs that

are attached to each wedge.

3. Remove the two screws securing the retaining guides and remove the

retaining guides.

4. Remove the wedges from the grip body.

5. Remove any debris from the grip body that might have collected during

testing.

6. Apply a thin coat of Nikal lubricant to the surfaces of the wedge that contact

the grip body.

7. Place the wedges in the grip body.

8. Replace the retaining guides so that the pin on the wedge is in the slot.

Secure with two screws.

Operation

26

9. Replace springs on each wedge.

Manual Name

Page 27

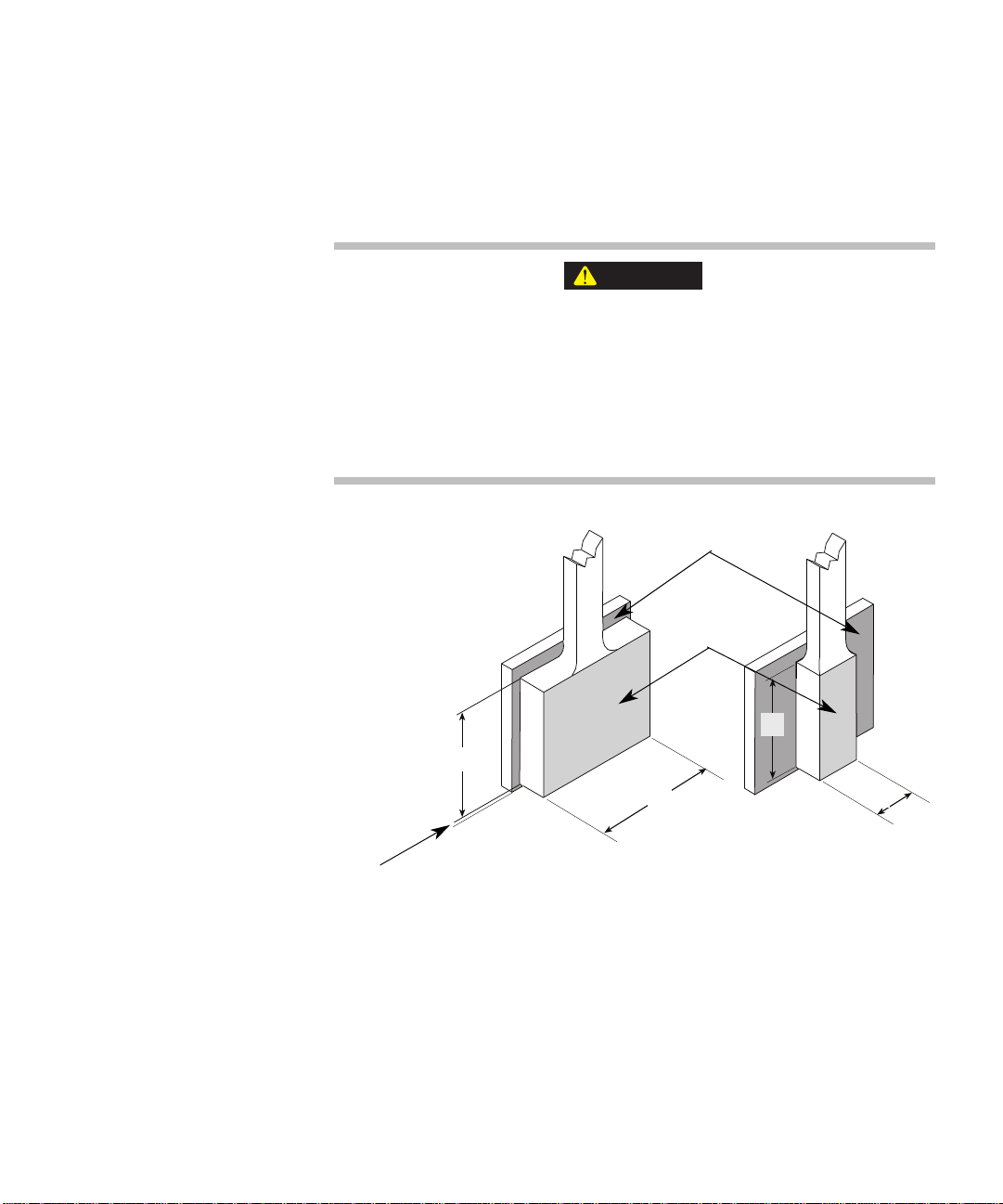

Installing a Specimen

CAUTION

W

W

H

H

Large contact area

recommended

Small contact area can

cause premature wear

and damage the grips

Wedge face

Contact area

Bottom gap

specification

(3-6 mm)

(H x W)

The following procedure describes how to install a specimen in the MTS

Advantage Wedge Grips. This procedure assumes a set of wedges has been

properly installed.

The contact area between the grip face and specimen should be as large as

possible.

A small contact area between the grip face and specimen can cause

premature wear to the grip face surface.

MTS recommends that specimens should be machined to provide the largest

possible surface contact area between the grip face and the specimen.

Manual Name Operation

27

Page 28

Improper specimen installation can damage the wedges.

CAUTION

6 mm (0.25 in) Maximum

6 mm (0.25 in) Maximum

Specimen

To prevent damage to the grips, follow the installation procedure. Do not install

specimens with hardness of Rc 52 or greater.

28

Operation

Specimen Installation

1. Apply power to the load frame or load unit.

Manual Name

Page 29

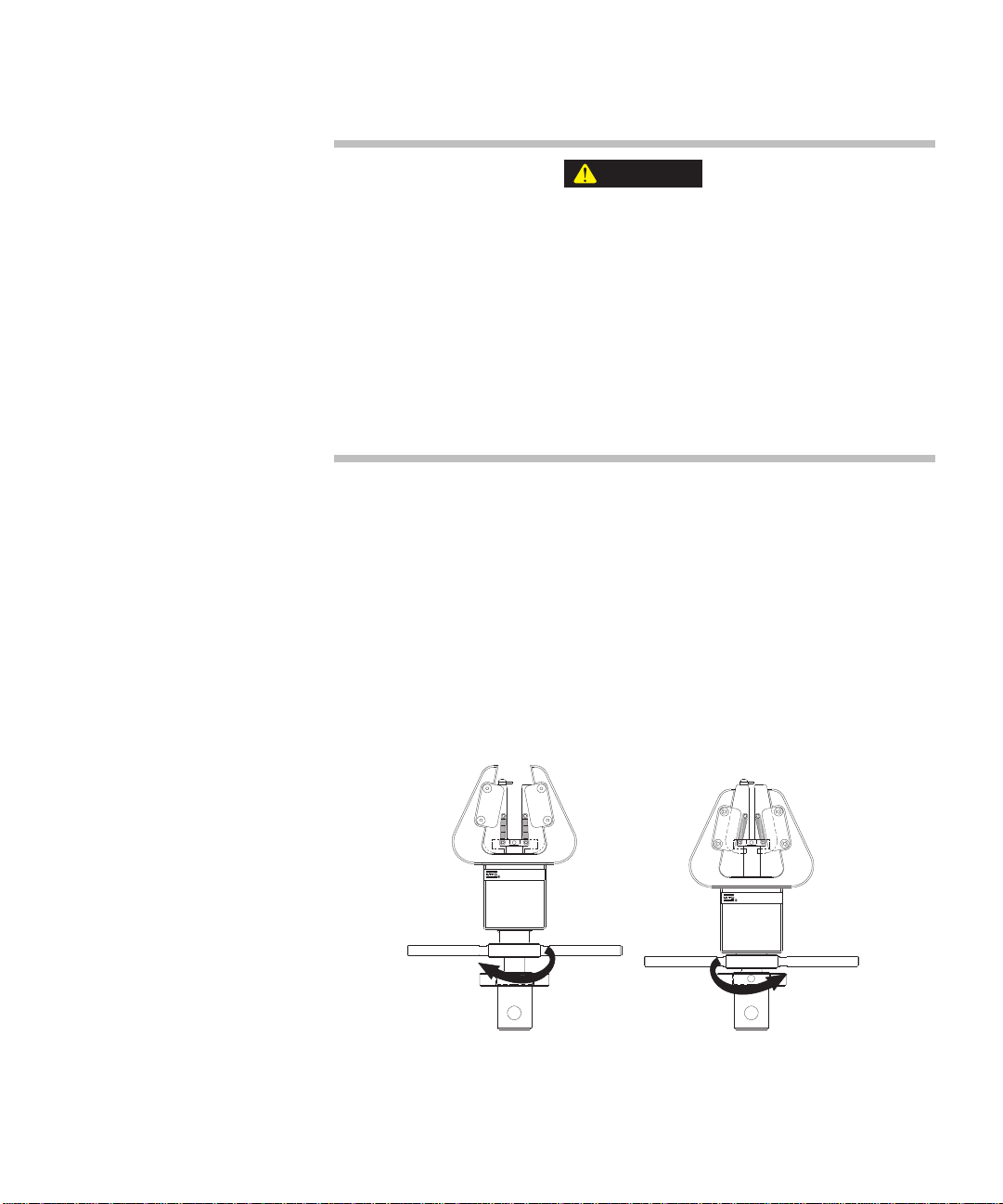

2. Open the upper and lower grips.

CAUTION

Grips Closed

Grips Open

Specimen slippage during the test can damage the grips.

Specimen slippage typically occurs when:

• Insufficient grip pressure is used to securely grip the specimen.

• Grip faces or wedges with rounded or flattened serrations are used.

• The specimen is harder than the wedge or face material.

Do not exceed the maximum pressure rating of the grip. Increasing the pressure

setting to hold round specimens can reduce the life of the vee-notched wedges.

Do not install specimens with hardness of Rc 52 or greater.

3. Place the specimen in the lower grip allowing a space of at least 3 mm (0.12

in), but not greater than 6 mm (0.25 in), between the bottom of the specimen

and the bottom inner edges of the lower grip wedges. Turn the grip handles

until specimen is firmly secured in place.

4. Lower the crosshead or extend the actuator until the specimen is positioned

in the upper grip allowing a space of at least 3 mm (0.12 in) but not greater

than 6 mm (0.25 in), between the top of the specimen and the inner top

edges of the wedges. Turn the grip handles until the specimen is firmly

secured in place.

Manual Name Operation

29

Page 30

30

Operation

Manual Name

Page 31

Maintenance

Service kits The following table lists the part numbers of the available service kits. The kits

After approximately 500 uses (or weekly, whichever comes first), the wedges of

the grip should be removed and an anti-seizing compound applied to the edges of

the wedge which contact the wedge chamber. The grip wedges should also be

lubricated if the grips have been in extended storage. Perform the following steps

to lubricate the wedges. Material required is Nikal lubricant (MTS part number

011-354-402).

1. Remove the wedges from the grip body.

2. Clean the grip assemblies to remove any dust or particales that might scatch

the grip surfaces or wedge faces.

3. Apply a thin layer of Nikal lubricant to the edges of the wedge which

contact the wedge chamber and grip piston.

4. Repeat Steps 1 and 2 for the other grip.

5. Place each wedge back into the grip body.

include components needed to replace the springs and restore the wedge action.

M

ODEL PART NUMBER

10 kN

30 kN

50 kN

100 kN

150 kN

300 kN

Manual Name Maintenance

560116-01

560116-01

560116-01

560116-02

560116-02

560116-02

31

Page 32

32

Maintenance

Manual Name

Page 33

Page 34

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

Internet: www.mts.com

ISO 9001 Certified QMS

Loading...

Loading...