Page 1

be certain.

m

Model 680.01 High-Temperature Grips

Product Information

015-018-801 F

Page 2

Copyright information © 1991, 2001, 2002, 2008, 2009 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation within the United

States. This trademark may be protected in other countries.

DTE and SHC are registered trademarks of Mobil Corporation. All other

trademarks or service marks are property of their respective owners.

Publication information

MANUAL PART NUMBER PUBLICATION DATE

015-018-801 A January 1991

015-018-801 B March 2001

015-018-801 C October 2002

015-018-801 D March 2008

015-018-801 E September 2008

015-018-801 F April 2009

Page 3

Contents

Technical Support 5

How to Get Technical Support 5

Before You Contact MTS 5

If You Contact MTS by Phone 6

Problem Submittal Form in MTS Manuals 7

Preface 9

Before You Begin 9

Conventions 10

Documentation Conventions 10

Introduction 13

Model 680.01 High-Temperature Grips Functional Description 14

Model 680.01 High-Temperature Grip Accessories 15

Model 680.01 High-Temperature Grips Specifications 17

Model 680.01 High-Temperature Grips Dimensions 18

Safety Information 19

Hazard Placard Placement 19

Installation 21

Install the Grips 22

Install the Hand-Operated Hydraulic Pump 25

Install the Cooling Kit 26

Preload the Spiral Washers 27

Grip Water Cooling Assembly Configurations for Servohydraulic Frames 29

Model 680.01 High-Temperature Grips Contents

3

Page 4

Operation 33

Determine the Gripping Pressure 33

Install Threaded Specimens 35

Install Button-End Specimens 37

Adjust the Water Flow 38

Remove Specimens from the Grips 39

Maintenance 41

Clean the Grips 41

Add Hydraulic Fluid to the Hand Pump 42

4

Contents

Model 680.01 High-Temperature Grips

Page 5

Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

MTS web site

www.mts.com

E-mail techsupport@mts.com

Telephone MTS Call Center 800-328-2255

Fax 952-937-4515

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes MTS software, look

for online help and README files that contain additional product inform ation.

If you cannot find answers to your technical questions from these sources, you

can use the internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact MTS in one of the

following ways.

The MTS web site gives you access to our technical support staff by means of a

Technical Support link:

www.mts.com > Contact Us > Service & Technical Support

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Please include “Technical Support” in the subject line.

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

Model 680.01 High-Temperature Grips

The site number contains your company number and identifies your equipment

type (material testing, simulation, and so forth). The number is usually written on

a label on your MTS equipment before the system leaves MTS. If you do not

have or do not know your MTS site number, contact your MTS sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies

which system you are calling about. You can find your job number in the papers

sent to you when you ordered your system.

Example system number: US1.42460

5

Page 6

Know information from

prior technical

If you have contacted MTS about this problem before, we can recall your file.

You will need to tell us the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem you are experiencing and know the answers to the

following questions:

• How long and how often has the problem been occurring?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the model numbers of the suspect equipment?

• What model controller are you using (if applicable)?

• What test configuration are you using?

Know relevant

computer information

Know relevant

software information

If you are experiencing a computer problem, have the following information

available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive in which the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

For software application problems, have the following information available:

• The software application’s name, version number, build number, and if

available, software patch number. This information is displayed briefly

when you launch the application, and can typically be found in the “About”

selection in the “Help” menu.

• It is also helpful if the names of other non-MTS applications that are

running on your computer, such as anti-virus software, screen savers,

keyboard enhancers, print spoolers, and so forth are known and available.

If You Contact MTS by Phone

Your call will be registered by a Call Center agent if you are calling within the

United States or Canada. Before connecting you with a technical support

specialist, the agent will ask you for your site number, name, company , company

address, and the phone number where you can normally be reached.

6

Model 680.01 High-Temperature Grips

Page 7

If you are calling about an issue that has already been assigned a notification

number, please provide that number. You will be assigned a unique notification

number about any new issue.

Identify system type To assist the Call Center agent with connecting you to the most qualified

technical support specialist available, identify your system as one of the

following types:

• Electromechanical materials test system

• Hydromechanical materials test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

Prepare yourself for troubleshooting while on the phone:

troubleshoot

• Call from a telephone when you are close to the system so that you can try

implementing suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

Write down relevant

Prepare yourself in case we need to call you back:

information

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording

or performance monitoring.

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action

is taken regarding your problem or request. If you have questions about the status

of your problem or have additional information to report, please contact MTS

again and provide your original notification number.

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems you are experiencing

with your MTS software, hardware, manuals, or service which have not been

resolved to your satisfaction through the technical support process. This form

includes check boxes that allow you to indicate the urgency of your problem and

your expectation of an acceptable response time. We guarantee a timely

response—your feedback is important to us.

The Problem Submittal Form can be accessed:

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form (electronic form to

be e-mailed to MTS)

Model 680.01 High-Temperature Grips

7

Page 8

8

Model 680.01 High-Temperature Grips

Page 9

Preface

Before You Begin

Safety first! Before you attempt to use your MTS product or system, read and understand the

Safety manual and any other safety information provided with your system.

Improper installation, operation, or maintenance of MTS equipment in your test

facility can result in hazardous conditions that can cause severe personal injury or

death and damage to your equipment and specimen. Again, read and understand

the safety information provided with your system before you continue. It is very

important that you remain aware of hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional MTS manuals in paper or

electronic form.

If you have purchased a test system, it may include an MTS System

Documentation CD. This CD contains an electronic copy of the MTS manuals

that pertain to your test system, including hydraulic and mechanical component

manuals, assembly drawings and parts lists, and op eration and preventive

maintenance manuals. Controller and application software manuals are typically

included on the software CD distribution disc(s).

Model 680.01 High-Temperature Grips

9

Page 10

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions As necessary, hazard notices may be embedded in this manual. These notices

contain safety information that is specific to the task to be performed. Hazard

notices immediately precede the step or procedure that may lead to an associated

hazard. Read all hazard notices carefully and follow the directions that are given.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury, equipment damage, or

endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. It is important for you to be

Electronic manual

conventions

10

aware that these illustrations are examples only and do not necessarily represent

your actual system configuration, test application, or software.

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

Model 680.01 High-Temperature Grips

Page 11

Conventions

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

Model 680.01 High-Temperature Grips

11

Page 12

Conventions

12

Model 680.01 High-Temperature Grips

Page 13

Introduction

Contents Model 680.01 High-Temperature Grips Functional Description 14

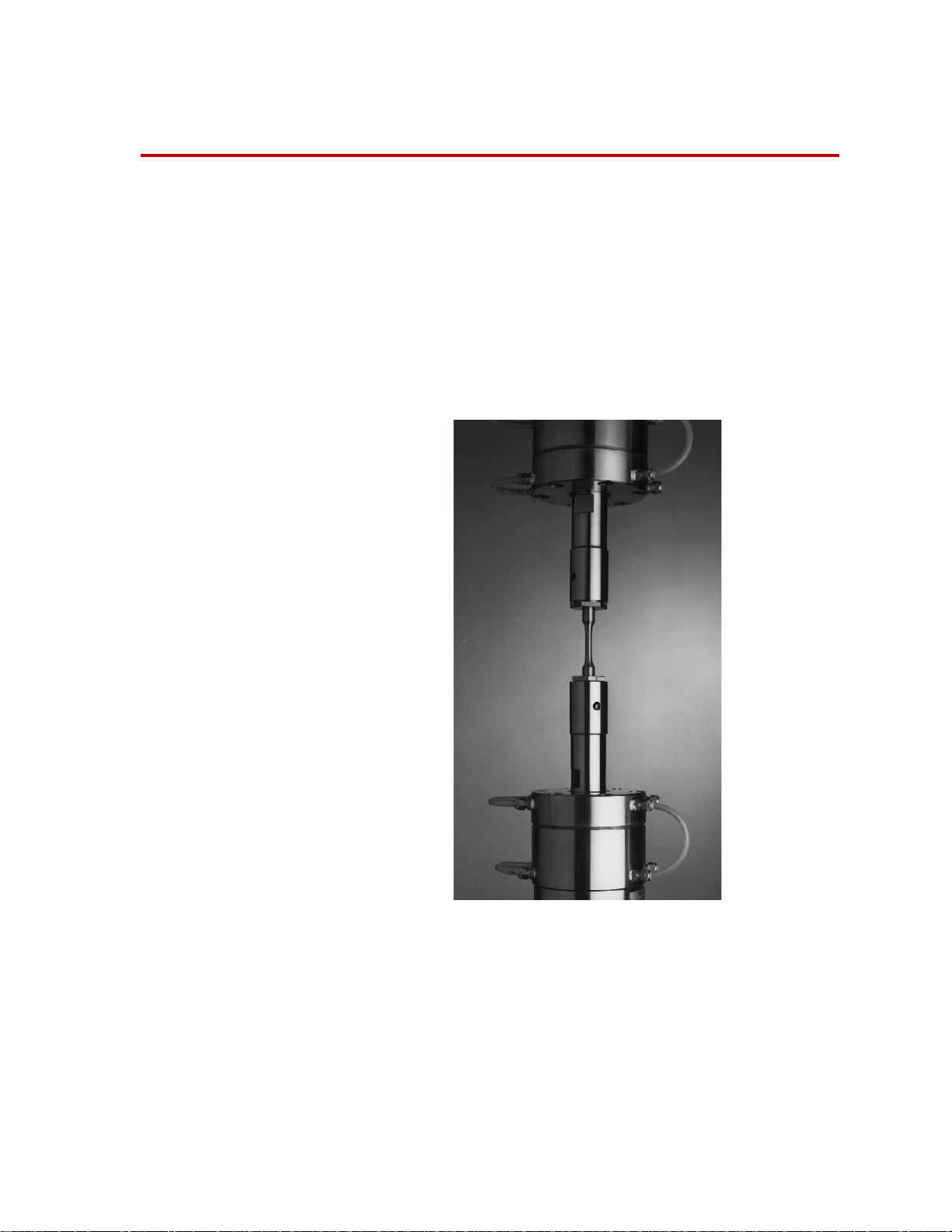

The MTS Model 680.01 High-Temperature Hydraulic Grips are used with a high

temperature furnace installed in a load unit for tension-compression testing of

metallic specimens at elevated temperatures. The grips can be heated at

temperatures up to 1000°C (1832°F).

Model 680.01 High-Temperature Grip Accessories 15

Model 680.01 High-Temperature Grips Specifications 17

Model 680.01 High-Temperature Grips Dimensions 18

What you need to

know

Model 680.01 High-Temperature Grips

MTS Systems Corporation assumes that you know how to use your controller.

See the appropriate manual for information about performing any controllerrelated step in this manual’s procedures. You are expected to know how to

perform the following procedures:

• Turn hydraulic pressure on and off.

• Select a control mode.

• Position the actuator.

13

Page 14

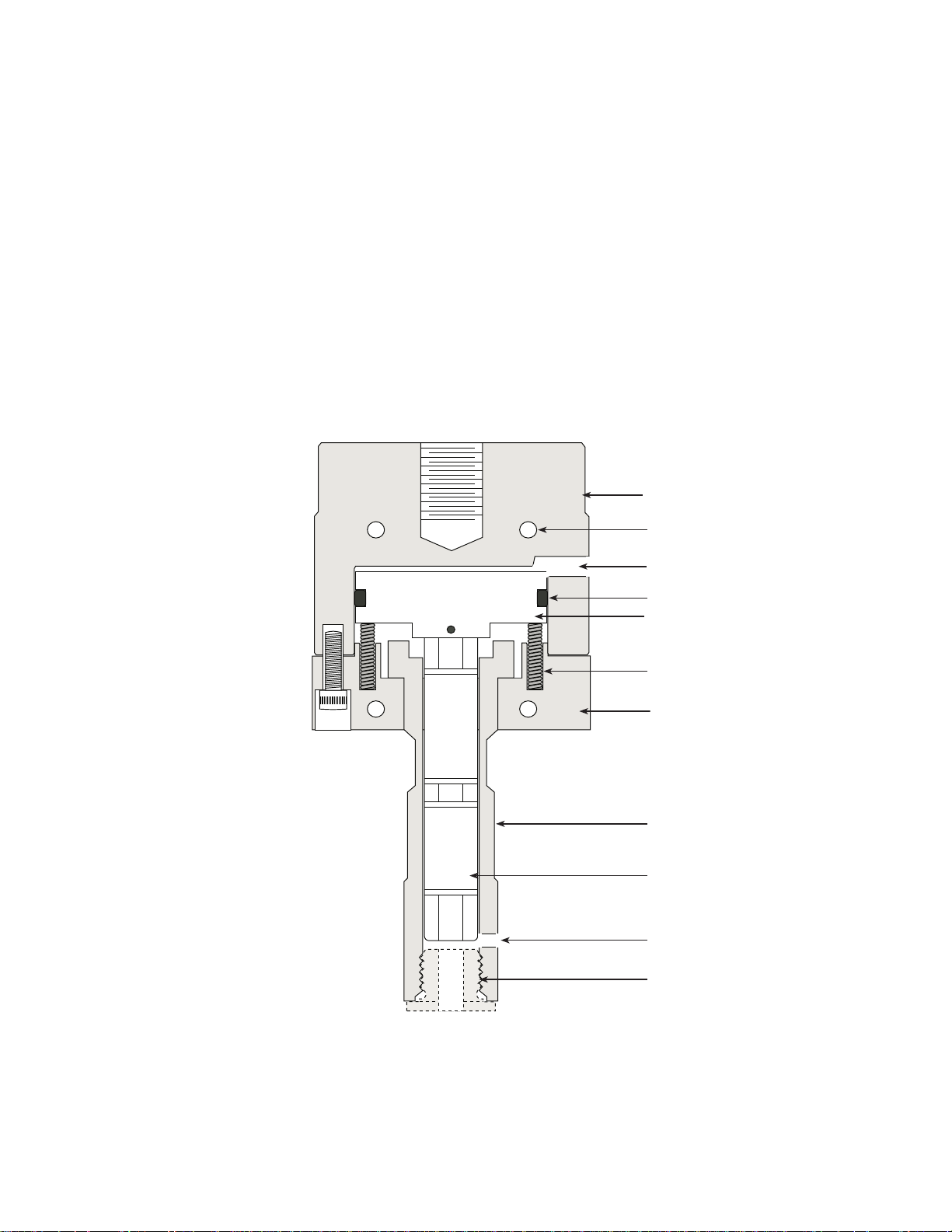

Model 680.01 High-Temperature Grips Functional Description

Base

Cooling water passages

Hydraulic Pressure Port

O-Ring

Piston

Spring, helical,

compression (6 ea.)

Grip Body

Grip Extension

Pushrod

Viewing Port

Specimen adapter

The pushrod, grip extension, and replaceable specimen adapters are made of

special alloy steel to withstand high furnace temperatures. The base and the grip

body are cooled by water flowing through internal passages.

The ends of correctly dimensioned button-end specimens are automatically

positioned with proper relationship to the pushrod by specimen adapters.

Viewing ports allow the end of a threaded specimen to be viewed for proper

insertion length into the specimen adapters.

A specimen with appropriate specimen adapters is installed in the grips.

Hydraulic fluid is applied to the pressure ports. The grip pistons move and push

their pushrods against the ends of the specimen. After testing, hydraulic pressure

is removed and the compression springs in each grip retract the pistons and

pushrods, releasing the specimen.

14

Component Identification

Model 680.01 High-Temperature Grips

Page 15

Model 680.01 High-Temperature Grip Accessories

E

Button-End Specimens

Threaded Specimens

max radius

The following accessories are available for the grips:

• Specimen adapters

• Attachment kits

• Cooling kits

• A hand-operated hydraulic pump.

Specimen adapters Specimen adapters are available in various sizes for both button-end and threaded

specimens. Specimen adapters are supplied in sets of two and are designed to be

used with specimens machined in either SI International or U.S. Customary

dimensions.

Specimen Dimensions (Grip-Ends Only)

For specimen dimensions which must be considered in order to meet an ASTM

(or any other) standard, refer to the appropriate standard. Special adapters, for

specimens not shown here, can be provided. Contact your local MTS sales

representative.

Button-End Dimensions

ART NUMBER ABC

P

041-901-901 0.85 in 0.53 in 0.5 in, +.000, -.001

041-901-902 0.85 in 0.53 in 0.25 in, +.000, -.001

041-901-907 21 mm 13 mm 12 mm, +.00, -.02

Threaded Dimensions

ART NUMBER DE

P

041-901-801

041-901-802 M12 x 1.75mm 28 mm

1/2

–13 UNC

1.1 in

Attachment kits Two attachment kits are needed to mount the grips in a load unit. One kit is

needed to mount a grip to the load unit’s force transducer; another kit is needed to

Model 680.01 High-Temperature Grips

15

Page 16

mount a grip to the actuator rod. Attachment kits are not supplied with a grip set,

Load cell

Load cell to grip

attachment kit

Upper Grip

Lower Grip

Actuator to grip

attachment kit

Actuator rod

1 Stud and

1 pair of

spiral

washers

and they must be ordered separately. Th e MTS base part number is 052-101-0xx.

Each kit contains a mounting stud, a set of spiral washers, and sometimes a shim

kit. Each kit is designed to mount the grip to a specific actuator or force

transducer.

16

Grip Attachment Components

Cooling kits Accessory kits for connecting a cooling water source and drain to the grips are

available in several configurations. A cooling kit is required for grip operation at

elevated temperatures. Each kit includes two water service manifolds (one to be

mounted to each load unit column), flow metering valve, polyethylene tubing,

and all required fittings.

Water Cooling Kits

IT PART NUMBER LOAD UNIT COLUMN

K

048-974-801 2.5–4.0 in diameter

048-974-802 2.5–4.0 in diameter

048-974-803 2.5–4.0 in diameter

048-974-804 6.0 in diameter

048-974-805 all

Model 680.01 High-Temperature Grips

Page 17

Hand-operated

Specimen Temperature

66.7 kN up to 700º C

(15 kip up to 1292º F)

8.9 kN at 1

000º C

(2 kip at 1832º F)

1

038º C

(1900º F)

482º C

(900º F)

0 kN

(0 kip)

66.7 kN

(15 kip)

Load

hydraulic pump

A hand-operated hydraulic pump kit (MTS part number 038-634-701) is a

required accessory for operating the grips. The kit includes the pump, with shutoff and release valves, a pressure gage, and hydraulic hoses for connecting the

pump to the grips. The kit also contains an extra supply of hydraulic fluid.

The pump is usually mounted to the base of the load unit (or near it). It includes

two hydraulic hoses; one is 1829 mm (72 in) long; and the other is 2286 mm (90

in.) long.

Model 680.01 High-Temperature Grips Specifications

The following are the specifications for the Model 680.01 high-temperature

Hydraulic Grips.

P

ARAMETER SPECIFICATION

Force rating See the following figure

Maximum specimen temperature 1000°C (1832°F)

Cooling water requirements

Temperature:

Flow

35°C (95°F) maximum

3.8 L/min (1 gpm) minimum,

at 0.276 MPa (40 psi)

Grip Load Rating as a Function of Temperature

Model 680.01 High-Temperature Grips

17

Page 18

Model 680.01 High-Temperature Grips Dimensions

B

C

D

F

A

E

Mounting holes in the base of each grip are threaded in either SI International

(millimeter) or U.S. Customary (inch) thread dimensions, as shown for

dimension “A” in the pervious table.

ARAMETER

P

A (mounting threads)

DIMENSION

M27 x 2mm (1 in

A

B 113 mm (4.44 in)

C 241 mm (9.48 in)

D 123 mm (4.96 in)

E (wrench flats) 29 mm (1.125 in)

F (travel) 10 mm (0.375 in)

G (specimen adapter wrench flats) 32 mm (1.25 in)

H (maximum diameter) 38 mm (1.5 in)

Weight (each grip) 9 kg (20 lb)

a SI International (U.S. Customary)

–14UNS)

18

Model 680.01 High-Temperature Grips

Page 19

Safety Information

Hazard Placard Placement

Hazard placards contain specific safety information and are affixed directly to the

system so they are plainly visible.

Each placard describes a system-related hazard. When possible, international

symbols (icons) are used to graphically indicate the type of hazard and the

placard label indicates its severity. In some instances, the placard may contain

text that describes the hazard, the potential result if the hazard is ignored, and

general instructions about how to avoid the hazard.

The following label is typically located on the grips.

ABEL DESCRIPTION

L

Grip Identification Placard.

Model

Assy. Rev

Cpty

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, MN U.S.A. 55344-2290

See Manual

SN

PN 507258-01

Contains the following information:

• Model number

• Assembly number

• Revision

• SN

• Capacity

Model 680.01 High-Temperature Grips

19

Page 20

20

Model 680.01 High-Temperature Grips

Page 21

Installation

➊

➋

➌

Install the Grips

Install the HandOperated

Hydraulic Pump

Install the

Cooling Kit

Preload the Spiral

Washers

➍

This section describes how to install the Model 680.01 High Temperature Grips

into a load unit.

Contents Install the Grips 22

Install the Hand-Operated Hydraulic Pump 25

Install the Cooling Kit 26

Preload the Spiral Washers 27

Grip Water Cooling Assembly Configurations for Servohydraulic Frames

29

Typical installation The following diagram shows the main steps to install the grips. Usually the grips

are installed along with a furnace. In such cases, these instructions should be

used in conjunction with those provided for the furnace.

Typical Grip Installation

Model 680.01 High-Temperature Grips

21

Page 22

Install the Grips

Crosshead or

Force Transducer

Spiral

Washer

Set

Stud

Upper Grip

Lower Grip

Spiral

Washer

Set

Stud

Actuator Rod

Load Unit

Base Plate

An attachment kit is required for attaching each grip to the load unit. Kit

selection should be based on the mounting threads provided on the grips, which

must match corresponding threads on the device (force transducer or actuator

rod), to which the grip is to be attached. Refer to the information about the

attachment kits.

Grip Installation Components

Required equipment • An attachment kit for the actuator

• An attachment kit for the force transducer

• Molykote G•N paste lubricant (MTS part number 011-010-217 is a 2.8 oz.

tube; other sizes are available)

22

Model 680.01 High-Temperature Grips

Page 23

Preparation Ensure that the threads of all threaded components in the force train (between the

load cell and the actuator rod) are clean and in good condition.

As necessary, clean the connector studs and the internal threads of the force train

element(s) with a wire brush. Inspect all threads for signs of particle

contamination or corrosion. All damaged threads should be repaired or the

component should be replaced.

Installation procedure The following procedure assumes that the actuator is mounted in the base of the

load unit and the force transducer is mounted to the crosshead. If you have a load

unit with the actuator mounted to the crosshead, make the appropriate changes to

the following procedure.

1. Set up the load unit.

A. Turn on the system hydraulic pressure.

B. Adjust the actuator and crosshead position as necessary to allow

adequate room to install the grips.

C. Turn the hydraulic pressure off and ensure that system hydraulic

pressure has been reduced to zero before proceeding.

D. Lubricate all of the surfaces that will contact each other (screw threads,

spacers, and so forth) with Molykote G-n paste.

2. Mount the lower grip.

Mount the lower grip to the actuator piston rod. The attachment kit drawing

shows what components (such as shims, spiral washers, and so forth) should

be installed.

Note Insert a plug (with the same diameter as the stud) of compliant material,

such as cardboard or styrofoam, into the threaded mounting holes in

each grip, actuator, and force transducer. This will aid future grip

removal.

A. Thread the stud into the actuator. The connector stud should turn freely .

If any resistance is encountered, disassemble and correct the problem

before proceeding.

B. Add any required shims, spacers, or spiral washers to the stud. Ensure

that the spiral washers are set to their minimum thickness.

C. Position the lower grip to align it with the connecting stud and stabilize

the grip. Slowly screw the lower grip into the lower element of the

force train until it is snugged tight against the spiral washers. Ensure

that the spiral washers remain set to their minimum thickness.

3. Mount the upper grip.

Mount the upper grip to the force transducer on the crosshead. The

attachment kit drawing shows what components (such as shims, spiral

washers, and so forth) should be installed.

Note Ensure that the force transducer is properly aligned (see your load unit

A. Thread a stud into the upper grip.

Model 680.01 High-Temperature Grips

manual).

23

Page 24

B. With the connector stud is facing up, add any required shims, spacers,

or spiral washers to the stud. Ensure that the spiral washers are set to

their minimum thickness.

C. Reposition the grip as necessary for proper thread alignment. Slowly

screw the upper grip into the upper element of the force train until it is

snugged tight against the spiral washers. Ensure the spiral washers

remain set to their minimum thickness.

4. Align the grips.

Orientation is not critical. Just orient the grips so the hoses and water tubing

lines will provide the least interference with future work activities around

the load unit. You may also want to align the grips so that you can see the

view port which is helpful during specimen installation.

• It may be possible to rotate the actuator rod to achieve the desired

orientation. If the actuator rod cannot be rotated, remove the lower grip

and install shim washers between the spiral washers and the lower

element of the force train. Reinstall the grip (go to Step 2).

• It may be possible to rotate the force transducer when preloading the

spiral washers (see Step 5). If proper alignment of the force transducer

is not possible, remove the upper grip and install shim washers between

the spiral washers and the upper element of the force train. Reinstall the

grip (go to Step 3).

5. Tighten the grips.

See the appropriate procedure to preload the connector stud and return to

this procedure when done.

6. Connect the hydraulics.

The hydraulic source to operate the grips is from a hand-operated hydraulic

pump. Install the hand-operated hydraulic pump according to the

appropriate procedure, and return to this procedure when done.

Using the provided hydraulic hoses, make connections between the pressure

ports on each grip and the ports on the hand-operated hydraulic pump.

7. Install the cooling kit.

Install water hoses to the grips according to the appropriate procedure.

24

Model 680.01 High-Temperature Grips

Page 25

Install the Hand-Operated Hydraulic Pump

Reservoir Filler plug

Pressure Release

Output Pressure

Shut-off Va lve

When space permits, the hand-operated hydraulic pump can be mounted to the

sheet metal base of the load unit. If not, other mounting arrangements will need

to be devised. As a minimum, mount the pump on a board or on an adjacent

tabletop.

Note In order for the pump to operate, the reservoir end of the pump assembly

must be higher than the output end (or at least the same elevation).

1. Mount the pump. The preferred location is on the base of the load unit.

2. Connect hoses between the pump and the grips. Tighten both of the hoses at

the pump end. At the grip ends, leave the hoses connected, but loose

3. With the reservoir end of the pump pointed up, fill the reservoir with Quaker

Quintolubric hydraulic fluid, or equivalent. If the level is ever low, add more

hydraulic fluid.

4. With the hoses loose at the grip ends, close the pump’s pressure release

valve and actuate the pump until all air is expelled from the hoses, and then

tighten the hose fittings at the grips.

5. Apply 13.8 MPa (2000 psi) pressure to the grips and check for leaks at all

fittings.

6. After ensuring that all connections are leak free, open the pressure release

valve to release the pressure in the grips.

Model 680.01 High-Temperature Grips

25

Page 26

Install the Cooling Kit

Column Clamp

Water Manifold

The tubing loops

around the back of

the grips

Cool Supply

Hot Return

Hot Return

Cool Supply

Needle

Valve

Polyethylene Tubing

Compression Fitting

Compression Sleeve

Pipe Tube Adapter

Cooling kits circulate water through the grips to cool the them when they are

used in high-temperature situations. The water supply should go to the grip

component closest to the force transducer to help keep any heat transfer from the

force transducer.

1. Mount a water manifold on each load unit column.

2. Make up and install the tubing loops that are required (as shown in the

following figures). Make up the shorter loops first, then the longer ones.

3. Install the water supply and drain hoses.

26

Cooling Water Flow Schematic

Note Each grip uses a water manifold, one on each column. This keeps the

temperature of each column balanced.

Cooling Water Tubing Loop Assembly

Model 680.01 High-Temperature Grips

Page 27

Preload the Spiral Washers

WARNING

CAUTION

The components in the force train must be preloaded to prevent backlash during

operation. Preloading is done while a high tensile load is applied to a dummy

specimen mounted in the grips. While this load is applied, the spiral washers are

adjusted to remove any slack in the force train. When the applied load is

removed, the force train remain preloaded.

The load to be applied while preloading the studs should be at least 10% greater

than the maximum load that the force train will experience during actual testing.

Or, to preload the studs for grip operation at full rated load, the studs should be

preloaded to about 110% of the grips fatigue rating.

The procedure requires that the spiral washers be installed on each connector stud

in the force train. The spiral washers should be set to minimum thickness You

will also need two spanner wrenches.

1. Select force control.

2. Turn on the system hydraulic pressure.

3. Select a dummy specimen that will withstand a tensile force 10%– 20%

4. Install a dummy specimen in the grips according to the appropriate

greater than the maximum force to be applied during the test.

procedure.

The next step may apply a force greater than the force train capacity.

Exceeding the tensile load capacity of any element in the force train can

cause personal injury or equipment damage.

It is necessary to temporarily exceed the tensile load capacity to achieve the

requirements of Step 5 in this procedure. This is accomplished by increasing the

output pressure of the HPU.

5. Apply a static tensile force 10%– 20% higher than the maximum force to be

applied during testing.

If the spiral washers are not sufficiently tightened, the connector stud can

break when subjected to cyclic loads.

Improper preloading of the connector stud can cause eventual fatigue

resulting in connector stud breakage.

Sufficiently tighten the spiral washers as described in Step 6.

Model 680.01 High-Temperature Grips

27

Page 28

6. Using spanner wrenches, rotate the two halves of the spiral washers in

Connector Stud

Decrease Thickness

Medium Thickness

Do not exceed.

Connector

Stud

Increase Thickness

opposite directions to tighten them. The opening between the washers must

not exceed an arc of 30° from the closed position.

If more than a 30° arc is created, remove the tensile load from the specimen.

Remove the specimen and tighten the grips on the mounting studs, taking

care not to misalign the wedge openings. Repeat Step 4 through Step 6 of

this procedure.

7. Reduce tensile force to zero and remove the specimen.

8. Remove the system hydraulic pressure.

28

Connector Stud and Spiral Washers

Model 680.01 High-Temperature Grips

Page 29

Grip Water Cooling Assembly Configurations for Servohydraulic Frames

Hoses to

water

service

Cut hoses to required length at installation. MTS provides a hose (quantity 1)

with the water cooling assembly for conection to the water service. See the

following table for the hose length provided by MTS.

ART NUMBER COLUMN DIAMETER HOSE LENGTH FOR

P

ATER SERVICE

W

UPPLIED BY MTS

S

QUANTITY 1)

(

048-974-801 2.5–4 in (63.5–101.6 mm) none

048-974-802 2.5–4 in (63.5–101.6 mm) 12 ft (3.65 m)

048-974-803 2.5–4 in (63.5–101.6 mm) 24 ft (7.30 m)

048-974-804 6.0 in (152.4 mm) 12 ft (3.65 m)

048-974-805 All 12 ft (3.65 m)

048-974-801, 048-974-802, and 048-974-803

Model 680.01 High-Temperature Grips

29

Page 30

048-974-804

Hoses to

water

service

30

Model 680.01 High-Temperature Grips

Page 31

Hoses to

water

service

048-974-805

Model 680.01 High-Temperature Grips

31

Page 32

32

Model 680.01 High-Temperature Grips

Page 33

Operation

This section describes how to use the grips.

Contents Determine the Gripping Pressure 33

Install Threaded Specimens 35

Install Button-End Specimens 37

Adjust the Water Flow 38

Remove Specimens from the Grips 39

Determine the Gripping Pressure

The amount of hydraulic pressure to be applied to the grips must be sufficient to

prevent backlash between the specimen ends and the specimen adapters, and also

between the mating threads of the specimen adapters and the grip extensions,

during all parts of the loading cycle.

To also ensure that the grips will not be loaded beyond their force rating,

however, determining hydraulic pressure must start with temperature

considerations, rather than the forces to be applied to the specimen.

Note If the gripped ends of the specimen become deformed, reduce the

hydraulic gripping pressure. Re-compute the amount of pressure

required to grip the specimen.

Force versus

temperature

Determining the required hydraulic pressure is a two step process:

1. Determine that the maximum force (whether tensile or compressive) to be

applied to the specimen is within the grip rating, considering the

temperatures that the specimen will experience.

2. If anticipated forces are appropriate, use the “Required Pressure for the

Applied Force” graph to find the required gripping pressure.

The following figure shows that the grip force rating for specimen temperatures

up to 700°C is 67 kN (1292°F at 15,000 lb) is stable. The figure also shows that

the force rating is reduced proportionately for specimen temperatures between

700°C and 1000°C (1292°F and 1832°F), with a maximum force rating of 8.9 kN

at 1000°C (2000 lb at 1832°F).

Model 680.01 High-Temperature Grips

33

Page 34

Grip Force Rating versus Specimen Temperature

Specimen Temperature

66.7 kN up to 700º C

(15 kip up to 1292º F)

8.9 kN at 1

000º C

(2 kip at 1832º F)

1

038º C

(1900º F)

482º C

(900º F)

0 kN

(0 kip)

66.7 kN

(15 kip)

Load

Force versus hydraulic

pressure

The horizontal scale at the bottom of the graph shows required gripping pressure

versus maximum force to be applied, which is shown on the left hand vertical

scale.

The right hand vertical scale is provided as a convenience. Assuming that the

gage portion of the specimen has a diameter of 0.25 inches, the right hand scale

shows maximum engineering stress (for a 0.25 inch diameter specimen), versus

required gripping pressure on the bottom horizontal scale and also the equivalent

force on the left hand vertical scale.

34

Required Pressure for the Applied Force

Model 680.01 High-Temperature Grips

Page 35

Install Threaded Specimens

WARNING

Upper Grip Extension

Viewing Port

Specimen Adapter

Threaded Specimen

Perform the following procedure to mount threaded specimens in the grips.

Ensure that all grip parts are sufficiently cool before touching them.

Specimen mounting is a potentially hazardous procedure because hydraulic

pressure is applied to the system and actuator movement is required.

This can cause personal injury. It can also apply damaging forces to the

specimen, furnace, or to other fixtures.

Use extreme care while performing the following steps.

1. Determine the hydraulic pressure that must be applied to the grips in order

to adequately grip the specimen.

2. Ensure sure that the specimen adapters are clean and free of accumulated

oxide deposits.

3. Apply a liberal amount of anti-galling compound (supplied with the grips)

to the threads of both specimen adapters and to the threads of the specimen

to ensure easy removal after high-temperature operation.

4. Screw one end of the specimen into one of the specimen adapters until it

extends through the adapter.

Threaded Specimen Installation

5. Screw the specimen adapter fully into the grip extension of the upper grip.

6. While looking into the viewing port in the grip extension, screw the

specimen into the specimen adapter as required to center the end of the

specimen in the viewing port.

7. Screw the other specimen adapter fully into the extension of the lower grip.

Model 680.01 High-Temperature Grips

35

Page 36

Hydraulic power will be applied to the systems hydraulic actuator during the

WARNING

following steps.

This can cause personal injury and/or equipment damage.

Exercise caution to avoid having your hands pinched while working near the load

unit while hydraulic pressure is applied. If a high-temperature furnace is installed

in the load unit, exercise extreme care to prevent the actuator from applying any

force to the furnace; severe furnace damage will occur even if minimal force is

applied to the furnace.

8. Apply low hydraulic power to the system.

9. Select force control and adjust the actuator until the lower specimen adapter

just contacts the specimen.

Note When force control is selected to control the actuator and the force

command is set to zero, the actuator will automatically move the proper

amount when you screw the specimen into the specimen adapter.

10. While holding the specimen to prevent it from rotating, screw the specimen

into the lower specimen adapter by rotating the lower grip extension until

the specimen end is centered in the viewing port. (The extension rod has

flats for a 1-1/8” open end wrench.)

11. When satisfied that the specimen is properly installed (specimen adapters

fully screwed into grip extensions, specimen ends in centers of the viewing

ports), actuate the hand-operated pump until the required hydraulic pressure

is shown on the pressure gage.

36

Model 680.01 High-Temperature Grips

Page 37

Install Button-End Specimens

WARNING

Two Piece

Specimen Adapter

Upper Grip

Extension

Viewing Port

Specimen

Adapter

Button-end

Specimen

Perform the following procedure to mount button-end specimens in the grips.

Ensure that all grip parts are sufficiently cool before touching them.

• Specimen adapters for button-end specimens are two-piece adapters and

must be fully screwed into the grip extensions for operation.

• Specimens should have a button thickness no larger than 33 mm (0.540 in).

This will correctly position the specimen end for grip operation.

Specimen mounting is a potentially hazardous procedure because hydraulic

pressure is applied to the system and actuator movement is required.

This can cause personal injury. It can also apply damaging forces to the

specimen, furnace, or to other fixtures.

Use extreme care while performing the following steps.

1. Determine the hydraulic pressure that must be applied to the grips in order

to adequately grip the specimen.

2. Make sure that the specimen adapters are clean and free of accumulated

oxide deposits.

3. Apply a liberal amount of anti-galling compound (supplied with the grips)

to the threads of both specimen adapters to ensure easy removal after hightemperature operation.

4. Place the two halves of one specimen adapter around one end of the

specimen and screw the specimen adapter fully into the upper grip

extension.

Note Each grip specimen adapter for button-end specimens is made up of a

matched pair of halves. Each piece is marked with an alphabetic

identifier. Select a matched pair of pieces for each specimen adapter.

Model 680.01 High-Temperature Grips

37

Page 38

Hydraulic power will be applied to the systems hydraulic actuator during the

WARNING

following steps.

This can cause personal injury and/or equipment damage.

Exercise caution to avoid having your hands pinched while working near the load

unit while hydraulic pressure is applied. If a high-temperature furnace is installed

in the load unit, exercise extreme care to prevent the actuator from applying any

force to the furnace; severe furnace damage will occur even if minimal force is

applied to the furnace.

5. Apply low hydraulic power to the system.

6. Place the two halves of the other specimen adapter around the lower end of

the specimen and hold in place.

7. Select force control and adjust the actuator until the lower grip’s extension

just contacts the lower specimen adapter.

Note When force control is selected to control the actuator and the force

command is set to zero, the actuator will automatically move the proper

amount when you screw the specimen into the specimen adapter.

8. While holding the lower specimen adapter in place, screw it into the lower

grip extension until the adapter is fully threaded into the extension. This

may be done by rotating the specimen adapter or the extension. (The

extension has wrench flats for a 1-1/8 inch open-end wrench.)

Adjust the Water Flow

9. When satisfied that the specimen is properly installed (specimen adapters

fully screwed into grip extensions), actuate the hand-operated pump until

the required hydraulic pressure is shown on the pressure gage.

Water flow through the grips must be sufficient to prevent damage to the grips.

Minimum cooling water requirements are for 4 L/min (1 gpm) flow at 2.75 Pa

(40 psi). Fully open the water flow control valves. The temperature of the outer

surface of the grip body should not exceed 121°C (250°F) under any

circumstances.

38

Model 680.01 High-Temperature Grips

Page 39

Remove Specimens from the Grips

WARNING

CAUTION

Parts of the grips can be very hot after gripping specimens inside a hightemperature furnace.

This can produce very serious skin burns.

Do not touch the outer surfaces of the grips while hot. After completing a test,

leave cooling water running until the grips are safe to touch.

Be aware that the grip extension and specimen adapters will typically be much

hotter than the water-cooled grip body or grip base after gripping specimens at

elevated temperatures.

1. Turn the hydraulic hand pump pressure release valve counterclockwise until

the pressure indicated on the pressure gage reads zero. This allows the grip

pistons to retract, releasing the specimen.

2. After the grips are cool, use open-end wrenches to remove the specimen

adapters from the grip extensions.

If the specimen has not fractured during the test, turn on hydraulic power

and select force control of the actuator. This allows the actuator rod to

retract properly as a specimen adapter is removed.

3. Remove both the specimen adapters from the specimen ends. If the

specimen was a threaded specimen, it may be necessary to place the

specimen in a vise while removing the adapters.

Specimens can create debris that can settle in the grips.

Debris in the grips can cause damage to the grips.

Clean any debris out of the grips before installing a new specimen.

4. Clean the specimen adapters, according to the appropriate procedure.

Model 680.01 High-Temperature Grips

39

Page 40

40

Model 680.01 High-Temperature Grips

Page 41

Maintenance

CAUTION

WARNING

Contents Clean the Grips 41

Clean the Grips

The Model 680.01 High-Temperature Grips are designed to be used in high

temperature environments. After every use in a high temperature environment,

the specimen, the adapters, and grip extensions should be cleaned and lubricated.

Add Hydraulic Fluid to the Hand Pump 42

Specimen adapters and the threaded ends of the grip extension rods should be

cleaned and lubricated after each use. Because they must be removed from the

grip before another specimen may be tested, the small amount of additional time

involved in wiping and re-lubricating the threads is worth while, especially when

the grips are repeatedly exposed to high-temperatures.

If grip cleaning procedures are not performed as recommended, the grips

may not operate properly.

When used repeatedly in high-temperature environments, grip parts can become

welded together if they are not properly maintained.

1. Loosen and remove all anti-galling compound from the threads of the

specimen adapters and also from the threads of the grip extensions. Use a

wire brush if necessary.

Many chemicals used for cleaning or as solvents, such as isopropyl alcohol,

are flammable and can be ignited by nearby objects at high-temperature.

This can cause burn injuries or cause larger fires that are dangerous to life

and property.

Make sure that the grips and nearby furnaces are cool before using any

flammable substances. Isopropyl alcohol may be used to loosen deposits that are

difficult to remove by wire brush alone.

2. If compressed air is available, blow any remaining debris from inside the

ends of the grip extensions.

3. Before re-installing the specimen adapters, apply anti-seize lubricant to the

threads of the adapters and grip extensions.

Model 680.01 High-Temperature Grips

41

Page 42

Add Hydraulic Fluid to the Hand Pump

Output Pressure

Shut-off Valve

Pressure Release

Reservoir Filler Plug

Check the fluid level in the reservoir of the hand pump occasionally by removing

the pump’s reservoir plug and observing the level shown on the dip stick. If the

level is low, add Quaker Quintolubric hydraulic fluid, or equivalent, only.

Difficulty in obtaining or maintaining the pressure required for grip operation

may be caused by low fluid level.

42

Model 680.01 High-Temperature Grips

Page 43

Page 44

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

Internet: www.mts.com

ISO 9001:2000 Certified QMS

Loading...

Loading...