Page 1

be certain.

m

Series 653 High-Temperature Furnaces

Product Information

015-059-101 J

Page 2

Copyright information © 1997–1999, 2004, 2008, 2013 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation within the United

States. This trademark may be protected in other countries.

Rath Inc. is a registered trademark of Rath, Inc.

Publication information

Manual Part Number Publication Date

015-059-101 A June 1997

015-059-101 B July 1997

015-059-101 C January 1998

015-059-101 D November 1999

015-059-101 E June 2004

015-059-101 F September 2004

015-059-101 G March 2008

015-059-101 H August 2012

015-059-101 J February 2013

015-059-101 J June 2014

(reissue)

2

Manual Template 4.3

Page 3

Contents

EC Declaration of Conformity 5

Technical Support 7

How to Get Technical Support 7

Before You Cont act MTS 7

If You Contact MTS by Phone 8

Problem Submittal Form in MTS Manuals 9

Preface 11

Before You Begin 11

Conventions 12

Documentation Conventions 12

Introduction 15

653 High-Temperature Furnace Physical Description 15

653 High-Temperature Furnace Functional Description 17

Series 653 High-Temperature Furnace Construction 18

Series 653 High-Temperature Furnace Specifications 19

Safety Information Hazard Placard Placement 21

Installation 23

About Series 653 High-Temperature Furnace Installation 23

Mounting the 653 Furnace to the Load Unit 25

Series 653 High-Temperature Furnace Cable Connections 27

Filing Insulation Inserts 28

About the Extensometer 29

Series 653 High-Temperature Furnace Contents

3

Page 4

Operation 31

Preparing to Run a Test 32

Achieving a Low-Temperature Gradient 33

Maintenance 35

Cleaning the Series 653 High-Temperature Furnace 35

4

Contents

Series 653 High-Temperature Furnace

Page 5

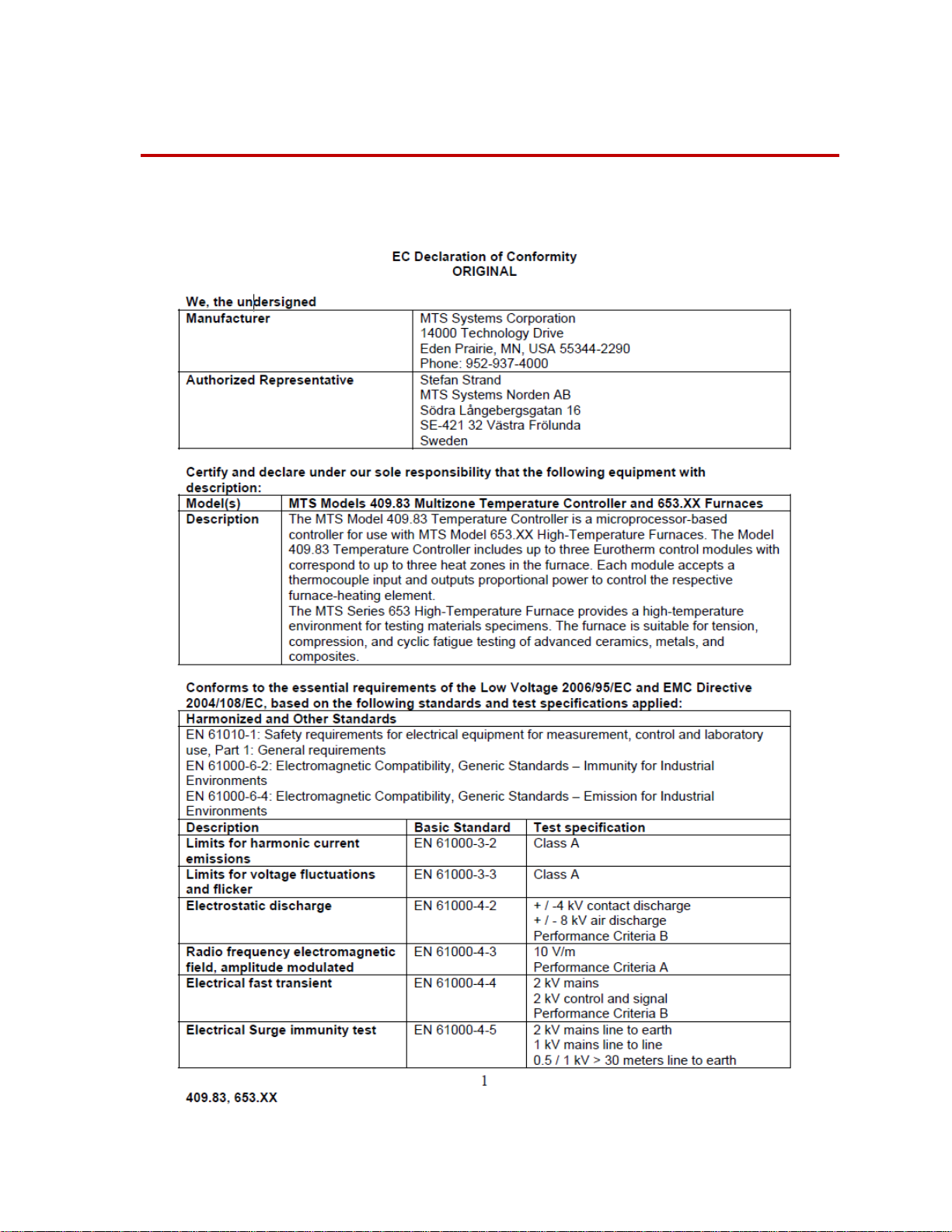

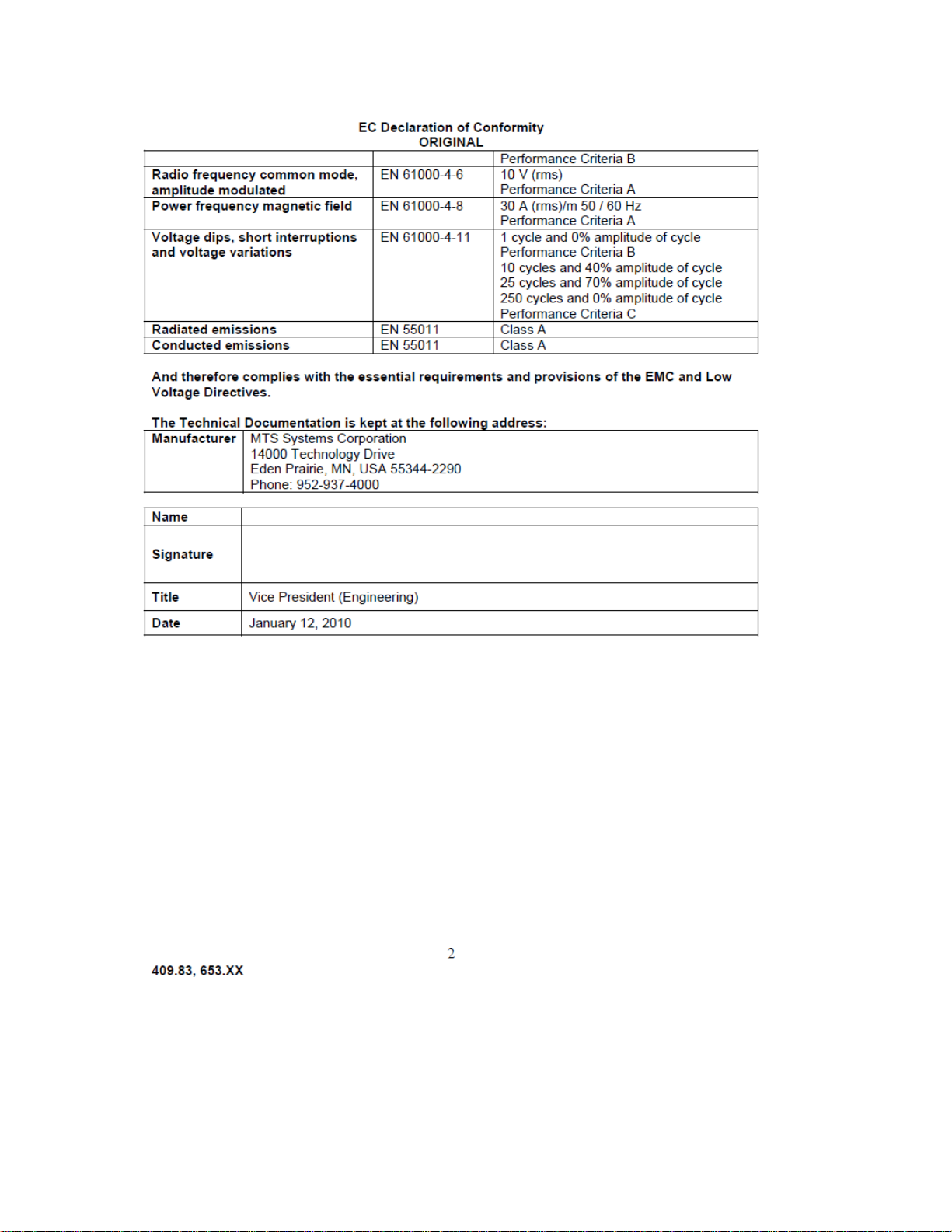

EC Declaration of Conformity

Series 653 High-Te mperature Furnace EC Declaration of Conformity

5

Page 6

EC Declaration of Conformity

6

Series 653 High-Temperature F urnace

Page 7

Technical Support

How to Get Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

MTS web site

www.mts.com

E-mail techsupport@mts.com

Telephone MTS Call Center 800-328-2255

Fax 952-937-4515

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes MTS software, look

for online help and README files that contain additional product inform ation.

If you cannot find answers to your technical questions from these sources, you

can use the internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact MTS in one of the

following ways.

The MTS web site gives you access to our technical support staff by means of a

Technical Support link:

www.mts.com > Contact Us > Service & Technical Support

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Please include “Technical Support” in the subject line.

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

Series 653 High-Temperature Furnace Technical Support

The site number contains your company number and identifies your equipment

type (material testing, simulation, and so forth). The number is usually written on

a label on your MTS equipment before the system leaves MTS. If you do not

have or do not know your MTS site number, contact your MTS sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies

which system you are calling about. You can find your job number in the papers

sent to you when you ordered your system.

Example system number: US1.42460

7

Page 8

If You Contact MTS by Phone

Know information from

prior technical

If you have contacted MTS about this problem before, we can recall your file.

You will need to tell us the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem you are experiencing and know the answers to the

following questions:

• How long and how often has the problem been occurring?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the model numbers of the suspect equipment?

• What model controller are you using (if applicable)?

• What test configuration are you using?

Know relevant

computer information

If you are experiencing a computer problem, have the following information

available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive in which the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

Know relevant

For software application problems, have the following information available:

software information

• The software application’s name, version number, build number, and if

available, software patch number. This information is displayed briefly

when you launch the application, and can typically be found in the “About”

selection in the “Help” menu.

• It is also helpful if the names of other non-MTS applications that are

running on your computer, such as anti-virus software, screen savers,

keyboard enhancers, print spoolers, and so forth are known and available.

If You Contact MTS by Phone

Your call will be registered by a Call Center agent if you are calling within the

United States or Canada. Before connecting you with a technical support

specialist, the agent will ask you for your site number, name, company , company

address, and the phone number where you can normally be reached.

Technical Support

8

Series 653 High-Temperature Furnace

Page 9

Problem Submittal Form in MTS Manuals

If you are calling about an issue that has already been assigned a notification

number, please provide that number. You will be assigned a unique notification

number about any new issue.

Identify system type To assist the Call Center agent with connecting you to the most qualified

technical support specialist available, identify your system as one of the

following types:

• Electromechanical materials test system

• Hydromechanical materials test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

Prepare yourself for troubleshooting while on the phone:

troubleshoot

• Call from a telephone when you are close to the system so that you can try

implementing suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

Write down relevant

Prepare yourself in case we need to call you back:

information

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording

or performance monitoring.

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action

is taken regarding your problem or request. If you have questions about the status

of your problem or have additional information to report, please contact MTS

again and provide your original notification number.

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems you are experiencing

with your MTS software, hardware, manuals, or service which have not been

resolved to your satisfaction through the technical support process. This form

includes check boxes that allow you to indicate the urgency of your problem and

your expectation of an acceptable response time. We guarantee a timely

response—your feedback is important to us.

The Problem Submittal Form can be accessed:

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form (electronic form to

be e-mailed to MTS)

Series 653 High-Temperature Furnace Technical Support

9

Page 10

Problem Submittal Form in MTS Manuals

Technical Support

10

Series 653 High-Temperature Furnace

Page 11

Before You Begin

Preface

Before You Begin

Safety first! Before you attempt to use your MTS product or system, read and understand the

Safety manual and any other safety information provided with your system.

Improper installation, operation, or maintenance of MTS equipment in your test

facility can result in hazardous conditions that can cause severe personal injury or

death and damage to your equipment and specimen. Again, read and understand

the safety information provided with your system before you continue. It is very

important that you remain aware of hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional MTS manuals in paper or

electronic form.

If you have purchased a test system, it may include an MTS System

Documentation CD. This CD contains an electronic copy of the MTS manuals

that pertain to your test system, including hydraulic and mechanical component

manuals, assembly drawings and parts lists, and op eration and preventive

maintenance manuals. Controller and application software manuals are typically

included on the software CD distribution disc(s).

Series 653 High-Temperature Furnace Preface

11

Page 12

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions As necessary, hazard notices may be embedded in this manual. These notices

contain safety information that is specific to the task to be performed. Hazard

notices immediately precede the step or procedure that may lead to an associated

hazard. Read all hazard notices carefully and follow the directions that are given.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury, equipment damage, or

endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. It is important for you to be

Electronic manual

conventions

Preface

12

aware that these illustrations are examples only and do not necessarily represent

your actual system configuration, test application, or software.

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

Series 653 High-Temperature Furnace

Page 13

Documentation Conventions

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

Series 653 High-Temperature Furnace Preface

13

Page 14

Documentation Conventions

14

Preface

Series 653 High-Temperature Furnace

Page 15

653 High-Temper ature Furnace Physical Description

Introduction

The MTS Series 653 High-Temperature Furnace provides a high-temperature

environment for testing material specimens. The furnace is suitable for tension,

compression, and cyclic fatigue testing of advanced ceramics, metals, and

composites. It is usually installed in an MTS load unit and is used with MTS

temperature controllers. The Series 653 Furnace accommodates MTS Model

632.59, 632.53, 632.50, 632.51, and 632.54 Extensometers and various MTS

specimen grips.

653 High-Temperature Furnace Physical Description

The Series 653 Furnace has a hot zone produced by two, four, or six horizontallyoriented silicon carbide heating elements. An insulation plate separates the

elements to provide reliable zone separation. On standard models, the heating

elements are controlled as a single, double, or triple hot zone. Each furnace

comes with a K (Type “R” optional) thermocouple, MTS digital PID temperature

control system, and mounting bracket.

All furnace insulation is made of polycrystalline alumina fiber material. For the

653.01 & 653.02, you must file a hole in the insulation inserts to accommodate a

specific specimen cross section. The 653.03 comes with insulation inserts that are

precut for MTS hot grip extensions, and uncut inserts. The 653.04 furnace comes

with precut insulation for MTS hot grip extensions. You can order and modify

additional inserts to suit a variety of test needs.

MTS furnace mounting accessories combine with the center-split furnace design

to provide convenient installation and removal of test specimens and insulation

inserts. Adjustable pivot mounts built into the mounting bracket allow for smooth

Series 653 High-Temperature Furnace Introduction

15

Page 16

653 High-Temperature Furnace Physical Description

furnace opening and easy operation. Latches built into the front of the furnace

ensure tight furnace sealing.

16

Introduction

Series 653 High-Temperature Furnace

Page 17

653 High-Temperature Furnace Functional Description

High

Temperature

Furnace

Upper Control

Signal

Lower Control

Signal

Lower Thermocouple Signal

Upper Thermocouple Signal

element

element

Temperature

Controller

653 High-Temperature Furnace Functional Description

Temperature control

system

The Series 653 High-Temperature Furnace is monitored and controlled by the

Model 409.83 Temperature Controller. The temperature controller contains a

control module for each hot zone in the furnace. Each control module accepts a

thermocouple input and outputs proportional power to the respective furnace

heating element. With certain controller cables, power to the elements is shut off

when there is a controller interlock.

Series 653 High-Temperature Furnace Introduction

Temperature Controller/Furnace Block Diagram

(Two-Zone Model Shown)

17

Page 18

Series 653 High-Temperature Furnace Construction

Series 653 High-Temperature Furnace Construction

The furnace uses a center-split design which provides easy specimen and fixture

access. Ports allow thermocouples and an extensometer to extend into the hot

zone.

Heating elements The silicon carbide heating elements provide rapid heating, low heat loss, and

long life.

Insulation The insulation material is made of polycrystalline alumina fiber and is capable of

long-term operation at the maximum operating range of the furnace.

Furnace Heating Elements and Insulation Inserts

(Model 653.02 shown)

18

Introduction

Series 653 High-Temperature Furnace

Page 19

Series 653 High-Temperature Furnace Specifications

Series 653 High-Temperature Furnace Specifications

a

B

653.04

†

Temperature

Max/Min

d

High-Temperature Furnace Specificat ions

653.01 653.02

1400°C/100 °C 1400°C/100 °C 1400°C/100 °C 1400°C/100°C

653.03

Overall Height 55 mm 86 mm 126 mm 220 mm

Hot Zone

19 mm 50 mm 90 mm 185 mm

Height

Hot Zone

50 mm 50 mm 62.5 mm 62.5 mm

Width and

Depth

Number of

12 23

Zones

Heater Element

Power

Control Point

Stability

d

Heating Ramp

100/120 V or

220/240 V

50/60 Hz

±1°C from 100 °C

to 1400 °C

d

100°C/min 100°C/min 100°C/min 100°C/min

100/120 V or

220/240 V

50/60 Hz

±1°C from 100 °C to

1400 °C

100/120 V or

220/240 V

50/60 Hz

±1°C from 100 °C

to 1400 °C

220/240 V

50/60 Hz

±1°C from 100

°C to 1400 °C

C

Minimum Time

15 min 15 min 15 min 15 min

to Reach

Maximum

Temperature

d

a Specifications are subject to change without notice. Contact MTS for verification of

specifications critical to your needs.

b This furnace is particularly well-suited for use when a lower thermal gradient is desired on a

tensile or fatigue specimen.

c Designed to accommodate high-temperature bend testing of ceramic materials per ASTM

C1211 or JIS R1604.

d Unloaded, sealed furnace. Furnace performance is dependent on a number of factors including

test type, specimen type, grip configuration, and furnace size. Adding a specimen or grips to the

furnace will reduce4 the maximum achievable temperature and increase the time to reach

temperature. Typical performance of a 653.04 Furnace with MTS 680 grips is 1050 °C maximum

temperature in approximately 1 hour and 15 minutes. A low heat load specimen such as a thin

wire (with grips outside the furnace) will be able to reach a higher temperature in a shorter period

of time.

Series 653 High-Temperature Furnace Introduction

19

Page 20

Series 653 High-Temperature Furnace Specifications

20

Introduction

Series 653 High-Temperature Furnace

Page 21

Safety Information Hazard Placard

High Temperature Furnace

MTS Systems Corporation Eden Prairie, MN U.S.A. 55344-2247

Assy. No.

PN 525462-01

Model No.

Rev.

Serial No.

Placement

Hazard placards contain specific safety information and are affixed directly to the

system so they are plainly visible.

Each placard describes a system-related hazard. When possible, international

symbols (icons) are used to graphically indicate the type of hazard and the

placard label indicates its severity. In some instances, the placard may contain

text that describes the hazard, the potential result if the hazard is ignored, and

general instructions about how to avoid the hazard.

The following labels are typically located on the furnace.

ABEL DESCRIPTION

L

High Temperature Furnace ID label.

Lists the following:

• Model number

• Serial number

• Assembly number

• Revision

Series 653 High-Te mperature Furnace Safety Information Hazard Placard Placement

21

Page 22

ABEL DESCRIPTION

L

WARNING

Hot surface.

Can burn skin.

WARNING

Hazardous voltage.

Can cause severe injury or death.

Turn off power before servicing.

Safety Information Hazard Placard Placement

22

Series 653 High-Temperature Furnace

Page 23

About Series 653 High-Temperature Furn ace

Installation

The Series 653 High-Temperature Furnace is usually supplied as part of a

complete testing system, and the installation procedures are performed by MTS

personnel. However, furnaces purchased as replacement or add-on items require

installation as described in this section.

Items required The following items are required to install a Series 653 High-Temperature

Furnace in an MTS load unit:

• The basic furnace and bracket assembly

• A socket wrench (socket size depends on bracket installed)

• A round or flat file for shaping the insulation inserts to fit the test specimen

if using 653.01, .02, or .03 (one spare s et of insu latio n ins erts is su ppli ed wit h

the furnace.)

Pre-installation tasks The following tasks should be completed prior to installing or replacing the

furnace:

1. Install the load train components (load cell, grips, and so forth) that will be

used during the testing.

2. Install a specimen in the grips using appropriate procedures.

3. Adjust the vertical position of the load unit crosshead, if necessary, so that,

with the specimen in the grips, the actuator is at the desired position for

testing.

Installation overview The following is an overview of furnace installation tasks:

1. Mount the furnace on the load unit columns.

2. Connect all electrical cables and jumpers.

3. File, drill, or cut holes in the insulation inserts to suit the test specimen.

4. Install the extensometer.

Use Available installation videos for detailed instructions.

The extensometer, if used, is mounted independently and its extension rods

extend into the furnace through an opening in the front of the furnace.

About Series 653 High-Temperature Furnace Installation

This procedure requires that a specimen be installed in the load unit to act as a

reference point for furnace installation. If the upper and lower insulation inserts

have not yet been notched to accommodate the specimen, perform the

appropriate procedure before proceeding here. The specimen and inserts used

during installation should resemble those used during actual testing.

The furnace is attached by means of a mounting bracket to two columns of the

load unit.

Series 653 High-Temperature Furnace Installation

23

Page 24

About Series 653 High-Temperature Furnace

WARNING

Mounting

considerations

Consider the following when mounting the furnace in the load unit:

• Proper vertical position of the furnace depends on the dimensions of load

unit components (such as the load cell, grips, cooling adapters, extension

rods, and so forth) and the specimen to be tested.

• The furnace should be positioned so that the axis of the specimen is centered

in the hot zone of the furnace.

• When properly positioned in the vertical plane, the middle of the specimen

length will be in the vertical center of the hot zone and the actuator will be at

the desired position for testing.

• When properly positioned in the horizontal plane, the specimen will be

centered on the holes you have cut in the insulation inserts when the furnace

is closed for operation.

• The furnace must be mounted such that the lamps on the controller are

visible from the furnace.

Materials heated in the furnace are hot and can ignite flammable materials.

Materials on fire can cause serious injury to per sonnel, damage to

equipment, or both.

Do not operate the furnace near flammable materials. Allow sufficient time for the

test materials to cool before handling them.

24

Installation

Series 653 High-Temperature Furnace

Page 25

Mounting the 653 Furnace to the Load Unit

CAUTION

Furnace

Halves

Clamp

Support Bar

Temperature Controller

1. Assemble the bracket assembly to the rear of the furnace.

The furnace insulation inserts are fragile.

Improper installation can damage furnace installation inserts.

Exercise caution to avoid damaging the insulation inserts during installation.

2. Open the furnace and support it in the approximate proper position while

fastening the support bar and clamp to the load unit column.

3. Make sure that all of the socket head cap screws are sufficiently tightened to

support the furnace.

Mounting the 653 Furnace to the Load Unit

Load Unit Installation Using Bracket Assemb ly

Series 653 High-Temperature Furnace Installation

25

Page 26

Mounting the 653 Furnace to the Load Unit

Furnace Assembly Front View

26

Installation

Series 653 High-Temperature Furnace

Page 27

Series 653 High-Temperature Furnace Cable

WARNING

Input Power Socket

Furnace

(Rear View)

Furnace

Output

Thermocouple

Assemblies

Feedthrough

Series 653 High-Temperature Furnace Cable Connections

The thermocouple cables must be connected between the Series 653 HighTemperature Furnace and the temperature controller.

Procedure 1. Connect the furnace thermocouple output cables (MTS cable 525655-xx).

Temperature measurements are provided through a Type K (Type “R”

optional) thermocouple lead for each zone. The thermocouple assembly

should be connected to the rear furnace panel. The other end should be

plugged into the outlet labeled “J1” or “J2” on the temperature controller

bottom panel.

The furnace/controller must be connected to a supply source which

incorporates a residual current operated circuit-breaker which interrupts the

supply at a differential current of 30 mA or less.

Due to the fact that the heaters are hazardous live and are accessible, the

equipment must be connected to a supply source that incorporates such a circuit

breaker.

2. Connect the furnace power input cables (MTS cable 518818-xx).

Socket style connectors “J4” and “J5” transfer the heater control signal (line

voltage) from the temperature controller to the furnace heater elements.

Furnace Connections (Model 653.02 shown)

Series 653 High-Temperature Furnace Installation

27

Page 28

Filing Insulation Inserts

WARNING

Filing Insulation Inserts

The Series 653 High-Temperature Furnace includes one set of insulation inserts

installed in the unit, and one spare set. Before testing, you must file (or cut) holes

for the specimen in the inserts. If specimens of various sizes are to be tested, you

will need inserts accommodating each different size.

Abrasion of insulation inserts produces airborne dust. This product

contains a substance which has been identified by the International Agency

for Research on Cancer (IARC) as possible carcinogenic to humans.

Airborne dust from the insulation may cause temporary irritation to the

eyes, skin, and respiratory tract, and possibly cause a cancer hazard by

inhalation.

Take precautionary measures by minimizing airborne fibers with engineering

controls. Wear a NIOSH/MSHA approved respirator. Wear long sleeved loose

fitting clothing, eye protection and gloves. Wash work clothing separately and

rinse washing machine after use.

The insulating component material is listed below. It is important to minimize

exposure to the dust from this material.

ANUFACTURER INSULATION TRADE NAME APPLICABLE MSDS

M

Rath Inc. KVS 164/302 Rath-NRK-MSDS

Procedure To remove the inserts:

1. Pivot the furnace halves fully open to expose the inserts.

2. Grasp and pull the inserts from the furnace.

To shape the inserts for the test specimen:

1. Use a round or flat file to make a hole in the insulation inserts that closely

match the specimen geometry.

To reinstall or replace the inserts:

1. Push the inserts back into their sockets.

022

Available from MTS

28

Installation

Series 653 High-Temperature Furnace

Page 29

About the Extensometer

About the Extensometer

The extensometer, if used, is mounted independently. Its extension rods extend

into the furnace through an opening filed in the front of the furnace. Refer to the

product manual (or installation drawing, if provided) that accompanied the

extensometer for installation information.

Series 653 High-Temperature Furnace Installation

29

Page 30

About the Extensometer

30

Installation

Series 653 High-Temperature Furnace

Page 31

Operation

CAUTION

WARNING

Prior to performing a materials test at high temperatures, familiarize yourself

with the operation of the other components that make up the complete testing

system.

Adapting furnace

insulation

Before using the 653.01 or 653.02 furnace, you must file holes in the upper and

lower layers of insulation to accommodate the ends of the specimen. These ends

extend outward from the furnace toward the grips. Filing the insulation produces

dust. Be sure to use proper filing methods when working with or handling

furnace insulation.

Proper furnace use • To reduce the possibility of damage to or destruction of the furnace, make

sure that the hydraulic control electronics are set for appropriate

displacement limits.

• When maximum operating temperatures are to be used, note the maximum

recommended heating ramp is 100°C (212°F) per minute.

• The heater elements are designed to operate at temperatures between 100°C

(212°F) and 1400°C (2552°F). Using the furnace above 1400°C can

significantly shorten the life of the heating elements and insulation.

Improper use can shorten the life of heater elements and insulation

components.

Do not open the high-temperature furnace while it is hot or operating. Allow

sufficient time for the furnace to cool before opening the furnace. Rapid

cooling reduces heating element life.

Avoid contacting the heating elements when installing a test specimen or test

fixtures. The heating elements are easily broken.

Avoid contaminating the heating elements with foreign substances which can

reduce service life. Wear gloves if it is necessary to handle heating elements.

Explosions in the furnace can cause death or serious in jury.

Do not use this furnace to heat materials that pose hazards of explosion,

implosion, or the release of toxic or flammable gases

Series 653 High-Temperature Furnace Operation

31

Page 32

Preparing to Run a Test

WARNING

WARNING

Preparing to Run a Test

Materials heated in the furnace are hot and can ignite flammable materials

or cause serious burns.

Do not operate the furnace near or above flammable materials. Allow sufficient

time for the test materials to cool before handling them.

The protection provided by this equipme nt can be impaired if this furnace is

not used in its intended manner.

Do not operate the furnace in a manner contrary to its intended use.

Detailed instructions for operating and adjusting all of the devices involved can

be found in the applicable manuals.

Before proceeding, make sure that the furnace is installed properly.

Procedure 1. Open the furnace.

2. Install the insulation inserts.

If the insulation inserts are not suitable for the cross section of the

specimens to be tested, install new insulation inserts.

3. Install the test specimen.

Refer to the grip or grip power supply manual for the proper installation

procedure.

4. Install the extensometer.

No direct mechanical connection between the furnace and the extensometer

is required. The extensometer is supported by independent means and its

extension rods enter the furnace through holes in the furnace in order to

contact the specimen. Refer to the extensometer manual or installation

drawing, if provided, for the proper installation procedures.

5. Close the furnace.

Fasten the latches on the front of the furnace.

6. Adjust the extensometer cooling water supply for the required flow rate, if

equipped.

32

Operation

7. Run a test.

Refer to the temperature controller manual for information on running a test.

Series 653 High-Temperature Furnace

Page 33

Achieving a Low-Temperature Gradient

Several factors affect the specimen thermal gradient. To establish and ensure

temperature uniformity, some experimentation should be done prior to

performing a test.

The following factors should be considered:

• Position of the heater element.

• T o minimize chimney effect, make sure that the insulation inserts closely fit

the specimen geometry.

• Reduce excessive water flow through the extensometer heat shield and through

the extensometer and grips. However, do not reduce the water flow below the

requirements of each water cooled device. Each water cooled device that may

be used with the furnace has minimum requirements for flow, pressure, and/or

constant cooling water temperature. Refer to the specifications for each water

cooled device. The grip water cooling manifold has flow switches that will

shut off the furnace if cooling water drops below a safe level.

• The furnace should be situated in a controlled environment which is free of

drafts and temperature changes.

Achieving a Low-Temperature Gradient

• The position of the feedback thermocouple affects how close the furnace

tracks the programmed temperature setting. Positioning the thermocouple

on the specimen provides the most accurate specimen temperature reading.

• The temperature reading near the heating element may not be the same as

the temperature reading near the specimen. This is due to the thermal losses

caused by the process of radiating heat between the heating elements and the

specimen.

• Deteriorated thermocouples can produce inaccurate readings.

Series 653 High-Temperature Furnace Operation

33

Page 34

Achieving a Low-Temperature Gradient

34

Operation

Series 653 High-Temperature Furnace

Page 35

Cleaning the Series 653 High-Temperature Furnace

WARNING

WARNING

Maintenance

This section provides information regarding service of the high-temperature

furnace.

The surface of the furnace can become extremely hot.

Touching the furnace before it has cooled can severely burn skin.

Allow sufficient time for the furnace to cool off before servicing the furnace.

Cleaning the Series 653 High-Temperature Furnace

The surface of the furnace can become extremely hot.

Touching the furnace before it has cooled can severly burn skin.

Allow sufficient time for the furnace to cool off before servicing the furnace.

Keep the exterior of the Model 653 High-Temperature Furnace free from dust

and other debris. Should the furnace require cleaning, keep the following points

in mind:

• Power should be disconnected from the furnace before cleaning.

• Use a soft cloth to remove dust and other debris from the exterior of the

furnace. If a cleaning agent is required, use only a mild detergent and water.

• Allow for sufficient dry time before reconnecting power to the furnace.

Series 653 High-Temperature Furnace Maintenance

35

Page 36

Cleaning the Series 653 High-Temperature Furnace

36

Maintenance

Series 653 High-Temperature Furnace

Page 37

Page 38

m

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, Minnesota 55344-2290 USA

Toll Free Phone: 800-328-2255

(within the U.S. or Canada)

Phone: 952-937-4000

(outside the U.S. or Canada)

Fax: 952-937-4515

E-mail: info@mts.com

Internet: www.mts.com

ISO 9001 Certified QMS

Loading...

Loading...