Page 1

m

be certain.

MTS Model 793.10 MultiPurpose TestWare® and

Series 793 Application Software

User Information and Software Reference for Model 793.10

MultiPurpose TestWare

- Model 793.11 Profile Editor™

- Model 793.12 Trend Monitoring

- Model 793.14 Fatigue Monitoring

- Model 793.71 Time History Playout

- Model 793.72 THP with Acquisition

and the following:

100-147-131 H

Page 2

Copyright information © 2011 MTS Systems Corporation. All rights reserved.

Trademark information MTS, FlexTest, RPC, Temposonics, and TestWare are registered trademarks of

MTS Systems Corporation; MPT, Station Builder, Station Manager, and TestStar

are trademarks of MTS Systems Corporation within the United States. These

trademarks may be protected in other countries.

Microsoft and Windows are registered trademarks of Microsoft Corporation. All

other trademarks or service marks are property of their respective owners.

Proprietary information Software use and license is governed by MTS’s End User License Agreement

which defines all rights retained by MTS and granted to the End User. All

Software is proprietary, confidential, and owned by MTS Systems Corporation

and cannot be copied, reproduced, disassembled, decompiled, reverse

engineered, or distributed without express written consent of MTS.

Software validation and

verification

Publication information

MTS software is developed using established quality practices in accordance

with the requirements detailed in the ISO 9001 standards. Because MTSauthored software is delivered in binary format, it is not user accessible. This

software will not change over time. Many releases are written to be backwards

compatible, creating another form of verification.

The status and validity of MTS’s operating software is also checked during

system verification and routine calibration of MTS hardware. These controlled

calibration processes compare the final test results after statistical analysis

against the predicted response of the calibration standards. With these established

methods, MTS assures its customers that MTS products meet MTS’s exacting

quality standards when initially installed and will continue to perform as intended

over time.

MANUAL PART NUMBER PUBLICATION DATE MTS 793 SOFTWARE RELEASE

100-147-131 H July 2011 Version 5.35A or later

MTS MultiPurpose TestWare®

Page 3

Technical Support 7

Preface 13

Conventions 14

Chapter 5 About MultiPurpose TestWare 17

Application Overview 18

The MultiPurpose TestWare Interface 21

MPT Procedure Editor 36

Chapter 6 Performing Common Tasks 43

Chapter 7 MPT Options Editor 61

Chapter 8 Working with MPT Processes 83

Chapter 9 Working with MPT Variables 105

Variable Editor 115

Chapter 10 Working with MPT Specimens 125

MPT Specimen File Types 134

MPT Specimen Loading Examples 143

MTS MultiPurpose TestWare® Contents

3

Page 4

Chapter 11 Creating a Practice Test Procedure 153

Chapter 12 Command Processes 179

Segment Command Process 181

Cyclic Command Process 186

Dwell Command Process 195

Profile Process 198

External Command Process 211

Sweep Command Process 220

Signal Based Command Process 226

Profile with ALC Process 233

Cyclic with ALC Process 241

Model 793.71/72 Time History Output Process 247

Road Surface Output Process 261

Chapter 13 Data Acquisition Process Descriptions 271

Peak/Valley Acquisition Process 279

Timed Acquisition Process 284

Max/Min Acquisition Process 289

Level Crossing Acquisition Process 296

High Speed Timed Acquisition Process 301

Cyclic Acquisition Process 310

Fatigue Process 319

Time History Input Process 331

Trend Process 336

Chapter 14 Event Process Descriptions 345

Data Limit Detector Process 346

Digital Input Detector Process 353

Operator Event Process 359

4

MTS MultiPurpose TestWare®

Page 5

Peak/Valley Change Detector Process 364

Program Event Process 373

Periodic Time Event Process 377

Failure Detector Process 382

Chapter 15 External Control Process Descriptions 387

Digital Output Process 388

Temperature Control Process 393

Chapter 16 Other Process Descriptions 399

Program Control Process 400

Group Process 405

MPT Calculation Process 408

Operator Information Process 410

Start Application Process 420

Send Mail Process 426

Set Controller Value Process 430

Auto Offset Process 436

Data Display Process 440

Chapter 17 Trend and Fatigue Monitoring Applications 457

Model 793.12 Trend Monitoring Application 458

Model 793.14 Fatigue Monitoring Application 465

Chapter 18 Model 793.11 Profile Editor 473

Profile Editor 476

Creating Profiles 487

Design Considerations 495

Transitions 514

MTS MultiPurpose TestWare® Contents

5

Page 6

How to Play Out Profiles 519

Profile Editor Controls and Displays 521

Appendix 19 Default Templates 553

Appendix 20 Excel File Converter 557

Appendix 21 MPT Shortcuts 561

Index 567

6

MTS MultiPurpose TestWare®

Page 7

Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes software, look for

online help and README files that contain additional product information.

If you cannot find answers to your technical questions from these sources, you

can use the internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact Technical Support in

one of the following ways.

www.mts.com The web site provides access to our technical support staff by means of an online

form:

www.mts.com > Contact MTS > Service & Technical Support button

E-mail tech.support@mts.com

Telephone MTS Call Center 800-328-2255

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Fax 952-937-4515

Please include “Technical Support” in the subject line.

Outside the U.S. For technical support outside the United States, contact your local sales and

service office. For a list of worldwide sales and service locations and contact

information, use the Global MTS link at the MTS web site:

www.mts.com > Global MTS > (choose your region in the right-hand

column) > (choose the location closest to you)

MTS MultiPurpose TestWare® Technical Support

7

Page 8

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

Know information from

prior technical

The site number contains your company number and identifies your equipment

type (such as material testing or simulation). The number is typically written on a

label on your equipment before the system leaves MTS. If you do not know your

MTS site number, contact your sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies

your system. You can find your job number in your order paperwork.

Example system number: US1.42460

If you have contacted MTS about this problem before, we can recall your file

based on the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem and know the answers to the following questions:

• How long and how often has the problem occurred?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

Technical Support

8

• What are the equipment model numbers?

• What is the controller model (if applicable)?

• What is the system configuration?

MTS MultiPurpose TestWare®

Page 9

Know relevant

computer information

For a computer problem, have the following information available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive where the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

Know relevant

For software application problems, have the following information available:

software information

• The software application’s name, version number, build number, and (if

available) software patch number. This information can typically be found

in the About selection in the Help menu.

• The names of other applications on your computer, such as:

– Anti-virus software

– Screen savers

– Keyboard enhancers

– Print spoolers

– Messaging applications

If You Contact MTS by Phone

A Call Center agent registers your call before connecting you with a technical

support specialist. The agent asks you for your:

• Site number

• Name

• Company name

• Company address

• Phone number where you can be reached

If your issue has a notification number, please provide that number. A new issue

will be assigned a unique notification number.

MTS MultiPurpose TestWare® Technical Support

9

Page 10

Identify system type To enable the Call Center agent to connect you with the most qualified technical

support specialist available, identify your system as one of the following types:

• Electromechanical material test system

• Hydromechanical material test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

Prepare to perform troubleshooting while on the phone:

troubleshoot

• Call from a telephone close to the system so that you can implement

suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

Write down relevant

In case Technical Support must call you:

information

• Verify the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions.

After you call MTS logs and tracks all calls to ensure that you receive assistance for your

problem or request. If you have questions about the status of your problem or

have additional information to report, please contact Technical Support again and

provide your original notification number.

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems with your software,

hardware, manuals, or service that are not resolved to your satisfaction through

the technical support process. The form includes check boxes that allow you to

indicate the urgency of your problem and your expectation of an acceptable

response time. We guarantee a timely response—your feedback is important to

us.

Technical Support

10

MTS MultiPurpose TestWare®

Page 11

Access the Problem Submittal Form:

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form button (electronic

form to be e-mailed to MTS)

MTS MultiPurpose TestWare® Technical Support

11

Page 12

Technical Support

12

MTS MultiPurpose TestWare®

Page 13

Preface

Before You Begin

Safety first! Before you use your MTS product or system, read and understand the Safety

manual and any other safety information provided with your system. Improper

installation, operation, or maintenance can result in hazardous conditions that can

cause severe personal injury or death, or damage to your equipment and

specimen. Again, read and understand the safety information provided with your

system before you continue. It is very important that you remain aware of

hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional manuals in paper or

electronic form.

You may also receive an MTS System Documentation CD. It contains an

electronic copy of the manuals that pertain to your test system, such as:

• Hydraulic and mechanical component manuals

• Assembly drawings

• Parts lists

• Operation manual

• Preventive maintenance manual

Controller and application software manuals are typically included on the

software CD distribution disc(s).

MTS MultiPurpose TestWare® Preface

13

Page 14

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions Hazard notices may be embedded in this manual. These notices contain safety

information that is specific to the activity to be performed. Hazard notices

immediately precede the step or procedure that may lead to an associated hazard.

Read all hazard notices carefully and follow all directions and recommendations.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

14

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury or equipment damage,

or could endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Preface

MTS MultiPurpose TestWare®

Page 15

Conventions

Illustrations Illustrations appear in this manual to clarify text. They are examples only and do

not necessarily represent your actual system configuration, test application, or

software.

Electronic manual

conventions

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

MTS MultiPurpose TestWare® Preface

15

Page 16

Conventions

16

Preface

MTS MultiPurpose TestWare®

Page 17

Chapter 5

About MultiPurpose TestWare

Contents About MTS MultiPurpose TestWare (MPT) 18

About MPT Test Procedures 18

About MPT Processes 19

Default Test Procedure Locations 19

Test Procedures in Projects 20

About the MPT User Interface 21

About the MPT Control Panel 25

MPT Control Panel Toolbar 26

MPT Test Progress Panel 28

MPT Specimen Panel 29

MPT Power Panel 31

MPT Channel Counters Panel 32

MPT Sequence Counters Panel 33

About Process Specific Panels 34

MPT Run/Stop/Hold Panel 35

About the MPT Procedure Editor 36

MPT Procedure Editor Menu 37

Group Menu 37

Display Menu 37

Tools Menu 38

MPT Procedure Editor Toolbar 38

Procedure Table 40

Process Palette 42

MTS MultiPurpose TestWare® About MultiPurpose TestWare

17

Page 18

Application Overview

Application Overview

About MTS MultiPurpose TestWare (MPT)

MTS Model 793.10 MultiPurpose TestWare is an advanced test design

application available to MTS 793 Controllers.

With MultiPurpose TestWare, you can:

• Create complex test designs that include command, data acquisition, event

detection, and external control instructions.

• Generate programs based on profiles created with a text editor application, a

spreadsheet application, or the Model 793.11 Profile Editor application.

• Acquire and monitor real-time trend or fatigue data.

About MPT Test Procedures

With MultiPurpose TestWare, you create test procedure (.000) files. A test

procedure contains two types of information:

• Process information, which defines your processes (command, data

acquisition, signal monitoring, and so forth) and the sequence in which each

process runs.

• MPT application information, which includes test unit and dimension

assignments, the behavior of hold and resume functions, the data file format,

and so on.

To create procedures You create procedures by linking together processes that represent individual test

activities, such as ramping the actuator or acquiring peak/valley data.

To run procedures You run test procedures with the run, stop, and hold controls on the Station

Controls panel in the Station Manager application.

For more information For information on how to create a procedure, see “Creating a Practice Test

Procedure” on page 153.

For more information about how to run test procedures, see“How to Run a

Procedure” on page 48.

About MultiPurpose TestWare

18

MTS MultiPurpose TestWare®

Page 19

About MPT Processes

When you create tests with the MPT application, you use MPT processes like

building blocks to define test actions such as sending command signals,

performing data acquisition, and responding to test events.

A complete MPT test normally consists of a number of MPT processes linked

together and saved as an MPT procedure.

Process categories Processes are grouped on the palette in the following categories:

• Command Processes send commands to a servovalve or external controller

to apply forces to the physical specimen.

• Data Acquisition Processes acquire sensor data from the physical

specimen.

• Event Processes monitor test signals and perform actions when specified

conditions are met.

• External Control Processes control external controllers or logic devices.

• Other Processes perform miscellaneous functions.

Application Overview

Default Test Procedure Locations

In MTS 793 software version 3.5x or earlier, the default location of test files is:

C:\MTS software product name (for example, “FTGT”)\MPT\Procs

In MTS 793 software version 4.0 or later, the default location of test files is:

C:\MTS 793\Projects\Project name (for example, “Project 1”)\MPT\Procedures

MTS MultiPurpose TestWare® About MultiPurpose TestWare

19

Page 20

Application Overview

Test Procedures in Projects

A Project is a folder that contains or references files that are used and generated

by MTS 793 applications. When you start Station Manager, you select a Project.

MultiPurpose TestWare inherits the Project selected for Station Manager. The

current Project determines the location of MultiPurposeTestWare test procedures.

By default, Projects contain test procedures in the Procedures subfolder. You can

use the Project Manager application to change the location of test procedures.

For more information about the Project Manager and Projects, see the MTS 793

Control Software manual (PN 100-147-130), and the MTS 793 Controller

Overview manual (PN 100-162-928).

About MultiPurpose TestWare

20

MTS MultiPurpose TestWare®

Page 21

The MultiPurpose TestWare Interface

The MultiPurpose TestWare Interface

About the MPT User Interface

When you have an existing station configuration open with the Station Manager

application, then select MultiPurpose TestWare from the Applications menu,

the display changes and appears as shown.

• The MPT control panel provides access to all the functions needed to create,

edit, and run procedures for the current station configuration.

• The run, stop, and hold controls pertain to procedures.

• Also, if the current procedure includes an Operator Event process, a special

panel appears in the initial display.

Note When you select MPT this way, you can create, edit, and run

procedures. You can also select an ‘edit only’ instance of MPT

(Applications > MultiPurpose TestWare (Edit Only)) to run one

procedure while editing other procedures.

MTS MultiPurpose TestWare® About MultiPurpose TestWare

21

Page 22

The MultiPurpose TestWare Interface

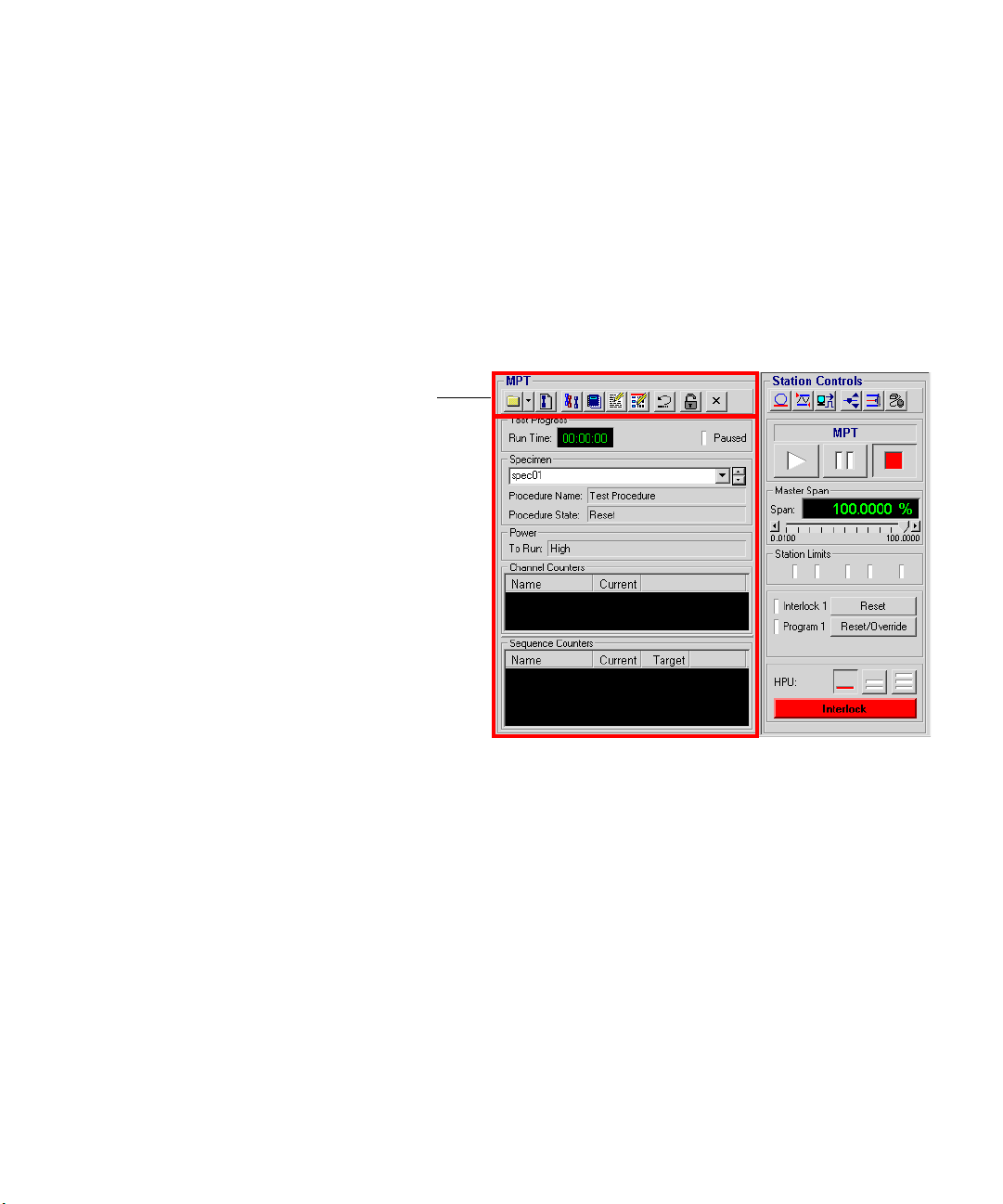

MPT application button

When you launch MPT this

button appears in the

applications control panel.

You can quickly select

among launched

applications with the buttons

in this panel.

Channel Counters

Channel Counters display

the cumulative count of

segments applied to

specific channels.

MPT toolbar

Sequence Counters

Sequence counters display

current and target counts for

processes. Individual process

counters are arranged

according to the process icons

on the Procedure Editor. Group

process counters are indented

to show nesting.

MPT Procedure Editor button

Displays the Procedure Editor and

Process Palette, as shown on the

next page.

Station Controls

You run MPT procedures with

the run, stop, and hold

controls.

MPT control panel The MPT control panel appears in the application area of Station Manager, as

shown.

About MultiPurpose TestWare

22

MTS MultiPurpose TestWare®

Page 23

Status and progress

indicators for

processes lets you

watch the progress

of the test

(not shown):

A blue arrow indicates that the process is

executing.

A red “X” indicates that the process is disabled.

A green arrow indicates that the process is

configured to issue a done signal immediately

without performing its programmed activity.

Procedure Editor

(default view)

The Procedure

Editor contains a

table on which you

build MPT test

procedures.

Navigation Pane

Provides a tree view

of the processes in

the procedure table

pane.

Active Process Parameters Pane

The parameters for the currently selected

process appear in this pane.

The MultiPurpose TestWare Interface

Procedure Editor The Procedure Editor contains a table on which you build MPT test procedures

by selecting, assigning parameters to, and sequencing individual test processes.

Test processes represent individual test activities.

The contents of the currently selected nesting level is displayed in the procedure

table pane. If a nested group process is selected, the general parameters for the

group are shown in the active process parameters pane.

Double-clicking on a parameter in the navigation pane or procedure table will

maximize the active process parameters pane. The contents of pane (default

view) and the expanded window are both editable. Minimizing or closing this

window restores the default view.

MTS MultiPurpose TestWare® About MultiPurpose TestWare

23

Page 24

The MultiPurpose TestWare Interface

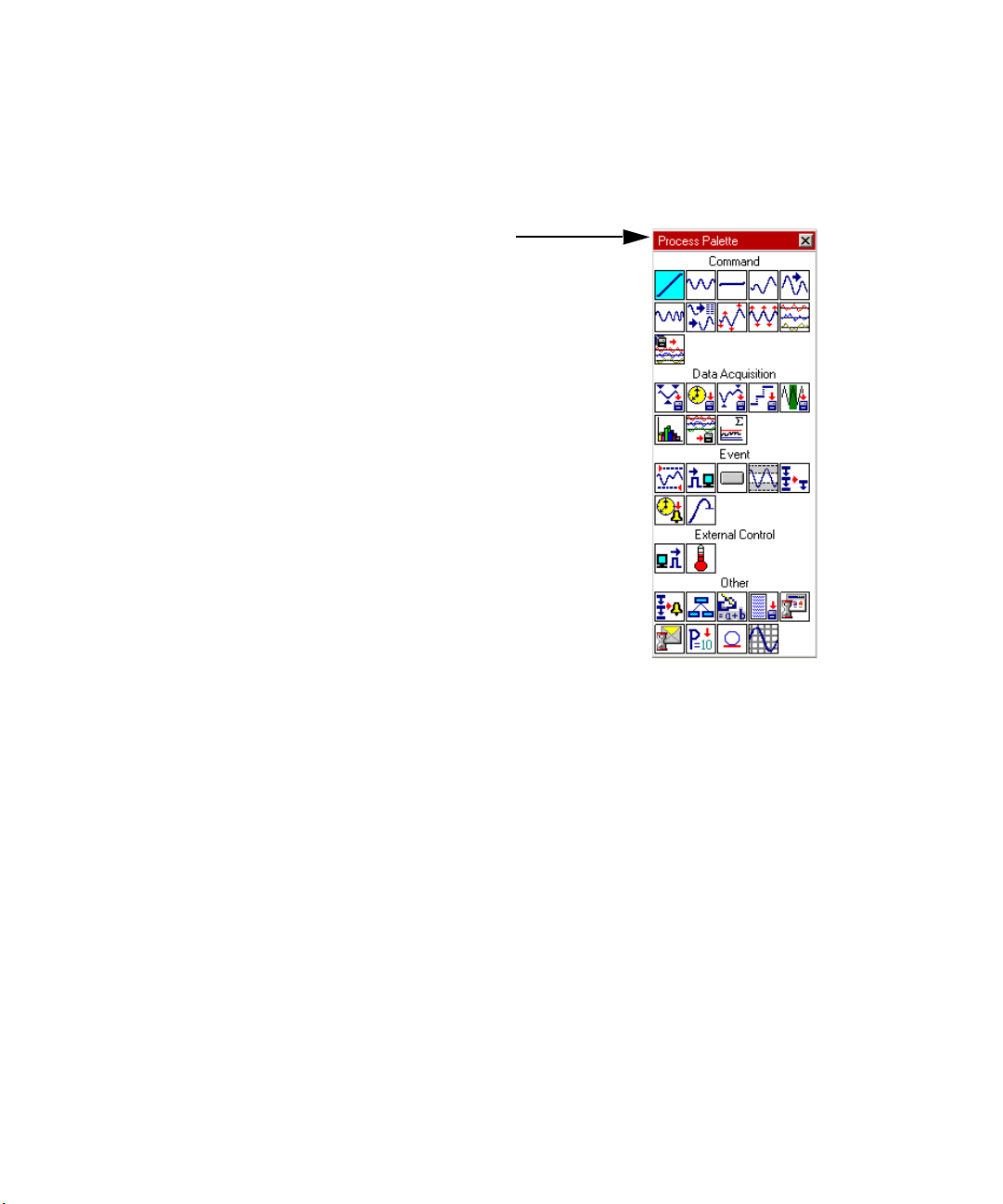

Process Pallete

Individual processes are

arranged on the palette by type.

You can double-click a process

on the Process Palette to copy

an instance of it to the table on

the Procedure Editor, or you can

use the drag-and-drop method.

Process Palette The processes available are displayed on the Process Palette. Individual

processes are arranged on the palette by type. You can double-click a process on

the Process Palette to copy an instance of it to the procedure table, or you can use

the drag-and-drop method.

About MultiPurpose TestWare

24

MTS MultiPurpose TestWare®

Page 25

About the MPT Control Panel

The MPT control panel

includes a toolbar that

performs actions (like

unlocking procedures) and

provides access to editors

(like the MPT Procedure

Editor and the MPT

Specimen Editor) and the

MPT Specimen Log.

With the MPT control panel you can:

• Access common controls from the toolbar (including the MPT Procedure

Editor, the place where you build procedures)

• Monitor the test’s status and counter information (channel, sequence, and

run time counters)

• Create and rename MPT specimens

The MultiPurpose TestWare Interface

For more information For more information about setting MPT control panel preferences, see “MPT

MTS MultiPurpose TestWare® About MultiPurpose TestWare

Options Editor Control Panel Tab” on page 79.

25

Page 26

The MultiPurpose TestWare Interface

MPT Control Panel Toolbar

The buttons that comprise the MPT control panel toolbar provide quick access to

common commands and windows.

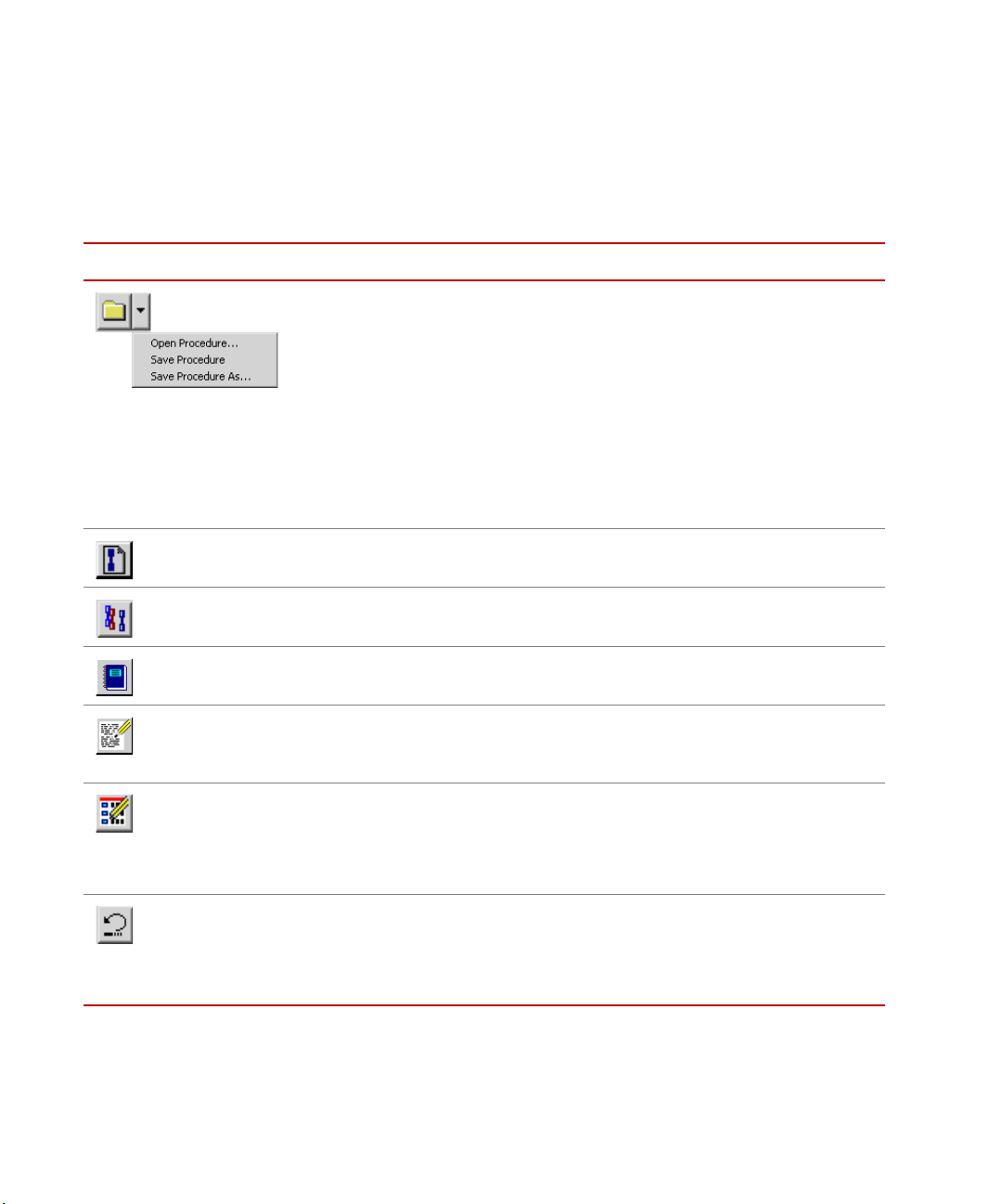

MPT Control Panel Toolbar (part 1 of 2)

I

TEM DESCRIPTION

Displays the Open Procedure window, saves the current procedure, or displays

the Save Procedure As window.

You can use the Open Procedure window functions to navigate to, select, and

open an existing procedure. You can use the Save Procedure As window

functions to save the current procedure as a new file with a specified name and

location.

Note If you select Save Procedure for a procedure that has never been

Creates a new MPT specimen for the procedure that is currently loaded. The

new folder is immediately visible in the Specimen panel.

save, the application displays the Save Procedure As window. With

this window you can name the procedure and save it to the location

you desire.

About MultiPurpose TestWare

26

Displays the MPT Specimen Editor . You can use the MPT Specimen Editor to

create and edit multiple MPT specimens.

Displays the MPT Specimen Log which contains messages that pertain to the

current MPT specimen.

Displays the MPT Options Editor. With the MPT Options Editor, you can

customize the MPT interface to suit your needs by defining control options and

preferences.

Displays the MPT Procedure Editor, the place where you create and edit

procedures consisting of MPT test processes.

Note To edit a selected procedure on the MPT Procedure Editor, you must

first be in the Edit mode.

Resets the current procedure to the beginning. Pressing run after pressing reset

restarts the procedure from the beginning.

Note After the procedure completes, you must click Reset before you can

run the procedure again on the same MPT specimen.

MTS MultiPurpose TestWare®

Page 27

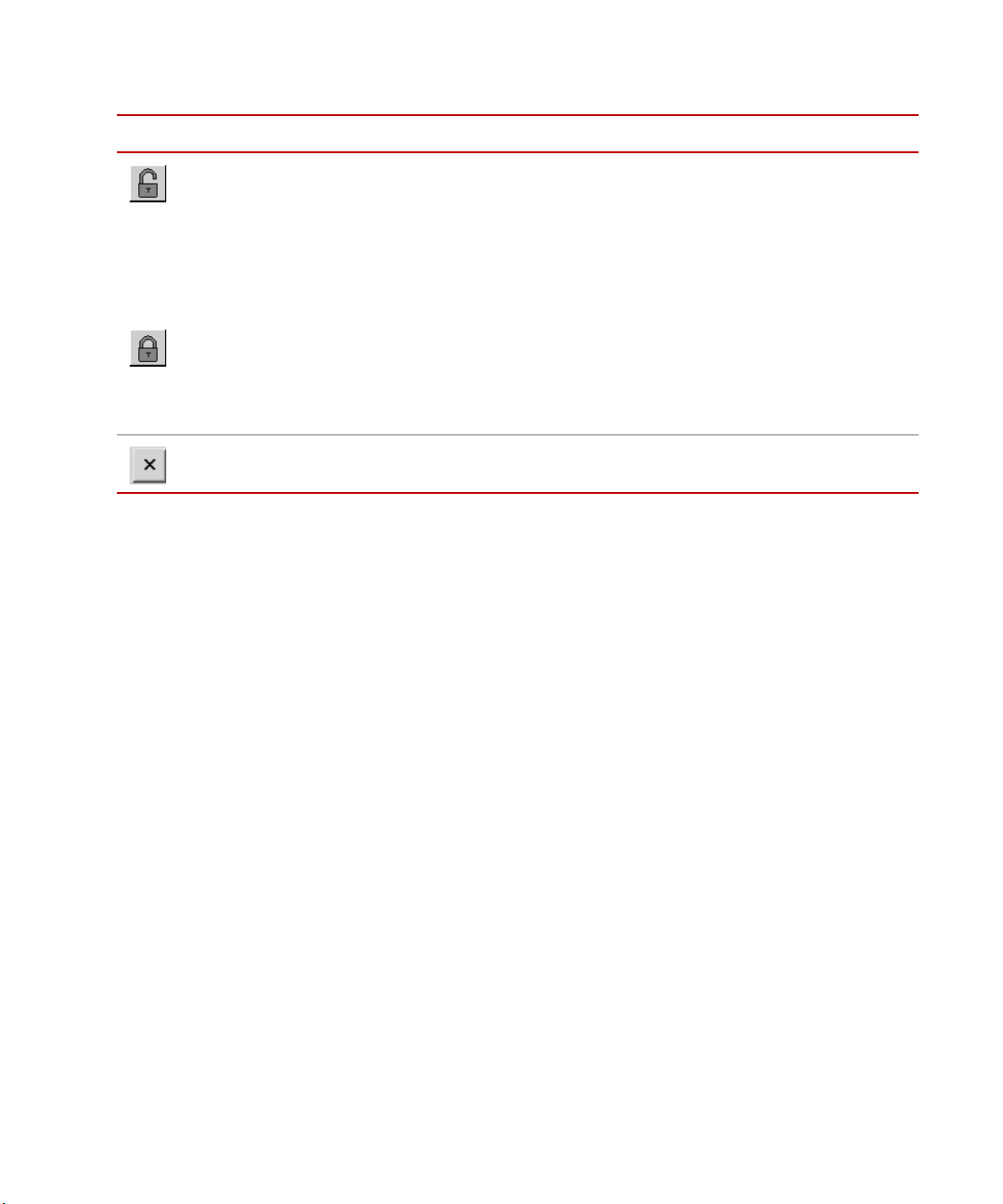

MPT Control Panel Toolbar (part 2 of 2)

I

TEM DESCRIPTION

Changes between edit and execute test modes. To change (toggle between)

modes, click the edit /execute mode button.

The MultiPurpose TestWare Interface

Edit mode

You must be in edit mode to create or make changes to your procedure.

Note You cannot switch to edit mode if the procedure is running or holding.

You must be in the execute mode to run your test. The procedure automatically

switches to execute mode if you click run on the Statio n Controls panel.

Note When you change to execute mode, the MPT application becomes the

Execute mode

controlling application of the control channels used in the procedure.

You cannot use the Station Managermanual command controls on

the control channels used in the procedure.

Quits the MultiPurpose TestWare application.

For more information See “MPT Specimen Editor” on page 131.

See “About the MPT Procedure Editor” on page 36.

See “Edit mode” on page 27.

MTS MultiPurpose TestWare® About MultiPurpose TestWare

27

Page 28

The MultiPurpose TestWare Interface

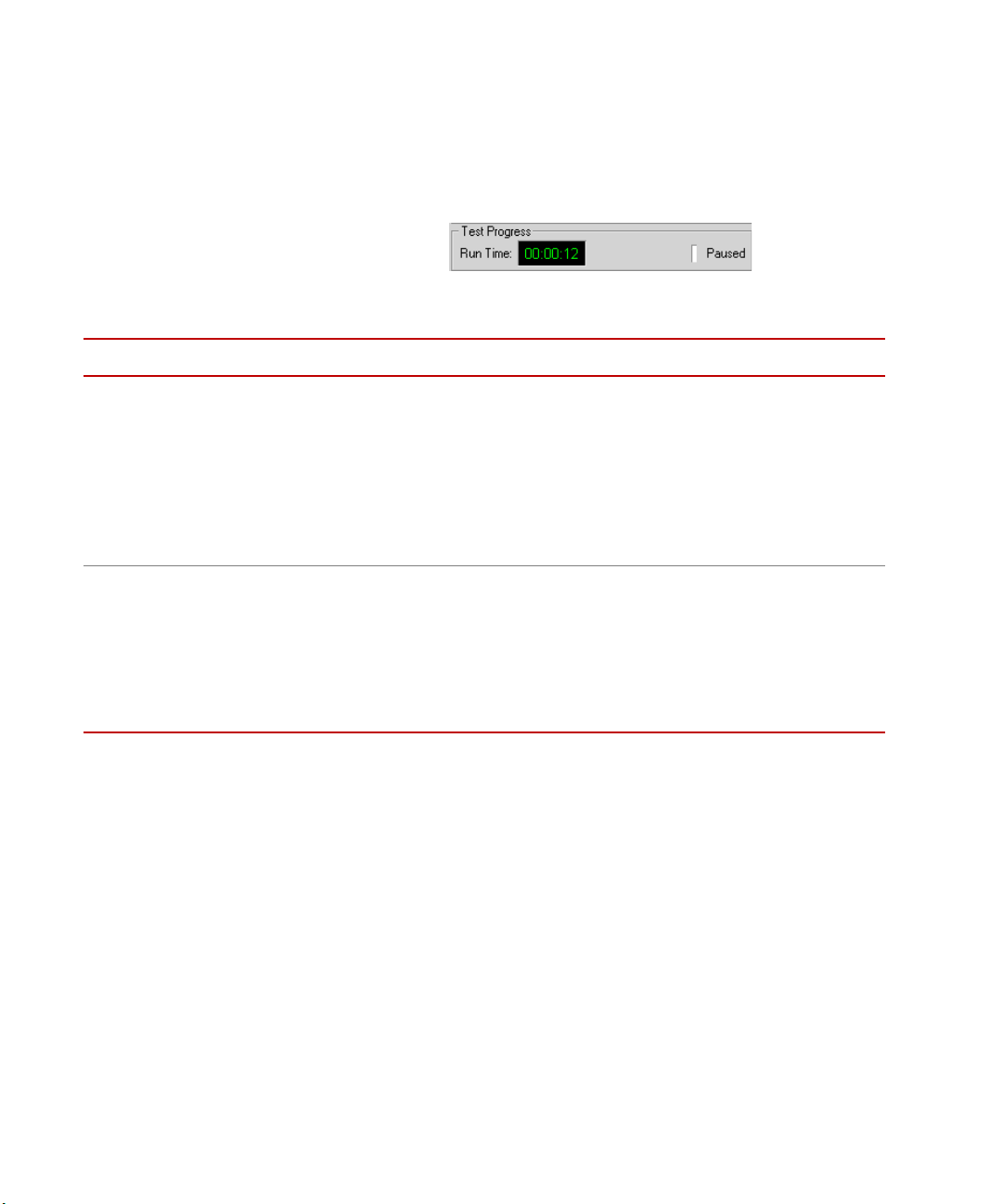

MPT Test Progress Panel

The Test Progress panel displays the elapsed run time of the test that is in

progress and indicates if the test is currently paused.

I

TEM DESCRIPTION

MPT Test Progress Panel

Run Time

Displays the elapsed time of the current test (the elapsed run time does not

include time spent in hold or stop states).

You can turn the Run Time display on-and-off and select a display format

using the Control Panel tab of the MPT Options Editor.

To access the Run Time menu when the procedure is locked and reset, rightmouse click with the cursor positioned over the Run Time counter to display.

Select the Reset menu item to reset the Run Time counter to zero.

Paused

Indicates when the procedure has been paused by a Program Control process.

The paused state is not the same as the hold state.

• When the test is holding, you must click the run button to resume the test.

• When the test is paused, the test must be resumed by another Program

Control process (set to Program Resume).

For more information See “MPT Options Editor Control Panel Tab” on page 79.

For more information about pausing a test with the Program Control process, see

“About the Program Control Process” on page 400.

About MultiPurpose TestWare

28

MTS MultiPurpose TestWare®

Page 29

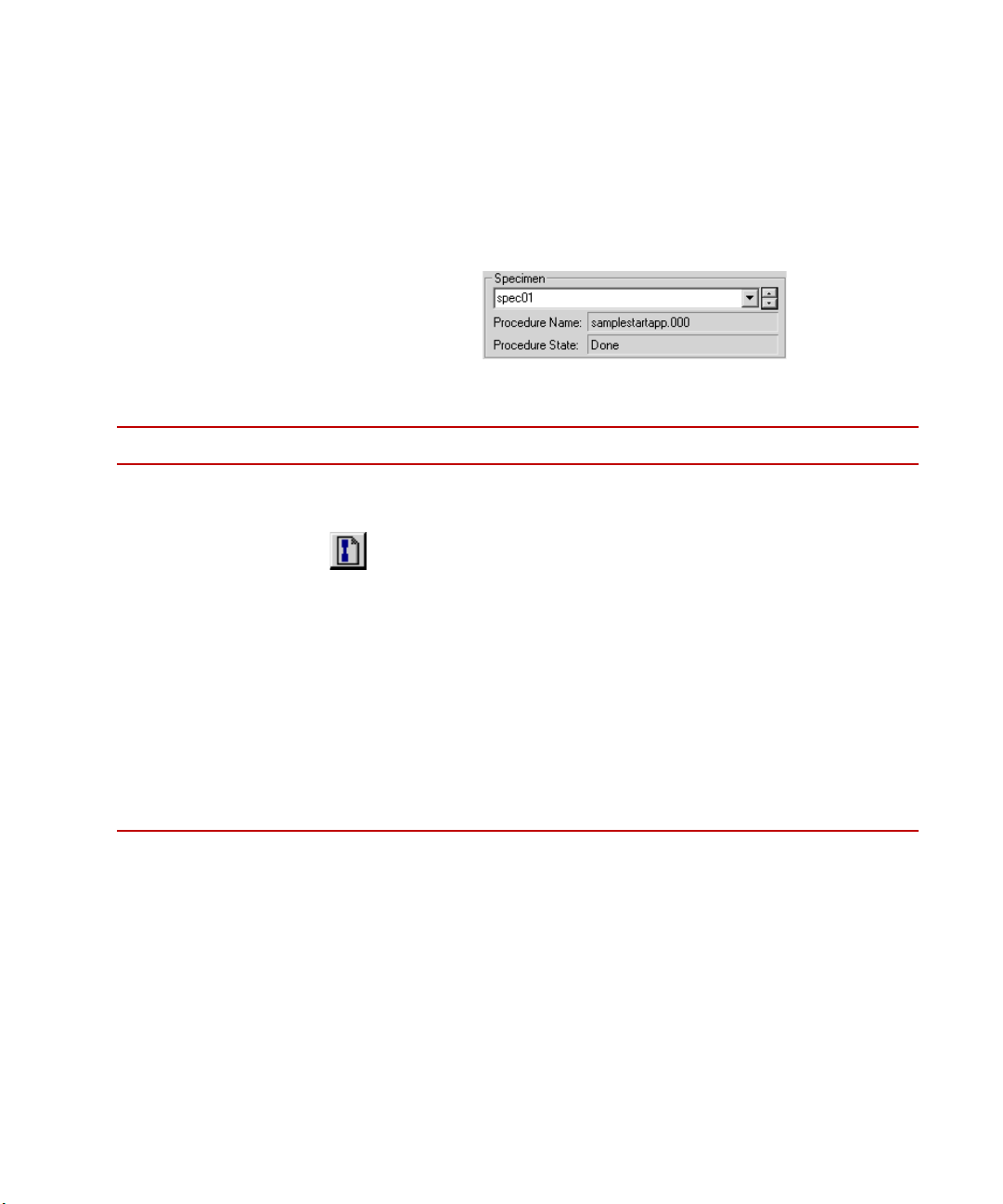

MPT Specimen Panel

The Specimen panel displays the current MPT specimen selection and the

Procedure Name and Procedure State associated with the selected specimen. In

addition, you can use this panel to navigate to other MPT specimens displayed in

the Specimen list.

I

TEM DESCRIPTION

The MultiPurpose TestWare Interface

MPT Specimen Panel (part 1 of 2)

Specimen

Displays the MPT specimen that is linked to the procedure.

You can select the desired MPT specimen from the Specimen list or click

to create a new MPT specimen.

Use the up and down scroll arrows to select an available MPT specimen from

the list. You can rename the selected MPT specimen (if you are in edit mode)

by typing over the folder name in the Specimen box.

Note New MPT specimens that are created using the new specimen icon are

assigned names that are based on a default root name (for example,

“spec”) with an incremental number suffix. The default root can be

changed with the Project Manager application.

Note To cut, copy, paste, or delete the displayed MPT specimen name,

right-mouse click on the current MPT specimen name and select the

desired right-mouse menu item.

MTS MultiPurpose TestWare® About MultiPurpose TestWare

29

Page 30

The MultiPurpose TestWare Interface

I

TEM DESCRIPTION

MPT Specimen Panel (part 2 of 2)

Procedure Name

Displays the name of the current procedure selection. The procedure name is

established when you save the procedure.

Procedure State

Displays the current state of the procedure, which may be one of the following:

• Reset—The test is at the beginning but has not been started.

• In Progress—The test has started but is not yet completed.

• Done—The test has been completed.

Note To run the procedure on the same MPT specimen again, press Reset.

Otherwise, create a new MPT specimen for the next instance of

running the same procedure.

• Error—An error has occurred (you must click Reset to run the test

again).

For more information For more information about MPT specimens, see “Working with MPT

Specimens” on page 125.

About MultiPurpose TestWare

30

MTS MultiPurpose TestWare®

Page 31

MPT Power Panel

The Power panel displays the hydraulic supply pressure required to run the

selected test.

I

TEM DESCRIPTION

The MultiPurpose TestWare Interface

MPT Power Panel

To R u n

Displays the hydraulic pressure required to run the control channels in the

current procedure (hydraulic pressure options are High, High/Low, Off/

Interlocked, or Off).

Note Power status applies only to control channels. If a procedure does not

contain control channels, the power status has no effect on the

procedure. For instance, if you remove hydraulic power from a

procedure that does not include control channels, the procedure is still

valid.

You can specify the required hydraulic pressure for the control channels of the

current procedure using the Execution tab of the MPT Options Editor.

Note You must be in edit mode to change settings on the Execution tab.

The High selection applies to most testing situations. High requires you to

operate MPT with high hydraulic pressure applied to the station’s Hydraulic

Service Manifolds (HSM).

The Off/Interlocked and Off selections are typically used while you are

learning the application software or running test simulations.

The Off/Interlocked selection disregards active interlocks for the sake of

allowing you to run the test unhindered.

For more information See “MPT Options Editor Execution Tab” on page 62.

MTS MultiPurpose TestWare® About MultiPurpose TestWare

31

Page 32

The MultiPurpose TestWare Interface

MPT Channel Counters Panel

The Channel Counters panel displays the running total of completed command

channel cycles or segments during test execution.

I

TEM DESCRIPTION

MPT Channel Counters Panel

Channel Counters

Displays a running total of the cycles or segments that have been run during

the test for each command channel specified in the procedure.

The Channel Counters panel displays all channels that are selected for use

during a test. A channel does not have to be used in every process to be

displayed.

You can specify the Channel Counters display format using the Control

Panel tab of the MPT Options Editor. You must be in edit mode to change the

Control Panel settings.

To access menu items that pertain to Channel Counters position the cursor

over the Channel Counters display and perform a right-mouse click. When

you do this, the Reset Counters and Set Counters... menu items appear

(provided that the procedure is locked and in the reset state). The Reset

Counters selection resets all active channel counters to zero. With the Set

Counters... selection you can manually set each channel counter to a user

specified value.

For more information See “MPT Options Editor Control Panel Tab” on page 79.

About MultiPurpose TestWare

32

MTS MultiPurpose TestWare®

Page 33

MPT Sequence Counters Panel

The Sequence Counters panel displays process counters for each specified

counter using the selected process counter format.

MPT Sequence Counters Panel

I

TEM DESCRIPTION

The MultiPurpose TestWare Interface

Sequence Counters

Displays individual process counters. You can specify the counter type using

the General tab of each process parameters window.

• If you specified a Fixed counter, the counter label and counter are

displayed for the duration of the procedure.

• If you specified a Transient counter, the counter label and counter are

displayed only while the process is active.

For more information For more information about using counters, see “About Counters” on page 49.

MTS MultiPurpose TestWare® About MultiPurpose TestWare

33

Page 34

The MultiPurpose TestWare Interface

Note Applies to Time History

Output, Time History

Input, and Road

Surface Output

processes only.

About Process Specific Panels

Process specific panels display only when certain processes are selected from the

Process Palette and are configured specifically to display at or during run time.

Examples of some of these displays are shown below.

Profile Counter Panel

Process Status Panel

Operator Events Panel

For more information For more information about these panels, see “About MPT Processes” on page

84.

About MultiPurpose TestWare

34

MTS MultiPurpose TestWare®

Page 35

MPT Run/Stop/Hold Panel

The run/stop/hold panel controls run, stop, and hold test activities for the current

application. When you select MultiPurpose TestWare from the Applications

menu, it becomes the controlling application and “MPT” appears on this panel.

I

TEM DESCRIPTION

Starts the procedure. When you click this button, the run indicator blinks while

the procedure transitions from the current state to the “run” state. Once the run

state is achieved the indicator remains constant unless additional transitions or

program induced pauses occur. Additional blinks may occur depending on the

duration of the transition or pause.

Suspends all active command and data acquisition processes.

The MultiPurpose TestWare Interface

MPT Run/Stop/Hold Panel

Note Active limit detector and digital input processes remain active.

When you click hold, the hold indicator blinks while the procedure transitions

from the current state to the “hold” state. Once the hold state is achieved, the

indicator remains constant. To resume the run state from the hold state, click

run.

Note The hold button may be disabled if Ignore Hold Event is selected on

the MPT Options Editor window Execution tab.

Stops the procedure. When you click stop, the stop indicator blinks while the

procedure transitions from the current state to the “stop” state. Once the stop

state is achieved, the indicator remains constant.

MTS MultiPurpose TestWare® About MultiPurpose TestWare

35

Page 36

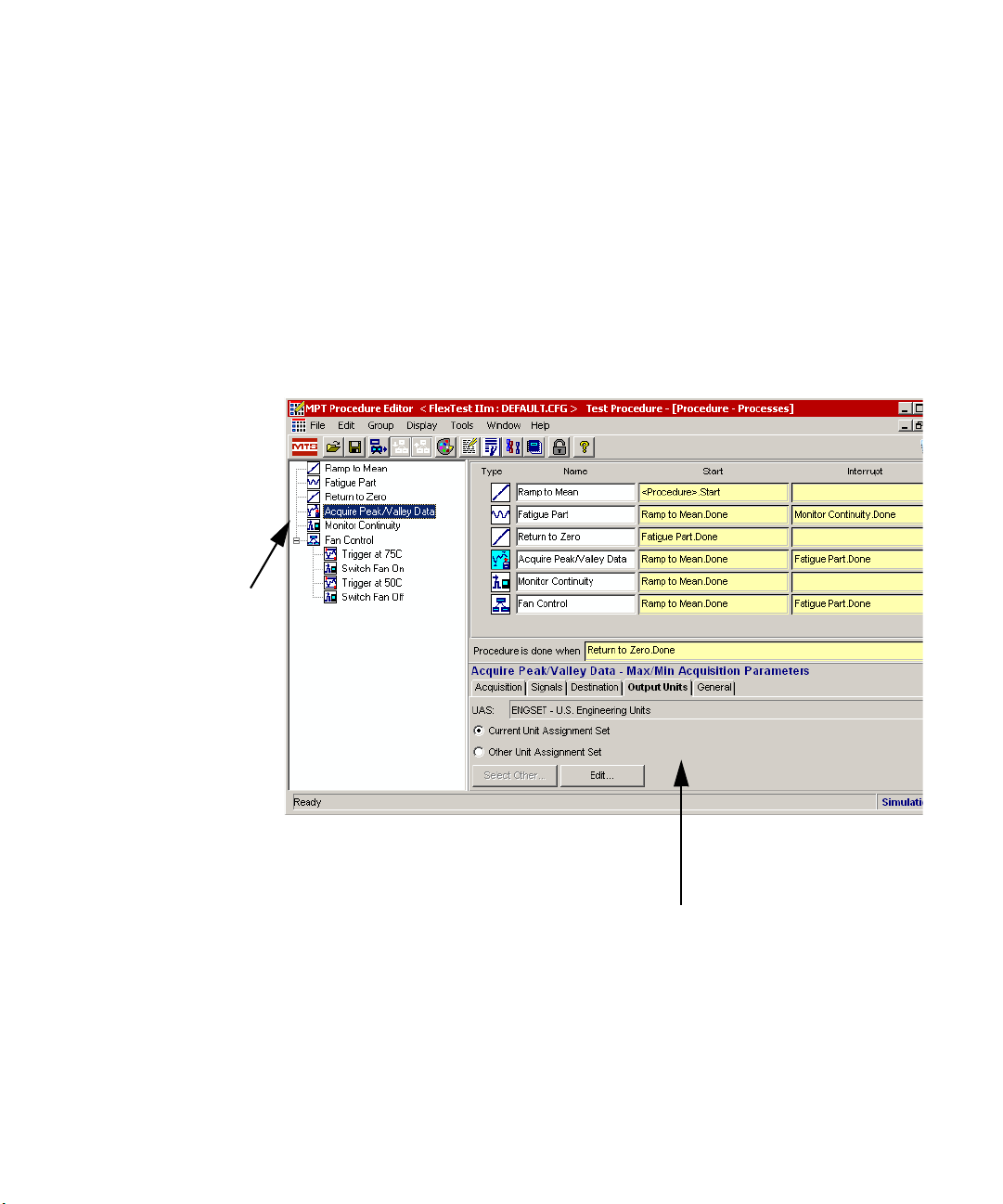

MPT Procedure Editor

The MPT Procedure

Editor includes the

menu, toolbar,

procedure table,

navigation pane, and

active process

parameter information

pane.

You create procedures

by populating the

procedure table with

test processes from the

Process Palette.

“Simulation” appears in the status bar when you run the “Demo”

(demonstration) System Loader program.

MPT Procedure Editor

About the MPT Procedure Editor

The MPT Procedure Editor is where you create procedures by combining and

defining the parameters of individual test processes available on the Process

Palette.

To display the MPT Procedure Editor, click on the icon in the MPT

toolbar.

About MultiPurpose TestWare

36

MTS MultiPurpose TestWare®

Page 37

MPT Procedure Editor Menu

The following menus are available on the MPT Procedure Editor window:

• Group Menu

• Display Menu

• Tools Menu

• MPT Procedure Editor Toolbar

Note When viewing the output files generated by the Print Procedure, Print

Group Menu

Use the Group menu commands to restore, navigate through, and control

specific Group table functions.

I

TEM DESCRIPTION

MPT Procedure Editor

Preview, and Print to File selections, items preceded by an asterisk (*)

have been changed since the procedure was last opened or saved.

Group Menu

Procedure

Next

Previous

Restores the main procedure table if it has been minimized or hidden.

Opens the Group table for the selected group process.

Note This command is only available when you select a Group process

icon.

Displays the parent procedure table for the current Group table.

Note This command is only available when you are in a Group table.

Display Menu

Use the Display menu commands to:

• Change between the test edit mode and test execution mode.

• Display the Process Palette.

• Display the MPT Specimen Log

MTS MultiPurpose TestWare® About MultiPurpose TestWare

37

Page 38

MPT Procedure Editor

Tools Menu

I

TEM DESCRIPTION

Use the Tools menu commands to display various editors used to customize the

MPT environment and/or the current procedure.

Tools Menu

Specimen Editor

Unit Set Editor

Options Editor

MPT Procedure Editor Toolbar

The buttons that comprise the MPT Procedure Editor toolbar provide quick

access to common commands and windows.

MPT Procedure Editor Toolbar (part 1 of 2)

I

TEM DESCRIPTION

Deletes the process (or processes) selected in the active procedure table.

Opens the next group table. This button is only active if there are multiple

group tables available.

Opens the previous group table. This button is only active if there are multiple

group tables available.

Displays the Process Palette. You can select processes from the palette to copy

to the MPT Procedure Editor, or you can drag and drop processes from the

palette to the MPT Procedure Editor.

Displays the MPT Specimen Editor.

Displays the Unit Set Editor.

Displays the Options Editor.

About MultiPurpose TestWare

38

Displays the MPT Options Editor. With the MPT Options Editor, you can

select control options and preferences for the current procedure.

Displays the MPT Variables Editor.

Displays the MPT Specimen Editor. You can use the MPT Specimen Editor to

create and edit multiple MPT specimens.

MTS MultiPurpose TestWare®

Page 39

MPT Procedure Editor Toolbar (part 2 of 2)

I

TEM DESCRIPTION

Displays the MPT Specimen Log for the current MPT specimen.

Changes between edit and execute test modes. To change (toggle between)

modes, click the edit /execute mode button.

MPT Procedure Editor

Edit mode

You must be in edit mode to create or make changes to your procedure.

Note You cannot switch to edit mode if the procedure is running or holding.

You must be in execute mode to run your test. The procedure automatically

Execute mode

switches to execute mode if you click Run on the Station Controls panel.

Note When you change to execute mode, MPT takes control of the various

resources used in the procedure, such as control channels, digital

output channels, and so on. You cannot use these resources with

Station Manager until you unlock the procedure and attain the edit

mode.

Trash can. Processes are not stored in the trash can as they are in the Windows

Recycling Bin. They are deleted immediately after you drag them to the trash

can icon.

For more information See “Process Palette” on page 84.

See “About the MPT Options Editor” on page 62.

See “MPT Specimen Editor” on page 131.

MTS MultiPurpose TestWare® About MultiPurpose TestWare

39

Page 40

MPT Procedure Editor

Process Type

Name

Start Trigger

Interrupt Trigger

Navigation

Pane

Active

Process

Parameters

Procedure Table

Access From the MPT Procedure Editor pane, the access paths are:

You use this pane to organize and synchronize the processes that make up your

test.

File > Open (or New) Procedure

Or

Group > Procedure

40

About MultiPurpose TestWare

MTS MultiPurpose TestWare®

Page 41

I

TEM DESCRIPTION

MPT Procedure Editor

Procedure Table

Process indicators

Typ e

Start

Interrupt

Procedure is done

when

Indicate the status of the adjacent process. Indicators have the following

meanings:

The process is enabled and active.

The process has been disabled.

The process is enabled, but configured to run zero times.

Displays the individual process icons that you have selected. You can doubleclick an icon to open the associated process parameters window. In addition, if

you right-click on an icon you can open the parameters window associated

with the process, open a new process (or group) table, enable or disable the

process, and delete the process.

Specifies the triggers or events that cause this process to start.

Specifies the triggers or events that interrupt this process.

Specifies the triggers or events that cause the end of the procedure.

MTS MultiPurpose TestWare® About MultiPurpose TestWare

41

Page 42

MPT Procedure Editor

Note Some processes

are optional and

appear on the

Process Palette

only when

purchased

separately.

Process Palette

Access From the MPT Procedure Editor window, the access paths are:

Use the Process Palette to select test processes by using their representative

icons.

Display > Process Palette

Or:

The Process Palette contains the icons of processes that you can add to the

procedure table to build a procedure.

For more information See “How to Add Processes to the Procedure Table” on page 85.

About MultiPurpose TestWare

42

MTS MultiPurpose TestWare®

Page 43

Chapter 6

Performing Common Tasks

Contents How to Start MultiPurpose TestWare 44

How to Display the MPT Procedure Editor 44

How to Create a New Procedure 44

Considerations for Test Design and Execution 45

How to Open a Procedure 47

How to Save a Procedure 47

How to Preview a Procedure 47

How to Print a Procedure 47

How to Run a Procedure 48

About Counters 49

Types of Counters 49

How to Display Counters and Status Panels 51

About the Clear Counters on Reset Function 53

About Working with Unit Assignment Set Editor 55

About the MPT Specimen Log 57

MTS MultiPurpose TestWare® Performing Common Tasks

43

Page 44

How to Start MultiPurpose TestWare

How to Start MultiPurpose TestWare

From Station Manager To start the MultiPurpose TestWare application, you must first start the Station

Manager application and open a station configuration.

Once the configuration file is open, on the Station Manager Applications menu,

click MultiPurpose TestWare to display the MPT control panel.

You can run existing procedures from the MPT control panel. If you want to edit

or create new procedures, you need to access the MPT Procedure Editor.

From other MTS

applications

From the Station Desktop Organizer Start Applications menu: click Station

Manager, open a station configuration, and on the Applications menu, click

MultiPurpose TestWare.

On the Project Manager tool bar: click the Station Manager icon, or from the

Applications menu, click Station Manager. Then on the Applications menu,

click MultiPurpose TestWare.

For more information For more information, see “About the MPT Procedure Editor” on page 36.

How to Display the MPT Procedure Editor

On the MPT control panel toolbar, click .

How to Create a New Procedure

When you start MPT a new (undefined) procedure is automatically created. To

create a new procedure any time MPT is active, from the MPT Procedure Editor,

select the File menu, then click New Procedure.

Even so, if you follow along and create a less complex version of the test

procedure, or even if you just review the pages without using your software, you

still benefit by learning the fundamentals of creating test procedures.

Note The hardware resources and label names provided in this section are for

illustration purposes only. Your hardware resources and label names

typically vary with the hwi file and station configuration file you use.

For more information If you would like to review a sample test design, see “Creating a Practice Test

Procedure” on page 153.

Performing Common Tasks

44

MTS MultiPurpose TestWare®

Page 45

Considerations for Test Design and Execution

Considerations for Test Design and Execution

Undesirable latencies

in test procedures

Design tests to

minimize undesirable

latencies

Other considerations

to minimize

undesirable latencies

One consideration of test procedure design is the potential for undesirable

latencies between test activities. There is, of course, a certain amount of latency

between test activities due to intra-system communication which cannot be

avoided. Latencies beyond this though, may be undesirable for some tests,

especially if your test involves rapid switching between test activities of short

durations. The way you design test procedures and manage the execution of test

procedures can minimize unwanted latencies.

If your command waveform is all in the same control mode, it is best to design

your test using a Profile file, and run the Profile file with the MPT Profile

process.

You create a Profile file with a spreadsheet application or the MTS Model 793.11

Profile Editor application. A Profile file consists of a series of segments. When

MPT runs the segments within a Profile file they are not vulnerable to delays (as

compared to executing a series of individual MPT command processes). MPT

queues multiple rows of the Profile file to the segment generator simultaneously,

and if you specify multiple passes, the output proceeds with the next pass without

delay.

Many tests, of course, require control mode changes in the command waveform.

In this case, you must choose individual MPT command processes as required,

and assign triggers to link their execution.

Triggering from one MPT process to the next occurs on the Microsoft Windows

workstation, which makes them vulnerable to undesirable latencies due to other

activity on the workstation. Likely candidates include networking, video drivers

without adequate hardware acceleration, and other communication with the

controller, including running other test stations simultaneously.

To reduce unwanted latencies in this scenario, minimize operations involving the

Microsoft Windows operating system while your test is running.

Avoid the use of third

party software

MTS MultiPurpose TestWare® Performing Common Tasks

MTS also recommends that you avoid running third-party software applications,

including virus-checking software, when running any of the MTS 793 software

applications. Testing has revealed that some third-party software can consume

the majority of the PC is available processing power. These applications, if run

along with MTS 793 software applications, may cause communication with the

controller to cease. Ultimately, this causes the station and applications on it to

terminate.

45

Page 46

Considerations for Test Design and Execution

Design elements that

may lock up your

You can inadvertently design an MPT procedure that can lock up your system.

The cause is generally from:

system

• Requesting too much data acquisition or command generation, or

• Setting up a group process to repeat continuously when it does not contain

command or data acquisition processes. To understand this, think of

processes in these categories:

– Command and Data Acquisition—These processes initiate activity

within the machine, and wait for it to complete.

– Immediate Action (Digital Output and Program Control)— These

processes execute an action and complete immediately.

– Detectors (Digital Input and Data Limit)—These processes complete

immediately if their condition is initially met.

Note If you create a repeating group process that contains only “Immediate

Action” and “Detector” processes, care must be taken so that the

detectors do not complete and repeat a number of times in quick

succession without waiting for some other test activity. For example, if a

data limit is set up in a repeating group with no other actions, and the

data value always causes a limit detect, the system may lock up.

For more information See “About Sequencing Processes” on page 87.

Performing Common Tasks

46

MTS MultiPurpose TestWare®

Page 47

How to Open a Procedure

1. From the MPT control panel (or from the MPT Procedure Editor), click the

2. Double-click the desired procedure, or click the desired procedure once,

How to Save a Procedure

From the MPT Procedure Editor, click the Save Procedure icon, or click the File

menu and select the desired save option.

Alternately, from the MPT control panel, on the toolbar, click the Open

Procedure icon’s pull down menu, then select the desired save option.

Note MultiPurpose TestWare automatically appends “.000” to the file name

How to Open a Procedure

Open Procedure icon. Alternately, from the MPT Procedure Editor, click

the File menu, then click Open Procedure to display the Open Procedure

window.

then click the Open button.

you type. If you do not want to include the .000 extension, type a period

(.) at the end of your file name.

How to Preview a Procedure

From the MPT Procedure Editor, select the File menu, then click Print Preview

to view your procedure on-screen. Items preceded by an asterisk (*) have been

modified since the procedure file was open.

How to Print a Procedure

From the MPT Procedure Editor, select the File menu, then click Print

Procedure.

Click Print to File to save the procedure to a text file.

MTS MultiPurpose TestWare® Performing Common Tasks

47

Page 48

How to Run a Procedure

How to Run a Procedure

Running a procedure begins with station preparation and physical specimen

installation, both tasks that you accomplish with the Station Manager application.

The following steps assume you have already done the following:

• Created a configuration file with Station Builder, and tuned control channels

and calibrated sensor/conditioner pairs

• Opened Station Manager and selected the configuration file

• Applied hydraulic pressure to the station

• Installed the physical specimen into the test fixturing

• Set station limits

• Set up readout devices to monitor station signals

• Opened MultiPurpose TestWare

• Selected a procedure

1. Create or select an MPT specimen

Performing Common Tasks

48

Before you can run a procedure, you have to either create a new specimen or

select an existing MPT specimen for the test.

The term “MPT specimen” refers to a directory of information associated

with a specific execution of a procedure—not the physical specimen being

tested.

Your test data, as well as the procedure you ran, messages generated during

the test, recovery information, and so forth, is captured in the MPT

specimen you create for this test.

A. To create a new MPT specimen:

On the MPT control panel toolbar, click and a new MPT

specimen appears in the list box (for example, (“spec01,” “spec02,”

and so forth.). Rename the new MPT specimen as desired.

B. To select an existing MPT specimen:

On the MPT control panel toolbar, select an existing MPT specimen

from the Specimen list box.

MTS MultiPurpose TestWare®

Page 49

About Counters

About Counters

2. Start your test.

On the Station Controls panel click the run button to start the test. Look at

and listen to your test station after you start the test. If everything seems

normal, you can let your test run to completion.

Note After the completion of a test you have to press the reset button or create

a new MPT specimen to run subsequent tests.

When you create a procedure with MPT, you define the parameters of each

process in the procedure, including counter parameters.

In procedures, counters are linear tools used to indicate test progress and

facilitate recovery. It is important to understand counters and to realize that how

you define a counter can affect your test outcome and, as a result, the data that is

generated from the test.

Note Counters are not the only tools provided by the MPT application to

indicate test progress. The MPT Procedure Editor displays special

symbols when individual processes are active.

The various types of counters available for procedures are displayed on the MPT

control panel, provided the MPT control panel has been configured to display

them.

For more information See “About the MPT Control Panel” on page 25 for more information.

See “Procedure Table” on page 40 for more information about process indicators.

Types of Counters

The most prominent counters on the MPT control panel are the Run Time

counter, the Channel Counters, and the Sequence Counters.

There are also specialized counters that display only in association with specific

types of processes, such as:

• Profile counters, that appear only with the Profile Command and Profile

with ALC processes

• Status counters, that appear only with the Time History Input, Time History

Output, and Road Surface Output processes

MTS MultiPurpose TestWare® Performing Common Tasks

49

Page 50

Types of Counters

This sample procedure includes a group process labeled “Cooling

Cycles,” which contains four nested processes (with indented

label names, “Trigger at 75C,” and so forth).

Name displays the assigned process label.

Current displays the current value of the counter.

Tar get displays the assigned number of times the process should

run (or repeat).

Run time counter The Run Time counter displays the elapsed time of the current test since the last

time it was reset.

Channel counters Channel Counters display a cumulative count of segments or cycles that have

been applied to a specific channel since the start of the test.

Sequence counters Sequence Counters display the progress of individual processes within the test.

They can be especially useful for procedures that contain nested groups, because

you can configure them to show test progress within the nested structure of the

procedure.

Profile counters Note Applies only to Profile and Profile with ALC processes.

Profile Counters display counters that increment according to special markers

that profile designers put in profiles.

Status counters Note Applies only to Time History Output, Time History Input, and Road

Surface processes.

Performing Common Tasks

50

MTS MultiPurpose TestWare®

Page 51

Status counters display Elapsed Time (or Distance) and Total Time (or To ta l

Distance) counters, and a Percent Completed status bar.

• Elapsed Time displays the time since the process started. Distance displays

the distance traveled since the process started, which is calculated from the

Vehicle Speed entry on the process’ Status tab.

• Tota l Tim e displays the anticipated total time required to complete the

process (this does not include any other processes that may be part of the

test). Tot a l Di s ta n ce displays the anticipated total distance required to

complete the process, calculated from the Vehicle Speed entry on the

process’ Status tab.

• The Percent Completed status bar displays the percentage relationship of

the elapsed time (or distance) versus the total time (or distance) for the

process (the status bar updates according to the update rate of the test,

typically every 10 seconds or so).

How to Display Counters and Status Panels

You can choose to show or hide the various types of counters and status panels on

the MPT control panel when running tests.

How to Display Counters and Status Panels

Note The Run Time Counter, Channel Counters, and Sequence Counters

display by default.

Display Channel and

To display Channel Counters and Sequence Counters:

Sequence Counters

1. Open the MPT Options Editor and select the Control Panel tab.

2. Locate the Counters panel.

3. Check the boxes as desired to show or hide the counters and to choose their

display format. By default these counters are displayed.

To display the Run Time counter:

1. Open the MPT Options Editor and select the Control Panel tab.

2. Locate the Test Progress panel.

3. Check the box as desired to show or hide the Run Time counter.

Display Status panels To display Status panels:

1. Open the relevant process on the procedure table (Time History Input, Time

History Output, and Road Surface Output) and select the Status tab.

MTS MultiPurpose TestWare® Performing Common Tasks

51

Page 52

How to Display Counters and Status Panels

2. Check the Show Status Panel at Run Time box as desired. By default

status panels are not displayed.

Note If you enable the Show Status Panel at Run Time box, you have the

option of having the status panel display the distance traveled by the

vehicle, for which you type a nominal vehicle speed for the distance

calculations.

Profile Counters To display profile counters, you must include a Profile Command or Profile with

ALC process in your procedure that uses a profile that includes the keyword

“Action.”

Display individual

processes on the

Sequence Counters

panel

The Sequence Counters panel displays by default, but each counter that populates

the Sequence Counters panel must be enabled for display individually. To do

this you must open each process on the procedure table to display its Parameters

window, select the General tab, then select the desired Counter Type option.

The Counter Type options are:

• None—The counter label and counter are not displayed on the Sequence

Counters panel.

• Transient—The counter label and counter are only displayed on the

Sequence Counters panel when the process is active. When the process

ends, transient counters disappear.

• Fixed—The counter label and counter are displayed on the Sequence

Counters panel for the duration of the test.

For more information For more information, see “Action and Counter Syntax” on page 498.

For information about changing default settings, see “How to Customize the

Default Template” on page 553.

Performing Common Tasks

52

MTS MultiPurpose TestWare®

Page 53

About the Clear Counters on Reset Function

About the Clear Counters on Reset Function

With the Clear Counters on Reset check box (found on the Specimen tab of the

MPT Options Editor), you can choose whether run time, channel counters, and

profile counters:

• Clear when you reset the test (default setting), or

• Continue to increment after reset

Note Sequence Counters are always cleared on reset as this counter is used

in the recovery process.

Reset counters manually If the Clear Counters on Reset control is disabled and you want to manually

reset counters, you can:

• Select a new specimen (before resuming or between tests), or

• Right-click to reset each type of counter individually (applies to run time

counters, channel counters, and profile counters)

Use the right-mouse

menu for run time

counters

On the MPT control panel, position the cursor over the run time counter

(ensuring the procedure is locked and reset), and click the right-mouse button to

display the Reset menu. With the Reset menu, you can reset the counter.

MTS MultiPurpose TestWare® Performing Common Tasks

53

Page 54

About the Clear Counters on Reset Function

With the Reset Counters selection you can

manually reset the channel counters to zero.

With the Set Counters... window you can

manually set counter values.

Use the right-mouse

menu for channel

counters

On the MPT control panel, position the cursor in the channel counter panel

(ensuring the procedure is locked and reset) and click the right mouse button. The

Reset menu appears, which includes Reset Counters and Set Counters...

selections.

Use the right-mouse

menu for profile counters

Performing Common Tasks

54

On the MPT control panel, position the cursor over the profile counter panel

when the counters are active and click the right-mouse button to display the

Reset Counters button. With the Reset Counters button, you can manually reset

the counters to zero.

Note The procedure does not have to be in the reset state to use the Reset

Counters button for profile counters. You can reset profile counters on-

the-fly, while the test is running.

MTS MultiPurpose TestWare®

Page 55

About Working with Unit Assignment Set Editor

Use the Unit Assignment Set Editor to create and modify unit assignment sets

(UAS). Unit assignment sets define the units of measurement that are available

for each dimension used in procedures.

Access From the MPT Procedure Editor windows the access path is:

Tools > Unit Set Editor

Note To use a UAS other than the default UAS, use the Unit Selection Tab of

the MPT Options Editor. To change the default UAS selection, use the

Project Manager application, or change the selection in the Station

Options window (Station Manager > Tools > Station Options > Unit

Selection).

Unit Assignment Set Editor (part 1 of 2)

I

TEM DESCRIPTION

About Working with Unit Assignment Set Editor

Open

Save

Save As

Delete

UAS Name

UAS File

Displays the Unit Assignment Set Open window. With this window you can

select the appropriate unit assignment set and to complete the open function by

selecting the Open button.

Saves any changes to the selected unit assignment set.

Displays the Unit Assignment Set Save As window. With this window you can

view and edit the selected UAS Name and to complete the save function by

selecting the Save button.

Deletes the selected unit assignment set.

Displays the name of the unit set currently selected.

Displays the file name of the unit set currently selected.

MTS MultiPurpose TestWare® Performing Common Tasks

55

Page 56

About Working with Unit Assignment Set Editor

Unit Assignment Set Editor (part 2 of 2)

I

TEM DESCRIPTION

Comment

Displays a comment about the selected UAS. We recommend you describe the

characteristics of the unit set you create.

Dimension and Units

Displays the dimensions and corresponding units used by the system software.

When you click a dimension name, the units assigned to the current set are

highlighted. To change a setting, click the dimension, and then click the

desired units.

Note You can quickly find an item in the Dimensions or Units list boxes

with the keyboard by typing the first letter of the desired item until it is

displayed. For example: To select the engineering force unit kN, type

the letter ‘k’ repeatedly until kN is highlighted in the list box.

Standard unit sets CGSSET - Centimeters-Grams-Seconds—Defines a set of units that is based

upon centimeters, grams, and seconds.

ENGSET - U.S. Engineering Units—Defines a set of units that contains

customary U.S. engineering units. It provides force-related units in “kip,” and

length-related units in “in.”

ENGSETSM - U.S. Engineering Units (small)—Defines a set of units that

contains customary U.S. engineering units. It provides force-related units, in

“lbf,” and length-related units in “in.”

SISET - SI (Systeme International d’Unites)—Defines a set of units that

contains customary international (metric) units. It provides force-related units in

“kN,” and length-related units in “mm.”

Performing Common Tasks

56

SISETSM - SI (Systeme International d’Unites) - small—Defines a set of

units that contains customary international (metric) units. It provides force, and

force-related units in “N,” and length-related units in “mm.”

SYSDEF - System Units Definition—Contains a copy of the units that are used

in the hardware and software to represent test values of interest.

MTS MultiPurpose TestWare®

Page 57

About the MPT Specimen Log

Use the MPT Specimen Log to display a record of test events in the Message

Logs window.

Access From the MPT Procedure Editor window, the access paths are:

Display > Specimen Log

Or:

MPT control panel >

About the MPT Specimen Log

The MPT Specimen Log records selected station and test events as they occur.

Note The MPT Specimen Log is displayed on the Message Logs window,

which can also display Station Log information (by selecting Station

Log in the Log list).

Events that can be logged include file events, resource conflicts, hydraulic status

changes, station state changes, detector activity, hardware over temperature

conditions, and full-scale changes.

Counter data is saved to the MPT Specimen Log automatically and manually .

Auto-archive function The MPT application automatically saves your MPT Specimen Log when it

accumulates at least 1000 log entries. When log entries are saved to the log file,

they are cleared from the MPT Specimen Log display.

Specimen log file

The default name for the current MPT Specimen Log file is specimen .log.

naming

MTS MultiPurpose TestWare® Performing Common Tasks

57

Page 58

About the MPT Specimen Log

CAUTION

Archived log files are named specimen000.log, specimen001.log,

specimen002.log, and so forth, up to specimen500.log.

Note The maximum number of log files that can be saved for a particular test

is 500.

Once you reach 500 log files, additional log files overwrite the oldest log files in

order (typically archiving restarts at specimen 000.log).

When a log file is saved (either manually or automatically), a log entry is made

noting the archival. This entry includes a time/date stamp and information about

where the file was saved. This entry becomes the first entry in the current log.

The MPT software can unexpectedly quit if you run out of disk space when

saving log files.

Quitting while a test is in progress can result in a loss of data.

If you think your test may generate an excessive number of MPT Specimen Log

entries, you should filter the messages written to the MPT Specimen Log with the

MPT Options Editor.

If the MPT application shuts down as a result of log files exhausting disk space,

you must remove some of the MPT Specimen Log files from your disk before

you restart the system software.

Message Logs Window (part 1 of 3)

I

TEM DESCRIPTION

Displays the Open Message Log File window where you can open any

archived or saved message log file (.log) you wish to view.

Saves message log entries to a log file.

If you click the Save icon and no log entries are selected, all of the

messages in the MPT Specimen Log are saved to file and the entire log is

cleared.

If you click the Save icon and one or more log entries are selected, all of

the messages up to and including the last selected message are saved to

file and cleared from the log.

Performing Common Tasks

58

MTS MultiPurpose TestWare®

Page 59

Message Logs Window (part 2 of 3)

ITEM DESCRIPTION

Closes the selected MPT Specimen Log and removes the log from the Log

list.

Opens the Message Log Print window.

With the Message Log Print window you can set certain print parameters

(such as Print Range and Print Filters), access the Print Setup window,

and initiate printing of the selected message log.

Displays the Message Log Print To File window. With the Message Log

Print To File window you can save your log as a text (.txt) file.

Adds your message entry to all active logs.

Note User entries are sent to all active logs (Station log, Basic

TestWare log, MPT Specimen log); user entries are not affected

by filtering attributes.

Deletes user-entered messages from the message log.

Note You can only delete user-entered messages.

Copies the selected Message Log entries to the clipboard.

About the MPT Specimen Log

Enables all the display options or allows individual display option enable/

disable functions.

If you click on the enable icon, all display functions (Date/Time, Severity,

Source) are enabled.

If you click on the down arrow, the individual display functions appear. If

you click on a function, the function state changes between enabled and

disabled. If a check mark appears next to the function, that function is

enabled.

Log

Displays the current log file. Use the down arrow to display other log files

that are available.

Log File

MTS MultiPurpose TestWare® Performing Common Tasks

Displays the path to the current log file.

59

Page 60

About the MPT Specimen Log

Message Logs Window (part 3 of 3)

I

TEM DESCRIPTION

Scroll to new entry

Disables or enables the MPT Specimen Log scrolling function. This

function allows the message log to automatically shift (scroll) to display

new entries as they occur.

Note By default, the Scroll to new entry box is enabled.

If you select Scroll to new entry, new log entries appear at the bottom of

the log as they occur. The log scrolls down automatically to ensure that the

latest entry is displayed.

If you clear the Scroll to new entry, the application adds new log entries

to the bottom of the log as they occur, but the log does not automatically

scroll down to the latest entry. New entries may not be visible unless you

manually scroll to the bottom of the log. With this selection you can

review the contents of the log without the window ‘jumping’ to the bottom

of the display each time a new log entry arrives.

For more information See “About Counters” on page 49.

For information about filtering MPT Specimen Log entries, see “MPT Options

Editor Specimen Tab” on page 73.

Performing Common Tasks

60

MTS MultiPurpose TestWare®

Page 61

Chapter 7

MPT Options Editor

Contents About the MPT Options Editor 62

MPT Options Editor Execution Tab 62

About Setpoint Use with MPT Test Procedures 66

About Command Hold and Stop Behaviors 67

About Data Acquisition Resulting From Command Stop Behavior 68

About Command Stop Behaviors and Automatic Setpoint Adjustments

69

About Transition States 70

MPT Options Editor Specimen Tab 73

MPT Options Editor Recovery Tab 74

About Test Recovery 75

MPT Options Editor Specimen Log Tab 77

MPT Options Editor Control Panel Tab 79

MPT Options Editor Properties Tab 80

MPT Options Editor Unit Selection Tab 81

MTS MultiPurpose TestWare® MPT Options Editor

61

Page 62

About the MPT Options Editor

About the MPT Options Editor

Use the MPT Options Editor to set preferences that are saved with the

procedure.

Saving option

preferences

When you create a new procedure, it contains default settings for all of the

controls in the Options Editor, such as preferences for the data file format,

command hold behavior, unit assignment set, and so forth. You can change these

default settings by modifying the “default.000” file.

For more information See “Default Templates” on page 553.