Page 1

Model 685.53 Grip Control Module

Product Information

l

015-029-701 C

Page 2

Copyright information © 1992 - 2004 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation.

Contact information MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255 (within the U.S. or Canada)

Phone: 952-937-4000 (outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

http://www.mts.com

Publication information

Manual Part Number Publication Date

150297-01A November 1992

150297-01B January 1999

015-029-701 C August 2000

015-029-701 C

* Style changes only. No revision letter change required.

July 2004

*

Page 3

Contents

Introduction 5

Functional Description 6

Specifications 7

Installation 9

Crush Point Hazards 10

Installation Procedure 11

Operation 15

Controls 16

Determining the Grip Operating Pressure 18

Adjusting the Output Pressure 19

Adjusting the Rate Control 20

Gripping Specimens 21

Removing Specimens from the Grips 23

Model 685.53 Grip Control Module Contents

3

Page 4

4

Contents

Model 685.53 Grip Control Module

Page 5

Introduction

Contents Functional Description 6

The Model 685.53 Hydraulic Grip Control Module provides an easy way to grip

specimens for testing. It mounts on the front of a load unit or grip supply to

provide control of the hydraulic grips. The Model 685.53 Hydraulic Grip Control

Module is a control only; it depends on an external source for hydraulic pressure.

Specifications 7

Hydraulic Grip Control

What you need to

know

Pressure

56

4

7

8

9

10

Rate

3

2

1

MTS Systems Corporation assumes that you know how to use your controller.

See the appropriate manual for information about performing any controllerrelated step in this manual’s procedures. You are expected to know how to

perform the following procedures.

• Turning hydraulic pressure on and off

• Selecting a control mode

• Manually adjusting the actuator position

• Installing a specimen

• Defining a simple test

• Running a test

Model 685.53 Grip Control Module Introduction

5

Page 6

Functional Description

Functional Description

The 685.53 Hydraulic Grip Control Module is designed to provide the hydraulic

grip control for specimen grips and includes the following features.

• Hydraulic flow control determines how fast the grips operate.

• The hydraulic pressure can be adjusted between 0.7 and 20.7 MPa (100 and

3000 psi).

• Provides independent grip/release control for each of two grips.

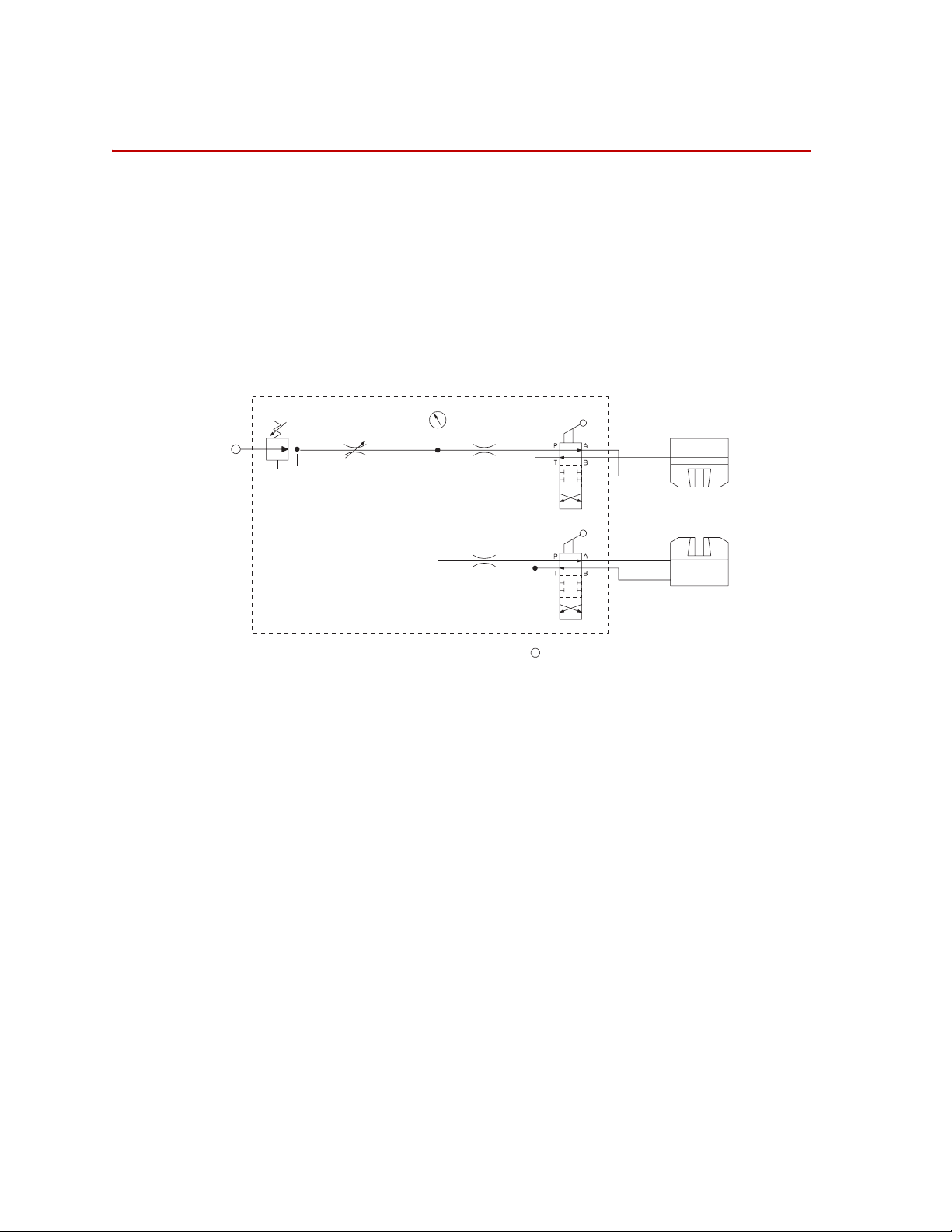

Hydraulic schematic The following figure shows the hydraulic schematic for the grip control.

Hydraulic

Output

Hydraulic

Source

-4P

Rate

Control

Pressure

030 DIA

Upper Grip

Grip

Pressure Reducing Valve

0.720.7 MPa

(1003000 psi)

adjustment range

Grip Control Manifold

030 DIA

-6R

Hydraulic

Return

Release

Release

Grip

Lower Grip

Model 685.53 Hydraulic Schematic

Hydraulic power unit The Model 685.53 Hydraulic Grip Control Module gets its hydraulic pressure

from the hydraulic power unit in the lab.

Control manifold The control manifold outputs the hydraulic control to the grips. The control

manifold includes all of the front panel controls.

Rate control The Rate control is a needle valve that restricts the hydraulic flow, and

determines how fast the grips clamp and unclamp.

Pressure control The Pressure control establishes the final output pressure to the grips. It works in

conjunction with another pressure reducing valve which is being used as a

pressure relief valve. These two valves work in the same fashion as the valves on

the supply manifold.

6

Grip control The grip controls port the final output pressure to the grips. Each grip has two

Introduction

ports, a grip port and a release port. The grip controls change the output pressure

from the grip port to the release port and vice versa. The controls also have a

midpoint where the hydraulic pressure is stopped at the grip control; this causes

the grip to stop its hydraulic movement.

Model 685.53 Grip Control Module

Page 7

Specifications

The following table lists the hydraulic specifications for the grip control.

Parameter Specification

Maximum Input Pressure 21 MPa (3000 psi)

Specifications

Pressure Control Range

Pressure Stability

(at all pressures)

Grip and Pressure Fittings male, JIC 37º flare -6

Drain Fitting male, JIC 37º flare -4

0.7–21 MPa (± 0.06 MPa) (100–3000 psi (± 10 psi))

± 0.03 MPa (± 5 psi)

Model 685.53 Grip Control Module Introduction

7

Page 8

Specifications

8

Introduction

Model 685.53 Grip Control Module

Page 9

Installation

Contents Crush Point Hazards 10

Hydraulic Grip Control

Installing a Model 685.53 Hydraulic Grip Control module consists of installing

the control panel and manifold in the load unit and making the hydraulic hose

connections to the upper and lower grips.

Installation Procedure 11

Pressure

56

4

Rate

3

2

1

7

8

9

10

685.53 Control Module (Front)

Upper

Grip

From “Pressure” on

Lift/Lock Manifold

685.53 Control Module (Rear)

Upper

Release

Grip

Release

Upper

Upper

From “Drain” on

Lift/Lock Manifold

Lower

Grip

Lower

Release

Grip

Lower

Release

Lower

Model 685.53 Grip Control Module Installation

9

Page 10

Crush Point Hazards

Crush Point Hazards

It is important to stay clear of any potential crush points during installation or when

the system is operating. Know where the crush points are in your system and protect

yourself and others from those crush points with appropriate safety devices. The

following paragraphs describe crush points and precautions to take while working

around crush points, and apply to most systems.

ydraulicWedgeGri

p

H

7

4

6

6

4

7

H

ydraulicWedgeGri

Crush

p

Point

Areas

Locations A crush point exists between the platen and crosshead on load units where the

actuator piston rod and specimen move (both areas are shown). Another potential

crush point exists where the lower end of the actuator piston rod extends below

the platen and the bottom of the load unit/load frame.

Precautions Keep clear of any mechanical linkage that moves within a closed area. If the

linkage should move (when the system starts or due to mechanical failure), very

high forces can be present that could pinch, cut, or crush anything in the path of

linkage movement.

10

Installation

Never allow any part of your body to enter the path of machine movement or to

touch moving machinery, linkages, hoses, cables, specimens, and so forth. These

present serious crush points or pinch points.

Model 685.53 Grip Control Module

Page 11

Installation Procedure

Installing a Model 685.53 Hydraulic Grip Control module consists of installing

the control panel and manifold in the load unit and making the hydraulic hose

connections to the upper and lower grips. The following procedure assumes that

the grips to be controlled by the hydraulic grip supply have been properly

installed on a load unit.

Installation Procedure

WARNING

Never leave a crosshead unlocked.

It can drift slowly down when hydraulic pressure is turned off and damage

any test fixtures, grips, and specimen in its path.

Unlock the crosshead only to reposition it. Always lock the crosshead after

you have repositioned it.

1. Lock the crosshead on the load unit.

If the load unit has manual locks, tighten the crosshead clamping bolts

according to the sequence and torque settings specified in the load unit

product information manual.

If the load unit has hydraulic locks, use the Crosshead Lift/Lock

Controls to clamp the crosshead to its current position.

Wait 30 seconds for the locks to fully clamp the columns.

2. Turn off the load unit hydraulic pressure.

If you have a separate hydraulic service manifold, turn its hydraulic pressure

off also.

3. Switch off electrical power at the test controller.

Wait two minutes for pressure to fall to zero before opening any fittings.

4. Access the control panel.

A. Lift the baseplate cover to access the four screws securing the control

panel to the base.

CAUTION

Model 685.53 Grip Control Module Installation

Do not remove the control panel screws without restraining the possible

movement of the control panel.

The control panel is hinged. Unless restrained, the control panel will drop

when the screws that secure the control panel to the base are removed. The

control panel is heavy; when the last screw is removed, the control panel

will drop. possibly causing equipment damage.

When removing the screws that secure the control panel to the base, restrain the

panel to keep it from falling in an uncontrolled manner. When all screws are

removed, you can grasp the control panel and let it swing down in a controlled

fashion.

11

Page 12

Installation Procedure

B. Restrain the control panel and remove the four screws securing the

panel to the base.

C. Grasp the control panel and slowly lower it to the mechanical stop of

the securing cables.

5. Install the grip control module in the control panel.

Refer to the drawings that accompany the module and the illustrations on

page 9.

WARNING

WARNING

Do not use hydraulic hoses rated for less than 21 MPa (3000 psi).

Under-rated hoses may rupture and can cause injury to personnel or

damage to equipment.

Use only hydraulic hoses that have a working pressure greater than 21 MPa

(3000 psi).

6. Connect the hydraulics.

A. Connect the pressure (“P”) and drain (“D”) ports on the grip manifold

to the corresponding pressure and drain ports on the hydraulic lift/lock

manifold.

B. Connect the grip and release ports on the grip manifold to the

corresponding grip and release ports on each of the upper and lower

grips.

7. Switch electrical power on at the test controller.

Do not turn hydraulic pressure on without verifying that the control channel

error is zero.

A nonzero error may result in unexpected actuator movement and can

cause injury to personnel or damage to equipment.

12

Installation

Verify that the control channel error is zero before applying hydraulic pressure.

8. Turn load unit hydraulic pressure to low.

Inspect for leaks at all connections. If there are leaks, turn off hydraulic

pressure and correct them.

9. Turn load unit hydraulic pressure to high.

Inspect for leaks at all connections. If there are leaks, turn off hydraulic

pressure and correct them.

Model 685.53 Grip Control Module

Page 13

Installation Procedure

CAUTION

Do not clamp the grips without a specimen installed.

Some grips may be damaged by closing the grip without a specimen

inserted or with a specimen only partially inserted.

See the appropriate grip product information manual for detailed specimen

mounting instructions.

10. Check the grip operation.

Change the grip controls between grip and release a few times and check for

leaks at all connections (correct as needed).

11. Secure the control panel.

Lift the control panel back up to the base and secure with the screws

removed in Step 4. Do not overtighten.

12. Replace the baseplate cover.

Model 685.53 Grip Control Module Installation

13

Page 14

Installation Procedure

14

Installation

Model 685.53 Grip Control Module

Page 15

Operation

Contents Controls 16

This section describes how to use the hydraulic grip supply. Some operating

details depend on the particular grips you have. You should have your grip

product information manual available for specimen installation and removal

procedures.

Determining the Grip Operating Pressure 18

Adjusting the Output Pressure 19

Gripping Specimens 21

Removing Specimens from the Grips 23

Model 685.53 Grip Control Module Operation

15

Page 16

Controls

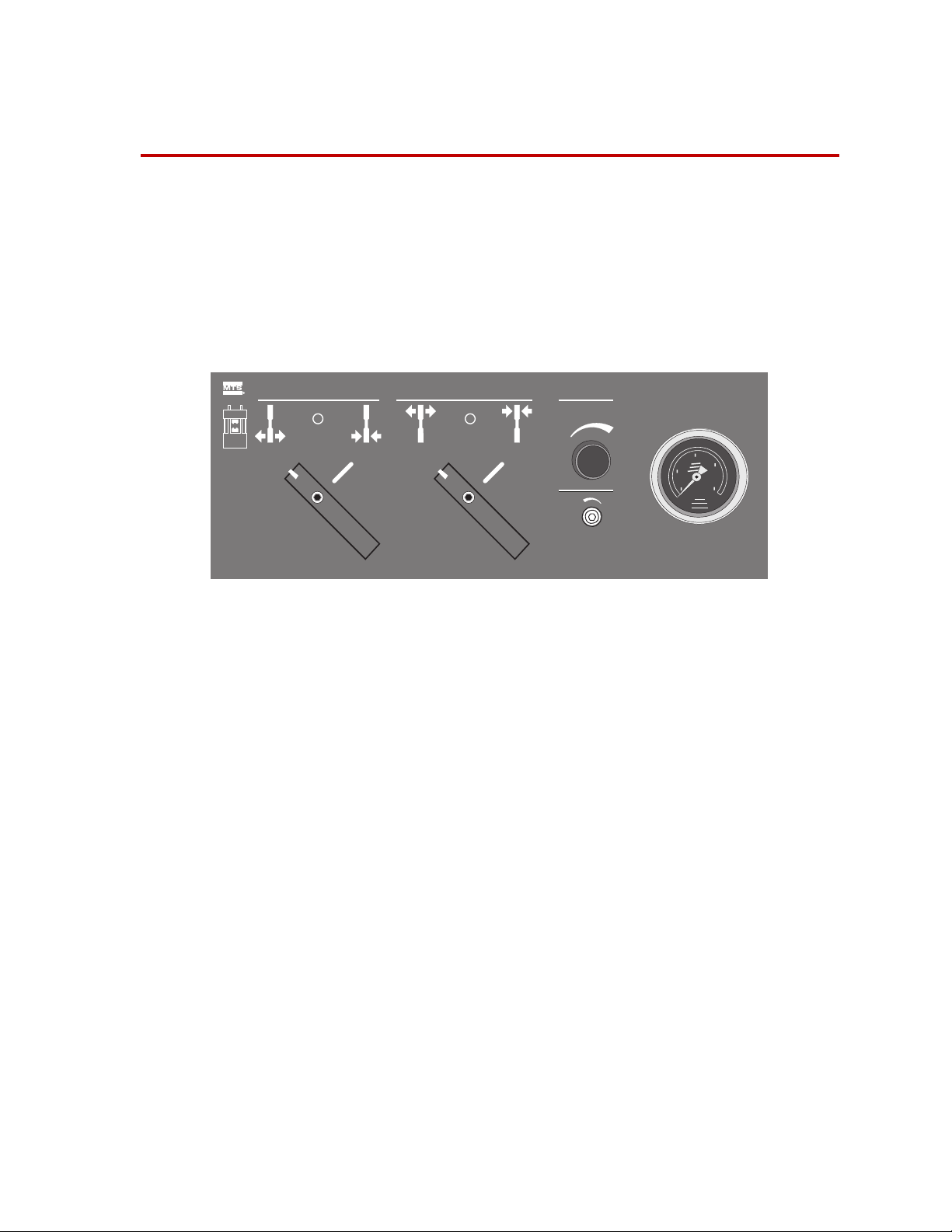

Controls

Hydraulic Grip Control

The controls and indicators are located on the control panel shown below.

Pressure

56

Rate

4

3

2

1

7

8

9

10

Control Description

Lower Grip Control

Upper Grip Control

Controls the lower grip for specimen installation and removal. The threeposition control can grip or release one end of a specimen.

This indicates the lower clamp is gripping the specimen. Turn the

control clockwise to clamp a specimen into the lower grip.

This indicates the lower clamp is open and not gripping a specimen.

Turn the control counterclockwise to release a specimen from the

lower grip.

The gripping action can be stopped midway between grip and ungrip by

putting the control midway between the two lower grip symbols.

Controls the upper grip for specimen installation and removal. The threeposition control can grip or release one end of a specimen.

This indicates the upper clamp is gripping the specimen. Turn the

control clockwise to clamp a specimen into the upper grip.

This indicates the upper clamp is open and not gripping a specimen.

Turn the control counterclockwise to release a specimen from the

upper grip.

The gripping action can be stopped midway between grip and ungrip by

putting the control midway between the two upper grip symbols.

16

Operation

Model 685.53 Grip Control Module

Page 17

Control Description

Controls

Pressure

Pressure

Rate

Rate

Pressure Gage

56

4

3

2

1

Adjusts the amount of hydraulic pressure applied to the grips for gripping the

specimen.

This is a multiturn knob. Pressure increases as the knob is turned clockwise

and decreases as the knob is turned counterclockwise.

To determine the correct operating pressure, see “Adjusting the Output

Pressure” on page 19.

Adjusts how fast the grips clamp and unclamp. This control requires the use of

a hex-key wrench for adjustment.

Adjust the Rate control clockwise to slow the clamping of the specimen.

Otherwise, adjust the Rate control counterclockwise to increase the clamping

speed.

To adjust the clamping rate, see “Adjusting the Rate Control” on page 20.

Shows the current hydraulic pressure setting for grip operation.

The gage includes scales for both MPa and psi units.

7

8

9

10

Use the gage while adjusting the Pressure control to achieve the desired

clamping pressure. See the grip product information manual for gripping

pressures.

Model 685.53 Grip Control Module Operation

17

Page 18

Determining the Grip Operating Pressure

Determining the Grip Operating Pressure

You must consider the following factors to determine the appropriate grip

operating pressure:

• The type of grips to be used

• The specimens to be tested

• The tests to be performed

• The model number of the grip supply

Grip product information manuals (from MTS) describe how to determine the

required operating pressure. They include formulas and/or graphs to determine

the grip pressure (also called minimum operating pressure). The minimum

pressure, as referred to in the grip manual, is the calculated least pressure that

will provide adequate gripping of the specimen while it is being tested at specific

maximum loads.

If practice indicates that the calculated pressure proves to be too low (because the

specimen slips under load due to hardness or other characteristics), then the

actual minimum pressure will have to be increased to provide adequate gripping.

Use the grip product information manual to determine the minimum grip

operating pressure that is best for the test situation at hand.

The grip control can be configured to produce different output pressures. Check

the model number specification. See “Adjusting the Output Pressure” on page 19

for the procedure.

18

Operation

Model 685.53 Grip Control Module

Page 19

Adjusting the Output Pressure

The output pressure of the hydraulic grip control determines the gripping force

applied to the specimen by the grips. The output pressure can be adjusted up to

the maximum output pressure of the system hydraulic power unit which is

usually 21 MPa (3000 psi).

1. Determine the required grip operating pressure.

See “Determining the Grip Operating Pressure” on page 18 and also see the

grip product information manual.

2. Put both grip controls in the release (open) position.

If it is necessary to adjust output pressure while there is a specimen in the

grips, install the specimen and turn the grip controls to the grip position

(clockwise).

3. Set the operating pressure.

Turn the Pressure control to obtain the desired operating pressure as shown

on the control panel pressure gage.

Adjusting the Output Pressure

Model 685.53 Grip Control Module Operation

19

Page 20

Adjusting the Rate Control

Adjusting the Rate Control

The Rate control may be adjusted at any time. If the grips act too fast to suit your

personal preference, turn the Rate control clockwise to slow the speed of grip

action. Turning the Rate control counterclockwise speeds up grip action.

Turning the Rate control fully clockwise stops the flow of fluid to the grips. If

the grips do not operate, check to be sure that the Rate control has not been

turned fully clockwise.

Adjustment of rate is a matter of personal preference. It should be based on the

desired speed of grip action during the gripping and ungripping processes. (The

speed of grip action is dependent both on the adjustment of the rate control and

the particular grips being used.)

When first operating the grips, use a slower speed (lower rate setting). Then

increase the operating speed to your satisfaction.

20

Operation

Model 685.53 Grip Control Module

Page 21

Gripping Specimens

Prerequisite This procedure assumes that the output pressure has been adjusted.

Have the appropriate grip product information manual handy for more specific

specimen mounting information.

Gripping Specimens

WARNING

Do not put anything in a crush zone when turning on hydraulic power.

Unexpected actuator movement can occur when hydraulic pressure is

turned on. This can cause personal injury or equipment damage.

Be sure you read and understand all safety information provided with your

system. Follow all applicable system operating procedures before turning on

hydraulic power.

Also, make sure that all systems or equipment that use the same hydraulic power

source are in appropriate condition for application of hydraulic power.

1. Select a force control mode to control the actuator.

Select force control at the system controller and use the most sensitive

(lowest load) range available.

If your controller has a channel-limited-channel control mode for specimen

installation, use one defined with displacement control and force limiting.

2. Release the grips.

Make sure that both grip controls are in the release position.

3. Apply full system hydraulic pressure.

Use applicable system procedures to turn on the system hydraulic pressure.

Model 685.53 Grip Control Module Operation

21

Page 22

Gripping Specimens

CAUTION

Do not clamp the grips without a specimen installed.

Some grips may be damaged by closing the grip without a specimen

inserted or with a specimen only partially inserted.

See the appropriate grip product information manual for detailed specimen

mounting instructions.

4. Grip the specimen as follows:

Because of the large variety of load frame, grip, and controller equipment in

use, it is impossible to give explicit instructions for this process.

Pliers or tong-like tools such as those used for installing or removing

cartridge-type electrical fuses are often used for holding small specimens in

proper position within the grips to lessen the possibility of having fingers

pinched or crushed during the gripping process.

Gripping a specimen typically involves manually holding the specimen in

place within the upper grip and then, with the specimen correctly in place,

applying hydraulic gripping pressure to the upper grip. And finally, it

involves moving the actuator as necessary to correctly position the lower

end of the specimen within the lower grip. Hydraulic gripping pressure is

then applied to the lower grip.

A. Perform any operations necessary to correctly position one end of the

specimen within the upper grip.

B. When the specimen is properly positioned within the upper grip, rotate

the upper grip control clockwise to the grip position.

C. Perform any operations necessary to correctly position one end of the

specimen within the lower grip.

D. When the specimen is properly positioned within the lower grip, rotate

the lower grip control clockwise to the grip position.

Note While applying test loads to specimens mounted in the grips, leave the

grip controls in the grip position.

22

Operation

Model 685.53 Grip Control Module

Page 23

Removing Specimens from the Grips

Removing Specimens from the Grips

Perform the following steps to remove a specimen from the grips.

WARNING

Do not put anything in a crush zone when turning on hydraulic power.

Heavy specimens or specimen fragments falling from the grips can injure

you or damage test equipment.

Take adequate precautions to support heavy specimens while releasing them

from the grips.

1. If needed, provide adequate support for the specimen, and turn the upper

grip control to the release position.

2. If the specimen is broken, remove the upper portion.

3. Determine whether it is necessary to reposition the crosshead or actuator to

provide adequate clearance for removal of the lower part of the specimen.

Reposition the crosshead or actuator, as needed.

4. If needed, provide adequate support for the specimen, and rotate the lower

grip control to the release position.

5. Remove the specimen.

Model 685.53 Grip Control Module Operation

23

Page 24

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

http://www.mts.com

ISO 9001:2000 Certified QMS

Loading...

Loading...