Page 1

be certain.

709 Alignment System

Product Information

100-111-028 M

Page 2

Copyright information © 2003-2008 MTS Systems Corporation. All rights reserved.

Trademark information MTS, TestStar, and TestWare are registered trademarks of MTS Systems

Corporation within the United States. These trademarks may be protected in

other countries.

Windows Vista is a registered trademark of Microsoft Corporation.

Proprietary information Software use and license is governed by MTS’s End User License Agreement

which defines all rights retained by MTS and granted to the End User. All

Software is proprietary, confidential, and owned by MTS Systems Corporation

and cannot be copied, reproduced, disassembled, decompiled, reverse

engineered, or distributed without express written consent of MTS.

Software validation and

verification

Publication information

MTS software is developed using established quality practices in accordance

with the requirements detailed in the ISO 9001 standards. Because MTSauthored software is delivered in binary format, it is not user accessible. This

software will not change over time. Many releases are written to be backwards

compatible, creating another form of verification.

The status and validity of MTS’s operating software is also checked during

system verification and routine calibration of MTS hardware. These controlled

calibration processes compare the final test results after statistical analysis

against the predicted response of the calibration standards. With these established

methods, MTS assures its customers that MTS products meet MTS’s exacting

quality standards when initially installed and will continue to perform as intended

over time.

Manual Part Number Publication Date

100-111-028 A

100-111-028 B

100-111-028 C

100-111-028 D

100-111-028 E

100-111-028 F

100-111-028 G

100-111-028 H

100-111-028 J

100-111-028 K

100-111-028 L

100-111-028 M

July 2003

August 2003

November 2003

December 2003

January 2004

February 2004

February 2004

February 2004

April 2004

January 2005

March 2006

December 2008

2

709 Alignment System

Page 3

Contents

Preface 7

About This Manual 8

What You Are Expected to Know 9

Conventions 10

Technical Support 11

Introduction 15

709 Alignment Software 16

609 Alignment Fixture 17

Additional Information 18

CE Hardware Specifications 19

Alignment Procedure Overview 21

Installation 23

Obtain the License File and NIC Installation 25

Hardware Installation 27

709 Alignment System Installation 27

Specimen Installation 30

Software Installation 32

Remove previous installations 32

.Net Framework Installation 33

709 Alignment Software Installation 35

National Instruments (NI) FieldPoint Installation 39

Upgrading The Firmware Located On The FieldPoint FP-2000 Hardware 45

TCPIP Configuration 47

Note for Windows Vista Systems 47

TCPIP Configuration for Systems Running Windows XP 47

TCPIP Configuration for Systems Running Windows 2000 50

FieldPoint Configuration 52

MTS Licensing Software Installation (New License) 58

Updating MTS Licenses (Replacement License) 64

Options 65

FieldPoint Data Acquisition 66

709 Alignment System Contents

3

Page 4

Global Settings 66

User Preferences 69

Specimen 75

Specimen Offsets 83

Printable Symbols 86

Get Specimen Offset Values 87

Align 93

Alignment Wizard 97

Angular Adjustments 100

If the X coordinate is positive 101

If the X coordinate is negative 102

If the Y coordinate is positive 103

If the Y coordinate is negative 104

Concentric Adjustments 105

Crosshead Mounted 609 Alignment Fixture 106

If the upper gauge X coordinate is positive 106

If the upper gauge X coordinate is negative 107

If the upper gauge Y coordinate is positive 108

If the upper gauge Y coordinate is negative 109

Base Mounted 609 Alignment Fixture 110

If the upper gauge X coordinate is negative 110

If the upper gauge X coordinate is positive 111

If the upper gauge Y coordinate is negative 112

If the upper gauge Y coordinate is positive 113

Validate 115

Legend 117

Data Acquisition 119

Start/Resume/Stop/Clear 119

Data acquisition with static load 120

Data acquisition with dynamic load 121

Pass/Fail indicators 122

4

Contents

709 Alignment System

Page 5

File Output 123

Fill 127

Report 128

Report Generator and Templates 129

Run Report Generator 130

MTS Provided Templates 132

Creating Custom Templates 133

Appendix 145

Resetting the FP-20xx 146

Resetting the FieldPoint Configuration 147

Possible Local Area Connection Problems 148

Possible Problem with Large Fonts 149

Changing the FieldPoint IP Address Sub-Net 150

FLEXlm Licensing Error 151

Firewall Licensing Error 153

Using the 793 Station Manager Function Generator 154

709 Alignment System Contents

5

Page 6

6

Contents

709 Alignment System

Page 7

Preface

Safety first! Before you attempt to use your MTS system, read and understand all safety

Contents About This Manual 8

information. Safety information can be found in a separate Safety manual or in a

section titled “Safety Practices” in one of the manuals in your documentation set.

Improper installation, operation, or maintenance of your system can result in

hazardous conditions that can cause personal injury or death, and damage to your

equipment and specimen. It is very important that you remain aware of hazards

that apply to your system.

What You Are Expected to Know 9

Conventions 10

Technical Support 11

709 Alignment System Preface

7

Page 8

About This Manual

About This Manual

This manual includes information on installing and operating the MTS

Alignment software. The 709 Alignment software works in conjunction with

the MTS Model 609 Alignment Fixture and strain-gaged specimens. There are

options in the 709 Alignment software that allows specimens with fewer

channels to be used for alignment.

Preface

8

709 Alignment System

Page 9

What You Are Expected to Know

What You Are Expected to Know

Microsoft Windows

knowledge

You should have a working knowledge of the Microsoft Windows operating

system before you use your system. For example, you should be able to:

• Use the mouse.

• Maneuver around the desktop.

• Locate, open, close, copy, and save documents.

If you are not sure how to do these things, take some time to learn them before

you continue.

Testing knowledge A premise of this manual is that you have had some experience or exposure to

servohydraulic testing, or access to someone who has.

709 Alignment System Preface

9

Page 10

Conventions

Conventions

Notes Notes provide additional information about operating your system or highlight

Control names References to items shown in windows, including window names, window

Illustrations Illustrations appear in this manual to clarify text. It is important for you to

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

easily overlooked items. For example:

Note Using multiple instances of the scope (on multiple stations) can slow

system response time.

controls, menu names, and menu commands are shown in bold font style.

References to controls on equipment, including keyboards, control panels, and

consoles are also shown in bold font style.

remember that these illustrations are examples only and do not necessarily

represent your actual system configuration or application.

10

Preface

709 Alignment System

Page 11

Technical Support

Technical Support

Start with your

manuals

Technical support

numbers

MTS web site

www.mts.com

E-mail: info@mts.com

Telephone HELPLine 800-328-2255

The manuals supplied by MTS provide most of the information you will need to

use and maintain your equipment. If your equipment includes MTS software, you

should look for README files for additional product information.

If you cannot find answers to your technical questions from these sources, you

can use the internet, telephone, or fax to contact MTS for assistance. You can also

fill out the Problem Submittal Form that is available on the MTS web site and in

the back of many MTS manuals that are distributed in paper form.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact MTS in one of the

following ways.

The MTS web site gives you access to our technical support staff by means of a

Problem Submittal Form and a Technical Support link.

• Problem Submittal Form:

www.mts.com > Contact MTS > Problem Submittal Form

• Technical Support:

www.mts.com > Contact MTS > Technical Support

Weekdays 7:00 A.M. to 6:00 P.M.,

Central Time

Fax 952-937-4515

Please include an MTS contact name if possible.

709 Alignment System Preface

11

Page 12

Technical Support

Before you

contact MTS

Know your site number

and system number

Know information from

prior technical

assistance

MTS can help you more efficiently if you have the following information

available when you contact us for support.

The site number contains your company number and identifies your equipmen t

type (material testing, simulation, and so forth). The number is usually written on

a label on your MTS equipment before the system leaves MTS. If you do not

have or do not know your MTS site number, contact your MTS sales engineer.

Example site number: 571167

When you have more than one MTS system, the system number identifies which

system you are calling about. Y ou can find your job number in the papers sent to

you when you ordered your system.

Example system number: US1.42460

If you have contacted MTS about this problem before, we can recall your file.

You will need to tell us the:

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem you are experiencing and know the answers to the

following questions.

• How long has the problem been occurring?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the model and serial numbers of the suspect equipment?

Know relevant computer

information

Preface

12

If you are experiencing a computer problem, have the following information

available.

• Manufacturer’s name and model number

• Operating software type and service patch information. Examples:

– Windows Vista

– Windows XP Service Pack 1 (SP2)

• Amount of system memory. Example: 640 MB of RAM.

• Amount of free space on the hard drive in which the application resides.

Example: 11.2 GB free space, or 72% free space.

• Current status of hard-drive fragmentation. Example: 3% total

fragmentation.

709 Alignment System

Page 13

Technical Support

Know relevant software

information

If you contact MTS

by phone

For MTS software application problems, have the following information

available.

• The software application’s name, version number, build number, and if

available, software patch number. This information is displayed briefly

when you launch the application, and can typically be found in the “About”

selection in the “Help” menu.

Example: Station Manager, Version 3.3A, Build 1190, Patch 4

• The same information for other MTS software included with your system

• Names of other non-MTS applications that are running on your computer,

such as screen savers, keyboard enhancers, print spoolers, and so forth

Your call will be registered by a HELPLine agent if you are calling within the

United States or Canada. Before connecting you with a technical support

specialist, your agent will ask you for your site number, name, company,

company address, and the phone number where you can normally be reached.

Identify system type To assist your HELPLine agent with connecting you to the most qualified

technical support specialist available, identify your system as one of the

following types:

• Electromechanical materials test system

• Hydromechanical materials test system

• Vehicles test system

• Vehicles component test system

• Aero test system

Be prepared to

Prepare yourself for troubleshooting while on the phone.

troubleshoot

• Call from a telephone close to the system so that you can try implementing

suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

709 Alignment System Preface

13

Page 14

Technical Support

Write down relevant

information

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action

Problem Submittal

Form in MTS manuals

Prepare yourself in case we need to call you back.

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording

or performance monitoring.

is taken regarding your problem or request. If you have questions about the status

of your problem or have additional information to report, please contact MTS

again.

In addition to the Problem Submittal Form on the MTS web site, there is also a

paper version of this form (postage paid) in the back of many MTS manuals. Use

this form to forward problems you are experiencing with your MTS equipment,

whether it be software, hardware, manuals, or service. This form includes check

boxes that allow you to select when you expect us to respond to your input. We

guarantee a timely response—your feedback is important to us.

14

Preface

709 Alignment System

Page 15

Introduction

This manual includes information on installing and operating the MTS 709

Alignment software. The 709 Alignment software works in conjunction with

the MTS Model 609 Alignment Fixture and strain-gaged specimens. There are

options in the 709 Alignment software that allows specimens with fewer

channels to be used for alignment.

What you need to

know

Contents 709 Alignment Software 16

MTS Systems Corporation assumes that you know how to use your controller.

See the appropriate manual for information about performing any controllerrelated step in this manual’s procedures. You are expected to know how to

perform the following procedures:

• Turn hydraulic pressure on and off (servo hydraulics only)

• Select a control mode

• Position the load train components

• Zero a sensor signal

• Zero a sensor output

• Use your grips and fixtures

• Define a simple test

• Run a test

609 Alignment Fixture 17

Additional Information 18

709 Alignment System Introduction

15

Page 16

709 Alignment Software

709 Alignment Software

MTS 709 Alignment system includes the hardware and software to acquire,

analyze, and display bending strains for alignment and bending strain verification

purposes. Its graphical interface allows you to quickly align your system or

verify how much bending strain is being applied to the specimen. One of the key

attributes of this software is that it can separate the bending strain of the

specimen from that of the tensile strain.

The best method of determining bending strain is to use a strain-gaged specimen.

The software interfaces directly with a strain-gaged specimen and displays

bending strain graphically on the monitor of your PC. Continual scanning of

bending strains allows you to align your system or verify the bending strain at

various levels that will occur during the test. For reports, a text data file can be

written to disk and opened in Microsoft Excel for further analysis and customer

report generation.

709 Alignment software requires an alignment specimen with a 37-pin

D-connector. The software also requires Windows 2000 or later and a dedicated

RJ45 ethernet connector. Calibrated load can be displayed with an analog I/O

channel.This is required for some certifications such as ASTM E1012. Thin and

thick flat specimens, as well as round specimens are supported.

16

Introduction

The 709 Alignment System includes data acquisition with conditioning,

software, a manual, and connections for ethernet, analog I/O, and an alignment

specimen. See “Hardware Installation” on page 27 for addition information.

709 Alignment System

Page 17

609 Alignment Fixture

The MTS Model 609 Alignment Fixture for material testing systems that saves

time compared to manual alignment methods. A product information manual is

provided describing the alignment process and the use of strain-gaged specimens.

The main feature of the 609 is its capability to perform alignment adjustments

while the load train is fully loaded. This eliminates any inaccuracies involved in

trying to account for the small changes in alignment that frequently occur during

the preloading process. In addition, because the fixture remains preloaded at all

times, previous alignment adjustments are not lost when small changes in

alignment are required.

These alignment fixtures are readily adaptable to other load units as well. Refer

to the Model 609 Alignment Fixture Product Information manual (MTS part

number 015-031-901) for any special adapter kit that might be required in

addition to the alignment fixture.

609 Alignment Fixture

709 Alignment System Introduction

17

Page 18

Additional Information

Additional Information

The following documents provide additional and background information as it

pertains to the importance of proper specimen and machine alignment in

materials testing.

• S-400-E: Certified Materials Test Laboratories (CMTL): Metallic Materials

• SAE AS7101 Revision B - NADCAP Alignment Requirements

• ASTM E 1012 - 99: Standard Practice for Verification of Specimen

Alignment Under Tensile Load

• Versailles Project on Advanced Materials and Standards (VAMAS)

Technical Working Area 13, Low Cycle Fatigue

Recent Intercomparisons on Low Cycle Fatigue and Alignment

Measurements

Report No. 41

ISSN 1016-2186

February 2003

18

Introduction

• Versailles Project on Advanced Materials and Standards (VAMAS)

Technical Working Area 13, Low Cycle Fatigue

A Procedure for the Measurement of Machine Alignment in Axial Testing

Report No. 42

ISSN 1016-2186

February 2003

709 Alignment System

Page 19

CE Hardware Specifications

PARAMETER SPECIFICATION

Additional Information

Environmental

Ambient Temperature

Relative Humidity

Altitude

Power Input

Input Voltage

Input Frequency

AC Power

Insulation Over

Voltage

Pollution Degree

AC Power Disconnect Remove the AC power cord from the power supply.

For Indoor Use Only

5°C (41°F) 40°C (104°F)

10% to 85%, non-condensing

For use at altitudes up to 2000m (6500 ft.)

Power Factor Corrected Universal Input

100 to 240 VAC

47 to 63 Hz

< 100 Watts

Category II

2

This will remove AC power from the 709 Alignment

System.

Be sure to locate the power supply so you have

adequate access to disconnect the power cord from

the power supply.

709 Alignment System Introduction

19

Page 20

Additional Information

20

Introduction

709 Alignment System

Page 21

Alignment Procedure Overview

Following is an overview of a typical alignment procedure. It is intended as a

guide and will apply to most system configurations.

1. Check the controller setup and tuning before inserting the alignment

specimen instrumented with strain gauges: With no specimen clamped in the

grips, verify the stroke control tracks without drift. With an expendable

specimen clamped in the grips, verify the load control smoothly tracks a

slow (less than 1 Hz) function generator ramp.

2. Insure that the specimen is properly connected to the 709 electronics. Wait

20 to 30 minutes to insure there are no temperature gradients.

3. Confirm the specimen geometry and end levels in the specimen tab. The end

levels are typically set to the Load @ 2000 µe shown in the second column.

4. In the align tab, check the specimen offsets. Do this by toggling between

None, Current Tare, and Specime n Gauge. Current Tare and Specimen

Gauge (stored and averaged offsets) should be very close (within 5%). If

they are not, the Specimen Gauge offsets should be cleared and reestablished.

5. With the system in displacement control install the specimen in the lower

grip (or upper grip if desired). Clamp that end of the specimen in the grip.

6. Zero the load cell.

7. Move the actuator until the other end of the specimen is in the proper

location of the other grip is in position to clamp.

8. Now check to see if the Bent Offset is properly established. Do this by

toggling between Current Tare and Bent Offset. Normally , you should see

very little change between Current Tare and Bent Offset. Note that Bent

Offset is not really needed unless the specimen is not straight (i.e. has

manufacturing eccentricities or has been deformed).

709 Alignment System Alignment Procedure Overview

21

Page 22

9. Once the offsets are established, the actual alignment can take place. Make

sure the specimen is in the front orientation.

10. Clamp the other grip.

11. Switch the controller to load control.

12. Zero the load command.

13. Start the Alignment Wizard.

14. Follow the adjustment recommendations.

15. Gather data as described in the validation section of the manual.

16. To improve the alignment validation, you might wish to re-measure the bent

offset (possibly less prone to 180 degree rotation error when the machine is

better aligned) and adjust the alignment a little more.

Alignment Procedure Overview

22

709 Alignment System

Page 23

Installation

Contents Obtain the License File and NIC Installation 25

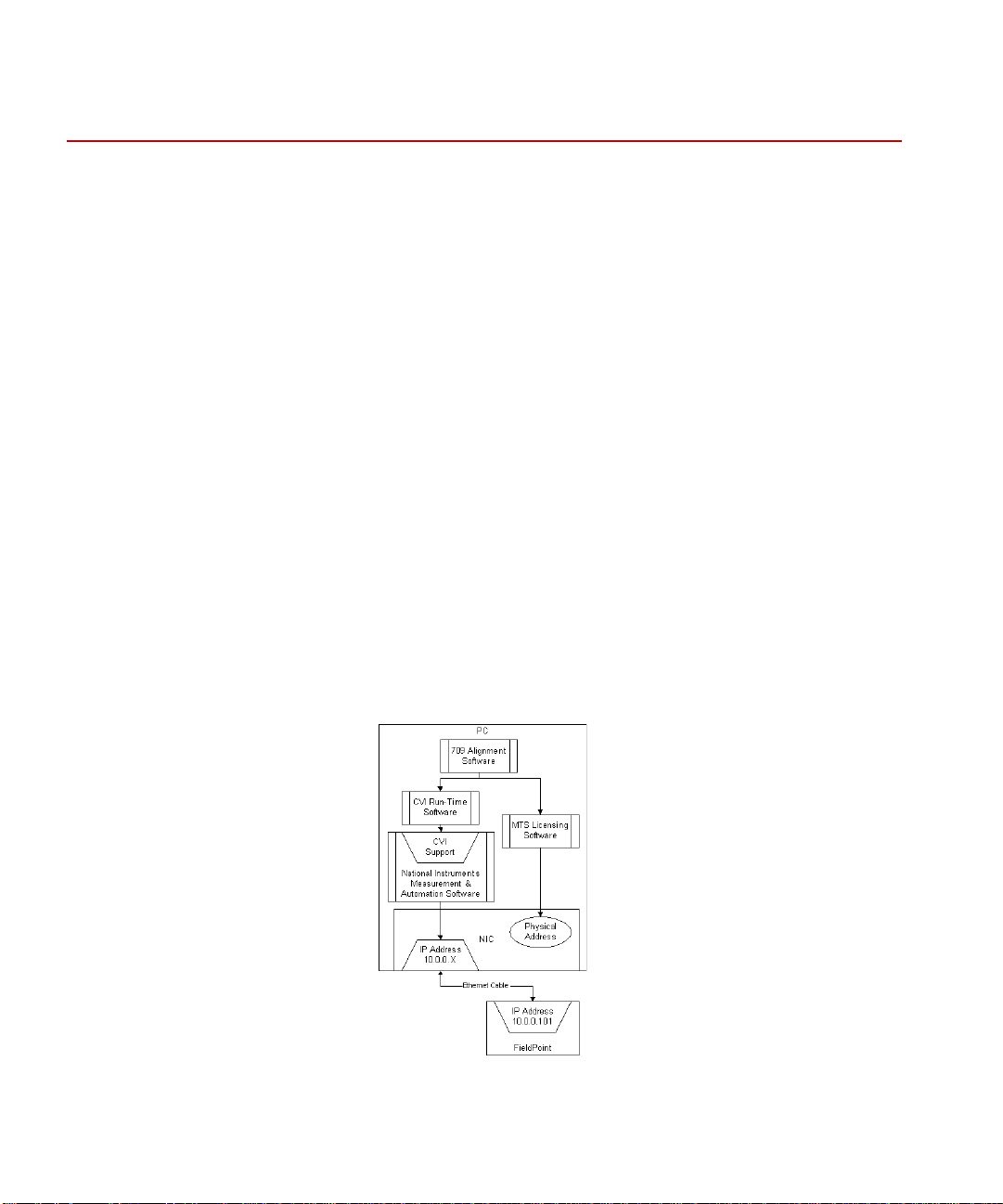

Installation of the 709 Alignment system consists of both hardware and software

installations.

The hardware installation consists of cabling the 709 Alignment System

hardware to the network and system controller, connecting the specimen strain

gauge connector, and connecting the power cord.

The software installation consists of installing the National Instruments Feild

Point software, the .Net Framework, and the 709 Alignment software application.

Hardware Installation 27

709 Alignment System Installation 27

Specimen Installation 30

Software Installation 32

.Net Framework Installation 33

709 Alignment Software Installation 35

National Instruments (NI) FieldPoint Installation 39

Upgrading The Firmware Located On The FieldPoint FP-2000

Hardware 45

TCPIP Configuration 47

FieldPoint Configuration 52

MTS Licensing Software Installation (New License) 58

Updating MTS Licenses (Replacement License) 64

709 Alignment System Installation

23

Page 24

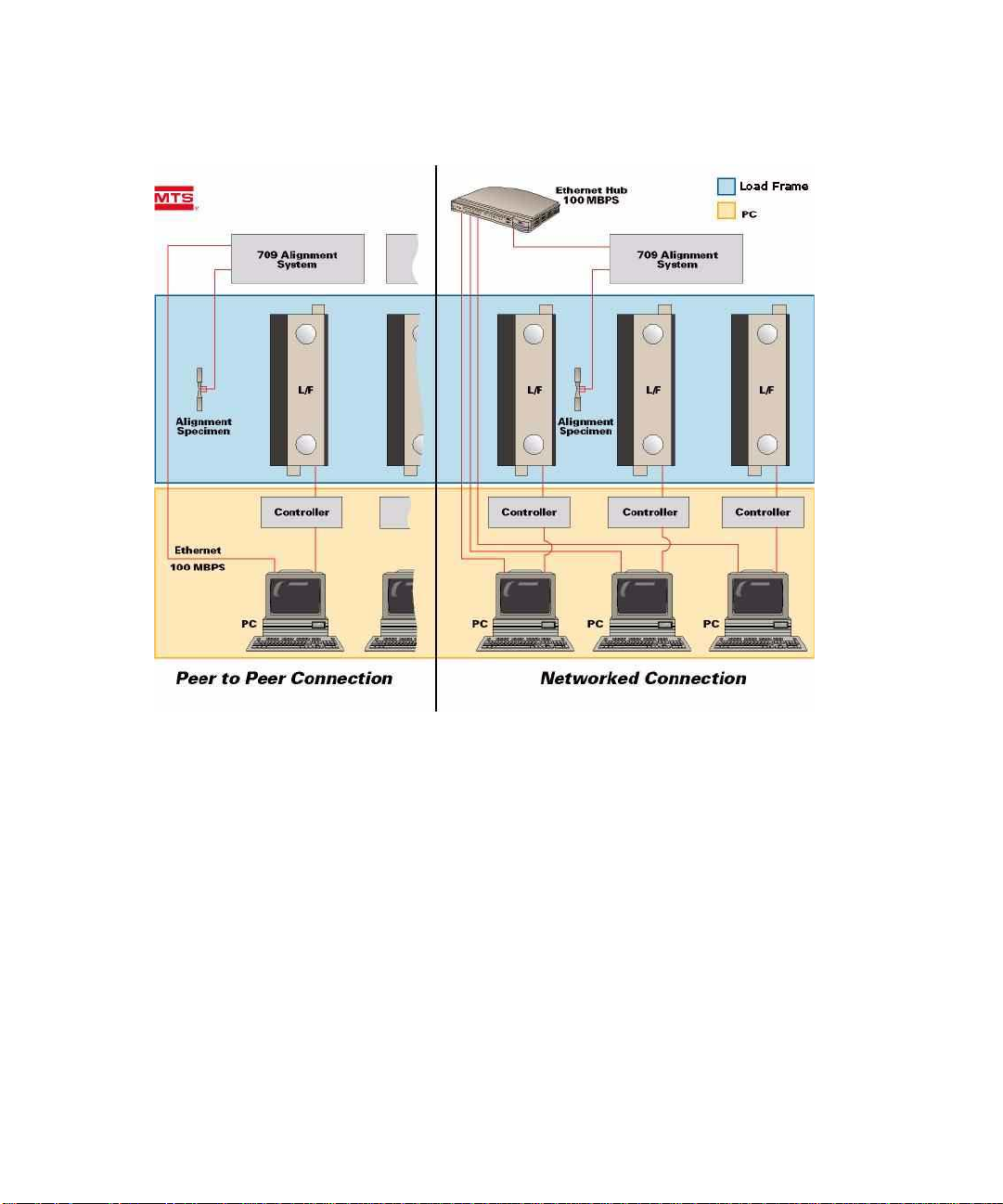

Typical installation environments

For peer to peer connections, a crossover ethernet cable is required.

For networked connections, a standard ethernet cable is required.

24

Installation

709 Alignment System

Page 25

Obtain the License File and NIC Installation

Obtain the License File and NIC Installation

Before you install the licensing software later in this section, you will need to

obtain a license file.

One license file is supplied for each 709 alignment system.

In a networked connection environment, the license file is created for the PC with

the NIC, which will be the “server” and any other PC on the network will be a

“client”. The client will use the same license file as used for the server in order to

install the MTS licensing software. The server PC will need to be running for the

client PC to run the Alignment software.

In most cases, the 709 Alignment system will be configured at MTS and the

licence file will be created and shipped with the system. However, in some cases,

the 709 Alignment system will be configured on site and you will need to obtain

a license file from the factory. If you already have a license, you only need to

install the network interface card (NIC) and skip the rest of this procedure.

T o obtain the license file, you need to get the Physical Address of the NIC and

send that physical address number to MTS. MTS will then send you the license

file required for the MTS licensing software installation.

1. The 709 Alignment software comes with two batch files that will retrieve

the information MTS needs to provide you with the license file. To start

with, insert the 709 Alignment software CD in the computer’s Compact

Disk drive. Copy the two batch files (IPConfigAfter.bat and

IPConfigBefore.bat) to your C:\ drive.

2. The first batch file should be run before you install the NIC; this will

retrieve physical addresses of any network card(s) that might already be

installed and generate a text file that contains that information. Locate the

file IPConfigBefore.bat that you just copied to your C:\ drive and dou ble

click to run it.When IPConfigBefore.bat is done running, a text file

(IPConfigBefore.txt) is generated and placed on your C:\ drive.

709 Alignment System Installation

25

Page 26

Obtain the License File and NIC Installation

3. Install the network interface card. Instructions for installing the NIC into the

computer and loading the appropriate drivers are supplied with the card.

4. The second batch file should be run after you install the NIC; this will

retrieve the physical addresses of all network cards including the one just

installed for the 709 Alignment system. Running this batch file also

generates a text file with the physical address information. Locate the file

IPConfigAfter.bat that you just copied to your C:\ drive and double click to

run it. When IPConfigAfter.bat is done running, a text file

(IPConfigAfter.txt) is generated and placed on your C:\ drive.

5. Open the two text files (IPConfigBefore.txt and IPConfigAfter.txt).

Compare the two files to find the Physical Address of the Ethernet adapter

you just added (which is not in IPConfigBefore.txt). Email the Host Name

(which is listed in both files) and the Physical Address to

709license@mts.com.

6. Yo u will be sent the license file on a floppy disk or as an attachment to a

reply email. You will need this in Step 6 of the MTS Licensing Software

Installation (New License) section.

26

Installation

709 Alignment System

Page 27

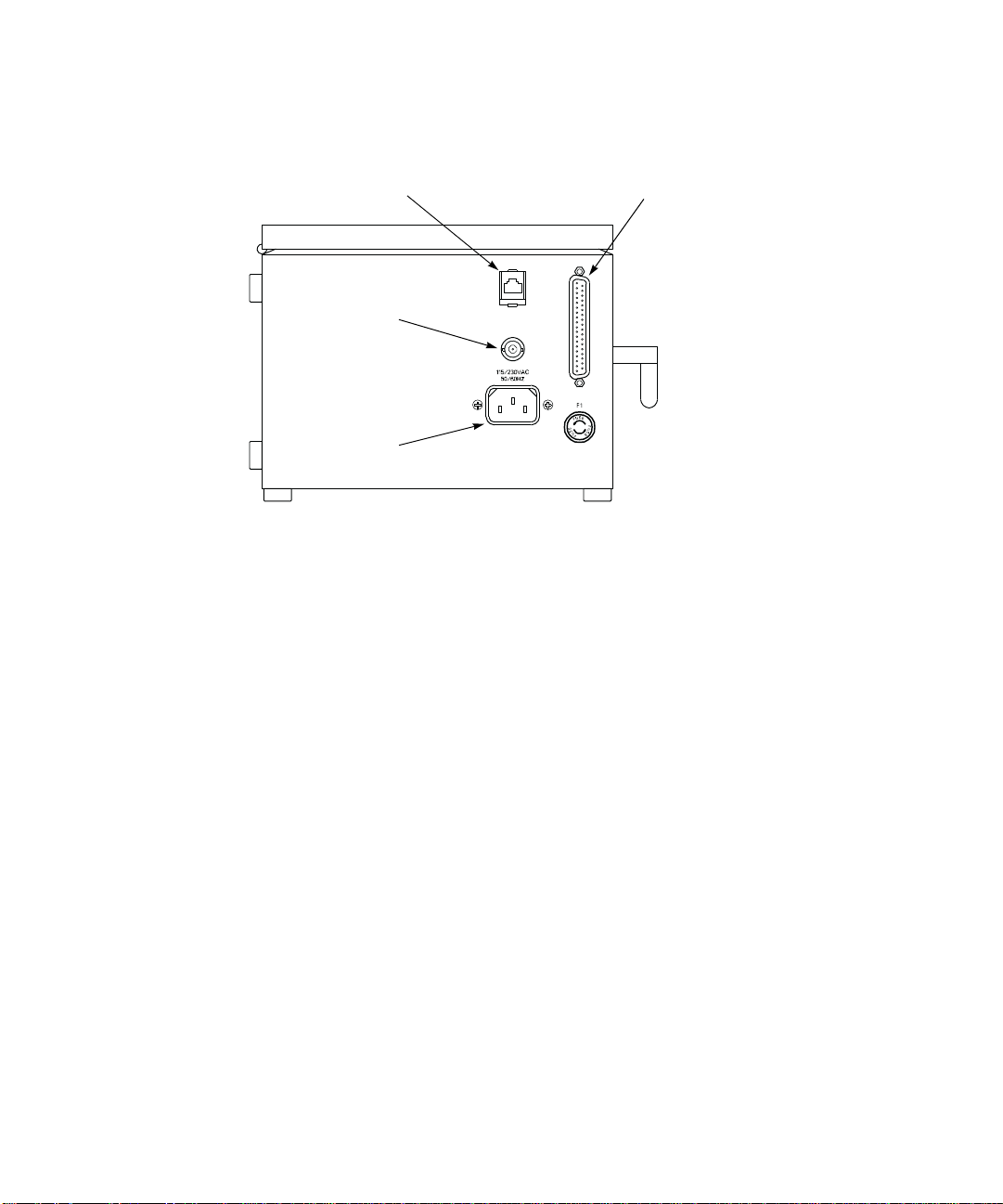

Hardware Installation

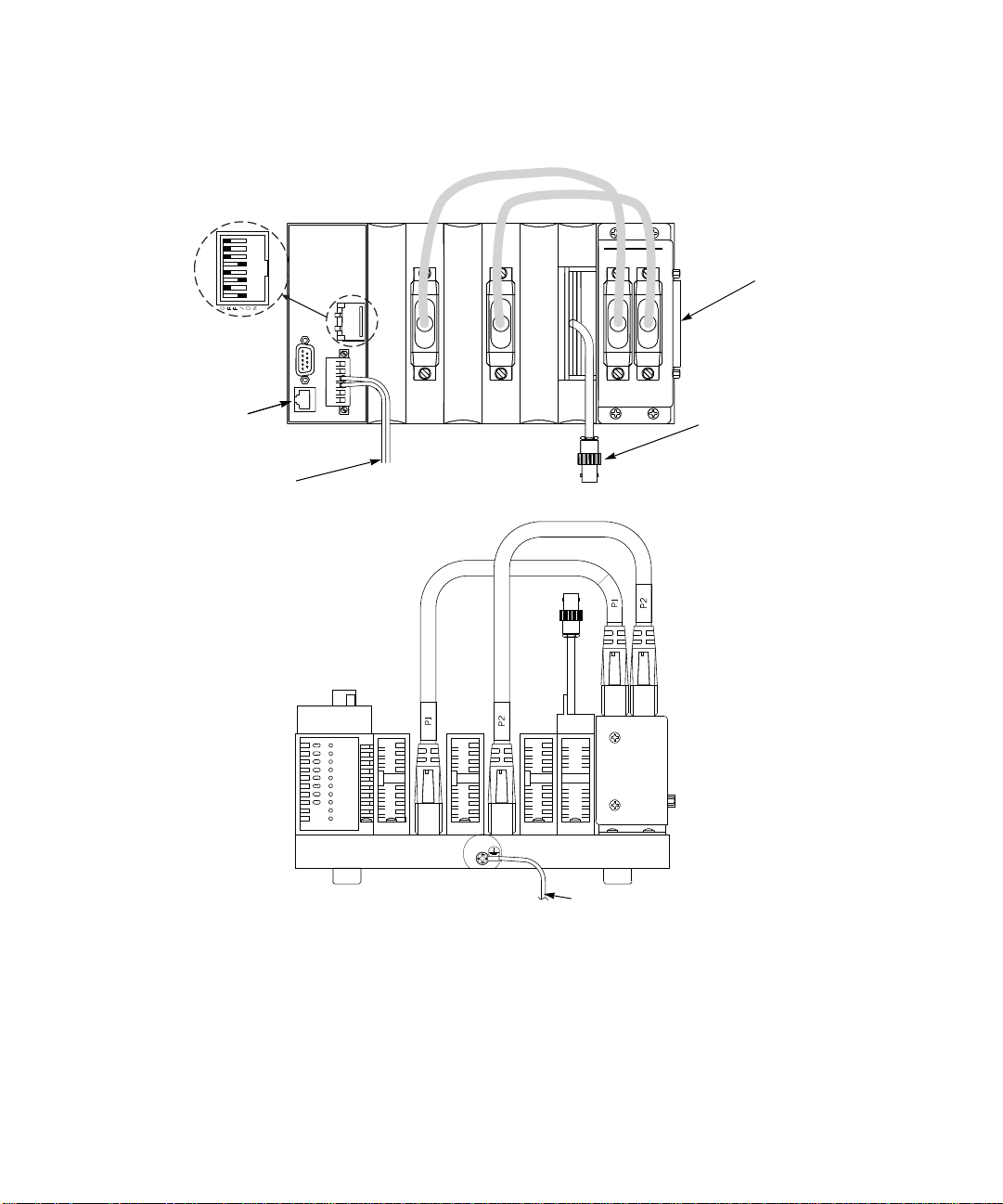

709 Alignment System Installation

Connect the 709 Alignment System as follows:

1. If Load From Analog Input Signal will be used (see “Load Analog Input

Signal” on page 66), connect the analog I/O cable from the system

controller. (Cabling for this connection must be supplied by the customer.)

For most MTS testing systems, this will be from the TestStar Controller

Analog 1 output configured for the load/force signal.

2. Connect the network cable.

The network connection can be to either a site network or directly to the

computer.

If the 709 Alignment System will be connected to a site network, ensure that

it is on the same subnet as the computer that will be used for the alignment

procedure.

Hardware Installation

3. Connect the alignment specimen cable.

Specimens purchased from MTS have the strain gages wired into a

37-pin D connector. If you are supplying your own specimen, refer to the

specimen wiring diagram for connector pin assignments.

4. Plug in the power cord to apply power to the 709 Alignment System.

There is no on/off switch on the 709 Alignments System.

Verify all modules in the 709 Alignment System box are seated properly

(both down on the base and sideways against the adjacent modules) and

have green lights for Power and Ready. If necessary, push on the end to

slide the modules towards the power supply.

709 Alignment System Installation

27

Page 28

Hardware Installation

Specimen

connection

Network

connection

Analog I/O connection

(Load cell signal from

Test Con tro ller)

Power

connection

Standard Configuration

709 Alignment System

cable connections

Installation

28

709 Alignment System

Page 29

Specimen

connection

Network

connection

Analog I/O connection

(Load cell signal from

Test Controller)

Power

connection

CE Configuration

Dip switch

settings

Protective earth ground. Connect the

ground terminal to the system safety

ground using 14 AWG (1.6mm) wire.

Hardware Installation

709 Alignment System Installation

29

Page 30

Hardware Installation

Thin

Thick Round

Thin - rotate 90 degrees

Specimen Installation

When installing the specimen in the grips, ensure the orientation of strain

gauge 12 (G12) with respect to the 609 Alignment Fixture matches the

following illustrations. G12 must be positioned as shown with respect to the

609 adjustments (A0, A90, A180, A270, C0, C90, C180, C270), for the

alignment wizard and 609 Alignment Fixture adjustments to function

properly.

30

Installation

709 Alignment System

Page 31

Hardware Installation

RED

WHT

BLK

RED

WHT

BLK

RED

WHT

BLK

RED

WHT

BLK

RED

WHT

BLK

RED

WHT

BLK

RED

WHT

BLK

RED

WHT

BLK

RED

WHT

BLK

RED

WHT

BLK

RED

WHT

BLK

RED

WHT

BLK

EXC

VIN +

COM

CH 0

EXC

VIN +

COM

CH 1

EXC

VIN +

COM

CH 2

EXC

VIN +

COM

CH 3

EXC

VIN +

COM

CH 4

EXC

VIN +

COM

CH 5

EXC

VIN +

COM

CH 6

EXC

VIN +

COM

CH 7

EXC

VIN +

COM

CH 8

EXC

VIN +

COM

CH 9

EXC

VIN +

COM

CH 10

EXC

VIN +

COM

CH 11

20

1

2

21

3

22

23

4

5

24

6

25

26

7

8

27

9

28

29

10

11

30

12

31

32

13

14

33

15

34

35

16

17

36

18

37

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

D-37P

Specimen wiring

diagram

709 Alignment System Installation

31

Page 32

Software Installation

Software Installation

Software installation consists of installing several pieces of software:

• .Net Framework Installation

• 709 Alignment Software Installation

• National Instruments (NI) FieldPoint Installation

• Upgrading The Firmware Located On The FieldPoint FP-2000 Hardware

• TCPIP Configuration

• FieldPoint Configuration

• MTS Licensing Software Installation (New License)

• Updating MTS Licenses (Replacement License)

The software is supplied on two CDs: one containing the 709, .Net, and CVI

runtime software, and one containing the FieldPoint software.

Demo mode The 709 Alignment software can also run in a demonstration mode. If you will

only be running the software in the demo mode, only the procedures for the

“.Net Framework Installation” on page 33 and the “709 Alignment Software

Installation” on page 35 need to be performed. The remaining installation

procedures are not required.

Remove previous installations

Important When upgrading from previous versions to version 3.3.1 of the 709

1. Select Add/Remove Programs in the Control Panel:

Start > Settings > Control Panel > Add/Remove Programs

2. Select MTS 709 Alignment. Click Remove.

3. A dialog window appears asking you to confirm the removal; click Yes.

4. When removal is complete, click Finish.

5. Repeat steps 1 through 4 for the Microsoft .Net Framework and the NI

FieldPoint applications.

Installation

32

Alignment software, all previous versions of 709 Alignment

software, .Net Framework, and FieldPoint must be removed.

709 Alignment System

Page 33

.Net Framework Installation

The MTS 709 Alignment software runs within the 2.0 .Net framework. Use the

following procedure to install the 2.0 .Net framework. If your system already has

the 2.0 .Net framework installed, you can skip this procedure.

1. Insert the 709 Alignment software CD in the computer’s Compact Disk

drive.

2. Start the .Net Framework installation.

A. Log in to your computer as an administrator.

B. Make sure no other programs are running.

C. Double click My Computer.

D. Double click the Compact Disk drive icon in which the 709 Alignment

software CD is installed.

E. Double click the DotNetSetup folder.

F. Double click the dotnetfx.exe icon. The initial installation dialog

appears. Click Yes.

Software Installation

3. As the .Net Framework setup is being installed, the progress is displayed.

709 Alignment System Installation

33

Page 34

Software Installation

4. After setup is installed, the licence agreement is displayed. Click I agree

then click Install to begin installation. The progress is displayed as the

installation progresses.

34

Installation

5. When installation is complete. the following information dialog is

displayed. Click OK to finish the installation.

709 Alignment System

Page 35

709 Alignment Software Installation

To install the 709 Alignment software, proceed as follows:

1. Start the software installation program.

The software installation program is run from an executable called

setup.exe. Perform the following steps:

A. Log in to your computer as an administrator.

B. Make sure no other programs are running.

C. Insert the MTS 709 Alignment software CD.

D. Double-click the My Computer icon.

E. Double-click the MTS 709 Alignment Software CD icon.

F. Double-click the 709AlignSetup folder con.

G. Double-click on the setup.exe file to start the application installation.

H. The MTS 709 Alignment main window is displayed.

Software Installation

2. Read the welcome message and click Next.

709 Alignment System Installation

35

Page 36

Software Installation

3. Select the installation folder and click Next. It is recommended that you

accept the default installation location. In most cases you would change the

veryone/Just me selection to Everyone.

E

36

Installation

709 Alignment System

Page 37

Software Installation

4. At this point you are given a chance to go back and make any changes in the

previous windows. If your selections have been satisfactory, click Next. If

you need to make changes, click Back to revert to previous installation

windows.

5. Read the licence agreement, Click I Agree to accept the licence agreement,

and click Next to begin installation.

709 Alignment System Installation

37

Page 38

Software Installation

6. As the 709 Alignment software is being installed, the progress is displayed.

7. When installation is complete, click Close. Although not required, it is

recommended you restart your system.

38

Installation

709 Alignment System

Page 39

National Instruments (NI) FieldPoint Installation

The NI FieldPoint installation consists of installing the FieldPoint software and

configuring the 709 Alignment System with an TCP/IP Address.

Note Always use the FieldPoint setup supplied on the FieldPoint software CD.

Other versions of FieldPoint might not be compatible and can cause a

FieldPoint error when running the 709 Alignment software.

1. Insert the FieldPoint software CD in the computer’s Compact Disk drive.

2. Start the FieldPoint installation.

A. Log in to your computer as an administrator.

B. Make sure no other programs are running.

C. Double click My Computer.

D. Double click the Compact Disk drive icon in which the FieldPoint

software CD is installed.

E. Double click the FieldPointSetup folder.

Software Installation

F. Double click the autorun.exe icon.

The FieldPoint menu window appears. Click the Install FieldPoint option.

709 Alignment System Installation

39

Page 40

Software Installation

3. The initial welcome window appears. Read the information shown. When

the installer has finished initializing, click Next.

40

Installation

709 Alignment System

Page 41

Software Installation

4. Read the licence agreement, click the I accept the licence agreement

choice and click Next.

709 Alignment System Installation

41

Page 42

Software Installation

5. Change the features to install. Selections should match the illustration

below.

42

Installation

709 Alignment System

Page 43

Software Installation

6. At this point, installation is ready to proceed. If you want to make any

changes to previous selections, use the Back button to return to previous

windows where you can change your selections. If you are satisfied with the

selection’s you have made, click Next to begin the installation.

7. Once installation starts, a progress window is displayed.

709 Alignment System Installation

43

Page 44

Software Installation

8. When installation is complete, click Finish to exit the installation program.

44

Installation

709 Alignment System

Page 45

Software Installation

Upgrading The Firmware Located On The FieldPoint FP-2000 Hardware

General Information The current version of the 709Align application is compatible with FieldPoint

6.0.3 software and firmware.

If the 709Align application is being installed on an existing system as an upgrade

to an older version of 709Align, the firmware residing on the FieldPoint FP-2000

hardware may need to be upgraded. The following information details the steps

in performing the firmware upgrade.

Upgrading FieldPoint

Firmware

1. From the Windows Task Bar:

Click on Start > Programs > National Instruments > Measurement and

Automation. This launches the Measurement and Automation application.

2. In the left window pane, click on Software. This displays the dialog in the

right window pane shown above.

709 Alignment System Installation

45

Page 46

Software Installation

3. On the top of the right window pane, click on “Add/Remove Software”.

This displays the following dialog.

4. Select the “FieldPoint 6.0.3” item as shown below.

46

Installation

5. Click the “Next” button.

6. Follow the remaining steps to download the new firmware to the FieldPoint

hardware.

709 Alignment System

Page 47

TCPIP Configuration

Two procedures for the TCPIP configuration are provided:

• TCPIP Configuration for Systems Running Windows XP

• TCPIP Configuration for Systems Running Windows 2000

Before configuring the TCPIP address, it is recommended to unplug all network

cables except for the connection to the FieldPoint. This will ensure that the

TCPIP address is being configured for the proper device.

Note for Windows Vista Systems

Systems running Windows Vista should use the TCPIP Configuration for

Systems Running Windows XP procedure as a reference. When setting the IP

address and Subnet Mask in step 5, the Default gateway might need to be set to

the same value as the IP address.

TCPIP Configuration for Systems Running Windows XP

1. Click on Start menu bar. Click on Control Panel menu item

Software Installation

2. Double click on “Network Connections” icon

709 Alignment System Installation

47

Page 48

Software Installation

Enabled

Disabled

Note The Local Area Connection in the next step must be the one

associated with the added network interface card; typically Local Area

Connection #2. This connection must be enabled. If th e connection is

disabled (red X next to the icon), see “Possible Local Area Connection

Problems” on page 148 in the Appendix section for additional

information.

3. Right click on Local Ar ea Connection icon. Click on Properties menu

item.

4. Check Internet Protocol (TCP/IP) box. Click Properties button.

48

Installation

709 Alignment System

Page 49

Software Installation

5. Check Use the following IP address circle. Enter

10.0.0.1 for the IP

address; the last number can be any number other than 101. Enter

255.255.255.0 for the Subnet mask. Click OK.

709 Alignment System Installation

49

Page 50

Software Installation

Enabled

Disabled

TCPIP Configuration for Systems Running Windows 2000

1. Right click the My Network Places icon and select Properties.

Note The Local Area Connection in the next step must be the one

associated with the added network interface card; typically Local Area

Connection #2. This connection must be enabled. If th e connection is

disabled (red X next to the icon), see “Possible Local Area Connection

Problems” on page 148 in the Appendix section for additional information

2. Right click the Local Area Connection icon and select Properties.

50

Installation

709 Alignment System

Page 51

Software Installation

3. Highlight Internet Protocol (TCP/IP) and click Properties.

4. Select Use the following IP address. Enter the address assigned by your

network administrator. If you have not been assigned an address, the address

as shown in the following figure should work for most situations.

709 Alignment System Installation

51

Page 52

Software Installation

FieldPoint Configuration

Once the NI FieldPoint is installed, you need to configure the Measurement and

Automation Explorer software and configure the TCP/IP Address.

1. Open the Measurement & Automation Explorer from the Start menu:

Start > National Instruments > Measurement & Automation

An initial splash screen appears momentarily and the Measurement &

Automation Explorer window appears.

52

Installation

709 Alignment System

Page 53

Software Installation

Enabled

Disabled

B

A

C

D

Note If the FieldPoint has already been configured, you can skip to step 4.

2. Set up the IP address.

A. Expand the Remote System selection (double click or click the +).

Note If there is a warning icon ( ) next to the FieldPoint device, it indicates a

communication problem. If the Local Area Connection (on page 40)

status shows enabled (i.e. no red X) then see “Resetting the FP-20xx” on

page 146 in the Appendix section for additional information

B. Expand 0.0.0.0.

C. Ensure the Network Setti ngs tab is selected.

D. Enter IP address 10.0.0.101.

709 Alignment System Installation

53

Page 54

Software Installation

B

A

C

3. Apply the IP Address.

A. Click Apply.

B. A dialog window opens explaining the changes will not take effect

until the system is rebooted; the system in this case is the FieldPoint

system, not the computer.

C. After the FieldPoint system reboots, the IP address is displayed.

54

Installation

709 Alignment System

Page 55

Software Installation

4. From the Tools menu, select FieldPoint > Open.

5. Locate the Config10.0.0.101.iak file. This file is install e d during the 709

Alignment software installation and typically located in the 709Align folder

on the C: drive; see “709 Alignment System Installation” on page 27. Click

Config10.0.0.101.iak to select it and click Open.

709 Alignment System Installation

55

Page 56

Software Installation

B

A

C

D

E

Note If the FieldPoint has already been configured, you can skip the next step.

6. If this is a new installation and the FieldPoint has not been configured

before, you will get a warning message saying values do not match current

file settings for each unconfigured module.

A. Click OK

B. Ensure FP-SG-140@1 is selected.

C. In the File/Device Conflict Resolution, select File and click Use

These Settings.

D. In the Channel Attributes, ensure the Excitation Voltage is 5

Volts.

E. Repeat for FP-SG-140@2 and FP-AI-110@3.

56

Installation

709 Alignment System

Page 57

Software Installation

A

B

C

D

E

F

7. Verify that the FieldPoint has been configured properly and data acquisition

is functioning.

A. Expand Data Neighborhood down to FP Res.

B. Click (select) FP-SG-140@1.

C. Click Start.

D. Verify that Range and Timestamp values are being recorded. If all

strain gages are being used, all Status checks should be successful. If

some of the strain gages are not being used, the status might be out of

range.

E. Click Stop.

F. Repeat steps C through E for FP-SG-140@2 and FP-AI-110@3.

709 Alignment System Installation

57

Page 58

Software Installation

MTS Licensing Software Installation (New License)

Before installing the MTS Licensing software, make sure you have the license

file available. See “Obtain the License File and NIC Installation” on page 25 for

additional information.

There is a separate setup on the 709 Alignment software CD for installing the

MTS licensing software.

Note Before you install the MTS Licensing sof tware, make sure the system

clock and date are set correctly. If the date is incorrect, the software can

lock up and you will not be able to be run the alignment software.

1. Insert the 709 Alignment software CD in the computer’s Compact Disk

drive.

2. Start the MTS License installation.

A. Log in to your computer as an administrator.

B. Make sure no other programs are running.

C. Double click My Computer.

58

Installation

D. Double click the Compact Disk drive icon in which the 709 Alignment

software CD is installed.

E. Double click the MTSLicenseSetup folder.

F. Double-click on the Setup.exe file to start the MTS License

installation.

709 Alignment System

Page 59

3. Read the welcome message and click Next.

4. Read the licence agreement and click Yes.

Software Installation

709 Alignment System Installation

59

Page 60

Software Installation

5. Select the installation type based on your network environment and click

Next.

• For Peer-to-Peer Connection select Server.

• For Networked Connection:

–Click on Server if this PC has the NIC (Ethernet) card (whose

network address is specified in the 709 Alignment license file).

Server must be selected if there is only one PC. See “Obtain the

License File and NIC Installation” on page 25.

–Click on Client if this PC does NOT have the Ethernet card (whose

network address is specified in the 709 Alignment license file).

The licensing software must first be installed on the server PC,

before installing on a client PC (both must be connected to the

same network).

60

Installation

709 Alignment System

Page 61

Software Installation

6. If you received a license floppy, insert it at this time. Verify the server name

in the mts_license.dat file.

A. Insert the 709 Alignment software CD in the computer’s Compact

Disk drive. Copy the batch file IPConfigAfter.bat to your C:\ drive.

B. Locate the file IPConfigAfter.bat that you just copied to your C:\

drive and double click to run it.When IPConfigAfter.bat is done

running, a text file (IPConfigAfter.txt) is generated and placed on

your C:\ drive.

C. Open the IPConfigAfter.txt and note the host name.

D. Open the mts_license.dat with a text editor . Compare the host name in

the IPConfigAfter.txt file with the server name in the mts_license.dat

file. If necessary, change the mts_license.dat file to match the

IPConfigAfter.txt file.

709 Alignment System Installation

61

Page 62

Software Installation

7. If this is a client installation and a license server contains a license file for

your PC, browse to the location of the license file on network drive when

prompted by the installation for the license file.

62

Installation

709 Alignment System

Page 63

Software Installation

8. At this point you are given a chance to go back and make any changes in the

previous windows. If your selections have been satisfactory, click Next, and

the MTS software license will be installed. If you need to make changes,

click Back to revert to previous installation windows.

9. During installation, several screens will flash indicating installation

progress. When installation is successful, an information dialog is

displayed; click OK.

709 Alignment System Installation

63

Page 64

Software Installation

Updating MTS Licenses (Replacement License)

Use the following procedure to install a new license that replaces a license that

has expired or when a replacement ethernet card is installed.

1. Do not uninstall or reinstall the MTS License Manager.

2. Verify the new license file (e.g. A:\mts_license.dat) has the correct server

name as the current license file (e.g. C:\MTS\License\mts_license.dat).

Refer to Step 6 in the previous procedure, MTS Licensing Software

Installation (New License).

3. Copy the new license file and replace the old license file.

Reboot the PC or restart the service if the 709 Alignment software gets an license

error.

64

Installation

709 Alignment System

Page 65

Options

Contents FieldPoint Data Acquisition 66

The Options tab provides information about the FieldPoint data acquisition

settings, global settings that apply to everyone in the lab, and user preferences for

customizing the display for individual users.

Global Settings 66

User Preferences 69

709 Alignment System Options

65

Page 66

FieldPoint Data Acquisition

Validate tab x-axis selections

Options tab

Analog input selections

Strain Gauge selections

The fields in this section of the tab show the read only parameters relating to the

FieldPoint hardware.

Global Settings

Load Analog Input

Signal

The entries in this area define the parameters relating to the load signals used by

the 709 alignment software.

Add - Click this button to add a load input signal. This could be a load signal

from a second load cell for a given load unit, a load signal from a different

calibrated load range, or a load signal from another load frame station.

Remove - Deletes the load signal shown in the pulldown menu field.

Gain - This field defines the scaling used by the 709 Alignment software when

displaying or graphing the load analog input signal.

check box - The Enable in Align and Validate tabs check box, when checked,

enables the load analog input signal to be displayed in the indicated tabs; AI in

the Align tab Load bar graph, Load (AI) in the Validate tab.

Validate Chart X-Axis These radio buttons determine whether the analog input (AI) or the strain gauges

(SG) will be used for the validate chart. The choice here also determines the

starting selection for the x-axis on the validate chart.

Options

66

709 Alignment System

Page 67

Thin Rectangular

Options tab

Align tab

Specimen Orientation

Typically, for systems using the thin rectangular specimen, the mounting

orientation of the specimen will be such that the back of the specimen (G12) will

face the back of the test machine (load unit). However, because of mounting

requirements for some systems (for example, side loading grips inside an

environmental chamber), the specimen might be mounted such that the front of

the specimen faces to one side on the test machine.

When the Turn 90 Degrees Sideways In Grips is checked, the software adjusts

the readouts and displays on the Align tab.

709 Alignment System Options

67

Page 68

609 Alignment Fixture

Mounting Location

In most cases the 609 Alignment Fixture is mounted to the crosshead. However,

some situations require mounting the 609 Alignment Fixture to the base.

Mounting the 609 fixture to the base requires the concentric adjustment

instructions in the alignment wizard be reversed. This option lets you select

where the 609 fixture is mounted and changes the concentric alignment

instructions in the alignment wizard accordingly.

68

Options

709 Alignment System

Page 69

User Preferences

Significant Digits To

Display

The entry in this field defines the number of significant digits displayed for the

values on the Specimen, Align, and Validate tabs.

Validate Target Limit Selecting Strain Trough here will cause the target on the validate screen to be

displayed in strain.

Selecting Percent Level here will cause the target on the validate screen to be

displayed in percent.

709 Alignment System Options

69

Page 70

Bending Percent The 709 Alignment software offers two choices for calculation bending percent.

e12100=

e22000=

e31900=

a

e

1e2e3

++

3

---------------------------=

a 2000=

b1e1a–=

b1100=

b2e2a–=

b20=

b3e3a–=

b

3

100–=

B

b

1

2

3

------ -

b

2

b

1

---- -

1

2

-- -+

⎝⎠

⎛⎞

•atancos

----------------------------------------------------------------=

B 115=

Bmaxb1 b2 b

3

()()=

B 100=

e12100=

e22100=

e31900=

e41900=

a

e

1e2e3e4

+++

4

-------------------------------------- -=

a 2000=

b1e1a–=

b1100=

b2e2a–=

b2100=

b3e3a–=

b

3

100–=

b4e4a–=

b

4

100–=

B

1

2

-- -

b1b3–()2b2b4–()

2

+=

B 141=

Bmaxb1 b2 b3 b

4

()()=

B 100=

One complies with MTS’s interpretation of ASTM 1012 and the other to MTS’s

interpretation of GEAE S-400. In general, you would select the method that

satisfies your particular auditing requirements. Following are the calculations for

each method.

Cylindrical specimens,

three strain sensors

ASTM E 1012 True Max

GEAE S-400 Simple Max

Cylindrical specimens,

four strain sensors

ASTM E 1012 True Max

GEAE S-400 Simple Max

Options

70

709 Alignment System

Page 71

Display Units This selection determines whether the values are displayed in English or metric

Options tab

Align tab

units on the Specimen, Align, and Validate tabs.

Days Reminder for

License Renewal

This can be used as a reminder that the licence needs to be renewed. Once this

number of days has been reached, a reminder message will appear when the 709

Alignment software is started.

Align Load Chart This selection determines what signals are displayed in the load chart on the

Align tab. As indicated, the load analog input signal (AI) is only displayed if the

signal is enabled in the Global Settings.

709 Alignment System Options

71

Page 72

Align Bending Chart The selections in this area define how the upper (red), middle (green), and lower

(blue) indicators in the bending strain alignment graph are displayed. The

following illustration shows some examples.

The Use Solid Symbols is only applicable when there isn't a history trail

(because there is only one symbol you can choose outline or solid).When there is

a history trail, the current symbol is always solid and the history is always

outline. The history trail is composed of the specified number of previous points

which decrease in size.

Validate Text Box The selections in this group define how the test displays in the text box of the

Validate tab.

• Word Wrap (when text box fills the window)

72

Options

When this box is checked, the information displayed in the text box will wrap

onto the next line if it does not fit. Word wrap is useful when reading the

comments of the specimen, which might be longer than can fit in the width of the

window. Word wrap might not be desired when viewing the data because the

rows of values will wrap onto the next line making it hard to distinguish which

row is part of which line. This text box is normally on the right of the Validate

tab, in which case it does not word wrap because the text box is so narrow. This

word wrap option is only in effect when the text box has been enlarged to fill the

window (by clicking the 'Fill' button).

709 Alignment System

Page 73

Note Move the mouse cursor outside of the text box (e.g., to the top of the

Fill button

Move cursor outside

text box to restore

original view.

window - that is the area containing the window title) to restore the

original view.

• Replace with u

For some applications, when opening the text data file, there can be

problems displaying the Greek symbol . Under normal conditions, strain is

represented by the greek symbol . If your system cannot display the Greek

symbol, check this box to replace the symbol with the letter u in the

709 Alignment System Options

Validate text bo x and the text file written to disk.

73

Page 74

Use Black Instead of

Color Lines On

Validate Screen

If this box is checked, the lines connecting the data point markers in the graphical

display area of the Validate tab will be black instead of matching the color of the

data point marker. This can improve printing in black and white.

Do Not Save User

Preferences When

Options

74

Exiting

If this box is checked, user preferences defined on the Options tab will not be

saved when the program is closed; that is, changes will be ignored. This can be

useful when changing the appearance of the software for the current instance

only, and reverting back to the original conditions next time. This also applies to

the check box options on the Alignment Wizard.

709 Alignment System

Page 75

Specimen

Open/Save As/Save The Open button allows you to open an existing specimen file. Save As allows

you to save the information shown on the Specimen tab to a file with a different

file name. Save allows you to save the information shown on the Specimen tab

into the current file.

Note The software automati cally attempts to open the last specimen when it

launches.

709 Alignment System Specimen

75

Page 76

Channel Calculation This selection determines which set of gages are used to calculate the applied

load and the axial strain. The Middle Gauges are typically used for 12-channel

specimens. The other settings can be used when fewer channels are available, all

12 channels are not functioning properly, or for diagnostic purposes. For

example, if an 8-channel specimen is used (a specimen with only the upper and

lower gauges attached), typically the Ave Upper + Lower selection would be

chosen. Another example, Middle Only can be selected when the specimen does

not have upper nor lower gauges. Not having upper and lower gauges prevents

the calculation of concentric misalignment. The specimen can be used to validate

angular misalignment (as in MTS’s interpretation of Mil Std 1312 B appendix

C0).

Cross Section Type This selection determines the type of specimen being used for specimen

alignment. The thick specimen has gauges on all four sides similar to the round

°specimen. The thin specimen has gauges on the front and back surfaces.

4x90

The round 3x120

°specimen has gauges equally spaced about the circumference.

Parameter Units This selection defines the units type used on the Specimen tab.

76

Specimen

709 Alignment System

Page 77

Target Class This selection defines the target class for the alignment resolution.

400

300

200

100

0

0

Class 20

-3000 -2000 -1000 1000 2000 3000

Class 10

Class 5

Class 2

Compression

Axial Strain, a (micro-strain)

Tension

Maximum bending strain, b

max.mc

(micro-strain)

The level of the machine alignment can be described according to the criteria

specified in the following table and shown graphically in the following figure

where:

a is the axial strain

b

β

CLASS ABS (A) < 1000 MICRO-STRAIN ABS (A) ≥ 1000 MICRO-STRAIN

is the maximum bending strain

max.mc

is the percent bending

mc

2

5

10

20

709 Alignment System Specimen

b

max.mc

b

max.mc

b

max.mc

b

max.mc

≤ 20 micro-strain

≤ 50 micro-strain

≤ 100 micro-strain

≤ 200 micro-strain

β

mc

β

mc

β

mc

β

mc

≤ 2%

≤ 5%

≤ 10%

≤ 20%

77

Page 78

Target Strain This field shows the value of the target strain defined by the Target Class

selection. This is also the value of the target area on the graph displayed on the

Align tab.

Specimen Parameters The values in these fields are entered by the user and define the alignment

specimen. The specimen dimensions available (Specimen Diameter, Rectangular

Width, Distance to Edge) are determined by the cross section type of the

specimen. The Axial Boundary is explained in a following paragraph; see “Axial

Boundary” on page 79.

78

Specimen

The other specimen parameters in the grayed fields and calculated values based

on the user entered values for the specimen above.

709 Alignment System

Page 79

Axial Boundary This feature avoids the situation where the bending percent become infinite as the

axial strain gets very small (i.e. when zero load is applied). The default value is

200 µe.

When the axial strain is within this range, the bending percent will not be

calculated or displayed on the graph, so the text box and data file will show NaN

(Not a Number) for the bending percent. The Validation Status will show if the

data passes or fails the bending percent criteria only for the values that are

calculated. The Reports and the Validation Status will still agree because the NaN

will be shown where the bending percent is not calculated.

The bending percent is not plotted when the axial strain is within the boundary,

which will create a gap in the bending percent line. If the axial strain crosses over

the boundary to the other side, then the bending percent line will cross over the

boundary. The strain will still be plotted even if the axial strain is within the

boundary. When plotting strain and percent, the strain data point in the boundary

will not have a corresponding percent data point.

709 Alignment System Specimen

79

Page 80

If the user starts sampling data when at no load, the graph will not change,

although the progress bar and text box will. If the user is accustomed to watching

the data as it is plotted, it may appear that the software is not sampling because

the graph is not changing.

A gap is displayed in the bending percent target level to represent the axial strain

boundary.

80

Specimen

709 Alignment System

Page 81

Offsets The offsets section of the Specimen tab shows the offset values determined by

performing the specimen offsets procedure.See “Specimen Offsets” on page 83

for additional information.

709 Alignment System Specimen

81

Page 82

82

Specimen

709 Alignment System

Page 83

Specimen Offsets

Strain Offset Relationship

The bent front and bent back measurements are taken before the gauge offset is

removed, therefore both the bent front and bent back offset values include the

gauge offset. Because the bent mean offset is the average of the bent front and

bent back values, it also includes the gauge offset, and is always in the middle of

the bent front and bent back when graphed. The following figure (Strain Offset

Relationship) shows this relationship for the middle gauges.

It is noteworthy to determine the amount of bending that is due to the

straightening of the specimen, and the amount of bending that is due to the

misalignment of the load unit. The bending due to the straightening of the

specimen is interesting because it indicates how straight the specimen was

manufactured and can potentially indicate if the specimen has deformed over

time due to use, handling, etc. The bending due to the misalignment of the load

unit is interesting because it indicates how well the load unit was aligned when

the bent mean was calculated. A large load unit misalignment can conceivably

cause more error in the bent front and bent back measurements, and thus lead to

more error in the calculated bent mean value.

709 Alignment System Specimen Offsets

83

Page 84

Conceptually, the graphed bent measurements can be reached by adding vectors.

Bending Strain Depiction

First there is the bending due to the gauge offsets, then add the bending if the

specimen were bent straight, and then add the load unit imposed bending (bent

front or bent back). The following figure (Bending Strain Depiction) shows this

depiction for the middle gauges.

Specimen Offsets

84

709 Alignment System

Page 85

T o see the bending due to the straightening of the specimen, the gauge offset can

Bending Components

be subtracted from the bent mean offset (bent mean relative to the gauge offset).

T o see the bending due to the misalignment of the load unit, the bent mean offset

can be subtracted from the bent front offset (bent front relative to the bent mean).

The bending has X and Y components for each:

Xs – specimen bending strain in the x-axis

Ys – specimen bending strain in the y-axis

Xm – load unit bending strain in the x-axis

Ym – load unit bending strain in the y-axis

The following figure (Bending Components) shows the specimen bending and

load unit bending components for the midd le gauges.

709 Alignment System Specimen Offsets

85

Page 86

Printable Symbols

Printable Symbols

The Use Printable Symbols option on the Specimen Offsets window allows

you to select either unique printable shapes for each symbol or change the solid

symbol to correspond to the selected tab.

Specimen Offsets

86

709 Alignment System

Page 87

Get Specimen Offset Values

A

B

Note It is recommended that the lo ad unit be aligned prior to setting the

specimen offset values. In order to get an accurate specimen offset

reference, the load unit should first be aligned.

A typical sequence to get the specimen offset values would be:

1. Start the 709 Alignment program.

A. Select the Align tab.

B. Click Specimen Offsets.

Get Specimen Offset Values

709 Alignment System Specimen Offsets

87

Page 88

Get Specimen Offset Values

2. Establish the gauge offset reading.

Because specimens cannot be perfectly machined and placement of the

strain gauges on the specimen cannot be perfectly aligned, some initial

offsets are inherent.

A. Select the Gauge tab.

B. Click the Read button to take a reading.

C. Click the Add button to save the values.

D. Wait for approximately 15 seconds.

E. Repeat steps B, C, and D until you have saved three sets of gauge

values.

Specimen Offsets

88

These values will be used when the Specimen Gauge selection is active in

the Use Offsets section of the Align tab.

709 Alignment System

Page 89

Get Specimen Offset Values

3. Establish the bent front offset reading.

Because load train components cannot be perfectly machined, some initial

offsets are inherent. Establishing bent front values allows the 709 Alignment

System to take this into account during the alignment adjustments.

A. Select the Bent Front tab.

B. Install and clamp the specimen in the standard orientation; that is

install the specimen such that gauges G4, G8, and G12 are facing

toward the front on the load unit with G4 being the top gauge.

C. Click the Read button to take a reading.

D. Click the Add button to save the values.

E. Unclamp and clamp the lower grip.

F. Repeat steps C, D, and E until you have saved three sets of bent front

values.

G. Unclamp and clamp the upper grip.

H. Click the Read button to take a reading.

I. Click the Add button to save the values.

J. Repeat steps G, H, and I until you have saved three sets of bent front

values.

709 Alignment System Specimen Offsets

89

Page 90

Get Specimen Offset Values

4. Establish the bent back offset reading.

Because load train components cannot be perfectly machined, some initial

offsets are inherent. Establishing bent back values allows the 709 Alignment

System to take this into account during the alignment adjustments.

A. Select the Bent Back tab.

B. Install and clamp the specimen in the standard orientation; that is

install the specimen such that gauges G4, G8, and G12 are facing

toward the back on the load unit with G4 being the top gauge.

C. Click the Read button to take a reading.

D. Click the Add button to save the values.

E. Unclamp and clamp the lower grip.

F. Repeat steps C, D, and E until you have saved three sets of bent front

values.

G. Unclamp and clamp the upper grip.

H. Click the Read button to take a reading.

I. Click the Add button to save the values.

J. Repeat steps G, H, and I until you have saved three sets of bent back

values.

Specimen Offsets

90

709 Alignment System

Page 91

Get Specimen Offset Values

5. Check the bent mean offset values.

The bent mean values are the average of both the bent front and bent

back values taken in steps 3 and 4. These values will be used when the

Specimen Bent selection is active in the Use Offset section of the

Align tab.

Also included are the X and Y bending components due to the specimen

and the load unit:

• bending strain due to straightening the specimen (bent mean offset

relative to the gauge offset)

Xs - bending strain in the x-axis

Ys - bending strain in the y-axis

• bending strain due to load unit misalignment (bent front offset relative

to the bent mean offset)

Xm - bending strain in the x-axis

Ym - bending strain in the y-axis

709 Alignment System Specimen Offsets

91

Page 92

Get Specimen Offset Values

Specimen Offsets

92

709 Alignment System

Page 93

Align

The Align tab provides a variety of displays to indicate the alignment process.

On the left side, numerical values are displayed for the gages and bending offsets.

In the center, a bar graph shows the load values. Depending on the check box

selections in the Options tab, one or two bars wil l be displaye d. The Strain bar is

the load calculated from stain based on the setting on the Specimen tab. The

Signal bar is the scaled Load Analog Input Signal based on the gain on the

Options tab.

On the right, points representing the bending strain are plotted on a x-y graphical

coordinate system. The color coding of these points on the graph on the right

directly relates to the color coding of the specimen gauge values on the left.

709 Alignment System Align

93

Page 94

Note There could be a display problem if large fonts are selected in the display

properties. See “Possible Problem with Large Fonts” on page 149 in the

Appendix section for additional information.

Note Although the shade d area of the graph will always be rectangular, the

actual target area is within the oval (or circle) outline for round

specimens (as shown below) or within the diamond outline for

rectangular specimens.

Chart Interaction You can use the chart interaction options to view specific areas of the graph.

• Translation: Shift + Drag with left mouse button.

• Scaling: Control + Drag with left mouse button.

• Zooming: Alt + Drag with left mouse button.

T o undo the interaction, use the options to revert back to the original display, use

the Plot Bending Set and Reset buttons, or restart the application.

94

Align

709 Alignment System

Page 95

Plot Bending In this section you can select the plot to be in Strain values or Percent. The Auto

Scale feature, when checked, will automatically scale the graph on the right of

this tab as the points representing the load values of the three gauges approach

the target microstrain.

If Auto Scale is not checked you can set the full scale range on the graph using

the Set button. or set the graph to optimum scale using the Reset button.

Specimen Offsets Clicking this button will bring up the specimen offsets window. See “Specimen

Offsets” on page 83 for additional information.